Page 1

AP1684

Document number: DS36547 Rev. 3 - 2

1 of 13

www.diodes.com

February 2014

© Diodes Incorporated

AP1684

A Product Line of

Diodes Incorporated

Description

The AP1684 is a high performance AC/DC power factor corrected

LED driver controller which is driving high voltage bipolar transistor.

The device uses Pulse Frequency Modulation (PFM) technology to

regulate output current while achieving high power factor and low

THD. It operates as a boundary condition mode (BCM) buck controller

which is good for EMI.

The AP1684 provides accurate constant current (CC) regulation while

removing the opto-coupler and secondary control circuitry. It also

eliminates the need of loop compensation circuitry while maintaining

stability. It can meet the requirement of IEC6100-3-2 harmonic

standard.

The AP1684 features low start-up current, low operation current and

high voltage driving bipolar transistor. It adopts dynamic base driver

control technology and valley on switching mode to achieve high

efficiency. It also has rich protection features including over voltage,

short circuit, over temperature protection.

The AP1684 is available in SO-8 package.

Applications

LED Bulb Lamp

LED Down Light

GU10/E27

Other Non-dimmable LED Lighting

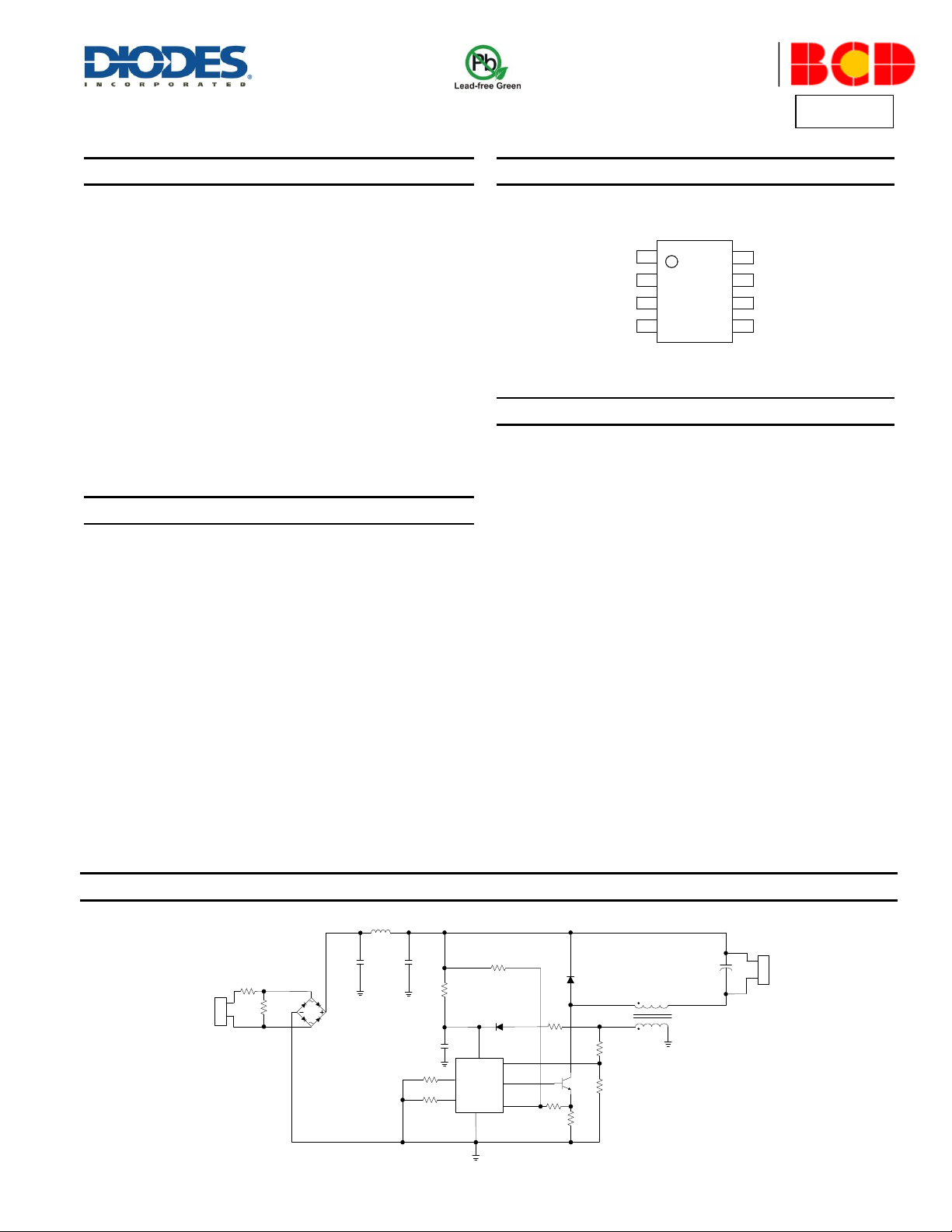

Pin Assignments

(Top View)

1

2

3

4

8

7

6

5

NC

RI

RM

CS

FB

GND

OUT

VCC

(SO-8/ M Package)

Features

Low Start-up Current

High PF and Low THD (PF > 0.9, THD < 30%)

High Efficiency up to 92%

BCM Mode

Output Current Accuracy on IC Level: ±2%

Tight LED Open Voltage

Valley-mode Switching to Minimize the Transition Loss

BJT Transistor Driver

Dynamic Base Driver Control

Open-load and Reload Detection

Internal Protections:

Under Voltage Lock Out (UVLO)

Leading-edge Blanking (LEB)

Output Short Protection

Output Open Protection

Over Temperature Protection

Low System Cost

SO-8 Package

Totally Lead-Free & Fully RoHS Compliant (Notes 1 & 2)

Halogen and Antimony Free. “Green” Device (Note 3)

T1

OUT

+

VCC

FB

OUT

CS

GND

C 3

R7

R5

R6

R4

D1

C4

R3

Q1

AC

Input

F 1

VR1

DB1

C2

L1

C1

R8

D2

R1

R2

RI

RM

R9

AP

1684

5

7

4

6

3

2

8

AC/DC, HIGH PF, HIGH EFFICIENCY LED DRIVER CONTROLLER

Notes: 1. No purposely added lead. Fully EU Directive 2002/95/EC (RoHS) & 2011/65/EU (RoHS 2) compliant.

2. See http://www.diodes.com/quality/lead_free.html for more information about Diodes Incorporated’s definitions of Halogen- and Antimony-free, "Green"

and Lead-free.

3. Halogen- and Antimony-free "Green” products are defined as those which contain <900ppm bromine, <900ppm chlorine (<1500ppm total Br + Cl) and

<1000ppm antimony compounds.

Typical Applications Circuit

Page 2

AP1684

Document number: DS36547 Rev. 3 - 2

2 of 13

www.diodes.com

February 2014

© Diodes Incorporated

AP1684

A Product Line of

Diodes Incorporated

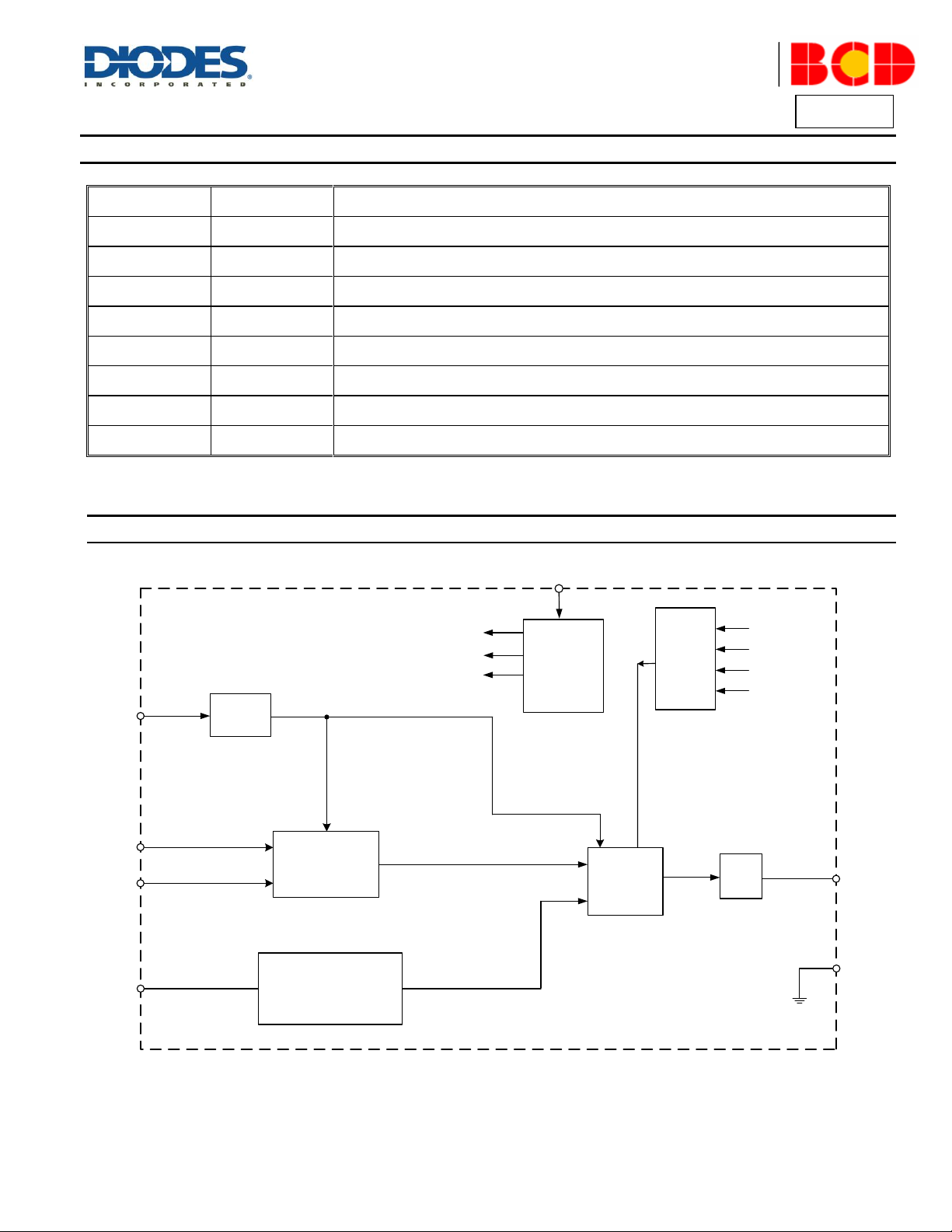

Pin Number

Pin Name

Function

1

NC

No connection 2 RI

The initial Tonp tuning resistor

3

RM

Set the operating mode

4

CS

Primary current sensing

5

FB

The feedback voltage sensing from the auxiliary winding

6

GND

Ground

7

OUT

Gate driver output

8

VCC

Supply voltage of gate driver and control circuits of the IC

Regulator &

Bias

Tons

Detector

Tons

Power_EN

Driver

FB

VCC

OUT

PFM

R

S

Q

Vref

CC_CTRL

TONP_CTRL

CS

GND

Vdd

Protection

& Latch

PRO

CS_OCP

FB_CV

FB_OVP

VCC_OVP

Logic

Set Initial Tonp

& Set the IC

Working in BCM

RM

RI

Constant Turn-on Time

Generation

5

2

3

4

6

7

8

Pin Descriptions

Functional Block Diagram

Page 3

AP1684

Document number: DS36547 Rev. 3 - 2

3 of 13

www.diodes.com

February 2014

© Diodes Incorporated

AP1684

A Product Line of

Diodes Incorporated

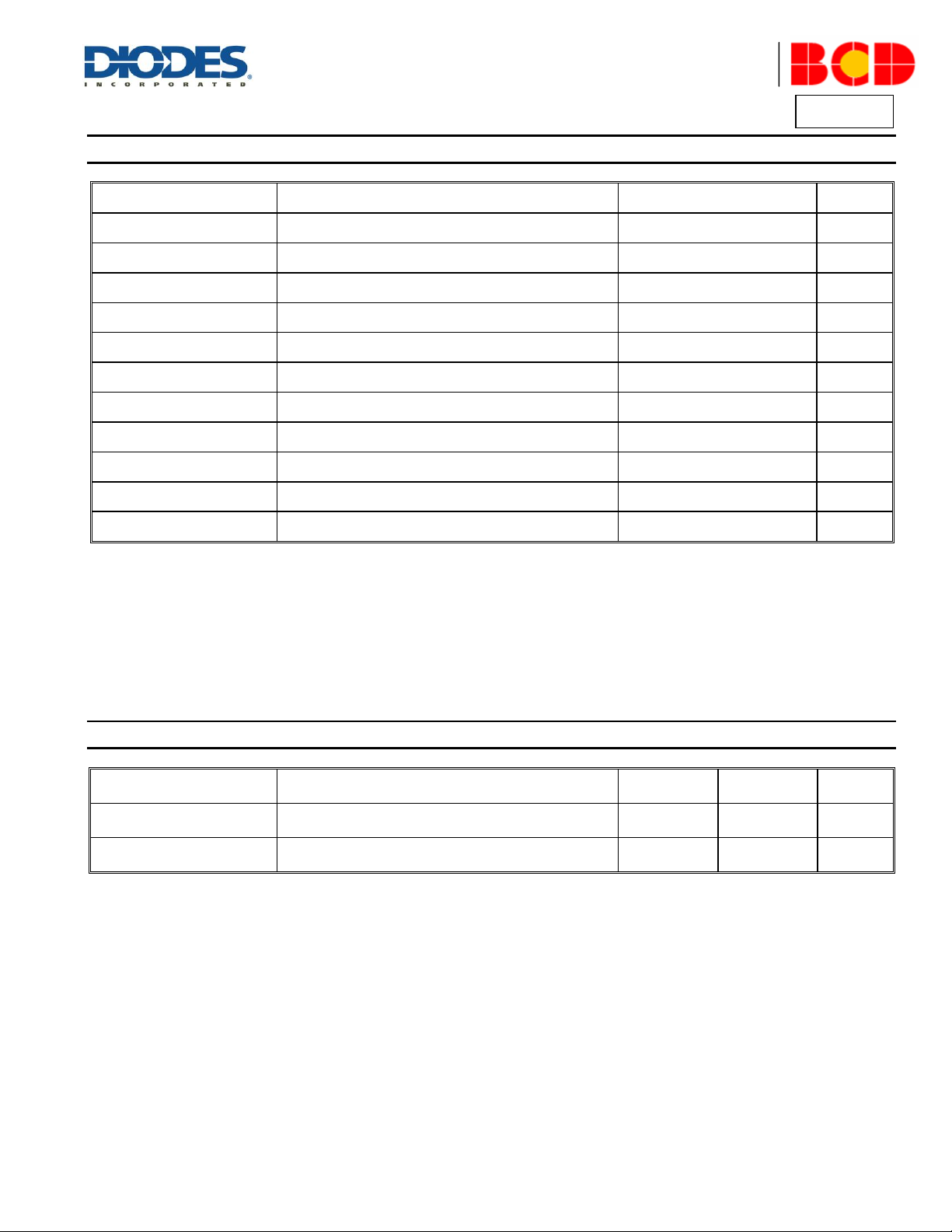

Symbol

Parameter

Rating

Unit

VCC

Power Supply Voltage

-0.3 to 35

V

I

OUT

Driver Output Current

150

mA

VCS

Voltage at CS to GND

-0.3 to +7

V

VFB

FB Input Voltage

-40 to +10

V

TJ

Operating Junction Temperature

-40 to +150

°C

T

STG

Storage Temperature

-65 to +150

°C

T

LEAD

Lead Temperature (Soldering, 10 sec)

+300

°C

PD

Power Dissipation (TA = +50°C)

0.65

W

JA

Thermal Resistance (Junction to Ambient)

160

°C/W

–

ESD (Human Body Model)

2000

V

–

ESD (Charged-device Model)

±1000

V

Symbol

Parameter

Min

Max

Unit

VCC

Power Supply Voltage

7

25

V

TA

Ambient Temperature

-40

+105

°C

Absolute Maximum Ratings (@T

= +25°C, unless otherwise specified. Note 4)

A

Note 4: Stresses greater than those listed under “Absolute Maximum Ratings” may cause permanent damage to the device. These are stress ratings only, and

functional operation of the device at these or any other conditions beyond those indicated under “Recommended Operating Conditions” is not implied. Exposure to

“Absolute Maximum Ratings” for extended periods may affect device reliability.

Recommended Operating Conditions

Page 4

AP1684

Document number: DS36547 Rev. 3 - 2

4 of 13

www.diodes.com

February 2014

© Diodes Incorporated

AP1684

A Product Line of

Diodes Incorporated

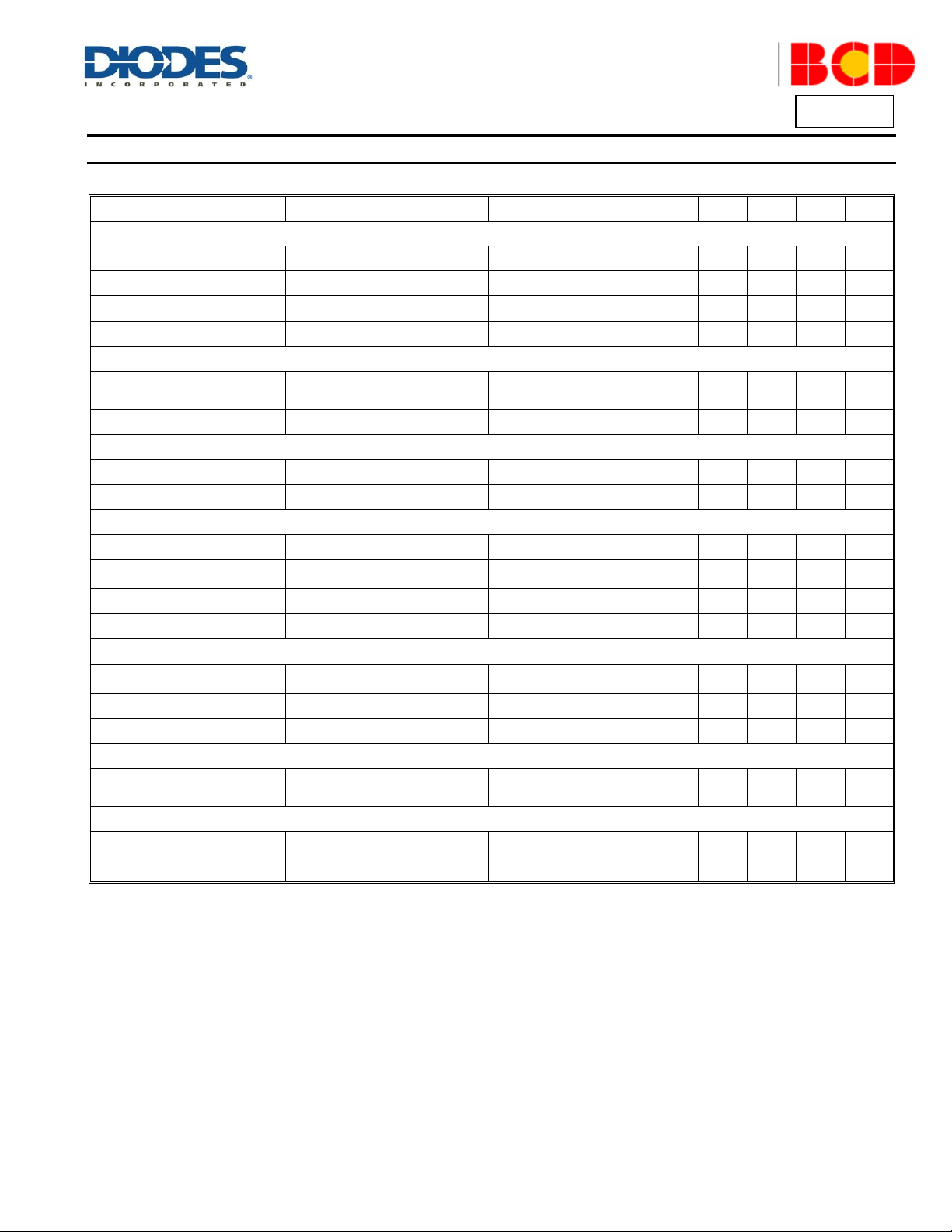

Symbol

Parameter

Conditions

Min

Typ

Max

Unit

UVLO Section

V

TH

(ST)

Start-up Threshold

–

18

19

20

V

V

OPR

(Min)

Minimum Operating Voltage

After turn on

5.5

6.5

7.5

V

V

CC_OVP

VCC OVP Voltage

–

30

32

34

V – VCC Delatch Voltage (Note 5)

–

3 4 5

V

Standby Current Section

IST

Start-up Current

V

CC

= V

TH

(ST)-0.5V,

Before start up

– – 20

μA

ICC (OPR)

Operating Current

Static – 900

1300

μA

Drive Output Section

I

OUT

Output Current (Note 5)

V

CS_PEAK

= 1V

– – 60

mA

VOS

UVLO Saturation Voltage

V

CC

= 0 to V

CC-ON

, I

SINK

= 10mA

– – 1.1

V

Current Sense Section

V

CS_REF

Current Sense Reference

–

– 1 –

V

V

CS_CLAMP

Current Sense Reference

Clamp

–

1.2

1.4 – V

t

ONP_MIN

Minimum t

ONP

–

700 – 1000

ns

t

D(H-L)

Delay to Output (Note 5)

–

50

150

250

ns

Feedback Input Section

IFB

Feedback Pin Input Leakage

Current

V

FB

= 2V

–

–

4

μA

V

FB_CV

FB CV Threshold

–

3.8 4 4.2

V

V

FB_OVP

FB OVP Threshold

–

4.5 6 7.5

V

Output Current

–

System Output Current on Final

Test Board

–

– – ±2

%

Over Temperature Protection Section

–

Shutdown Temperature (Note 5)

–

+150 – –

°C

–

Temperature Hysteresis (Note 5)

– – +20 – °C

Electrical Characteristics (@T

= +25°C, unless otherwise specified.)

A

Note 5: These parameters, although guaranteed by design, are not 100% tested in production.

Page 5

AP1684

Document number: DS36547 Rev. 3 - 2

5 of 13

www.diodes.com

February 2014

© Diodes Incorporated

AP1684

A Product Line of

Diodes Incorporated

6 8 10 12 14 16 18 20 22 24 26 28 30

3.6

3.7

3.8

3.9

4.0

4.1

4.2

CV Threshold (V)

Supply Voltage (V)

-40 -20 0 20 40 60 80 100 120

16.8

17.2

17.6

18.0

18.4

18.8

19.2

Start-up Voltage (V)

Ambient Temperature (oC)

-40 -20 0 20 40 60 80 100 120

6.2

6.3

6.4

6.5

6.6

6.7

6.8

6.9

7.0

7.1

7.2

Minimal Operating Voltage (V)

Ambient Temperature (oC)

-40 -20 0 20 40 60 80 100 120

0.0

0.1

0.2

0.3

0.4

0.5

Start-up Current (

A)

Ambient Temperature (oC)

-40 -20 0 20 40 60 80 100 120

750

800

850

900

950

1000

Operating Current (

A)

Ambient Temperature (oC)

0 5 10 15 20 25 30

0

100

200

300

400

500

600

700

800

900

1000

Supply Current (

A)

Supply Voltage (V)

Performance Characteristics

Supply Current vs. Supply Voltage CV Threshold vs. Supply Voltage

Start-up Voltage vs. Ambient Temperature Minimal Operating Voltage vs. Ambient Temperature

Start-up Current vs. Ambient Temperature Operating Current vs. Ambient Temperature

Page 6

AP1684

Document number: DS36547 Rev. 3 - 2

6 of 13

www.diodes.com

February 2014

© Diodes Incorporated

AP1684

A Product Line of

Diodes Incorporated

-40 -20 0 20 40 60 80 100 120

3.00

3.25

3.50

3.75

4.00

4.25

4.50

CV Threshold (V)

Ambient Temperature (oC)

-40 -20 0 20 40 60 80 100 120

1.00

1.25

1.50

1.75

2.00

2.25

FB Leakage Current (

A)

Ambient Temperature (oC)

Performance Characteristics (Cont.)

CV Threshold vs. Ambient Temperature FB Leakage Current vs. Ambient Temperature

Page 7

AP1684

Document number: DS36547 Rev. 3 - 2

7 of 13

www.diodes.com

February 2014

© Diodes Incorporated

AP1684

A Product Line of

Diodes Incorporated

T1

OUT

+

VCC

FB

OUT

CS

GND

C 3

R7

R5

R6

R4

D1

C4

R3

Q1

AC

Input

F 1

VR1

DB1

C2

L1

C1

R8

D2

R1

R2

RI

RM

R9

AP

1684

5

7

4

6

3

2

8

8

1

_

_

R

V

kI

refcs

meano

meano

refcs

I

V

kR

_

_

8

min__

_

2

8)2(

fVV

VRVV

L

rmsinrefcs

oormsin

Application Information

The AP1684 is designed for single voltage application, and it features high power factor correction (PFC), low total harmonic distortion (THD), low

BOM cost and good EMI performance. The device can be widely used in non-dimmable LED application such as GU10, bulb lamps, down lamp,

etc. The AP1684 adopts constant on time control method within one AC cycle to achieve the high power factor and low THD. The control scheme

is very simple, the power factor correction effectiveness is obvious, and the constant current control is also good enough.

Design Parameters

Setting the Current Sense Resistor R8

As the AP1684 adopts constant on time control method, the current of the inductance will follow the input voltage to get a sinusoidal wave. The

current sense pin CS of the AP1684 will sense the peak current of the inductance by sensing the voltage dropped on the current sense resistor R8,

and the constant current control is realized by controlling the peak current. In buck structure, when the Vo is higher than Vin, no energy will be

transferred from input to output which is called dead zone, and considering the dead zone of buck structure, the output current can be calculated

as below:

Where,

V

is the reference of the current sense, and the typical value is 1V.

cs_ref

K is the current modification coefficient, and the value of k is approximate to be 0.7.

So, the current sense resistor R8 is determined:

Transformer Selection (T1)

The non-isolated buck circuit in Figure 1 is usually selected, and the system is operating at boundary conduction mode. The system’s operating

frequency does not keep constant, and considering the limit of the BJT’s operating frequency, the minimum switching frequency at the crest is set

as f

, and then the buck inductance value L can be got:

min

Where,

Vo is the output voltage.

V

in_rms

is the RMS value of the input voltage.

Figure 1. Typical Application Circuit

Page 8

AP1684

Document number: DS36547 Rev. 3 - 2

8 of 13

www.diodes.com

February 2014

© Diodes Incorporated

AP1684

A Product Line of

Diodes Incorporated

8_RBA

VL

BA

IL

N

me

refcs

me

pk

L

do

cc

Laux

VV

V

NN

sRt

initialon12_

10180

10

max__

10

28

25.1

1

rmsin

UR

L

R

0.1V

1µs

Valley

FB

Application Information (Cont.)

The next step is determining the transformer’s winding turns number, the worst case operation condition of transformer is at the peak voltage area

of sine waveform input voltage where the current of across the inductance is the maximum value. The transformer design should be based on the

worst case operation condition to guarantee that the transformer is not saturated. According to Ferrari's law of electromagnetic induction, the

winding turns number of the buck inductance NL is:

Where,

Ae is the core effective area.

Bm is the maximum magnetic flux density.

The auxiliary winding is power supply for VCC, the winding turns number N

aux

is:

Where,

Vcc is the power supply voltage for IC from auxiliary winding.

Vd is the voltage drop of the freewheel diode.

Setting the Initial On Time

As the AP1684 adopts constant on-time control method, the AP1684 will generate an initial on time to start a working cycle. If the initial on time is

longer than the rated on time, overshoot will happen which could damage the LED. And a good system performance does not permit overshoot, so

the appropriate initial on time should be guaranteed. And initial on time is determined by resister R1 shown in Figure 1.

According to initial on time generation mechanism, the t

To guarantee the system with no overshoot phenomenon, the resistor is selected

The system operation mode is determined by R2, to guarantee the system working at BCM mode, resistance R2 is generally selected as R2≤R1.

Valley on Control Method

The valley on function can provide low turn-on switching losses for buck converter. The voltage across the collector and emitter of the BJT is

reflected by the auxiliary winding of the buck transformer. The voltage is sensed by the FB pin.

is

on_initial

Figure 2. Valley on Control

Page 9

AP1684

Document number: DS36547 Rev. 3 - 2

9 of 13

www.diodes.com

February 2014

© Diodes Incorporated

AP1684

A Product Line of

Diodes Incorporated

VCC

FB

R

FB1

R

FB2

AP1684

AC Power Input

Output Voltage Range

Max Output Current

Low Mains Input

20V to 70V

200mA (13005)

High Mains Input

20V to 120V

200mA (13005)

Item

Description

Related Components

IO

LED current

R8

Output Current Ripple

Small current ripple is good for LED life

C4

t

on_initial

System initial on time, used to start up the system

R1

Output Open Voltage

Setting the output voltage when the LED is open

R5, R6

Line Compensation

To get a good line regulation

R7, R9

Startup Time

System startup time

R3, C3, T1

EMI

Pass EN 55022 class B with 6DB margin

L1, C1, C2

Application Information (Cont.)

According to Figure 2, when the falling edge of 0.1V is sensed by the FB pin, the AP1684 will see the t

new operating cycle. In this way we can realize valley on function.

Fault Protection

Over Voltage Protection and Output Open Protection

time is over and delay 1µs to start a

OFF

Figure 3. OVP Circuit

The output voltage is sensed by the auxiliary winding voltage of the buck transformer, the VCC pin and FB pin provide over voltage protection

function. When the output is open or large transient happens, the output voltage will exceed the rated value. When the voltage of VCC cap exceeds

V

or V

cc_ovp

a new work cycle and the VCC cap is charged again by start resistance. If the over voltage condition still exists, the system will work in hiccup

mode.

Output Short Protection

When the output is shorted, the output voltage will be clamped at 0. At this condition, VCC will drop down without auxiliary winding for power supply.

And the VCC will drop to UVLO threshold voltage, the IC will shut down and restart a new operating cycle, and the VCC is charged by startup

resistance. When the VCC is higher than V

energy stored in the VCC cap, because of no VCC supply from the auxiliary winding, the VCC will drop down to VCC UVLO threshold voltage again. If

output short condition still exists, the system will operate in hiccup mode.

Over Temperature Protection

The AP1684 has two kinds of over temperature protection processes. First, the system is operating normally, the ambient temperature is changed

to +170°C suddenly, the IC will trigger over temperature protection which leads to a latch work mode. Second, if the system starts, the over

temperature protection will be triggered when the ambient temperature is higher than +150°C. So the AP1684 can startup successfully when the

ambient temperature is less than +150°C.

Recommended Applications

The AP1684 is designed to drive BJT as the power switch, because of the BJT’s current limit, the maximum output current is limited. In buck

structure, the output voltage has some limitation because of the dead zone. The device is designed for single voltage application, so the

recommended application is given in the table below.

, the over voltage is triggered and the IC will discharge VCC. When the VCC is below the UVLO threshold voltage, the IC will start

FB_CV

voltage, the IC will output a bunch of pulse to control BJT on and off, which will consume the

cc_start

Components Selection Guide

If the system’s output spec is changed, please refer to the design sheet of the AP1684 and select the compatible system parameter. When the

system needs to be adjusted slightly, please refer to the table below and adjust the value of the related component.

Page 10

AP1684

Document number: DS36547 Rev. 3 - 2

10 of 13

www.diodes.com

February 2014

© Diodes Incorporated

AP1684

A Product Line of

Diodes Incorporated

AP1684 X XX – XX

PackingPackageProduct Name

TR : Tape & Reel

M : SO-8

G1 : Green

RoHS/Green

Package

Temperature

Range

Part Number

Marking ID

Packing

SO-8

-40°C to +105°C

AP1684MTR-G1

1684M-G1

4000/13”Tape & Reel

1684

M-G1

YWWAXX

First and Second Lines: Logo and Marking ID

Third Line: Date Code

Y: Year

WW: Work Week of Molding

A: Assembly House Code

XX: 7th and 8th Digits of Batch No.

Ordering Information

Diodes IC’s Pb-free products with "G1" suffix in the part number, are RoHS compliant and green.

Marking Information

(Top View)

Page 11

AP1684

Document number: DS36547 Rev. 3 - 2

11 of 13

www.diodes.com

February 2014

© Diodes Incorporated

AP1684

A Product Line of

Diodes Incorporated

0

°

8

°

1

°

7

°

R

0

.

1

5

0

(

0

.

0

0

6

)

R0.150(0.006)

1.000(0.039)

0.300(0.012)

0.510(0.020)

1.350(0.053)

1.750(0.069)

0.100(0.004)

0.300(0.012)

3.800(0.150)

4.000(0.157)

7

°

7

°

20:

1

D

1.270(0.050)

TYP

0.150(0.006)

0.250(0.010)

8

°

D

5.800(0.228)

6.200(0.244)

0.600(0.024)

0.725(0.029)

0.320(0.013)

8

°

0.450(0.017)

0.820(0.032)

4.700(0.185)

5.100(0.201)

Note: Eject hole, oriented hole and mold mark is optional

.

Option 1

Option 1

Option 2

0.

350

(0.014)

TYP

TYP

TYP

9

°

~

9

°

~

Package Outline Dimensions (All dimensions in mm(inch).)

(1) Package Type: SO-8

Page 12

AP1684

Document number: DS36547 Rev. 3 - 2

12 of 13

www.diodes.com

February 2014

© Diodes Incorporated

AP1684

A Product Line of

Diodes Incorporated

Grid

placement

courtyard

ZG

Y

E X

Dimensions

Z

(mm)/(inch)

G

(mm)/(inch)

X

(mm)/(inch)

Y

(mm)/(inch)

E

(mm)/(inch)

Value

6.900/0.272

3.900/0.154

0.650/0.026

1.500/0.059

1.270/0.050

Suggested Pad Layout

(1) Package Type: SO-8

Page 13

AP1684

Document number: DS36547 Rev. 3 - 2

13 of 13

www.diodes.com

February 2014

© Diodes Incorporated

AP1684

A Product Line of

Diodes Incorporated

DIODES INCORPORATED MAKES NO WARRANTY OF ANY KIND, EXPRESS OR IMPLIED, WITH REGARDS TO THIS DOCUMENT,

INCLUDING, BUT NOT LIMITED TO, THE IMPLIED WARRANTIES OF MERCHANTABILITY AND FITNESS FOR A PARTICULAR PURPOSE

(AND THEIR EQUIVALENTS UNDER THE LAWS OF ANY JURISDICTION).

Diodes Incorporated and its subsidiaries reserve the right to make modifications, enhancements, improvements, corrections or other changes

without further notice to this document and any product described herein. Diodes Incorporated does not assume any liability arising out of the

application or use of this document or any product described herein; neither does Diodes Incorporated convey any license under its patent or

trademark rights, nor the rights of others. Any Customer or user of this document or products described herein in such applications shall assume

all risks of such use and will agree to hold Diodes Incorporated and all the companies whose products are represented on Diodes Incorporated

website, harmless against all damages.

Diodes Incorporated does not warrant or accept any liability whatsoever in respect of any products purchased through unauthorized sales channel.

Should Customers purchase or use Diodes Incorporated products for any unintended or unauthorized application, Customers shall indemnify and

hold Diodes Incorporated and its representatives harmless against all claims, damages, expenses, and attorney fees arising out of, directly or

indirectly, any claim of personal injury or death associated with such unintended or unauthorized application.

Products described herein may be covered by one or more United States, international or foreign patents pending. Product names and markings

noted herein may also be covered by one or more United States, international or foreign trademarks.

This document is written in English but may be translated into multiple languages for reference. Only the English version of this document is the

final and determinative format released by Diodes Incorporated.

Diodes Incorporated products are specifically not authorized for use as critical components in life support devices or systems without the express

written approval of the Chief Executive Officer of Diodes Incorporated. As used herein:

A. Life support devices or systems are devices or systems which:

1. are intended to implant into the body, or

2. support or sustain life and whose failure to perform when properly used in accordance with instructions for use provided in the

labeling can be reasonably expected to result in significant injury to the user.

B. A critical component is any component in a life support device or system whose failure to perform can be reasonably expected to cause the

failure of the life support device or to affect its safety or effectiveness.

Customers represent that they have all necessary expertise in the safety and regulatory ramifications of their life support devices or systems, and

acknowledge and agree that they are solely responsible for all legal, regulatory and safety-related requirements concerning their products and any

use of Diodes Incorporated products in such safety-critical, life support devices or systems, notwithstanding any devices- or systems-related

information or support that may be provided by Diodes Incorporated. Further, Customers must fully indemnify Diodes Incorporated and its

representatives against any damages arising out of the use of Diodes Incorporated products in such safety-critical, life support devices or systems.

Copyright © 2013, Diodes Incorporated

www.diodes.com

IMPORTANT NOTICE

LIFE SUPPORT

Loading...

Loading...