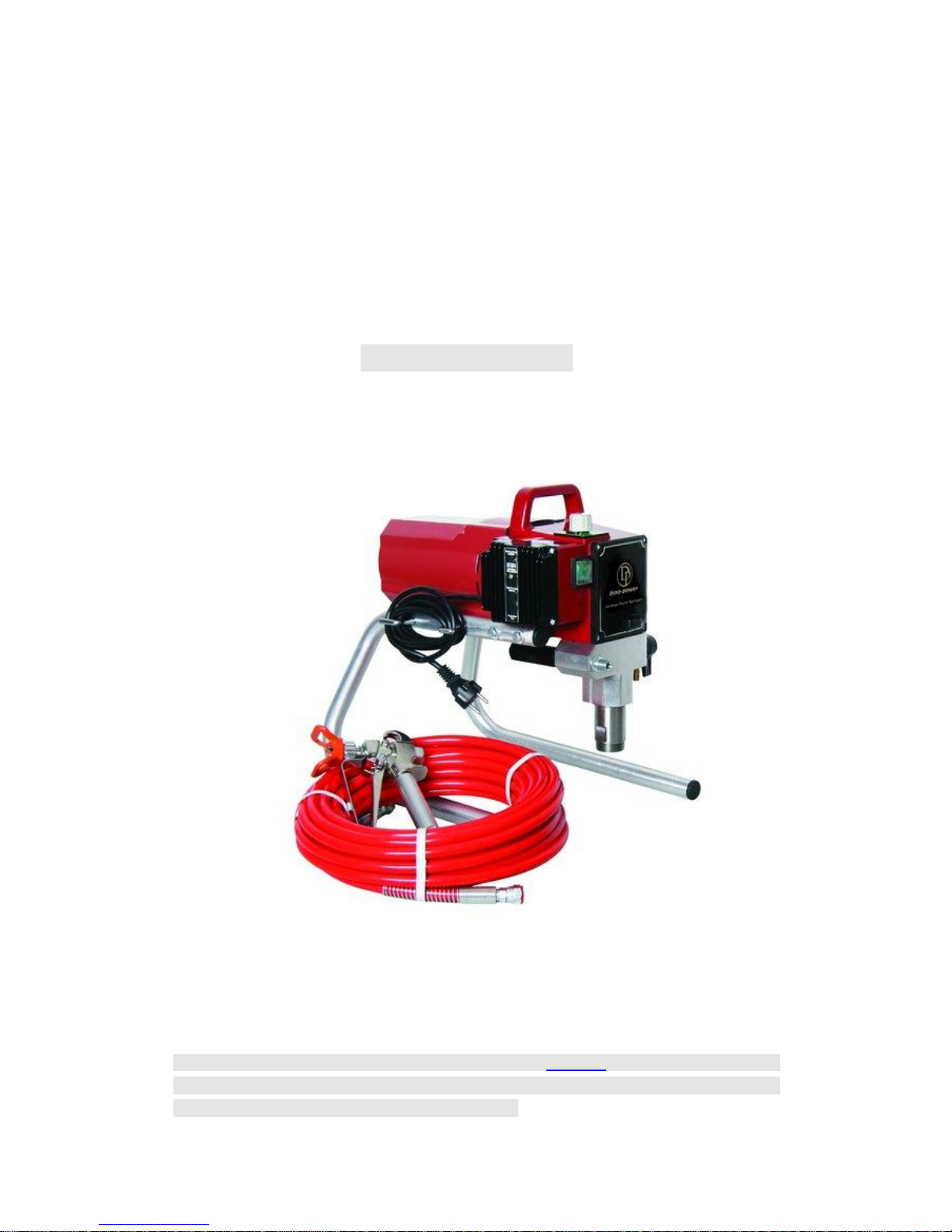

Dino-Power Titan 440i Operation Manual

Operation manual for Airless paint

sprayer

High Pressure Electric Airless paint sprayer Titan 440i model

intelligent series

Remark: this guide manual is the same with model DP-6389 ,the content include :the

operation of equipment,cleaning ,maintenance ,and repair,be sure to pre-operational ,read

the manual carefully before you use this machine.

2

1. warning and precautions

Safety Precautions

This manual contains information that must be read and understood before using

the airless sprayer equipment. When you come to an area that has one of the following

symbols, pay particular attention and make certain to heed the safeguard.

WARNING

This symbol indicates a potential hazard that may cause serious injury or loss of life.

Important safety information will follow.

CAUTION

This symbol indicates a potential hazard to you or to the equipment. Important information

that tells how to prevent

damage to the equipment or how to avoid causes of minor injuries will follow.

NOTE: Notes give important information which should be given special attention.

WARNING

HAZARD: Injection injury – A high pressure fluid stream produced by this equipment can

pierce the

skin and underlying tissues, leading to serious injury and possible amputation. See a

physician immediately.

DO NOT TREAT AN INJECTION INJURY AS A SIMPLE CUT! Injection can lead to

amputation. See a physician immediately.

The maximum operating range of the sprayer is 3200 PSI/221BAR fluid pressure.

PREVENTION:

• NEVER aim the airless spray gun at any part of the body.

• NEVER allow any part of the body to touch the fluid stream. DO NOT allow body to touch

a leak in the fluid hose.

• NEVER put hand in front of the gun. Gloves will not provide protection against an

injection injury.

• ALWAYS lock gun trigger, shut pump off, and release all pressure before servicing,

cleaning tip or guard, changing

tip, or leaving unattended. Pressure will not be released by turning off the motor. The

PRIME/SPRAY valve handle

must be turned to PRIME to relieve the pressure. Refer to the PRESSURE RELIEF

PRESSURE described in the pump manual.

• ALWAYS keep airless tip guard in place while spraying. The tip guard provides some

protection but is mainly a warning device.

• ALWAYS remove the spray tip before flushing or cleaning the system.

• Paint hose can develop leaks from wear, kinking and abuse. A leak can inject material

into the skin. Inspect the hose before each use.

• NEVER use a spray gun without a working trigger lock and trigger guard in place.

• All accessories must be rated at or above 3200 PSI/221 BAR. This includes spray tips,

guns, extensions, and hose.

3

NOTE TO PHYSICIAN:

Injection into the skin is a traumatic injury. It is important to treat the injury as soon as

possible. DO NOT delay treatment to research toxicity. Toxicity is a concern with some

coatings injected directly into the blood stream. Consultation with a plastic surgeon or

reconstructive hand surgeon may be advisable.

HAZARD: EXPLOSION AND FIRE – Solvent and paint

fumes can explode or ignite. Severe injury and/or property damage can occur.

PREVENTION:

• Provide extensive exhaust and fresh air introduction to keep the air within the spray area

free from accumulation of flammable vapors.

• Avoid all ignition sources such as static electricity sparks, electrical appliances, flames,

pilot lights, hot objects, and sparks from connecting and disconnecting power cords or

working light switches.

• Do not smoke in spray area.

• Fire extinguisher must be present and in good working order.

• Place pump at least 20 feet (6.1 m) from the spray object in a well ventilated area (add

more hose if necessary).

Flammable vapors are often heavier than air. Floor area must be extremely well ventilated.

The pump contains arcing parts that emit sparks and can ignite vapors.

• The equipment and objects in and around the spray area must be properly grounded to

prevent static sparks.

• Use only conductive or grounded high-pressure fluid hose. Gun must be grounded

through hose connections.

• Power cord must be connected to a grounded circuit.

• Always flush unit into separate metal container, at low pump pressure, with spray tip

removed. Hold gun firmly against side of container to ground container and prevent static

sparks.

• Follow material and solvent manufacturer’s warnings and instructions.

• Use extreme caution when using materials with a flashpoint below 70° F (21° C).

Flashpoint is the temperature at which a fluid can produce enough vapors to ignite.

• Plastic can cause static sparks. Never hang plastic to enclose spray area. Do not use

plastic drop cloths when spraying flammable materials.

• Use lowest possible pressure to flush equipment.

GAS ENGINE (WHERE APPLICABLE)

Always place sprayer outside of structure in fresh air. Keep all solvents away from engine

exhaust. Never fill fuel tank with a running or hot engine. Hot surface can ignite spilled fuel.

Always attach ground wire from pump to a grounded object. Refer to engine owner’s

manual for complete safety information.

HAZARD: EXPLOSION HAZARD DUE TO INCOMPATIBLE

MATERIALS – will cause severe injury or property damage.

PREVENTION:

• Do not use materials containing bleach or chlorine.

• Do not use halogenated hydrocarbon solvents such as bleach, mildewcide, methylene

chloride and 1,1,1 – trichloroethane. They are not compatible with aluminum.

4

• Contact your coating supplier about the compatibility of material with aluminum.

HAZARD: HAZARDOUS VAPORS – Paints, solvents, insecticides, and other materials

can be harmful if inhaled or come in contact with body. Vapors can cause severe nausea,

fainting, or poisoning.

PREVENTION:

• Use a respirator or mask if vapors can be inhaled. Read all instructions supplied with the

mask to be sure it will provide the necessary protection.

• Wear protective eyewear.

• Wear protective clothing as required by coating manufacturer.

HAZARD: GENERAL – Can cause severe injury or property damage.

PREVENTION:

• Read all instructions and safety precautions before operating equipment.

• Follow all appropriate local, state, and national codes governing ventilation, fire

prevention, and operation.

• The United States Government Safety Standards have been adopted under the

Occupational Safety and Health Act (OSHA). These standards, particularly part 1910 of

the General Standards and part 1926 of the Construction Standards, should be consulted.

• Use only manufacturer authorized parts. User assumes all risks and liabilities when

using parts that do not meet the minimum specifications and safety devices of the pump

manufacturer.

• Before each use, check all hoses for cuts, leaks, abrasion or bulging of cover. Check for

damage or movement of couplings. Immediately replace hose if any of those conditions

exist. Never repair a paint hose. Replace with a grounded high-pressure hose.

• All hoses, swivels, guns, and accessories must be pressure rated at or above

3200PSI/221 BAR.

• Do not spray outdoors on windy days.

• Wear clothing to keep paint off skin and hair.

• Always unplug cord from outlet before working on equipment.

Grounding Instructions

This product must be grounded. In the event of an electrical short circuit, grounding

reduces the risk of electric shock by providing an escape wire for the electric current. This

product is equipped with a cord having a grounding wire with an

appropriate grounding plug. The plug must be plugged into an outlet that is properly

installed and grounded in accordance with all local codes and ordinances.

DANGER — Improper installation of the grounding plug can result in a risk of electric

shock. If repair or replacement of the cord or plug is necessary, do not connect the green

grounding wire to either flat blade terminal. The wire with insulation

having a green outer surface with or without yellow stripes is the grounding wire and must

be connected to the grounding pin.

Check with a qualified electrician or serviceman if the grounding instructions are not

completely understood, or if you are in doubt as to whether the product is properly

grounded. Do not modify the plug provided. If the plug will not fit the

outlet, have the proper outlet installed by a qualified electrician.

Grounded Outlet

5

Grounding Pin

Cover for grounded outlet box

CAUTION

Use only a 3-wire extension cord that has a 3-blade grounding plug and a 3-slot

receptacle that will accept the plug on the product. Make sure your extension cord is in

good condition. When using an extension cord, be sure to use one heavy enough to carry

the current your product will draw. An undersized cord will cause a drop in line voltage

resulting in loss of power and overheating.

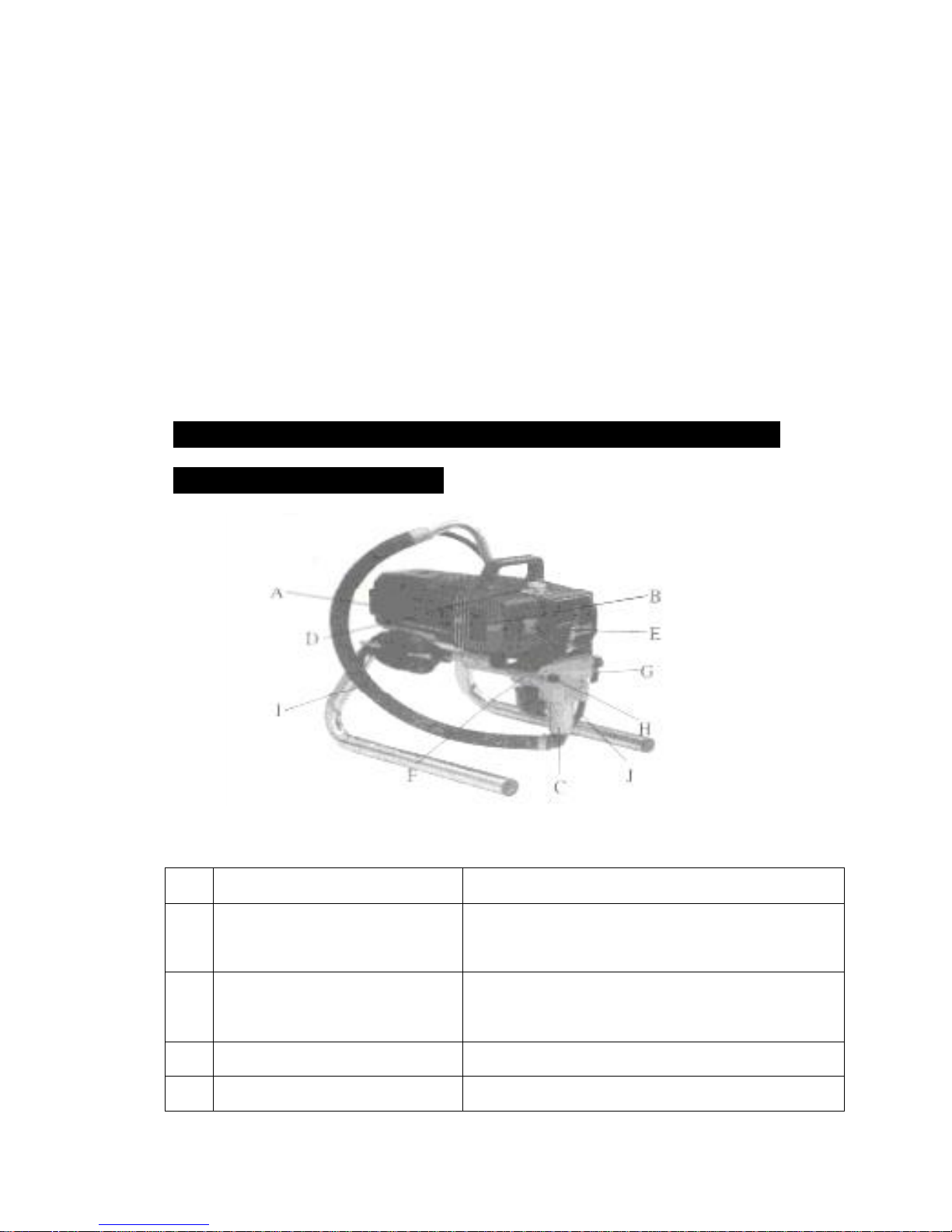

2.Name of equipment Components and features

introduction

A

Motor DC motor ,220V,50HZ,single-phase

B ICS intelligent Pressure controller. Pressure sensors and equipment have suggested that

the status of the equipment fuction

Suction Components

C

Use Within the upper and lower Components for the

two valve coating will be added after the supercharger

and exhaust

D Pressure adjustment Knob /Button Control the coating Pressure export

E On/off switch Control an equipment operation or stop

6

F Pump filters The percolation gets into the coating in the equipment

G Return Valve return to vertical direction for the state open ,the

horizontal direction for spraying state (close)

H Coating painting outlet Link Coating tube and manometer Position

I Suction tube

J Paint return tube Return to the state paint or solvent outflow from here

Will be from buckets in the paint inhalation equipment

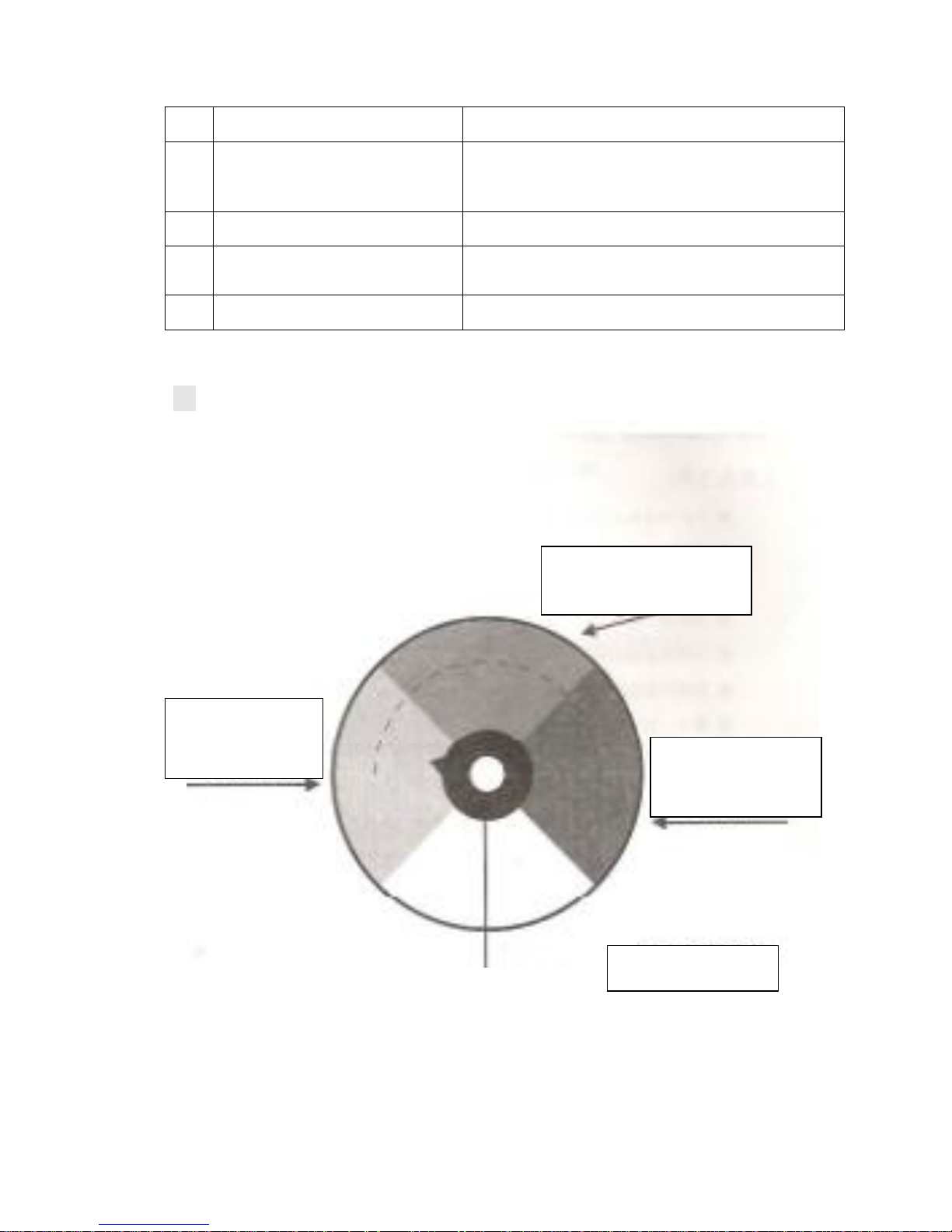

※The pressure control button operating Constructions

Middle pressure area(green)

indicate that middle pressure

Nopressurearea(yello

w) indicate that close

state

High pressure (red)

indicate that high

pressure

pressure control button

7

3. operation

I prepare before switching on.

1. prepare tool:

i. 5-inch,6-inch all within a hexagonal wrench.

ii. Cross screw 4

iii. 14-17、17-19of a double-headed wrench

iv. a blender or a stirring rod

v. antivirus mask and a set of overalls

vi. a brush

vii. some rags

viii. a multimeter

ix. 30-meter,2.5MM² power line extension

x. a power regulator

2. preparetory steps:

⑴assurance suction tube and the reflux tube link the right of position and screwed tightly

⑵firstly contect on the coating manometer exit ,then 15 meter high presure nylon coating

of pressure gauges connected to the export terminal and screwed tightly (pressure gauge

in the first coating to the exit)

⑶havig to use two wrench will be no high-pressure airless spray gun connected to the

head and another screwed tightly .

⑷detemine pressure manometer control buttons set in the display more than 150

locations

(5)multimeter detemined by measureing power supply is 220-250(equipment allowing

fluctutation of voltage )volts of voltage.

(6)equipment will be displayed at the distance of at least 7.5meters in construction place

dry region .

8

3. the initial use of new equipment:

the new equipment of the factory contain a protective effect lubricants,so

the initial use of new equipment need to join the clean water of few soap to

take in to clean ,the flollowing step is cleaning:

⑴add to suction tube containing a little soapy water in the buckets

⑵add to the waste will be returned in the paint barrels\buckets.

(3)return valve will be installed in the vertical direction .

(4)open equipment power switch..

(5)let soapy water to peration equipment in the equipment within the circle ,until the

outflow of clean water from the return tube .

II preparetive before spraying:

before spraying ,they must first determine spray paint has been good

and have been initially harmonic filtering ,otherwise undesirable coating

equipment will in creas wear and reduce the life span of equipment .in

addition ,each time before spraying ,the paint must be used by delicated

diluent (such as spraying latex paint water can be used )to allow equipment

to cycle again and again spraying ,the following is operation steps:

⑴add suction tube will be fitted with special diluent or clean in the bucket.

⑵add to the waste will be returned in paint bucket.

⑶Pressure control buttons will be set in the middle (yellow areas) but the bottom

of the location of equipment functioning.

⑷return valve will be installed in the vertical direction.

⑸Power equipment opened.

⑹equipment to operation 15 to 30 seconds until the clean diluent from the outflow

of return

⑺shut the powers switch.

⑻set the reflux valve to the position of level.

⑼turn on the power switch

Loading...

Loading...