Dino-Power DP-X3, DP-X6 Operation Manual

Operation Manual

Read all warnings and instructions in this manual, related manuals, and on the unit.

Be familiar with the controls and the proper usage of the equipment. Save these

instructions. Read carefully and practice good safety habits.

DP-X3 DP-X6

Electric Airless Paint Sprayer

www.dpairless.com

Important Safety Instructions

1

Review Warnings for Important Safety Information

Important! Read carefully and practice good safety habits.

Review Manuals and Watch Videos

Always carefully read manuals and watch videos before doing the spraying jobs.

Not approved for use in explosive atmospheres or hazardous locations.

For portable airless spraying of architectural paints and coatings.

FIRE AND EXPLOSION HAZARD

DP-X3/DP-X6 Models:

•

Use only non-flammable or water-based/oil-based materials, or non-flammable paint thinners. Do

not use materials having flash points lower than 100° F (38° C). This includes, but is not limited to,

acetone, xylene, toluene, or naphtha. For more information about your material, request Safety

Data Sheet (SDS) from the supplier.

•

Spraying flammable or combustible materials in a factory or fixed location must comply with NFPA

33 and OSHA 1910.94(c) requirements in the USA and with all similar local regulations in other

countries.

Before You Spray

2

Contents

Contents

Before You Spray

Warnings

Know Your Sprayer

Setup

Start Up

How to Spray

Cleanup

Storage

Reference

Maintenance

Troubleshooting

Explosion View and Spare Parts List

.........................................................................................................................................

.................................................................................................................................................

............................................................................................................................................

Pressure Relief Procedure

Adjust Pressure Control

Spray Techniques

Clear Tip Clog

..........................................................................................................................................

...........................................................................................................................................

......................................................................................................................................

Spray Tip Selection

Cleaning Fluid Compatibility

Static Grounding Instructions (Oil-Based materials)

..........................................................................................................................

.......................................................................................................................

.....................................................................................................

................................................................................................................................

.......................................................................................................

.................................................................................................................

........................................................................................................................

...............................................................................................................

................................................................................................

........................................................

.................................................................................................................................

..........................................................................................................................

....................................................................................

1

3

6

7

9

9

12

13

13

14

15

17

19

19

20

20

22

26

30

Warnings

3

Warnings

Flammable fumes, suchas solventand paint fumes, in work area can ignite or explode. To help

prevent fire and explosion:

•

Do not spray or clean with materials having flash points lower than 100°F (38° C). Use only

•

Do not spray combustible materials near an open flame or sources of ignition such as

•

Do not spray combustible liquids in a confined area.

•

Do not spray flammable or combustible materials near an open flame or sources of ignition

•

Do not spray flammable or combustible liquids in a confined area.

•

Paint or solvent flowing through the equipment is able to result in static electricity. Static

•

Verify that all containers and collection systems are grounded to prevent static discharge.

•

Connect to a grounded outlet and use grounded extensions cords. Do not use a 3-to-2

•

Do not use a paint or a solvent containing halogenated hydrocarbons.

•

Keep spray area well-ventilated. Keep a good supply of fresh air moving through the area.

•

Sprayer generates sparks. Keep pump assembly in a well ventilated area a least 20 feet

•

Do not smoke in the spray area or spray where sparks or flame is present.

•

Do not operate light switches, engines, or similar spark producing products in the spray

•

Keep area clean and free of paint or solvent containers, rags, and other flammable

•

Know the contents of the paints and solvents being sprayed. Read all Safety Data Sheets

•

Fire extinguisher equipment shall be present and working.

The following warnings are for the setup, use, maintenance, and repair of this equipment. The

exclamation point symbol alerts you to a general warning and the hazard symbols refer to

procedure-specific risks. When these symbols appear in the body of this manual or on

warning labels, refer back to these Warnings. Product-specific hazard symbols and warnings

not covered in this section may appear throughout the body of this manual where applicable.

FIRE AND EXPLOSION HAZARD

DP-X3/DP-X6 airless sprayer Models:

non-flammable or water-based materials, or non-flammable paint thinners. For complete

information about your material, request the Safety Data Sheet (SDS) from the material

distributor or retailer.

cigarettes, motors, and electrical equipment.

such as cigarettes, motors, and electrical equipment.

electricity creates a risk of fire or explosion in the presence of paint or solvent fumes. All

parts of the spray system, including the pump, hose assembly, airless spray gun, and

objects in and around the spray area shall be properly grounded to protect against static

discharge and sparks. Use DP conductive or grounded high-pressure airless paint sprayer

hoses.

Do not use pail liners unless they are anti-static or conductive.

adapter.

(6.1 m) from the spray area when spraying, flushing, cleaning, or servicing. Do not spray

pump assembly.

area.

materials.

(SDSs) and container labels provided with the paints and solvents. Follow the paint and

solvents manufacturer’s safety instructions.

Warnings

4

SKIN INJECTION HAZARD

High-pressure spray is able to inject toxins intothe body and cause serious bodily injury. In the

event that injection occurs, get immediate surgicaltreatment.

•

Do not aim the gun at, or spray any person or animal.

•

Keep hands and other body parts away from the discharge. For example,do not try to stop

leaks with any part of the body.

•

Always use the nozzle tip guard. Do not spray without nozzle tip guard in place.

•

Use DP nozzle tips.

•

Use caution when cleaning and changing airless spray nozzle tips. In the case where the

nozzle tip clogs while spraying, follow the Pressure Relief Procedure for turning off the

unit and relieving the pressure before removing the nozzle tip to clean.

•

Equipment maintains pressure after power is shut off. Do not leave the equipment

energized or under pressure while unattended. Follow the Pressure Relief Procedure

when the equipment is unattended or not in use, and before servicing, cleaning, or

removing parts.

•

Check hoses and parts for signs of damage. Replace any damaged hoses or parts.

•

This system is capableof producing 2900 psi. UseDP replacementparts oraccessories

that are rated a minimum of 2900 psi.

•

Always engage the trigger lock when not spraying. Verify the trigger lock is functioning

properly.

•

Verify that all connections are secure before operating the unit.

•

Know how to stop the unit and bleed pressure quickly. Be thoroughly familiar with the

controls.

EQUIPMENT MISUSE HAZARD

Misuse can cause death or serious injury.

•

Always wear appropriate gloves, eye protection, and a respirator or mask when painting.

•

Do not operate or spray near children. Keep children away from equipment at all times.

•

Do not overreach or stand on an unstable support. Keep effective footing and balance at

all times.

•

Stay alert and watch what you are doing.

•

Do not operate the unit when fatigued or under the influence of drugs or alcohol.

•

Do not kink or over-bend the hose.

•

Do not expose the hose to temperatures or to pressures in excess of those specified by

DP.

•

Do not use the hose as a strength member to pull or lift the equipment.

•

Do not spray with a hose shorter than 25 feet.

•

Do not alter or modify equipment. Alterations or modifications may void agency approvals

and create safety hazards.

•

Make sure all equipment is rated and approved for the environment in which you are using

it.

ELECTRIC SHOCK HAZARD

This equipment must be grounded. Improper grounding, setup, or usage of the system can

cause electric shock.

•

Turn off and disconnect power cord before servicing equipment.

•

Connect only to grounded electrical outlets.

•

Use only 3-wire extension cords.

•

Ensure ground prongs are intact on power and extension cords.

•

Do not expose to rain. Store indoors.

Warnings

5

PRESSURIZED ALUMINUM PARTS HAZARD

Use of fluids that are incompatible with aluminum in pressurized equipment can cause serious

chemical reaction and equipment rupture. Failure to follow this warning can result in death,

serious injury, or propertydamage.

•

Do not use 1,1,1-trichloroethane, methylene chloride, other halogenated hydrocarbon

solvents or fluids containing such solvents.

•

Do not use chlorine bleach.

•

Many other fluids may contain chemicals that can react with aluminum. Contact your

material supplier for compatibility.

MOVING PARTS HAZARD

Moving parts can pinch, cut, or amputate fingers and other body parts.

•

Keep clear of moving parts.

•

Do not operate equipment with protective guards or covers removed.

•

Pressurized equipment can start without warning. Before checking, moving, or servicing

equipment, follow the Pressure Relief Procedure and disconnect all power sources.

TOXIC FLUID OR FUMES HAZARD

Toxic fluids or fumes can cause serious injury or death if splashed in the eyes or on skin,

inhaled, or swallowed.

•

Read MSDSs to know the specific hazards of the fluids you are using.

•

Store hazardous fluid in approved containers, and dispose of it according to applicable

guidelines.

PERSONAL PROTECTIVE EQUIPMENT

Wear appropriate protective equipment when in the work area to help prevent serious injury,

including eye injury, hearing loss, inhalation of toxic fumes, and burns. This protective

equipment includes but is not limited to:

•

Protective eyewear, and hearing protection.

•

Respirators, protective clothing, and gloves as recommended by the fluid and solvent

manufacturer.

Know Your Sprayer

6

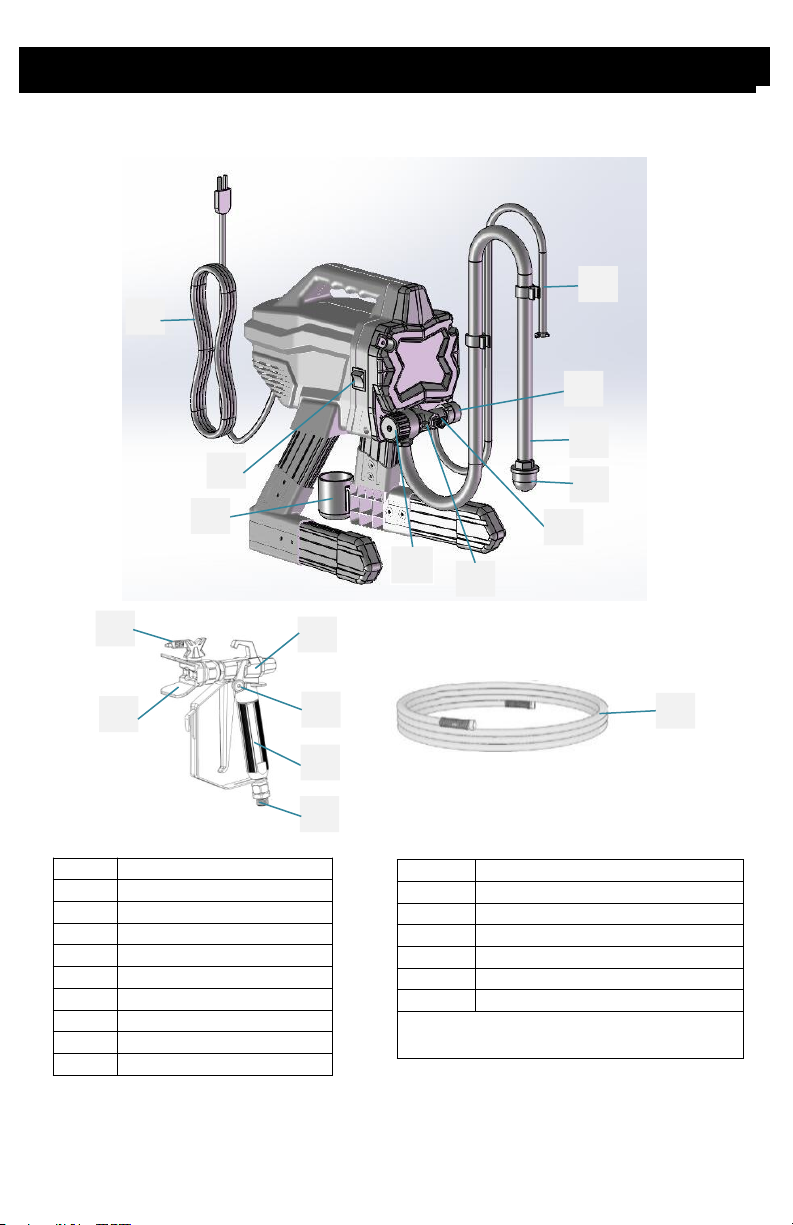

O

H

G

D

J

I

F

O

C

E

DP-X3 DP-X6

A

Prime/Spray Valve

B

Pressure Control Knob

C

ON/OFF Switch

D

Suction Tube

E

Drain Tube

F

Airless Spray Gun

G

Reversible Spray Tip

H

Tip Guard

I

Gun Trigger Lock

J

Gun Fluid Inlet Fitting

K

Gun Fluid Filter(inside handle)

L

Pump

M

Pump Fluid Outlet Fitting

N

High Pressure airless Hose

O

Suction Filter

P

Power Cord

Q

Suction Tube Drip Cup

See Quick Reference, page 21 for

more information.

L

B

A

M

N

K

D

Q

P

Know Your Sprayer

7

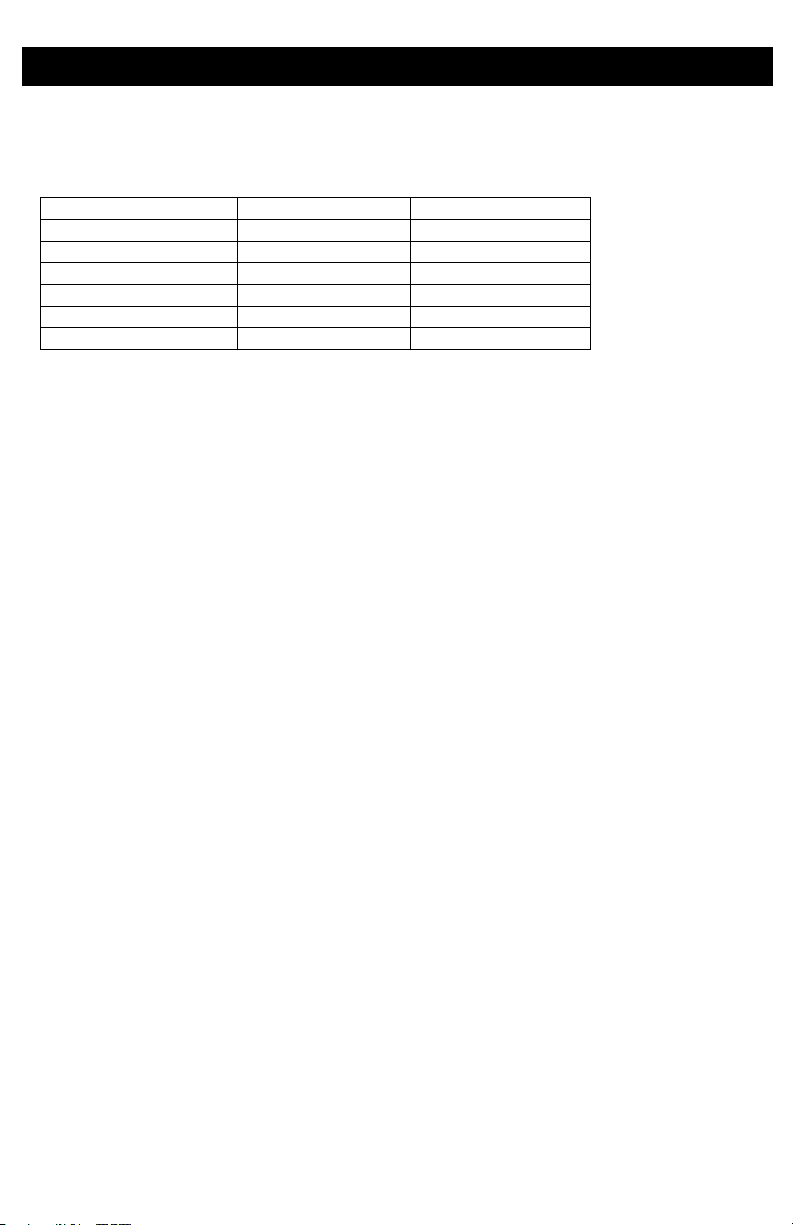

Technical Specifications:

Model No.

DP-X3

DP-X6

Pressure Controlling

Mechanical

Mechanical

Motor Power

550W

650W

Max. Flow Rate

1.0L/min 0.26GPM

1.4L/min 0.36GPM

Max. Tip Size

0.017”

0.019”

Max. Pressure

200bar/2900psi

200bar/2900psi

Max. Hose Length

15m

15m

Reminding Tips:

1. Clean the pump / hose / spray gun / airless spray tip throughly everyday when you

finish your painting job.

2. When pump is stored with non-freezing fluid. Pump damage will occur if water or

latex paint freezes in pump.

3. Damage to plastic parts may result if impact occurs in low temperature conditions.

Changes in paint viscosity at very low or very high temperatures can affect sprayer

performance.

Start Up

8

ti26

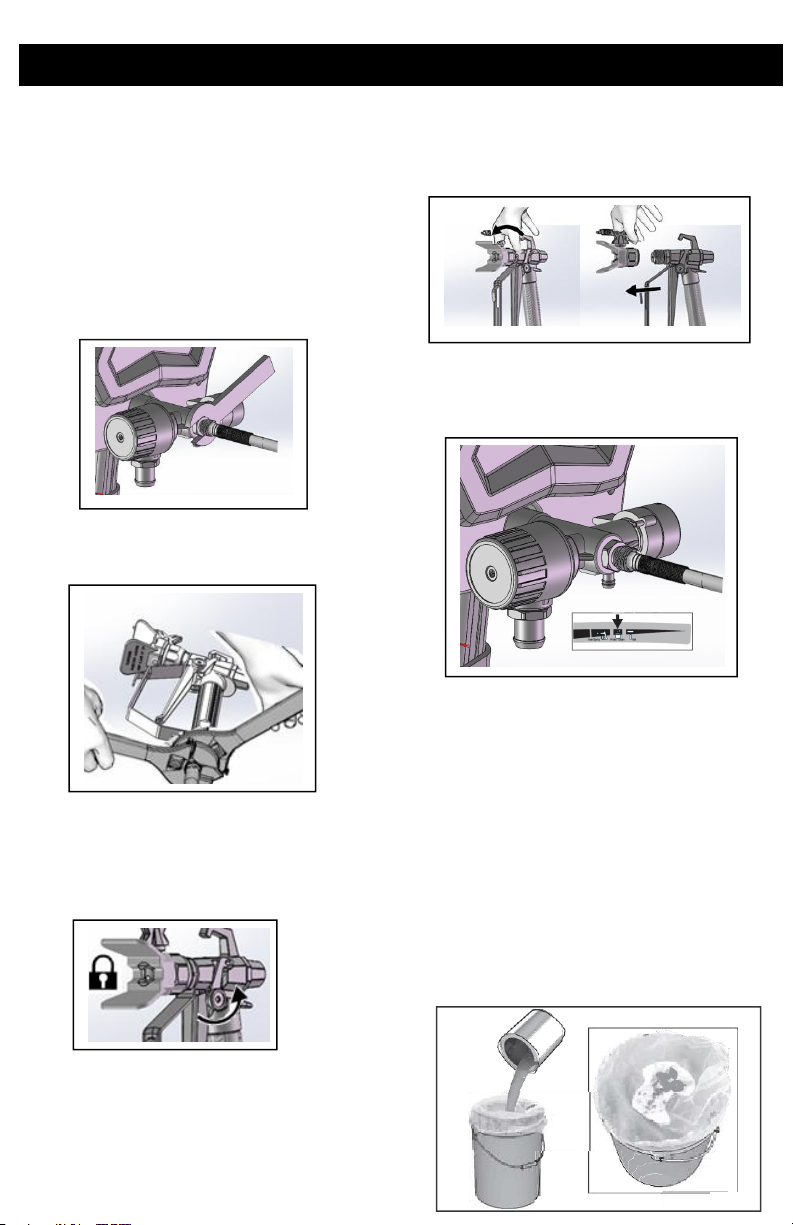

Setup

When unpacking sprayer for the first time

or after long term storage perform setup

procedure.

1.

Connect DP airless hose to fluid

outlet. Use wrench to tighten

securely.

6. Turn pressure control knob all the

2.

Connect other end of hose to gun.

7. After long term storage check

inlet strainer for clogs and debris.

3.

Use two wrenches to tighten securely.

If hose is already connected, make

sure connections are tight.

4.

Engage trigger lock.

5.

Remove tip guard. Be careful tip seal

may fall out when tip guard is

removed.

Strain the Paint

Previously opened paint may contain

dried paint or other debris. To avoid

priming problems and spray tip clogs it is

recommended to strain the paint before

using. Paint strain- ers are available

where paint is sold. Stretch a paint

strainer over a clean pail and pour the

paint through the strainer to capture any

dried paint and debris before spraying.

Assemble Your Sprayer

Setup

way left (counter-clockwise) to

lowest set- ting.

Loading...

Loading...