Dino power DP-6386 User Manual

Owner´s Manual

Airless Spray Technology For professional use only

Do not use this equipment before reading this manual!

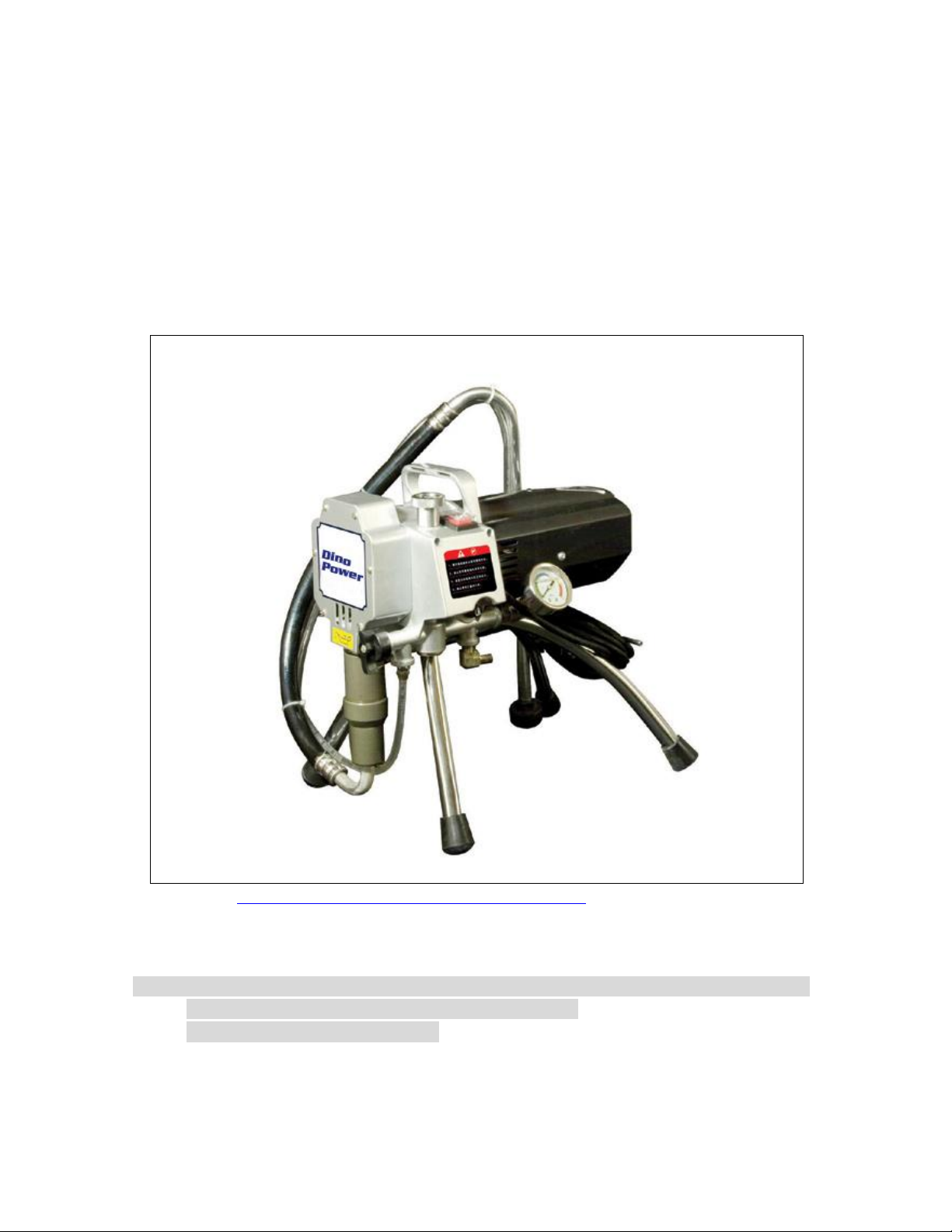

DP-6386 Airless Sprayer

Web site: http://www.airlesspaintsprayer-pump.com

NOTE:This guide manual is for Model DP-6386 airless painting equipment, including the

operation,cleaning and maintenance,please read this

manual before using the machine.

Contents

1.Warning and special cautions

2.Introduction of components and functions

3.Operation

·Preparation before operation

·Preparation before spraying

·Spraying

·Procedure of releasing pressure

·Daily maintenance

4.Spraying technique

5.Cleaning

6.Repair

7.General problems and troubleshooting

8.Parts Listing

9.Accessories

1、Warning and special cautions

Warning!

Don´t operation the equipment without reading the following special cautions

1.Special cautions when operating

1、Never put your fingers,hands or any other part of the body into the spray jet.

2、Never point the spray gun at yourself or any other else

3、Never use the spray gun without the spray tip cover

4、Close the safety guard at any time except spraying and cleaning

5、Please release the pressure before the repair and the maintenance

6、Don´t clean it with bleached water or solvent containing strong acid and

alkali

7、It should be equipped with correspondent electric pressure stabilizing device.

8、Please operate the machine in a bright place

9、Never operate the machine in a place with sparks or combustible substances

10、Never operate the machine beyond 10 seconds without paints

11、Paints with glue, pellets ,strong corrosive or without solvent are prohibited.

12、This machine should only be linked with 220V electricity,380V electricity is

prohibited, otherwise it will be burned

13、Never pull the electric wire

14、Never smoke when operating the machine

2、Introduction of components and functions

Motor Direct current motor, 220V,50HZ,single phase motor

Pressure Control Knob

Switch Controlling the power on or off

PRIME/SPRAY Valve

Oil Cup Cup for oiling(PLS oil or 45#super sewing machine oil

Siphon Hose Siphoning paints from bucket to the machine

Return Tube Paints or solvent flows from here in return state

Controlling paint´pressure outlet

Horizontal direction is for Prime state(ON)

Vertical direction is for Spraying(OFF)

3、Operation

Preparation before operation

1、Tools:

Tools Quantity

6 inch,8 inch,10 inch wrench One each

“╋”Screwdriver One

Iron bucket Two

Plastic bucket One

Agitator or stirring stick One

Preventive mask and uniform One each

Brush One

Rag One

Electric meter One

Electric wire within 30 meters,25mm²

Electric pressure stabilizing device One

One roll

2、Preparation procedure

1、Siphon Hose and Return Tube should be linked correctly and whirl tight

2、Link 15 meter high pressure nylon paint tube to the outlet fitting and whirl tight

3、Link FTX airless spray gun to the other end of paint tube with two wrenches and whirl tight

4、Make sure the PRIME/SPRAY Valve is set horizontal state(ON)

5、Inject 5-6 drops PLS oil at oil cup

6、Check the voltage with a electric ammeter,and make sure it is between 200–250V(permitted

by machine)

7、Place the machine in a dry area at least 7.5 meters away from the operation area.

3、When it is used for the first time

Because there is protective lubricating oil in new machine,you should use some

soapsuds to wash it when using it for the first time,Follow the instructions as below:

1、Put siphon hose in a clean water bucket added with little soapsuds

2、Put Return Tube in a waste bucket

3、Set the Pressure Control Knob middle pressure by which the machine could

work(Don´t whirl too tight)

4、Set the PRIME/SPRAY Valve horizontal

5、Turn on the electricity

6、Operate the machine to circulate the soapsuds until clean water flows out

of the return tube

7、Turn off the electricity

Preparation before spraying

Before spraying, make sure the paints is in harmonious proportion and is simply

filtered, otherwise unpurified paints will cause wear and tear to the machine and

reduce the machine´s life.Besides,circulate the special diluent,and then spray.Follow

the instructions as below:

1、Put siphon hose in a bucket full of special diluent or clean water

2、Put return tube in a waste bucket

3、Set Pressure Control Knob middle pressure by which the machine could work

(Don´t whirl too tight)

4、Set PRIME/SPRAY Valve horizontal

5、Turn on electricity

6、Let the machine work for 15-30 seconds,until clean diluent flow out of return

tube

7、Turn off electricity

8、Set PRIME/SPRAY Valve vertical

9、Turn on electricity

10、Open safety guard

11、Point the spray gun at the inside of waste bucket,pull the trigger until clean

solvent flows out so that old solvent in paint tube and spray gun flows out

12、Close safety guard(see upper picture)

13、Slowly set Pressure Control Knob high pressure(Whirl tight)

14、Carefully check every component whether it leaks,in that case,release the

pressure according to the “pressure releasing procedure” then whirl tight

where it leaks

Spraying

1、Put siphon hose into painting bucket

2、put return tube into waste bucket

3、Set Pressure Control Knob middle pressure by which the machine could work

(Don´t whirl too tight)

4、Set PRIME/SPRAY Valve horizontal

Loading...

Loading...