Dini Argeo DFWATEX2GD, DFWATEX2GDIO, DFWATEX2GDM, DFWATEX2GDMI Technical Manual

TECHNICAL MANUAL

WEIGHT INDICATOR

DFWATEX2GD, DFWATEX2GDIO, DFWATEX2GDM,

DFWATEX2GDMI

DFWATEX2GD_05.03_12.09_EN_T

1 of 49

INDEX

1 WARNINGS ........................................................................................................................................................................ 3

2 REQUIREMENTS FOR AN EFFECTIVE INSTALLATION ................................................................................................. 4

3 TECHNICAL FEATURES ................................................................................................................................................... 4

4 SETUP ENVIRONMENT ..................................................................................................................................................... 5

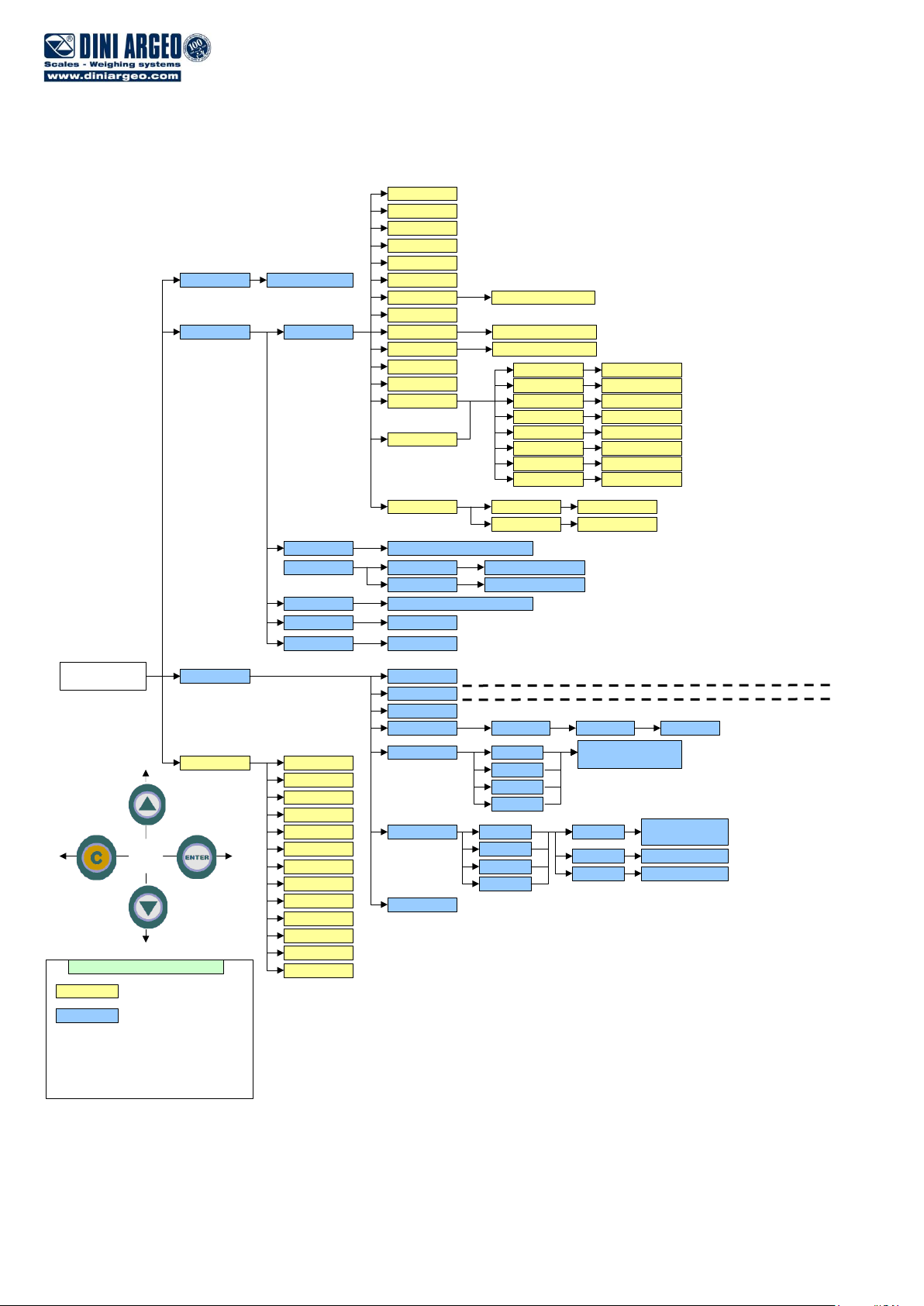

4.1 SET-UP ENVIRONMENT BLOCK DIAGRAM ............................................................................................................... 7

4.2 DESCRIPTION OF THE STEPS ................................................................................................................................... 9

5 CALIBRATION .................................................................................................................................................................. 21

5.1 SCALE CONNECTED TO A SINGLE CHANNEL ....................................................................................................... 22

5.2 SCALE WITH NON INDEPENDENT CHANNELS (could eventually be digitally equalised) ....................................... 22

5.3 IF THE ZONE OF USE IS DIFFERENT THAN THE CALIBRATION ZONE ONE SHOULD: ...................................... 23

5.4 QUICK CALIBRATION OF ZERO ............................................................................................................................... 24

5.5 QUICK CALIBRATION OF A DEFINED WEIGHT ...................................................................................................... 24

5.6 MANUAL CALIBRATION OF A DEFINED WEIGHT ................................................................................................... 24

6 DISPLAY OF THE GRAVITY ACCELERATION AND CORRECTION OF THE WEIGHING ERROR DUE TO THE

DIFFERENT GRAVITY ACCELERATION BETWEEN CALIBRATION ZONE AND UTILISATION ZONE. ......................... 25

7 SERIAL OUTPUT .............................................................................................................................................................. 25

7.1 FIBER OPTIC PORT .................................................................................................................................................. 25

7.2 SERIAL PORT TRANSMISSION MODES .................................................................................................................. 25

7.2.1 PC PORT ............................................................................................................................................................. 25

7.2.2 PRN PORT ........................................................................................................................................................... 28

7.3 FORMAT OF THE SERIAL COMMANDS ................................................................................................................... 28

7.4 TRANSMISSION PROTOCOLS ................................................................................................................................. 34

7.4.1 STANDARD STRING ........................................................................................................................................... 34

7.4.2 EXTENDED STRING ........................................................................................................................................... 35

7.4.3 MASTER MODE STRINGS .................................................................................................................................. 36

8 PROGRAMMING THE PRINTOUTS ................................................................................................................................. 36

8.1 FORMATTING DATA AND LAYOUT .......................................................................................................................... 39

8.2 SAVING THE LABEL IN THE LABELLER’S PERMANENT MEMORY ....................................................................... 45

8.2.1 SAVING THE LABEL IN THE LABELLER’S PERMANENT MEMORY IN MASTER/SLAVE SYSTEMS ............. 45

9 PRINTING THE HEADING ................................................................................................................................................ 46

10 CONNECTION SCHEMES .............................................................................................................................................. 49

10.1 EXPLANATION OF EXPANSION BOARDS (PRESENT DEPENDING ON THE MODEL) ...................................... 49

For the simplest usage in this manual, the name DFWATEX stands for both DFWATEX2GD, DFWATEX2GDIO,

DFWATEX2GDM and DFWATEX2GDMI,

so where “DFWATEX” is used it is understood as “DFWATEX2GD, DFWATEX2GDIO, DFWATEX2GDM and

DFWATEX2GDMI”.

NOTE FOR THE TECHNICIAN

Please take note that when the “StEP….(USER MAN.REF.)is mentioned, this refers to the user manual.

DFWATEX2GDxxx 2 of 49

1 WARNINGS

These warnings apply to DFWATEX2GDxxx weight indicators and

to the optional ATEX version JB4Q junction box

ESSENTIAL PREREQUISITE

ALONG WITH THIS TECHNICAL MANUAL ONE SHOULD

ALSO READ AND UNDERSTAND THE CORRESPONDING

DFWATEX2GD USER MANUAL

IN WHICH IMPORTANT WARNINGS ARE INDICATED

DFWATEX2GDxxx 3 of 49

POWER SUPPLY

- with power adapter PW200XRD:

- 230Vac input / 10.5Vdc

- 115Vac input / 10.5Vdc

- 24Vac input / 10.5Vdc

- 24Vdc input / 10.5Vdc

- with rechargeable battery DFWBP76ATEX: 9,6 Vdc

120mA with a nominal capacity of 7,6 Ah

MAXIMUM RECHARGING TIME OF THE

BATTERY

With the appropriate 12V 2A charger, the complete recharge

is made from 15 to 18 hours

MAXIMUM POWER ABSORBED

Pi = 1,44W

OPERATING TEMPERATURE

- 20°C ÷ +40°C

DISPLAY DIVISIONS

10000e, 3 x 3000e for legal for trade weighing, expandable up

to 100.000 for internal use.

COUNTING RESOLUTION

150'000 points

DISPLAY

LCD with 6 digits, 25 mm. high

INDICATIONS

25 multifunction symbols on LCD display

KEYBOARD

Waterproof in polycarbonate with membrane keys having a

tactile and acoustic feedback.

LOAD CELL POWER SUPPLY

1, 6Vdc / 3,2Vdc

(up to 4 cells 350 Ω, with power adapter SG160.x.2 and

DFWBP76ATEX battery )

(up to 8 cells 350 Ω, with power adapter PW200XRD)

LOAD CELL CONNECTION

- 6 wires with remote sense on terminal board

- 4 wires using the AMP connection on the motherboard

CONTAINER

Stainless steel metallic case with IP67 protection, suitable for

mounting on shelf or column.

2 REQUIREMENTS FOR AN EFFECTIVE INSTALLATION

To obtain the best results it is recommended to install the indicator and the platform (or transducer) in a place with the

following conditions:

A flat and level resting surface

Stable and vibration free

No dusts and aggressive vapours

No draughts

Make sure the platform is level or that the loading cells are resting evenly

3 TECHNICAL FEATURES

DFWATEX2GDxxx 4 of 49

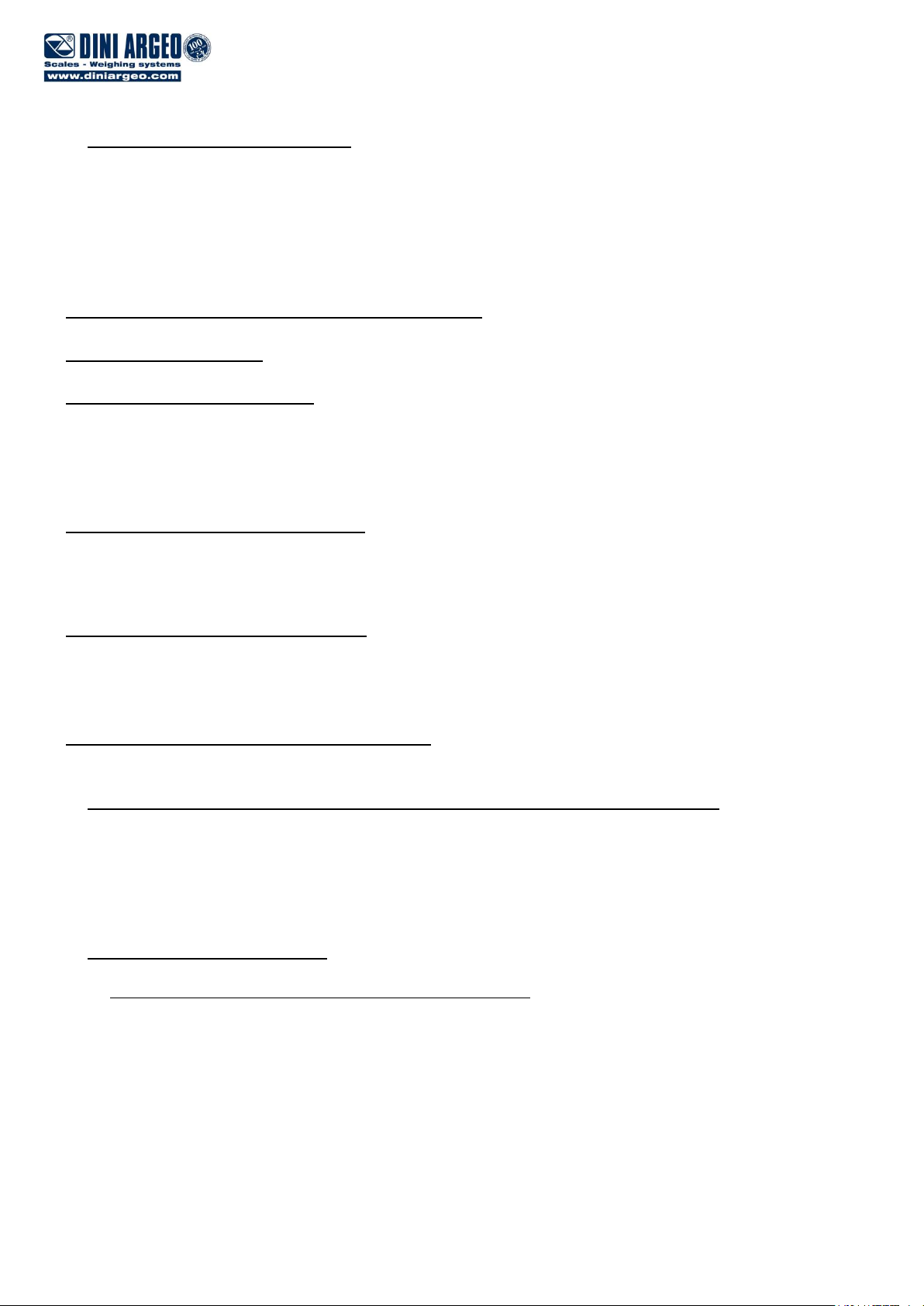

“uSEr”

for an instant on the

display

“tECh”

for an instant on the

display

“tECh”

for an instant on

the display

KEY

FUNCTION

Allows scrolling ahead through the programming steps.

Allows to scroll backwards through the programming steps.

Allows to quickly position on the first step of a menu.

“F.ModE”

on the display

“PrG.VEr”

on the display

PARTIAL SET-UP

MENU

(only user)

ENTER THE

PASSWORD

SUBSTITUTING THE

DISPLAYED VALUE

(*)

Press

ENTER

COMPLETE SET-UP

MENU

(technical personnel)

Press TARE/ZERO

during the

visualisation of the

“uSEr”

message

on the display

ACCESS

PASSWORD

ENABLED

ACCESS

PASSWORD

DISABLED

COMPLETE SET-UP

MENU

(technical personnel)

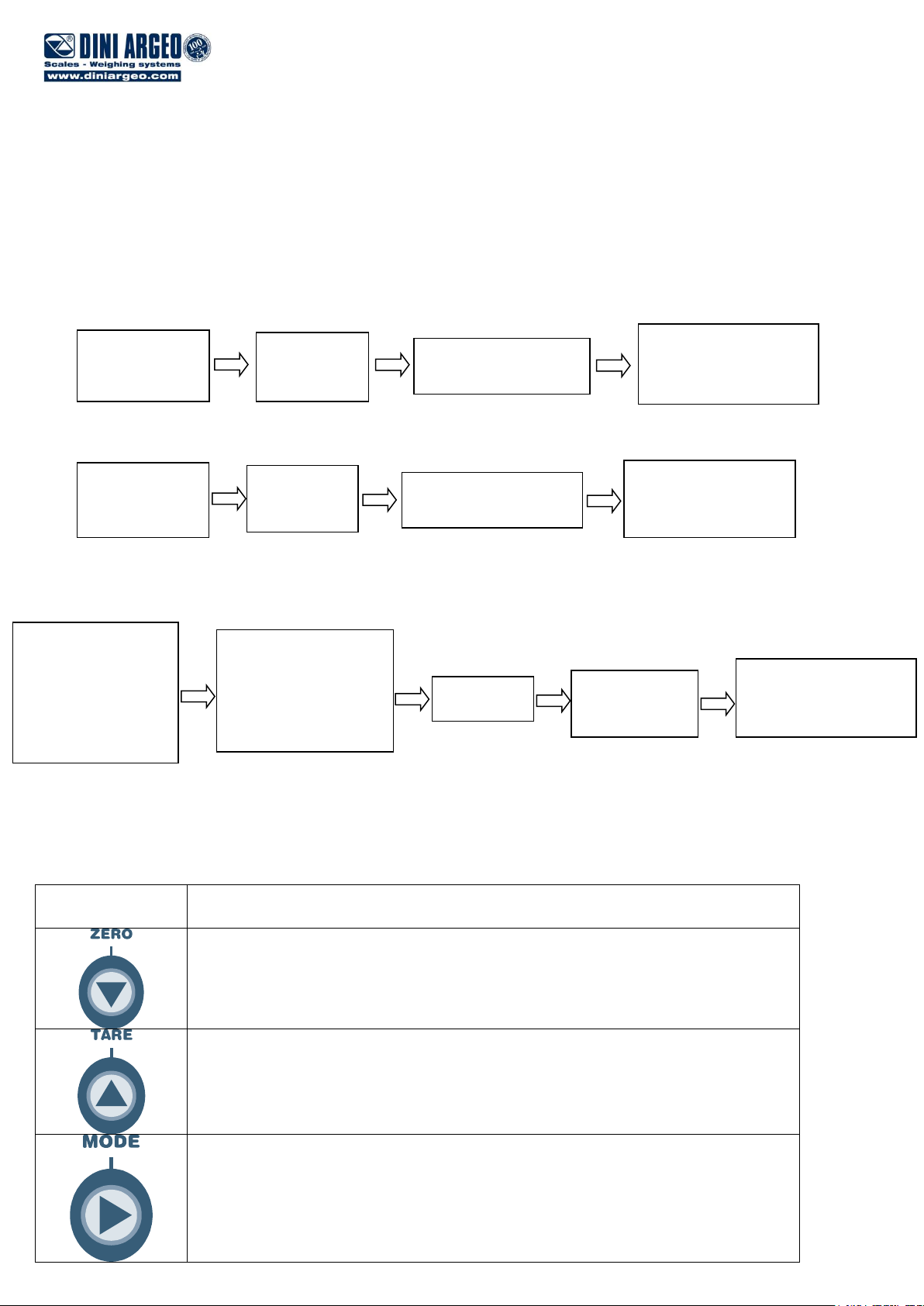

4 SETUP ENVIRONMENT

With "SETUP ENVIRONMENT" we intend a specific menu, where it’s possible to set all the functioning parameters of the

indicator.

To enter it, turn on the instrument and, while the firmware version is being displayed, press the TARE key for an

instant.

The indicator shows :

1)

or

2)

If you are in choice 2) and you want to access the complete set-up menu one should:

(*) If one has forgotten the password, one should communicate the displayed number to the manufacturer, who will supply a

valid password JUST FOR THAT SPECIFIC NUMBER.

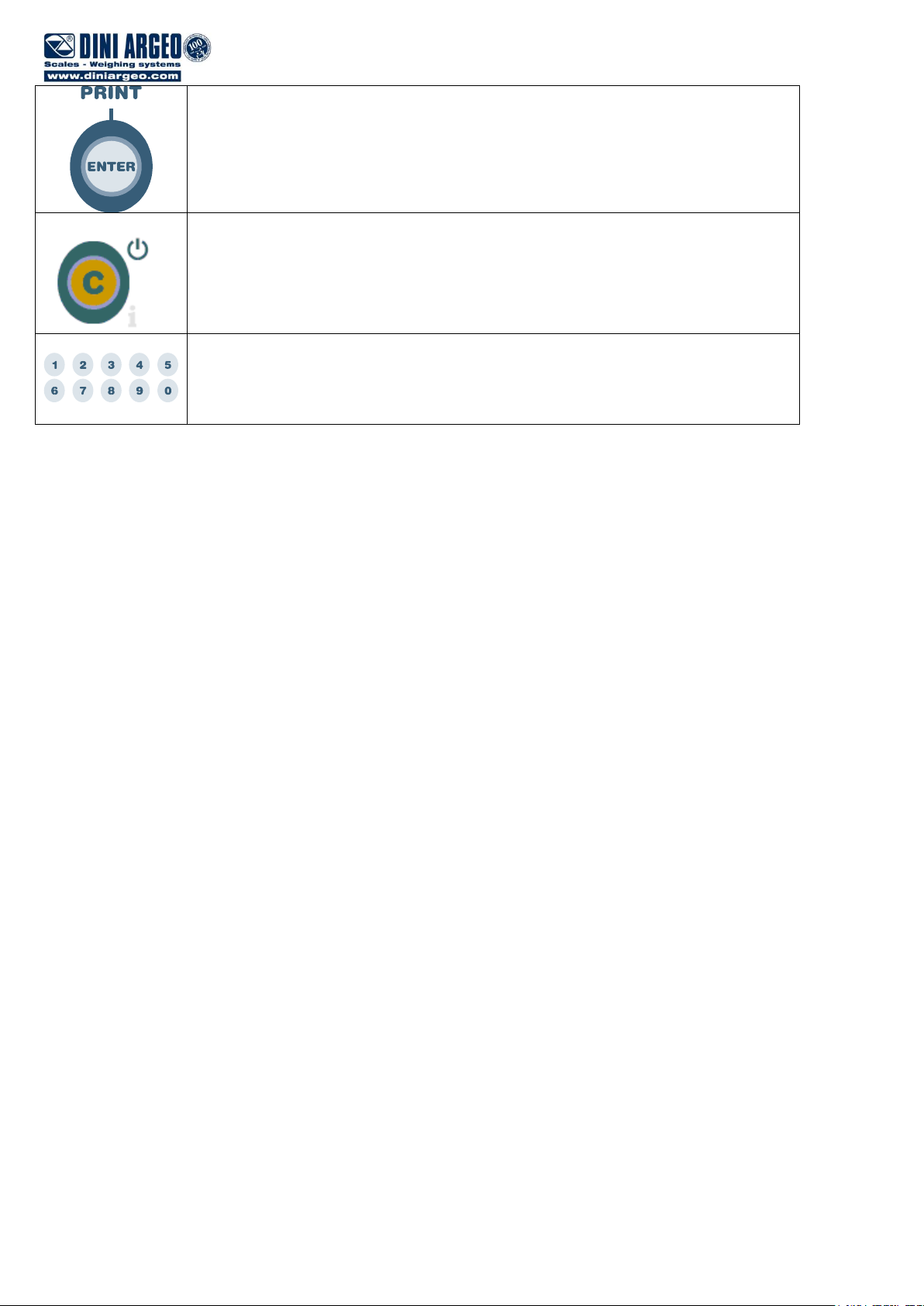

In the SET-UP environment, the instrument keys take on the following functions:

DFWATEX2GDxxx 5 of 49

Allows to enter a step or confirm a parameter inside a step.

Allows to exit a step without confirming the possibly modified parameter and go to the

preceding level.

When entering a numeric value it quickly zeros the displayed value.

Allow to enter numeric values, from right to left.

The display indicates the abbreviation of the step whose meaning is described below.

In the parameter description and in the block diagram:

- The METRIC parameters are shown with the (*) symbol, and, with approved instrument, these may not be visible or

read only. See the explanation of the parameter for the details.

NOTE: The indicator is approved when the J1 jumper (CAL) of the motherboard is open

- The CONDITIONAL STEPS are shown with the (§) symbol, and are not displayed in specific conditions, shown in

the step description.

- The DEFAULT VALUES are shown with the (!) symbol placed next to the step and at the end of it.

TO EXIT THE SET-UP ENVIRONMENT, PRESS THE C KEY MANY TIMES UNTIL THE INDICATOR SHOWS “SAVE?”

IN THE DISPLAY: CONFIRM WITH ENTER/PRINT TO SAVE ANY CHANGES MADE OR PRESS ANOTHER KEY TO

NOT SAVE.

DFWATEX2GDxxx 6 of 49

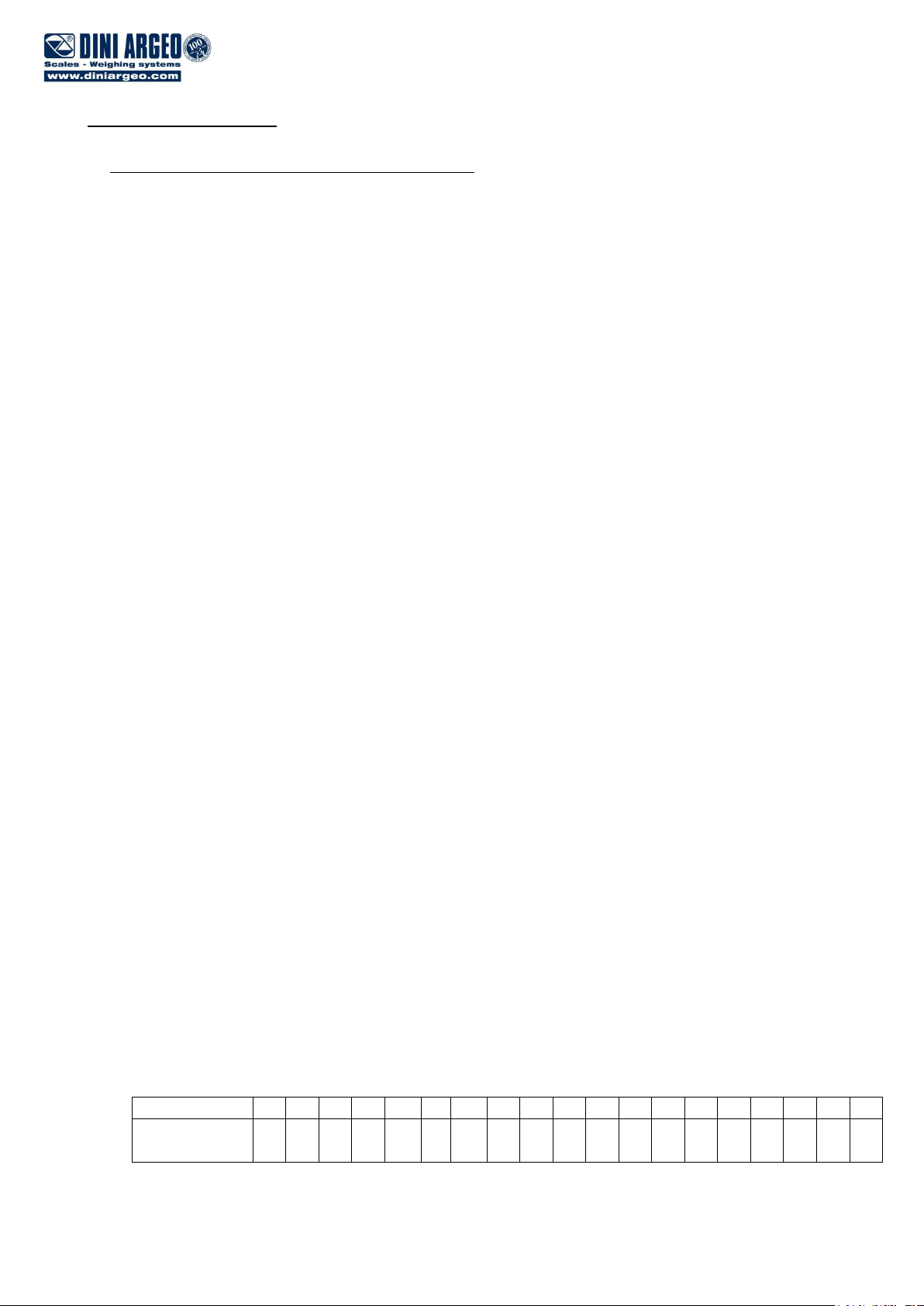

F.Mode

DiAG. PrG.VEr

diV.int (§)

diSPLA

kEyb.

SEr

CtS.St.

bt.AdC

SETUP

ENVIRONMENT

inPutS (§)

StPn

rEACt (§) (!) ZEro, inSt, ALWAyS

SEtuP

deFAu (§)

(*) Ini.AL (§)

inPutS (§)

outPut (§)

SEriAL

(*) d.SALE (§)

tArE (§) (!) LoCK, unLoCK, Auto, diSAb

ConFiG

(!) no, yES

inP.01

inP.02

inP.03

inP.04

(!) nonE, ZEro, tArE,

ModE, EntEr, diS.kEy

out.01

out.02

out.03

out.04

FunC

no / nC

onStAt

(!) rEL.no, iSt.,

no.ISt

(!) no, nC

(!) StbL, drCt

AdC.uV (§)

AdC.Pnt (§)

Ser.nuM

inout

Alibi

hLd

StPG

(!) ntGS

Std

(!) G. t., 1St.2nd, in.out

MAStr (§)

ViSS

tot o

tot S

Coun

(!)MAnuAL, Auto

uM.APW

Wait.t

(!) G, kG, t, Lb

tYPE (§) (!) Ind.Ch, dEP.Ch

n.WEiGh

tot.Mod

outPut (§)

PW.AdC

= USER & TECH MENU’

= ONLY TECH MENU’

(*) = METROLOGICAL PARAMETER

(§) = CONDITIONED STEP

(!) = DEFAULT VALUE

LEGEND

PErC

ChECk (!) GroSS, nEt

(!) 00.1

Min.WGt (!) 000.000

MAX.WGt (!) 000.000

MAX.tot (!) 00

(!) no, yES

Fr2.tot (!) no, yES

Wait.St (!) 000

CPS.tAr (!) no, yES

(!) 05.0

FunCt.

En.SAVE AutoFF (!) diSAb, EnAb

(*) tiLt (!) diSAbL, EnAbLE

PWd.SEt (!) oFF, on

LCk.kEy (!) oFF, on

rEM.DSP (!) no, yES

rEPE (§)

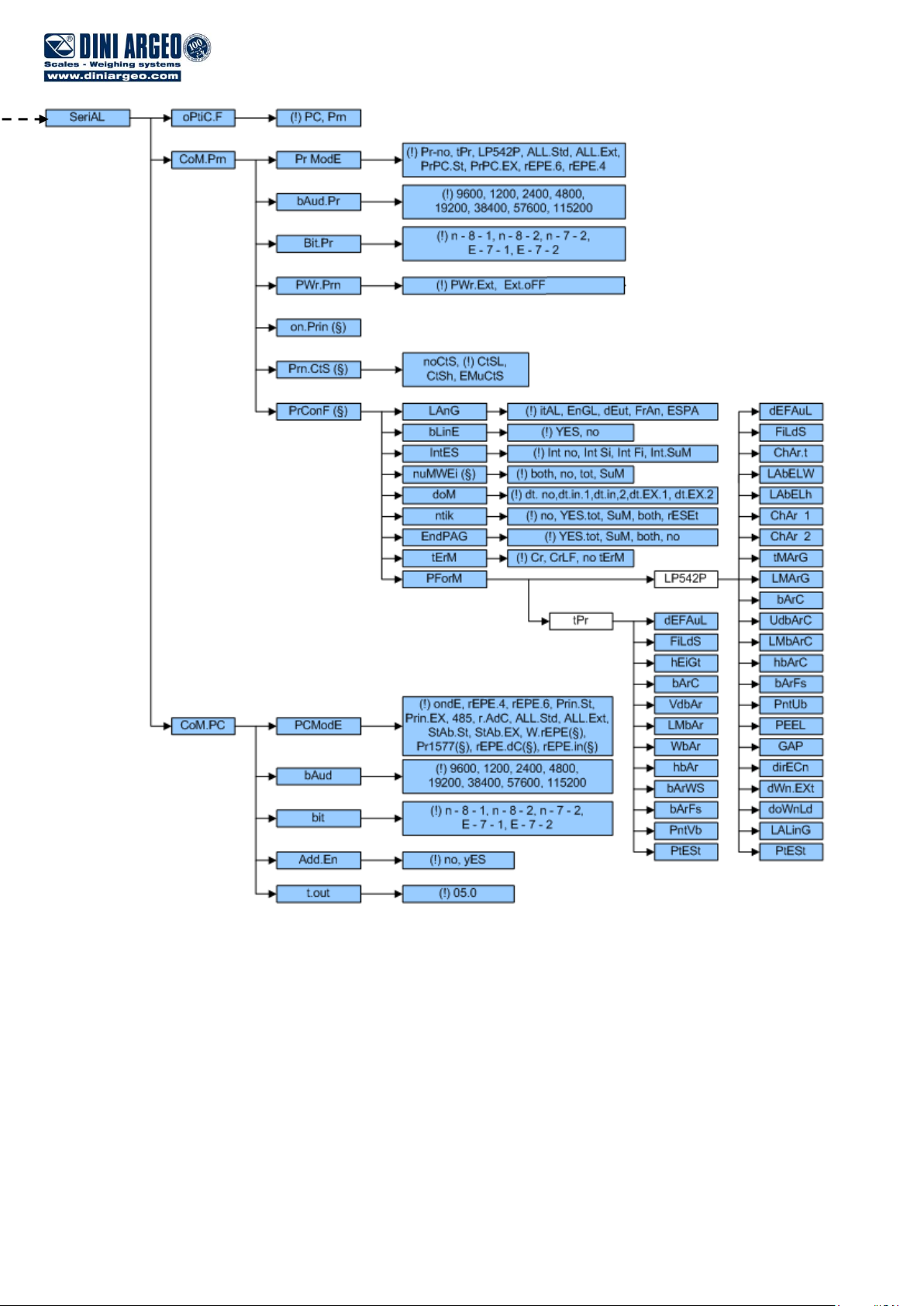

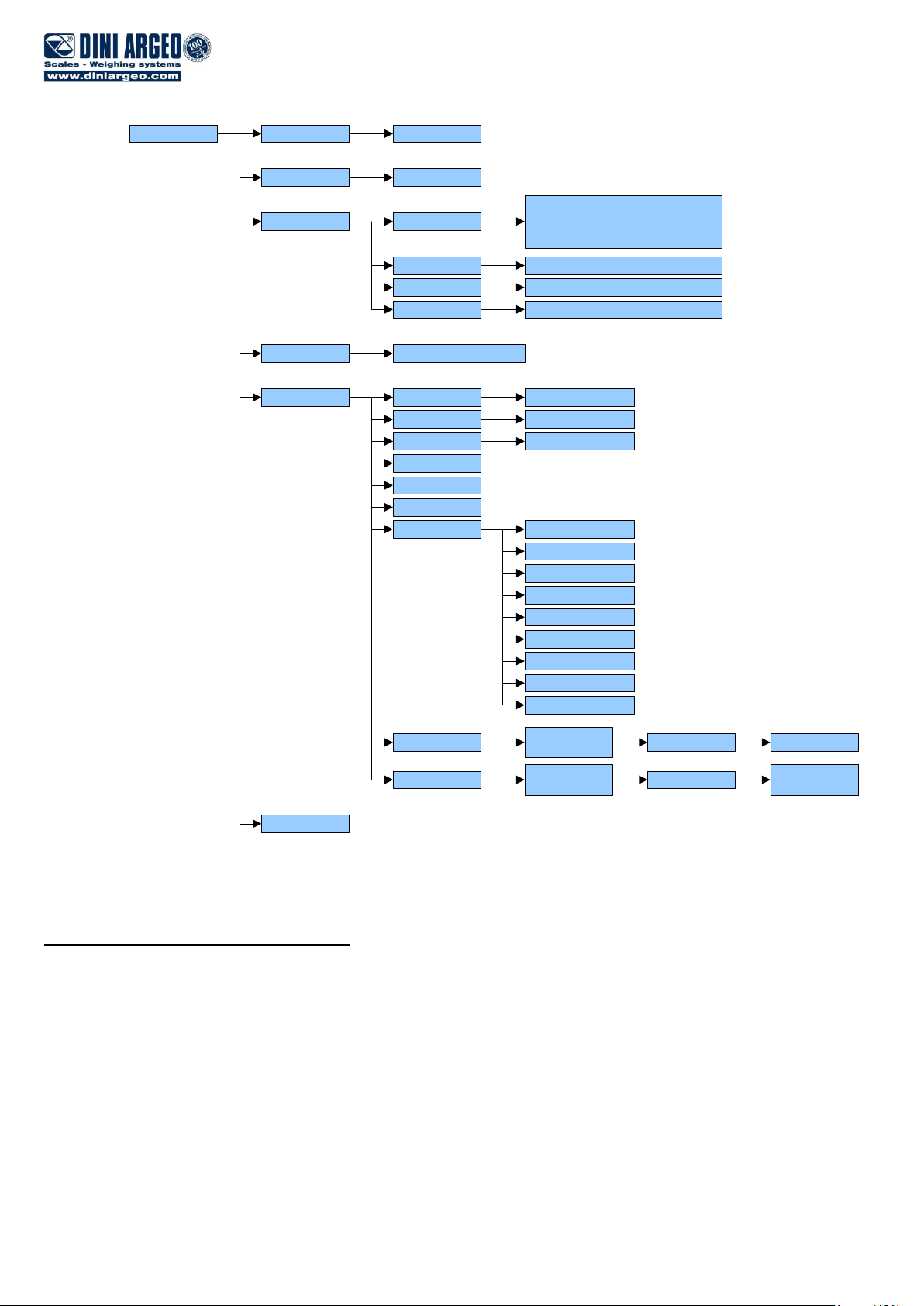

4.1 SET-UP ENVIRONMENT BLOCK DIAGRAM

The following diagram shows the structure of the indicator’s set-up environment; each step has been described in detail in

the “DESCRIPTION OF THE STEPS” section.

DFWATEX2GDxxx 7 of 49

DFWATEX2GDxxx 8 of 49

Stabil.

(!) FLt 3, FLt 0..3, doS.0..3,

h.r.0..7, dyn.0..3, SLW.0..3, hoLd

0...5, r.AdC 0...1, r.AdC d, r.AdC S

Calib (*)

Param.

ConFiG (§)

GrAV. (*)

Auto-0 (*)

0trACk (*)

diV.Stb. (*)

(!) EnAb, diSAb

(!) ½, ¼, 1, 2, no

(!) 2, 1...99

9,75001 … 9,84999

diV

dECi

u.M.

1, 2, 5, 10, 20, 50

G, Lb, t, kG

CALib.P

1, 2, 3, no

0.CALib (*)

rAnGE 1

rAnGE 2

tP 0

ddt 1

tp 1

ddt 2 (§)

n tP

EquAL (§)

tp 2 (§)

ddt 3 (§)

tp 3 (§)

nChan (*)(§) (!) Ch2 ... Ch4

rAnGE 3

VCEL Min, (!) MAX

AdJ.CAL (§)

Mod.Pnt

X

WEiGht tP X

MAn.CAL (§)

Mod.Pnt

X

WEiGht

PointS

XXXXXXXX

4.2 DESCRIPTION OF THE STEPS

(*) tYPE TYPE OF APPLICATION (§)

Here one selects the type of application: scale with a single channel or scale with dependent channels (eventually digitally

equalised).

ind.Ch. Instrument connected to 1 single-cell scale, or 1 scale with various cells equalised externally through the junction

box.

dEP.Ch. Instrument connected to 1 scale with 2, 3 or 4 dependent load cells (eventually equalised digitally through a

specific software procedure).

(!) ind.Ch

(*) In case of approved instrument the parameter is read only.

(§)The parameter is not displayed if the firmware is MASTER type.

DFWATEX2GDxxx 9 of 49

F.ModE SCALE FUNCTIONING

FunCt FUNCTIONING MODE

MAStr (M) Multiscale Repeater

rEPE (M) Single scale repeater

Std (S) Kg / lb conversion.

ntGS (S) Net weight / gross weight conversion.

StPG (S) Set point on gross weight

StPn (S) Set point on net weight

Inout (S) Input / output weigh.

ALibi (S) Alibi memory.

ChECk (S) +/- tolerance check.

PErC (S) Sample weight percentile

ViSS (S) Sensitivity times ten.

hLd (S) Freezing weight.

tot o (S) Horizontal totalizer.

tot S (S) Vertical totalizer.

Coun (S) Counting.

(!)ntGS if STANDARD firmware; (!) MAStr if MASTER firmware.

(S) The parameter is displayed if the firmware is STANDARD type.

(M) The parameter is displayed if the firmware is MASTER type.

For the functioning details and the relative parameters to be programmed, refer to section 14 “SELECTABLE

OPERATING MODES”, USER MAN.REF..

In case of a printer, it is necessary to execute the proper default printout in SEtuP >> SEriAL >> CoM.Prn >> Pr.ModE.

DFWATEX2GDxxx 10 of 49

rEACt REENABLING OF THE PRINTOUTS AND THE INDICATOR FUNCTIONS (§)

While using the indicator, it is possible to incur in the “no.0.unS” error shown on the display; this means that the printout

or the function which one wants to carry out must be renabled (in order to avoid accidental executions). It is possible to

set the reenabling in the following modes: “passage of the net weight by zero”, “weigh instability” or “always”.

ZEro passage of the net weight by zero

inSt instability

ALWAyS always

(!) ZEro

(§) The parameter is not displayed if the firmware is MASTER type.

En.SAVE ENERGY SAVING

AutoFF AUTO SWITCH-OFF

It is possible to enable the automatic switch off of the indicator (from 1 to 255 minutes), or disable it; the auto switch-off

starts working when, with an unloaded scale, the weight has not been moved or a key has been pressed during the set

time: the display shows the blinking “- oFF – “ message; then the indicator turns off.

diSAb auto switch-off disabled

EnAb auto switch-off enabled (one will be asked to enter the number of minutes after which the indicator must

turn off: enter a number from 1 to 255).

(!) diSAb

(*) tiLt TILT DEVICE ENABLING

If the indicator is fitted with the TILT device, in this step it’s possible to enable or disable its functioning.

EnAbLE enabled device

diSAbL disabled device

For further details see section 13.6, USER MAN.REF..

(!) diSAbL

(*) If the instrument is approved the parameter is read only.

tArE TARE TYPE SELECTION (§)

LoCk locked tare

unLoCk unlocked tare

diSAb disabled tare

Auto automatic unlocked tare

See the “TARE OPERATIONS” section for further functioning details, USER MAN. REF..

(!) LoCk

(§)The parameter is not displayed if the firmware is MASTER type.

PWd.SEt SET ACCESS PASSWORD

One selects whether to enable or disable the access password to the technical menu:

on password enabled

oFF password disabled

By selecting on, one can insert a password of up to 5 digits. When finished entering, press ENTER to confirm.

NOTE: The maximum enterable value is 65534.

(!) oFF

LCk.kEy KEYBOARD UNLOCKED/LOCKED (§)

One selects whether to enable or disable the keyboard locking in the weighing phase.

oFF keyboard lock disabled

on keyboard lock enabled

For further information see the section “KEYBOARD LOCK” (USER MAN.REF.).

(!) oFF

(§) The parameter is not displayed if the firmware is MASTER type.

DFWATEX2GDxxx 11 of 49

SEtuP SCALE CONFIGURATION

ConFiG METRIC CONFIGURATION

(*) nChAn SELECTION OF NR. OF INDICATOR CHANNELS (§)

2÷4 in SCALE WITH DEPENDENT CHANNELS functioning mode (“DEP.CH”)

(!) 2

(*) With approved instrument the parameter is read-only.

(§)The parameter is not displayed if the firmware is MASTER type. If the firmware is STANDARD type, the parameter is

not displayed in case of DEPENDENT CHANNELS functioning mode, tyPE parameter.

VCEL POWER SUPPLY VOLTAGE OF LOAD RECEIVERS

It is possible to select two voltage levels of the load cell power supply:

Min: power supply with voltage equal to 1,6V

Max: power supply with voltage equal to 3,2V

(!) MAX

PArAM METRIC PARAMETERS (§)

(§) The parameter is not displayed if the firmware is MASTER type.

(*) StAbiL FILTERING INTEGRATION

By pressing ENTER/PRINT one accesses the selection of the type and degree of filter intervention for the stability of

the weight indication:

FLt 0 – 3 filter for simple weighing

doS.0 – 3 filter for dosage

h.r.0 – 7 filter for high resolution

dyn.0 – 3 filter for a moving weight

SLW.0 – 3 filter for a rather unstable weight

hoLd 0 – 5 filter for animal weighing

r.AdC 0 – 1 filter for digital cells with fixed request interval

r.AdC d – S filter for digital cells with dynamic (d = fast, S = slow) request interval

The higher the filter value, and greater is its intervention relative to the type of filter used.

(!) FLt 3

(*) With approved instrument it is possible to select just the FLt 0–3, h.r.0, h.r.1, dyn.0, dyn.1, SLW.0, SLW.1

parameters.

(*) Auto-0 AUTOZERO AT THE START UP

By pressing ENTER/PRINT one chooses whether to enable (EnAb) or disable (diSAb) the automatic acquisition of

the gross zero upon start-up. By choosing EnAb, if upon start-up a detected weight is within +/- 10% of the capacity,

it is zeroed; if the weight is not within this tolerance, the non approved instrument’s display will show the present

weight after a few instants, while an approved instrument will continuously show “ZEro” on the display, until a weight

within tolerance is placed.

(!) EnAb

(*) With approved instrument the parameter is read-only.

(*) 0.trACk ZERO TRACKING

This menu allows setting the zero tracking, in other words, the compensation parameter of the scale’s thermal drift;

the set value corresponds to the number of divisions that is reset in the fixed time of 1 second.

tr. ½ +/- half division.

tr. ¼ +/- one fourth of a division

tr. 1 +/- one division.

tr. 2 +/- two divisions.

tr. no tracking disabled.

DFWATEX2GDxxx 12 of 49

(!) tr. ½

(*) With approved instrument it is possible to select just the tr. no, tr. ½, tr. ¼ parameters. .

(*)diV.Stb DIVISIONS BY STABILITY

In this step one enters the number of divisions by which the instrument detects the weight stability; the higher the

number of divisions, less is the sensitivity, and consequently the stability is more easily detected. The possible values

are 0 (weight always stable)…99.

(!) 2

(*) With approved instrument.

the parameter is read-only.

(*) GrAV. GRAVITY ZONE AND ZONE OF USE (§)

Through this step one selects the acceleration value of calibration and of use of the instrument:

Manual entry of the g value: one may manually enter the gravitational acceleration value; one must modify the 6

decimal digits of the gravitational acceleration.

In case one enters a wrong g value: the minimum decimal value is suggested (9,75001); a wrong value is any decimal

number that is not between 9,75001 and 9,84999 (inclusive).

(!) g = 9,80655

(*) With approved instrument the parameter is read-only.

(§) The parameter is not displayed if the firmware is MASTER type.

(*) CALib SCALE CALIBRATION (§)

See the section “SCALE CALIBRATION”

(*) With approved instrument the parameter is read-only.

(§)The parameter is not displayed if the firmware is MASTER type

(*) 0.CALib ZERO CALIBRATION (§)

See the section “SCALE CALIBRATION”.

(*) If the indicator is approved, the step is not displayed.

(§)The parameter is not displayed if the firmware is MASTER type.

SEriAL SERIAL LINES, PRINTOUTS, ETC…

(TO BE SET ONLY WITH THE EXPANSION BOARD CONNECTED, PRESENT DEPENDING ON THE MODEL)

optiC.F SELECTION OF THE PORT TO BE USED FOR COMMUNICATING WITH THE PC

In this step it’s possible to select the use of the fiber optic serial port:

Pc: The fiber optics is used for the transmission configured in the pc port, SEtuP >> SEriAL >> CoM.Pc step

Prn: The fiber optics is used for the transmission configured in the printer port, SEtuP >> SEriAL >> CoM.Prn

step

(!) Pc

CoM.Prn PRINTER SERIAL LINE

Pr.ModE TRANSMISSION ON THE PRINTER SERIAL LINE

Pr- no transmission not enabled

tPr enables the printing with ASCII printer (for example DP190 or TPR).

LP542P enables to print with the LP542S labeller.

By confirming the “LP542P” or “tPr” parameter one is asked (through the “dEF.Pr?”

message) to set, for the selected printer, the default parameters in the steps of the printer

serial port (“bAud.Pr”, “bit.Pr”, “Prn.CtS”) and in the steps of printout configuration (see the

description of the “dEFAuL” step in the section “FORMATTING DATA AND LAYOUT”):

press ENTER/PRINT to confirm or C to cancel; then the “tESt?” message is displayed:

press ENTER/PRINT to execute the printout test or C to cancel (see the description of the

“PtESt” step in the section “FORMATTING DATA AND LAYOUT”).

ALL.Std continuous transmission with standard string.

ALL.EXt continuous transmission with extended string.

DFWATEX2GDxxx 13 of 49

PrPC.St transmission of the standard string upon the pressing of the ENTER/PRINT key.

PrPC.EX transmission of the extended string upon the pressing of the ENTER/PRINT key.

NOTE: The transmission of the standard or extended string upon the pressing of the PRINT key is confirmed by

“trAnSM” on the display. If the “TOTALIZER” mode (horizontal or vertical) is active, the transmission through the

key is carried out by pressing the MODE key.

rEPE.4 transmission to 4-digit remote display.

rEPE.6 transmission to 6-digit remote display.

MEMorY if enabled allows to store the weigh list on the EEPROM

(!) Pr-no

For the protocol and transmission mode specifications, see the sections “SERIAL PORT TRANSMISSION

MODES” and “TRANSMISSION PROTOCOLS”.

bAud.Pr SET BAUD RATE

By pressing the ENTER/PRINT key one accesses the selection of the data transmission speed (measured in

Baud = bit/second). The possible values are: 1200, 2400, 4800, 9600, 19200, 38400, 57600, 115200.

(!) 9600

bit.Pr SET PARITY, WORD, STOP BIT

By pressing the ENTER/PRINT key one accesses the selection of the available values: n-8-1, n-8-2, n-7-2, E-7-1,

E-7-2.

(!) n-8-1

PWr.Prn PRINTER MANAGEMENT

In this step one programmes the management of a printer (if connected):

PWr.EXt with instrument on, printer managed.

EXt.oFF printer managed; the start-up characters are sent to the printer, because the printer is

considered to be configured in the energy saving mode.

(!) PWr.EXt

on.Prin ENABLING OF PRINTER IN ENERGY SAVING MODE (§)

If in the preceding step the EXt.oFF management is set, by entering this step one turns on the printer in the

energy saving mode (the “onPri” message is blinking on the display).

To exit this step press any button. The enabling may be carried out quickly also during the weighing, by pressing

the ZERO key for a few seconds (except in the REPEATER functioning mode).

(§) The parameter is displayed if “EXt.oFF” has been selected in the “PWr.Prn” step.

Prn.CtS RTS/CTS STATUS CONFIGURATION (§)

Using the fibre optic transmission, it is possible to manage the CTS signal; device (like a printer) that is slow in

processing the data received, can interrupt the transmission by temporarily using this signal.

noCtS no signal

CtSL CTS active low (for LP542P, TPR, DP24 printers)

CtSh CTS active high (for DP190 printers)

EMuCtS emulation of the CTS signal: one is asked to enter the number of characters (nChrS), in 3 digits,

which will be transmitted to the printer upon each transmission; then one needs to enter the

waiting time in milliseconds (tiME), in 4 digits, between a transmission and another.

The TIME OUT of a printout is a minute, in other words, after a minute that the printout is

blocked, it is cancelled.

(!) noCtS

(§) The parameter is not displayed unless “tPr” or “LP542P” has been selected in the “Pr.ModE” step.

Pr.ConF CONFIGURATION OF THE PRINTOUTS (§)

See the section “PROGRAMMING THE PRINTOUTS” section for the description of all the menu’s parameters.

(§) The parameter and all its submenus are not displayed unless “tPr” or “LP542P” has been selected in the

“Pr.ModE” step.

DFWATEX2GDxxx 14 of 49

Received string

h

h

,

k

k

,

p

p

p

p

p

p

p

p

,

u

u

CR

LF

Position of the

character

00 01 02 03 04 05 06 07 08 09 10 11 12 13 14 15 16 17 18

CoM.PC PC SERIAL LINE

PCModE TRASMISSION ON THE PC SERIAL LINE

ondE transmission on external command PC).

rEPE.4 transmission to 4-digit remote display.

rEPE.6 transmission to 6-digit remote display.

Prin.St. transmission of standard string when the ENTER/PRINT key is pressed.

Prin.EX transmission of extended string when the ENTER/PRINT key is pressed.

NOTE: The transmission of the standard or extended string upon the pressing of the PRINT key is confirmed by

“trAnSM” on the display. If the “TOTALIZER” mode (horizontal or vertical) is active, the transmission through the

key is carried out by pressing the MODE key.

485 transmission with 485 protocol, by confirming with ENTER/PRINT, one is required to enter the

machine code (the message “Ad485” appears for an instant): enter a value between 0 and 98.

r.AdC transmission to digital cells (§) : by confirming with ENTER/PRINT, one is required to enter

the 485 address (the message “Ad485” appears for an instant), then one has to enter the offset

address (“Add.oFF” is displayed for an instant); in this transmission mode it is not possible to

communicate with the PC (for this purpose one has to set temporarily the 485 mode and the

instrument has to be in the setup environment).

(§) The parameter is not displayed if the firmware is MASTER type.

ALL.Std continuous transmission with standard string.

ALL.EXt continuous transmission with extended string.

StAb.St transmission with each weigh with standard string.

StAb.EX transmission with each weigh with extended string.

rEPE.dC transmission protocol. (§) The parameter is displayed only if one has selected the “rEPE” functioning

mode in the F.ModE >> FunCt step.

rEPE.in transmission protocol (§) It allows to manage the received string.

Pr1577 (§) reception of the “rEPE.6” string. (§) The parameter is displayed only if one has selected the “rEPE”

functioning mode in the F.ModE >> FunCt step.

W.rEPE (§) reception of string from remote scale. (§) The parameter is displayed only if one has selected the

“rEPE” functioning mode in the F.ModE >> FunCt step.

By confirming with ENTER/PRINT one is requested to set the following parameters for the

management of the remote scale:

tErM REMOTE SCALE TERMINATOR

In this step one enters the decimal ASCII code (up to 2 digits) of the terminator characters of the weight string (I.E.

13 for CR or 10 for LF or 0 for NULL).

(!) 10

WEi.PoS REMOTE SCALE WEIGHT POSITION

In this step one sets the position of the first character of the weight value, in the string transmitted by the remote

scale, knowing that the first character on the left of the string has the 00 position.

A possible character sign is also part of the weight value.

For example, if the received string is hh,kk,pppppppp,uu + CR + LF (see the section “TRANSMISSION

PROTOCOLS” for the description of the string),

one should set the 06 value.

It is possible to set up to 2 characters (from 0 to 39).

(!) 05

DFWATEX2GDxxx 15 of 49

Loading...

Loading...