Dini Argeo 3590EXT series, 3590EKR series, 3590EXP series, CPWE series, CPWET series User Manual

USER MANUAL

WEIGHT INDICATOR

E-AF09: PROGRAM VERSION FOR DYNAMIC OR STATIC

AXLES WEIGHING WITH INPUT/OUTPUT FUNCTION

3590EKR, 3590EXP, 3590EXT, CPWE, CPWET series indicator

E-AF09_02_13.01_EN_U

3590EKR, 3590EXP, 3590EXT, CPWE, CPWET series indicator E-AF09_02_13.01_EN_U

1

INDEX

1. INTRODUCTION ................................................................................................................................................................... 4

2. MAIN TECHNICAL SPECIFICATIONS ................................................................................................................................. 5

2.1 ACCESSORIES AVAILABLE ......................................................................................................................................... 6

2.2 SYMBOLS USED ........................................................................................................................................................... 6

3. INSTALLATION .................................................................................................................................................................... 7

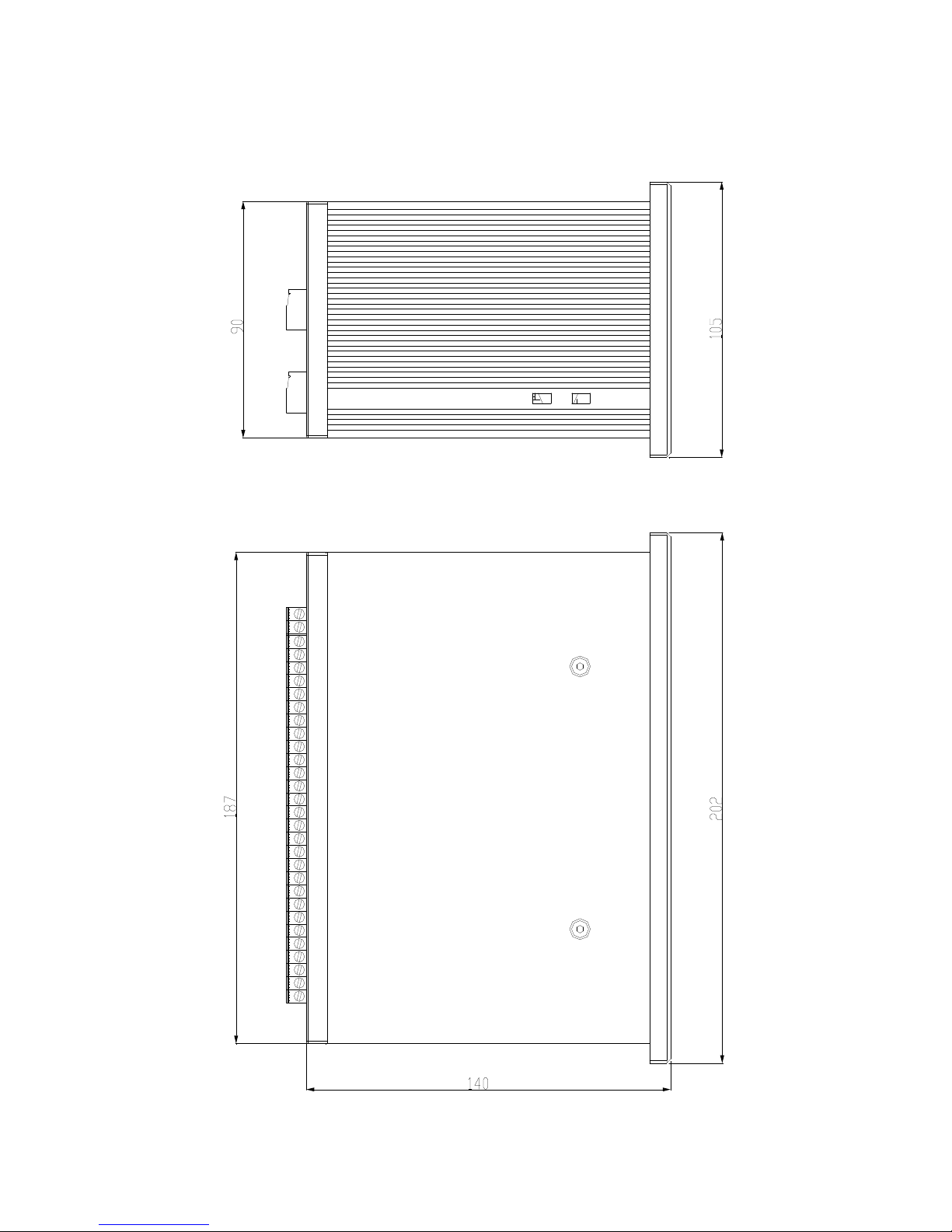

3.1 CPWE DRILLING TEMPLATE, CASE AND DIMENSIONS ........................................................................................... 7

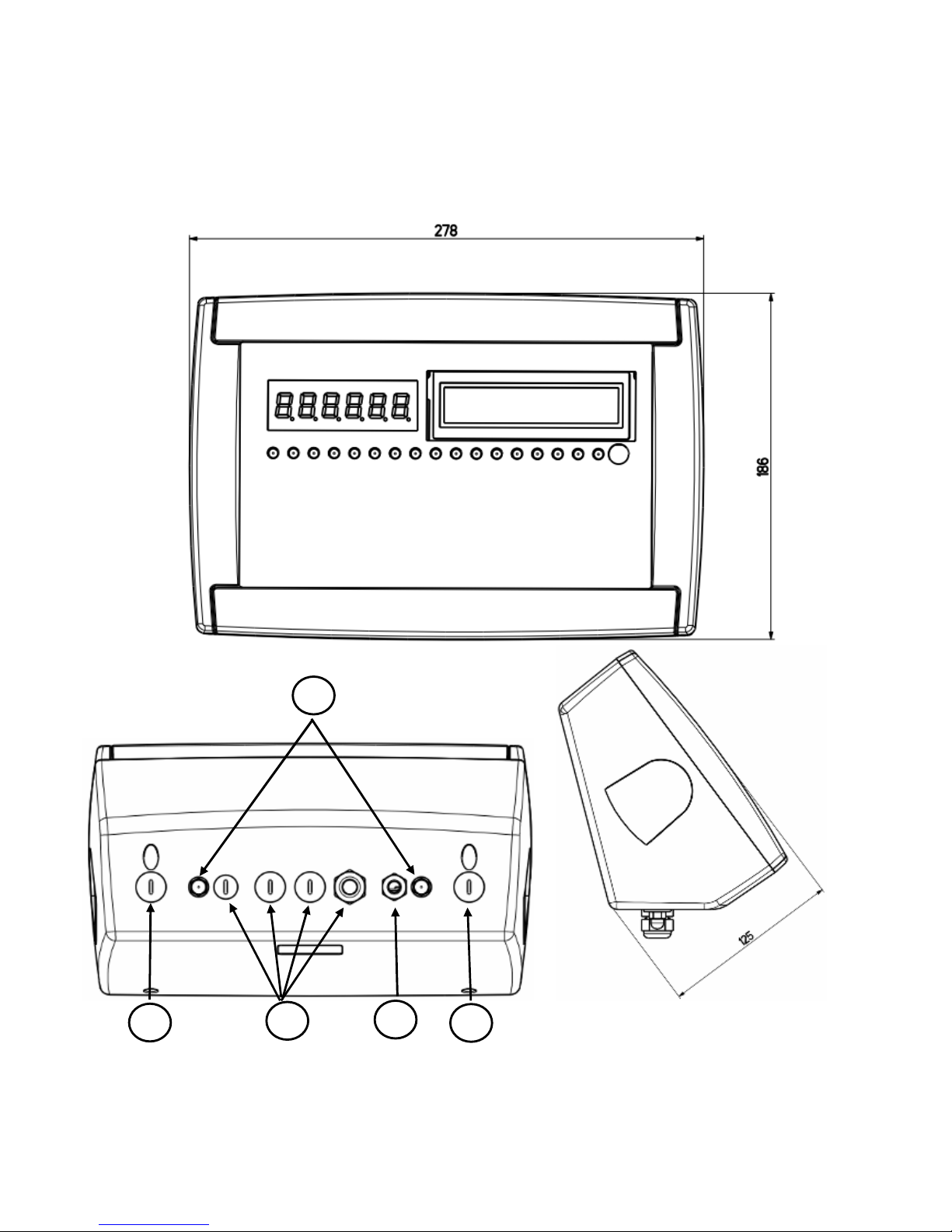

3.2 3590E CASE AND DIMENSIONS .................................................................................................................................. 8

3.2.1 ABS MODEL ........................................................................................................................................................ 8

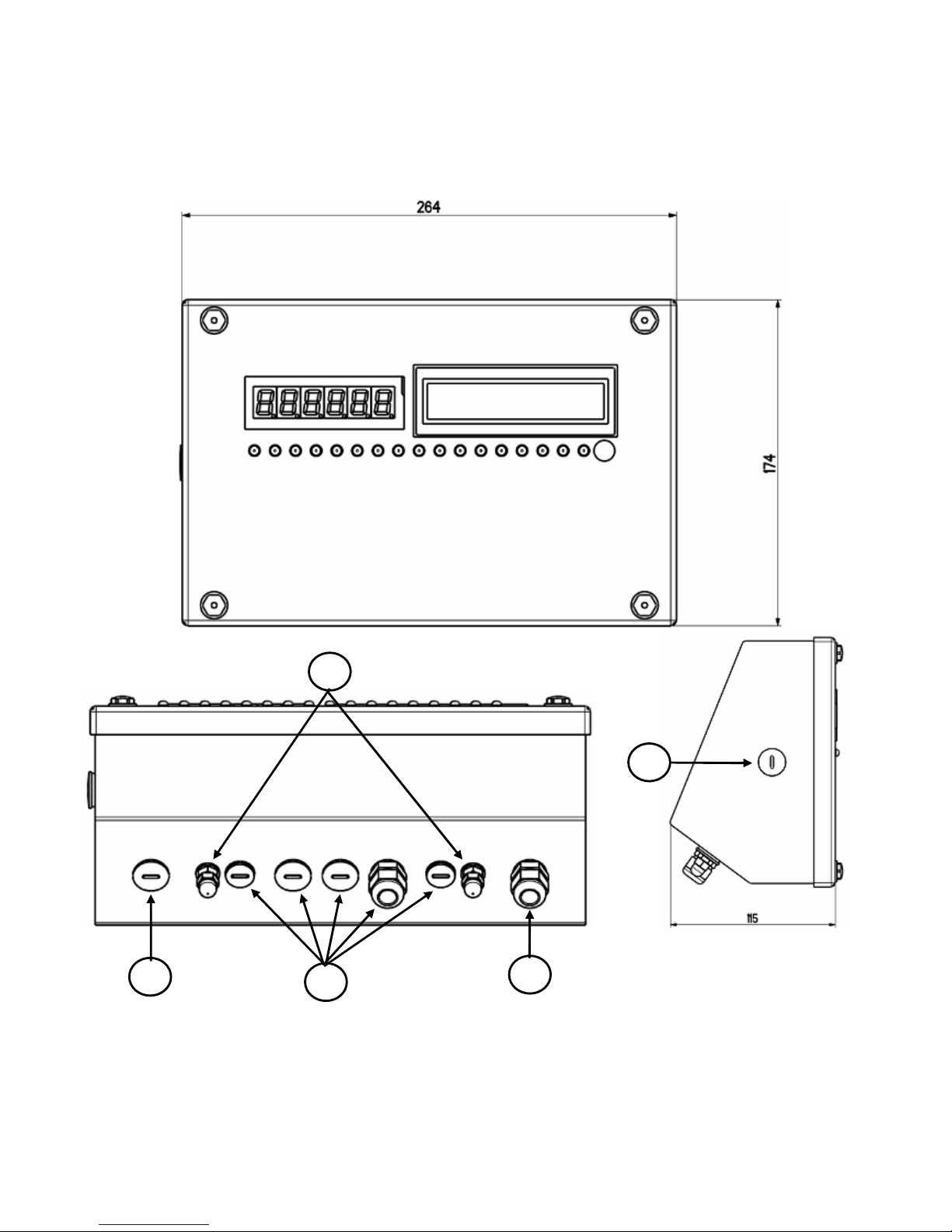

3.2.2 STAINLESS STEEL MODEL ............................................................................................................................... 9

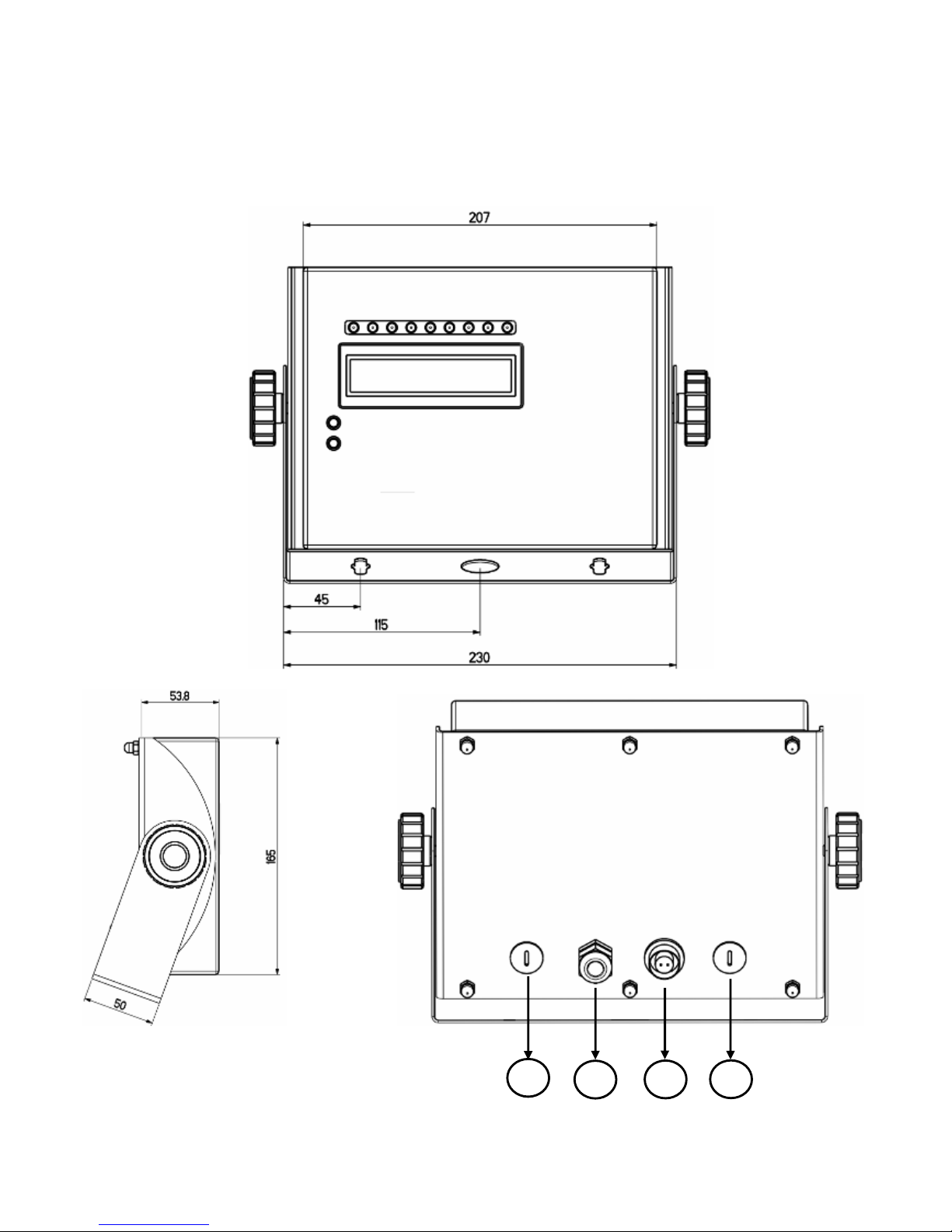

3.3 CPWET CASE AND DIMENSIONS.............................................................................................................................. 10

3.4 POWER SUPPLY ......................................................................................................................................................... 11

3.5 START UP .................................................................................................................................................................... 11

3.6 TURNING OFF THE INSTRUMENT ............................................................................................................................ 11

3.7 TURNING ON PRINTER IN ENERGY SAVING MODE ............................................................................................... 12

4. FRONT PANEL KEYS ........................................................................................................................................................ 12

4.1 FUNCTION OF THE KEYS .......................................................................................................................................... 13

4.2 "2ndF" KEY: SECOND FUNCTION OF THE KEYS ..................................................................................................... 15

4.3 ENTERING ALPHANUMERIC TEXT ........................................................................................................................... 15

4.4 DISABLING THE KEYBOARD ..................................................................................................................................... 16

4.5 HELP MENU ................................................................................................................................................................ 16

4.6 INDICATOR CONNECTED TO REMOTE KEYBOARD ............................................................................................... 16

4.7 REMOTE CONTROL.................................................................................................................................................... 17

4.7.1 “19-KEY” INFRARED REMOTE CONTROL ...................................................................................................... 17

4.7.2 “6-KEY” RADIO REMOTE CONTROL ............................................................................................................... 18

5. DISPLAY FUNCTIONS ....................................................................................................................................................... 19

5.1 WEIGHT ZOOM (available only on CPWE and CPWET models) ................................................................................ 20

5.2 STATUS INDICATORS ................................................................................................................................................ 20

5.3 BATTERY LEVEL INDICATION ................................................................................................................................... 21

5.4 DISPLAYED DATA ....................................................................................................................................................... 22

5.4.1 LCD DISPLAY CUSTOMIZATION (ONLY FOR 3590E INDICATORS) ............................................................. 23

5.5 MESSAGES OF THE INSTRUMENT ........................................................................................................................... 24

5.5.1 INSIDE THE SET-UP OR MENU OR AT START-UP ........................................................................................ 24

5.5.2 IN WEIGHING.................................................................................................................................................... 25

6. SCALE ZERO FUNCTION .................................................................................................................................................. 25

7. TARE FUNCTIONS ............................................................................................................................................................. 25

7.1 MANUAL PRESET TARE TO BE SUBTRACTED TO THE TOTAL ACCUMULATED WEIGHT .................................. 25

7.2 CALCULATED MANUAL TARE ................................................................................................................................... 26

7.3 TARE CANCELLATION ............................................................................................................................................... 26

7.4 LOCKED/UNLOCKED TARE ....................................................................................................................................... 26

7.5 LIMITATION OF THE TARE FUNCTIONS ................................................................................................................... 26

7.6 TARE EXECUTION MODE OR DISABLING OF THE TARE ....................................................................................... 26

7.7 ENTERING OF A PRESET TARE IN A VEHICLE IN THE DATABASE. ...................................................................... 26

8. MULTIRANGE AND MULTIDIVISION FUNCTION ............................................................................................................. 27

9. DISPLAY OF METRIC DATA (inFO) .................................................................................................................................. 27

10. FILLING IN THE INPUT TEXT .......................................................................................................................................... 27

11. DATABASE....................................................................................................................................................................... 28

11.1 CUSTOMER DATABASE ........................................................................................................................................... 28

11.1.1 ENTRY ............................................................................................................................................................ 28

3590EKR, 3590EXP, 3590EXT, CPWE, CPWET series indicator E-AF09_02_13.01_EN_U

2

11.1.2 MODIFICATION ............................................................................................................................................... 29

11.1.3 CANCELLATION ............................................................................................................................................. 29

11.1.4 PRINTING ....................................................................................................................................................... 29

11.1.5 SELECTION / DESELECTION ........................................................................................................................ 30

11.1.6 ENTRY, MODIFICATION AND QUICK SELECTION OF CUSTOMER 000 .................................................... 31

11.1.7 ALPHABETICAL RESEARCH ......................................................................................................................... 31

11.1.8 HELP ............................................................................................................................................................... 31

11.2 MATERIALS ............................................................................................................................................................... 31

11.2.1 ENTRY ............................................................................................................................................................ 31

11.2.2 MODIFICATION ............................................................................................................................................... 32

11.2.3 CANCELLATION ............................................................................................................................................. 32

11.2.4 PRINTING ....................................................................................................................................................... 32

11.2.5 SELECTION / DESELECTION ........................................................................................................................ 33

11.2.6 ENTRY, MODIFICATION AND QUICK SELECTION OF MATERIAL 000 ....................................................... 33

11.2.7 ALPHABETICAL RESEARCH ......................................................................................................................... 34

11.2.8 HELP ............................................................................................................................................................... 34

11.3 VEHICLES .................................................................................................................................................................. 34

11.3.1 ENTRY ............................................................................................................................................................ 34

11.3.2 MODIFICATION ............................................................................................................................................... 35

11.3.3 CANCELLATION ............................................................................................................................................. 35

11.3.4 PRINTING ....................................................................................................................................................... 35

11.3.5 SELECTION / DESELECTION ........................................................................................................................ 36

11.3.6 ENTRY, MODIFICATION AND QUICK SELECTION OF VEIHCLE 000 ......................................................... 36

11.3.7 ALPHABETICAL RESEARCH ......................................................................................................................... 37

11.3.8 HELP ............................................................................................................................................................... 37

12. DATABASE ACCESS PASSWORD ................................................................................................................................. 37

13. WEIGHING PROCEDURES .............................................................................................................................................. 37

13.1 GENERAL DESCRIPTION OF THE SYSTEM ........................................................................................................... 37

13.2 SIMPLE AXLES WEIGHING ...................................................................................................................................... 38

13.2.1 MANUAL AXLE WEIGHING ............................................................................................................................ 38

13.2.1.1 CONFIGURATION ............................................................................................................................. 38

13.2.1.2 WEIGHING PROCEDURE ................................................................................................................. 38

13.2.2 AUTOMATIC STATIC AXLE WEIGHING ........................................................................................................ 40

13.2.2.1 CONFIGURATION ............................................................................................................................. 40

13.2.2.2 WEIGHING PROCEDURE ................................................................................................................. 40

13.2.3 AUTOMATIC DYNAMIC AXLE WEIGHING ..................................................................................................... 43

13.2.3.1 CONFIGURATION ............................................................................................................................. 43

13.2.3.2 WEIGHING PROCEDURE ................................................................................................................. 43

13.3 INPUT-OUTPUT AXLE WEIGHING ........................................................................................................................... 46

13.3.1 MANUAL AXLE WEIGHING ............................................................................................................................ 46

13.3.1.1 CONFIGURATION ............................................................................................................................. 46

13.3.1.2 INPUT WEIGHING PROCEDURE ..................................................................................................... 46

13.3.1.3 STARTING OUTPUT WEIGHING THROUGH ID CODE ................................................................... 48

13.3.1.4 STARTING OUTPUT WEIGHING THROUGH LICENSE PLATE ....................................................... 49

13.3.1.5 OUTPUT WEIGHING PROCEDURE ................................................................................................. 49

13.3.2 AUTOMATIC STATIC AXLE WEIGHING ........................................................................................................ 51

13.3.2.1 CONFIGURATION ............................................................................................................................. 51

13.3.2.2 INPUT WEIGHING PROCEDURE ..................................................................................................... 51

13.3.2.3 STARTING OUTPUT WEIGHING THROUGH ID CODE ................................................................... 54

13.3.2.4 STARTING OUTPUT WEIGHING THROUGH LICENSE PLATE ....................................................... 54

13.3.2.5 OUTPUT WEIGHING PROCEDURE ................................................................................................. 55

13.3.3 AUTOMATIC DYNAMIC AXLE WEIGHING ..................................................................................................... 57

13.3.3.1 CONFIGURATION ............................................................................................................................. 57

13.3.3.2 INPUT WEIGHING PROCEDURE ..................................................................................................... 57

13.3.3.3 STARTING OUTPUT WEIGHING THROUGH ID CODE ................................................................... 60

3590EKR, 3590EXP, 3590EXT, CPWE, CPWET series indicator E-AF09_02_13.01_EN_U

3

13.3.3.4 STARTING OUTPUT WEIGHING THROUGH LICENSE PLATE ....................................................... 60

13.3.3.5 OUTPUT WEIGHING PROCEDURE ................................................................................................. 61

13.3.3.6 SELECTING INPUT OR OUTPUT BEFORE OR AFTER HAVING ACQUIRED THE AXLES ............ 63

13.3.4 NOTES ON THE INPUT WEIGHING ............................................................................................................... 63

13.3.5 NOTES ON THE OUTPUT WEIGH ................................................................................................................. 64

13.3.6 DETERMINATION OF THE TRUCK’S NET WEIGHT BY SUBTRACTING THE PRESET TARE ................... 64

13.3.7 DELETING ALL THE INPUT MEMORY STORAGES ...................................................................................... 65

13.4 FUNCTIONS OF THE AUTOMATIC AXLE WEIGHING CYCLE (STATIC OR DYNAMIC) ........................................ 65

13.4.1 CANCELLING OF THE CYCLE ....................................................................................................................... 65

13.4.2 ERRORS ON THE AUTOMATIC AXLES WEIGHT ACQUISITION ................................................................. 66

13.4.2.1 ERROR ON THE DYNAMIC AXLES WEIGHT ACQUISITION ........................................................... 66

13.4.2.2 ERROR ON THE STATIC AXLES WEIGHT ACQUISITION .............................................................. 66

13.4.3 RESET OF THE ERROR AXLE IN THE DYNAMIC CYCLE ............................................................................ 67

13.4.4 MANAGING AN INPUT FOR THE CYCLE START/END ................................................................................. 67

13.4.5 MANAGING THE OUTPUTS ........................................................................................................................... 67

13.4.6 PAUSE AXLES CAPTURING .......................................................................................................................... 67

13.5 SETTING AXLES SO THAT THESE ARE NOT TOTALISED .................................................................................... 68

13.6 ADDITIONAL TARE FUNCTION ................................................................................................................................ 68

13.7 REENABLING THE WEIGH ....................................................................................................................................... 69

13.8 WEIGHT THRESOLDS FOR EXECUTING THE WEIGH ........................................................................................... 69

13.9 VISUALISATION AND CLEARING OF THE ACCUMULATED TOTALS ................................................................... 69

13.10 PROGRESSIVES ..................................................................................................................................................... 70

13.10.1 PROGRESSIVE DIGITS ................................................................................................................................ 70

13.10.2 TICKET PROGRESSIVE ............................................................................................................................... 70

13.10.3 LOT PROGRESSIVE ..................................................................................................................................... 70

14. PRINTOUTS ...................................................................................................................................................................... 71

14.1 LINKING OF THE FORMATS TO THE PRINT FUNCTIONS ..................................................................................... 74

14.1.1 QUICK LINKING OF THE FORMATS ............................................................................................................. 75

14.2 NUMBER OF TICKET COPIES .................................................................................................................................. 75

14.3 REPETITION OF THE LAST EXECUTED PRINTOUT .............................................................................................. 76

14.4 DEFAULT PRINTING FORMATS............................................................................................................................... 76

15. OTHER FUNCTIONS ........................................................................................................................................................ 76

15.1 DIAGNOSTIC PERIPHERALS ................................................................................................................................... 76

15.2 COM DATA DIAGNOSTIC ......................................................................................................................................... 76

15.3 CALCULATOR ........................................................................................................................................................... 77

15.3.1 HELP FUNCTION ............................................................................................................................................ 77

15.4 DISPLAY OF NET WEIGHT WITH SENSITIVITY X 10 (for testing use during calibration) ........................................ 77

15.5 SETTING DATE / TIME .............................................................................................................................................. 77

15.6 SET-POINT FUNCTION ............................................................................................................................................. 78

DECLARATION OF CONFORMITY ....................................................................................................................................... 82

WARRANTY ........................................................................................................................................................................... 82

3590EKR, 3590EXP, 3590EXT, CPWE, CPWET series indicator E-AF09_02_13.01_EN_U

4

1. INTRODUCTION

This manual was created to help you install and learn all about the functional possibilities of the purchased indicator.

The instrument is suitable for use in various weighing environments.

Not only does it have all the normal features of high-precision scales, but it also gives you the possibility to work in specific

environments due to the functioning modes contained in the software implemented in the FLASH MEMORY on the internal

board; This makes the instrument extremely flexible and it can be used in many different industrial applications linked to

weighing. The double numerical and interactive alphanumerical display, the alphanumerical and function keyboard, allow the

operator an easy and immediate use and provide the microcontroller with DATA ENTRY functions in addition to the normal

weighing functions. The input/output allows the instrument to control various external devices, to receive external commands,

control a printer and communicate with a personal computer or to be inserted in a network of weight indicators controlled by a

PC.

WARNING

Please note that this instrument is covered by a warranty and MUST NOT BE OPENED BY THE USER for any reason

whatsoever. Any attempt to repair or modify the unit exposes the user to the risk of electric shock and will invalidate the entire

warranty.

If any problems are found in the unit or with the system in which it is used, the fact must be communicated to the

manufacturer or the dealer from whom it was purchased.

In any case, DISCONNECT THE POWER SUPPLY before taking any action.

With the 6V rechargeable battery version, it has to be completely

recharged

(12 hours) in the first installation of the

instrument; we RECOMMEND disconnecting the battery if the instrument is not going to be used for more than 30

days. In order to avoid the deterioration of the rechargeable battery:

- In standard conditions, never leave the battery partially or completely uncharged; at least once a week recharge it

completely.

- In case the instrument is not used for a long period, one needs to

1. completely recharge the battery before the system is switched off for the last time;

2. recharge completely every 3 months.

Do not pour liquids on the weight indicator.

Do not use solvents to clean the weight indicator.

Do not expose the instrument to direct sunlight nor place it near heat sources.

Place or anchor the weight indicator and platform on a non-vibrating base.

All the connections of the indicator have to be made respecting

the rules applicable in the zone and in the installing environment.

Read carefully and apply what is described in the section 3.

Do not install in any area where there is a risk of explosion.

The crossed-out wheeled bin on the product means that at the product end of life, it must be taken to

separate collection or to the reseller when a new equivalent type of equipment is purchased. The

adequate differentiated refuse collection in having the product recycled, helps to avoid possible negative

effects on the environment and health and supports the recycling of the materials of which the equipment

is made. The unlawful disposal of the product by the user will entail fines foreseen by the current

regulations.

3590EKR, 3590EXP, 3590EXT, CPWE, CPWET series indicator E-AF09_02_13.01_EN_U

5

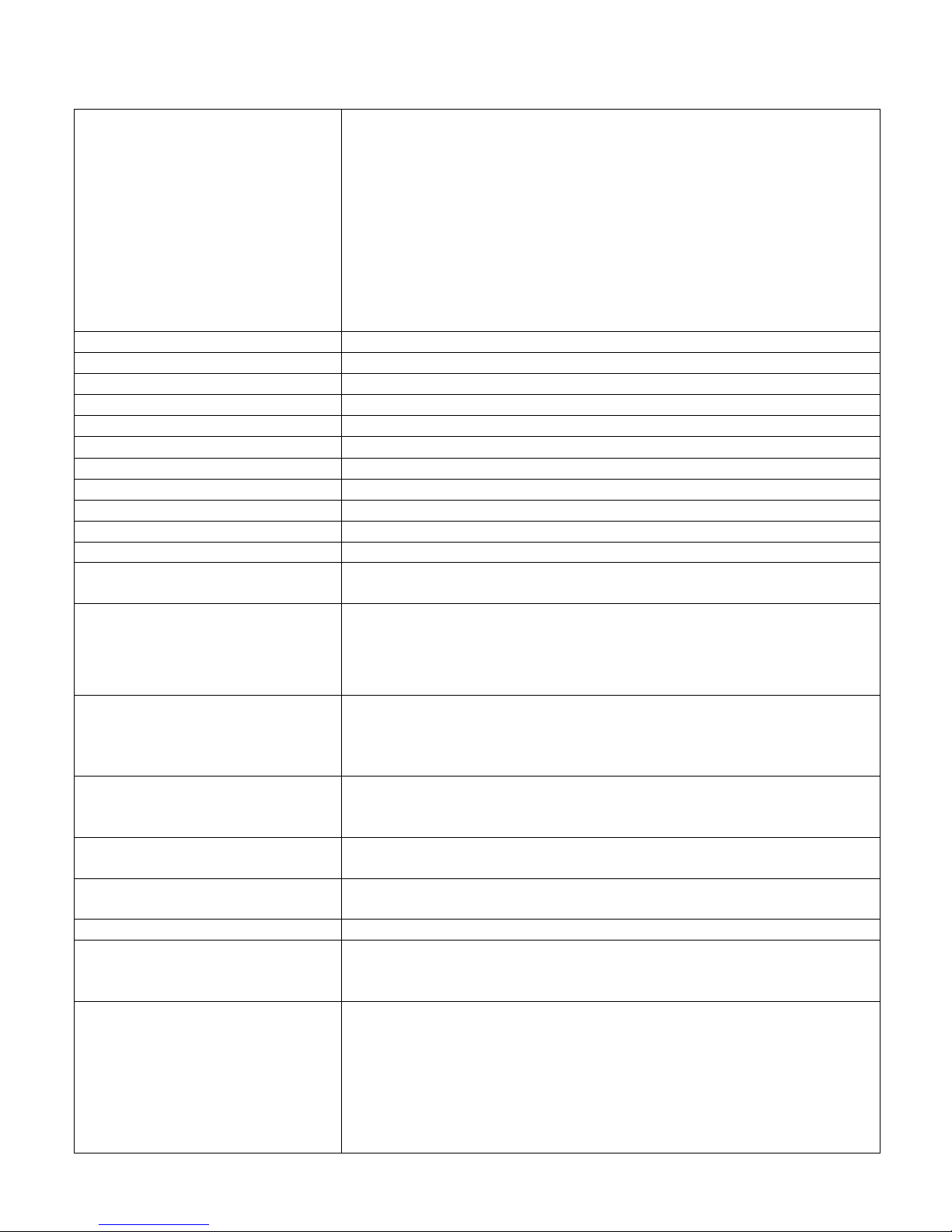

2. MAIN TECHNICAL SPECIFICATIONS

POWER SUPPLY

3590E

:

- 12 Vdc ( 8 ÷ 36 Vdc in the IO versions), with internal 100 ÷ 240 Vac (50÷60 Hz)

/ 12 Vdc adapter.

- 6 Vdc from rechargeable built-in battery, fitted depending on the model.

CPWE:

- 8 ÷ 2436 Vdc

- 6 Vdc from external rechargeable battery (upon request).

CPWET:

12 Vdc with external 100 ÷ 240 Vac (50÷60 Hz) / 12 Vdc adapter.

6 Vdc from external rechargeable battery (upon request).

MAXIMUM POWER

16 VA.

OPERATING TEMPERATURE

From

-

10 to +40 °C.

CONVERTER

24 bit Sigma Delta.

CONVERSION SPEED

200 conv./sec with automatic selection.

RANGE OF INPUT SIGNAL

0,6 mV/V

- 3,2 mV/V.

MINIMUM VOLTAGE PER DIVISION

0.3 µV (approved instrument); 0.03 µV (non-approved instrument).

AUTOMATIC ZERO DETECTION

Only in gross mode

, programmable at +/

- ¼, ½, 1, 2 divisions.

ZERO RANGE

Configurable up t

o +/- 50%

of max load capacity.

AUTO ZERO AT START

-UP

Configurable up to +/

- 50% of max load capacity.

LOAD CELL POWER SUPPLY

5Vdc ± 5%, 120mA

(max 8 350

-

Ohm cells).

LOAD CELL CONNECTIONS

6 wires with Remote Sense.

DISPLAY DIVISIONS

10000e, 3 x 3000e f

or legal for trade weighing, expandable up to 800.000 for

internal use (with minimum signal coming from the 1,6 mV/V cell).

DISPLAYS

3590E:

- Red, high-luminosity LED indicators, with six digits (h 13 mm).

- Back lit graphic 160x32 dot LCD.

CPWE: Back lit graphic 160x32 dot LCD.

DATABASE/MEMORY

Database of 500 customers

(3

descriptions of 20 characters).

Database of 500 products (2 descriptions of 20 characters).

Database of 500 vehicles (description of 20 characters, plate of 10 characters,

linked tare).

SIGNALS

3590E:

16 status LEDs. Graphic icons on LCD display.

CPWE: Graphic icons on LCD display.

CPWET: 3-way control light. Graphic icons on LCD display

KEYBOARD

I

mpermeable polycarbonate keyboard with 24 multifunction

(IP65 protection

degree), with membrane keys with audible and tactile feedback.

PARAMETER SETUP

Calibration and linearity (up to 8 points), fully digital and programmable from the

keyboard or from PC with Dinitools ™.

CLOCK/DATE

Fitted

, with buffer RAM.

SERIAL OUTPUTS

- 2 input/output RS232 ports on terminal board/ amp connector.

- 1 input/output RS485 port on terminal board or RS232 on amp connector.

- Management of PC keyboard or barcode reader

INPUTS AND OUTPUTS

3590EXP

,

3590EXT

and

CPWET

:

- 2 optoisolated inputs (optoisolated photo couplers), 12Vdc – 24Vdc, 20mA max

- 4 outputs (optoisolated photomosfets), 48Vac / 0.15A, 60Vdc / 0.15A, 10 Ω

max.

3590EXT (in IO version) and CPWE:

- 8 inputs (optoisolated photo couplers), 12Vdc – 24Vdc, 20mA max.

- 16 outputs (optoisolated photomosfets), 48Vac / 0.15A, 60Vdc / 0.15A.

3590EKR, 3590EXP, 3590EXT, CPWE, CPWET series indicator E-AF09_02_13.01_EN_U

6

ANALOGUE OUTPUT (Option

available on the 3590EXT in IO version

and CPWE version)

- 16-bit analogue output configurab

le from keyboard (full

-

scale value; zero scale

value and minimum value) from 0 to 10 Vdc, from 0 to 20mA or from 4 to 20mA;

the maximum resistance applicable on the output current is 350 Ohm and the

minimum resistance applicable on the output voltage is 10 kohm.

2.1 ACCESSORIES AVAILABLE

On the indicator is possible to implement internal and external modules used to increase interfacing possibilities.

For example, the number of usable outputs, various types of printers, in order to have a report of the weighs made, or giant

display in order to better see the weigh operations. Also, one can connect a PC in order to simply program the instrument

through Dinitools™, or in order to have a complete management of the weighs.

Contact the reseller for the list of the available hardware and software accessories.

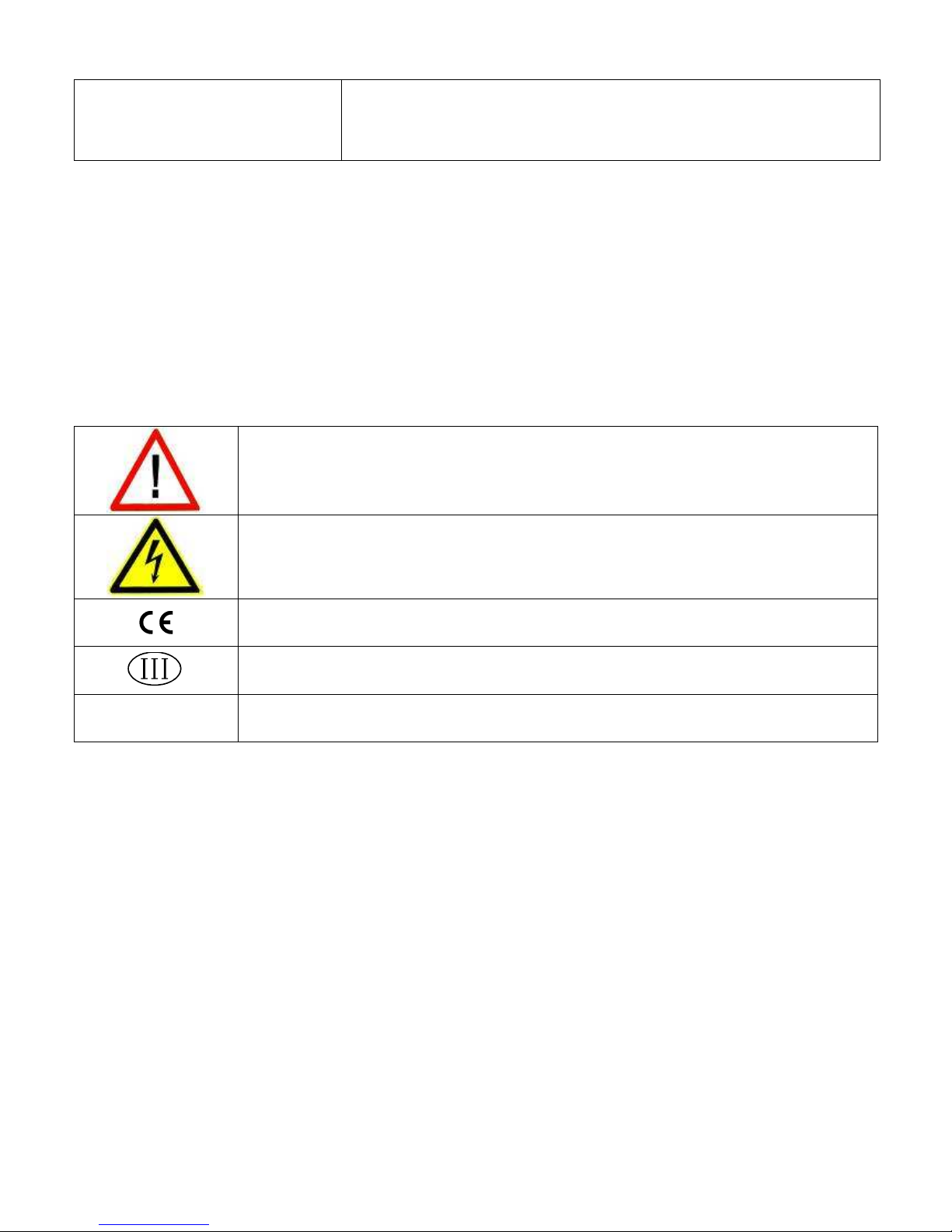

2.2 SYMBOLS USED

Below are the symbols or texts used in the manual to recall the reader’s attention and on the instrument to recall the

user’s attention

ATTENTION!

Only qualified personnel must perform this operation

ATTENTION!

This is referred to working on energized lines: only qualified personnel must require or perform

this operation.

CE CONFORMITY

IDENTIFIES THE CLASS OF PRECISION.

“TECH.MAN.REF.”

It means that an advanced function is being described (therefore for the technical personnel)

which will be further explained in the corresponding technical manual.

THE INSTRUMENT’S DANGEROUS VOLTAGE PARTS AND THE PARTS THE USER CAN ACCESS HAVE BEEN

ELECTRICALLY INSULATED.

3590EKR, 3590EXP, 3590EXT, CPWE, CPWET series indicator E-AF09_02_13.01_EN_U

7

Figure 1

3. INSTALLATION

3.1 CPWE DRILLING TEMPLATE, CASE AND DIMENSIONS

The weight indicator has an anodized aluminium case, whose external dimensions are shown in the figure 1.

It should be mounted on a panel board respecting the safety norms.

DRILLING TEMPLATE DIMENSION: 187,5mm x 91,5mm

3590EKR, 3590EXP, 3590EXT, CPWE, CPWET series indicator E-AF09_02_13.01_EN_U

8

Figure 2

– Measurements and dimensions in mm

1) RJ45 connector

2) Fixing for shelf or column mounting

3/5) Available for load cells / serial lines / inputs / outputs.

4) Power supply input.

3.2 3590E CASE AND DIMENSIONS

3.2.1 ABS MODEL

The indicator has an IP65 ABS case, whose external dimensions are shown in the Figure 2. It can be simply put on a table

or fixed to a shelf; or on a column, available on request.

NOTE: If the identification plate is supplied separately (therefore not attached to the indicator), it is advisable to

attach it to the indicator, in order to be able to identify the instrument.

1

2

3

4

5

3590EKR, 3590EXP, 3590EXT, CPWE, CPWET series indicator E-AF09_02_13.01_EN_U

9

Figure 3

– Measurements and dimensions in mm

1) RJ45 connector

2) Fixing for shelf or column mounting

3) Available for load cells / serial lines / inputs / outputs.

4) Power supply input.

3.2.2 STAINLESS STEEL MODEL

The indicator has a STAINLESS STEEL case, whose external dimensions are shown in the Figure 3. It can be simply put on

a table or fixed to a shelf; or on a column, available on request.

NOTE: If the identification plate is supplied separately (therefore not attached to the indicator), it is advisable to

attach it to the indicator, in order to be able to identify the instrument.

1

2

3

4

3

3590EKR, 3590EXP, 3590EXT, CPWE, CPWET series indicator E-AF09_02_13.01_EN_U

10

Figure 4

– Measurements and dimensions in mm

1/2) Available for load cells / serial lines / inputs / outputs

3) Power supply input.

4) RJ45 connector

3.3 CPWET CASE AND DIMENSIONS

The weight indicator has a STAINLESS STEEL case, whose external dimensions are shown in the figure 4. The instrument

may be installed on the wall.

NOTE: If the identification plate is supplied separately (therefore not attached to the indicator), it is advisable to

attach it to the indicator, in order to be able to identify the instrument.

1

2

3

4

3590EKR, 3590EXP, 3590EXT, CPWE, CPWET series indicator E-AF09_02_13.01_EN_U

11

3.4 POWER SUPPLY

- The 3590E indicator is powered with 12Vdc voltage ( 8 ÷ 36 Vdc in the IO version), through an internal adapter which

converts the 100 ÷ 240Vac, 50÷60Hz mains voltage and 6 Vdc, from the built-in battery (fitted, depending on the model).

TO POWER the instrument through the 240 Vac mains, or TO RECHARGE the battery, insert the plug and the adapter to the

240 Vac mains socket.

- The CPWE indicator is powered with 8÷36 Vdc voltage or with 6 Vdc external battery (upon request).

- The CPWET indicator is powered with 12 Vdc voltage or with 6 Vdc external battery (upon request).

To connect it to the power mains, the safety regulations must be observed, including the use of a "clean" line without

disturbances or interference caused by other electronic equipment.

Version with rechargeable battery: the battery inside the indicator, lasts about 25 hours (without the expansion board, with

1-cell platform) and it needs a recharging time of about 12 hours.

BATTERY FEATURES

Material LEAD

Power 4,5 Ah

Voltage 6 V

THE BATTERY MUST BE SUPPLIED DIRECTLY FROM THE MANUFACTURER.

NOTE: it is advisable to completely recharge it (12 hours) in the first installation of the instrument; we RECOMMEND

disconnecting the battery if the instrument is not going to be used for more than 30 days.

Do not connect other equipment to the same socket as the one that the adapter is in.

Do not step on or crush the power supply cable

3.5 START UP

TO TURN ON the 3590E or the CPWET press the C key until the display turns on; then release.

The CPWE instead is automatically turned on as soon as it is powered.

The display shows:

- Initially a welcome message (settable in the TECHNICAL SET-UP, << LoGo >> StEP, TECH.MAN.REF) while the

instrument carries out a series of checking and preheating self tests.

- E-AF09 - XX name of the installed software, in which XX identifies the software language.

XX.YY is the software version installed.

- “EXECUTION AUTOZERO”

The instrument carries out the "autozero at start-up” function: if a weight is detected within the percentile set in the <<

Auto-0 >> step (TECH.MAN.REF.), it is cleared; if the weight is not within this tolerance:

- with a non approved instrument, the display shows the weight after a few instants,

- with an approved instrument, the message “EXECUTION AUTOZERO” appears continuously on the display, until the

weight is within tolerance.

The autozero function at start-up can be disabled in the set-up environment (only with a non approved instrument), see the

<<Auto-0>> parameter.

By pressing the 2ndF key for an instant while the version is shown in the display, the indicator will show in this order:

XX.YY in which XX indicates the instrument type, YY indicates the metrological software version.

XX.YY.ZZ is the installed software version.

HH is the installed hardware version (08).

LEGAL FOR TRADE or HIGH RESOLUTION if the instrument is APPROVED or UNAPPROVED, respectively.

9.XXXXX is the g gravity value (only with APPROVED instrument).

3.6 TURNING OFF THE INSTRUMENT

TO TURN OFF the 3590E/CPWET or TO RESTART the CPWE keep the C key pressed until the “- OFF -“ message appears

on the LED display and “ *** POWER OFF *** ” on the LCD display.

TO TURN OFF the CPWE remove the instrument’s power supply.

3590EKR, 3590EXP, 3590EXT, CPWE, CPWET series indicator E-AF09_02_13.01_EN_U

12

3.7 TURNING ON PRINTER IN ENERGY SAVING MODE

Premise: the SEtuP >> SEriAL >> CoMPrn >> PWrPrn parameter must be set as “EXt.oFF” or “PWrint”,

(TECH.MAN.REF).

In a system where the indicator is connected to a printer, both are battery powered, the printer is normally maintained in

STAND-BY and powered only when a printout is needed. This function reduces the energy absorbed by the battery when the

printer is not being used.

If, in this configuration, one should power the printer to change the paper and other maintenance jobs, one needs to press in

sequence the ENTER and 0 keys during the weighing: the LED display shows Prn – on (Blinking), and the printer is kept on.

Press any key to exit from this condition.

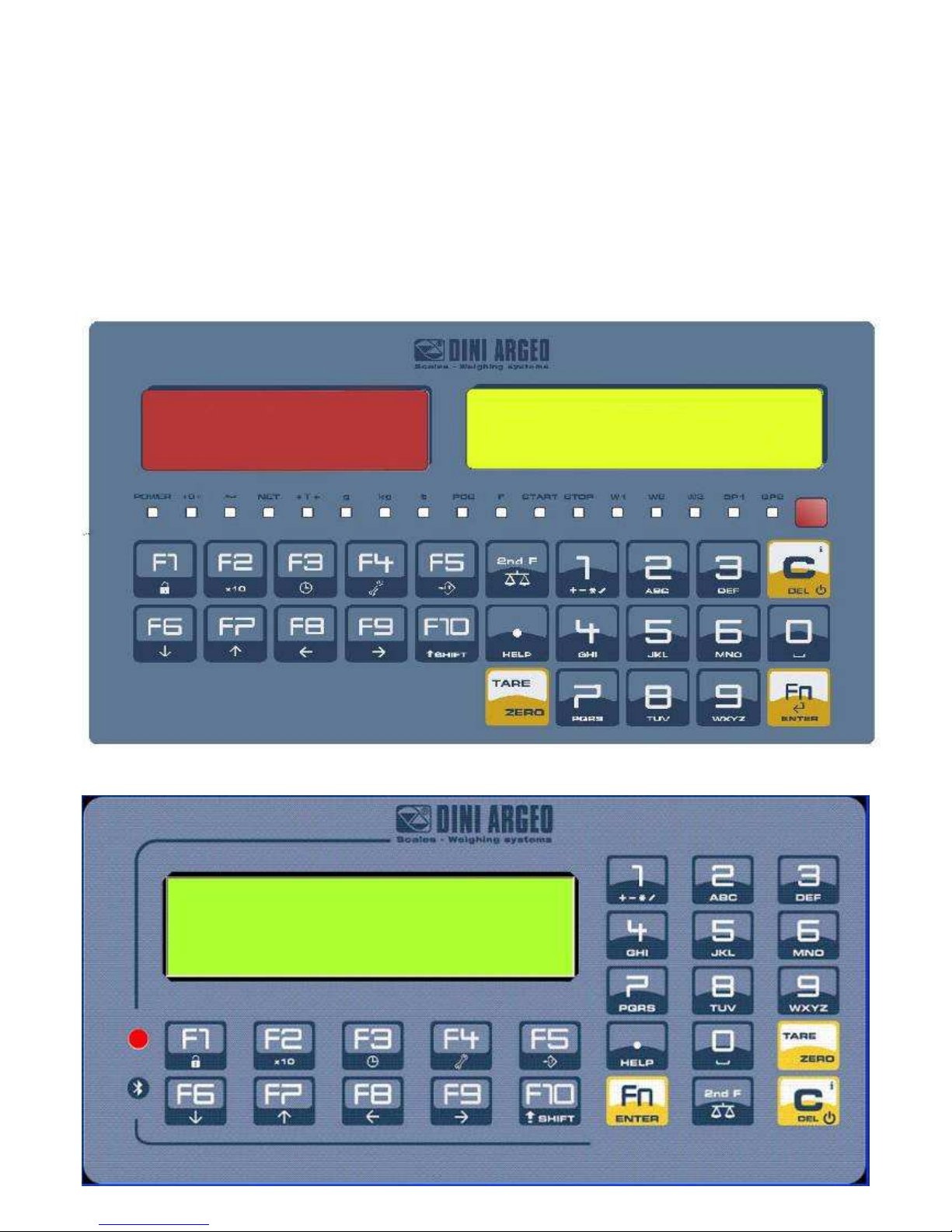

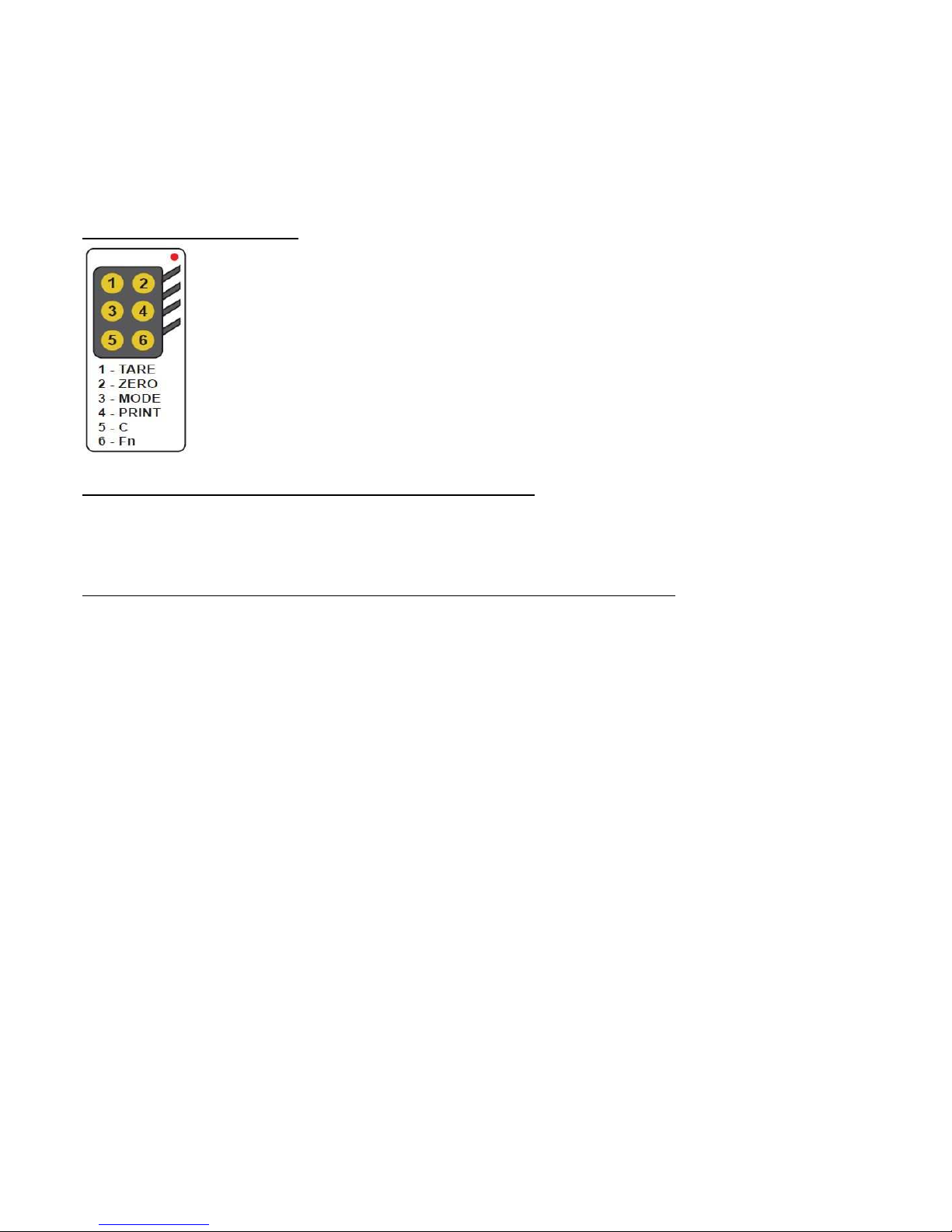

4. FRONT PANEL KEYS

3590E:

CPWE:

3590EKR, 3590EXP, 3590EXT, CPWE, CPWET series indicator E-AF09_02_13.01_EN_U

13

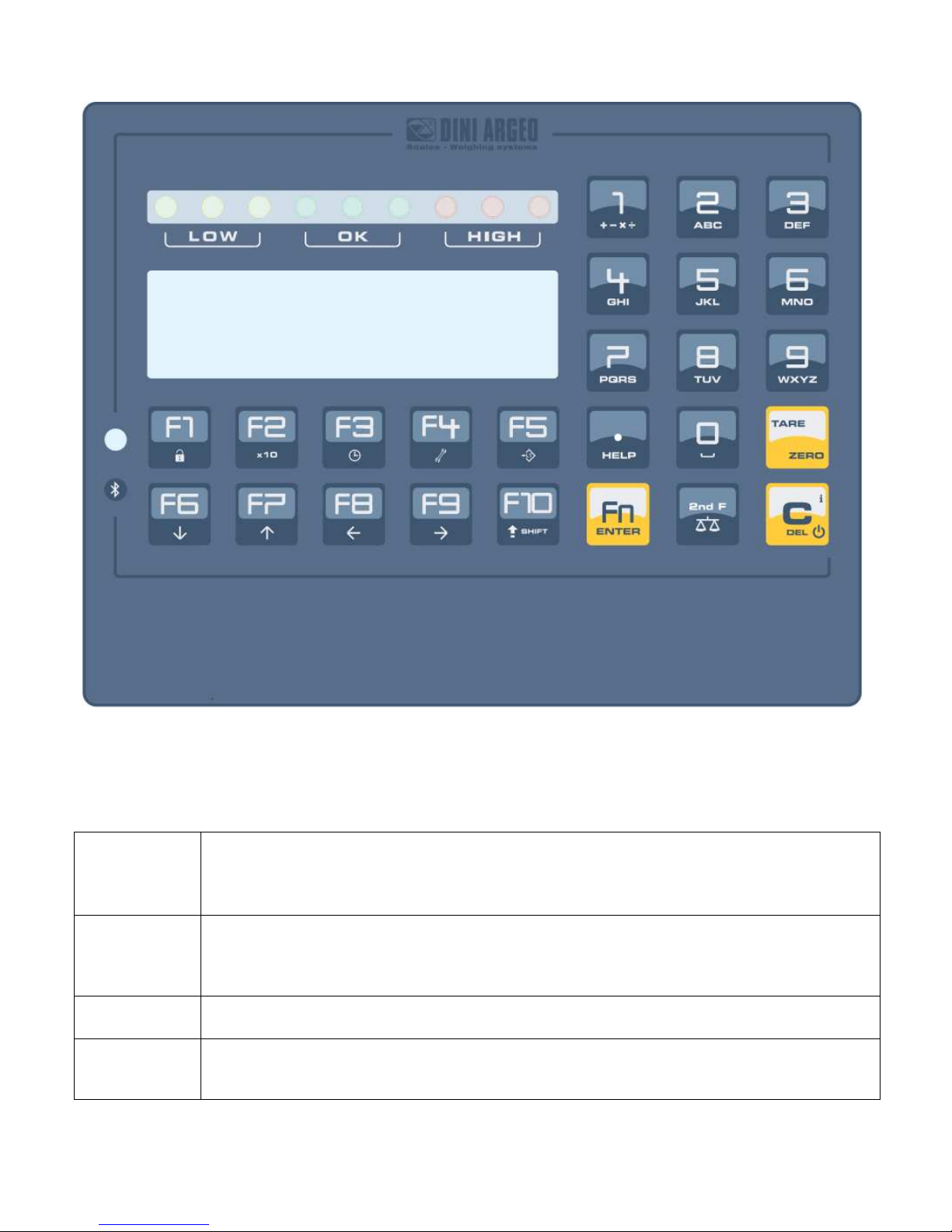

CPWET

4.1 FUNCTION OF THE KEYS

In the following section, and later on in the manual, the keys’s functioning is described in accordance to how these are

configured by factory.

It is possible to customise the functionality of the keys through the << F.KEYS >> step.

C/DEL

- Turns the instrument on/off

- If pressed for an instant, it clears the tare value.

- Exits the parameter without confirming and saving the modifications.

- In the numeric input phase, it quickly clears the present value

TARE/ ZERO

- If pressed for an instant it carries out the semiautomatic tare, or cancels the value of tare if the gross

weight is 0.

- If pressed at length, it clears the displayed gross weight, if it’s within the percentage configured in the

<< 0.PErC >> step.

Fn/ENTER

- In the alphanumeric input phase, it confirms the entry made.

- In the menu it allows to enter a step or to confirm a parameter inside a step.

2nd F

- In the

<< F.Keys >>

step, if pressed for an instant, the list of the available

functions appear

and it is possible to choose one of them.

- If pressed together with the other keys, it allows carrying out a specific function. (see section 4.1.1)

3590EKR, 3590EXP, 3590EXT, CPWE, CPWET series indicator E-AF09_02_13.01_EN_U

14

./HELP

In the calculator mode or when edits printer format, if pressed, the display

shows some help

descriptions.

In the numeric or alphanumeric input phase, it enters, in this order, the following characters: . , ; : # < > \

| ” % & / ( ) = ? ^ ’ [ ] { };

F1

In the

<< F.Keys >>

step, if pressed for an instant, it is possible to set

the default key functions.

- In the numeric or alphanumeric input phase, it allows to copy entered characters.

- If pressed for an instant, it enters into the CUSTOMER DATABASE.

- If pressed at length, it locks and unlocks the instrument’s keyboard (except the C key).

F2

- In the numeric or

alphanumeric

input phase

, it allows to stick with copied characters.

- If pressed for an instant, it enters into the MATERIAL DATABASE.

- If pressed at length, the weight visualisation function with sensitivity x 10 is enabled

F3

- If pressed for an instant, it enters into the

VEHICLE DATABASE

.

- If pressed at length, one can adjust the date and time of the instrument.

F4

- If pressed for an

instant

, it allows to fill in the free texts

,

(only

if configured

).

- If pressed at length, it enters the instrument’s diagnostics menu.

F5

- If pressed at length, it locks/unlocks the tare.

- Commands the data transmission to the printer serial port.

F6

- If pressed for an instant, it

starts

the simple axle totalisation or the

i

nput

axle totalisation (with

Input/Output function enabled).

- In the numeric or alphanumeric phase, it decreases the blinking digit.

- It allows scrolling ahead inside the menu steps or in the parameters within a step.

F7

- If pressed for an instant, it

starts output axle totalisation (with Input/Output function enabled).

- In the numeric or alphanumeric input phase, it increments the blinking digit.

- It allows scrolling backwards in the menu steps or in the parameters within a step.

F8

- If pressed for an instant, it executes the printing and the zeroing of the partial total.

- In the numeric or alphanumeric input phase, it selects the digit to be modified from right to left.

F9

- If pressed for an instant, it allows to manually close the

automatic

axl

e totalisation cycle with

consequent determination of the total weight. See section 13.2.2, 13.2.3, 13.3.2 and 13.3.3.

- In the numeric or alphanumeric input phase, it selects the digit to be modified from left to right.

F10

- If pressed for an instant, i

t allows to reset the

automatic

axle totalisation cycle, cancelling all the

totalized axles. See section 13.4.1

- In the numeric or alphanumeric input phase, introduces a space between two characters.

NUMERIC

KEYBOARD

Entry of digits or characters.

- During weighing, these enter a numeric value with which it’s possible to:

1) Set the tare value, by pressing subsequently the TARE key (see section 7.2).

2) Sum, subtract, or multiply the value entered from the keyboard to the current tare (see the 15.3

CALCULATOR section).

3590EKR, 3590EXP, 3590EXT, CPWE, CPWET series indicator E-AF09_02_13.01_EN_U

15

4.2 "2ndF" KEY: SECOND FUNCTION OF THE KEYS

In the weighing phase, by pressing the 2ndF key together with another key, it’s possible to execute various functions

(continue reading the manual for the details of the functions):

2ndF

F1

Pri

nt/

Clearing

of Customer Total.

2ndF

F2

Print/

Clearing

of Material Total.

2ndF

F3

Print/

Clearing

of Vehicle Total.

2ndF

F4 Deselecting

all the elements selected from the database

s.

2ndF

F5

Repetition of the last printout made.

2ndF

F8

Net/Gro

ss Conversion

2ndF

F9

Change LCD visualization

2ndF

C

Causes the display of the present metric scale information

(see section 9).

4.3 ENTERING ALPHANUMERIC TEXT

It might be necessary, while the weighing system is working, to enter some alphanumerical texts such as descriptions,

alphanumerical messages (operator, lot number, customer, etc.).

To enter the characters one uses the 0 to 9 keys.

By pressing one of these keys a few times, the characters shown on the key will be shown on the display: initially the first

letter in the bottom left will appear, and then the other characters towards the right.

After digiting a character, the blinking cursor, after a few instants, advances automatically of a position.

When the maximum number of characters has been reached, the indicator emits an acoustic signal and the cursor remains

in that positions.

TAKE NOTE:

In the updating of a text, if the cursor is at the beginning of the text and the first key pressed is C or a character/number key,

all the entered characters will be deleted.

Function of the keys

F5 S

witches the writing mode from “numeric”

(nuM)

to “characters”

(ChAr)

.

In the nuM mode one enters just the numbers, while in the ChAr mode one can enter all the characters of

a key. The last writing mode selected is stored by the instrument.

C If p

ressed for an instant, it

cancels the written characters: first the characters that follow the cursor are

cancelled; than those that precede it, one at a time.

If pressed at length, it deletes all entered characters.

With empty text, it exits the entry phase without confirming.

SHIFT

It enters a space in the middle of a text.

./HELP

If pressed a few times it allows entering the following characters:

. , ; : # < >

\ | ” % & / ( ) = ? ^ ’ [ ] { }.

0 In “characte

rs” mode

(ChAr),

by pressing once

, a space is entered;

by pressing twice it enters the “0”

character.

1 In “characters”

mode (ChAr),

when

pressed repeatedly, it

allows to enter the following symbols:

? ! 1 @ ’ + – * / = ~ € „ … † ‡ ˆ ‰ š < OE ž ı ’ “ ” • – – ˜ ™ Š > oe ž ¢ £ ¤ ¥ ¦ § ¨ © ª « ¬ - ® ‾ ° ± ² ³ ´ µ ¶ · ¸

¹ º » ¼ ½ ¾ ¿ ã.

Moves the blinking cursor to the left or to the right.

Scrolls in one sense or the other the list of all the enterable characters (0,

1…9, A, B…Y, Z)

Examples:

- To enter the letter “B” one should press the “2” key twice in the ChAr mode.

- To enter the number “3” one should press the “3” key four times (in the ChAr mode) or press the F5 key (one passes to

the nuM mode) and press the “3” key once.

3590EKR, 3590EXP, 3590EXT, CPWE, CPWET series indicator E-AF09_02_13.01_EN_U

16

4.4 DISABLING THE KEYBOARD

It is possible to disable all the keyboard functions (except the C key for turning on and off), in order to avoid undesired

pressings of the scale keys:

- To lock the keyboard, press at length the F1 key: the display shows the “LoCK” message for a few instants. Now the

keyboard is LOCKED: if one presses a key, the display shows for a few instants the “PRESS AT LENGTH F1 FOR

UNLOCKING” message.

- To unlock the keyboard, press again at length, the F1 key: the display shows the “unLoCk” message for a few instants.

NOTE: It’s possible to lock all keys individually in a permanent way through the TECHNICAL SET-UP, TECH.MAN.REF.

4.5 HELP MENU

By pressing at length the HELP key it is possible to access a menu containing the list of keys with the relative function, and

status (locked or unlocked) indication.

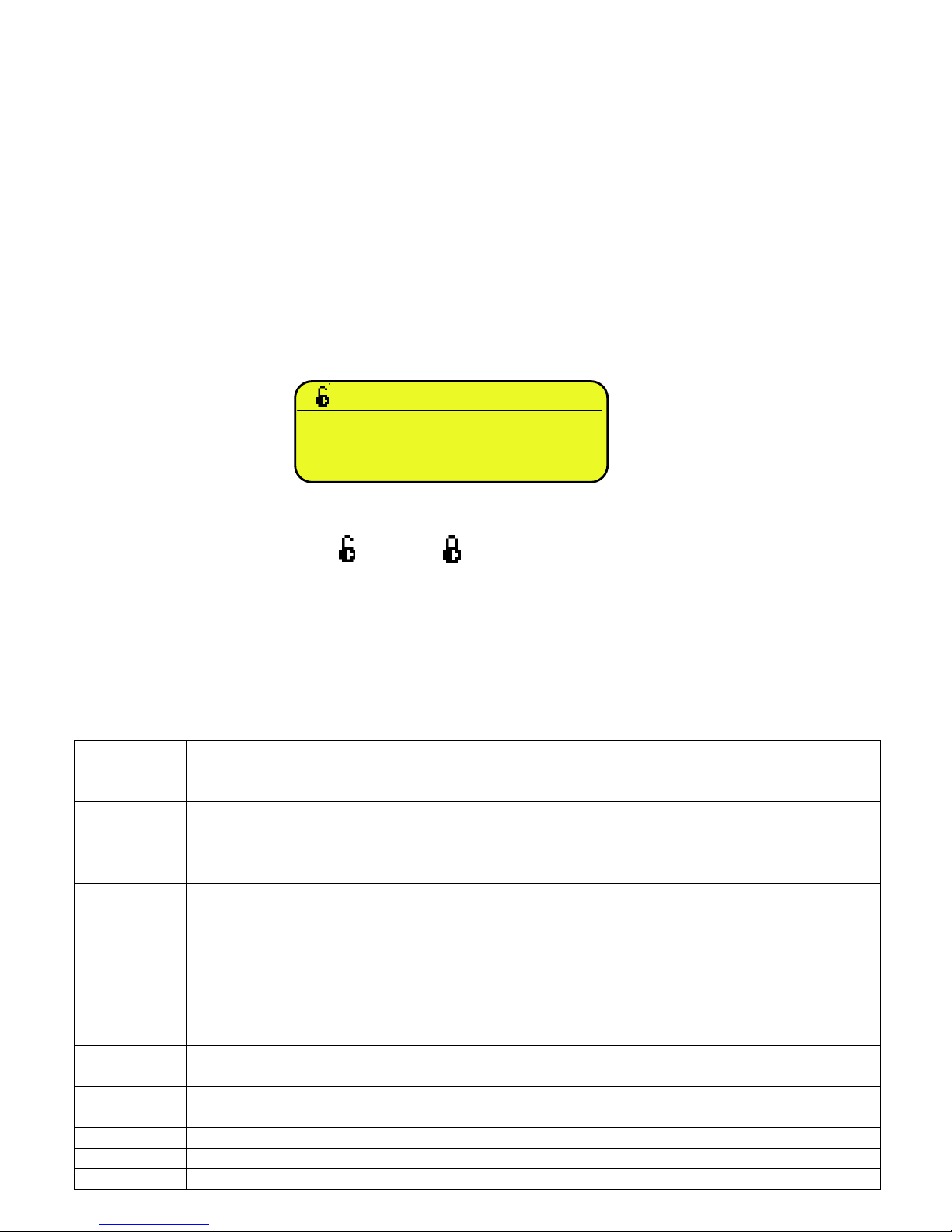

The display shows:

- in the upper part: the key, followed by the code of the linked function in the << F.Keys >> step, and a symbol

indicating whether the key is unlocked ( ) or locked ( ) in the << EN.KEYS >> step.

- in the lower part: the description of the linked function.

Scroll the list with the arrow keys , press the C key to exit.

4.6 INDICATOR CONNECTED TO REMOTE KEYBOARD

It’s possible to connect a PC keyboard (optional), used to emulate the functions of the keys of the indicator.

The keys are managed in the following way:

Esc

-C key.

- If pressed at start-up, it allows entering in the technical set-up.

In the alphanumeric input, it deletes all entered characters.

and Canc

-C key.

- If pressed at start-up, it allows entering in the technical set-up.

In the alphanumeric input, it cancels first the characters which follow the cursor, then the ones which

precede it, one at a time.

Enter

- Fn

key.

- Confirms the entered value.

- Enters the displayed step

Numeric and

alphanumeric

keys, SHIFT

and CAPS

LOCK

- Quick entry of a numeric and alphanumeric string: through the CAPS/LOCK or SHIFT key it is possible to

switch from the capital letters to the lower case letters, and vice versa, or enter the second character

corresponding to the key (for example ", %, &, /, ? ). The entered string is shown on the LCD display.

Cursor keys

- Scroll the parameters

- Increase or decrease the blinking digit while entering a value.

Cursor keys

- When entering a value or an alphanumeric string, it scrolls the digits to the right or to the left.

F1, F2….F10

F1,F2….F10 keys.

F11 2ndF

key

F12 TARE

key.

F1:302

C

CUSTOMER

DATABASES

3590EKR, 3590EXP, 3590EXT, CPWE, CPWET series indicator E-AF09_02_13.01_EN_U

17

The PC keyboard also allows to enter a numeric or alphanumeric string (max.32 characters) and then press a key to execute

the corresponding quick function.

For example, if the function 122 (Input text 1 configuration) is combined to the F4 key (see << F.KEYS >> step,

TECH.MAN.REF.), through PC keyboard it’s possible to enter a text and the press F4 to quickly modify the input text 1.

NOTE: through the remote keyboard, it’s not possible to carry out the functions made by pressing the keys at length.

4.7 REMOTE CONTROL

Depending on the model of indicator, it is possible to remotely control the instrument through one of the following types of

remote controls: 19-key infrared (ir),18-key infrared (ir) or 6-key radio (rd).

The type of remote control to be used must be selected in the Setup environment, in the << inF.rEd >> step

(TECH.MAN.REF.).

NOTE: The infrared remote controls are for indoor use only.

4.7.1 “19-KEY” INFRARED REMOTE CONTROL

With this type of remote control, the functioning of the keys will be as described in the following table.

FUNCTION OF THE KEYS

KEYBOARD

KEY OR FUNCTION EMULATED

F1…F3

F1…F3 keys

C C key

NUMERIC KEYS

Entry of digits or characters

TARE /

Tare/zero function

or increase of a digit while entering a

value

.

.

/HELP key

ZERO /

Decrease of a digit while entering a value

MODE /

Scrolls the digits to the right while entering a value

PRINT /

Confirms the entered value or enters the displ

ayed step

3590EKR, 3590EXP, 3590EXT, CPWE, CPWET series indicator E-AF09_02_13.01_EN_U

18

4.7.2 “6-KEY” RADIO REMOTE CONTROL

With this type of remote control, the functioning of each key can be programmed so that it is matched to one of the available

keys of the indicator.

This configuration must be carried out in the Setup environment, in the << inF.rEd >> step (TECH.MAN.REF.), after the

selection of this type of remote control.

By pressing the ./HELP key of the indicator, it’s possible to see, while weighing, the list of the functions matched to the keys

of the indicator and also to the keys of the remote control (see section 4.1.4 “HELP MENU”).

EXAMPLE OF CONFIGURATION

USE OF MORE REMOTE CONTROLS WITH ONLY ONE INDICATOR

If one works with only an indicator, it is possible to use any 6-key remote control, without combining it to the indicator,

therefore without limiting the number of usable remote controls.

To enable this mode one has to first select “RD 6 BR” in the << inF.rEd >> (TECH.MAN.REF.).

USE OF MORE REMOTE CONTROLS WITH SEVERAL INDICATORS IN THE SAME AREA

If one needs to use several indicators in the same area, it is possible to combine each remote control to the desired indicator,

in order to execute the function only on it and therefore avoid emulating the function on all indicators in use.

By enabling this mode it will be possible to combine up to 3 different remote controls (e.i. for 3 different operators) for each

indicator.

To enable this mode one has to first select “RD 6” in the << inF.rEd >> (TECH.MAN.REF.).

To link a new remote control to the indicator one has to:

- press at length 1 and 2 keys together (3 seconds).

- the instrument displays "aut.rd?"

- press the ENTER key of the indicator

- the new remote control is linked

To remove the linking of a remote control one has to:

- press at length 1 and 2 keys together (3 seconds).

- the instrument displays "aut.rd?"

- press the C key of the indicator; if the remote control was previously linked, it will be removed.

3590EKR, 3590EXP, 3590EXT, CPWE, CPWET series indicator E-AF09_02_13.01_EN_U

19

5. DISPLAY FUNCTIONS

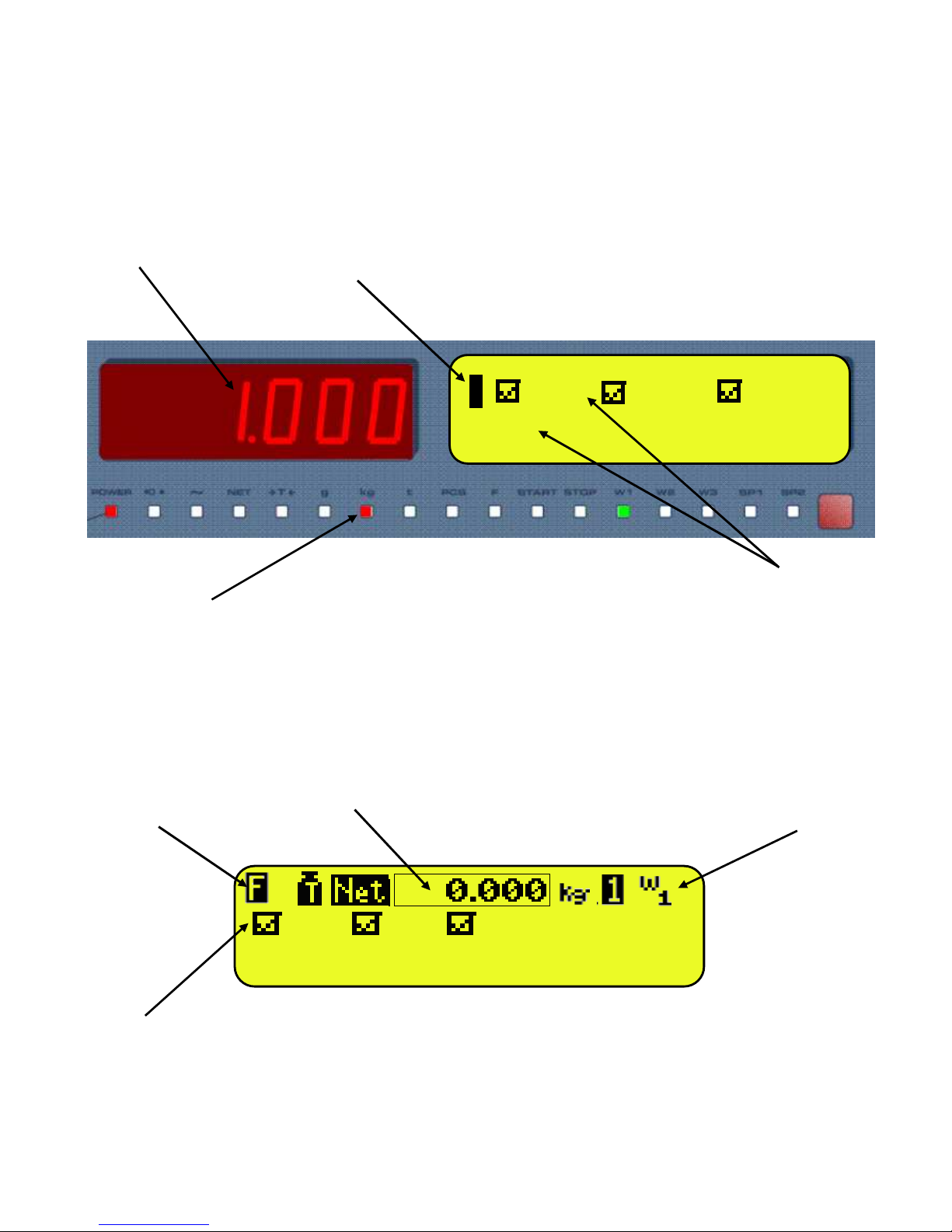

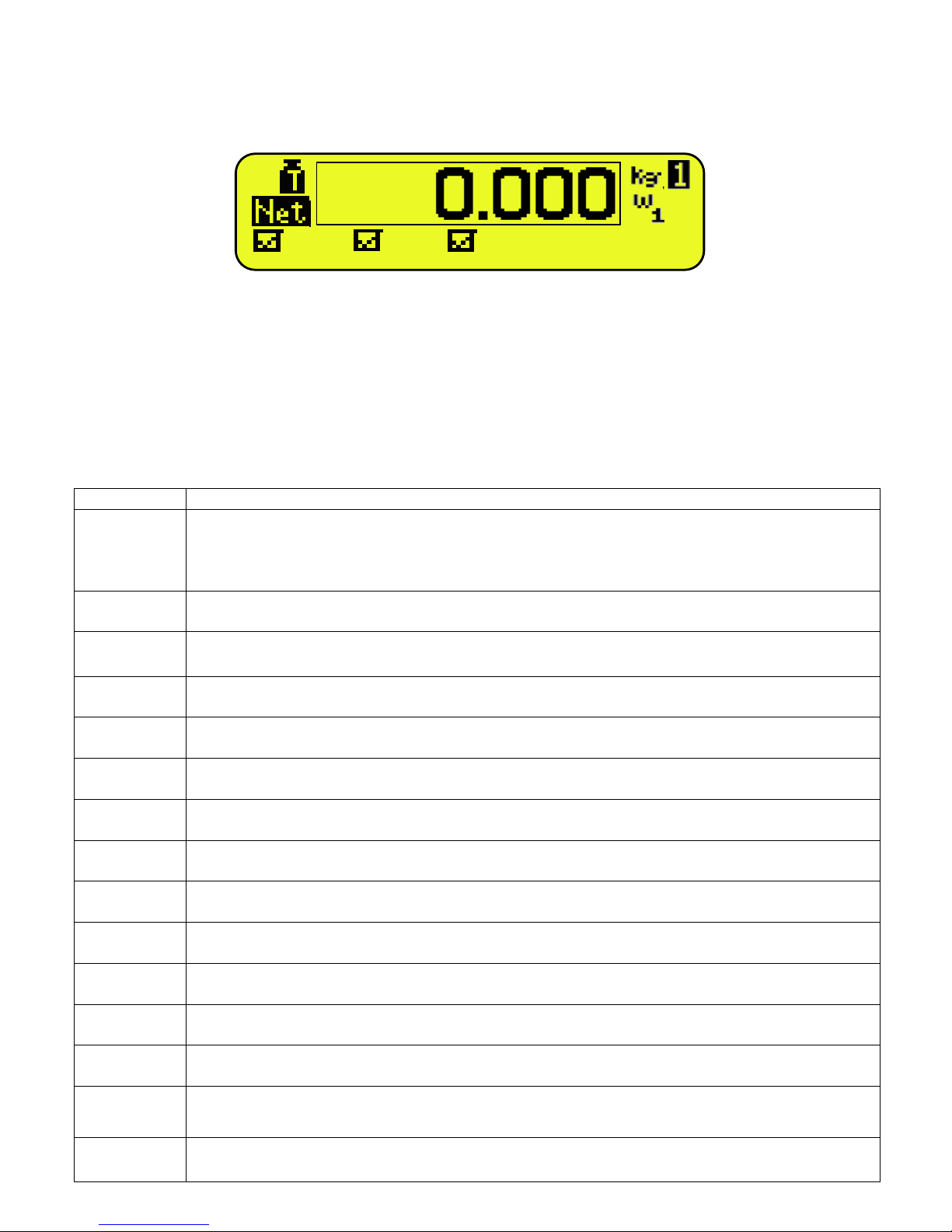

During the weighing the displays are subdivided mainly in 3 sections, shown in the figure below:

- WEIGHT

- STATUS INDICATORS (led pilot lights and / or graphic symbols)

- DATA (two lines in the 3590E; one or two lines in the CPWE, depending on the weight zoom function described in the

following section). See section 5.4.

Figure 1: 3590E displays

Figure 2: CPWE/CPWET display

CUS MAT VEH

PT: 1.000kg

1 CUS MAT VEH

PT: 1.000kg

WEIGHT

STATUS

INDICATORS

STATUS

INDICATORS

DATAS

WEIGHT

STATUS

INDICATORS

STATUS

INDICATORS

DATAS

3590EKR, 3590EXP, 3590EXT, CPWE, CPWET series indicator E-AF09_02_13.01_EN_U

20

5.1 WEIGHT ZOOM (available only on CPWE and CPWET models)

The zoom function allows to increase the size of the weight digits, in order to ease the reading from a distance; with the

active zoom, the data is shown on a single line.

Through the << ZOOM.W >> step, one can disable/enable the function and set a delay which determines the activation

mode:

- Always active function (with delay equal to 0), or

- Disabled function at the pressing of a key and re-enabled automatically when the keyboard inactivity time reaches the

configured delay period (with delay greater than 0).

5.2 STATUS INDICATORS

LED FUNCTION

POWER

Indicates the type of indicator power supply:

- red pilot light: through built-in power adapter;

- green pilot light: through battery (charged battery);

- pilot light off: through battery (discharged battery).

0

Indicates that the weight detected by

the weighing system is near zero, including the interval of 1/4 +1/4

of the scale’s division.

~

Indicates that the weight is unstable.

NET

Indicates that the weight shown by the LED display is a NET WEIGHT.

T

Indicates that a tare value has been acquired or entered.

g

Indicates that the unit of measure in use is the gram.

kg

Indicates that the unit of measure in use is the kilogram.

t

Indicates that the unit of measure in use is the ton.

PCS

Not used in this application

F

Indicates that an axle totalization cycle is in execution.

START

Not used in this application

STOP

Not used in this application.

W1 W2 W3

See section 8.

SP1

Not used in this application

SP2

Not used in this application

CUS MAT VEH

3590EKR, 3590EXP, 3590EXT, CPWE, CPWET series indicator E-AF09_02_13.01_EN_U

21

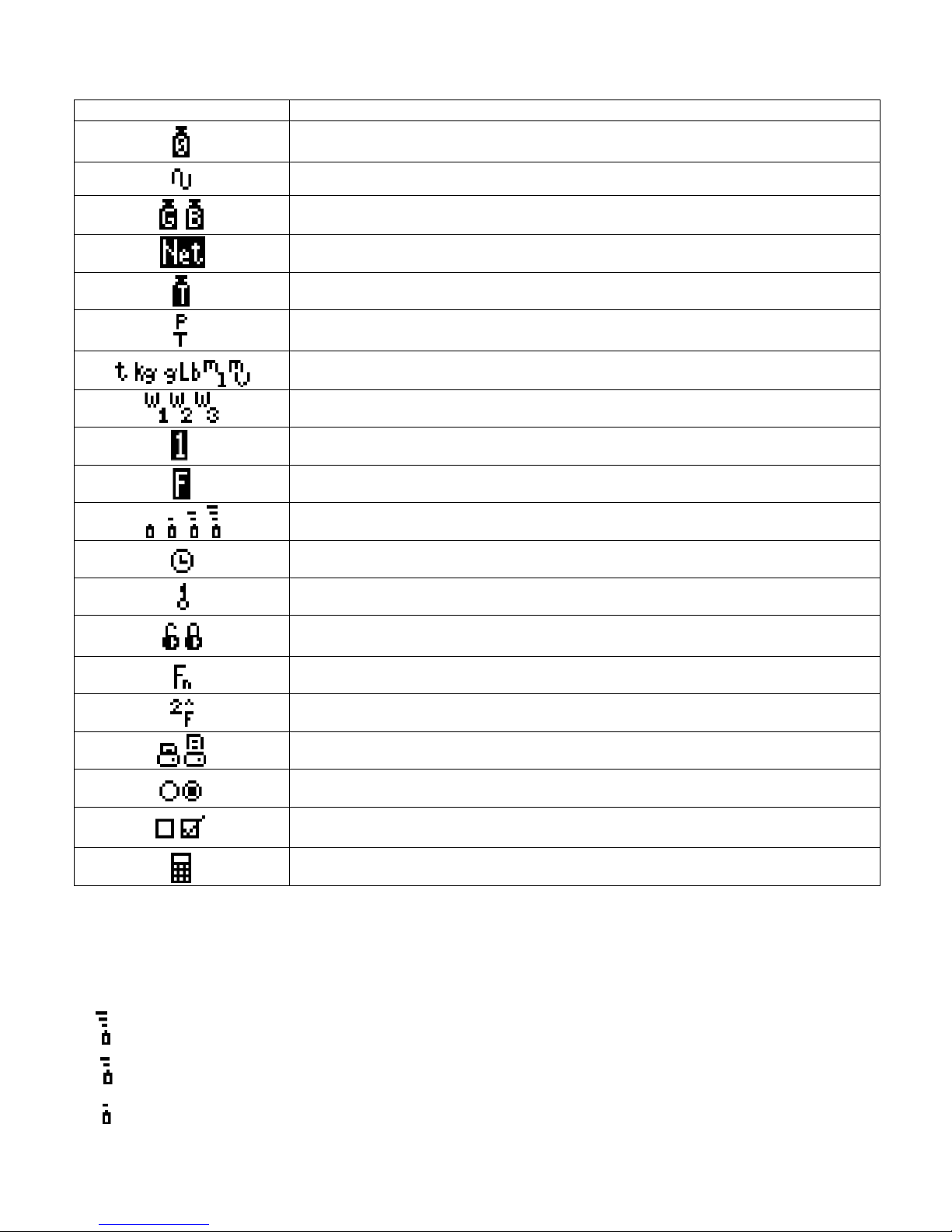

SYMBOLS FUNCTIONS ON THE LCD DISPLAY

5.3 BATTERY LEVEL INDICATION

The indicator is able to recognise whether it is powered by mains or by battery, and to indicate its charge level; to enable the

battery level indication, one should configure the << bt.LEVEL >> step.

The charge level is shown during weighing by the battery symbol.

- : charged battery.

-

: partially charged battery.

- : discharged battery: connect the indicator to the mains for recharging the battery (if provided by that model) or replacing

the battery.

SYMBOL ON LCD DISPLAY

FUNCTION

The weight detected by the weighing system is near the zero, included within the interval

of –1/4 and +1/4 of the scale division.

The weight is unstable.

The displayed weight is a GROSS WEIGHT (depending on the software language).

The displayed weight is a NET WEIGHT.

A tare value has been acquired.

A manual tare value has been entered.

Unit of measure in use: ton, kilogram, gram, pounds, millilitres, or millivolts.

Active weighing range, see section 8.

Active scale (always 1).

Indicates that an axle totalization cycle is in execution.

Battery charge level: see section 5.3.

Active during the configuration of the date and time.

Locked keyboard, see section 4.4

In the HELP menu these respectively indicate whether a key is unlocked or locked in the

SETUP level (<< En.KEYS >> step, see section 4.5)

The Fn key has been pressed.

The 2nd F key has been pressed.

Transmission of the data to the printer serial port under way.

Inside the step, these respectively indicate an unselected or selected parameter.

These indicate

respectively

if an element of the database is

unselected or

selected (see

section 5.4).

Active calculator function, see section 15.3 CALCULATOR.

3590EKR, 3590EXP, 3590EXT, CPWE, CPWET series indicator E-AF09_02_13.01_EN_U

22

The indicator shows also when the battery is being recharged (if provided for the model):

RECHARGE PHASE: …

COMPLETED RECHARGE:

NOTES:

- During the recharge the instrument can be normally used.

- The instrument automatically turns off when the voltage goes below the minimum level.

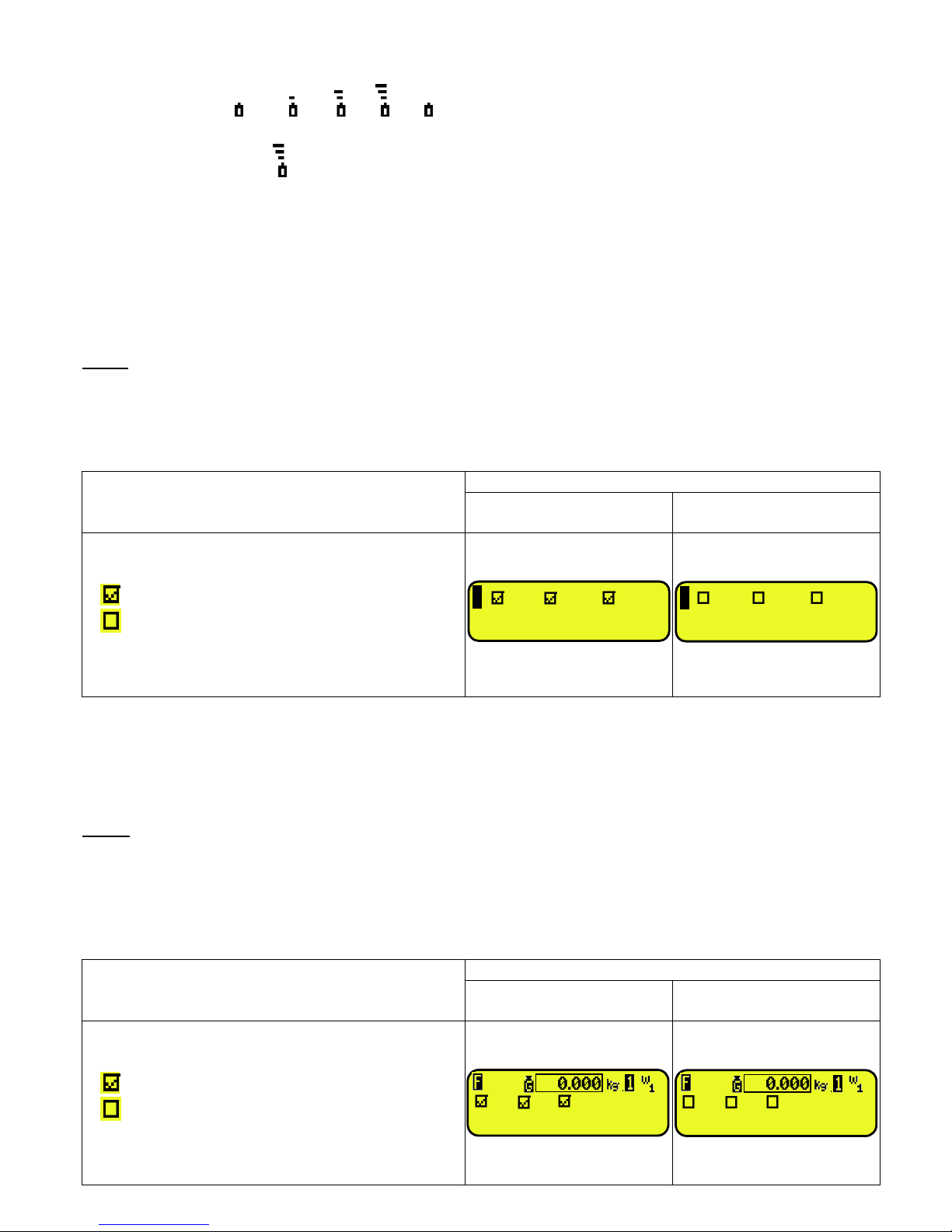

5.4 DISPLAYED DATA

3590E:

The data is displayed on two lines and depends on the status of the instrument:

- When not in the axle totalization cycle, the visualization will be as follow:

VISUALISATION

EXAMPLE

S

WITH ELEMENT

SELECTED

WITH ELEMENT

NOT SELECTED

- Indication of the selected elements (CUS:customer /

MAT:material / VEH:vehicle):

Element selected

Element not selected

- PT is Preset tare (if set) to be subtracted from the total

accumulated weight (see section 13.3.6).

- During the axle totalization cycle the display will guide the operator to execute the weighing procedure depending on the

selected functioning mode. Refer to section 13 for details.

CPWE:

VISUALISATION WITH NON ACTIVE WEIGHT ZOOM

The data is shown on two lines under the “weight” section depending on the status of the instrument:

- When not in the axle totalization cycle, the visualization will be as follows:

VISUALISATION

EXAMPLE

S

WITH ELEMENT

SELECTED

WITH ELEMENT

NOT SELECTED

- Indication of the selected elements (CUS:customer /

MAT:material / VEH:vehicle):

Element selected

Element not selected

- PT is Preset tare (if set) to be subtracted from the total

accumulated weight (see section 13.3.6).

CUS MAT VEH

1 CUS MAT VEH

PT:

10

00kg

1 CUS MAT VEH

PT:

10

00kg

CUS MAT VEH

PT: 1.000kg

3590EKR, 3590EXP, 3590EXT, CPWE, CPWET series indicator E-AF09_02_13.01_EN_U

23

- During the axle totalization cycle the display will guide the operator to execute the weighing procedure depending on the

selected functioning mode. Refer to section 13 for details.

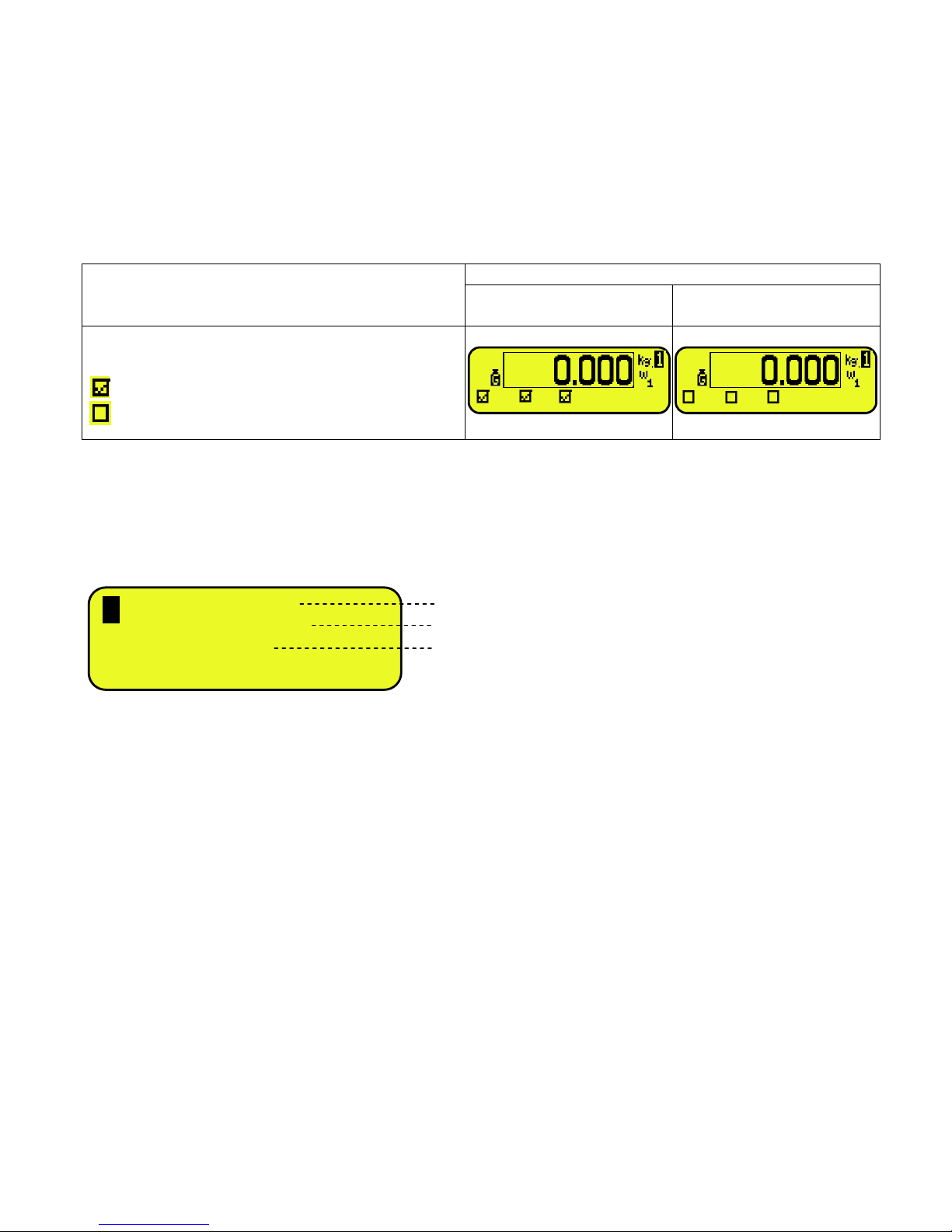

VISUALISATION WITH ACTIVE WEIGHT ZOOM

The data is shown on one line under the “weight” section depending on the status of the instrument:

- When not in the axle totalization cycle, the visualization will be as follows:

VISUALISATION

EXAMPLE

S

WITH ELEMENT

SELECTED

WITH ELEMENT

NOT SELECTED

- Indication of the se

lected elements (CUS:customer

/

MAT:material / VEH:vehicle):

Element selected

Element not selected

5.4.1 LCD DISPLAY CUSTOMIZATION (ONLY FOR 3590E INDICATORS)

On the 3590E models it is possible to customize the data displayed on the LCD display, through the print format 99 (see the

section “DISPLAY CUSTOMIZATION”, TECH.MAN.REF.), by using the DiniTools™ software.

By pressing in sequence the Fn and F9 keys it’s possible to activate the customized visualization.

The default configuration for this visualization is the following:

If more than 4 lines have been programmed, it’s possible to scroll the visualizations by pressing in sequence the Fn and F9

keys.

Once that this visualization has been activated, press in sequence the 2ndF and F9 keys to display again the standard

visualisations described in the previous sections.

CUS

MAT

VEH T

1.000

CUS

MAT

VEH

first description of the selected material

first description of the selected customer

first description of the selected vehicle

MAT.:

MATERIAL 1

CUS.: CUSTOMER 1

VEH.: TRUCK 1

TARE

0.000

kg

1

3590EKR, 3590EXP, 3590EXT, CPWE, CPWET series indicator E-AF09_02_13.01_EN_U

24

5.5 MESSAGES OF THE INSTRUMENT

While using the indicator, it is possible to incur into the following errors:

5.5.1 INSIDE THE SET-UP OR MENU OR AT START-UP

MESSAGE DESCRIPTION

Error S X Cell Y Communication error on scale X (E.G. Range 1), to Platform number Y

Err. – 98

Connection error between the indicator and the platforms, after have showed this

error, the instrument, show which platform has problems.

C.Er. – 8.03

When carrying out the multirange or multidivisional calibration, the ranges have not

been entered in an increasing manner (RANGE 1 < RANGE 2 < RANGE 3).

C.Er.

– 36

CALIBRATION ERROR

During the calibration some internal negative points have been calculated:

- the calibration point is less than the zero point.

-

the signal is negative (check the connections)

Er – 37 / alternately with No.Cal

CALIBRATION ERROR

During the calibration some internal points less than the minimum value have been

calculated:

- the calibration point is equal to the zero point.

-

A capacity too high in relation to the division has been set.

Err. – 38

NO CALIBRATION

Range not valid: please check that RANGE 1 < RANGE 2 < RANGE 3.

Er – 39

NO CALIBRATION

Invalid calibration range number (there is the value 0 or values greater than 3); one

must execute a TECHNICAL DEFAULT (dFLt.t parameter of the SET-UP

environment), if not already executed previously, and carefully carry out the

calibration.

Er – 40

The value 0 is in the “range 1” parameter of the calibration; one must execute a

TECHNICAL DEFAULT (dFLt.t parameter of the SET-UP environment) and carefully

carry out the calibration.

Er – 41

The value 0 is in the “diV 1” parameter of the calibration; one must execute a

TECHNICAL DEFAULT (dFLt.t parameter of the SET-UP environment) and carefully

carry out the calibration.

Err. – 72

Equalizati

on coefficient adjustment not allowed because a too low sample weight has

been used.

Err. – 85

Equalization coefficient adjustment not allowed because the instrument has not been

calibrated.

ErPnt

During the acquisition of a calibration point, a null val

ue from the converter has been

read.

hW-Err

HARDWARE ERROR: software not compatible with the installed hardware; t

he

hardware expansion component, which allows the software to function, is missing.

EXITING SETUP:

SAVE ?

The instrument requests the saving

when exiting the set

-

up; press

ENTER

to confirm

or C to not continue..

SURE?

The instrument requests a confirmation before proceeding: press

ENTER

to confirm

or C to not continue.

Error

Generic error. Possible motives can be:

- Division not valid: please check that DIVISION 1 < DIVISION 2 < DIVISION 3;

- An error has taken place in the connection, configuration, equalisation,

calibration of the cells, etc.

EXECUTION

AUTOZERO

“autozero at start-up” function is active (see section 3.4)

Loading...

Loading...