Dini Argeo 3590EGT Series User Manual

Indicators series 3590EGT EGTCHECK_05_15.08_IT_U

USER MANUAL

WEIGHT INDICATOR

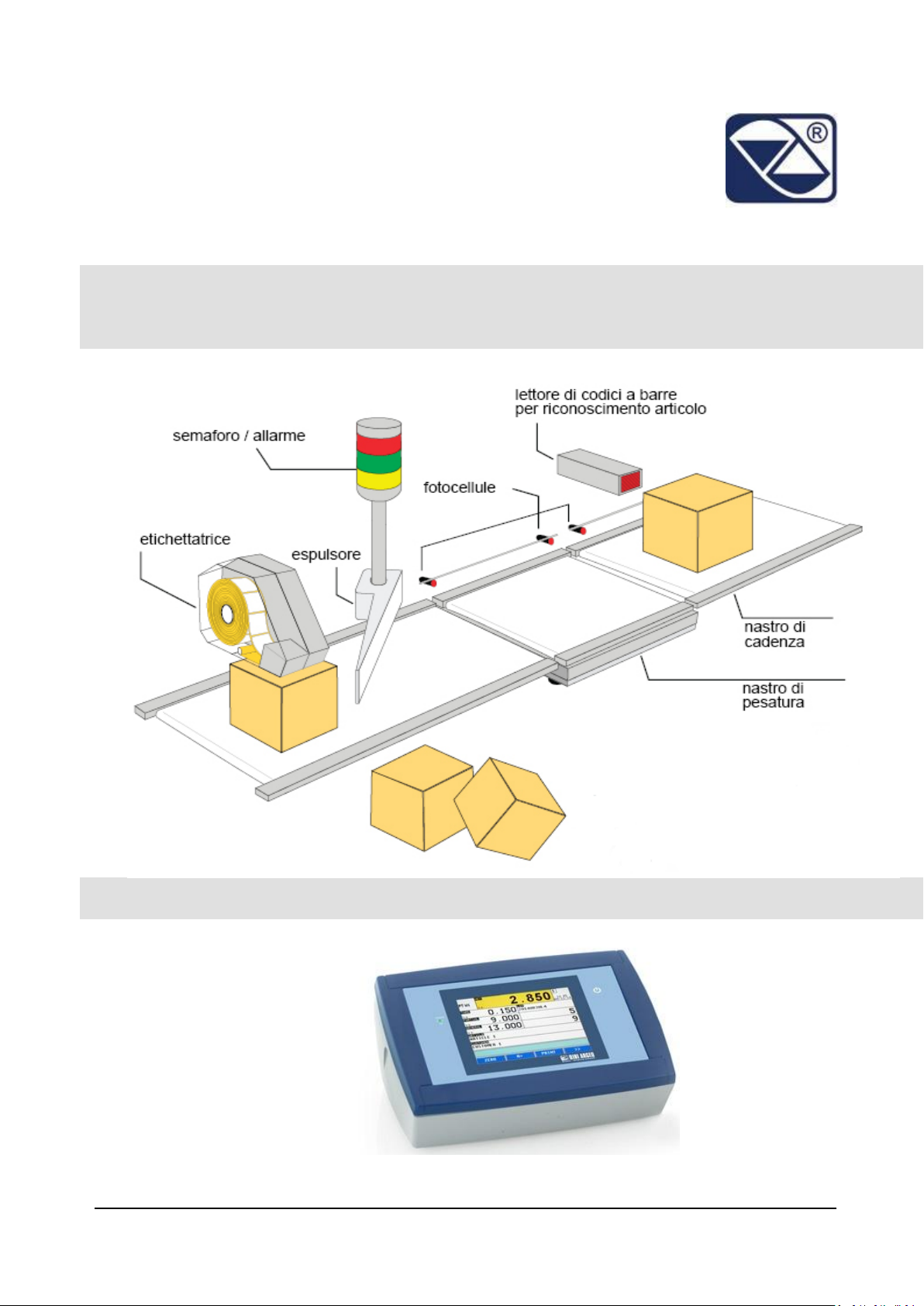

EGTCHECK: DINAMIC OR STATIC WEIGHT CONTROL ON

TAPE

Indicators series 3590EGT

1

3590EGTCHECK_05_15.08_IT_U

INDEX

1 INTRODUCTION .......................................................................................................................................... 5

2 TECHNICAL SPECIFICATIONS ...................................................................................................................... 7

3 INSTALLATION ............................................................................................................................................ 8

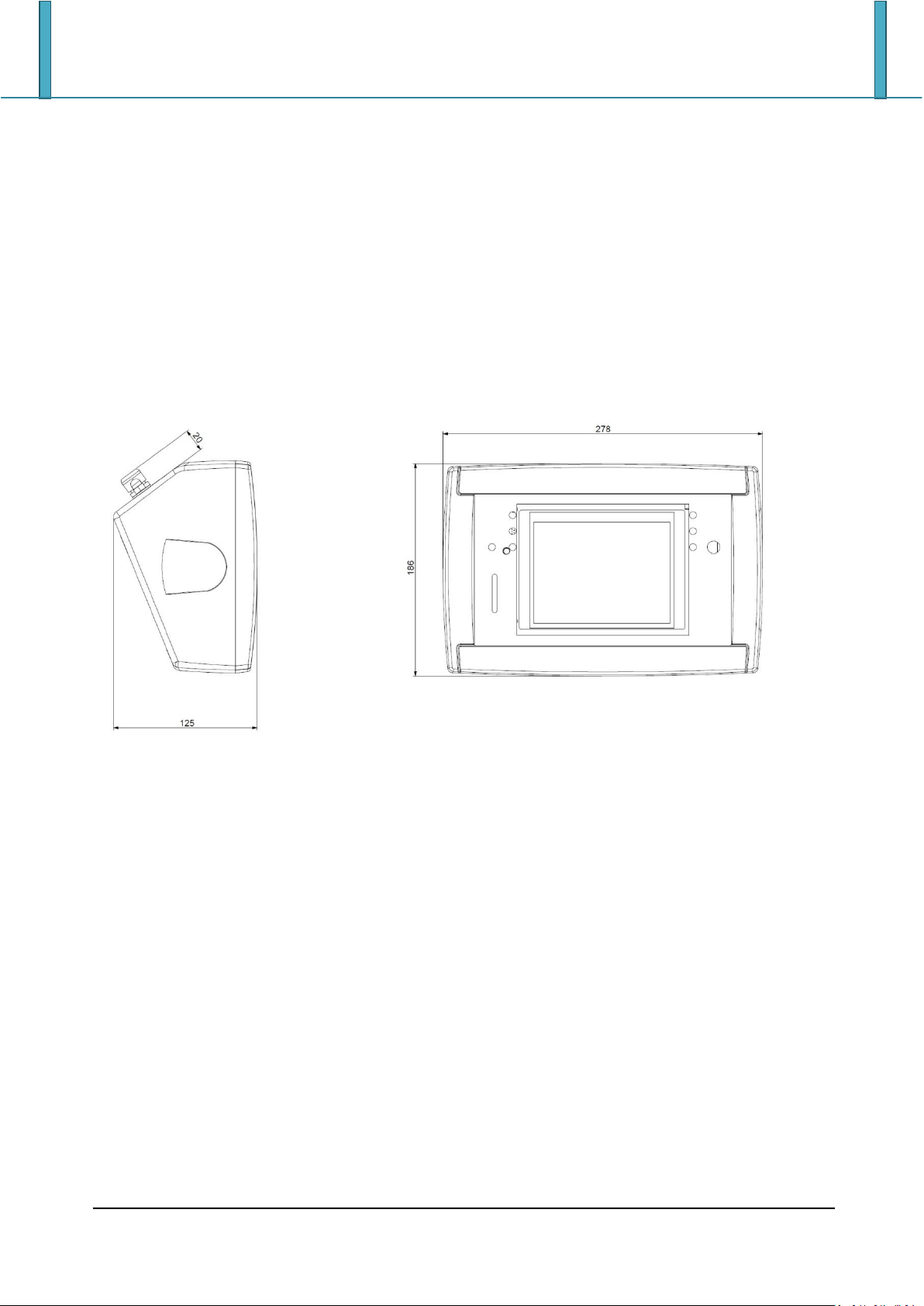

3.1 Case and dimensions ....................................................................................................................... 8

3.2 Connectors....................................................................................................................................... 9

3.3 Power supply ................................................................................................................................... 9

3.4 Start up .......................................................................................................................................... 10

3.5 Turning off the instrument ............................................................................................................ 10

4 INDICATOR PARTS .................................................................................................................................... 11

4.1 display ............................................................................................................................................ 12

4.1.1 Display indicators .............................................................................................................. 14

4.1.2 Numeric input ................................................................................................................... 14

4.1.3 Alphanumeric input .......................................................................................................... 14

5 MAIN FUNCTIONING DESCRIPTION ......................................................................................................... 15

5.1 Zeroing ........................................................................................................................................... 15

5.2 Tare ................................................................................................................................................ 16

5.2.1 Semiautomatic tare .......................................................................................................... 16

5.2.2 Preset tare ........................................................................................................................ 17

5.2.3 Link a preset tare to an article .......................................................................................... 17

5.2.4 Tare cancellation............................................................................................................... 17

5.2.5 Locked/unlocked tare ....................................................................................................... 17

5.3 Input texts...................................................................................................................................... 18

5.4 Databases ...................................................................................................................................... 19

5.4.1 Insertion ............................................................................................................................ 19

5.4.2 Modification ..................................................................................................................... 20

5.4.3 Cancellation ...................................................................................................................... 21

5.4.4 Alphanumeric search ........................................................................................................ 22

5.4.5 Search by element index .................................................................................................. 23

6 SYSTEM STATUS ....................................................................................................................................... 24

7 WEIGHING PROCEDURE ........................................................................................................................... 25

2

7.1 SYSTEM STATUS CONTROL ............................................................................................................ 25

7.2 ENABLING/DISABLING THE WEIGHIG CYCLE ................................................................................. 25

7.3 DESCRIPTION OF THE CYCLE PHASES............................................................................................. 26

7.4 WEIGHT ACQUISITION ................................................................................................................... 26

7.4.1 AT HALF WITH A SENSOR .................................................................................................. 26

7.5 DESCRIPTION OF THE SYSTEM ....................................................................................................... 26

7.5.1 IN MOTION WITH 1 PHOTO CELL ...................................................................................... 28

7.5.2 IN MOTION WITH 2 PHOTO CELLS .................................................................................... 29

7.5.3 IN MOTION WITHOT PHOTO CELLS .................................................................................. 30

7.6 TOLERANCE CHECK ........................................................................................................................ 31

7.6.1 CHECKING WITH ARTICLE AND T1, T2, T3 TOLERANCE SETTING ...................................... 32

7.6.2 CHECKING WITH ARTICLE AND MINIMUM AND MAXIMUM THRESHOLD SETTING ........ 33

7.6.3 CHECKING WITHOUT ARTICLE AND FAST MINIMUM AND MAXIMUM THRESHOLDS

SETTING ......................................................................................................................................... 33

7.6.4 DETERMINATION OF THE TOLERANCE RANGE ................................................................. 33

7.6.5 CHECKING QUANTITIES IN ml ........................................................................................... 34

7.6.6 AUTOMATIC TARGET RECALCULATION AFTER N WEIGHTS WITHIN TOLERANCE ............ 35

7.7 CORRECTION OF THE OUT OF TOLERANCE WEIGHT ..................................................................... 35

7.8 NOT MANDATORY CORRECTION OF THE WEIGHT ........................................................................ 35

7.9 MANDATORY CORRECTION OF THE WEIGHT ................................................................................ 36

7.10 WEIGHT RESULT INDICATION AND ENABLING OF THE LINKED OUTPUTS .................................... 37

7.11 OUTPUTS MANAGED IN THE FUNCTIONING WITH ARTICLE AND TOLERANCE ............................. 38

7.12 STOP AND RESTART OF THE BELTS ................................................................................................ 39

7.12.1 STOP OF BELTS FOR WEIGH OUT OF TOLERANCE/MANUAL EXPLUSION ......................... 39

7.12.2 STOP OF BELTS AFTER EVERY WEIGH ............................................................................... 39

7.12.3 STOP OF BELTS AFTER A NUMBER OF WEIGHTS OUT OF TOLERANCE ............................. 40

7.13 EVACUATION AND AUTOMATIC EXPULSION ................................................................................. 40

7.14 WEIGHING BELT AUTOZERO .......................................................................................................... 40

7.15 CYCLE AND INTERRUPT OF THE WEIGH (NOT WEIGHED PACK) .................................................... 42

7.16 DOWNSTREAM BLOCK ................................................................................................................... 43

7.17 EMERGENCY/MOTOR LOCK ........................................................................................................... 43

7.18 UNDERLOAD/OVERLOAD WEIGHT LOCK ....................................................................................... 43

7.19 CYCLE RESTORAL AFTER POWER OUTAGE .................................................................................... 43

7.20 MANAGEMENT OF CADENCE PHOTOCELL AND BELT ................................................................... 44

3

7.21 ALARM OUTPUT MANAGEMENT ................................................................................................... 45

8 Printouts .................................................................................................................................................. 46

9 Error Messages ........................................................................................................................................ 47

10 Progressives ............................................................................................................................................. 48

10.1 Additional value ............................................................................................................................. 48

10.2 Progressive digits ........................................................................................................................... 48

10.3 Ticket Progressive .......................................................................................................................... 48

10.4 Lot Progressive .............................................................................................................................. 48

4

INTRODUCTION

AVERTENZE

1 INTRODUCTION

This manual was created to help you install and learn all about the functional possibilities of the

purchased indicator.

The instrument is suitable for use in various weighing environments.

Not only does it have all the normal features of high-precision scales, but it also gives you the

possibility to work in specific environments due to the functioning modes contained in the

software implemented in the FLASH MEMORY on the internal board. This makes the instrument

extremely flexible and it can be used in many different industrial applications linked to weighing.

The touch screen, the numerical and function keyboard, allow the operator an easy and

immediate use and provide the microcontroller with DATA ENTRY functions in addition to the

normal weighing functions. The input/output allows the instrument to control various external

devices, to receive external commands, control a printer and communicate with a personal

computer or to be inserted in a network of weight indicators controlled by a PC.

Please note that this instrument is covered by a warranty and MUST NOT BE OPENED BY THE

USER for any reason whatsoever. Any attempt to repair or modify the unit exposes the user to the

risk of electric shock and will invalidate the entire warranty.

If any problems are found in the unit or with the system in which it is used, the fact must be

communicated to the manufacturer or the dealer from whom it was purchased.

In any case, DISCONNECT THE POWER SUPPLY before taking any action.

Do not pour liquids on the weight indicator.

Do not use solvents to clean the weight indicator.

Do not expose the instrument to direct sunlight nor place it near heat sources.

Place or anchor the weight indicator and platform on a non-vibrating base.

All the connections of the indicator have to be made respecting the rules applicable in the

zone and in the installing environment.

Everything not expressly described in this manual has to be considered as improper use of the

equipment.

5

INTRODUCTION

ATTENTION!

Only qualified personnel must perform this operation

ATTENTION!

This is referred to working with live wires: only qualified personnel must

perform this operation.

CE CONFORMITY

IDENTIFIES THE CLASS OF PRECISION.

It identifies an advanced function explained in the technical manual (for

technical personnel).

Do not install in any area where there is a risk of explosion.

The crossed-out wheeled bin on the product means that at the product end of life, it

must be taken to separate collection or to the reseller when a new equivalent type of

equipment is purchased. The adequate differentiated refuse collection in having the

product recycled, helps to avoid possible negative effects on the environment and

health and supports the recycling of the materials of which the equipment is made. The unlawful

disposal of the product by the user will entail fines foreseen by the current regulations.

Used symbols through the manual

6

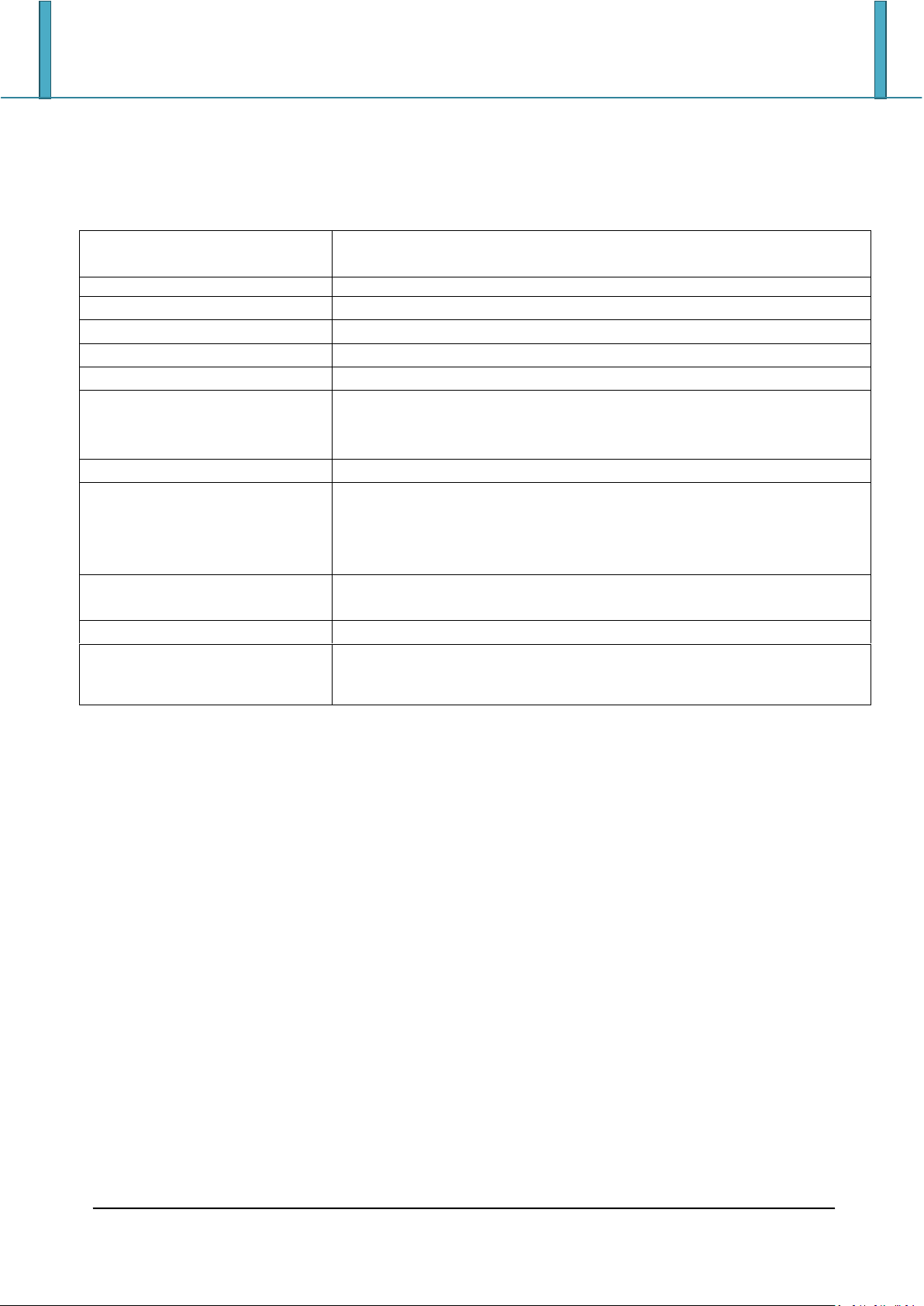

TECHNICAL SPECIFICATIONS

POWER SUPPLY

12 Vdc ( 8 ÷ 24 Vdc in the IO versions), with internal 100 ÷ 240 Vac

(50÷60 Hz) / 12 Vdc adapter.

OPERATING TEMPERATURE

From -10 to +40 °C.

CONVERTER

24 bit Sigma Delta.

AUTOMATIC ZERO DETECTION

Only in gross mode, programmable at +/- ¼, ½, 1, 2 divisions.

ZERO RANGE

Configurable up to +/- 50% of max load capacity.

AUTO ZERO AT START-UP

Configurable up to +/- 50% of max load capacity.

DISPLAY DIVISIONS

10000e, 3 x 3000e for legal for trade weighing, expandable up to

800.000 for internal use (with minimum signal coming from the 1.6

mV/V cell).

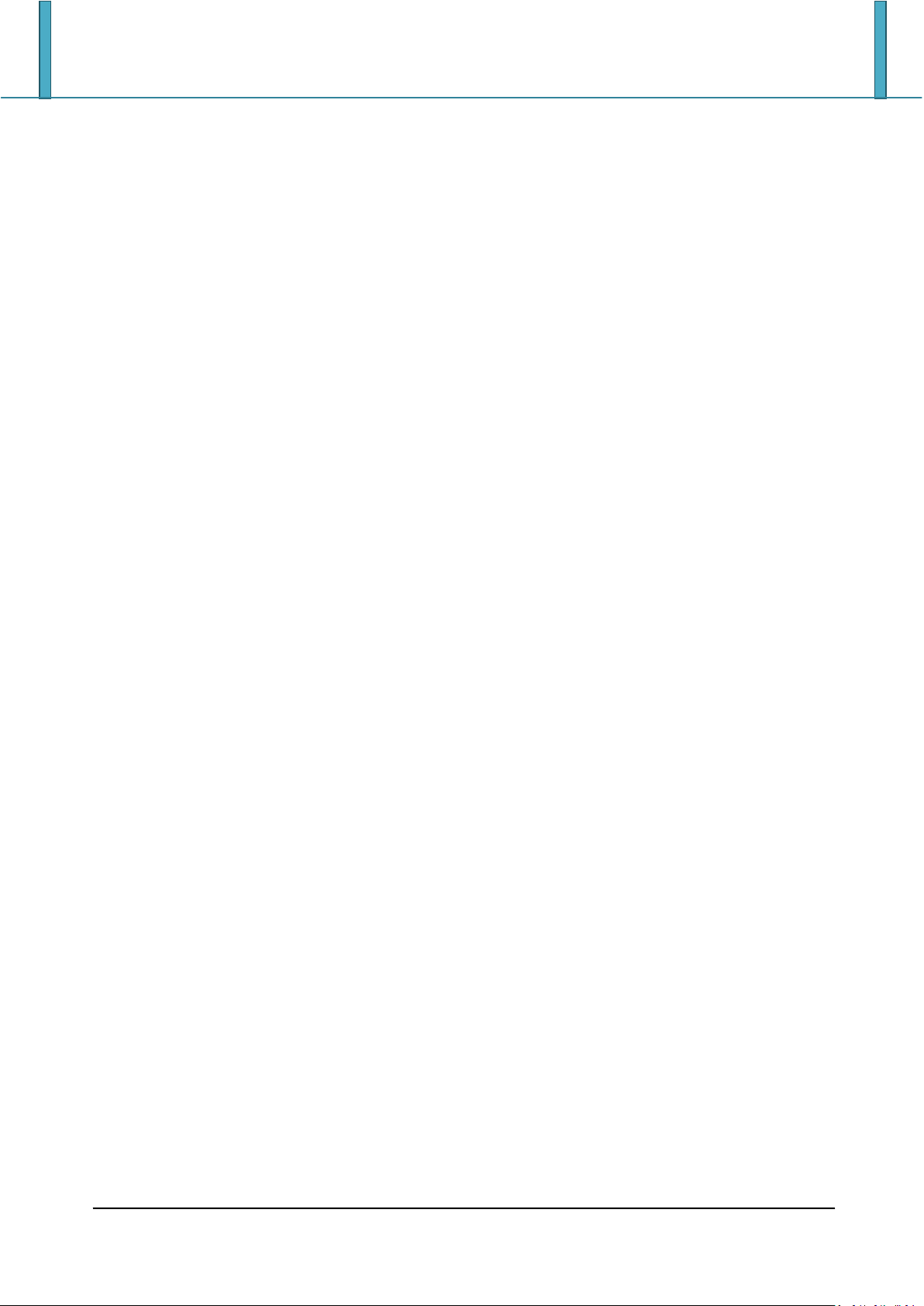

DISPLAY

Graphic touch screen 320x240 dots (black & white)

DATABASE/MEMORY

Articles database of 1000 items (3 descriptions of 20 characters

each, density, target weight, preset tare, tare acquisition before

sampling, and 3 thresholds and number of samples for the

personalized check type)

KEYBORD

Impermeable polycarbonate keyboard (IP65 protection degree), with

membrane keys with audible and tactile feedback.

CLOCK/DATE

Fitted, with buffer RAM.

SERIAL OUTPUTS

- 2 input/output RS232 ports on terminal board/ amp connector.

- 1 input/output RS485 port on terminal board or RS232 on amp

connector.

2 TECHNICAL SPECIFICATIONS

7

INSTALLATION

3 INSTALLATION

3.1 Case and dimensions

The indicator has a STAINLESS STEEL case, whose external dimensions are shown in the Figure 1. It

can be simply put on a table or fixed to a shelf or column available on request.

NOTE: If the identification plate is supplied separately (therefore not attached to the indicator),

it isadvisable to attach it to the indicator, in order to be able to identify the instrument.

8

3.2 Connectors

Part

Description

1

RJ45 connector

2

Fixing for shelf or column mounting

3

Available for load cells / serial lines / inputs / outputs

4

Power supplì input

1

4 3

2

ET:

INSTALLATION

3.3 Power supply

The indicator is powered with 12Vdc voltage (8 ÷ 36 Vdc in the IO version), through an internal

adapter which converts the 100 ÷ 240Vac, 50÷60Hz mains voltage.

To power the instrument through the 240 Vac mains insert the plug and the adapter to the 240

Vac mains socket.

To connect the indicator to the power mains, the safety regulations must be observed,

including the use of a "clean" line without disturbances or interference caused by other

electronic equipment.

Do not connect other equipment to the same socket as the one that the adapter is in.

Do not step on or crush the power supply cable.

9

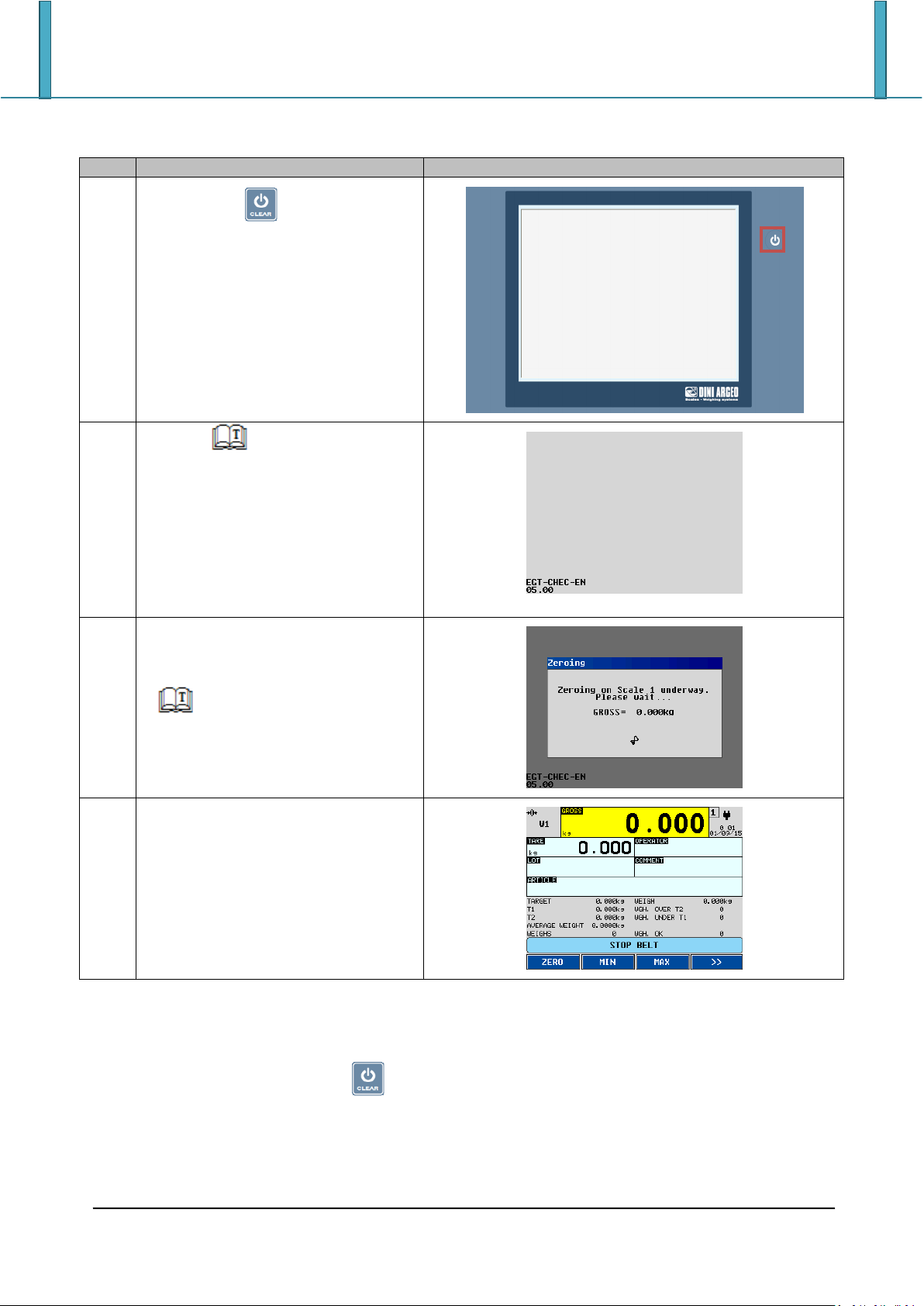

3.4 Start up

Step

Description

Screen

1

Press the key until the

instrument poker on.

2

Il logo ( Logo to show at the

start up) and the software version

appear for some instants.

EGT-CHECK-XX is the name of the

installed software, in which XX

identifies the language.

XX.YY is the installed software

version.

3

The zeroing procedure clears the

weight on the scale within the

tolerance.

( Automatic zeroing at start

up)

4

The main screen appears on the

display.

INSTALLATION

3.5 Turning off the instrument

To turn off the indicator press the key until the logo appears on the display.

10

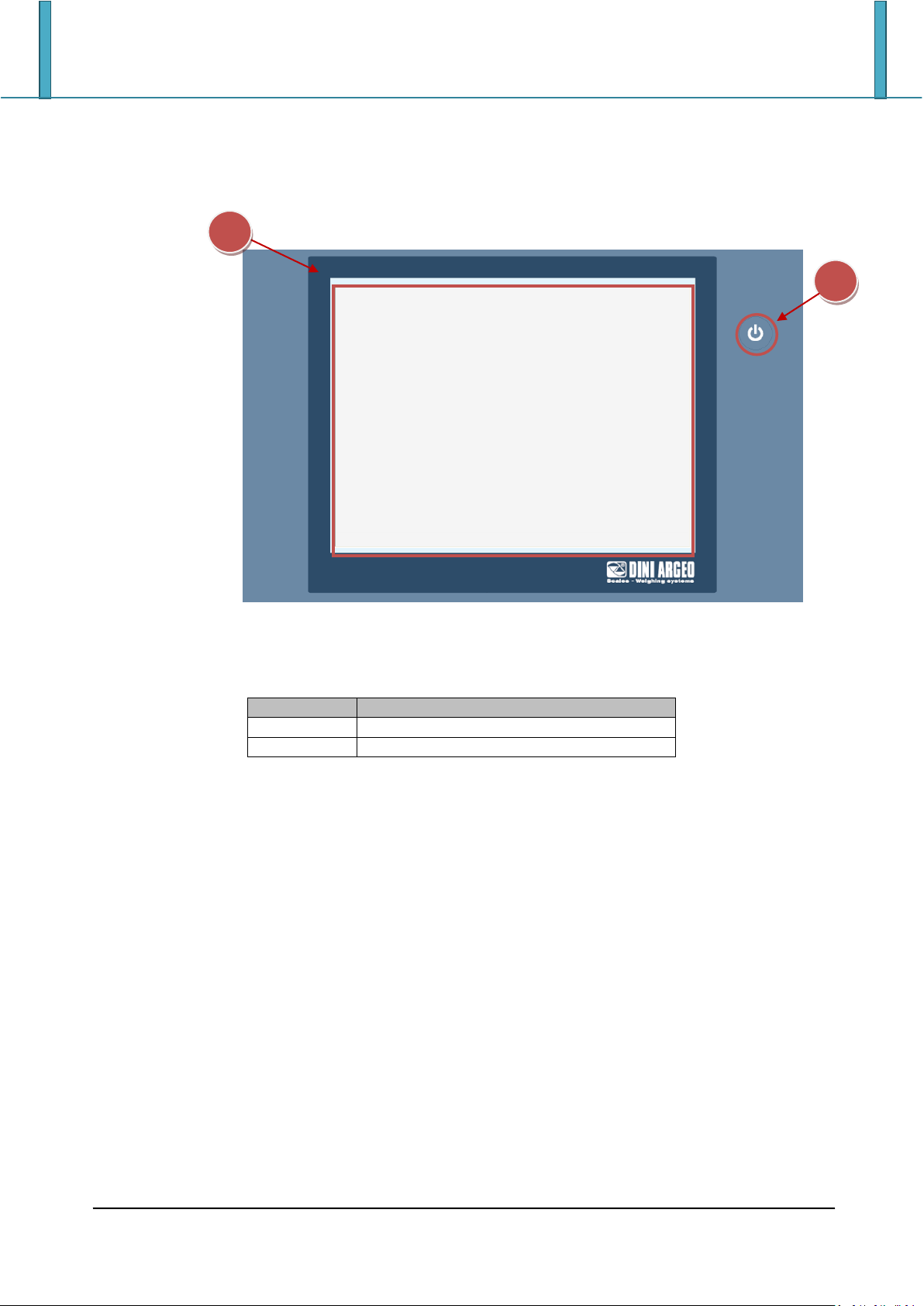

4 INDICATOR PARTS

Part

Description

1

Touch screen

2

Power button

2

1

INDICATOR PARTS

11

INDICATOR PARTS

1 1 2 4 3

6 8

15 14 13

12

11

5 7 9

10 16 18

17

20

19

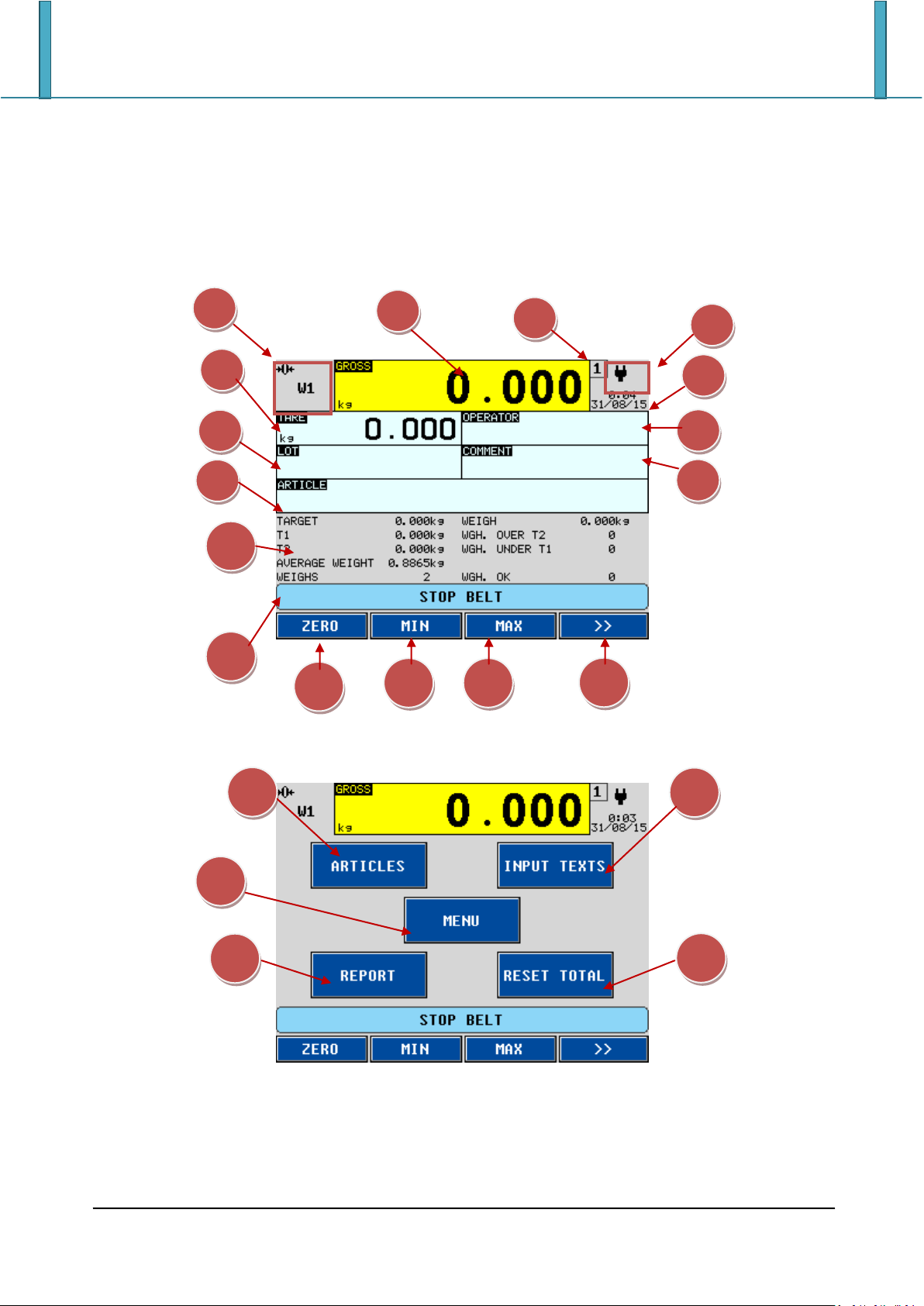

4.1 display

The indicator presents 2 main screens, Figure 1 and

Figure 2:

Figure 1. First main screen

Figure 2. Second main screen

12

INDICATOR PARTS

Element

Description

1

Display indicators

2

Active scale

Touch to switch to the next scale

3

Time and date

Touch to change the date

4

Weight/Volume value on the active scale

Touch to tare the gross weight

5

Tare value

Touch to insert a preset tare

6

Description of the first input text (OPERATOR)

Touch to change the description of the first input text

7

Touch to select the lot

8

Description of the second input text (COMMENT)

Touch to change the description of the second input text and print it

9

Selected article

10

Last weigh

11

System messages area

12

Touch to zeroing the weight

13

Press to set the minimum threshold

14

Press to set the maximum threshold

15

Touch to switch to the next screen

16

Touch to manage the articles database

17

Touch to manage the input texts

18

Touch to access to the indicator functions

19

Touch to print the last sampling report

20

Touch to print the article report

13

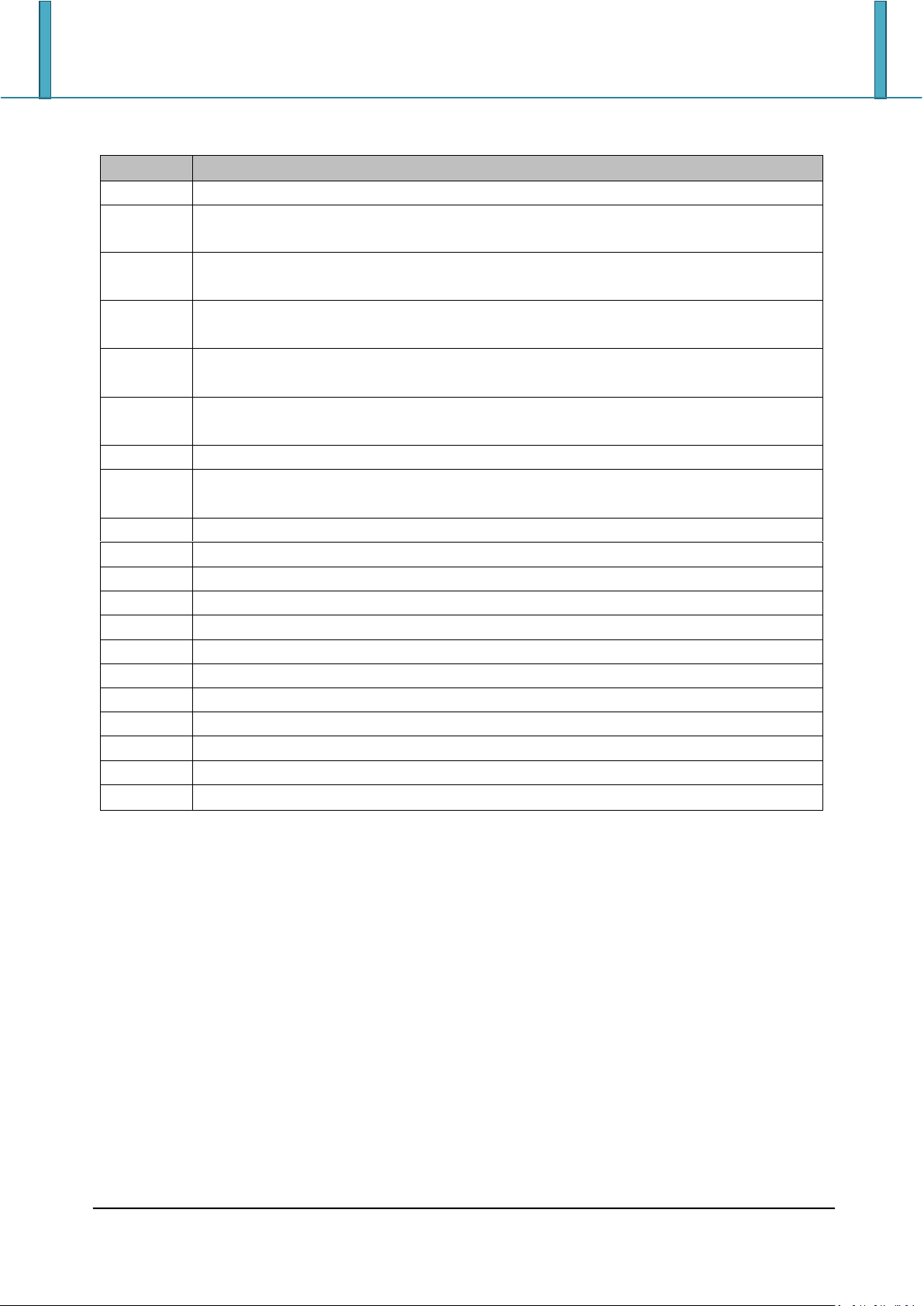

4.1.1 Display indicators

Symbol

Description

Il peso rilevato dal sistema di pesatura si trova in prossimità

dello zero, compreso nell’intervallo –1/4 +1/4 della

divisione della bilancia

The weight in unstable

A tare value has been acquired

A preset tare value has been entered

Active weighing range

Locked keybord

v

Transmission of the data to the printed serial port

underway

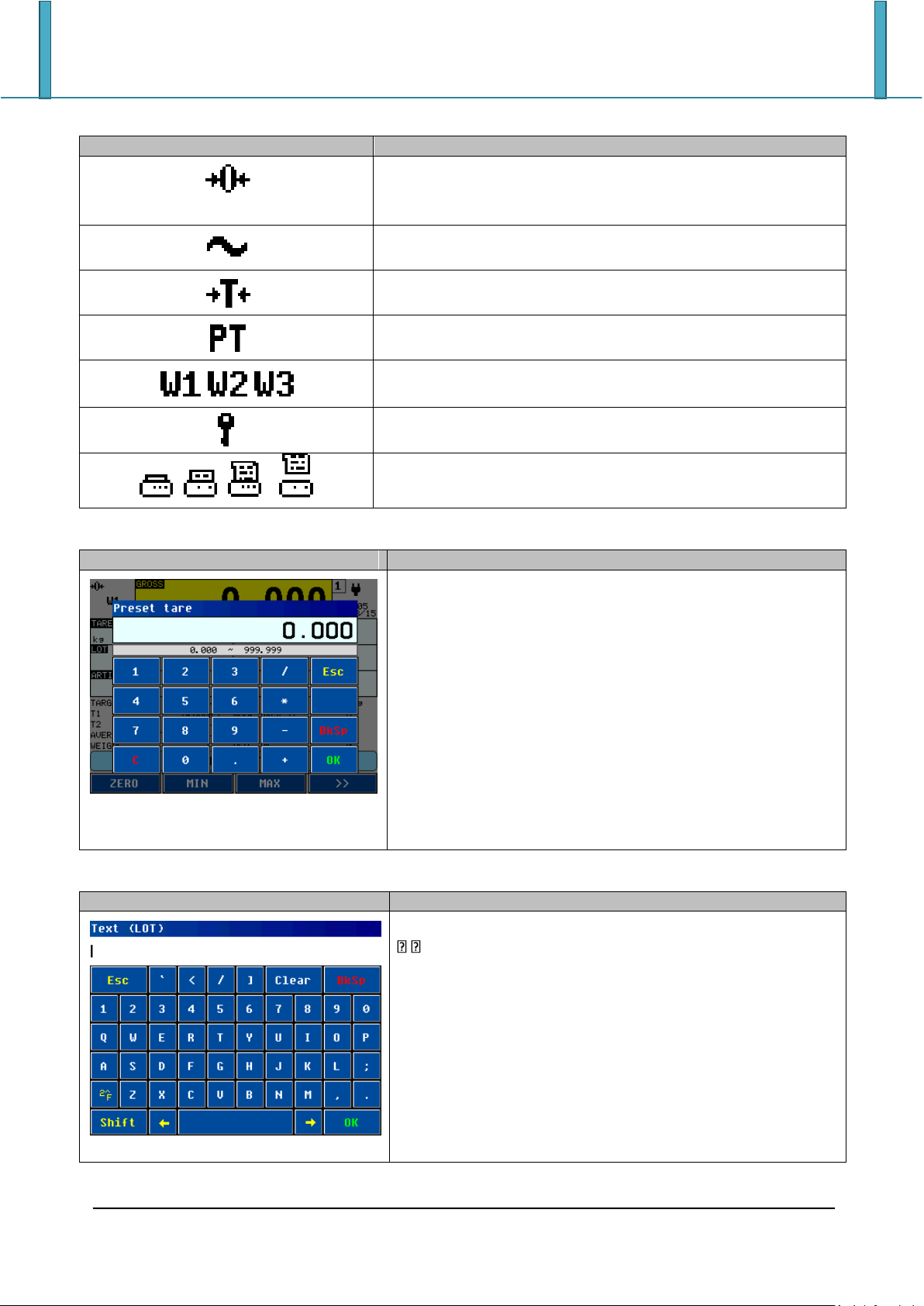

Screen

Function

Allows to insert a numeric value within the range.

X ~ Y: valid range for the value to insert

0…9: numbers

.: decimal point

+/-: positive or negative sign

/ * - +: arithmetic operations

C: clears all the value

BkSp: backspace

OK: exit saving the value

Esc: exit without saving the value

Screen

Function

Allows to insert an alphanumeric text.

:scroll left or right

Clear: clears all the text

Bksp: backspace

2^F: switches to special characters

Shift: changes the character case and switches between

letter and number modes

OK: exit saving the text

Esc: exit without saving the text

NOTE: on the first pressed key all the field is replaced

INDICATOR PARTS

4.1.2 Numeric input

4.1.3 Alphanumeric input

14

MAIN FUNCTIONING DESCRIPTION

Group

Description

Scale functions

Operations to the weight (zeroing, tare,…)

Printout

Print functions management

Generic functinos

Generic operations to the indicator (Lock keyboard,

calculator,…)

Diagnostic

Functions to check the peripheral units working state

Input texts

Input texts management

Archivi

Databases management

Check Function

Threshold settings

Totals

Print and reset of the totals

Progressives

Weigh progressives management

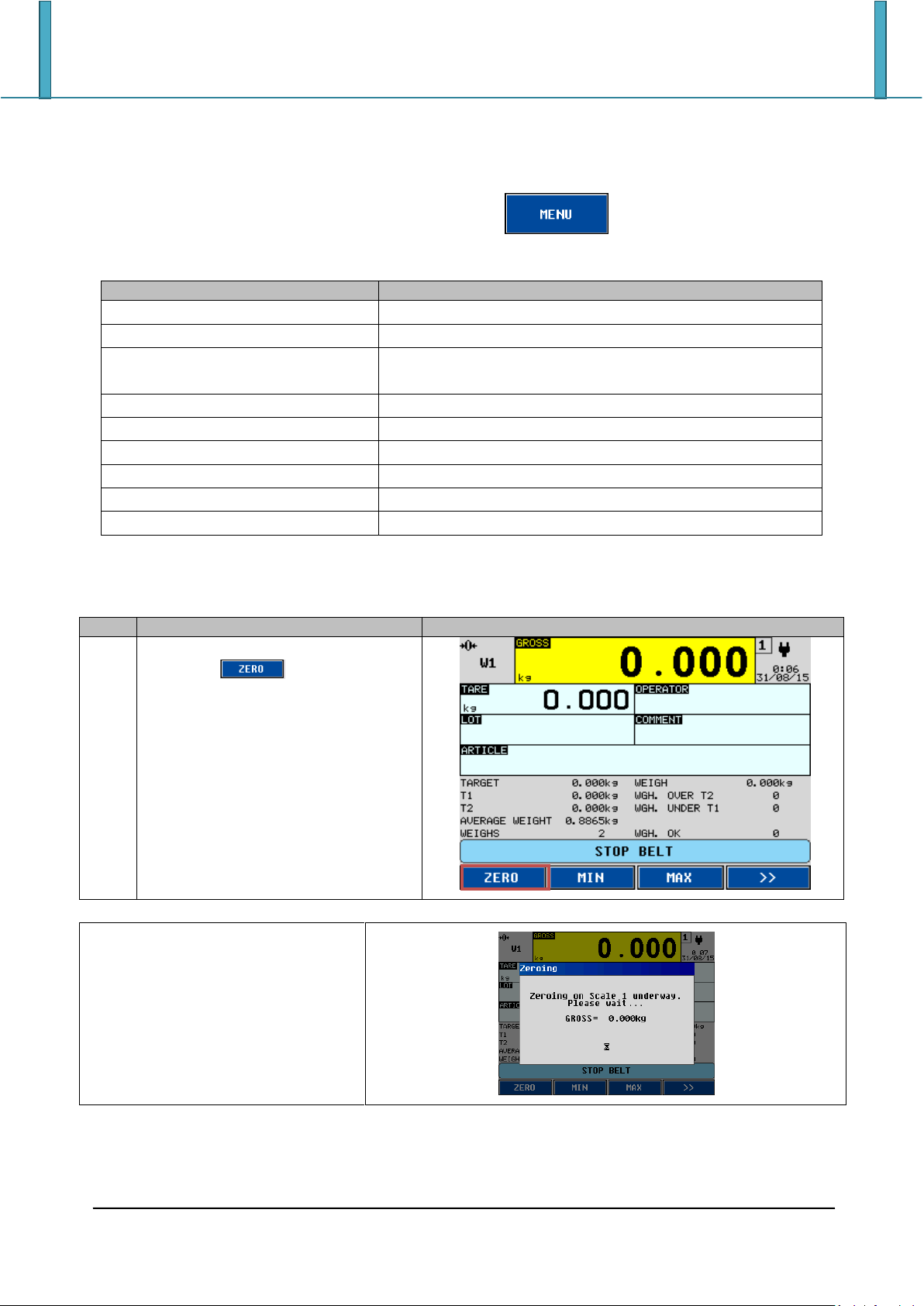

Step

Description

Screen

1

Press the key

A message appears on the display

during the zeroing.

5 MAIN FUNCTIONING DESCRIPTION

All the functions of the indicator are available from the button in the second screen.

The functions are divided into the following groups:

5.1 Zeroing

15

Loading...

Loading...