Dini Argeo 3590EKR Series, 3590EXP Series, 3590EXT Series, 3590 EBOX Series, CPWE Series Technical Manual

...

WEIGHT INDICATOR

TECHNICAL MANUAL

E-AF03: IN/OUT WEIGHING WITH

CUSTOMER/PRODUCT/VEHICLES DATABASE

3590EKR, 3590EXP, 3590EXT, 3590 EBOX, CPWE, CPWET

series indicator

E-AF03_05.01_14.07_EN_T

3590EKR, 3590EXP, 3590EXT, 3590 EBOX, CPWE, CPWET series indicator E-AF03_05.01_14.07_EN_T.doc

2

INDEX

1. REQUIREMENTS FOR AN OPTIMAL INSTALLATION ...................................................................................................................... 4

1.1 ELECTRICAL PRECAUTIONARY MEASURES ............................................................................................................................ 4

1.1.1 CABLE CLASSIFICATION ................................................................................................................................................. 5

1.1.2 RECOMMENDED DISTANCES AMONG CABLES ........................................................................................................... 5

1.1.3 MAXIMUM CABLE LENGTH .............................................................................................................................................. 5

1.2 EARTHING SYSTEM .................................................................................................................................................................... 6

2. CONNECTION TO THE LOAD RECEIVER .......................................................................................................................................... 9

2.1 ANOLOG LOAD CELLS ................................................................................................................................................................ 9

CONNECTION TO STANDARD “DINI ARGEO” FEMALE CONNECTOR ........................................................................................ 10

2.2 DIGITAL LOAD CELLS ................................................................................................................................................................ 10

2.3 CONNECTION OF LOAD CELLS TO INDICATOR ..................................................................................................................... 11

2.3.1 C16i DIGITAL CELL CONNECTION ............................................................................................................................... 12

2.3.2 RCD DIGITAL CELL CONNECTION ............................................................................................................................... 13

3. SETUP ENVIRONMENT ..................................................................................................................................................................... 14

3.1 SET-UP ENVIRONMENT BLOCK DIAGRAM ............................................................................................................................. 16

3.2 DESCRIPTION OF THE STEPS ................................................................................................................................................. 22

<< LAnG >> FIRMWARE LANGUAGE .................................................................................................................................... 22

<< nuM.SCA >> NUMBER OF CONNECTED SCALES (*)...................................................................................................... 22

<< F.ModE >> SCALE FUNCTIONING ................................................................................................................................... 23

<< SEtuP >> SCALE CONFIGURATION ................................................................................................................................. 32

<< diAG. >> DIAGNOSTICS MENU ......................................................................................................................................... 48

3.3 CALIBRATION OF THE SCALE .................................................................................................................................................. 52

3.3.1 CALIBRATION PROCEDURE.......................................................................................................................................... 52

3.3.2 LINEARIZATION POINTS ................................................................................................................................................ 54

3.3.3 ZONE OF USE DIFFERENT THAN THE ZONE OF CALIBRATION .............................................................................. 55

3.3.4 QUICK ZERO CALIBRATION .......................................................................................................................................... 55

3.3.5 CELL EQUALISATION PROCEDURE ............................................................................................................................. 56

3.3.6 ADJUSTMENT OF EQUALIZATION COEFFICIENT ....................................................................................................... 56

3.3.7 SETTING THE COMMUNICATION WITH DIGITAL CELLS ............................................................................................ 57

3.3.8 THEORETICAL CALIBRATION ....................................................................................................................................... 58

3.4 REMOTE SCALE CONFIGURATION ................................................................................................................................. 59

4. DISPLAY OF THE SCALE GRAVITY ACCELERATION AND CORRECTION OF THE WEIGHING ERROR DUE TO THE

DIFFERENT GRAVITY ATTRACTION BETWEEN THE CALIBRATION AND UTILISATION ZONE ................................................... 60

5. SERIAL OUTPUTS ............................................................................................................................................................................. 61

5.1 RS 485 CONNECTION ................................................................................................................................................................ 62

5.2 PC CONNECTION ....................................................................................................................................................................... 64

5.3 PRINTER CONNECTION ............................................................................................................................................................ 64

5.4 TRANSMISSION PROTOCOLS .................................................................................................................................................. 65

5.5 TRANSMISSION MODES ........................................................................................................................................................... 67

5.6 SERIAL COMMANDS FORMAT .................................................................................................................................................. 68

5.7 ADVANCED COMMANDS........................................................................................................................................................... 73

5.8 ALIBI MEMORY ........................................................................................................................................................................... 80

5.9 CUSTOMISATION OF THE STRING .......................................................................................................................................... 82

6. NETWORK MANAGEMENT ............................................................................................................................................................... 83

6.1 INSTRUMENT NETWORK CONFIGURATION ........................................................................................................................... 83

6.2 NETWORK FUNCTIONS............................................................................................................................................................. 84

7. SELF-SERVICE ................................................................................................................................................................................. 85

7.1 CONFIGURATION ....................................................................................................................................................................... 85

7.2 BADGE READER ....................................................................................................................................................................... 87

7.3 COIN BOX ................................................................................................................................................................................... 89

7.4 RFID READER ............................................................................................................................................................................ 91

8. ANALOGUE OUTPUT (OPTIONAL) .................................................................................................................................................. 97

8.1 OPERATING MODES ................................................................................................................................................................. 97

8.1.1 OUTPUT ON THE GROSS WEIGHT ............................................................................................................................... 97

8.1.2 OUTPUT ON THE NET WEIGHT ..................................................................................................................................... 98

8.2 CONFIGURATION ....................................................................................................................................................................... 99

9. PROGRAMMING THE PRINTOUTS ................................................................................................................................................ 100

9.1 PROGRAMMING EXAMPLE ..................................................................................................................................................... 102

9.2 ASCII CODE TABLES ............................................................................................................................................................... 103

9.2.1 CODE PAGE 1252 WINDOWS LATIN 1 ........................................................................................................................ 103

3590EKR, 3590EXP, 3590EXT, 3590 EBOX, CPWE, CPWET series indicator E-AF03_05.01_14.07_EN_T.doc

3

9.2.2 CODE PAGE 1251 WINDOWS CYRILLIC ..................................................................................................................... 104

9.2.3 CODE PAGE 1253 WINDOWS GREEK ........................................................................................................................ 105

9.3 LIST OF PRINT BLOCKS .......................................................................................................................................................... 106

9.3.1 ORDER BY KIND .......................................................................................................................................................... 106

9.3.2 NUMERICAL ORDER ................................................................................................................................................... 113

9.4 BLOCKS WITH PARAMETERS ................................................................................................................................................ 119

10. DISPLAY CUSTOMIZATION .......................................................................................................................................................... 127

11. ELECTRICAL SCHEMES ............................................................................................................................................................... 128

11.1 MOTHER BOARD ................................................................................................................................................................... 128

11.2 I/O EXPANSION BOARD (fitted with 3590EXT in IO version or CPWE) ................................................................................. 131

11.3 DISPLAY BOARD .................................................................................................................................................................... 132

11.4 CONTROL LIGHT .................................................................................................................................................................... 132

3590EKR, 3590EXP, 3590EXT, 3590 EBOX, CPWE, CPWET series indicator E-AF03_05.01_14.07_EN_T.doc

4

1. REQUIREMENTS FOR AN OPTIMAL INSTALLATION

To obtain the best results it is recommended to install the indicator and the platform (or transducer) in a place with the

following conditions:

A flat, level surface on which to rest

Stable and vibration free

No dust or strong vapours

No draughts

Make sure the platform is level or that the loading cells are resting evenly

Moderate temperature and humidity (15-30°C and 40-70%)

Do not install anywhere where there is the risk of explosion

All the indicator connections have to be made respecting the rules applicable in the zone and in the installing

environment. Respect the recommended electrical precautionary measures described in section 1.1.

Make sure that the grounding is made correctly, see section 1.2.

Everything not expressly described in this manual has to be considered as improper use of the equipment.

Avoid welding with load cells installed.

Use waterproof sheaths and couplings in order to protect the load cell cables.

Use a waterproof junction box to connect the cells.

1.1 ELECTRICAL PRECAUTIONARY MEASURES

Mains power supply is restricted to within ± 10% of the rated voltage

Electric protections (fuses etc.) are provided by the technician installing the instrument.

Respect the recommended minimal distances that are mentioned for the various cable categories, see sections

1.1.1 and 1.1.2.

The extension leads of the load cells or signal amplifiers, used for the connection of the serial ports and analogue

output must be within the allowed maximum lengths, see section 1.1.3.

The extension leads of the load cells or signal amplifiers must be screened. In addition they must be laid on their

own in a raceway or metal pipe as far away as possible from the power supply cables.

Install “RC” filters on the contactor coils, on the solenoid valves and on all devices producing electric

disturbances.

If it is possible that condensation could form inside the weight transmitter it is advisable to leave the instrument

powered at all times.

Every shielded cable or not (for instance PC cable, cell cable, power supply cable) connected to the indicator

should be as shorter as possible, then you have to come out of the shield the minimum length of cable, then

connect to the terminal box;

If the indicator is situated inside an electric panel, the power supply cable should be a shielded cable as shorter as

possible, distant from every coil supply cable, inverter, electromotive force, etc. and in addition dedicate an

uncoupler transformer in order to feed the indicator only.

3590EKR, 3590EXP, 3590EXT, 3590 EBOX, CPWE, CPWET series indicator E-AF03_05.01_14.07_EN_T.doc

5

1.1.1 CABLE CLASSIFICATION

The various cables are classified depending on the transmitted signals:

Category I

- Field bus, LAN (PROFIBUS, Ethernet, Devicenet…)

- Shielded data cables (RS232 …)

- Shielded cables for analogue/digital signals < 25V (sensors, load cells…)

- Low tension power supply cables (< 60V)

- Coaxial cables

Category II

- DC supply cables with tension > 60V and < 400V

- AC supply cables with tension > 25V and < 400V

Category III

- Power supply cables with tension > 400V

- Telephone cables

Category IV

- Any cable subject to lightning

1.1.2 RECOMMENDED DISTANCES AMONG CABLES

- When the cables are laid next to each other, these must be at the distances in the table below

- These distances are valid if in the air; these are reduced if the raceways are separated by grounded metallic shields.

- Different category cables can cross each other (90°)

Category I Category II Category III Category IV

≥ 100 mm

≥ 200 mm

≥ 500 mm

≥ 100 mm

≥ 500 mm

≥ 500 mm

1.1.3 MAXIMUM CABLE LENGTH

LOAD CELL CABLE

The maximum reachable length from the line using the appropriate load cell cable is:

- 50 m with cable 6 x 0,25 mm2

- 100 m with cable 6 x 0,5 mm

2

Over 100 metres is necessary to use a 6x1 mm2 cable

RS232 CABLE

The maximum reachable length from the line using the RS232 cable with a maximum baud rate of 19200, is about 15 m.

RS485 CABLE

The maximum reachable length from the line with the use of the appropriate cable for RS 485 connections (see section

5.1), is about 1200 meters.

3590EKR, 3590EXP, 3590EXT, 3590 EBOX, CPWE, CPWET series indicator E-AF03_05.01_14.07_EN_T.doc

6

ANALOG OUTPUT CABLE

The maximum length of the analogue output cable in current is:

- 100 m with cable 2 x 0,25 mm2

- 150 m with cable 2 x 0,5 mm2

- 300 m with cable 2 x 1 mm

2

The maximum length of the analogue output cable in voltage is:

- 50 m with cable 2 x 0,25 mm2

- 75 m with cable 2 x 0,5 mm2

- 150 m with cable 2 x 1 mm2

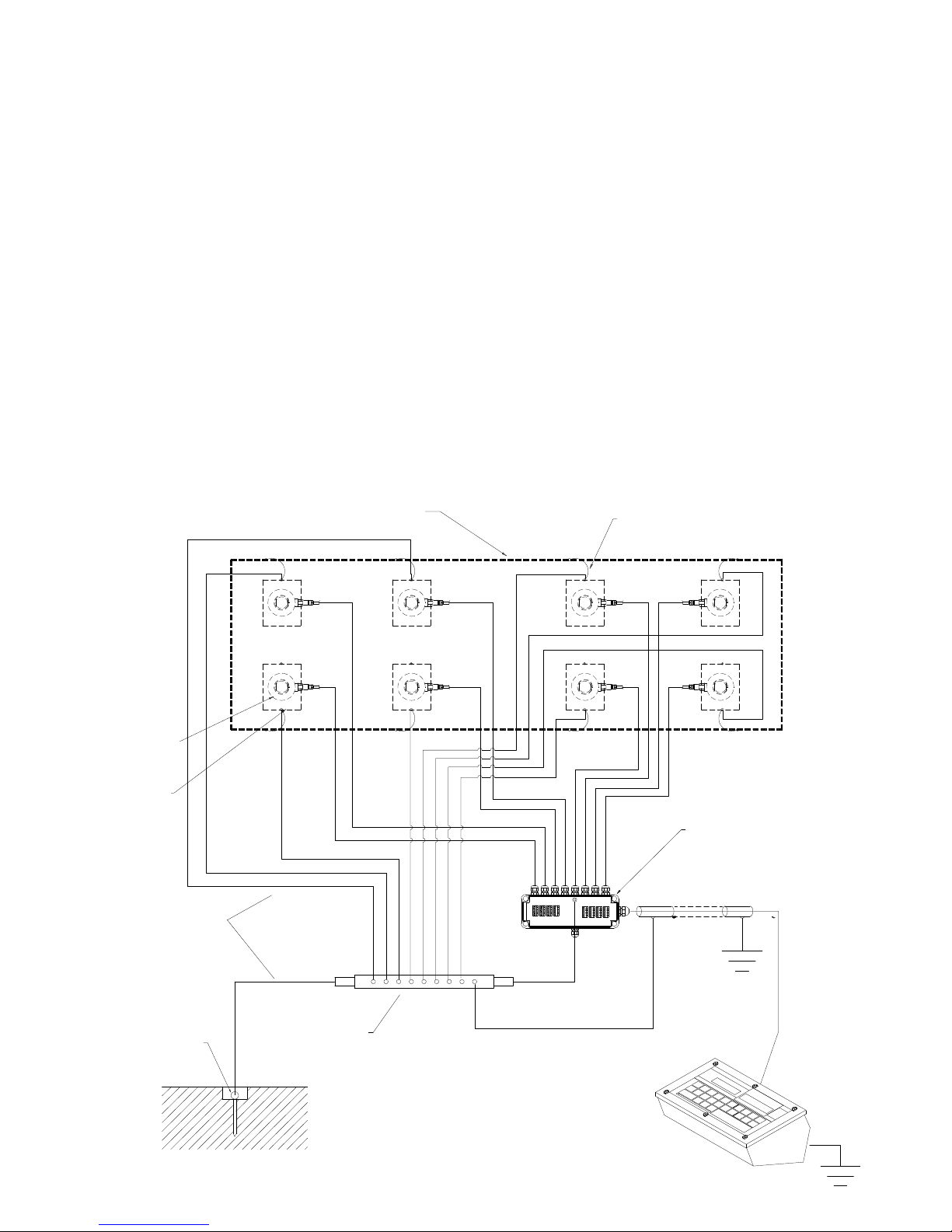

1.2 EARTHING SYSTEM

For the right earthing and the optimal functioning of the system, it is necessary to connect the indicator, the load cells, the

possible junction box and the weighing structure to the earth.

All earthing cables must have the shortest possible length in order to minimize their resistance.

INDICATOR

Connect the external earthing of the indicator to the earth through copper cables having at least a 16 mm2 cross-section.

LOAD CELLS AND JUNCTION BOX

The earthing must be done by connecting the earthing cables to a ground bar with cables having a cross-section of at least

16 mm2 and by connecting the ground bar to a ground pole with a cable having a cross-section of at least 50 mm2.

- In the case the load cells are connected to the indicator through a junction box, it is necessary to connect the sheathing

both of cells cables and of indicator cable to the earthing of the junction box (refer to the junction box manual) and

connect this to the earth through copper cables having at least a 16 mm2 cross-section.

- If the load cells are connected directly to the indicator (without the use of the junction box), one should connect the

shieldings of the load cell cables to the grounding point (or earthing bar) inside the container.

- If the weighing system concerns large and/or outdoor structures, like weighbridges, and the junction box is connected

to the indicator in a distance that is greater than 10 m, or in the presence of noise, the cable shield must be earthed

both in the junction box and in the indicator, and the two ground leads must be connected with an earth cable having a

cross-section of at least 16 mm2.

WEIGHING STRUCTURE

Connect the weighing structure and the possible connected structures (for example silos that release material on the

weighing structure) to the earth through copper cables having at least a 16 mm2 cross-section.

Furthermore it is necessary that for each cell, one connects the upper part with the lower part of the load cell through a

copper braid section not less than 16 mm2; the upper part must be short-circuited with the surface of the weighing structure

and the lower part must be grounded through a copper braid section not less than 16 mm2.

CONNECTED SERIAL CABLES AND INSTRUMENTS

Connect the shield of the serial cable at the grounding point (or grounding bar) inside the container (on the end of the cable

toward the indicator) and at the earth connection of the connected instrument (on the end of the cable toward the indicator),

and ground the earth connection of the connected instrument, through a copper cable section not less than 16 mm2.

To avoid possible side effects, the earth references of the connection and power supply cable of the indicator and of the

connected instrument must be at the same potential.

3590EKR, 3590EXP, 3590EXT, 3590 EBOX, CPWE, CPWET series indicator E-AF03_05.01_14.07_EN_T.doc

7

GROUND POLE

POSITIONED UNDER

OR NEAR

WEIGHBRIDGE (NOT

SUPPLIED)

GENERAL NOTES:

All the grounding cables must have an adequate length, in order to obtain an overall resistance of grounding

system less than 1 Ω.

In the case the weighing system regards great and/or outdoor structures, like weighbridges:

- The grounding connection is to be made by connecting the grounding cables to a grounding bar and the

grounding bar to the grounding pole with a cable section not less than 50 mm2.

- the cable cross-section must be greater (for example 50 mm

2

instead of 16 mm2 and 100 mm2 instead of 50

mm2), because the voltage into play is greater (for example thunderbolts);

- the ground pole must be positioned at a distance of at least 10 metres from the weighbridge structure;

- one needs to open the SENSE inside the indicator in order to offset the drifts due to the increase in temperature.

One should check and remove, if necessary, the connection between the earth and the neutral wire of the electrical

installation.

EARTHING EXAMPLE WEIGHBRIDGE

LOAD CELL

PLATE

UNDER CELL

(NOT SUPPLIED)

JB8Q POSITIONED ON

THE WALL

SURROUNDING THE PIT

COPPER HOLED PLATE

ON THE SURROUNDING

WALL (NOT SUPPLIED)

U-BOLT BETWEEEN PLATE UNDER

CELL AND WEIGHBRIDGE

(NOT SUPPLIED)

WEIGHBRIDGE

Ø 8 (50 mm² section)

Ø 11,3 (100 mm² section)

EARTH CABLES

(NOT SUPPLIED)

3590EKR, 3590EXP, 3590EXT, 3590 EBOX, CPWE, CPWET series indicator E-AF03_05.01_14.07_EN_T.doc

8

EARTHING EXAMPLE OF A SILO

Non weighing

structure (silo)

Weighing

structure

Load cell

U-bolt between

plate under cell

and weighing

structure (not

supplied)

Ø 4,6 – 16 mm²

earth cable

section (not

supplied)

Ø 8 – 50 mm²

earth cable

section (not

supplied)

Junction

box

3590EKR, 3590EXP, 3590EXT, 3590 EBOX, CPWE, CPWET series indicator E-AF03_05.01_14.07_EN_T.doc

9

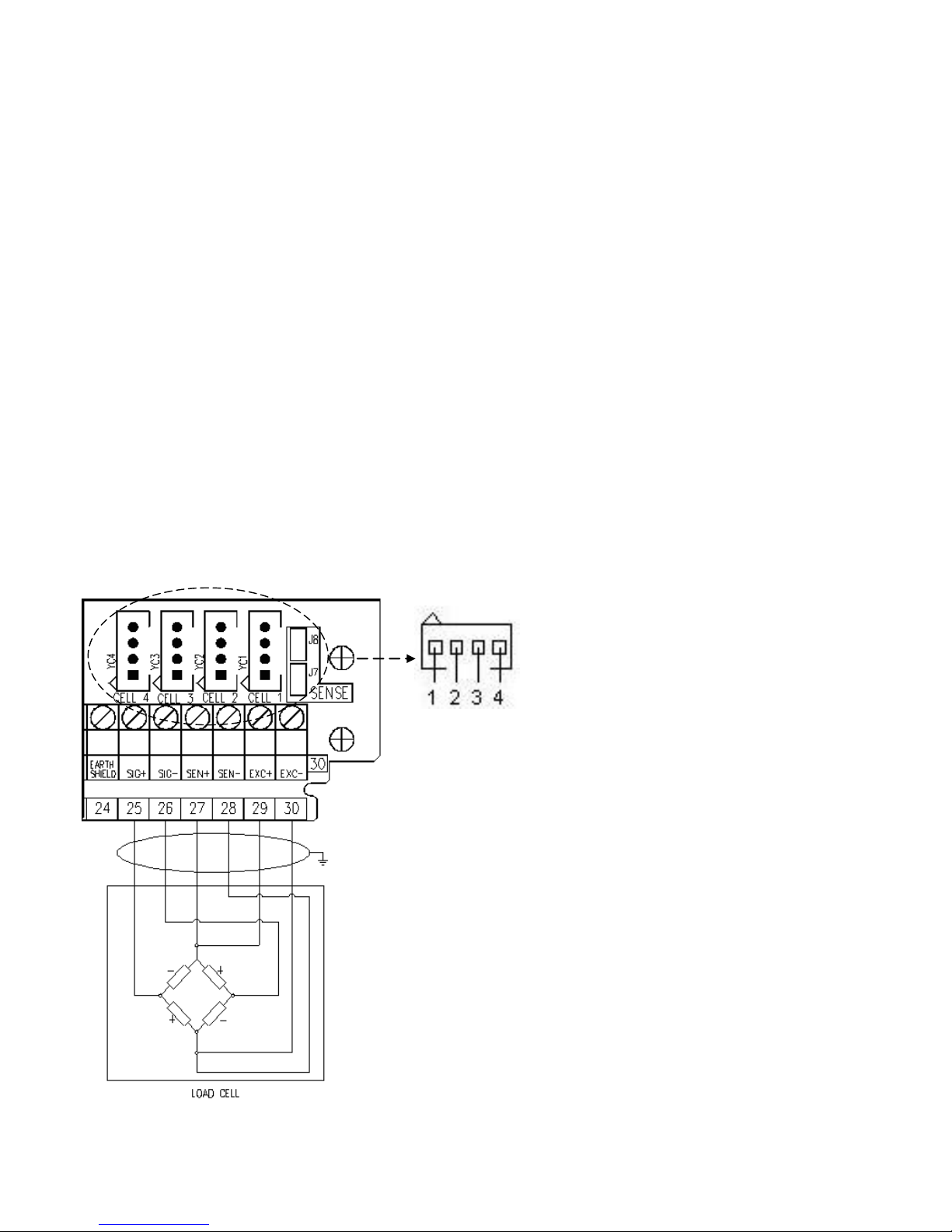

2. CONNECTION TO THE LOAD RECEIVER

2.1 ANOLOG LOAD CELLS

IMPORTANT: Respect the electrical precautionary measures indicated in section 1.

After having followed the instructions regarding the platform or the load receiver, the screened cable leading from the load

cell(s) must be connected to the instrument through the CELL1 terminal board and the CELL1, CELL2, CELL3, CELL4

connectors; see section 8.

The terminal board of the indicator may be connected to the 6-wire load receiver (with use of SENSE), or simply 4-wire; for

this, through jumper J7 and J8 it is possible to choose whether to short-circuit the SENSE with the POWER SUPPLY

(jumpers closed) or not (jumpers open).

The SENSE allows compensating for any drops in voltage in the part of the cable that connects the instrument to the

transducer. It is useful when the distance between the indicator and the transducer is greater than 10 m.

The 4-pin connectors instead allow just the 4-wire connection.

To make the connection qualified personnel must open the instrument (see terminal board connections section 8).

TAKE NOTE: if there is just one LOAD RECEIVER, it is possible to make a 6-wire connection (use of sense) directly

with the terminal board, removing the J7 and J8 jumpers.

If there are two or more LOAD RECEIVERS, one should close the J7 and J8 jumpers (sense and power supply are

short-circuited) and make the 4-wire connection.

Normally the indicator comes already connected to the platform and is ready to use. If this is a LEGAL FOR TRADE

instrument, access to the connection will be subject to a legal SEAL.

Follow the instructions for preparing the platform for use.

AMP 4 CONNECTOR

1. EXC + POWER SUPPLY +

2. EXC - POWER SUPPLY -

3. SIG + SIGNAL +

4. SIG - SIGNAL -

TERMINAL

25. SIG + SIGNAL +

26. SIG - SIGNAL -

27. SEN + REFERENCE +

28. SEN - REFERENCE -

29. EXC + POWER SUPPLY +

30. EXC - POWER SUPPLY -

See section 8 for further information.

3590EKR, 3590EXP, 3590EXT, 3590 EBOX, CPWE, CPWET series indicator E-AF03_05.01_14.07_EN_T.doc

10

CONNECTION TO STANDARD “DINI ARGEO” FEMALE CONNECTOR

1 EXCITATION +

2 EXCITATION –

3 SENSE -

4 SENSE +

5 SIGNAL -

6 SIGNAL +

7 NOT CONNECTED

8 SHIELD TO BE FOLDER AND PLACED UNDER THE

CONNECTOR CABLE TIGHTENER

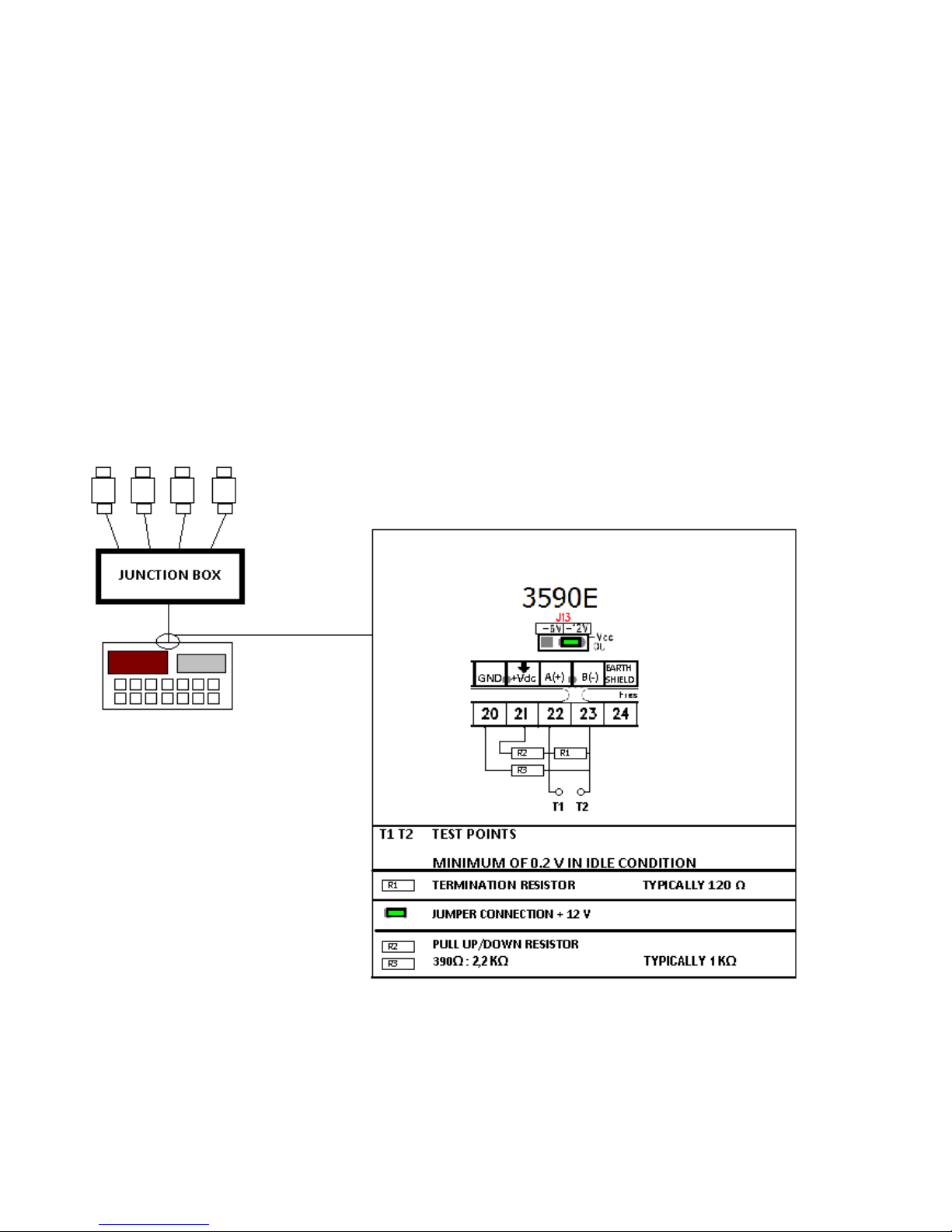

2.2 DIGITAL LOAD CELLS

IMPORTANT:

- Respect the electrical precautionary measures indicated in section 1.

- Read carefully and apply what is described in chapter 5.3

After having followed the instructions regarding the platform or the load receivers, the screened cable leading from the load

cell(s) must be connected to the instrument through the COM3 RS485 terminal board.

Below is the RS485 connection for digital load cells in the CoM3 of the indicator (with X15 integrated circuit):

TERMINAL MEANING

20. GND POWER SUPPLY -

21. +Vdc POWER SUPPLY +

22. TX+/RX+ Line 485 A(+)

23. TX-/RX- Line 485 B(-)

The voltage value of terminal 21 can be selected through J13 jumper, according to the

required load cells power supply.

The possible selections are 6V or 12V, working if the relative power supply is connected

to the indicator (respectively battery or external power supply, see J13 jumper description

in section 8.1).

Consequently, the functioning with only the battery doesn’t allow the connection of those

digital load cells that require 12V power supply.

In the case of digital load cells connected to a digital junction board, connect the COM3 RS 485 terminal board of the

indicator to the RS485 port of the junction board, by following the relative manual and the section 5.1.

In the case of ring connection of more digital junction boards or DGX, connect the COM3 RS 485 terminal board of the

indicator to the RS485 port of the first junction board/DGX, by following the relative manual and the section 5.1.

3590EKR, 3590EXP, 3590EXT, 3590 EBOX, CPWE, CPWET series indicator E-AF03_05.01_14.07_EN_T.doc

11

2.3 CONNECTION OF LOAD CELLS TO INDICATOR

The load cell has a digital output with an RS-485 interface (4-wire). In regards to the power supply, it needs an external

continuous voltage (CC).

To configure the cells it is necessary to go to the nuM.SCA >> 1 SCALE >> CELtyP step and then choose the type of cell:

AnALoG Cells type analog

dGX Cells type digital DGX

rCd Cells type digital RCD

CCi Ad Cells type digital CCI AD

rC3d Cells type digital RC3D

C16i Cells type digital C16i

WWS Cells type digital WWS

(!)AnALoG

In most cases in order to avoid to make a jumper connection between the cells one uses a junction box which is connected

to the indicator on the terminals dedicated to the 485 port. In between the terminals one needs to apply 2 Pull Up

resistances and a termination one in order to have a minimum 0,2 V voltage between A(+) and B(-) (terminals 22 and 23):

Since each cell uses a filter different than the default one, the functioning speed varies from one load cell type to another.

For the length and section of the connection cables, see the section “MAXIMUM LENGTHS ALLOWED FOR THE

CABLES”

3590EKR, 3590EXP, 3590EXT, 3590 EBOX, CPWE, CPWET series indicator E-AF03_05.01_14.07_EN_T.doc

12

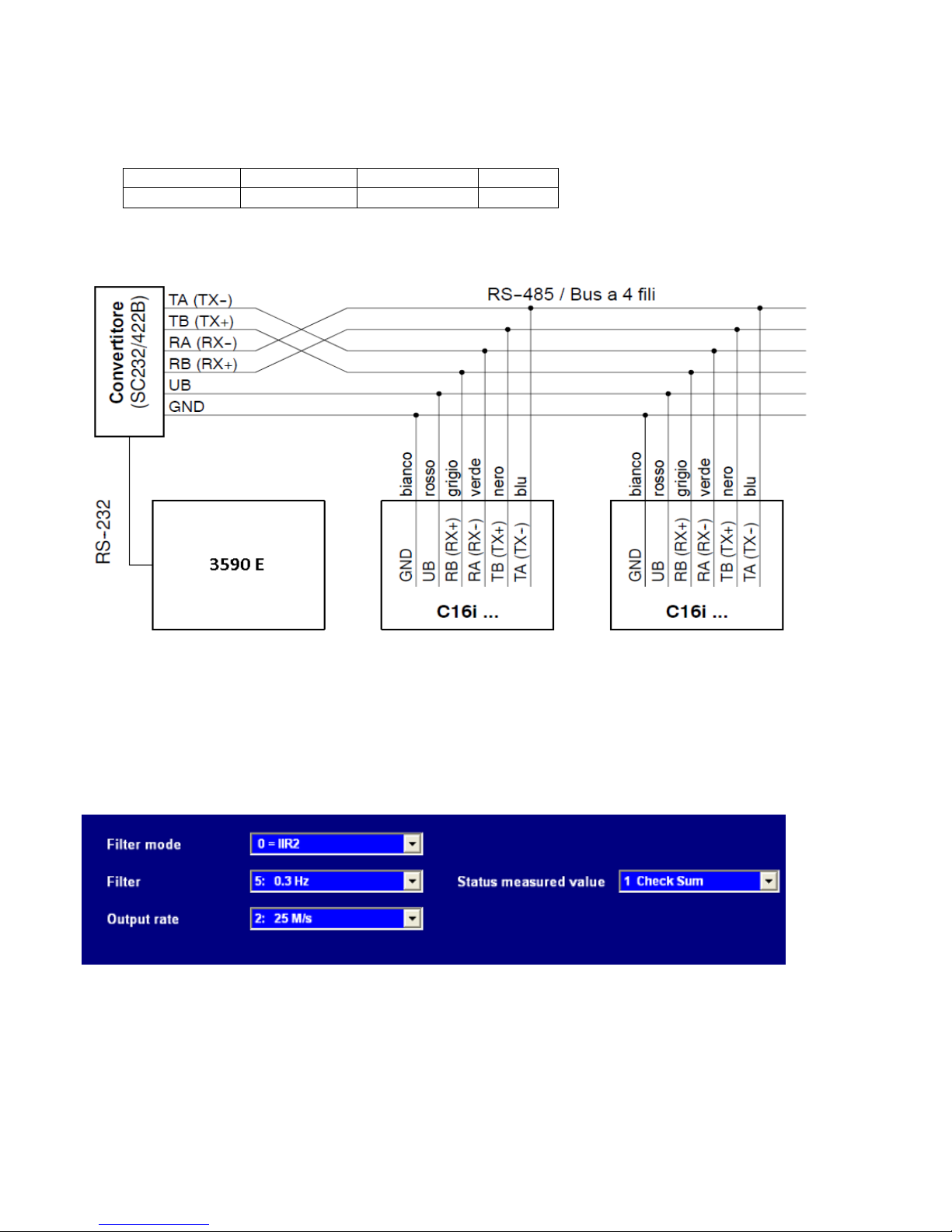

2.3.1 C16i DIGITAL CELL CONNECTION

In order to connect the C16i load cells to the indicator, a SC232/422B converter is necessary so that it is possible to

connect directly on the terminal board in 232 on the pins 14 15 and 16. To do this one should enter in the step SEtuP >>

SEriAL >> PortS and set the ports in this way:

The connection of the cells to the converter are to be made through the junction box or in parallel as described in the

following scheme

For these cells it is necessary to programme a few parameters of the configuration programme of the C16i cell, which may

be accessed by connecting the converter to the PC.

By entering in Parameters >> Basic settings one sets the type of filter one wants to use and the check sum is enabled:

Parameter

COM 1

COM 2

COM 3

AX.Pr.PC

ComAux

ComPrn

ComPC

3590EKR, 3590EXP, 3590EXT, 3590 EBOX, CPWE, CPWET series indicator E-AF03_05.01_14.07_EN_T.doc

13

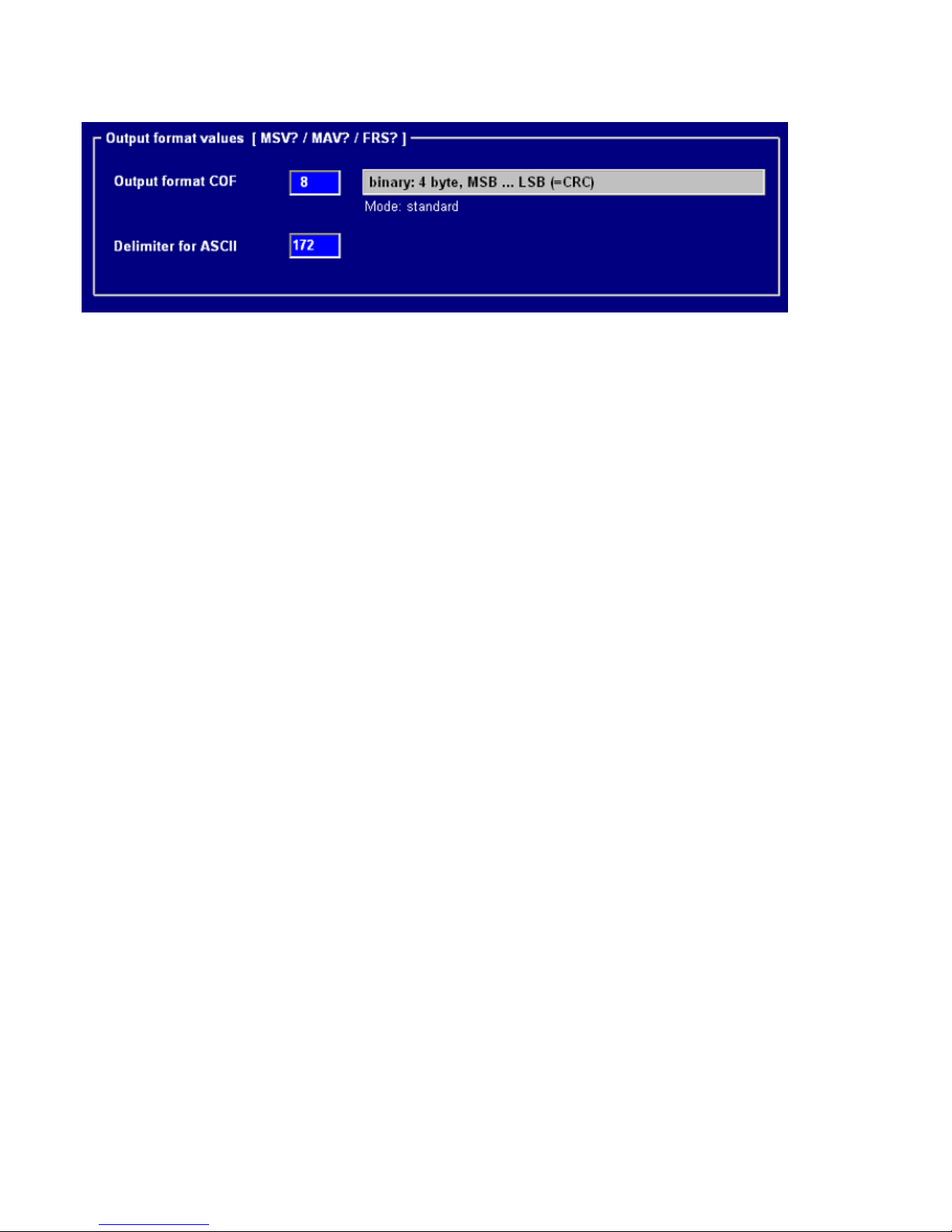

By entering in Parameters >> Communication it is necessary to insert the COF format and the ASCII delimitation as

shown in figure:

Once the type of cell is chosen (SEE 2.3) one needs to enter the number of cells used, and the indicator shows: Cells

Number.

After having chosen the number of cells the indicator automatically enters in the step

SEt.485 Set 485 Address cells

Enter the number of the cell and the relative serial number one after the other and at the end press C. The following

appears:

Snd.CFG Send configuration?

Press Enter and the setting from the indicator is finished.

2.3.2 RCD DIGITAL CELL CONNECTION

Once the type of RCD cell has been chosen, one should enter the number of cells used, the indicator shows: Cells

Number.

After having chosen the number of cells, the indicator automatically enters in the step

SEt.485 Set 485 Address cells

Enter the cell number and the relative serial number one after the other,and at the end,press C. The following appears:

Snd.CFG Send configuration?

Press Enter and the setting from the indicator is finished.

For the connection of the RCD cells to the indicator, a junction box is necessary, which is connected to the indicator

through 485, also necessary two bias resistors. (SEE SECTION “RS 485 CONNECTION)

3590EKR, 3590EXP, 3590EXT, 3590 EBOX, CPWE, CPWET series indicator E-AF03_05.01_14.07_EN_T.doc

14

“ tECh ”

for an instant on

the display

“ uSEr ”

for an instant on

the display

“ tECh ”

for an instant on

the LCD display

Part reserved for the Authorised Technical Personnel

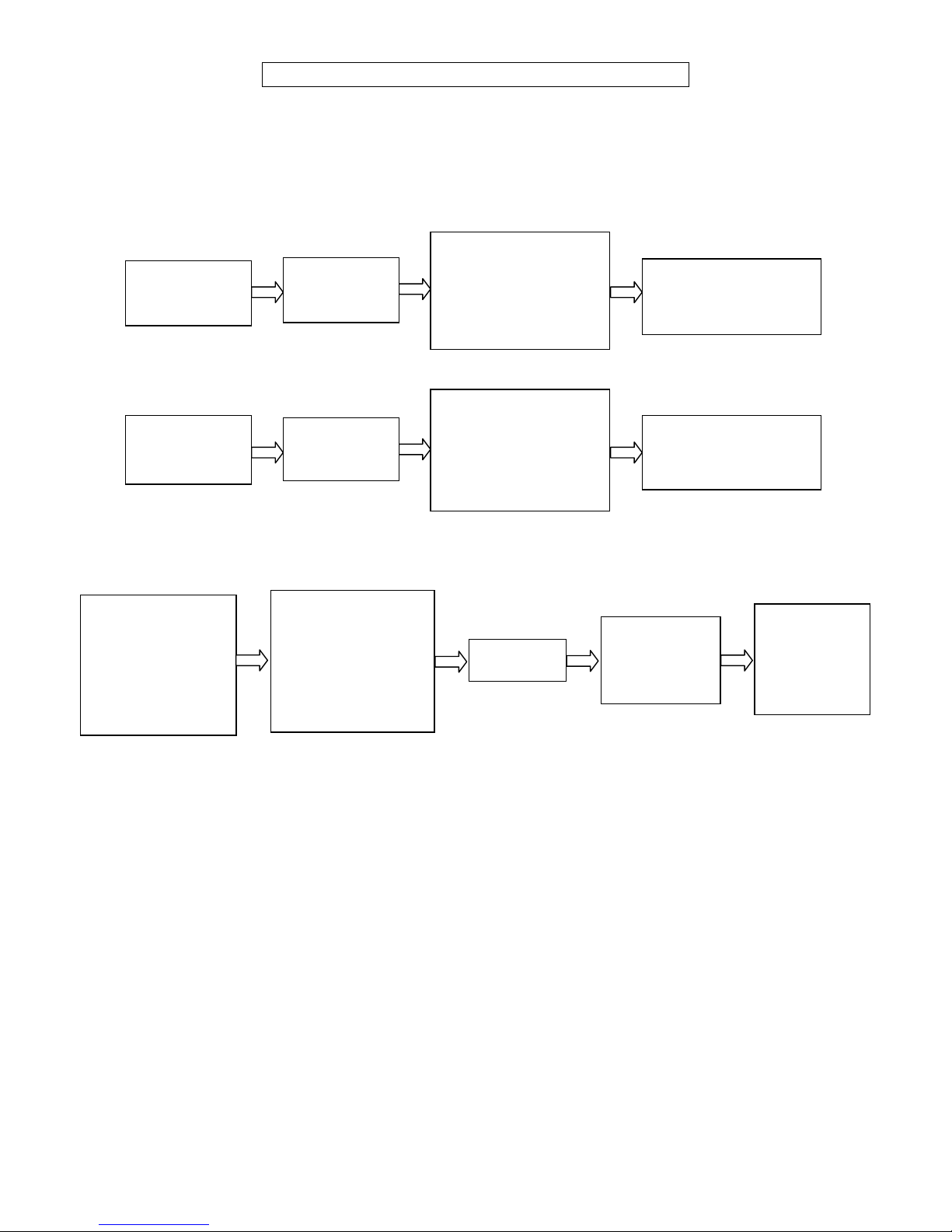

3. SETUP ENVIRONMENT

By "SETUP environment" we mean a certain menu inside which all the indicator operating parameters can be set.

To enter it, turn on the instrument and, while the firmware version is displayed, press the TARE key for an instant.

The indicator shows:

1)

Or

2)

If you are in choice 2) and you want to access the complete set-up menu one should:

(*) If one has forgotten the password, one should communicate the displayed number to the manufacturer, who will supply a

valid password JUST FOR THAT SPECIFIC NUMBER.

In the parameter description and in the block diagram:

- The METRIC parameters are shown with the (*) symbol, and, with approved instrument, these may not be visible

or read only. See the explanation of the parameter for the details.

NOTE: The indicator is approved when the J1 jumper of the motherboard is closed (see the electrical scheme

in the final chapter).

- The CONDITIONAL STEPS are shown with the (§) symbol, and are not accessible or displayed in specific

conditions, shown in the step description.

- The DEFAULT VALUES are shown with the (!) symbol placed next to the step and at the end of it.

“ LAnG ”

on the display on top;

“LANGUAGE”

on the display below

COMPLETE SET-UP

MENU

(technical personnel)

“PrG.VEr”

on the display on top;

“FIRMWARE”

on the display below

PARTIAL SET-UP

MENU

(only user)

ACCESS

PASSWORD

DISABLED

ACCESS

PASSWORD

ENABLED

ENTER THE

PASSWORD

SUBSTITUTING THE

DISPLAYED (*)

RANDOM VALUE

PRESS

“ENTER”

COMPLETE

SET-UP

MENU

(technical

personnel)

Press TARE/ZERO

during the

visualisation of the

“uSEr” message

on the LCD display

3590EKR, 3590EXP, 3590EXT, 3590 EBOX, CPWE, CPWET series indicator E-AF03_05.01_14.07_EN_T.doc

15

FUNCTION OF THE KEYS IN THE SET-UP ENVIRONMENT

KEY

FUNCTION

F6, F7

Allow to scroll forwards and backwards in the menu steps or in the parameters inside a step.

Fn / ENTER

Allows to enter a step or confirm a parameter inside a step.

C / DEL

Allows to exit a step without confirming any changes made and to go to the previous level.

While entering a code, it quickly zeros the displayed value.

F5

It allows to print the entire configuration of the set-up environment (if one is in the main menu), or

to print the configuration of the single step (if one is in the desired step).

The display shows the “PRINT” message: press ENTER to confirm or C to cancel.

NUMERIC

KEYBOARD

Allows entering digits or characters.

The display show the current parameter and its description; generally, when one exits a step the instrument places itself on

the following step.

TO EXIT THE SET-UP ENVIRONMENT, PRESS THE C KEY MANY TIMES UNTIL THE INDICATOR SHOWS:

CONFIRM WITH ENTER TO SAVE CHANGES MADE OR PRESS ANOTHER KEY TO NOT SAVE.

EXITING SETUP:

SAVE ?

3590EKR, 3590EXP, 3590EXT, 3590 EBOX, CPWE, CPWET series indicator E-AF03_05.01_14.07_EN_T.doc

16

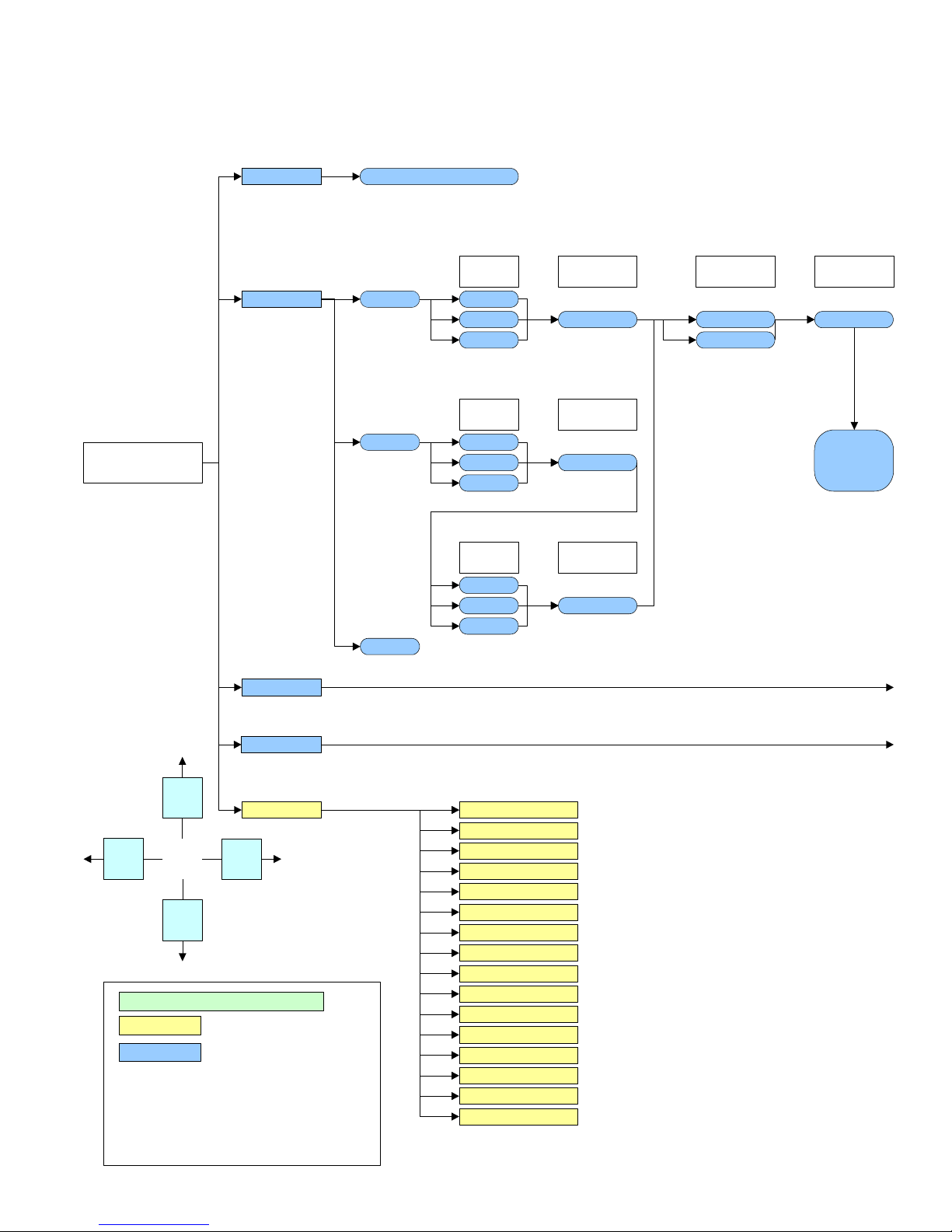

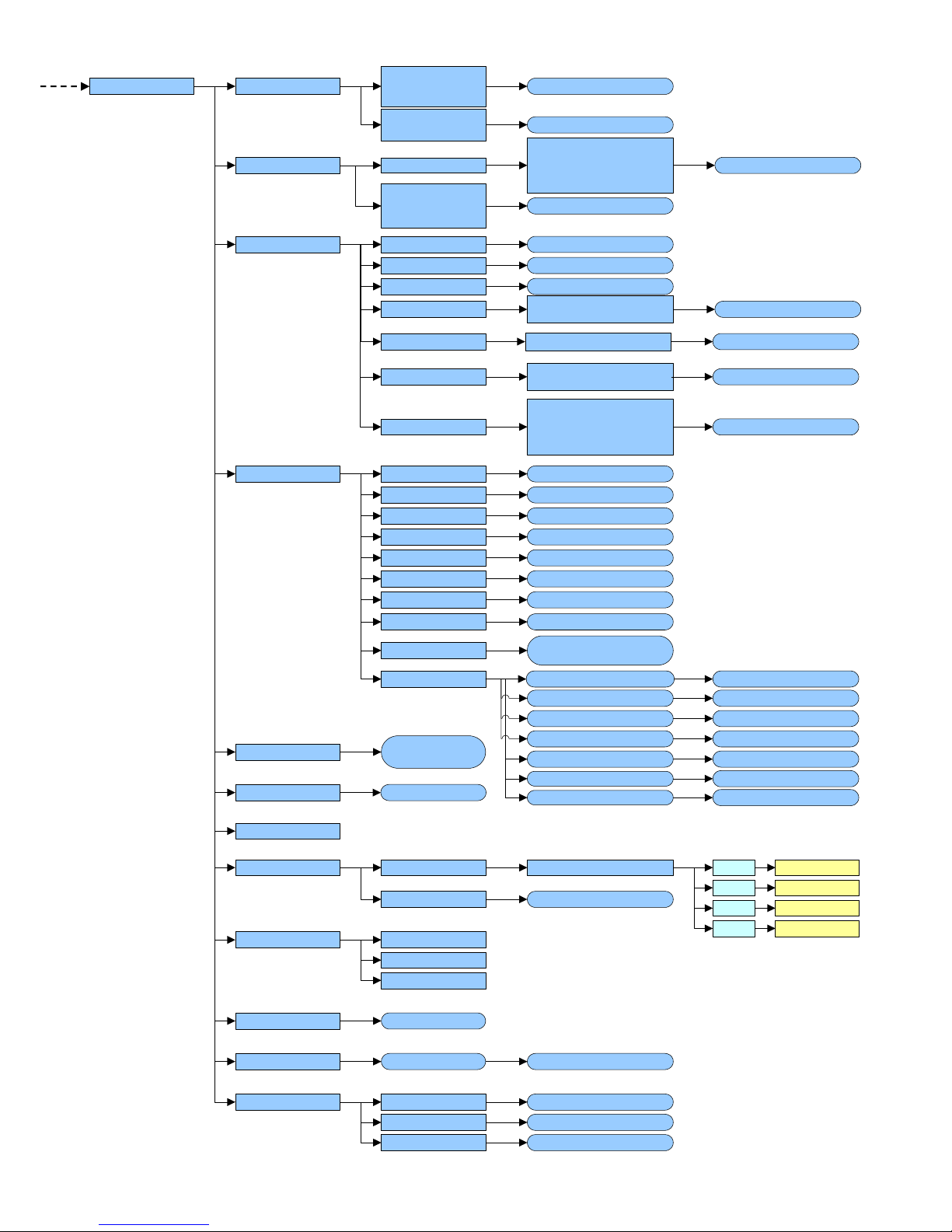

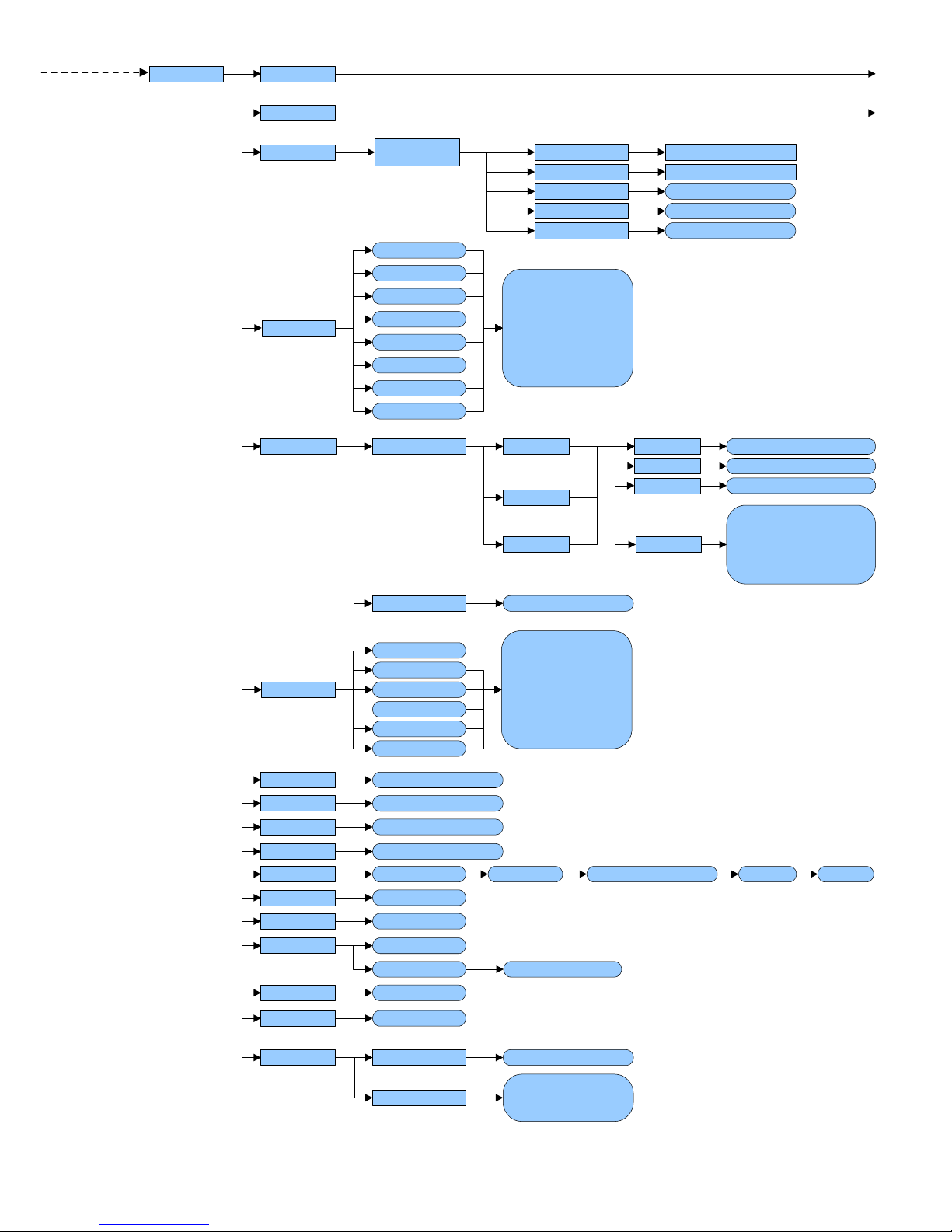

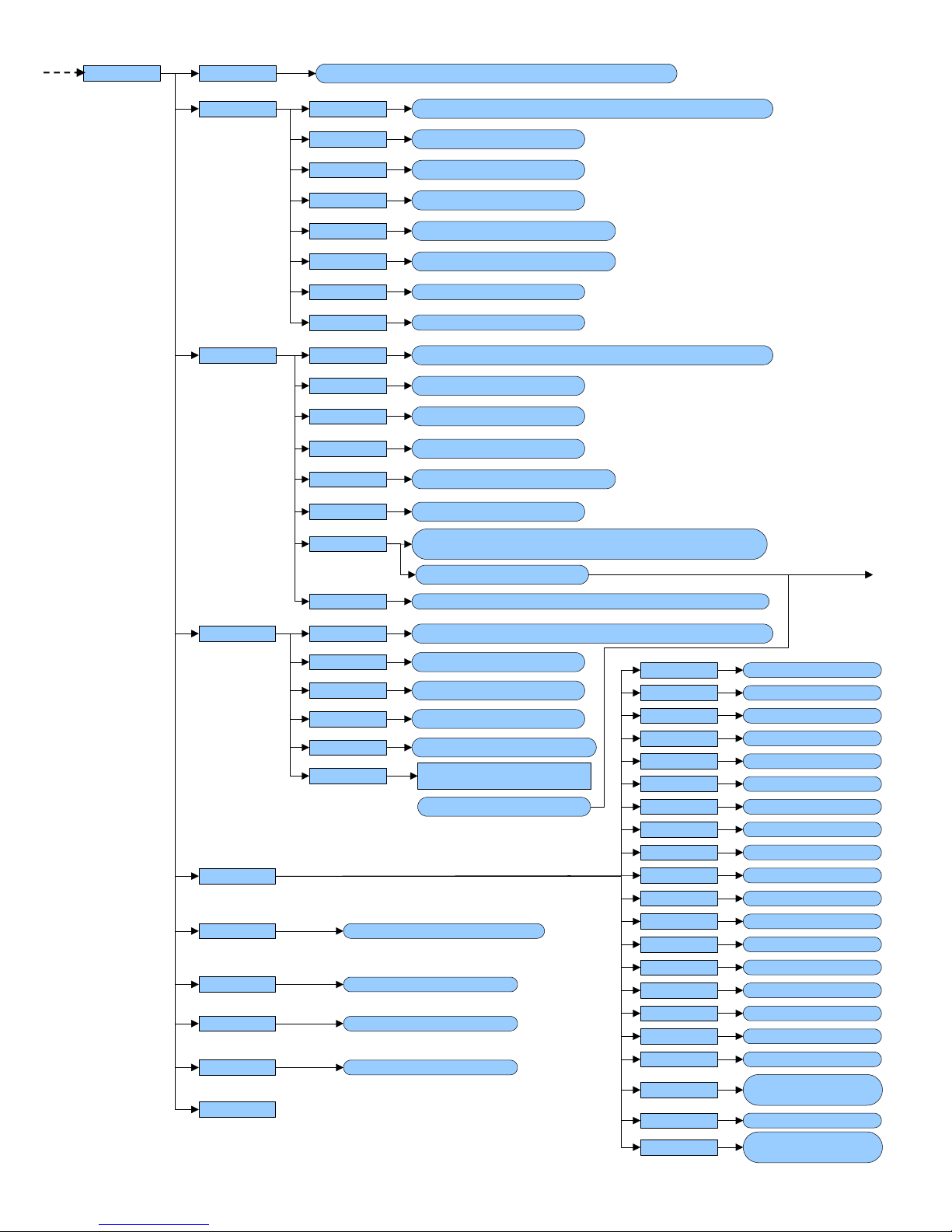

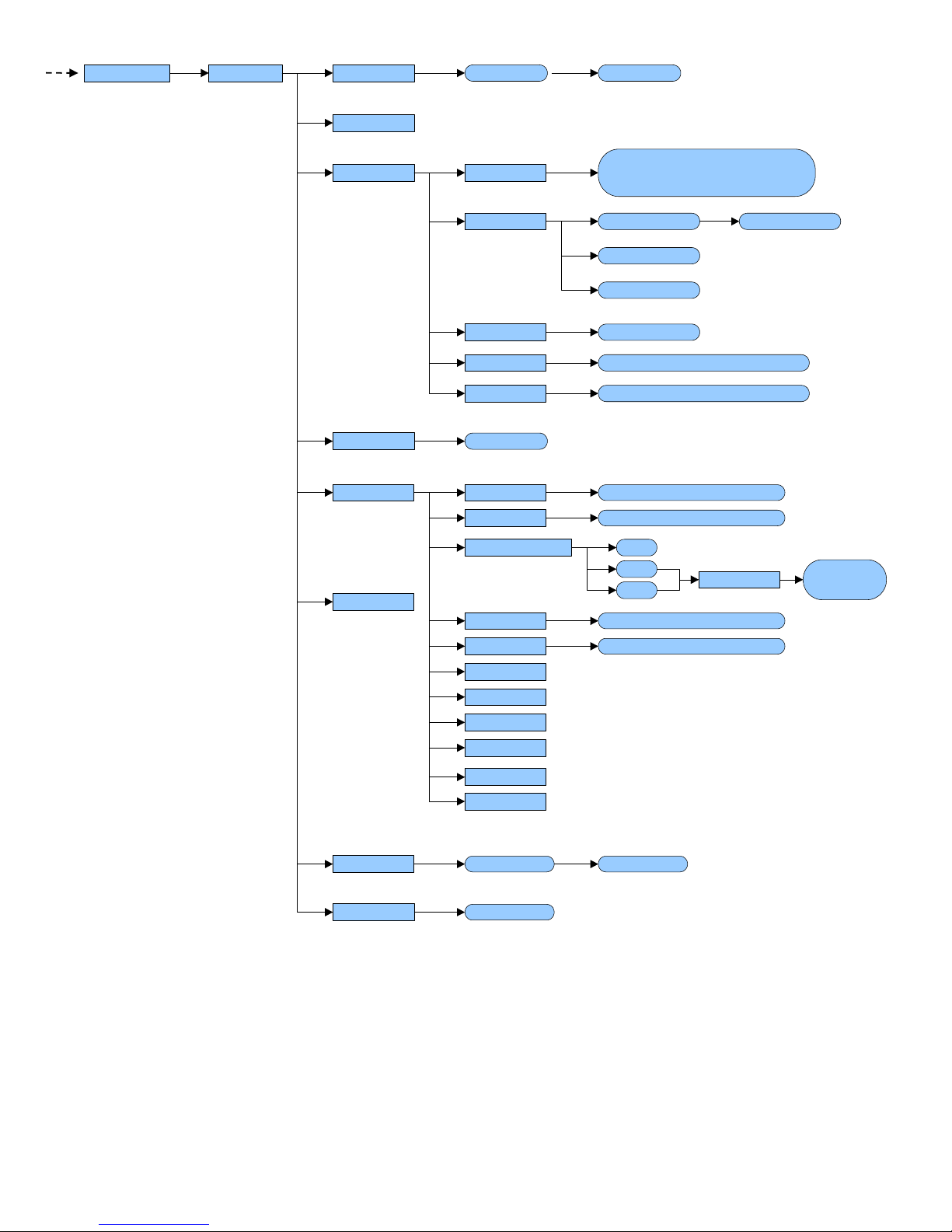

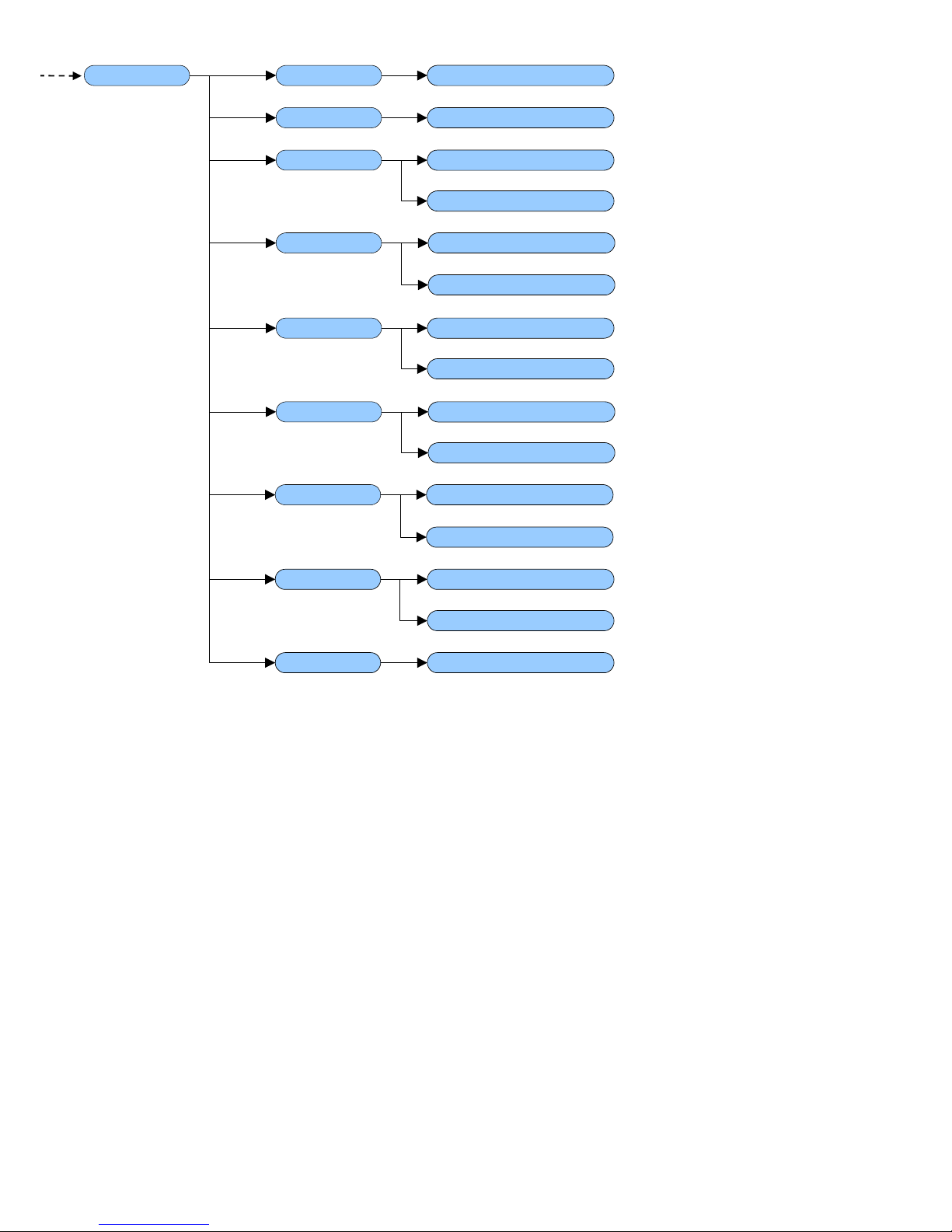

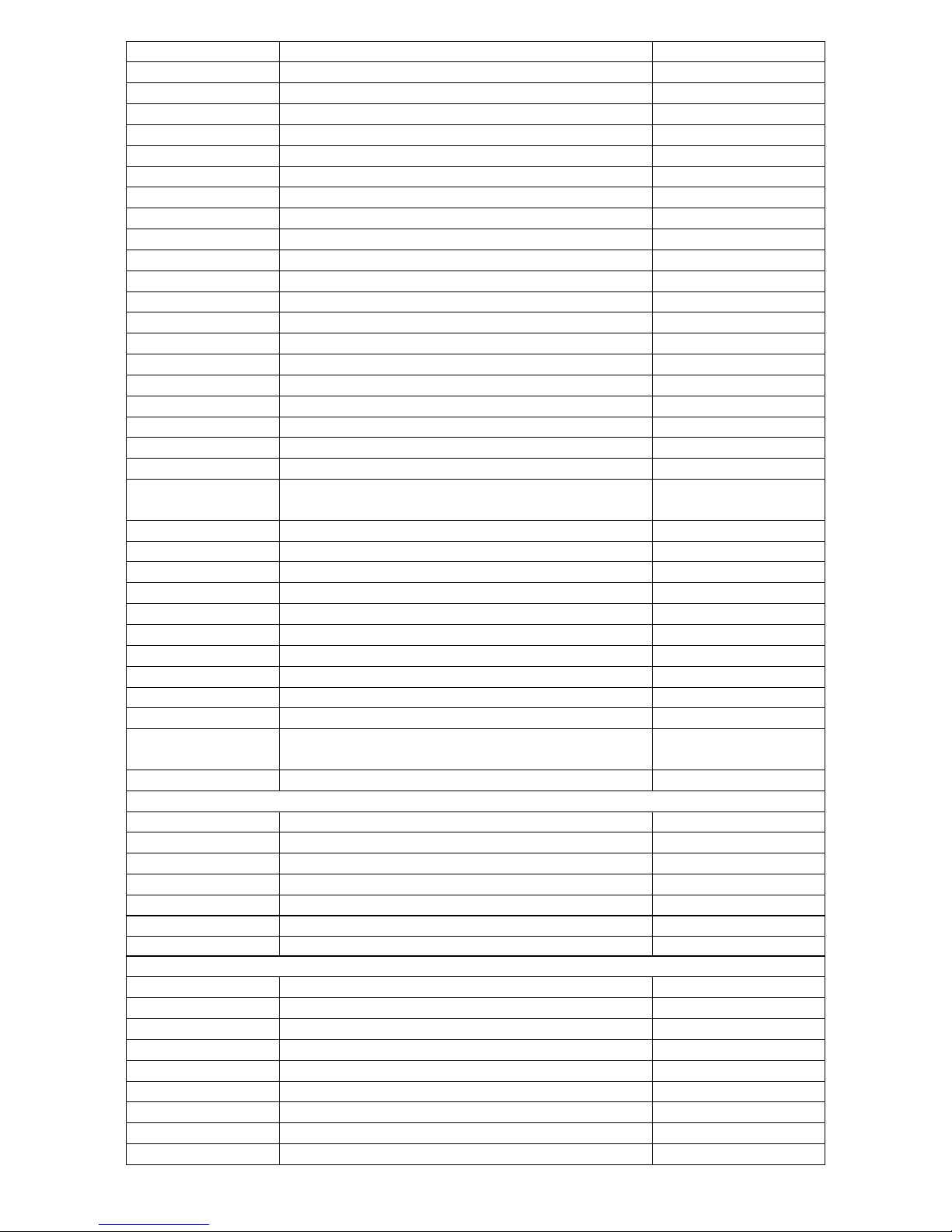

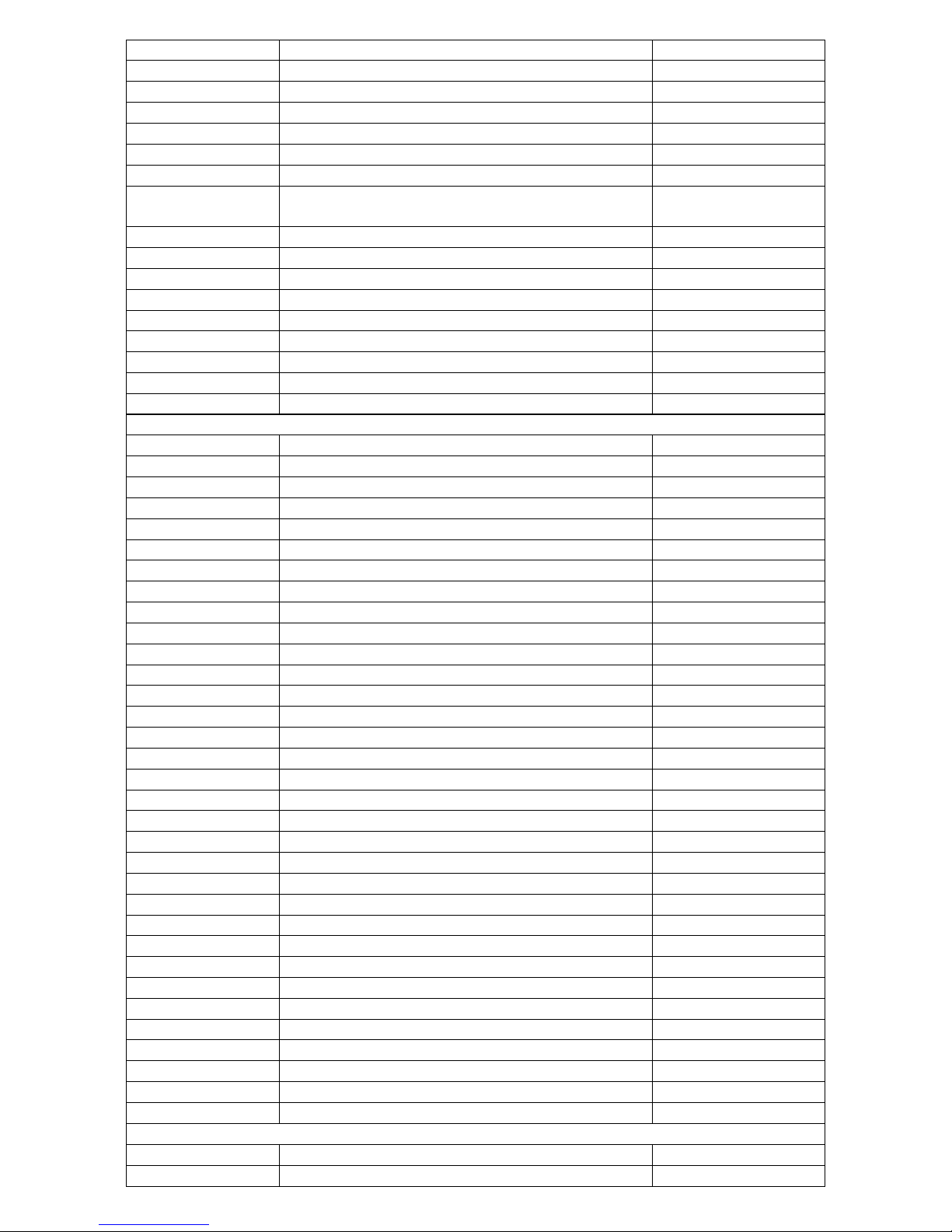

3.1 SET-UP ENVIRONMENT BLOCK DIAGRAM

The following diagram represents the structure of the indicator’s set-up environment; each step has been described in detail

in the paragraph 3.2.

F.ModE

diAG. PrG.VEr

WEiGht

MiLLiV

diSPLA

kEyb.

CtS.St

SEtuP

SETUP

ENVIRONMENT

rELE

inPutS

Anout

= USER & TECH MENU’

= ONLY TECH MENU’

(*) = METROLOGICAL PARAMETER

(§) = CONDITIONED STEP

(!) = DEFAULT VALUE

LEGEND

b.LEVEL

PoWEr

SEr.

SEr.nuM

F7

ENTER

F6

C

LAnG (!) En, Fr, dE, ES, Gr, it

AdC.Pnt

nuM.SCA 1 Scale

Remote

2 Scales

Analog

…

Scaime xx

Cel.typ

Scale 1

Num.Cel

Scale 1

Analog

…

Scaime xx

Cel.typ

Scale 1

Num.Cel

Scale 1

Analog

…

Scaime xx

Cel.typ

Scale 2

Num.Cel

Scale 2

Cel.add

(if at least 1

scale cel.typ is

<> Analag)

M.CELLS xx

J.boX

DGX mode DGX.number

P.tESt

EV.LoG

3590EKR, 3590EXP, 3590EXT, 3590 EBOX, CPWE, CPWET series indicator E-AF03_05.01_14.07_EN_T.doc

17

dtb

rEACt

LoGo

tXt

tXt.i

CLr.rAM

dtb.PWd

tAMAG

AbiL.C

init.

(!) inStAb, PASS.0

CFG.tXt

d.thrES

tHt.i 0

tHt.i 1

tHt.i 2

SurE?

(!) Disable, Enable 00000 … 65534

(!) 00 … 99

(!) 00000 … 99999

MonthS

WEiGh.

F.ModE EN.KEYS (!) Enable, Disable

F1...F10, 0...9,

POINT, TARE,

Fn, 2ndF, C

F.Keys F1…F10 xxx

En.M.Fld

(!) Enable, Disable

YES, NO

DATABASES,

TEXTS,CUSTOMERS

MATERIALS

VEHICLES

ENABLE ALL,

DISABLE ALL

SURE?

(!) 00 … 31

New

Edit

Delete

Print

F1

F2

F3

F5

In. 0 … In. 14

rESEt SurE?

totAL WEi.Mod

i.o.SCA

C.EntEr

(!) nor.WGt, SEC.WGt

rESEt

Wei.MEM

Pro.LSt

rES.tAr (!) Disable, Enable

En.C.Fld (!) Enable, Disable

Add.tAr

Description1

Description2

2nd F+F1…

2nd F+F10,

Fn+F1…Fn+F10

xxx

LIST 1:

:

:

10:

T.ModE

AbiL.M

AbiL.V

(!) Enable, Disable

(!) Enable, Disable

Description2 (!) Enable, Disable

En.V.Fld

Description

Tare

(!) Enable, Disable

A.inout

(!) Wei.Cod, PLAtE

(!) Disable, Enable

(!) MAnuaL, ALWAYS

(!) Enable, Disable

(!) Disable, Enable

(!) FrEE, Set.i.o1, Seti.o2

(!) ConFEr, inVErt

(!) Disable, Enable, Simple

Printout

SELF.C r.S.WGht

dF.WGht

r.Auto0

t.Auto0

t.StAbi

LoCK.K

t.End

XXXXXX

XXXXXX

XXXXXX

XXXXXX

XX

XXXXXX

(!) Disable, Enable

3590EKR, 3590EXP, 3590EXT, 3590 EBOX, CPWE, CPWET series indicator E-AF03_05.01_14.07_EN_T.doc

18

(*) dFLt.t

(*) Ini.AL

(*) d.SALE (!) NO, YES

PoW.oFF

bt.StAt

dFLt

PWd.SEt

tArE t

SURE?

(!) DISABLED, ENABLED

(!) DISABLED, ENABLED

SURE?

SURE?

SEriAL

(!) Lock, Unlock, Disable

SEtuP

Anout

ModE

AoMA

AoZE (!) 00000 … 65535

(!) 00000 … 65535AoMi

SLot (!) SLot 1, Slot 2

(!) AoG, Aon

(!) 00000 … 65535

KEYuSEPC.KEYb

LAYout

(!) Normal, READER

(!) ENGLISH, ELLENIKA,

ITALIANO, FRANCAIS,

DEUTSCH

(*) ConFiG

IN.2

inPutS

outPut rL.1

rL.16

no/nC

onStAt

rLFunC

rL.iSt

r.ConF.

r.ModE

(!) None, TARE, 2nd F,

Fn, POINT, C, F1 …

F10, 0 … 9, PLT-0, PLT-

1, PLT-2, PLT-3, PLT-4,

LOC.IN, OFF, -OK-

ERROR, READY,

START, STOP, RL.OFF,

LNG.KEY, LEVEL,

R.START

(!) n.o., n.C.

(!) drCt, StAbiL

(!) iSt.oFF, iSt.on

(!) nonE, GroSS, nEt, Gro.0,

nEt.0, Motion, totAL, T.W.1,

T.W.2, T.W.3, nEt.nEG, in-

out, WEiGh, t.LiGht

(!) Normal, EXCLUS

inF.rEd

None

IR 4

IR 18

RD 6

(!) None, TARE, 2nd F,

Fn, POINT, C, F1 …

F10, 0 … 9, PLT-0, PLT-

1, PLT-2, PLT-3, PLT-4,

LOC.IN, OFF, -OK-

ERROR, READY,

START, STOP, RL.OFF,

LNG.KEY, LEVEL

...

SCALE1,

SCALE2

00000 … 65534

(!) DISABLED

ENABLED

IN.3

IN.4

IN.5

IN.6

IN.7

IN.8

IN.1

ZOOM.W (§) (!) DISABLED, ENABLED

RD BR 6

bACkuP SURE? PWD XXXXX (!) DISABLED, ENABLED Bak.PWD XXXXX

IR 19

3590EKR, 3590EXP, 3590EXT, 3590 EBOX, CPWE, CPWET series indicator E-AF03_05.01_14.07_EN_T.doc

19

CoMPrn

CoM PC

Add.485

ProtoC

PC.ModE

bAud

PAritY

Word

StoP b

bAud

PAritY

Word

StoP b

Prn.FMt

tErMin

dEF.Prn

CtS.St.

PWrPrn

ProtoC

CtS.St.

ProtoC

CoMAuX bAud

PAritY

Word

StoP b

CtS.St.

PortS

rEM.SCA(*)(§)

rEAdEr

r71.rEP

EnAb.

tErM

WEi.PoS

WEi.LEn

CAPAC.

diV.

dECiM.

u.M.

StAb.

StA.int

Str.LEn

tAr.Pos

tAr.LEn

tAr.tYP

ZEro

tArE

W.tYPE

round.S

MAn.tAr

rEq.WEi

(!) PC.Pr.AX, PC.AX.Pr, Pr.PC.AX, Pr.AX.PC, AX.PC.Pr, AX.Pr.PC

(!) 9600, 1200, 2400, 4800, 19200, 38400, 57600, 115200

(!) None, Odd, Even

(!) 8 bit, 7 bit

(!) 1 bit, 2 bit

(!) LOW, HIGH, EMUCTS, NO.CTS

(!) 9600, 1200, 2400, 4800, 19200, 38400, 57600, 115200

(!) None, Odd, Even

(!) 8 bit, 7 bit

(!) 1 bit, 2 bit

(!) NO.CTS, LOW, HIGH, EMUCTS

(!) 00 … 99

(!) 9600, 1200, 2400, 4800, 19200, 38400, 57600, 115200

(!) None, Odd, Even

(!) 8 bit, 7 bit

(!) 1 bit, 2 bit

(!) DISABLED, ENABLED

(!) Disable, CMd.VAL,

VAL.CMd

(!) DISABLE, COM.PRN, COM.AUX

(!) DISABLED, ENABLED

C.F.01 … 30

(!) LF, NO.TERM, CR, CR LF

(!) PWrint, EXtoFF, PWrEXt

(!) norMAL, riPE 6, ALibi, Cont.

(!) StAnd, AFXX, riPE 6, riPLCd, Mondir, ALibi, SMA, ModbuS, Profi.b,

b tyPE, riP.b, Eth.nEt.riP.b3, riP.b4

(!) rEquE., Cont., StAbiL, - 485 -, End.CYC

(!) NO.CTS, LOW, HIGH, EMUCTS

(!) nonE, Cont., riPE 6, riPEdC,

Ety.nEt

(!) DISABLED, ENABLED

(!) DISABLED, ENABLED

(!) DISABLED, ENABLED

(!) DISABLED, ENABLED

(!) 00 … 99

(!) 00 … 39

(!) 01 … 39

(!) GroSS, nET

000 … (!) 255

(!) 01 … 39

000 … (!) 255

(!) 00 … 39

(!) 00001 … 99999

(!) 001 … 200

0, 1, 2, (!) 3, 4, 5

(!) -g-, -kg-, -t-, -lb-

00… (!) 03, … 20

00… (!) 02, … 20

SEriAL

Err.CtS (!) DISABLED, ENABLED

tErM.tX

(!) CR, CR LF, LF,

NO.TERM

Coin

Coin

3590EKR, 3590EXP, 3590EXT, 3590 EBOX, CPWE, CPWET series indicator E-AF03_05.01_14.07_EN_T.doc

20

StAbiL.PArAM.

ConFiG (*)

Auto 0

0.trACK

diV.Stb

rAnGE tYPE

CAP.1

diV. 1

diV. 2

CAP.2

CAP.3

diV. 3

dECiM.

u.M.

CALib.P

0.CALib

SEL.SCA

CALib.

PointS

CELtyP

GrAV

EquAL (§)

thEo.CA (§)

AdJ.CEL (§)

SLW.0 (!)– 3, H.R.0, H.R.1, FLT 0 – 3,

DYN.0 - 1, DOS.0 – 3, H.R.2 – 7, DYN.2

– 3, FLT.OFF, FLT.AV2, Custom

(!) ENABLED

XXXXXX XX

(!) TR.1/2, TR.1, TR.2, TR. no, TR.1/4

00, … (!) 02, ... 99

(!) 9.800655

nuMbEr oF rAnGE 1

2

3

M.rAnGE,

M.diViS

(!) 1, 2, 5, 10, 20, 50, 100, 200

(!) 100 … 999999

(!) 3, no, 1, 2

(!) - kg -, - t -, - lb -, - g -

XXXXXX XXXXXX

XXXXXX

DISABLED

CYCLIC (§)

(!) 10

0.PErC (!) 02

3590EKR, 3590EXP, 3590EXT, 3590 EBOX, CPWE, CPWET series indicator E-AF03_05.01_14.07_EN_T.doc

21

Coin PriCE.d

SYMboL

bAnd1

(!) 0 … 6

(!) 000 … 255

XXXXXX

XXXXXX

bAnd2 XXXXXX

XXXXXX

bAnd3 XXXXXX

XXXXXX

bAnd4 XXXXXX

XXXXXX

bAnd5 XXXXXX

XXXXXX

bAnd6 XXXXXX

XXXXXX

hiSt (!) 0

3590EKR, 3590EXP, 3590EXT, 3590 EBOX, CPWE, CPWET series indicator E-AF03_05.01_14.07_EN_T.doc

22

3.2 DESCRIPTION OF THE STEPS

<< LAnG >> FIRMWARE LANGUAGE

Parameter Language Used Codepage (see section 7.2)

- En English 1252 Windows Latin 1

- Fr FranÇais 1252 Windows Latin 1

- dE Deutsch 1252 Windows Latin 1

- ES Español 1252 Windows Latin 1

- Gr Ellenika 1253 Windows Greek

- It Italiano 1252 Windows Latin 1

(!) En

<< nuM.SCA >> NUMBER OF CONNECTED SCALES (*)

- 1 scale.

- 2 scales.

- Remote (only remote scale): this value is not visible if one sets the SEtuP >> SEriAL >> rEAdEr on CoMAuX.

(!) n.SC. 1

(*) In case of approved instrument the parameter is read only.

For each connected scale, one is asked to configure the next steps:

<< CELtyP >> CELL TYPE

This menu allows setting the type of cells used (analogue or digital):

in case of analogue cells it will be possible to enter the number of analogue channels.

in case of digital cells / DGX conversion card, it will be possible to enter the number of cells forming the scale and

follow the instructions in section 3.3.6. Only load cells of the same model and the same capacity can compose two

digital platforms.

NOTE: The instrument is able to manage up to 4 analogue channels or 16 digital cells / 16 analogue load cells

converted as digital through DGX conversion cards.

(!) AnALoG

<< DGX.MOD >> DGX FUNCTION MODE

- M.CELLS: Conversion into digital of each single analogue load cell.

- J.boX: for use of the manufacturer.

Follow the instructions in section 3.3.6.

(!) J.boX

<< DGX.NUM >> NUMBER OF DGX CARDS

This menu allows setting the number of DGX composing ALL THE SCALES.

Follow the instructions in section 3.3.6.

<< CEL.Add >> SET 485 CELLS ADDRESS

See section 3.3.7.

3590EKR, 3590EXP, 3590EXT, 3590 EBOX, CPWE, CPWET series indicator E-AF03_05.01_14.07_EN_T.doc

23

<< F.ModE >> SCALE FUNCTIONING

<< En.kEyS >> KEYS ENABLING

It is possible to enable/disable each single key of the keyboard:

- select the desired key with F6/F7:

- press ENTER to modify the setting:

- Press F6/F7 to select “ENABLED” or “DISABLED” and ENTER to confirm.

QUICK FUNCTION RECALL THROUGH 999 + 123 + Fn

If the function 123 + Fn is not enabled, is possible directly recall the desired function with the keys combination 999 +

123 + Fn in weighing phase.

NOTES:

- It’s possible to enable/disable all the keys together, by selecting “ENABLE ALL” or “DISABLE ALL” (the

confirmation will be requested with the message “SURE?”).

- The disabling of the keys will have effect only the WEIGHING PHASE, in other words, not inside the menus,

databases, etc…

- The turning off of the instrument (long pressing of the C key) will always be enabled.

- The disabling of the keys will be applied also on the PC keyboard, if connected.

(!) ENABLE ALL

F1

○ DISABLED

● ENABLED

F1

ENABLED

Status

Key

3590EKR, 3590EXP, 3590EXT, 3590 EBOX, CPWE, CPWET series indicator E-AF03_05.01_14.07_EN_T.doc

24

<< F.kEyS >> FUNCTION KEYS COUPLING

It’s possible to modify the function of the F1, F2…..F10 keys, and the combination of these with the 2nd F or Fn keys

(i.e. “2nd F + F1”, “Fn + F2”, etc...).

Through THE FUNCTION LIST, it is possible to link to a key up to 10 functions, which are executed one after the

other.

F.Keys Default

List

Modify

F1Enter

F2

Enter

Preamble

F.Keys

Enter

- select the desired key with F6/F7:

- press ENTER to see the list:

- press ENTER to modify the setting:

Quick introduction of the maximum and minimum thresholds

It is necessary to associate the function 500 and 501,used for the settings of the totalisation thresholds, each to a

function key between F1 and F10. If one digits a value and then presses one of the programmed keys, the minimum or

maximum threshold is set.

F1

302

Art.dtb

Function

Function

code

Key

F1

302

Code function

(blinking)

Function Code

Function

Preamble

Key

LIST 1: 1+Art.dtb(302)

F1 2: 1+CUS.dtb(305)

3: txt.0(121)

4: NONE

3590EKR, 3590EXP, 3590EXT, 3590 EBOX, CPWE, CPWET series indicator E-AF03_05.01_14.07_EN_T.doc

25

Preamble function

It is possible to associate also a preamble (numeric value) to the F1, F2…F10 keys. In this way, when the key is

pressed, the preamble is automatically used as parameter of the function to be executed.

The functions to which can be associated a preamble are:

FUNCTIONS

PREAMBLE VALUE

Input text configuration (tXt)

Number of the input text that one wants to modify.

Coupling print formats (Prn.Fmt)

Number of the format on which one wants to modify the coupling.

Setpoint configuration (SETPNT)

Number of the setpoint that one wants to modify.

Article database (Art.dtb)

Number of the article that is automatically selected

By pressing a key with the function of an associated database (for example articles database) and the

preamble is enabled to the value 9999, it is required disable the eventually enabled record.

EXAMPLE:

9999 + F1(article database), deselect active article.

- press F2 to insert the preamble:

- select enable and confirm with ENTER

- insert the desired value through the numeric keyboard and confirm with ENTER (by confirming the value 0, the

preamble is disabled).

- If one sets the value 9999 as preamble of a key matched to a database function, by pressing the key the active

record is deselected

KEYS’ FUNCTIONS IN THIS STEP

scrolls backward inside the list of the keys.

scrolls forward inside the list of the keys.

F1 performs the default of the function pairing of the keys.

F2 inserts the preamble.

ENTER modifies the code of the function in the current key; while entering it confirms the enteredcode.

NOTE: by pressing the . /HELP key, it’s possible to display the list of the keys used inside this step and their functions.

The list is automatically shown. If one wants to scroll the list of the keys in manual mode, it is possible to use the arrow

keys (F6 and F7 ).

PREAMBLE

○ Disable

● Enable

PREAMBLE

00000

Preamble value

(blinking)

F1 (2 + F1)

304

Art.dtb

Key (preamble + function)

3590EKR, 3590EXP, 3590EXT, 3590 EBOX, CPWE, CPWET series indicator E-AF03_05.01_14.07_EN_T.doc

26

CODE

BASIC FUNCTION

DEFAULT KEY/S

100

Scale Zero (ZERO)

ZERO

101

Cyclic zero (0.CYCLE)

2ndF + ZERO

102

Tare Execution (TARE)

TARE

103

Activate printer (PRN-ON)

Fn + 0

104

Simple printout (PRINT)

F5

105

Repetition of the last executed printout (CPY.PRN)

2ndF + F5

106

Change weight visualization (WEI.VIS)

2ndF + F8

107

Change visualization on LCD display (LCD.VIS)

2ndF + F9

108

Lock/Unlock the keyboard (L. KEYB)

F1 pressed at length

109

Display of Net Weight with sensitivity x 10 (Disp.10)

F2 pressed at length

110

Setting Date/Time (CLOCK)

F3 pressed at length

111

Diagnostic Menu (Diag.)

F4 pressed at length

112

Lock/Unlock Tare (L. TARE)

F5 pressed at length

113 (*)

Input Texts Configuration (txt)

F4

114

Calculator (CALC)

115

Printout and Reset Partial Total (Prn.0.t0)

F8

116

Printout and Reset General Total (Prn.0.t1)

F9

117

Printout and Reset Grand Total (Prn.0.t2)

F10

118

Diagnostic peripheral units (P.DIAG)

119

Com data diagnostics (COM.DAT)

120

Customized display enabling or change of visualization

if already enabled (CST.DSP)

121

Input text 0 configuration (txt.0)

122

Input text 1 configuration (txt.1)

123

Input text 2 configuration (txt.2)

124

Input text 3 configuration (txt.3)

125

Input text 4 configuration (txt.4)

126

Input text 5 configuration (txt.5)

127

Input text 6 configuration (txt.6)

128

Input text 7 configuration (txt.7)

129

Input text 8 configuration (txt.8)

130

Input text 9 configuration (txt.9)

131

Input text cancellation: from 0 to 14, 99 erase all the

texts (txt.rSt) 132

Print format sending: from 0 to 30 (Send.P.F) OTHER FUNCTIONS

200

Format Linking to the Printout Functions (Prn.Fmt)

201

Format Linking to the Totalisation (SND.FMT)

202

Setpoint configuration (SETPNT)

203

Remote Scale selection (REM.SCA)

2ndF + 0

204

Channel 1 selection (PLT-1)

2ndF + 1

205

Channel 2 selection (PLT-2)

2ndF + 2

209

Change on to next channel (CHG.PLT)

2ndF + 2ndF

SPECIAL FUNCTIONS

300

Input Weigh (IN.WEI.)

F6

301

Output Weigh (OUT.WEI.)

F7

302

Customer database (DB.CUS.)

F1

303

Material database (DB.MAT.)

F2

304

Vehicle database (DB.VEH.)

F3

305

Deselect active records (UNS.ALL.)

2ndF + F4

306

Deselect customer (UNS.CUS.)

307

Deselect material (UNS.MAT.)

308

Deselect vehicle (UNS.VEH.)

3590EKR, 3590EXP, 3590EXT, 3590 EBOX, CPWE, CPWET series indicator E-AF03_05.01_14.07_EN_T.doc

27

309

Select A+B visualization

310

Format Linking to the Input Weigh Printout (FM.IN)

311

Format Linking to the Output Weigh Printout(FM.OUT)

312

Format Linking to the Single Weigh Printout (FM.SING)

313

Customer alpha-betic search (ALP.CUS)

314

Material alpha-betic search (ALP.MAt)

315

Vehicle alpha-betic search (ALP.VEh)

316

Change Of The Second Line Visualization In A+B Mode

(DISP.CH) 317

Network state (nEt.StA)

318

Network monitor (nEt.Mon)

319

Archives alignment (db.ALiG)

320

Unlock weighing list records (unLoCK)

321

Connect network (n.StArt)

322

Disconnect network (n.StoP)

323

Send remote key (rEM.KEY)

324

Send remote long key (r.KEY.L)

325

Remote scale change (rEM.CGH)

VISUALIZATION / PRINTOUT MENU

400

Number of Ticket Copies (CoPiES)

401

Set progressive digits (Prg.1)

402

Set progressive label (Prg.2)

403

Automatic Lot Resetting (0.Prg)

404

Display Customer Total (V.t.Cus)

405

Print Customer Total (Prn.Cus)

406

Reset Customer Total (0.Cus)

407

Reset all Customer Totals (0.CusS)

408

Display Material Total (V.t.Mat)

409

Print Material Total (Prn.Mat)

410

Reset Material Total (0.Mat)

411

Reset all Material Totals (0.MatS)

412

Display Vehicle Total (V.t.VEh)

413

Print Vehicle Total (Prn.VEh)

414

Reset Vehicle Total (0.VEh)

415

Reset all Vehicle Totals (0.VEhS)

416

Display Partial Total (V.t-0)

417

Print Partial Total (Prn.t-0)

418

Reset Partial Total (0.t-0)

419

Display General Total (V.t-1)

420

Print General Total (Prn.t-1)

421

Reset General Total (0.t-1)

422

Display Grand Total (V.t-2)

423

Print Grand Total (Prn.t-2)

424

Reset Grand Total (0.t-2)

425

Reset Scale Totals (0.t-ALL)

426

Reset Weighs List (0.W.LIST)

427

Alibi Memory Reading (ALIBI)

428

Printout and Reset Customer Total (Prn.0.CuS)

2ndF + F1

429

Printout and Reset Material Total (Pr.0.Mat)

2ndF + F2

430

Printout and Reset Vehicle Total (Pr.0.VEh)

2ndF + F2

431

Progressive edit (Pr.Edit)

432

Change the views from KG to Lb and vice-versa

WEIGHING THRESHOLDS

500

Set maximum threshold (tr.HI)

501

Set minimum threshold (tr.LO)

3590EKR, 3590EXP, 3590EXT, 3590 EBOX, CPWE, CPWET series indicator E-AF03_05.01_14.07_EN_T.doc

28

<< dtb >> DATABASES

<< AbiL.C >> ENABLING CUSTOMER DATABASE

It’s possible to enable or disable the CUSTOMER DATABASE:

ENABLED

DISABLED

- Press F6/F7 to select “ENABLED” or “DISABLED”, and ENTER to confirm.

- Proceed up to the last suggested field, after which it automatically exits the step.

(!) ENABLED

<< AbiL.M >> ENABLING MATERIAL DATABASE

It’s possible to enable or disable the MATERIAL DATABASE (like the AbiL.C step):

ENABLED

DISABLED

(!) ENABLED

<< AbiL.V >> ENABLING VEHICLE DATABASE

It’s possible to enable or disable the VEHICLE DATABASE (like the AbiL.C step):

ENABLED

DISABLED

(!) ENABLED

<< En.C.FLd >> CUSTOMER FIELDS ENABLING

It’s possible to enable one by one the fields required for the CUSTOMER DATABASE.

- Press F6/F7 to select “ENABLED” or “DISABLED”, and ENTER to confirm.

- Proceed up to the last suggested field, after which it automatically exits the step.

(!) ENABLED

NOTE: The first customer description is always enabled.

<< En.M.FLd >> MATERIAL FIELDS ENABLING

It’s possible to enable one by one the fields required for the MATERIAL DATABASE (like the En.C.FLd step).

(!) ENABLED

<< En.V.FLd >> VEHICLE FIELDS ENABLING

It’s possible to enable one by one the fields required for the VEHICLE DATABASE (like the En.C.FLd step).

(!) ENABLED

<< init. >> INITIALIZE DATABASES and INPUT TEXTS

By pressing ENTER one initialises the DATABASES (with the total values), the number of decimals and unit of

measure of the databases and the INPUT TEXTS: in this way all their contents will be cancelled.

The cancellation is not immediate; the indicator requests a further confirmation (the LCD display shows “RESET

DATABASES ? ENTER=YES C=NO”).

By pressing ENTER one confirms the operation, by pressing C, the indicator gives the possibility to cancel all the

databases individually in this order: INPUT TEXTS CUSTOMER DATABASE, MATERIAL DATABASE, VEHICLE

DATABASE.

DESCRIPTION2

○ DISABLED

● ENABLED

Name of field

Status

3590EKR, 3590EXP, 3590EXT, 3590 EBOX, CPWE, CPWET series indicator E-AF03_05.01_14.07_EN_T.doc

29

<< totAL >> TOTALIZER

<< WEi.Mod >> SELECTION OF WEIGHING MODE

One selects the type of weighing which one wants to carry out:

nor.WGt NORMAL WEIGHING (simple input/output)

With two scales, by confirming with ENTER one is asked whether to enable the “A+B” mode:

DISABLED

ENABLED

SEC.WGt SECOND WEIGH (input/output with trailer weighing)

(!) nor.WGt

<< WEi.MEM >> TYPE OF INPUT WEIGH MEMORISATION

- WEi.Cod ID CODE

- PLAtE LICENSE PLATE

(!) WEi.Cod

<< Pro.LSt >> LIST OF PROGRESSIVE WEIGHS (only for weighing through ID CODE)

If this parameter is DISABLED, each input weigh is linked to the lowest ID code available; if it is ENABLED, the ID

code following the last input weigh is linked to it.

(!)DISABLED

<< t.ModE >> TYPE OF TOTALISATION

It is possible to select the type of totalisation:

- MAnuAL manual totaliser (reenabling according to how the rEACt “REENABLINGS” step is set.

- ALWAYS totaliser always (always active).

(!) MAnuAL

<< rESEt >> CONFIRM RESET

It is possible to select the automatic resetting of the totals when these are printed (Disable) or the resetting upon

request (Enable).

(!) EnAbLE

<< i.o.SCA >> SETS INPUT/OUTPUT SCALES

With the possibility of connecting a second scale, one sets how the two scales will be used:

SEt.i.o1 BIL1=IN BIL2=OUT: one sets the first scale (in other words, the one connected to the terminal board or to

channel 1) as INPUT, and the second one (in other words the one connected to channel 2) as OUTPUT.

SEt.i.o2 BIL1=IN BIL1=OUT: one sets the first scale as INPUT as well as OUTPUT.

FrEE FREE: one can freely use the two scales as: INPUT in the first / OUTPUT in the second and vice versa, or

INPUT/OUTPUT in the first or INPUT/OUTPUT in the second.

(!) FrEE

<< C.EntEr >> CONFIGURED ENTER KEY

In the “second weigh” functioning mode (trailer weigh), it is possible to configure the ENTER key for acquiring the

weight of the trailer:

ConFEr CONFIRM SCALE: by pressing the ENTER key one confirms the second weigh on the current scale.

inVErt INVERT SCALE: By pressing the ENTER key one confirms automatically switching to the other scale.

(!) ConFEr

<< Add.tAr >> ADDITIONAL TARE

In this step one can enable (ENABLED) or disable (DISABLED) the request to enter an additional tare, at the

moment of the output weigh execution. (USER MAN.REF.).

(!) DISABLED

3590EKR, 3590EXP, 3590EXT, 3590 EBOX, CPWE, CPWET series indicator E-AF03_05.01_14.07_EN_T.doc

30

<< A.inout >> AUTOMATIC IN OUT WEIGHT

In this step you can enable (ENABLED) or disable (DISABLED) automatic input output function or print (SIMPLE

PRINTOUT) when vehicle is selected. When this step is enabled, in the vehicle selection moment is request

automatically the input weight, after, when you reselect the same vehicle will be request automatically the output

weight. This step is appropriate for the SELF SERVICE with badge reader.

In this way when you swipe the badge the indicator identify the veichle and it executes automatically the setted

printout (input/output or simple printout). (REF.NOT.U.)

(!) DISABLED

<< SELF.C >> SELF-SERVICE CONFIGURATION

This step is displayed only if F.ModE >> totAL >> A.inout is enabled (ENABLED) or set to simple printout (SIMPLE

PRINTOUT) or if the protocol COIN is enabled for the COIN on COMPC or COMAUX.

<< r.S.WGht >> WEIGHT THRESHOLD LEVEL INDICATOR: threshold beyond which authentication is required by

badge card or credit to see or ptiny the weight . Beyond this treshold are displayed dashes "-----" instead of weight.

Once you have selected the vehicle (eg. with the badge) or added the credit requested (in case of COIN) displays the

weight on the scale for a maximum time equal to the seconds set in MAX TIME END OPERATION.

(!) 000000

<< dF.WGht >> WEIGHT DIFFERENCE TO WEIGHT THE END: after the acquisistion and display of the weight, if

this increases or decreases by a value greater than this second treshold, the instrument redisplays “------“.

EXAMPLE OF USE:

You have two trucks in line and at the end of the weighing of the first, the second does not make the balance return

to zero. If in this case the treshold is not set in the balance, this one goes in error .

(!) 000000

<< r.Auto0 >> AUTOMATIC AUTOZERO TRESHOLD: treshold (in absolute value) within whch if the weight is

different from zero, remains stable for the time set in the step TIME STABILITY and persist for the time set in the step

TIME AUTOZERO, the instrument perform automatic zero.

EXAMPLE OF USE: you set 40 kg of treshold, TIME STABILITY= 5 s, TIME AUTOZERO = 10 s. If the weight on the

scale is 10 kg and stable, it is reset automatically after 10 second.

(!) 000000

<< t.Auto0 >> TIME AUTOZERO: time in seconds that must elapse before performing the autozero procedure (step

conditional to stability).

(!) 000000

<< t.Stabi >> TIME STABILITY: time in seconds that I have exactly the same weight to be able to declare stable.

(!) 01 sec

<< t.End >> MAX TIME END TRANSACTION: maximum time after which the operation ends. If you perform an

operation and the trucks remains on the weighing, after this time, however, declares ended weighing and requires reauthentication.

Consigliato: 10-20 seconds.

<< t.MonEY >> MAX TIME WAITING CREDIT: (only with coin and protocol COIN enabled) Maximum time to wait the

coin before declare however ended the operation. The time is reset at each introduction of the coin.

(!) 00 sec

LOCK KEYBOARD: if enabled lock all key.

(!) DISABLED

<< rEACt. >> REACTIVATIONS

It is possible to set whether to reactivate the printout and the input/output weigh through:

Loading...

Loading...