Dingsheng Tiangong PY180H Operating Manual

GRADER PY180H

Operating Manual

Product name: Grader

Product specification: PY180H

Add:No.5 Haitai North & South Street,Huayuan Industry Zone of

Tianjin New Technology Industry Zone China

Postal code: 300384

Tel:0086-22-58396099

Fax:0086-22-58396090

The People's Republic of China

Ding Sheng Tian Gong Construction Machinery Stock Co., Ltd

Foreword

This operating instructions is compiled for the grader operator, in order to find

and avoid the personal injury and machine accident, the machine operator shall be

familiar with different rules indicated in this instruction.

The operator shall take this operating instructions when carrying out operation.

The operation, repairs and maintenance shall be conducted by the qualified

personnel.

We can supply training on different models of graders for users at all times.

In order to insure the safety of person and machine, the operator shall do the as

follows:

- The working environment of grader shall be safe and reliable.

- The operation falling short of rules shall be forbidden.

- Report any abnormal phenomenon to higher level and the higher-level

department shall take measures accordingly.

- Refuse unapproved personnel to get on the machine or enter the working site.

- Forbid operating against rules, such as lateral drag, repairing on inclined or

uneven road surface and working under lifted heavy, etc.

- Once the operator take notice of possibility of happening dangers to personnel

or machine, necessary measures shall be taken to avoid accident.

We reverse the rights to make modification to the operating instructions. In case

of minor technical changes, this operating instruction will not be revised and

additional pages will be added to this operating instruction.

The copyright of this operating instruction belongs to Ding Sheng Tian Gong

Construction Machinery Stock Co., Ltd. All Rights Reserved.

Table of contents

1. Preamble .......................................................................................................................................1

1.1 Warranty clause ...........................................................................................................................1

1.2 Spare parts................................................................................................................................1

2. Sales service department...............................................................................................................1

3. Accident prevention ......................................................................................................................1

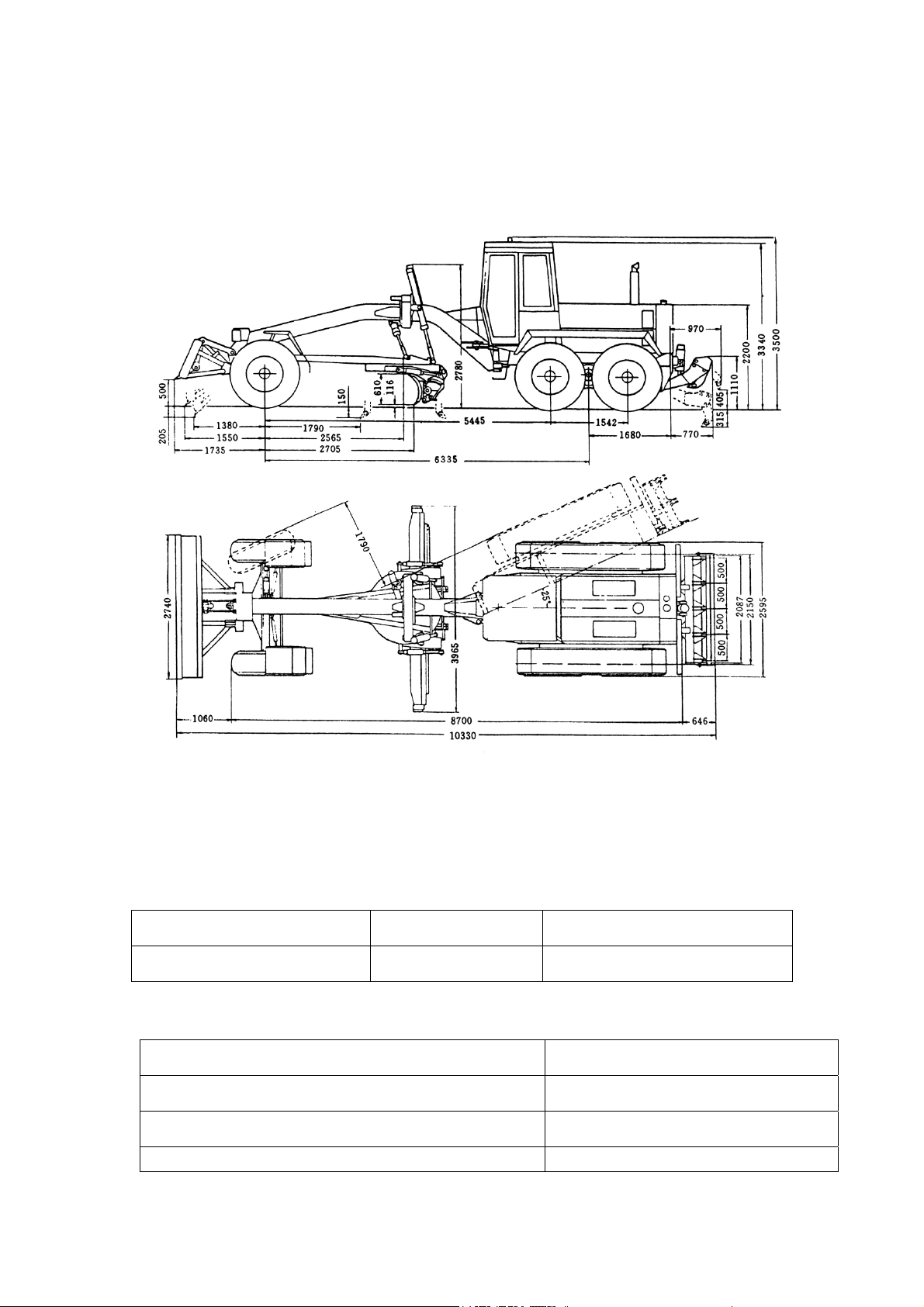

4. Performance parameter of complete machine...............................................................................3

4.1 Dimensions ...............................................................................................................................3

4.2 Working weight .........................................................................................................................3

4.3 Engine .........................................................................................................................................3

4.4 Torque converter –Transmission.................................................................................................4

4.5 Axle.............................................................................................................................................4

4.6 Tandem box.................................................................................................................................4

4.7 Speed...........................................................................................................................................4

4.8 Brake system...............................................................................................................................4

4.9 Steering system ...........................................................................................................................4

4.10 Hydraulic working system ........................................................................................................5

4.11 Work devices .............................................................................................................................5

4.12 Blade turning device .................................................................................................................5

4.13 Wheels and tyres .......................................................................................................................5

4.14 Front and rear frames ................................................................................................................5

4.15 Driver’s cab...............................................................................................................................5

4.16 Electrical system .......................................................................................................................5

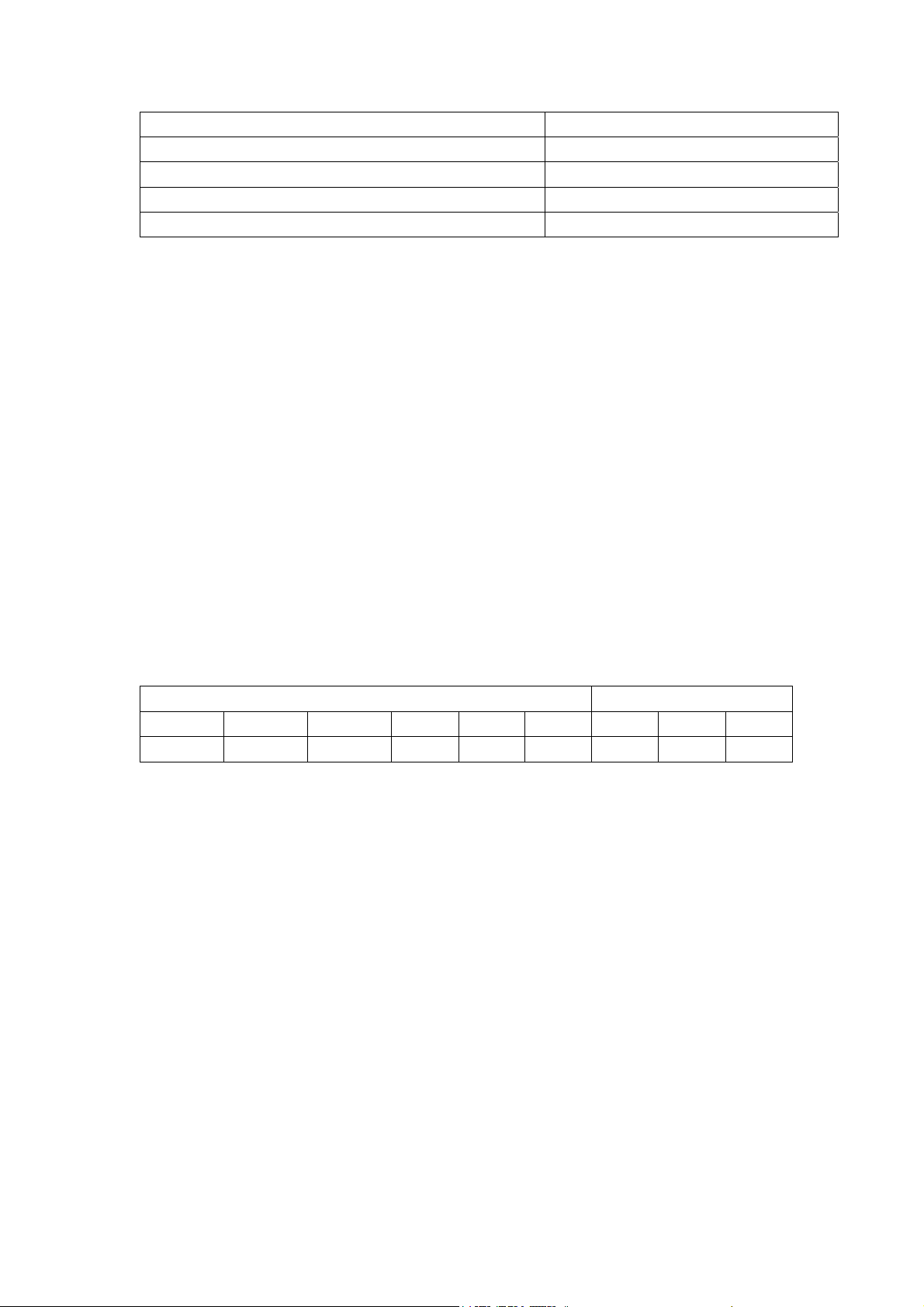

5. Layout and equipments .................................................................................................................6

6. Description....................................................................................................................................7

6.1 Grader .........................................................................................................................................7

6.1.1 Engine ......................................................................................................................................8

6.1.2 Hydrodynamic torque converter-transmission .......................................................................8

6.1.3 Traveling braking (Foot braking) hydraulic system ...............................................................9

6.1.4 Hydraulic operating system and hydraulic steering system...................................................10

6.1.5 Electrical devices ...................................................................................................................15

7. Operation instruction...................................................................................................................16

7.1 Adjust before operating for the first time ..................................................................................16

7.2 Running-in time ........................................................................................................................16

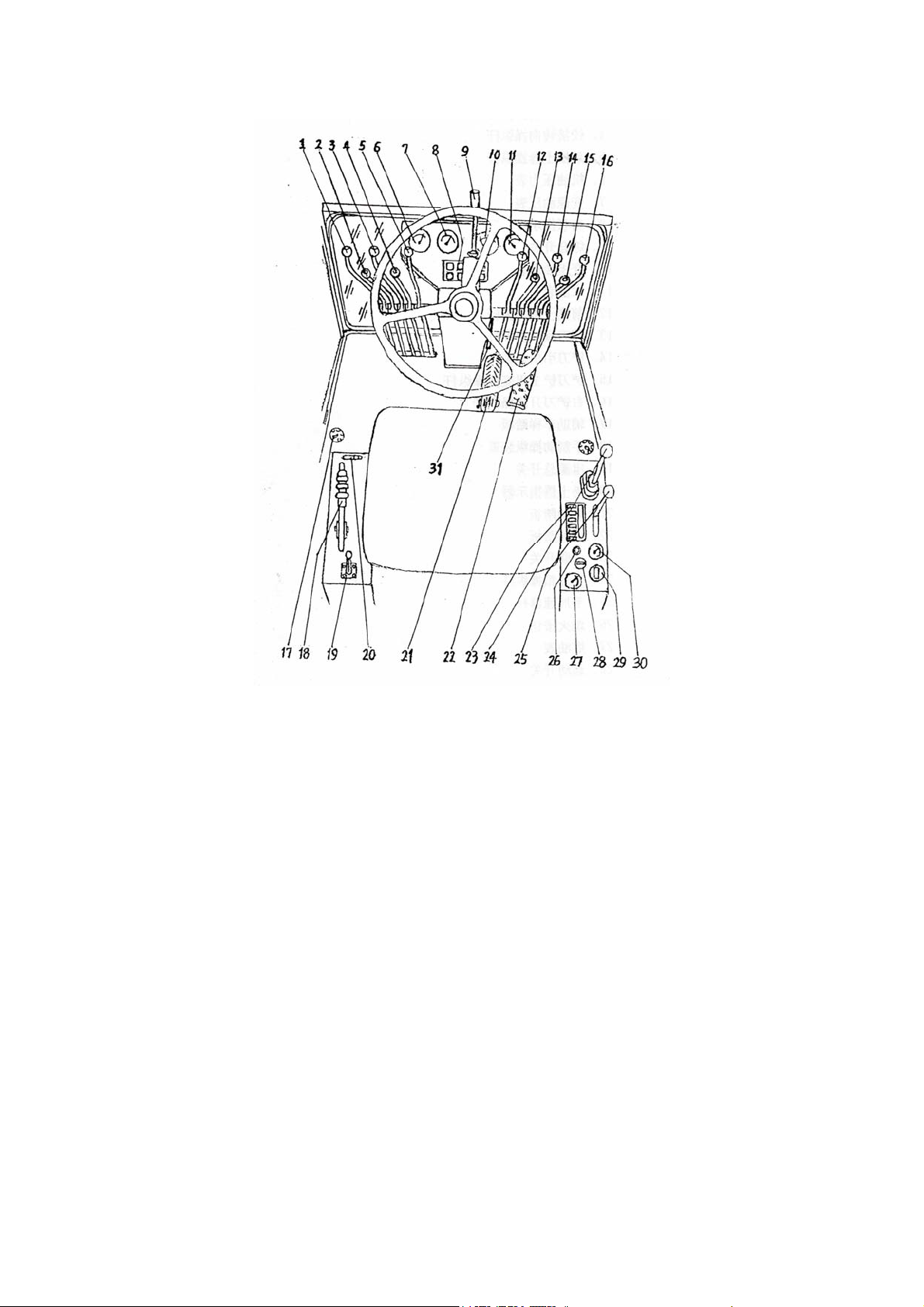

7.3 Diagrammatic representation of control instrument and operating lever of complete machine16

7.4 Driver’s cab...............................................................................................................................21

7.5 Operation of operating device...................................................................................................22

I

7.6 Driving ......................................................................................................................................28

8. Care and maintenance .................................................................................................................33

8.1 Safety rules................................................................................................................................33

8. 2 Lubrication chart ....................................................................................................................34

8.3 Check oil level, change oil and filter ........................................................................................39

8.4 Maintenance system..................................................................................................................45

8.5 Engine .......................................................................................................................................48

8.6 Brake system.............................................................................................................................50

8.7 Adjustment of the chain of tandem box ..................................................................................55

8.8 Lubrication and adjustment of front wheel bearing ..................................................................56

8.9 Work device- Blade...................................................................................................................57

8.10 Tyres........................................................................................................................................59

8.11 Fasten and change wheel.........................................................................................................60

8.12 Steering ...................................................................................................................................61

8.13 Hydraulic operating system ....................................................................................................61

8.14 Transmission shaft...................................................................................................................61

8.15 Electrical device of grader ......................................................................................................61

8.16 Notes to store the grader .........................................................................................................62

9. Fault analysis and troubleshooting..............................................................................................63

10. Front axle drive unit ................................................................................................................72

10.1 hydraulic system of front axle drive........................................................................................72

10.2 Front driving axle....................................................................................................................73

10.3 Operating instructions.............................................................................................................73

10.4 Care and maintenance .............................................................................................................76

10.5 Fault analysis and troubleshooting..........................................................................................76

II

1. Preamble

Our corporation has accumulated an abundance of experiences in complete

machines manufacture in engineering machinery; the grader manufactured by us has

advanced design level and level of technology. If the grader can be used correctly and

maintained properly, the service performance, production efficiency and service life

of the grader will be more reliable, higher and longer respectively.

The trouble-free operation and service life of the grader is depending on the

correct use and maintenance of the grader to a great extent, therefore this manual must

be read by operator and the different operating provisions must be complied with

before the first operation of the grader strictly.

Make sure that the system to be readjusted and the system performance checked

after repair work or replacing parts and components. The above mentioned adjustment

and inspection are very important for the brake system and steering system especially.

We will provide technical service for any necessary repairs upon the sales of the

grader.

GB/T 14782-93 Technical item of Motor Grader.

1.1 Warranty clause

We observe the contact and carry out guarantee of repair; replacement and refund

of substandard products and supply mating parts after the sales of engineering

machinery.

1.2 Spare parts

Make sure that in all repair work, only original spare parts supplied by our

company are used. This gives you the assurance that you will be protected from

damage and your machine will be kept in original conditions.

2. Sales service department

Sales department of Ding Sheng Tian Gong Construction Machinery Stock Co., Ltd

Tel: 008622-58396099

Fax: 008622-58396090

Telegraphic address: 4984

Address: No.5 , Haitai Nanbei Avenue, Huayuan Industrial Area, New

Technology Industrial Area, Tianjin

P.C.:300384

E-mail: export@dstg.com.cn

3. Accident prevention

1) When disassembling and assembling the grader, the works shall be done under

instruction of special technicians.

1

2) The person who received the driver’s license for the grader and is fully familiar

with the operation of the grader can operate the grader.

3) The grader driver must control the grader under good condition.

4) Before driving grader for each day, the driver must check the function of braking

and steering devices.

5) The grader driver shall report the abnormal phenomenon found to maintenance

and repair men and tell the next shift of person. The machine must be stopped if the

abnormal phenomenon brings about unsafe factors to operation.

6) Different control levers of grade can only be controlled in driver’s cab.

7) Make sure to insure the stability of grade during the whole operating process.

8) Must engage gear on downhill path.

9) The safe distance must be kept during operating process and working on busy

road.

10) The driver must take notice that there is no person near the grader before

operating and driving the machine and sound the horn.

11) If cannot see the blade working, the driver shall use flag signal or take

measures necessary.

12) This method can only be used for the driver who is familiar with flag signal.

13) When the grader is operating, any person is forbidden to enter the working area.

14) The operating device shall be fallen to the ground or fixed in case of down time

or not used.

15) Only when setting the grader to the ground or fixing the grader can the diver

leave and set the control device to their original positions.

16) The drive must have the hand brake engaged and all assistant safety devices

locked before leaving the driver’s cab.

17) After work interrupted or completed, shut down the engine and take off the

ignition key as well as switch off the main power switch (if equipped) to avoid

accidental starting.

18) The relevant personnel can go out or enter into the driver’s cab only when

approved by the driver and the grader is parking.

19) It is not allowed for the driver to let the unapproved personnel to enter into the

driver’s cab.

20) When repairing the grader, you should follow the steps as follows:

a) Shut down the engine and put all work devices on the ground or have them

firmly fixed.

b) If you must work under lifting device, the device must be locked or fixed.

c) Because of articulated-steering structure, front and rear frames must be locked.

d) When there is pressure in hydraulic system, don’t turn the joints.

e) After repairing, all safety devices must be returned to original positions (cotter

pins, etc).

It is very important for accident prevention to comply with above-mentioned

rules.

2

4. Performance parameter of complete machine

4.1 Dimensions (Fig.1)

(Tyre 17.5-25)

Fig.1

4.2 Working weight (Unit: kg)

Complete machine Front axle Rear axle

15400 4600 10800

4.3 Engine

Type 6CTA8.3-C215

Bore×stroke 114×135mm

Total displacement of the pistons 8.27L

Rated power 160kW

3

Rated speed 2200r/min

Max. torque 872N.m

Max. torque speed 1500r/min

Operations sequence of different cylinders 1-5-3-6-2-4

Generator 24V/35A

4.4 Torque converter –Transmission

Type: ZFW320 torque converter (with free wheeling) is integrated with 6WG200

transmission.

Direction change (power gear shifting): Forward gear –neutral gear – reverse gear

Speed gear (power gear shifting): Forward 6 speeds; Reverse 3 speeds.

4.5 Axle

4.5.1 Driving axle

Type: 3-stage driving axle with “no-spin” differential gear.

4.5.2 Driven axle

Type: Oscillating and steering front axle of box type, oscillating angle ±15°,

leaning angle of front wheel ±17°, steering angle 45°.

Ground clearance from center: 630mm

4.6 Tandem box

Type: Oscillating type tandem box, oscillating angle ±15°, heavy-duty roller

chains drive.

4.7 Speed

Forward (km/h) Reverse (km/h)

1st 2nd 3rd 4th 5th 6th 1st 2nd 3rd

5.23 7.94 11.84 17.85 25 40 5.23 11.84 25

4.8 Brake system

4.8.1 Service brake (foot brake)

Pipe system: Brake system consists of one circuit, hydraulic pump and

accumulator.

Brake: Pliers disc brakes are assembled on rear wheels. 4 on two front wheels; 2

on two rear wheels.

4.8.2 Parking brake (hand brake)

Type: Hub brake, mechanically operated and mounted on drive shaft of gear box.

4.8.3 Continuous service brake

The torque converter is designed to conduct continuous service brake.

4.9 Steering system

4.9.1 Front wheel steering

Feature in structure: Hydraulic oil from oil tank is obtained by gear pump to

supply hydraulic steering-gear which distributes hydraulic oil to steering cylinder.

Service pressure: 15MPa

Steering angle: 45°

Turning radius: Without wheel lean 10.9m

4

With wheel lean 10.4m

4.9.2 Articulated frame

System: The articulation operation between front and rear frames is driven by

double acting hydraulic cylinder.

Articulating angle: Right and left sides 25° respectively.

Min. turning radius with articulating steering: 7.8m over the front wheel.

4.10 Hydraulic working system

System: Hydraulic system of double pumps and double circuits.

Control valve: Two valve blocks, each is composed of 5 control valves.

Working pressure: 16MPa (180MPa while blade rotating and with front scraping

plate)

Hydraulic pump: Double-gear pump of high pressure mounted on power output

shaft of the gear box.

Cylinder: Double-acting hydraulic cylinders.

4.11 Work devices

System: Hydraulic adjustment of blade/back ripper and front bulldozing plate,

ring-gear with rolling plate, scarifier with 6 teeth mounted on blade back.

4.12 Blade turning device

Features in structure: worm gears are driven by hydraulic motor, there are two

types of structures, tooth ring or rolling disc.

4.13 Wheels and tyres

Rims: 14.00/1.5-25 (TB)

Standard tyres on all 6 wheels: 17.5-25 PR12

4.14 Front and rear frames

Construction: Front frame – steel beam structure, its section is pressed into

U-sleeve, welded like box.

Rear fame – solid beams welded in two sides.

4.15 Driver’s cab

Structure: Weld structure of the steel is conformed to the DIN AND ISO standards.

The driver’s cab is structure of preventing tipover and sliding down

(ROPS/FOPS), two sliding doors.

4.15.1 Driver’s seat

Structure: Spring vibration absorbing seats, adjustable in horizontal and vertical

position and in back rest inclination.

4.15.2 Air conditioning system

The system is configured according to the user’s requirement. The air

conditioners are heating and cooling devices designed specially for engineering

machinery. Before using air conditioner (for heating or cooling), please read the

instruction of air conditioner carefully.

4.16 Electrical system

Working voltage: 24V

Fuses: 5A, one piece; 10A, 5 pieces; 15A, 3 pieces; 20A, 2 pieces; 25A, 1 piece.

5

Batteries: every one 12V, 165AMP/h.

Lights: head lights 2; tail lights 2; flashlamps 6; brake lamps 2; working lights 2;

rear view lamps 2.

Sound signal: horn

5. Layout and equipments

Fig. 2

Frame and accessories:

1. Front frame 2. Rear frame 3. Articulation center 4. Engine cover 5. Splash guard

6. Driver’s cab 7. Driver’s seat 8. Air conditioner (optional) 9. Mark plate

10. Instrument plate 11. Removable console

Engine and accessories:

12. 6-cylinder-diesel engine 13. Air filter 14. Exhaust system 15. Fuel tank

Gear box, axle, wheel:

16. Driving shaft 17. Torque converter-transmission 18. Gear change lever

6

19. Torque converter oil cooler 20. Front axle 21. Rear axle 22. Tandem box

23. Front wheel

Steering:

24. Hydraulic steering-gear 25. Steering pump 26. Steering cylinder

Work devices:

27. Swing frame, 6 adjustable positions 28.Traction frame

29. Tooth ring with rolling disc 30. Blade turning hydraulic motor 31. Blade

32. Scarifier 33. Front bulldozing plate (front additional weight)

34. Back scarifier (Rear additional weight)

Hydraulic system:

35. Hydraulic tank 36. Working pump

37. Control valves (2 blocks) 39. Hydraulic cylinder, blade lift

40. Hydraulic cylinder, blade swing 41. Hydraulic cylinder, blade shift

42. Hydraulic cylinder, blade cutting angle 43. Hydraulic cylinder, wheel lean

44. Hydraulic cylinder, front bulldozing plate 45. Hydraulic cylinder, back ripper

46. Hydraulic cylinder, articulation

Brakes:

47. Brake accumulator 48. Brake pedal 49. Brake

50*. Relief pressure valve of the accumulator 51. Hand brake (disc brake)

Electrical devices:

52*. Batteries (left side of the engine) 53. Head lights

54. Tail lights 55*. Indicators, instruments, switches and cables

* Not shown in figure.

6. Description

6.1 Grader

The engine and transmission are mounted on the rear frame. The work devices are

mounted on the front frame. The additional front bulldozing plate can enlarge the

scope of application of the grader.

The grader is driven by water-cooling and turbo-change diesel engine that is

composed of 6 cylinders straight line and 4 strokes.

The power produced by engine is transmitted to the rear axle by hydraulic torque

converter, transmission and driver shaft, then to the 4 rear wheels via the tandem

chain.

The hydraulic steering for front wheel is combined with articulating frame giving

the frame a minimum turning radius of 7.8m.

The nouns such as “Left, Right, Front, Rear” describing directions used in this

instruction in relation to the forward direction of grader.

7

6.1.1 Engine

All driving devices (Engine-transmission) are fixed on the rear frame by 6 rubber

vibration reduction housing.

Viewed from the engine fan, the direction of the crankshaft is clockwise.

The combustion air is drawn through an air filter.

Lubrication of all bearings in the engine as well as cooling of some running

engine parts is conducted by forced feed lubrication. The lubrication system is fed by

a pump drawing oil from the engine oil sump.

The engine oil is cooled by internally hidden oil cooler mounted in the engine. For

details please refer to the operating instruction for diesel engine.

6.1.2 Hydrodynamic torque converter-transmission (ZF6WG200)

The ZF6WG200 hydraulic transmission is composed of torque converter and

dead-axle and multi-gear transmission of constant shaft, with the speed of 6 forwards

and 3 reverses.

The torque converter is simple 3 units construction with no-lock clutch, the circle

diameter is Φ 340,the torque coefficient Ko=2.55 at the lost speed. The torque

converter pump wheel is directed mounted on the engine fly-wheel by means of

spring plate. the oil temperature should be 80~110℃ when at normal work and it is

allowed to reach 120℃ at moment.

The transmission has 6 multi disk clutches controlled by hydraulic which can

engage and disengage under the load reach the power shift. The transmission gear is a

constant engagement drive. Its construction and principal can be seen in the following

attached figures The speed ratio of the transmission as follows:

Forward Reverse

1st 2

nd

3

rd

4

th

5

th

6

th

1

st

2

nd

3

rd

5.986 3.904 2.594 1.692 1.178 0.768 5.906 2.594 1.178

There are two pumps outside the transmission. They are dived by pump wheel of

torque converter. Output shaft of the transmission is combined with driving axle

backwards to transmit power to the rear axle. Output shaft is connected to the driving

shaft backward and transfers the power to the rear axle. Output shaft is linked to the

parking brake forward.

The gear shift of transmission is operated by electro-hydraulic shift (hand control

selector) at driver’s right side. The gear shift changes can be achieved by each

electro-magnetic valve connected to hand selector and then to control hydraulic

sliding valve.

Note! Here the user shoult notice that the operation should be done

gradually and sequentially without humping over any gear.

Besides, the transmession can achieve reverse control only in 1st gear.During

8

driving and sliding slope, the corresponding gear shall be controlled and the engine

speed shall not be lower than 1200r/min to meet the needs of lubrication of each part

of the transmession.

The operating pump for suplying oil to torque converter and operating is

mounted inside transmession and aslo controlled by pump wheel. Its flow is

35L/1000r/min,control pressure is 1.6~1.8Mpa (Liuzhou Transmession). Because of

the cushion construction inside the controlling valve, so the pressure of lowering and

rising should have a regularity. During gear change, in this way the geat change can

be smooth and less shock.. Besides, because of “Neutral insurrance” set in

transmession electric circuit, the driver can start the engine when the transmession is

in neytral, so this can prevent from mis-controlling.

The diesel lubrication oil L-ECD15W-40 is applied in this transmession. Filling

oil of the first time is about 28L. When checking oil level, the engine should be in idle

spped and transmession temperature is in normal working condition. At this time, two

oil scales indicate the levels 80℃(Upper scale) and 40℃(Lower scale). The oil level

will be higher than upper scale if check the engine without starting the engine.

Note: The transmission oil must be changed after operation of the

first 100 hours and later every 1000 hours or at least once a year. The

oil filter also should be changed with oil changing. Please notice that

the used filter could not be assembled again even no apparent

damage found.

Note: When the engine is shut down and the main machine is dragged,

this transmission require that the traction distance and speed of

grader cannot exceed 10km and 10km/h respectively.

Note: When conducting electric welding work on the main frame, the

gear selector circuit must be disconnected to avoid damaging its

internal circuit by unexpected over-current.

6.1.3 Traveling braking (Foot braking) hydraulic system (As shown in Fig. 9)

The foot brake has a one-circuit system with hydraulic pump and accumulator and

operates on four rear wheels of the grader.

When the engine is running, the double pump (2) of the working hydraulic draws

oil from the tank (4).

The oil from the pump is transmitted via the pressure limiting valve (9) into two

accumulators (11) to increase the pressure below 133 bars and to cut off oil when 150

bars.

Filling oil of the accumulator (11) requires only short time and then oil intaking

system makes oil flow into hydraulic circuit (130 bars).

The filling oil of the accumulator (11) has priority and therefore, the pressure oil

necessary for the braking system is available as soon as the engine is running.

9

When the pressure on the brake valve (10) drops below 100 bars, the indicator

lamp on the instrument panel lights. This lamp is controlled by controlling the power

switch. The pump is switched by brake service switch.

When pressing down the brake valve (10), pressure oil in the accumulator circuit

flows to the wheel-side brake (12). At the same time, the brake lights are switched on

by the brake light switch.

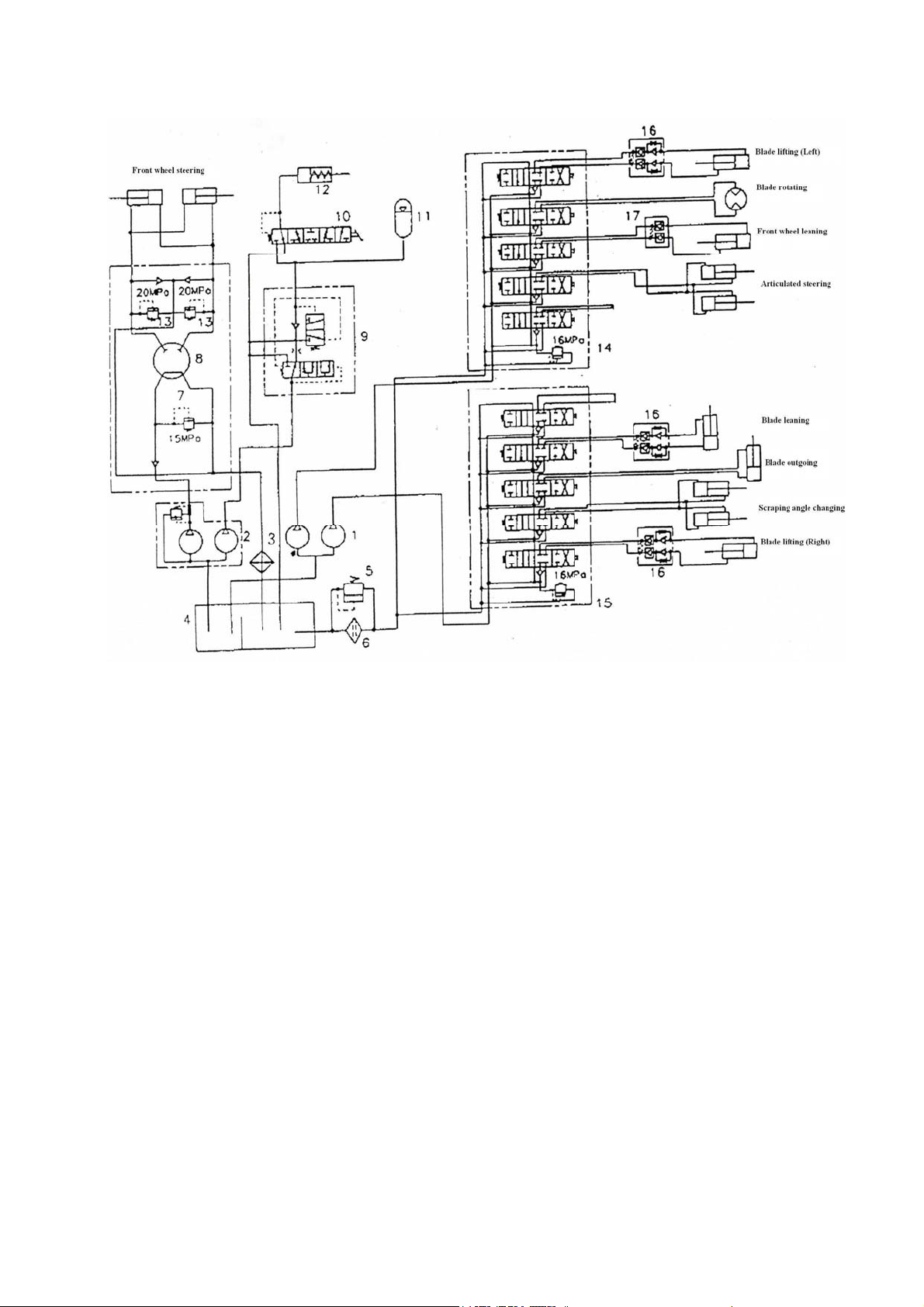

6.1.4 Hydraulic operating system and hydraulic steering system

a. Hydraulic operating system

This hydraulic operating system is composed of double pumps and double circuits

(Fig.9). It is made up of closed oil tank (4), a two-gang gear pump (1), two five-gang

multi-way reversing valves (Refer to 14, 15), hydraulic cylinders for operating

apparatuses, motor and hydraulic lines. Each system has its own hydraulic pump, but

the hydraulic oil is supplied from the same oil tank (4). The hydraulic oil from oil

tank (4) is pumped by a two-gang pump (1) into two circuits. Among them, oil flows

are equal. When multi-way reversing valves (14, 15) are in central position, the

hydraulic oil, passing through returning lines and the filter (6), returns to oil tank (4).

When moving one or two operating levers, hydraulic oil pushes one-way valve in

reversing valve to flow into hydraulic cylinders and motor. The action of one-way

valve prevents the oil in working apparatus from return oil tank (4).

It can insure that hydraulic system in correct working condition. The double

direction hydraulic lock (16) mounted on the returning lines for titling and lifting the

blade can guard against moving due to their own weight and the load to insure safety

running and operating accuracy of the blade.

Because of the supplying oil in the equal flow, double lift cylinders for up and

down operation in the simultaneous and same speed to raise operating performance of

the grader. System pressure is controlled by the throttle valve in reversing valve (14,

15) .The pressure value is16Mpa and system flow: 65L/min.

b. Steering system

When the hydraulic steering-gear (8) needs the oil, the oil from the oil tank (4) is

intaken by the steering pump and delivered. When turning the steering wheel, the oil

enters into two steering cylinders to make double front wheels steering. Double front

wheels are connected by a common pulling lever.

With safety valve (7), the oil pressure of steering system is limited in 150 bars to

guard steering system. Double safety valves (13) prevent hydraulic steering system

from over pressure. For example, because of the overload caused by road dump, it can

be transmitted from front wheels to steering system.

The oil tank (4) is equipped with pre-pressure air filter that can prevent the air

with dusts from entering into the oil tank and contaminate the hydraulic system.

If the return filter (6) is blocked and the oil cannot flow, the filter valve (5) allows

the oil over the filter from by pass-way and therefore it eliminates the block action of

the filter element. The micro- measuring coupler in the system allows gauge to be

fitted at various positions in the system to adjust the pressure.

10

Fig. 9 Service brake, hydraulic operating and steering systems

1. Double-gang operating pump

2. Double-gang operating pump for

steering and braking

3. Return oil cooler

4. Sealed type oil tank

5. Filter valve

6. Return oil filter

7. Steering safety valve

8. Hydraulic steering gear

9. Pressure limiting valve

10. Braking valve

11. Accumulator

12. Brake

13. Safety valve (20Mpa)

14. Operating valve, left

15. Operating valve, right

16. Bidirectional hydraulic lock

17. Hydraulic lock

11

A3 电气接线图

12

Fig.10 Electrical system

1 右转向示宽灯 Right-turn View-side lamp

2 右作业灯 Right working light

3 电喇叭 Electric horn

4 右前转向灯 Right-front turning lamp

5 右前照灯 Right head light

6 左照灯 Left light

7 左前转向灯 Left-front-turning lamp

8 左前作业灯 Left-front working light

9 左转向示宽灯 left-turn View-side lamp

10 插接器 Connector

11 插接器 Connector

12 插接器 Connector

13 插接器 Connector

14 插接器 Connector

15 插接器 Connector

16 插接器 Connector

17 插接器 Connector

18 插接器 Connector

19 插接器 Connector

20 插接器 Connector

21 插接器 Connector

22 插接器 Connector

23 插接器 Connector

24 插接器 Connector

25 制动压力开关 Brake pressure switch

26 电源开关 Power switch

27 起动机 Starter

28 插座 Socket

29 制动灯开关 Brake light switch

30 发电机 Alternator

31 回油滤油器 Oil filter for oil return

32 吸油滤油器 Oil filter for oil intaking

33 左组合后灯 Left combined tail lamp

34 测试插头 Test plug

35 变矩油温传感器 Torque-changing oil temperature sensor

36 水温传感器 water temperature sensor

37 变速油压传感器 Speed changing oil pressure sensor

38 机油压力传感器 Engine oil pressure sensor

39 油门踏板 Accelerator pedal

40 燃油传感器 Fuel oil sensor

41 插接器十六 Connector 16

13

42 变速箱 Transmission case

43 插接器七 Connector 7

44 倒车蜂鸣器 Astern running buzzer

45 右组合后灯 Right combined tail lamp

46 蓄电池 Battery

47 后照灯 Back lamp

48 收音机 Radio set

49 后刮水器 Rear wiper

50 前刮水器 Front wiper

51 顶灯 Overhead light

52 起动开关 Starting switch

53 后刮水器开关 Switch for rear wiper

54 闪光器 Flasher

55 电压表 Voltmeter

56 燃油表 Fuel gauge

57 起动继电器 1 Starting relay 1

58 倒车继电器 Astern running relay

59 起动继电器 2 Starting relay 2

60 报警灯 Alarm lamp

61 保养灯 Maintenance lamp

62 燃油含水灯 Fuel oil containing water indicating lamp

63 等候灯 Waiting lamp

64 停止灯 Stopping lamp

65 充电继电器 Charging relay

66 作业灯开关 Working light switch

67 后照灯开关 Light switch for rear lighting

68 顶灯开关 Overhead light switch

69 仪表示宽灯开关 Instrument view-side switch

70 熔断器 Fuse

71 中速控制开关 1 Intermediate speed control switch 1

72 中速确认开关 Intermediate speed conform switch

73 中速调整开关(双向自动复位) Intermediate speed adjust switch (Both-way auto

reset)

74 中速控制开关 2 Intermediate speed control switch 2

75 诊断开关 Diagnosis switch

76 怠慢/诊断开关(双向自动复位) Delay switch/ Diagnosis switch (Both-way auto

reset)

77 电子监控器 Electronic monitor

78 插接器十五 Connector 15

79 插接器二十 Connector 20

80 组合开关 Combined switch

黄-Yellow 蓝-Blue 绿-Green 白-White 黑-Black 棕-Brown 红-Red

空挡倒车 : Reverse through neutral position

14

插接器插头编号,从接线侧看:

(二线,四线,六线,八线, 九线,十线,十二线方法相同):

Viewed from connection side,number of connector plug

( The methods of lines 2, 4,6, 8, 9,10 and 12 are identical)

插接器插座编号,从接线侧看 :

(二线,四线,六线,八线,九线,十线,十二线方法相同)

Viewed from connection side,number of connector plug:

(The methods of lines 2,4,6, 8, 9,10 and 12 are identical )

技术要求:Technical requirements

凡图纸中未标注截面的面积为 1mm2:

The area of section is 1mm2 if not marked in figure.

Jk 406 起动开关挡位图:Jk 406 Gear figure of starting switch

Conecta

velocidad

III X X X

0 X

I X X X

II X X X X

B BR

10A

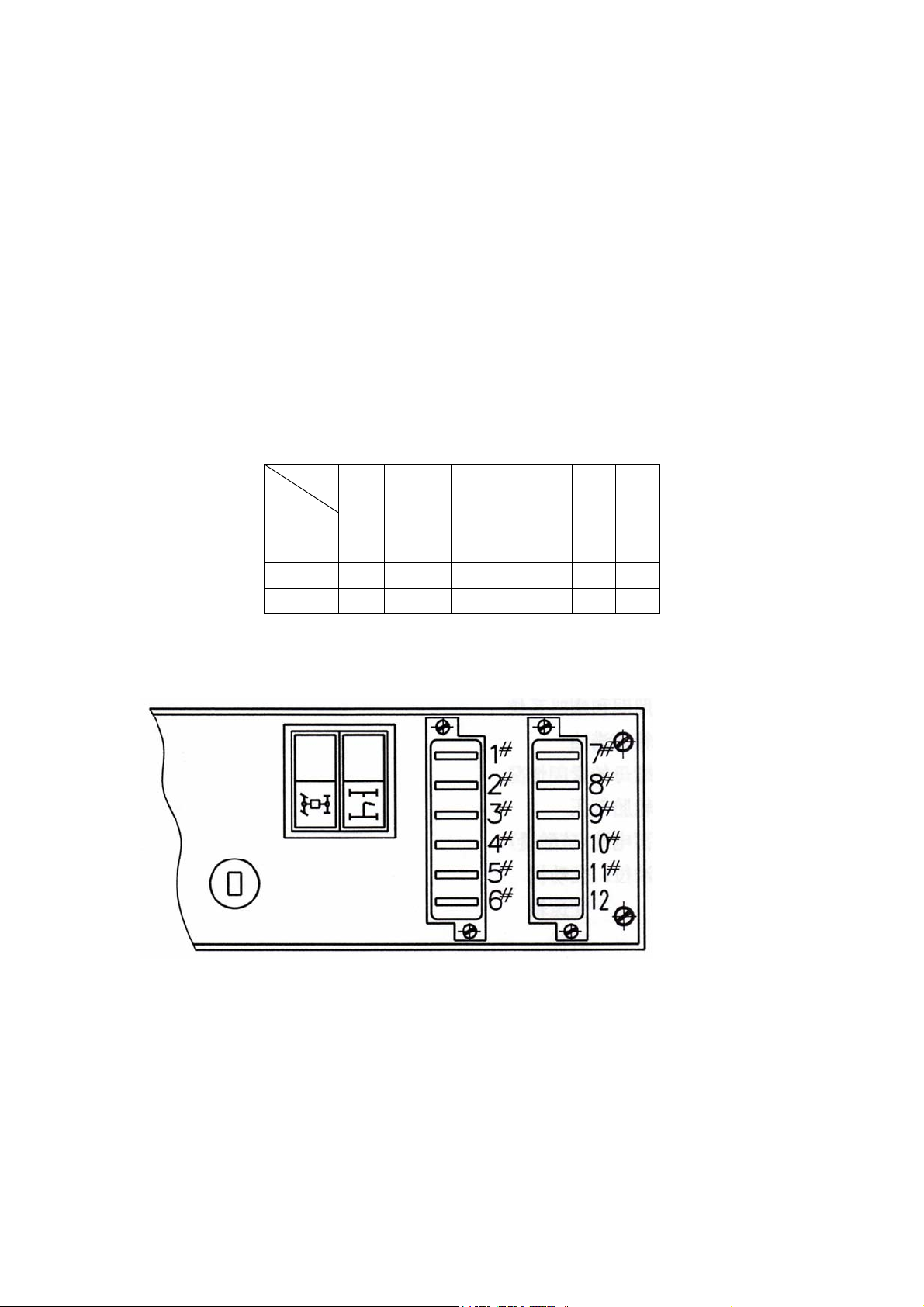

6.1.5 Electrical devices

A. Electrical connection diagram (Fig. 10)

B. Fuse description

ACC

10A

C

20A

R1

50A

R2

50A

1# 10A Oil cut off valve

2# 10A Starting relay

3# 10A Instrument

4# 10A Front and rear wipers,

overhead light

5# 15A Rear working light

6# 15A Front working light

7# 5A Charging relay

15

8# 10A Transmission

9# 20A Steering lamp, brake

light, pilot light and plug

10# 15A Head light

11# 20A Electric horn, magnetic

valve of front axle driving

12# 25A Air conditioning system

7. Operation instruction

7.1 Adjust before operating for the first time

Before unloading the grader, must check whether the machine has been damaged

during transportation. If find out damage, shall contact with the transport company or

commercial agent. The extent of damage or stolen extent shall be recorded on the

freight bill. Contact with the saler and report damage condition to them.They will help

you to repair the machine necessarily and handle your claim against Transport

Company.

The following inspection shall be conducted and the check result shall be

recorded:

a) Lighting and horn systems;

b) The oil levels of oil tank, engine, rear axle, rear balancing tank, rotating

impeller box of blade are in accordance with requirement;

c) Fastening condition of nuts;

d) Whether the tyre pressure is in accordance with regulations and requirement;

e) Whether the battery (sulfuric acid level) has been charged fully;

f) Check liquid levels: Engine

Transmission

Rear axle

Tandem box

Blade rotating turbine box

Hydraulic oil tank

After starting the engine: The working brake pressure signal lamp cannot light,

check the function of the brake and steering systems.

After the machine has worked for more than one week: all grease nipples should

be greased according to the lubrication chart and grease shall be filled.

Antifreezing: Antifreezing diesel oil shall be used if necessary.

7.2 Running-in time

It is recommended that all moving elements of the grader shall be run in, during

this period the grader shall not run under full load.

The grader shall not use full power during the first 50h operating time.

Full power can be used within 50h~100h, while the use time cannot be too long.

7.3 Diagrammatic representation of control instrument and operating lever of

complete machine

16

1. Control lever for lifting left blade

2. Control lever for rotating blade

3. Control lever for front wheel lean

4. Control lever for articulated steering

5. Control lever rear scarifier

6. Engine oil pressure gauge

7. Gear change oil pressure gauge

8. Four-gang indicator lamp

9. Comprehensive switch

10. Torque converting oil temperature

gauge

11. Water temperature gauge

12. Control lever for front bulldozing

plate

13. Control lever for front wheel lean

14. Blade outgoing control lever

15. Control lever for blade to scrape

Fig. 11

16. Control lever for lifting right blade

17. pedal of assistant vehicle ladder

18. Control device for hand brake

19. Main power switch

20. Scarifier indicator

21. Brake pedal

22. Accelerator pedal

23. Six-gang switch

24. Control lever for transmission

25. Hand accelerator lever

26. Flameout button

27. Fuel gauge

28. Starting switch

29. Timer

30. Ammeter

31. Lifting lever

17

7.3.1 Switches

1) Mains power switches

Push the handle (Fig. 11/19) of power switch downwards the mains power will

be switched on.

2) Starting switch (See Fig.11/28)

If turn the starting switch by gear clockwise, all power supplies of instruments Ⅰ

will be turned on and turn by gear the engine will be started. If turn back to gear Ⅱ 0

counterclockwise, the engine will be shut down.

7.3.2 Instruments

1) Oil temperature gauge at torque converter outlet (Fig.11 /10)

Measuring range: 40 ~ 140 . Under the normal condition, the temperature shall ℃

be ranged from 80 ~ 110 .Allow instant ℃ rise in temperature, the maximum

temperature is up to 120 .℃

Ammeter (Fig. 11/30)

2)

Measuring range: -40A~ +40A. If pointer points to direction “-”, which means

the battery is discharging; If pointer points to direction “+”, which means the battery

is charging.

3) Water temperature gauge (Fig. 11/11)

Measuring range: 50 ~ 115 . Indicates the cooling ℃ water temperature of engine.

Under normal condition, the water temperature shall be below 90 .℃

4) Timer (Fig. 11/29)

Accumulated range: 0~9999.9h. Accumulated operating time of engine.

5) Transmission control pressure gauge (Fig. 11/7)

Measuring range: 0~2.5MPa. When the oil temperature of transmission is 80~

90 , the variation range of oil pressure of transmission: 1.3~1.5 MPa.℃

The pointer shall always points to above range, if the point is out of this range,

the engine shall be shut down to check and repair faults.

6) Fuel gauge (Fig.11/27)

Measuring range: 0~1. Indicate the oil level in diesel oil tank. Do not start the

machine if there is no oil in oil tank; otherwise, the oil pipe will be blocked and air

enters into this system.

7) Engine oil pressure gauge (Fig.11/6)

Measuring range: 0~1Mpa. The minimum pressure shall not be lower than

0.2Mpa.

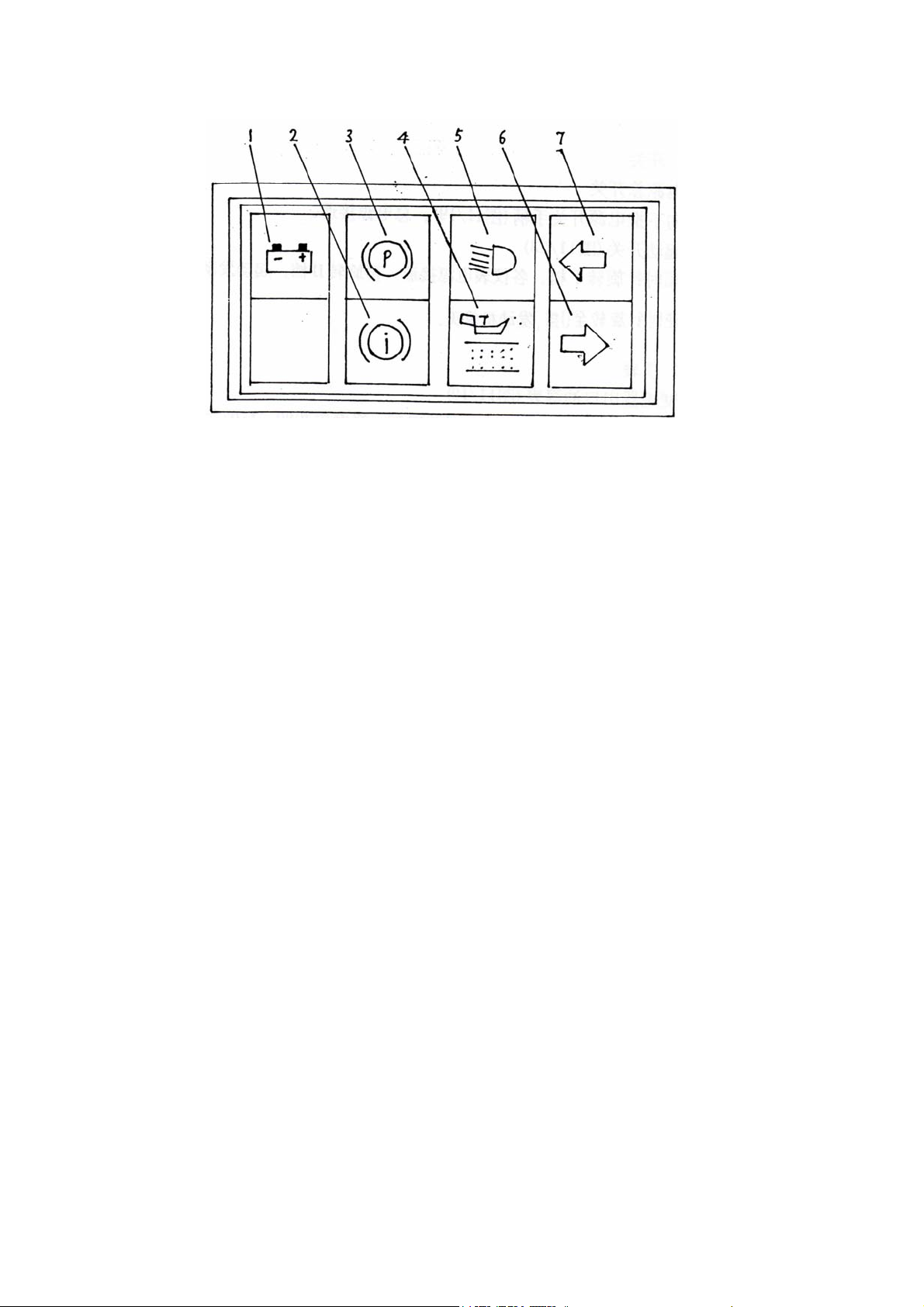

7.3.3 Four-gang indicator lamp (Fig. 12)

18

Fig. 12

1) Charge indicator lamp, red (Fig.12/1)

The indicator lamp lights when the engine is running, which means that the

charging line or alternator is at fault or the belt is loosened. The barratry is not

charged, stop the engine and carry on troubleshoot.

2)Indicator lamp for brake service pressure, red (Fig.12/2)

The indicator lamp lights when the engine is running; which means there are

some troubles in the brake system. Stop the grader and engine immediately and carry

out troubleshooting.

3) Indicator lamp for brake, red (Fig.12/11)

The indicator lamp lights in case of service brake.

4) Indicator lamp for hydraulic oil filter, red (Fig.12/4)

The indicator lamp lights when the engine is running; which means that the oil

filters are blocked. Clean or replace the filter element.

5) Indicator lamp for far light, blue (Fig.12/5)

The indicator lamp lights when the front light is switched to far light.

6) Indicator lamp for right turning, green (Fig.12/6)

The indicator lamp lights when steering switch is switched to right turning.

7) Indicator lamp for left turning, green (Fig.12/7)

The indicator lamp is on when the steering switch is switched to left turning.

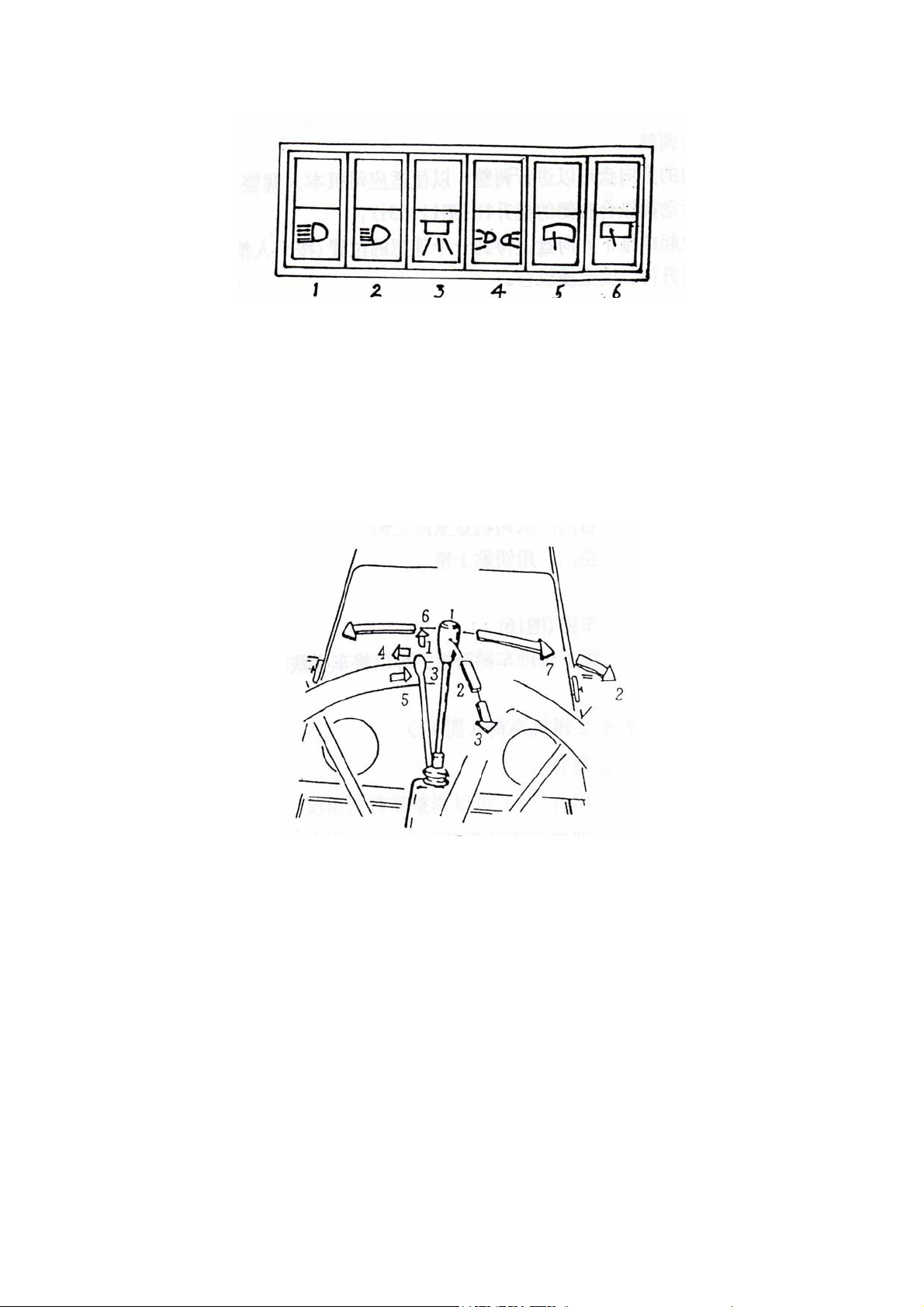

7.3.4 Six-gang switch (Fig. 13)

19

Fig. 13

1. Switch for working light 2. Switch for rear light

3. Overhead light switch in Driver’s cab 4. Switch for pilot light

5. Wiper switch for front window 6. Wiper switch for rear window

7.3.5 Comprehensive switch (Fig. 14)

Fig. 14

Control lever position:

1= Switch off

2= Big head of head lamp

3= Switch off

4= Left turning

5= Right turning

6= Horn

7= Small head of head lamp

7.3.6 Accelerating pedal (Fig. 11/21)

This pedal can be used to control the engine speed.

7.3.7 Brake pedal (Fig. 1 1/22 )

20

Loading...

Loading...