Dings Dynamics Group 60 Series End Mount NEMA 4X User Manual

60 Series End-Mount

Brake Instructions

NEMA 4 & NEMA 4X Enclosure

Bulletin No. BK4660 (8/07)

DESCRIPTION

These magnetic disc brakes are direct acting, electromagnetically released

and spring set. They use rotating friction and stationary disc contact to

supply positive brakeing action. They mount directly onto NEMA 56C,

143TC, and 145TC frame motors, on the end opposite the drive shaft.

Models 6-60000-543 and 6-60000-5115 are mounted directly to a motor

where a gasket between the brake and motor face prevents liquid media

from enering the brake.

Models 4-60000-530 and 6-60000-5116 are for TEFC motors or foot

mounting applications; brake design with hub seal prevents liquid media

from entering the brake through opeings in the motor fan cover or foot

mounting bracket.

Models 6-60000-543 and 4-60000-530 are standard end-mount series

NEMA 4 Enclosure.

Models 6-60000-5116 and 6-60000-5115 are washdown NEMA 4X endmount series (BISSC Std. #29).

WARNING: Do not install or use these brakes in

an explosive atmosphere.

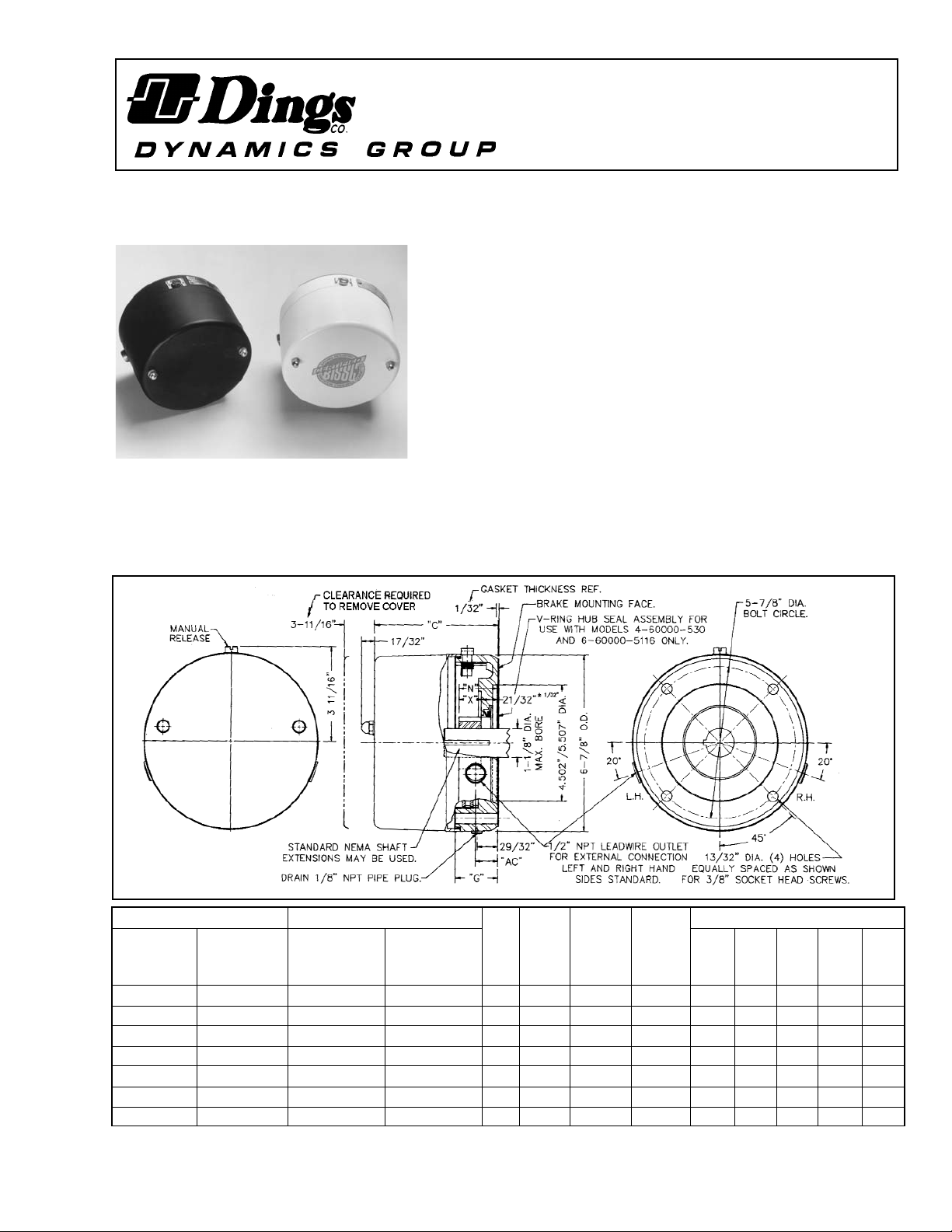

Figure 1

4740 W. Electric Avenue Milwaukee, WI 53219 414/672-7830 FAX 414/672-5354 www. dingsco.com

Read carefully before attempting to assemble, install, operate or maintain the product described. Protect yourself

and others by observing all safety information. Failure to comply with instructions could result in personal injury

and/or property damage! Retain instructions for future reference.

*Thermal capacity (HPS/MIN.) was determined under the following test conditions: a) Room temperature 72oF. b) Stopping time of one second or less.

c) Brake mounted in a horizontal position. d) Equal on and off times. e) 1800 RPM f) Coil energized with 110% of rated voltage.

**G Length of mounting hole through bracket

NEMA 4

NEMA 4X

NEMA 4 NEMA 4X

No.

of

Discs

Torque

Lb.Ft.

Thermal

Capacity

HPS/MIN*

Inertia of

Rotating

Parts

Lb.Ft.

2

Dimensions

Standard with hub seal Standard with hub seal C AC G** X N

6-61001-543 4-61001-530 6-61001-5115 6-61001-5116 1 1.5 6 .006 4.812 .937 1.625 .875 1.531

6-61003-543 4-61003-530 6-61003-5115 6-61003-5116 1 3 6 .006 4.812 .937 1.625 .875 1.531

6-62006-543 4-62006-530 6-62006-5115 6-62006-5116 2 6 6 .011 4.812 .937 1.625 .875 1.531

6-62010-543 4-62010-530 6-62010-5115 6-62010-5116 2 10 6 .011 4.812 .937 1.625 .875 1.531

6-63015-543 4-63015-530 6-63015-5115 6-63015-5116 3 15 6 .017 5.125 1.250 1.937 1.187 1.844

6-63020-543 4-63020-530 6-63020-5115 6-63020-5116 3 20 6 .017 5.125 1.250 1.937 1.187 1.844

6-64025-543 4-64025-530 6-64025-5115 6-64025-5116 4 25 6 .022 5.437 1.562 2.250 1.343 2.000

WARNING:

Brake performance and features must be carefully

matched to the requirements of the application.

Consideration must be given to torque requirements,

especially where an overhauling condition exists, as well

as thermal capacity, ambient temperature,

atmospheric explosion hazards, type of enclosure and

any other unusual conditions.

Improper selection and installation of a brake and/or lack

of maintenance may cause brake failure which could

result in damage to property and/or injury to

personnel.

If injury to personnel could be caused by brake failure,

additional means must be provided to insure safety of

personnel.

UNPACKING

When unpacking the brake, inspect it carefully for damage

that may have occurred during transit.

GENERAL SAFETY INFORMATION

NOTE: These brakes are not intended for accurate

positioning applications. They are designed for applications

that require rapid stopping and holding power, such as on

conveyors, door openers, etc.

1. For applications with high inertia-type loads or rapid

cycling, the thermal capacity of the brake must be

considered.

2. Observe all local electrical and safety codes, as well

as the National Electrical Code (NEC) and the

Occupational Safety and Health Act (OSHA).

3. Brake motors and brake gearmotors must be

securely and adequately grounded. This can be

accomplished by wiring with a grounded metal-clad

raceway system, by using a separate ground wire

connected to the bare metal of the motor frame, or

other suitable means. Refer to NEC Article 250

(Grounding) for additional information. All wiring

should be done by a qualified electrician.

4. Always disconnect power before working on or near

a brake motor, a brake gearmotor, or its connected

load. If the power disconnect point is out of sight,

lock it in the open position and tag it to prevent

unexpected application of power.

5. When working on the brake, be sure the load is

completely removed, secured or blocked to prevent

injury or property damage.

6. Provide guarding for all moving parts.

7. Be careful when touching the exterior of an operating

motor, gearmotor or brake. It may be hot enough

to cause injury or to be painful. This condition is

normal for modern motors, which operate at higher

temperatures when running at rated load and

voltage.

8. Protect all electrical lead wires and power cables

against contact with sharp objects or moving parts.

9. Do not kink electrical lead wires and power cables,

and never allow them to touch oil, grease, hot

surfaces, or chemicals.

2

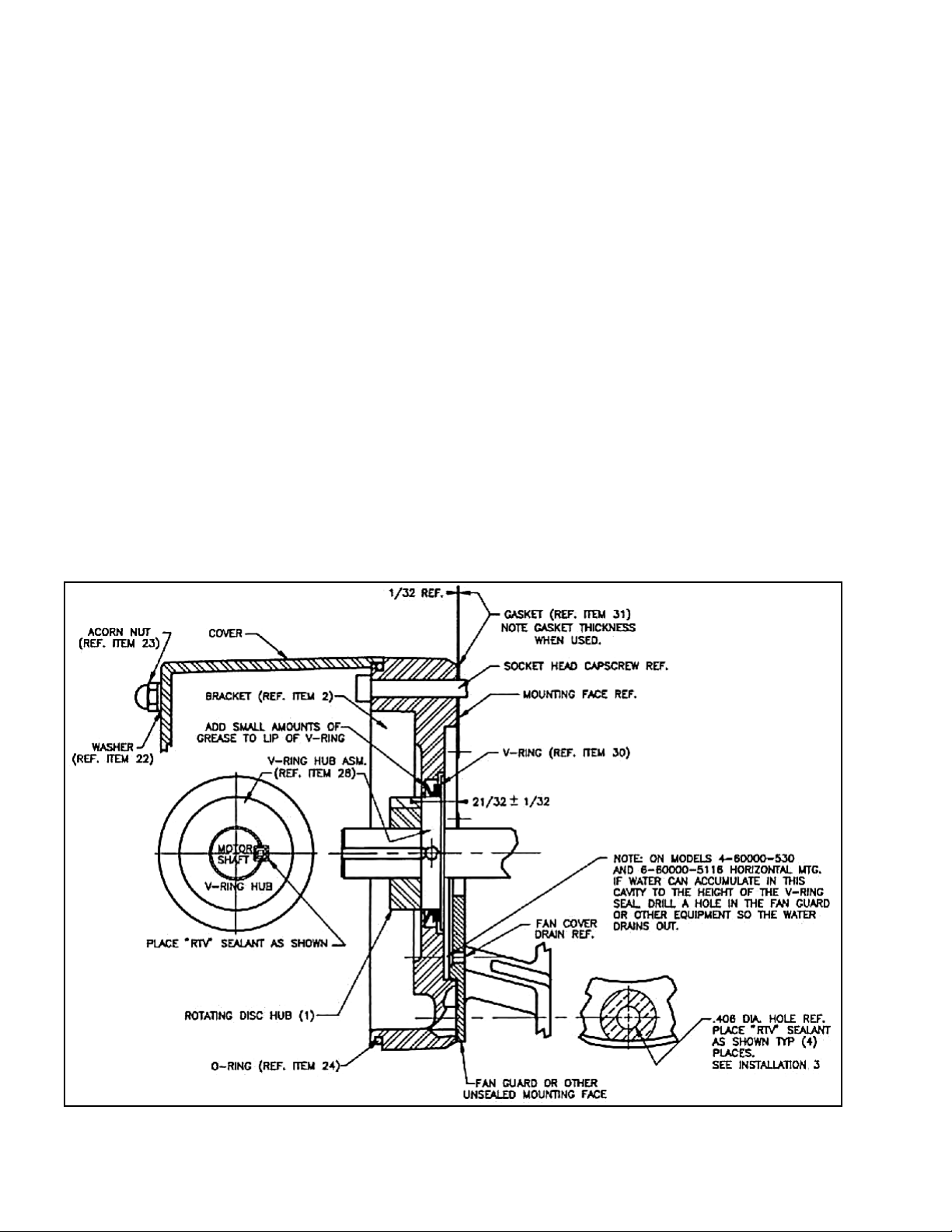

Figure 2

3

INSTALLATION

CAUTION: To preserve pre-alignment of rotating discs for

ease of installation, do not operate manual release or

energize brake coil before installation.

NOTE: The brakes are designed for horizontal mounting.

Modification is required for vertical mounting. Brakes that are

modified will have a prefix on the model number of VO

(Vertical Over) or VU (Vertical Under).

Numbers in parentheses refer to parts illustrated in Figs. 2, 4

and 10.

Mounting Hub on Motor Shaft

For models 6-60000-543 and 6-60000-5115:

1. Place rotating disc hub (1), with key, onto motor shaft

with part number facing away from motor to dimension shown in Fig. 2 (

21

/32 ± 1/32). Measure from brake

mounting face as shown.

For models 6-60000-530 and 6-60000-5116:

1. Remove V-ring (30) from V-ring hub assembly (28).

2. Place V-ring hub assembly (28) onto motor shaft with

part number facing away from motor to dimension

shown in Fig. 2 (

21

/32 ± 1/32).

NOTE: If motor shaft keyway extends into V-ring area,

install a key long enough to engage V-ring hub assembly

(28) and rotating disc hub (1). See Step 3 before tighten

ing setscrews. Tighten both setscrews to 35 lb. in. torque.

3. Place RTV sealant as shown (small amount to fill

crevices between V-ring hub assembly (.040” x 45°

chamfer), motor shaft, hub keyway and motor shaft

keyway. Use Dow Corning #739 RTV only; other

types may form acetic acid during curing if subjected

to water or high humidity. This will cause premature

failure of zinc plated parts.

CAUTION: If this proecedure is bypassed, liquid

media may seep into the brakes.

4. Replace V-ring (30) onto V-ring hub assembly as

shown in Fig. 2. Apply a small amount of grease to lip

of V-ring.

5. Place rotating disc hub (1) with key if not already in

place, onto motor shaft with part number facing away

from motor to dimension shown in Fig. 2 (

21

/

32 ±

1

/

32).

Rotating disc hub will butt against the V-ring hub as

shown.

6. Tighten both setscrews to 6 - 8 lb.ft. torque.

Placing Brake on Motor Shaft

1. Remove acorn nuts (23), washers (22), and cover (20).

Place brake on motor mounting face aligning hub

splines into brake disc splines. Make sure gasket (31)

is in place. Drain plug (25) to face down on horizontal

models.

NOTE: for models 4-60000-530 and 6-60000-5116 only: If

gasket (31) does not make contact around mounting face

totally (360°), exclude gasket (31) and place RTV sealant

around mounting bolt holes to approximately 1” dia. as

shown in Fig. 2. Use Dow Corning #739 RTV only; other

types may form acetic acid during curing if subjected to

water or high humidity. This will cause premature failure of

zinc plated parts.

If tapped holes in motor for mounting bolts are not totally

enclosed, place RTV sealant around threads before bolting

brake to motor. Use Dow Corning #739 RTV ony; other types

may form acetic acid during curing if subjeted to water or high

humidity. This will cause premature failure of zinc plated parts.

You may have to add drain in fan guard or other equipment as

shown in Fig. 2.

2. Tighten mounting bolts to 25 lb. ft. torque

3. Connect coil leads as outlined under “Connection of Coil

Leads” and Fig. 3.

4. Let RTV #739 cure 24 hours before replacing cover.

5. Replace cover (20) and fasten with three acorn nuts (23)

and washers (22). Tighten nuts to 5 lb. ft. torque.

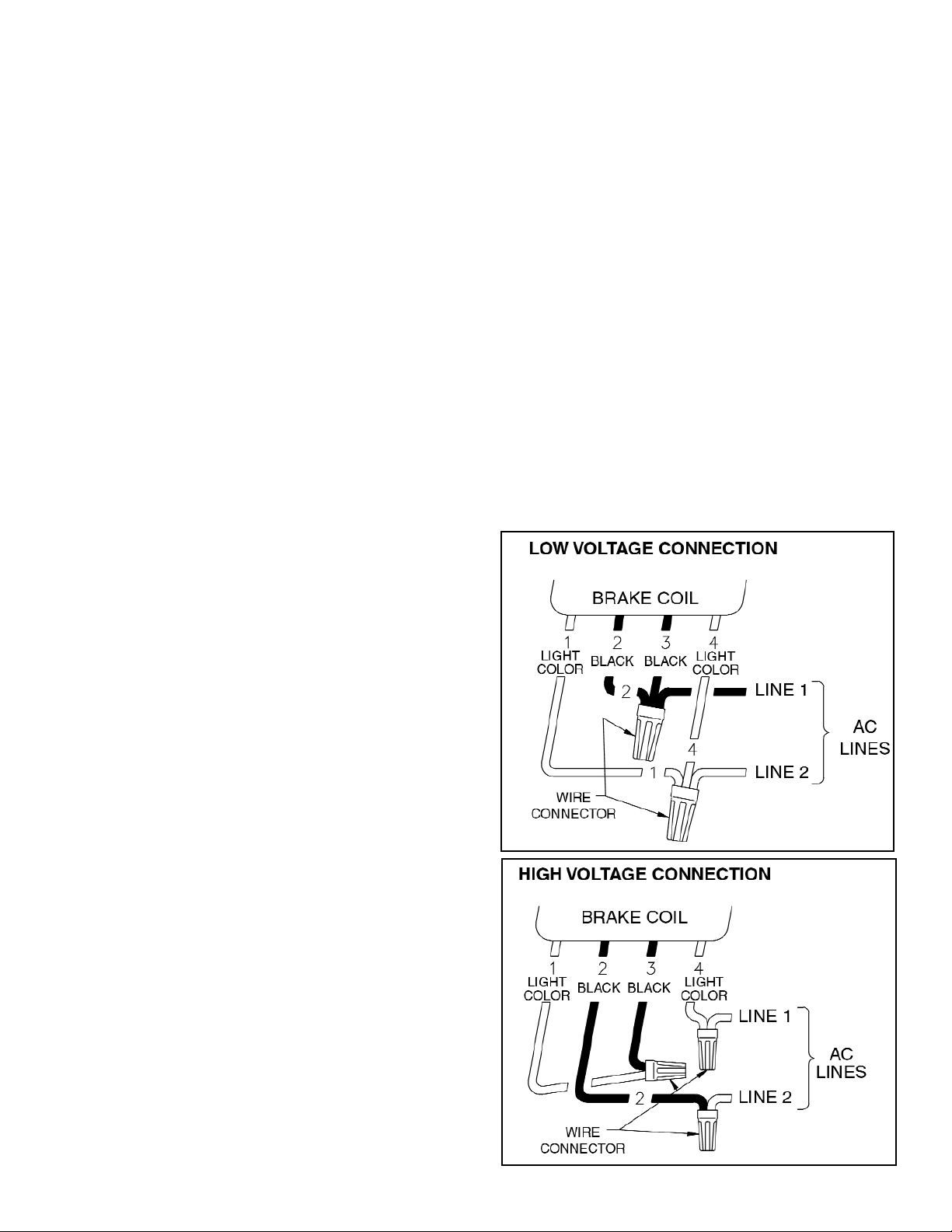

Connection of Coil Leads

After securing the brake to the motor, connect coil leads for

proper voltage per wiring diagram (Fig. 3 shows dual voltage

coil). Incorrect connection can result in brake failure.

CAUTION: The voltage supplied to the coil must match the

voltage that the coils are connected for, or the coils will

burn out.

Single voltage coil: Connect brake coil leads to any two line

leads (single or three phase) of same voltage and frequency

as brake.

Dual voltage coil: Connect leads 2 and 4 to any two motor line

leads (single or three phase) of same voltage as brake.

Connect leads 1 and 3 as shown for voltage desired. Brake

must be energized with motor.

Figure 3

Wiring Diagrams

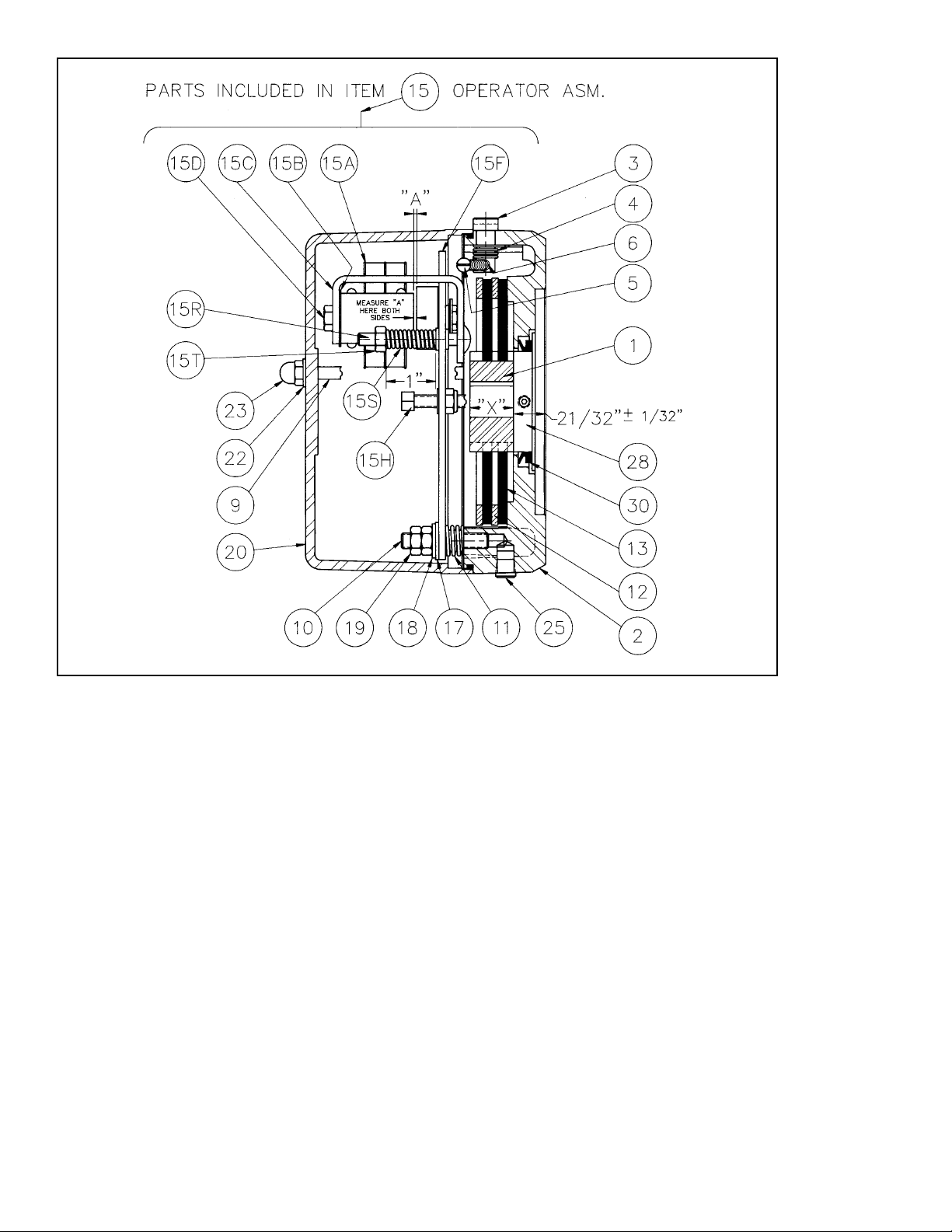

Figure 4

4

OPERATION

These brakes are spring set devices with an electrical

(magnet) release. They contain a rotating friction disc

which is driven by a hub mounted on the motor shaft. When

energized, the magnet compresses the torque springs,

removing the force pressing the stationary disc and friction

disc together. This permits free rotation of the shaft.

WARNING: Observe proper safety precautions in

applications where a brake failure would allow the load

to move in such a manner as to injure personnel. KEEP

PERSONNEL AWAY FROM LOAD AREAS.

If brake torque rating is higher than motor full-load torque

rating, use brake rating rather than motor rating when

selecting other drive components.

Take the following precautions when operating the brake:

1. Do not operate the brake at higher than normal static

torque capacity.

2. For applications with high inertia-type loads or rapid

cycling, the thermal capacity of the brake must be

considered.

3. High start-stop rates may damage motor. Consult

motor manufacturer if high cycling rates are

expected.

4. Be sure power supply conforms to electrical rating of

brake.

Manual Release

The brake is equipped with a manual release. Turn the

release knob (3) clockwise to stop position to release the

brake. The brake will remain released until the release knob

is turned counterclockwise (approx. 65

o

) or until the brake

coil is energized, automatically resetting the brake.

Loading...

Loading...