1

2

DINGO TOOLS TREMOR

CONTENTS OF BOOKLET

Warnings Check List Page 3

What Is In Your Box/Assembly Page 4

Mixing Fuel Page 5

Operation Page 6

Starting Sequence Page 7

Warm Engine Start/Maintenance and Storage Page 8

Air Filter Page 9

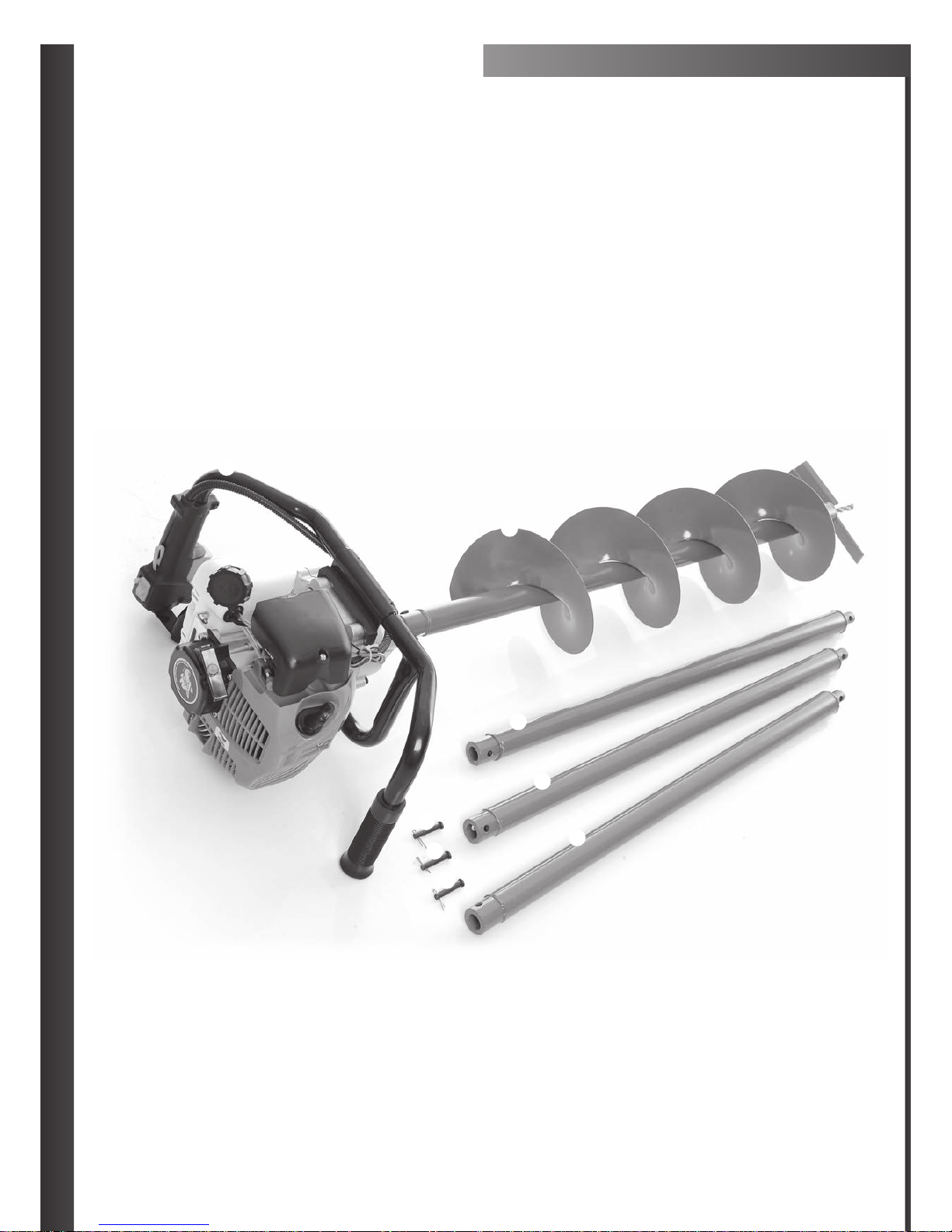

NOTE:

Extension Length May Vary Depending On Advertised Offer.

3

PLEASE READ SAFETY INSTRUCTIONS

» Carefully follow assembly instructions

» Maintain the auger according to directions and

schedule included in this Earthquake’s manual.

» Ensure that anyone who uses the Auger is familiar

with all controls and safety precautions.

BURNS AND FIRES

The muffl er, muffl er guard and other parts of the engine

become extremely hot during the operation of the engine.

These parts remain extremely hot after the engine

has stopped.

PREVENTION OF BURNS AND FIRES

Never remove the muffl er guard from the engine.

Never touch the muffl er guard because it is extremely hot

and will cause severe burns.

Never touch parts of the engine that become hot after

operation.

Always keep materials and debris away from the muffl er

guard and other hot parts of the engine to avoid fi res.

15m (50ft)

WARNING! PLEASE READ BELOW VERY IMPORTANT

*DO NOT CARRY THE AUGER POWERHEAD BETWEEN HOLES WITH

THE ENGINE RUNNING.

*THE AUGER SHOULD NOT ROTATE WHEN THE ENGINE IS IDLING.

IF IT DOES ROTATE WHEN ENGINE IS IDLING, CONTACT DEALER FOR

INSTRUCTIONS.

*ALWAYS KEEP HANDS, FEET, HAIR AND LOOSE CLOTHING AWAY

FROM ANY MOVING PARTS ON ENGINE AND AUGER.

*DO NOT ALLOW CHILDREN TO OPERATE THIS POWER AUGER. DO

NOT ALLOW ADULTS TO OPERATE THE AUGER WITHOUT PROPER

INSTRUCTION.

*DO NOT OPERATE ANY POWER EQUIPMENT UNDER THE INFLUENCE

OF ALCOHOL OR DRUGS.

*KEEP ALL SCREWS, NUTS AND BOLTS TIGHT.

*ENGINE SHOULD BE TURNED OFF AND COOL, SPARK PLUG WIRE

MUST BE REMOVED FROM SPARK PLUG BEFORE ANY REPAIRS ARE

ATTEMPTED.

*TEMPERATURE OF MUFFLER AND NEARBY AREAS MAY EXCEED 150

DEGREES. AVOID THESE AREAS.

*NEVER RUN ENGINE INDOORS OR IN AN ENCLOSED AREA. ENGINE

EXHAUST CONTAINS CARBON MONOXIDE, AN ODORLESS AND

DEADLY GAS.

*IF THE EARTH AUGER WILL NOT TURN IN A HOLE, TURN ENGINE

OFF AND ALLOW TO COOL BEFORE ATTEMPTING TO REMOVE IT

MANUALLY.

NEVER RUN ENGINE INDOORS

NEVER TRY TO VENTILATE ENGINE ENGINE EXHAUST INDOORS.

CARBON MONOXIDE CAN REACH DANGEROUS LEVELS VERY QUICKLY.

NEVER USE FUEL WHERE A SPARK OR FLAME MAY BE PRESENT.

NEVER USE FUEL WHERE A POTENTIAL SOURCE OF IGNITION COULD

OCCUR E.G HOT WATER OR SPACE HEATERS, CLOTHES DRYERS,

ELECTRIC MOTORS ETC.

KEEP FLAMES AND SPARKS AWAY FROM ENGINE AND FUEL TO

PREVENT FIRE. FUEL FIRES SPREAD VERY QUICKLY AND ARE HIGHLY

EXPLOSIVE.

NEVER REMOVE FUEL CAP OR ADD FUEL WITH THE ENGINE RUNNING.

STOP ENGINE AND ALLOW TO COOL BEFORE FILLING.

NEVER DRAIN FUEL FROM ENGINE IN AN ENCLOSED AREA.

ALWAYS WIPE UP EXCESS ΈSPILLEDΉ FUEL FROM ENGINE BEFORE

STARTING. CLEAN UP SPILLED FUEL IMMEDIATELY.

ALLOW SPILLED FUEL TO DRY, AFTER WIPING

AND BEFORE STARTING.KE WHILE REFUELING ENGINE FUEL TANK.

4

WHAT IS IN YOUR BOX.

STANDARD COMPONENTS

A. Bolts and drop pins

B. Augers 200mm

C. Motor

D1. Extension arms 800mm

D2. Extension arms 800mm

D3. Extension arms 800mm

A

A

A

B

C

D1

D2

D3

5

HOW TO MIX YOUR FUEL

Common mixtures are 25:1/30:1. If you fi nd your machine is

too smoky please use the higher ratio which is 30:1 as seen in

diagram C.

WHAT IS 25:1/30:1?

The fi rst part of the formula refers to how many parts of fuel

as seen in diagram A. The second part of the formula refers to

how many parts of oil (diagram B or C). For example, 25 parts

of unleaded fuel or low octane to 1 part of two stroke oil or 30

parts of unleaded or low octane fuel to 1 part of two stroke oil.

REMEMBER TO MIX WELL (SHAKE BOTTLE)

ONLY USE THIS RECOMMENDED 2 STROKE FUEL MIX WITH A GOOD QUALITY 2 STROKE OIL FROM YOUR LOCAL SUPPLIER, USING A MIX

RATIO OF 25:1/30:1 IN THE M ACHINE. UNLEADED OR LOW OCTANE FUEL ANY OTHER FUEL MUST BE USED IN A TWO STROKE MIX. MIX WELL

AS RECOMMENDED. INCORRECT MIX COULD DAMAGE YOUR ENGINE VOIDING YOUR WARRANTY, USE THIS FUEL MIX EVERY TIME YOUR

MACHINE IS IN OPERATION FOR THE BEST DINGO TOOLS PERFORMANCE YOU CAN EXPECT OUT OF YOUR DINGO TOOLS MACHINE.

1

:

25

OIL

600

576.92

500

400

300

200

100

GASOLINE

FULL

1

:

25

OIL

600

576.92

30:1

C

1

:

25

OIL

600

576.92

25:1

B

A

L

6.6.6.

92

AT ALL TIMES PLEASE KEEP THE FUEL TANK FULL WHEN IN OPERATION,

“AVOID HAVING THE YOUR ENGINE FINISHING OPERATION FROM FUEL

STARVATION. FUEL TANKS BEING KEPT FULL AT ALL TIMES WILL IMPROVE

YOUR MACHINE PERFORMANCE.

FUEL RUNNING OUT WHILE IN OPERATION MAY DAMAGE YOUR ENGINE,

PLEASE BE SURE TO REFILL THE TANK, KEEPING THE FUEL WELL FILLED

DURING OPERATION IN ASSISTING AND AVOIDING BREAK DOWNS OR

OPERATION INTERRUPTIONS. FUEL TANKS BEING EMPTIED DURING

OPERATION, MAY RISK DEBRIS ALL FOREIGN OBJECTS ENTERING INTO

THE FUEL INTAKE CONFIGURATION SYSTEM CAUSING BLOCKAGES, OVER

HEATING AND EVEN PISTON FAILURE. TO AVOID THESE CIRCUMSTANCES

PLEASE KEEP YOUR FUEL TANK WELL FILLED AT ALL TIMES, AVOIDING

ENGINE BREAKS INCURRED, FROM THE RESULT OF FUEL STARVATION.

6

OPERATION

FILING GAS TANK

1.

Shut off engine and allow engine to completely cool

before refilling the gas tank. (Show Picture Of Off

button on Engine)

2. Move to a well ventilated area, outdoors, away from

flames and sparks.

3. Clean debris from area around the gas cap

4. Loosen gas cap slowly. Please the cap on a clean, dry

surface. Picture of gas cap

5. Carefully add fuel without spilling.

6. Do not fil fas tank completely full, allow space for fuel to

expand.

7. Immediately replace gas cap and tighten. Wipe off

spilled fuel and allow to dry before starting engine.

NORMAL OPERATION

1.

The clutch will transfer maximum power after about two hours of normal operation. During this break-in period clutch slippage

may occur. The clutch should be kept free of oil or other moisture for efficient operation.

2. Drill holes without placing excessive body weight on the unit. The auger operates most efficiently with a shaving action caused

by the weight of the unit itself.

3. Never run engine indoors. Exhaust fumes are deadly.

4. Do not use an earth auger in the ice.

5. To attach auger to powerhead, align hole at top of auger shaft with the output shaft hole. Insert 3/8 – 16x1-1/2” bolt and secure

bolt with provided 3/8 bi-way lock nut using a wrench.

NOTE:

The ends of the bolt should be flush with the auger collar. Bolt head and thread end should never go beyond earth collar.

USING THE SCREW TYPE, MANUAL VENTING GAS CAP

1. Your power earth auger is equipped with a screw type, manual venting gas cap.

2. Before starting the engine, turn the screw in the top of the gas cap all the way open (counterclockwise) to its venting position.

To ensure that gas will not spill during use, check that the gas cap is screwed on tightly and the gas cap screw is in

the venting position.

3. After using the power earth auger and before putting away or transporting it in a vehicle, screw the gas cap screw on

(clockwise) tightly. This will prevent gas from leaking during storage. The gas cap will not leak gas during storage if the gas cap

is tight and the screw at the top is tight.

NOTE:

When storing unit in an upright position for pro-longed periods of time in warm weather, vent gas cap to prevent gas from leaking

from carburetor.

STOPPING THE ENGINE

7

EASY TO FOLLOW STARTING SEQUENCE

STEP 1

Open gas cap vent all of the way.

STEP 4

Move choke lever to CHOKE or

ON position.

NOTE: CHOKE position is defi ned by

moving the choke lever as far to the ON

position as possible.

STEP 7

Squeeze throttle trigger.

STEP 13

Pull the recoil starter until the engine

starts.

STEP 14

Slide chock all the way to the run

position.

STEP 15

To stop engine push rocker switch to

‘OFF’ position.

STEP 2

Move choke lever to choke position.

STEP 5

Push rocker switch to the ON position.

STEP 8

Apply locking button for the open

throttle position.

STEP 9

Push the primer four to fi ve times until

you see fuel return down the clear tube.

STEP 10

Pull the decompression switch out.

STEP 11

Pull the recoil starter until the engine

starts and stops.

STEP 2

Prime unit until primer hose is fi led

with gas.

STEP 6

Squeeze top lever on throttle control.

STEP 12

Slide the choke to half position.

8

WARM ENGINE START

1.

Open gas cap vent screw all the way (counter clockwise)

2. Move choke lever to CHOKE or ON position

NOTE:

CHOKE position is defined by moving the choke lever as far to the ON position as possible.

3. Continue with Step 5 of Cold Engine Starting

HOT ENGINE START

1. Open gas vent screw al the way (counterclockwise)

2. Continue with Step 5 of Cold Engine Starting

3. If engine does not fire, refer to Step 2 of Warm Engine Starting

DO NOT USE STARTING FLUID DO NOT SPRAY FLAMMABLE LIQUIDS OR VAPOURS INTO AIR CLEANER, CARBURETOR OR SPARK PLUG CHAMBER.

DO NOT REMOVE SPARK PLUG AND PULL ON STARTER ROPE. FLAMMABLE FUEL CAN SPRAY OUT AND IGNITE FROM A SPARK FROM SPARK PLUG.

MAINTENANCE AND STORAGE

AUGER MAINTENANCE

1.

The gear case has 4 oz of grease installed at the factory. It is recommended that once a year the gear case be split and the

grease level checked. Add grease only if level of grease is below top of the gears. DO NOT OVERFILL

2. Keep all screws, nuts and bolts tight.

3. For cold weather operation, store the unit in a cool environment. Transferring the unit from a warm to a cold place can cause

the build up of harmful condensation.

4. If blade performance decreases, turn unit off and disconnect spark plug wire. Carefully inspect cutting edge of blade for any

signs of wear. If blades show any of these signs, they need to be sharpened or replaced.

COOLING FINS

Cooling fins, air inlets and linkages must be free from any debris before each use.

9

AIR FILTER

Never run engine without aircleaner properly installed. Added wear and engine failure may occur if air cleaner is not installed.

Service air cleaner every 3 months or after 20 hours of operation. Clean filter in extremely dusty conditions.

STEPS FOR CLEANING AIR FILTER

1. Wash in warm water with mild soap until dirt and debris are removed. Press filter when washing do not twist.

2. Rinse in warm water until soap and dirt are removed.

3. Dry filter by wrapping in a clean cloth and pressing filter until it is dry.

4. Apply oil to the entire filter.

5. Remove excess oil.

6. Attach the filter and air cleaner cover to the engine.

CHECKING SPARK PLUG

1.

Check spark plug every 50 operating hours

2. Disconnect the spark plug cap, and clean any debris from around the spark plug area.

3. Remove spark plug and replace if any of the following occur, pitted electrodes, burned electrodes, cracked porcelain, or

deposits around electrodes.

4. After analysis, seat spark plug and tighten with spark plug wrench.

CARBURETOR

Never tamper with factory setting of the carburetor.

TRANSPORTING YOUR EARTH AUGER

1. Never transport engine inside an enclosed space of vehicle. Fuel or fuel vapors may ignite causing serious injury or death.

2. If fuel is present in the fuel tank , transport in an open vehicle in an upright position.

3. If an enclosed vehicle must be used, remove gas into an approved red fuel container. DO NOT siphon by mouth.

4. Run engine to use up the fuel in the carburetor and fuel tank. Always run engine in a well ventilated area.

5. Wipe away any spilled fuel from engine and earth auger. Alow to dry.

LONG TERM STORAGE

If your earth auger will not be used for more than one month, prepare it for long term storage.

STEPS FOR LONG TERM STORAGE

1. Add fuel stabilizer according to manufacturer’s instructions.

2. Run engine for 10-15 minutes to ensure that the stabilizer reaches the carburetor.

3. Remove the remainder of the fuel from the gas tank into an approved fuel container.

4. Remove auger from powerhead and apply a thin layer of grease to the output shaft.

5. Store auger and powerhead (engine) in a vertical position.

6. Remove all debris from auger and powerhead (engine).

Loading...

Loading...