SELF-PROPELLED ROUGH-TERRAIN SCISSOR LIFTS

OPERATOR’S MANUAL

with Maintenance Information

( For JCPT2223RTA )

WARN ING

THE MANUFACTURER SHALL NOT BE HELD LIABLE IN CASE OF FAULTS

OR ACCIDENTS DUE TO NEGLIGENCE, INCAPACITY, INSTALLATION BY

UNQUALIFIED TECHNICIANS AND IMPROPER USE OF THE MACHINE

DO NO T O PER ATE THIS M AC HIN E U NTI L YOU READ AND UNDERSTAND

ALL THE DANGERS,WARNINGS AND CAUTIONS IN THIS MANUAL

Part Number: SM0117123

Zhejiang Dingli Machinery Co., Ltd. First Edition, September 2017

OPERATOR’S MANUAL with Maintenance Information

Version of the Record

1

OPERATOR’S MANUAL with Maintenance Information

Version of the Record

Version of the Record

Version Number Create Date

SM01117123_Rev1.0 ………………………………………………………………………… 2017-09

i

OPERATOR’S MANUAL with Maintenance Information

Important

Read, understand and obey these safety rules

and operating instructions before operating

this machine.

Only trained and authorized personnel shall be

permitted to operate this machine. This

manual should be considered a permanent

part of your machine and should remain with

the machine at all times. If you have any

questions, please call DINGLI Machinery.

Owners, Users and operators:

We appreciate your choice of our machine for

your application. Our number one priority is

user safety, which is best achieved by our joint

efforts. We feel that you make a major

contribution to safety if you, as the equipment

users and operators:

1 Comply with employer, job site and

governmental rules.

2 Read, understand and follow the

instructions in this and other manuals

supplied with this machine.

3 Use good safe work practices in a

commonsense way.

4 Only have trained / certified operators,

directed by informed and knowledgeable

supervision, running the machine.

Contents

Page

Safety Rules 1

Legend 8

Decals 9

Specifications 13

Control panel 14

Pre-operation Inspection 18

Workplace Inspection 20

Function Tests 21

Operating Instructions 27

Transport and Lifting Instructions 34

Maintenance 37

If there is anything in this manual that is not

clear or which you believe should be added,

please contact us.

Contact us:

Zhejiang Dingli Machinery Co., Ltd.

1255 Baiyun South Road. Leidian Town.

Deqing Zhejiang

China

Tel: +86-572-8681688

Schematic 64

Inspection and Repair Log 68

Fax: +86-572-8681690

Web: www.cndingli.com

E-mail:market@cndingli.com

i

OPERATOR’S MANUAL with Maintenance Information

Safety Rules

Danger

Failure to obey the instructions and

safety rules in this manual will

result in death or serious injury.

Do Not Operate Unless:

√ You learn and practice the principles of

safe machine operation contained in this

operator's manual.

1 Avoid hazardous situations.

Know and understand the safety rules

before going on to the next section.

2 Always perform a pre-operation

inspection.

3 Always perform function tests prior to

use.

Decal Legend

DINGLI product decals use symbols, color

coding and signal words to identify the

following:

Safety alert symbol—used to alert

personnel to potential personal injury hazards.

Obey all safety messages that follow this

symbol to avoid possible injury or death.

Red—used to indicate the

presence of an imminently hazardous situation

which, if not avoided, will result in death or

serious injury.

Orange—used to indicate the

presence of a potentially hazardous situation

which, if not avoided, could result in death or

serious injury.

4 Inspect the workplace.

5 Only use the machine as it was

intended.

√ You read, understand and obey the

manufacturer's instructions and safety

rules— safety and operator's manuals and

machine decals.

√ You read, understand and obey employer's

safety rules and worksite regulations.

√ You read, understand and obey all

applicable governmental regulations.

√ You are properly trained to safely operate

the machine.

Yellow with safety alert

symbol—used to indicate the presence of a

potentially hazardous situation which, if not

avoided, may cause minor or moderate injury.

Blue without safety alert

symbol—used to indicate the presence of a

potentially hazardous situation which, if not

avoided, may result in property damage.

1

OPERATOR’S MANUAL with Maintenance Information

Safety Rules

The relevant conditions of using

the equipment

The surface of work ground should be flat and

hard with no obstacles in air and the safety

distance between the equipment and

high-tension line is adequate.

The environment temperature should be within

-20℃~40℃; Height above sea level ≤1000m.

The environment humidity ≤ 90%.

Electrical power: AC 110~230V±10%,

50~60Hz.

Work cycle

The life of designed work cycle is no more than

40000 times.

Intended Use

This machine is intended to be used only to lift

personnel, along with their tools and materials

to an aerial work site.

An operator on prescription or

over-the-counter drugs needs medical advice

on whether or not he/she can safely operate

machines.

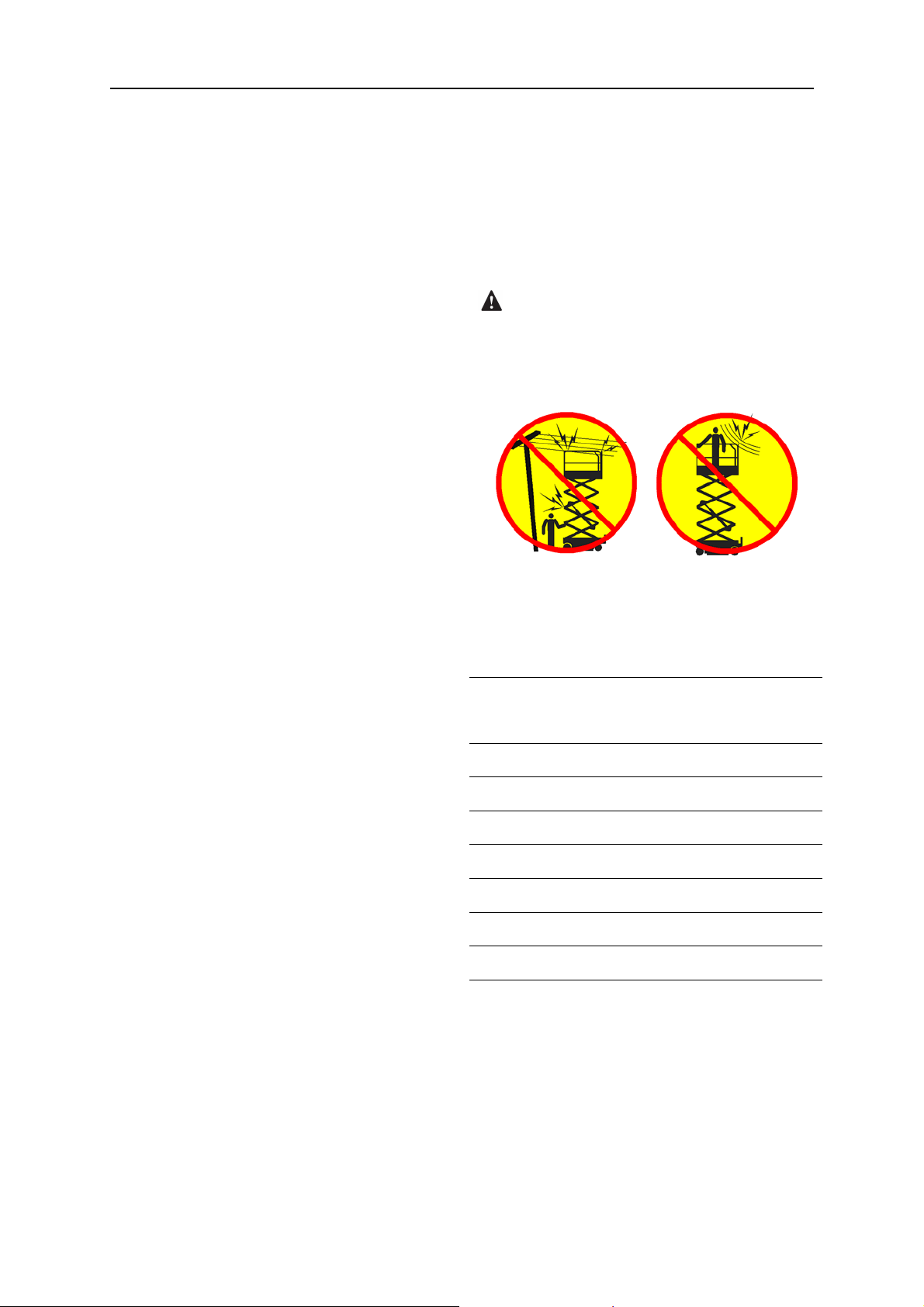

Electrocution Hazard

This machine is not electrically insulated and

will not provide protection from contact with or

proximity to electrical current.

Maintain safe distances from electrical power

lines and apparatus in accordance with

applicable governmental regulations and the

following chart.

Voltage

PhasetoPhase

Minimum Safe

Approach Distance

Meters

Safety Sign Maintenance

Replace any missing or damaged safety signs.

Keep operator safety in mind at all times. Use

mild soap and water to clean safety signs. Do

not use solvent-based cleaners because they

may damage the safety sign material.

Operator

Only the trained and qualified are permitted to

operate this machine. Always use safety belt

and helmet when aerially working.

If you are subject to dizziness or seizures, or

are bothered by heights, you must not operate

this type of machinery.

An operator must not use drugs or alcohol that

can change his/her alertness or coordination.

0 to 300V Avoid Contact

300V to 50kV 3.05

50kV to 200kV 4.60

200kV to 350kV 6.10

350kV to 500kV 7.62

500kV to 750kV 10.67

750kV to 1000kV 13.72

Allow for platform movement, electrical line

sway or sag and beware of strong or gusty

winds.

Keep away from the machine if it contacts

energized power lines. Personnel on the

ground or in the platform must not touch or

operate the machine until energized power

lines are shut off.

2

OPERATOR’S MANUAL with Maintenance Information

Safety Rules

Do not operate the machine during lightning or

storms.

Do not use the machine as a ground for

welding.

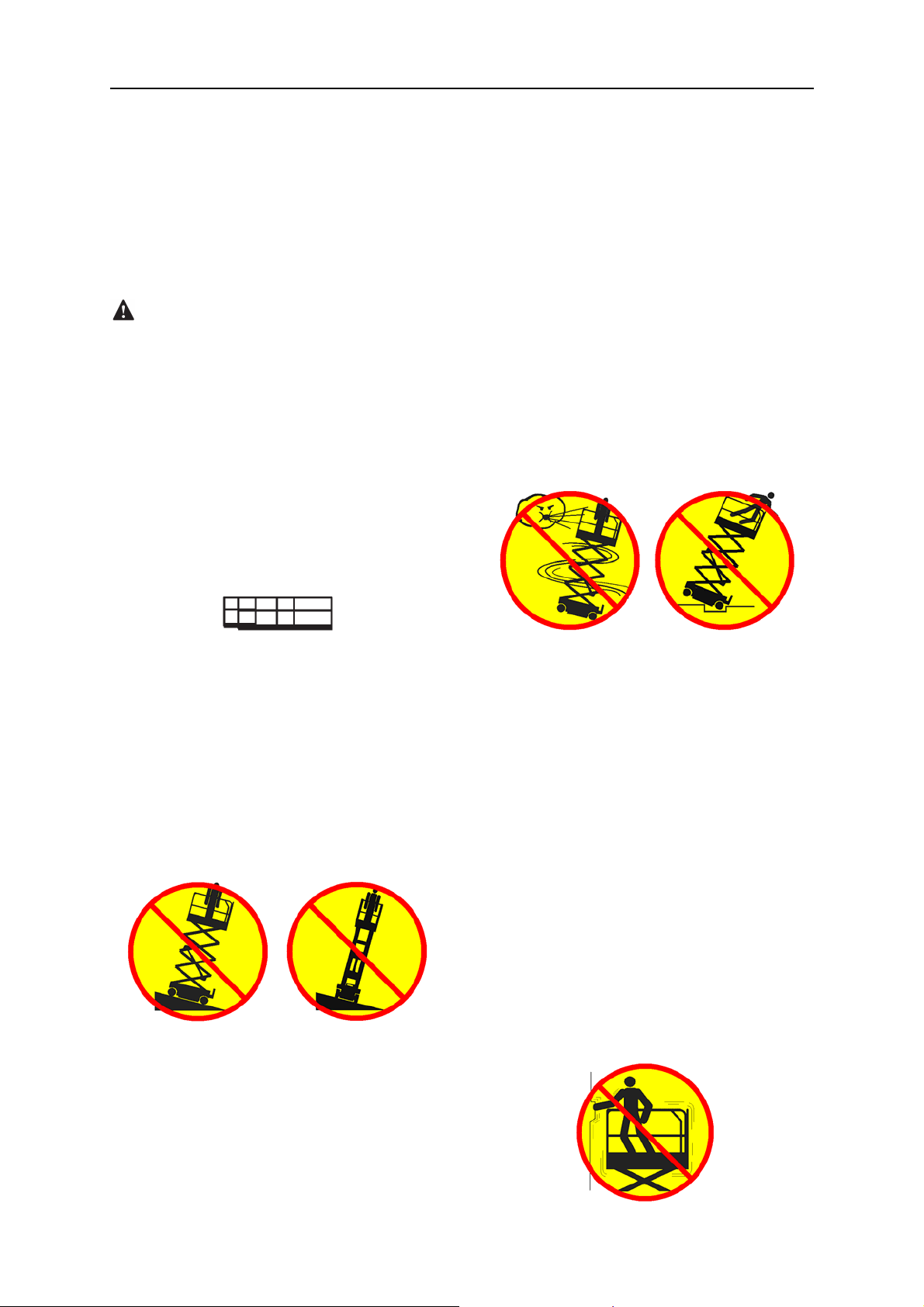

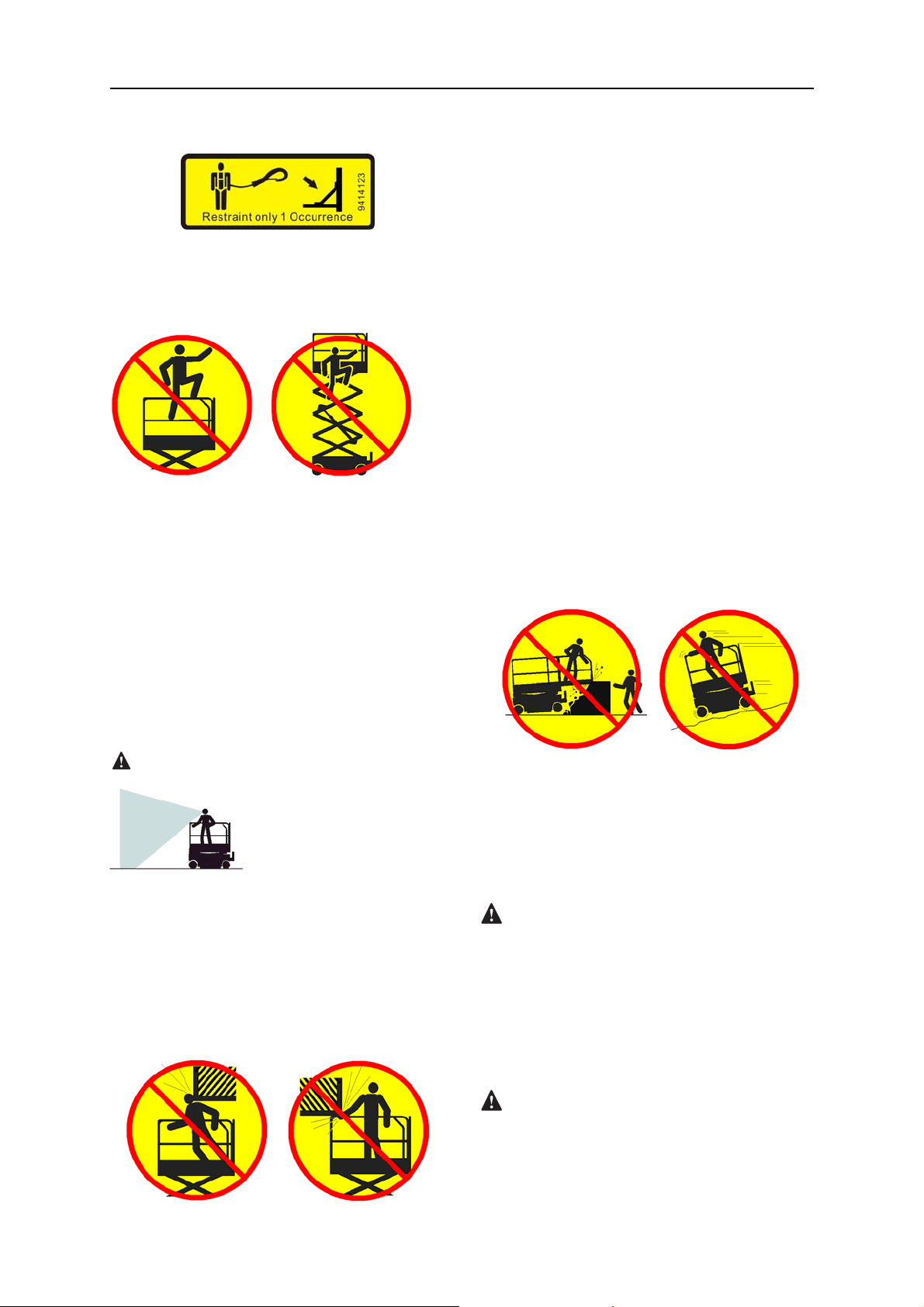

Tip-over Hazard

Occupants, equipment and materials must not

exceed the maximum platform capacity or the

maximum capacity of the platform extension.

Maximum capacity – JCPT2223RTA

Maximum occupants 4

Models with one extension deck

Platform allowable maximum load 750kg

Extension deck allowable maximum load 500kg

Only Only

firm, level surface. If the tilt alarm sounds

when the platform is raised, use extreme

caution to lower the platform.

For outdoor use machine, Do not raise the

platform when wind speeds may exceed 12.5

m/s. If wind speeds exceed 12.5 m/s when the

platform is raised, lower the platform and do

not continue to operate the machine.

Do not operate the machine in strong or gusty

winds. Do not increase the surface area of the

platform or the load. Increasing the area

exposed to the wind will decrease machine

stability.

Extension platform

deck

500kg 250kg

Work Area Safety

Do not raise the platform unless the machine

is on a firm, level surface.

Do not drive over 0.5km/h with the platform

raised.

Do not depend on the tilt alarm as a level

indicator. The tilt alarm sounds on the chassis

and in the platform when the machine is on a

slope.

Do not use the platform controls to free a

platform that is caught, snagged or otherwise

prevented from normal motion by an adjacent

structure. All personnel must be removed from

theplatformbeforeattemptingtofreethe

platform using the ground controls.

Use extreme care and slow speeds while

driving the machine in the stowed position

across uneven terrain, debris, unstable or

slippery surfaces and near holes and

drop-offs.

Do not drive the machine on or near uneven

terrain, unstable surfaces or other hazardous

conditions with the platform raised.

Do not push off or pull toward any object

outside of the platform.

If the tilt alarm sounds:

Lower the platform. Move the machine to a

3

OPERATOR’S MANUAL with Maintenance Information

Safety Rules

Maximum allowable manual force

Model Application

Outdoor 400N 4

JCPT2223RTA

Indoor 400N 4

Do not use the machine as a crane.

Do not place or attach fixed or overhanging

loads to any part of this machine.

Do not push the machine or other objects with

the platform.

Do not contact adjacent structures with the

platform.

Do not alter or disable the limit switches.

Do not tie the platform to adjacent structures.

Do not place loads outside the platform

perimeter.

manual

force

Maximum

occupants

handled by person(s) in the platform.

Do not use the machine on a moving or mobile

surface or vehicle.

Be sure all tires are in good condition, air-filled

tires are properly inflated and lug nuts are

properly tightened.

Crushing Hazard

Keep hands and limbs out of scissors.

Keep hands clear when folding rails.

Use common sense and planning when

operating the machine with the controller from

the ground. Maintain safe distances between

the operator, the machine and fixed objects.

Maintain a firm grasp on the platform rail when

removing the rail pins. Do not allow the

platform guard rails to fall.

Operation on Slopes Hazard

Do not alter or disable machine components

that in any way affect safety and stability.

Do not replace items critical to machine

stability with items of different weight or

specification.

Do not modify or alter an aerial work platform

without prior written permission from the

manufacturer. Mounting attachments for

holding tools or other materials onto the

platform, toe boards or guard rail system can

increase the weight in the platform and the

surface area of the platform or the load.

Do not place ladders or scaffolds in the

platform or against any part of this machine.

Do not drive the machine on a slope that

exceeds the slope and side slope rating of the

machine.

Slope rating applies to machines only in the

stowed position.

Maximum

Model

JCPT2223RTA 30% (17°) 25% (14°)

Note: Slope rating is subject to ground

conditions and adequate traction.

slope rating

stowed position

Maximum

side slope rating

stowed position

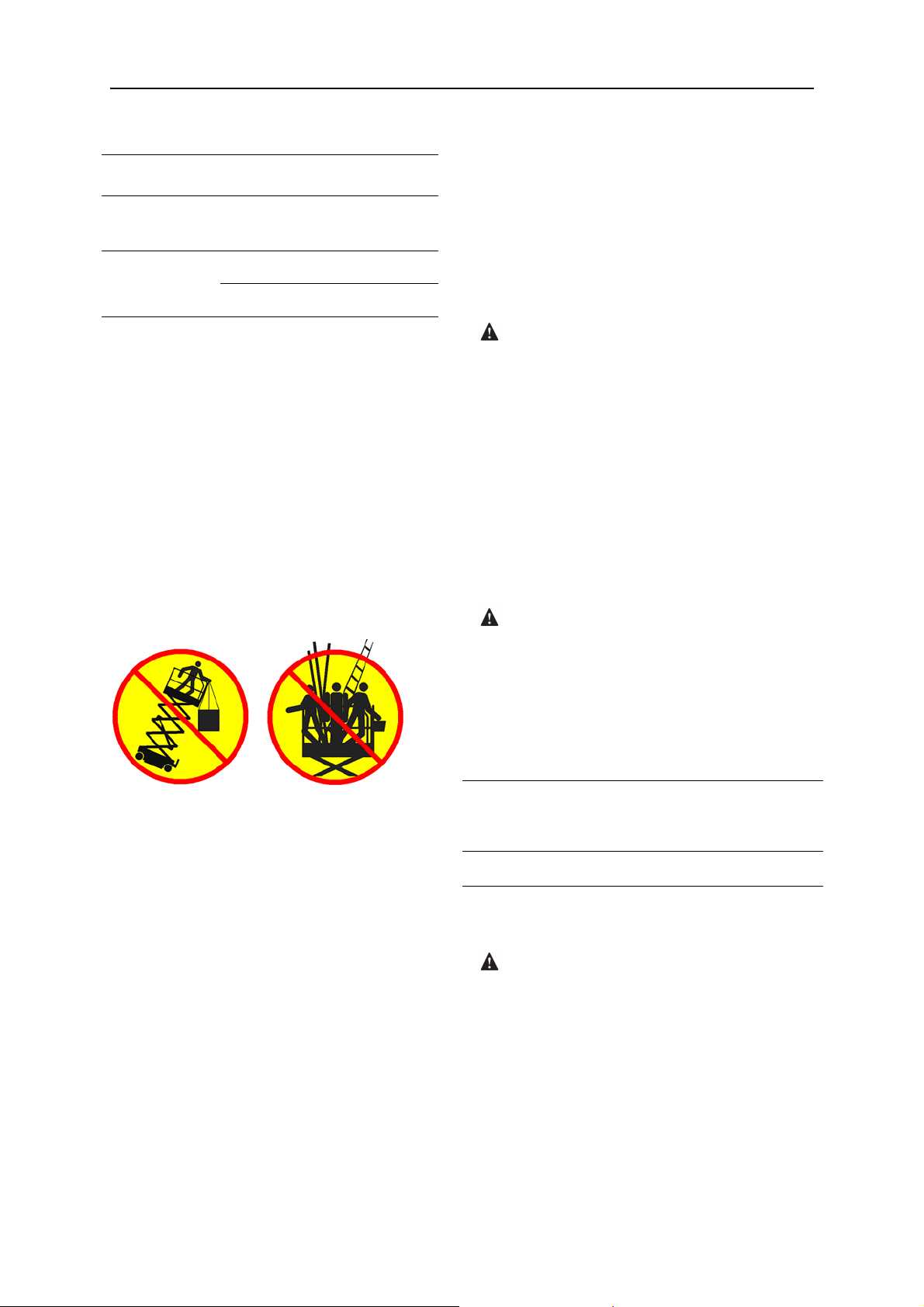

Fall Hazard

The guard rail system provides fall protection.

During operation, occupants in the platform

must wear a full body harness with a lanyard

attached to an authorized lanyard anchorage

point. Attach only one (1) lanyard per lanyard

anchorage point.

Do not transport tools and materials unless

they are evenly distributed and can be safely

4

OPERATOR’S MANUAL with Maintenance Information

Do not sit, stand or climb on the platform guard

rails. Maintain a firm footing on the platform

floor at all times.

Safety Rules

Be aware of crushing hazards when grasping

the platform guard rail.

Operators must comply with employer, job site

and governmental rules regarding use of

personal protective equipment.

Observe and use color-coded direction arrows

on the platform controls and platform decal

plate for drive and steer functions.

Do not operate a machine in the path of any

crane or moving overhead machinery unless

the controls of the crane have been locked out

and/or precautions have been taken to prevent

any potential collision.

Do not climb down from the platform when

raised.

Keep the platform floor clear of debris.

Close the entry gate before operating.

Do not operate the machine unless the guard

rails are properly installed and the entry is

secured for operation.

Do not enter or exit the platform unless the

machine is in the stowed position.

Collision Hazard

Be aware of limited sight distance and blind

spots when driving or operating.

Be aware of extended platform position(s)

when moving the machine.

No stunt driving or horseplay while operating a

machine.

Do not lower the platform unless the area

below is clear of personnel and obstructions.

Limit travel speed according to the condition of

the ground surface, congestion, slope, location

of personnel, and any other factors which may

cause collision.

Component Damage Hazard

Do not use any battery or charger greater than

12V to jump-start the engine.

Check the work area for overhead obstructions

or other possible hazards.

Do not use the machine as a ground for

welding.

Explosion and Fire Hazard

Do not start the engine if you smell or detect

liquid petroleum gas (LPG), gasoline, diesel

fuel or other explosive substances.

5

OPERATOR’S MANUAL with Maintenance Information

Safety Rules

Do not refuel the machine with the engine

running.

Refuel the machine and charge the battery

only in an open, well-ventilated area away

from sparks, flames and lighted tobacco.

Do not operate the machine in hazardous

locations or locations where potentially

flammable or explosive gases or particles may

be present.

Do not spray ether into engines equipped with

glow plugs.

Damaged Machine Hazard

Do not use a damaged or malfunctioning

machine.

Conduct a thorough pre-operation inspection

of the machine and test all functions before

each work shift. Immediately tag and remove

from service a damaged or malfunctioning

machine.

Be sure all maintenance has been performed

as specified in this manual. Be sure all decals

are in place and legible.

Be sure the operator’s manual is complete,

legible and in the storage container located in

the platform.

advised when performing a pre-operation

inspection. All compartments must remain

closed and secured during operation.

Outrigger Safety

Do not lower the outriggers unless the

machine is on a firm surface. Avoid drop-offs,

holes, unstable or slippery surfaces and other

possible hazardous conditions.

When the auto level function is not being used

and the outriggers are being lowered

individually, the steer-end outriggers must be

lowered first.

Do not raise the platform unless the machine

is level. Do not set the machine up on a

surface where it cannot be leveled using only

the outriggers.

Do not raise the platform unless all four

outriggers are properly lowered, the footpads

are in firm contact with the ground and the

machine is level.

Do not adjust the outriggers while the platform

is raised.

Do not drive while the outriggers are lowered.

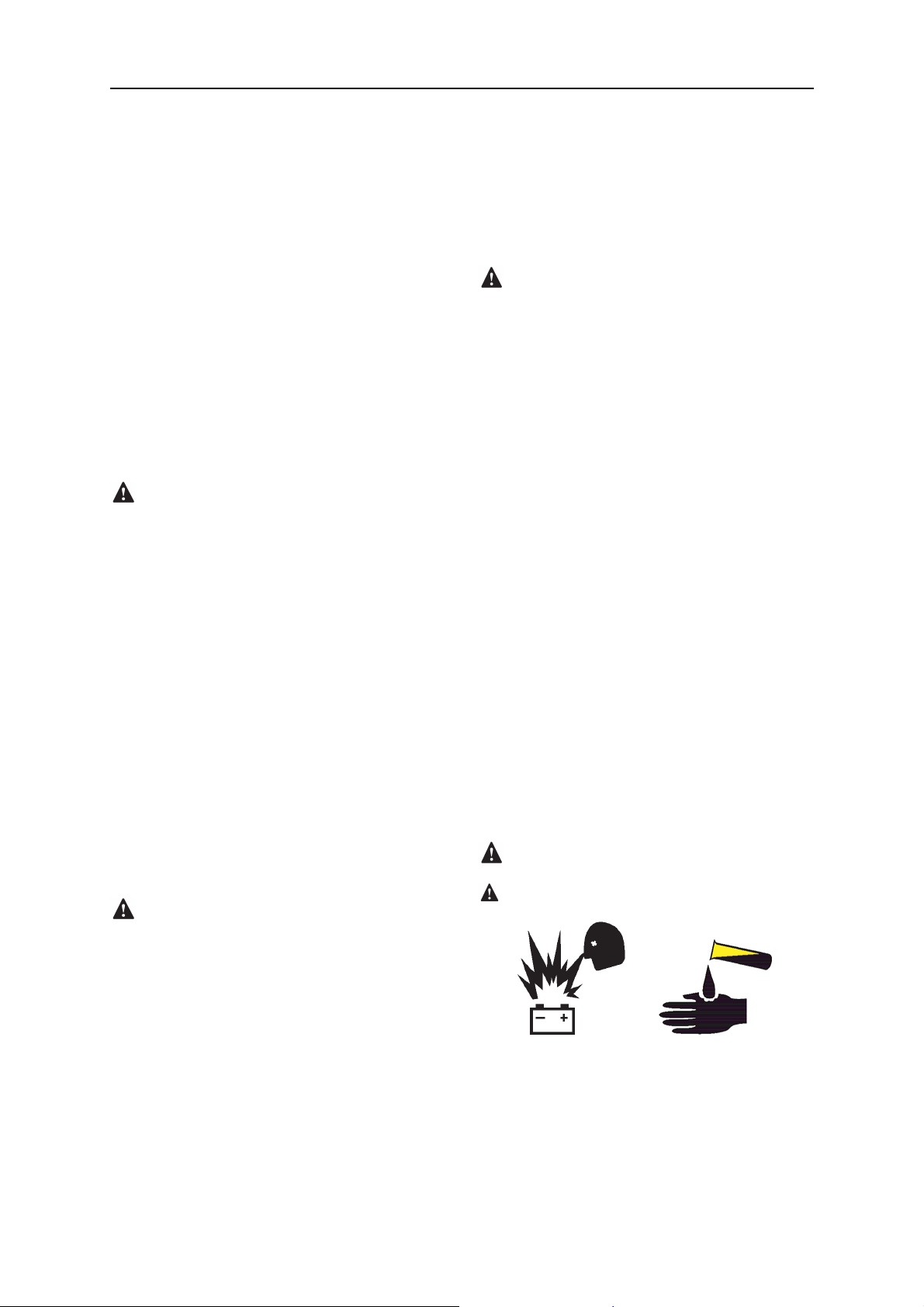

Battery Safety

Bodily Injury Hazard

Always operate the machine in a

well-ventilated area to avoid carbon monoxide

poisoning.

Do not operate the machine with a hydraulic oil

or air leak. An air leak or hydraulic leak can

penetrate and/or burn skin.

Improper contact with components under any

cover will cause serious injury. Only trained

maintenance personnel should access

compartments. Access by the operator is only

Burn Hazard

Batteries contain acid. Always wear protective

clothing and eye wear when working with

batteries.

Avoid spilling or contacting battery acid.

Neutralize battery acid spills with baking soda

and water.

6

OPERATOR’S MANUAL with Maintenance Information

Explosion Hazard

Keep sparks, flames and lighted tobacco away

from batteries. Batteries emit explosive gas.

Electrocution/ Hazard

Avoid contact with electrical terminals.

pollute Hazard

Safety Rules

Dispose of old battery must comply with job

site and governmental rules.

Lockout after Each Use

1 Select a safe parking location - firm level

surface, clear of obstructions and traffic.

2 Lower the platform.

3 Turn the key switch to the off position and

remove the key to secure from

unauthorized use.

4 Chock the wheels.

7

OPERATOR’S MANUAL with Maintenance Information

Legend

Legend

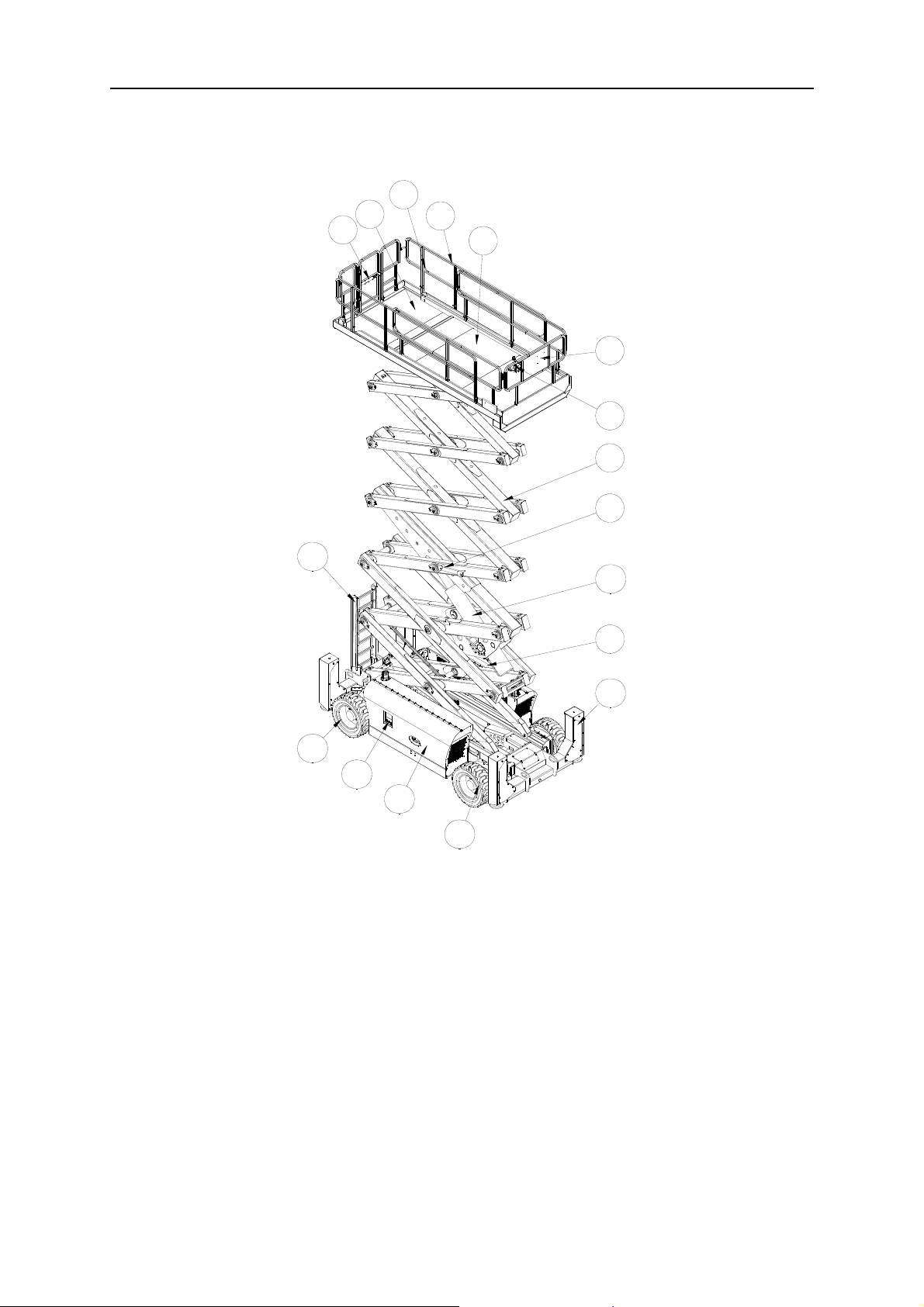

3

2

1

4

5

6

7

8

9

17

10

11

12

16

15

14

13

1 Platform entry gate 10 Lift Cylinder

2 Main Platform 11 Engine(behind cover)

3 Lanyard anchorage point 12 Outrigger

4 Platform guard rails 13 Front wheel

5 Platform extensions

14 Hydraulic tanks、Fuel tanks (behind cover)

6 Manual storage containers 15 Ground controls

7 Platform controls 16 Rear wheel

8 Scissor Arms 17.Entry ladder

9. Safety arm

8

OPERATOR’S MANUAL with Maintenance Information

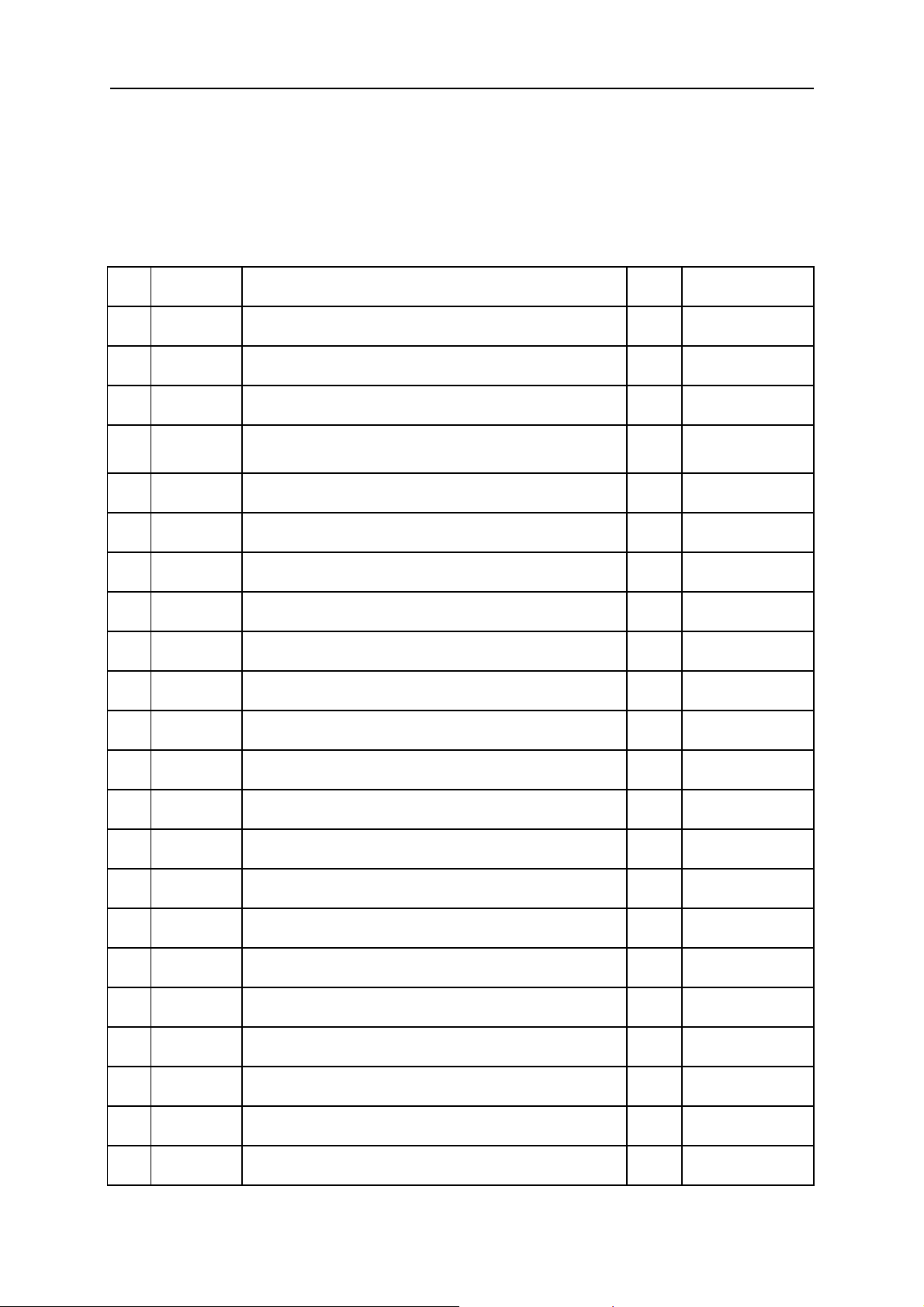

Decals

Decal Inspection

Use the pictures on the next page to verify that all decals are legible and in place.

Below is a numerical list with quantities and descriptions.

No. Part No. Description Qty. Remark

1 9334011 Notice – Operator’s Manual Storage 1

2 9414101 Danger – Safety Rules 1

3 9414119 Danger – Tip-over Hazard 1

4 9314013

5 9114013 Label – Platform Console Panel 1

6 9414123 Label – Lanyard Anchorage 6

7 9914025 Cosmetic – Warning 1

8 9414063 Label – Capacity 750kg 1

9 9914023 Cosmetic – Warning 1

10 9514011 Cosmetic – Mark 2

11 9414107 Caution – Max. Manual Force: 400N 2

12 9614091 Cosmetic – JCPT2223RTA 2

13 9514105 Cosmetic – Mark 1

14 9914021 Cosmetic – Warning 1

15 9514051 Cosmetic – Mark 1

Instructions – Refer the operator to the instructions

for use

2

16 9914019 Cosmetic – Warning 1

17 9413017 Warning – Crushing Hazard 7

18 9413015 Danger – Safety Arm 2

19 9411015 Danger – Tip-over hazard 1

20 9311557 Instructions – Maximum wheel load: 4030kg 4

21 9432013 Warning – Crushing Hazard 4

22 9331013 Instructions – Tie Down Point 4

9

OPERATOR’S MANUAL with Maintenance Information

Decals

No. Part No. Description Qty. Remark

23 9331011 Instructions – Lift Point 4

24 9211011 Decal – Manufacturer’s Plate 1

25 9311143 Instructions – Outrigger load: 4030kg 4

26 9411019 Warning – Crushing Hazard 4

27 9311105 Notice – Main power switch operation 1

28 9514301 Cosmetic – IPAF 2

29 9514201 Cosmetic – CE 2

30 9411011 Danger – Explosion/Burn Hazard 1

Instructions – JCPT2223RTA 4×4

31 9911023

SELF-PROPELLED ROUGH

TERRAIN SCISSOR LIFTS

2

32 9411021 Warning – Injection Hazard 1

33 9311109 Instructions – Emergency 1

34 9411013 Warning – Inspected and operating properly 1

35 9332013 Instructions – Hydraulic Oil 1

36 9332017 Instructions – Lowest Hydraulic Oil Level 2

37 9332015 Instructions – Highest Hydraulic Oil Level 2

9111011 Label – Ground Console Panel 1

38

9111013 Label – Ground Console Panel 1

39 9332011 Instructions – Diesel 1

On the Hydraulic

Oil Tank

On the Hydraulic

Oil Tank and

Diesel Tank

On the Diesel

Tank

10

OPERATOR’S MANUAL with Maintenance Information

Decals

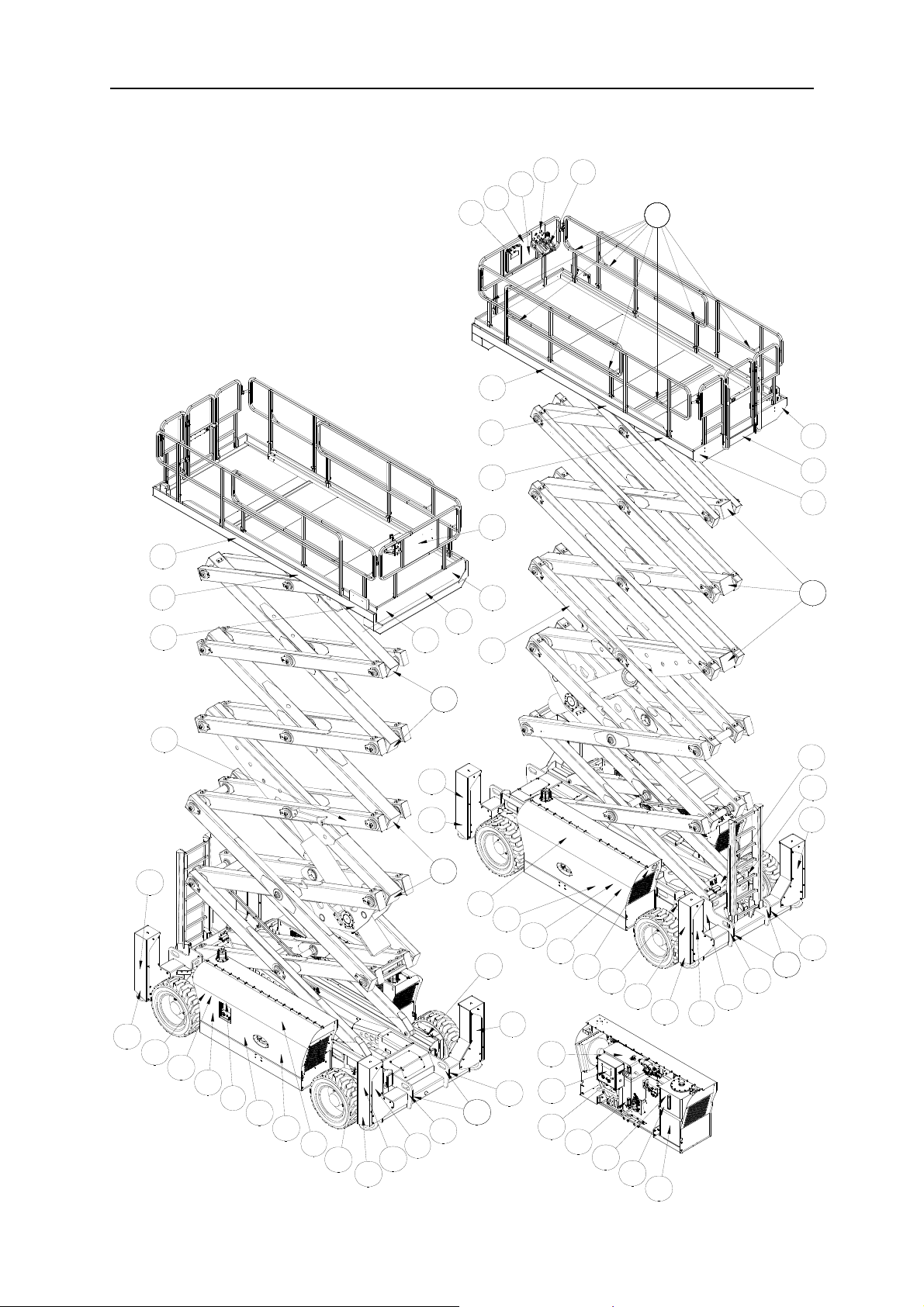

4

3

2

1

12

5

66666666

25

26

29

12

11

10

18

28

34

11

10

13

14

15

16

1717

26

25

1717

31

30

29

39

38

37

28

36

27

37

20

36

26

35

25

22

24

21

20

21

4

33

32

31

20

26

25

22

21

23

23

22

23

23

7

8

9

17181717

19

20

21

22

11

OPERATOR’S MANUAL with Maintenance Information

Decals

12

Model JCPT2223RTA

OPERATOR’S MANUAL with Maintenance Information

Specifications

Height, working maximum 22m

Height, platform maximum 20m

Height, drive maximum 12 m

Height, stowed maximum

Rails up

Height, stowed maximum

Rails folded

Width 2.35m

Length, platform retracted

Platform dimensions

Platform length x width

Platform extension length 2.0m

Maximum load capacity 750kg

Maximum wind speed 12.5m/s

4.35m×1.85m

3.68m

2.9m

4.9m

Airborne noise emissions <80 dB

Maximum sound level at normal operating

workstations (A-weighted)

Vibration value does not exceed 2.5m / s

Maximum slope rating ,

Stowed position

Maximum side slope rating

Stowed position

Note: Slope rating is subject to ground

conditions and adequate traction.

Maximum working slope

Drive speeds

Stowed, maximum 6.6 km/h

Platform raised, maximum 0.5 km/h

Floor loading information

2

30%

25%

X-2°, Y-3°

Wheelbase 3.13m

Turning radius (outside) 4.6m

Turning radius (inside) 2.1m

Ground clearance 30cm

Weight See Serial Label

Machine weights vary with option configurations

Controls Proportional

AC outlet in platform Standard

Maximum hydraulic pressure

(functions)

Tire size 355/55D625

240bar

Tire load, maximum 4030kg

Outrigger load, maximum 4030kg

Tire contact pressure

Occupied floor pressure

Note: Floor loading information is approximate

and does not incorporate different option

configurations. It should be used only with

adequate safety factors.

Continuous improvement of our products is a

DINGLI policy. Product specifications are

subject to change without notice or obligation.

740kPa

11. 8kP a

13

OPERATOR’S MANUAL with Maintenance Information

Control Panel

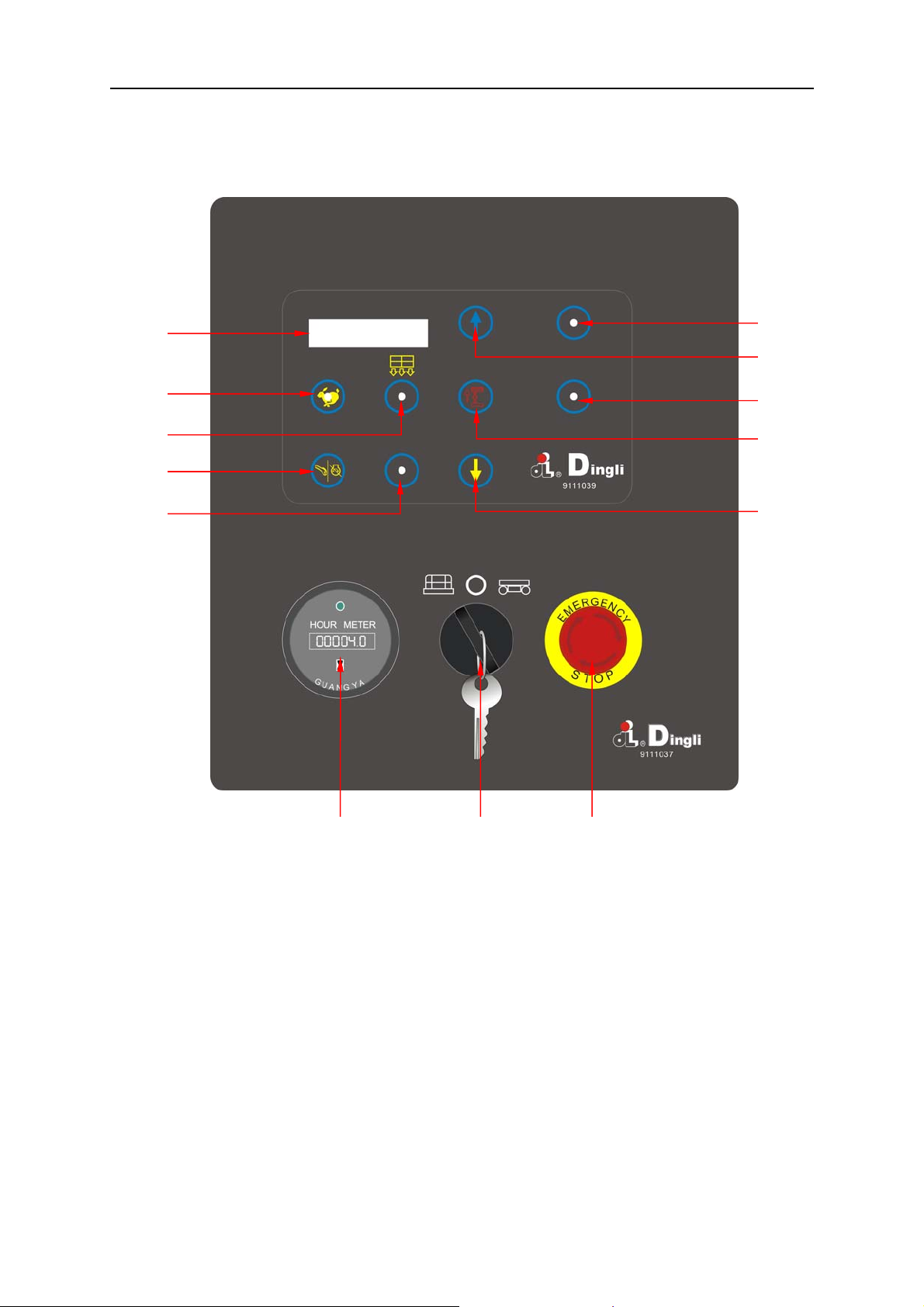

Ground Control Panel

1

13

12

2

3

11

10

4

5

9

678

1 LED readout screen 8 Red Emergency Stop button

2 Idle select button 9 Platform down button

3 Overload indicator light

4 Engine start/flameout button

5 Engine RPM display button

6 Hour meter

7 Key switch for platform / off / ground control

selection

14

10 Lift function enable button

11 Standby

12 Platform up button

13 Standby

Ground Control Panel

1LED

Diagnostic readout

2 Idle select button

Press this button to select the engine idle

setting. Light on indicates high idle is

selected. Light off indicates low idle is

selected.

3 Overload indicator light

OPERATOR’S MANUAL with Maintenance Information

Control Panel

8 Red Emergency Stop button

Push in the red Emergency Stop button to

the off position to stop all functions. Turn

the red Emergency Stop button clockwise

to the on position to operate the machine.

9 Platform down button

Press this button and the platform will

lower

Light on indicates when overloaded.

4 Engine start/flameout button

Press this button to start/flameout the

engine.

5 Engine RPM display button

Press this button to show the engine

RPM.

6 Hour meter

The hour meter displays the number of

hours the machine has operated.

7 Key switch for platform / off / ground Turn

the key switch to the platform position and

the platform controls will operate.

Turn the key switch to the off position and

the machine will be off. Turn the key

switch to the base position and the ground

controls will operate.

10 Lift function enable button

Press this button to activate the lift

function.

11 Standby

12 Platform up button

13 Standby

15

OPERATOR’S MANUAL with Maintenance Information

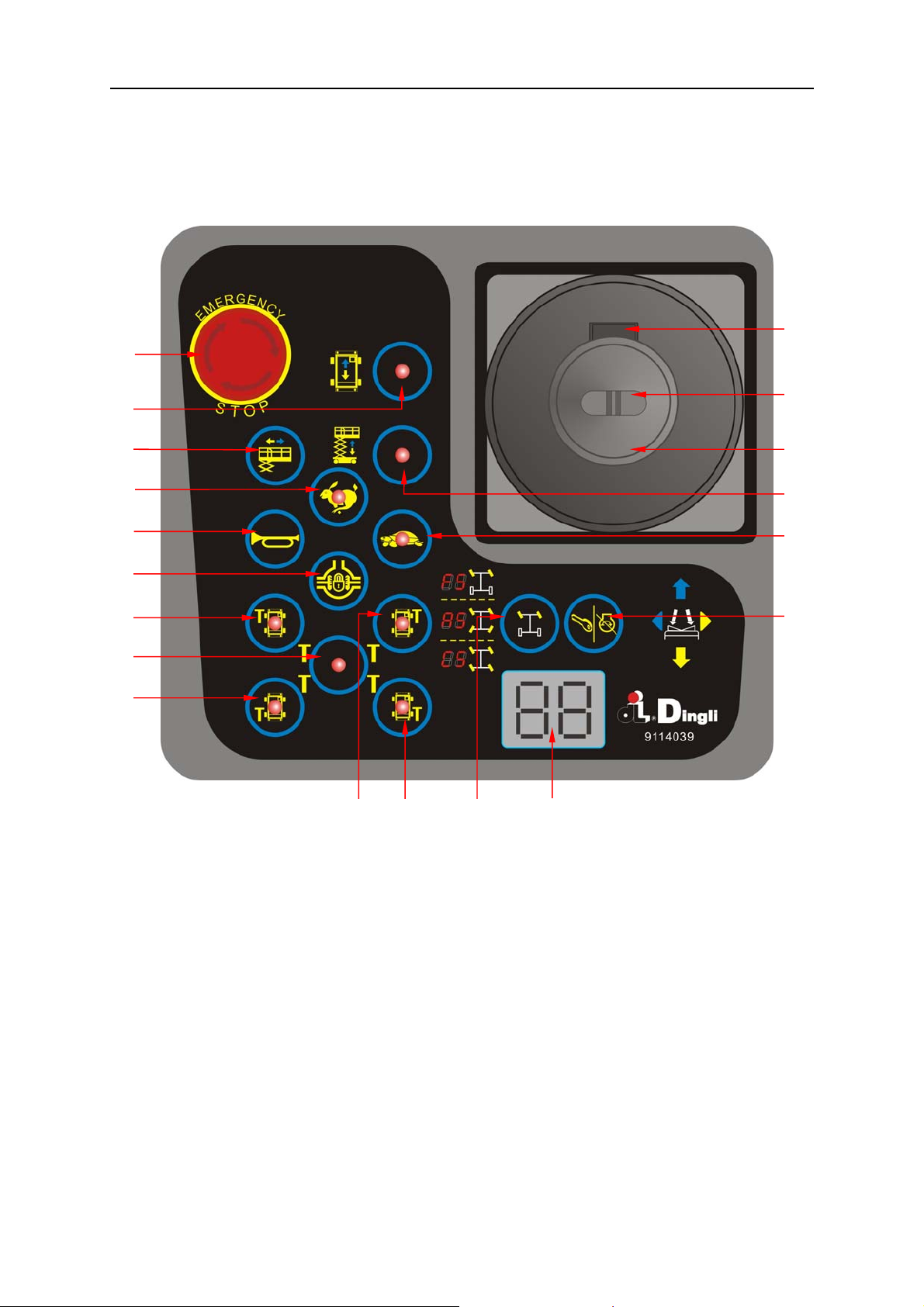

Control Panel

Platform Control Panel

1

16

2

15

3

4

5

14

13

12

6

7

8

11

7

77 9 10

1 Red Emergency Stop button 9 Steer mode select button

2 Drive function select button 10 LED

3 Platform retractable enable button

4 Engine high speed idle select button 12 Engine lower speed Idle select button

5 Horn button 13 Lift function select button

6 Differential lock enable button 14 Proportional control handle

7 Outrigger control button 15 Thumb rocker switch for steer function

8 Outrigger auto level button 16 Function enable button

11 Engine start / flameout button

16

OPERATOR’S MANUAL with Maintenance Information

Control Panel

Platform Control Panel

1 Red Emergency Stop button

Push in the red Emergency Stop button to

the off position to stop all functions. Pull out

the red Emergency Stop button to the on

position to operate the machine.

2 Drive function select button

Press this button to activate the drive

function.

3 Platform retractable enable button

Press and hold this button to activate the

platform retractable function.

4 Engine high speed idle select button

Press this button to select the engine idle

setting. Light on indicates high idle is

selected.

5 Horn button

Press this button and the horn will sound.

Release the button and the horn will stop.

6 Differential lock enable button

Press and hold this button to activate the

differential lock function.

7 Outrigger control button

Press this button to activate the individual

outrigger up/down function.

8 Outrigger auto level button

Press this button to activate the auto level

function.

9 Steer mode select button

Press this button to select steer mode :FS

mode (Front Steer mode), AS mode (All

wheel Steer mode), CS mode (Crab Steer

mode).

10 LED

Diagnostic readout and steer mode and

battery charge indicator.

11 Engine start / flameout button

Press this button to start/ flameout the

engine.

12 Engine lower speed Idle select button

Press this button to select the engine

idle setting. Light on indicates high idle

is selected.

13 Lift function select button

Press this button to activate the lift

function.

14 Proportional control handle

Move the control handle control the

drive function, Lift function, and platform

retractable function outrigger retractable

function

15 Thumb rocker switch for steer function

Press the thumb rocker switch in either

direction to activate steer function.

16 Function enable switch

Lift function: Press and hold the function

enable switch to enable the lift function

on the platform control handle. Move the

control handle in the direction indicated

by the blue arrow and the platform will

raise. Move the control handle in the

direction indicated by the yellow arrow

and the platform will lower. The descent

alarm should sound while the platform is

lowering.

Drive function: Press and hold the

function enable switch to enable the

drive function on the platform control

handle. Move the control handle in the

direction indicated by the blue arrow on

the control panel and the machine will

moveinthedirectionthatthebluearrow

points. Move the control handle in the

direction indicated by the yellow arrow

on the control panel and the machine

will move in the direction that the yellow

arrow points.

17

OPERATOR’S MANUAL with Maintenance Information

Pre-operation Inspection

Do Not Operate Unless:

√ You learn and practice the principles of

safe machine operation contained in this

operator's manual.

1 Avoid hazardous situations.

2 Always perform a pre-operation

inspection.

Know and understand the pre-operation

inspection before going on to the next

section.

3 Inspect the workplace.

4 Always perform function tests prior to

use.

5 Only use the machine as it was

intended.

Fundamentals

It is the responsibility of the operator to

perform a pre-operation inspection and routine

maintenance.

The pre-operation inspection is a visual

inspection performed by the operator prior to

each work shift. The inspection is designed to

discover if anything is apparently wrong with a

machine before the operator performs the

function tests.

The pre-operation inspection also serves to

determine if routine maintenance procedures

are required. Only routine maintenance items

specified in this manual may be performed by

the operator.

Refer to the list on the next page and check

each of the items.

If damage or any unauthorized variation from

factory delivered condition is discovered, the

machine must be tagged and removed from

service.

Repairs to the machine may only be made by

a qualified service technician, according to the

manufacturer's specifications. After repairs are

completed, the operator must perform a

pre-operation inspection again before going on

to the function tests.

Scheduled maintenance inspections shall be

performed by qualified service technicians,

according to the manufacturer's specifications

and the requirements listed in this manual.

18

Pre-operation Inspection

OPERATOR’S MANUAL with Maintenance Information

Pre-operation Inspection

Be sure that the operator’s manual are

complete, legible and in the storage

container located in the platform.

Be sure that all decals are legible and in

place. See Decals section.

Check for engine oil leaks and proper oil

level. Add oil if needed. See Maintenance

section.

Check for hydraulic oil leaks and proper oil

level. Add oil if needed. See Maintenance

section.

Check for engine coolant leaks and proper

level of coolant. Add coolant if needed.

See Maintenance section.

Check for battery fluid leaks and proper

fluid level. Add distilled water if needed.

See Maintenance section.

Check the following components or areas for

damage, improperly installed or missing parts

and unauthorized modifications:

□ Electrical components, wiring and

electrical cables

□ Safety arm

□ Platform extension(s)

□ Scissor pins and retaining fasteners

□ Platform control joystick

□ Oscillate Axle

□ Differential lock

□ Outrigger housings and footpads

Check entire machine for:

□ Cracks in welds or structural

components

□ Dents or damage to machine

□ Be sure that all structural and other

critical components are present and

all associated fasteners and pins are

in place and properly tightened

Note: If the platform must be raised to inspect

the machine, make sure the safety arm is in

place. See Operating Instructions section.

□ Hydraulic hoses, fittings, cylinders and

manifolds

□ Fuel and hydraulic tanks

□ Drive motors

□ Wear pads

□ Tires and wheels

□ Engine and related components

□ Limit switches, alarms and horn

□ Nuts, bolts and other fasteners

□ Platform overload components

□ Platform entry gate

□ Beacon and alarms (if equipped)

19

OPERATOR’S MANUAL with Maintenance Information

Workplace Inspection

Do Not Operate Unless:

√ You learn and practice the principles of

safe machine operation contained in this

operator's manual.

1 Avoid hazardous situations.

2 Always perform a pre-operation

inspection.

3 Inspect the workplace.

Know and understand the workplace

inspection before going on to the next

section.

4 Always perform function tests prior to

use.

5 Only use the machine as it was

intended.

Fundamentals

The workplace inspection helps the operator

determine if the workplace is suitable for safe

machine operation. It should be performed by

the operator prior to moving the machine to the

workplace.

It is the operator's responsibility to read and

remember the workplace hazards, then watch

for and avoid them while moving, setting up

and operating the machine.

Workplace Inspection

Be aware of and avoid the following hazardous

situations:

- Drop-offs or holes

- Bumps, floor obstructions or debris

- Sloped surfaces

- Unstable or slippery surfaces

- Overhead obstructions and high voltage

conductors

- Hazardous locations

- Inadequate surface support to withstand all

load forces imposed by the machine

- Wind and weather conditions

- The presence of unauthorized personnel

- Other possible unsafe conditions

20

OPERATOR’S MANUAL with Maintenance Information

r

Function Tests

Do Not Operate Unless:

√ You learn and practice the principles of

safe machine operation contained in this

operator's manual.

1 Avoid hazardous situations.

2 Always perform a pre-operation

inspection.

3 Inspect the workplace.

4 Always perform function tests prio

to use.

Know and understand the function tests

before going on to the next section.

5 Only use the machine as it was

intended.

Fundamentals

The function tests are designed to discover

any malfunctions before the machine is put

into service.

The operator must follow the step-by-step

instructions to test all machine functions.

A malfunctioning machine must never be used.

If malfunctions are discovered, the machine

must be tagged and removed from service.

Repairs to the machine may only be made by

a qualified service technician, according to the

manufacturer's specifications.

After repairs are completed, the operator must

perform a pre-operation inspection and

function tests again before putting the machine

into service.

21

OPERATOR’S MANUAL with Maintenance Information

Function Tests

1 Select a test area that is firm, level and

free of obstruction.

At the Ground Controls

2 Pull out the platform red Emergency Stop

button to the on position.

3 Turn the red Emergency Stop button

clockwise to the on position.

4 Turn the key switch to ground control.

5 0bserve the diagnostic LED readout on the

ground controls.

⊙ Result: The LED readout will come on and

display SYSTEM READY.

6 Start the engine. See Operating

Instructions section.

Test Emergency Stop

7 Push in the ground red Emergency Stop

button to the off position.

⊙ Result: The engine should turn off and no

functions should operate.

8 Turn the red Emergency Stop button

clockwise to the on position and restart the

engine.

Test Up/Down Functions and

Function Enable

A buzzer with different sound frequency is

controlled in central system. The descent

alarm sounds at 60 beeps per minute. The

alarm that goes off when the machine is not

level sounds at 150 beeps per minute. An

optional automotive-style horn is also

available.

9 Do not press the lift function enable button.

Press and hold the platform up/down

button.

⊙ Result: No function should operate.

10 Press and hold the lift function enable

button. Press and hold the platform up

button.

⊙ Result: The platform should rise.

11 Press and hold the lift function enable

button. Press and hold the platform down

button.

⊙ Result: The platform should lower then

stop at the height is 3.5m. The descent

alarm should sound while the platform is

lowering.

12 Press and hold the lift function enable

button. Press and hold the platform down

button.

⊙ Result: The platform should lower to end.

The descent alarm should sound while the

platform is lowering.

Test the Auxiliary Lowering

13 Activate the up function and raise the

platform approximately 60 cm.

14 Press the engine start/ flameout button to

engine off.

15 Press and hold the lift function enable

button. Press and hold the platform down

button.

⊙ Result: The platform should lower.

16 Turn the key switch to platform control and

restart the engine.

At the Platform Controls

Test Emergency Stop

17 Push in the platform red Emergency Stop

button to the off position.

⊙ Result: No functions should operate.

18 Pull the red Emergency Stop button out to

the on position.

⊙ Result: The LED readout will come on and

display SYSTEM READY

22

OPERATOR’S MANUAL with Maintenance Information

Function Tests

Test the Horn

19 Push the horn button.

⊙ Result: The horn should sound.

Test Up/Down Functions and

Function Enable

20 Start the engine.

21 Activate the up/down rocker switch in the

direction indicated by the blue arrow.

⊙ Result: The platform should not rise.

22 Press the lift function select button. The

indicator light should turn on.

23 Press and hold the function enable button.

Activate the proportional control handle in

the direction indicated by the blue arrow.

⊙ Result: The platform should rise.

24 Activate the proportional control handle in

the direction indicated by the yellow arrow.

⊙ Result: The platform should lower. The

descent alarm should sound while the

platform is lowering.

Test the Steering

Note: When performing the steer and drive

function test, stand in the platform facing the

steer end of the machine.

25 Press the drive function select button. The

indicator light should turn on.

26 Push the steer mode select button for

steer FS mode (Front Steer mode).

27 Press and hold the function enable switch

on the proportional control handle.

Depress the thumb rocker switch on top of

the proportional control handle in the

direction identified by the blue triangle on

the control panel.

⊙ Result: The front wheels should turn in the

direction that the blue triangle points on the

control panel.

28 Press and hold the function enable switch

on the proportional control handle.

Depress the thumb rocker switch in the

direction identified by the yellow triangle

on the control panel.

⊙ Result: The front wheels should turn in the

direction that the yellow triangle points on

the control panel.

29 Push the steer mode select button for

steer AS mode (All wheel Steer mode).

30 Press and hold the function enable switch

on the proportional control handle.

Depress the thumb rocker switch on top of

the proportional control handle in the

direction identified by the blue triangle on

the control panel.

⊙ Result: The front wheels should turn in the

direction that the blue triangle points on the

control panel and the rear wheels should

turn in the direction that the yellow triangle

points on the control panel

31 Press and hold the function enable switch

on the proportional control handle.

Depress the thumb rocker switch in the

direction identified by the yellow triangle

on the control panel.

⊙ Result: The front wheels should turn in the

direction that the yellow triangle points on

the control panel and the rear wheels

should turn in the direction that the blue

triangle points on the control panel

32 Push the steer mode select button for

steer CS mode (Crab Steer mode).

33 Press and hold the function enable switch

on the proportional control handle.

Depress the thumb rocker switch on top of

the proportional control handle in the

direction identified by the blue triangle on

the control panel.

⊙ Result: The front wheels should turn in the

direction that the blue triangle points on the

23

OPERATOR’S MANUAL with Maintenance Information

Function Tests

control panel and the rear wheels should

turn in the direction that the blue triangle

points on the control panel

34 Press and hold the function enable switch

on the proportional control handle.

Depress the thumb rocker switch in the

direction identified by the yellow triangle

on the control panel.

⊙ Result: The front wheels should turn in the

direction that the yellow triangle points on

the control panel and the rear wheels

should turn in the direction that the yellow

triangle points on the control panel

Test Drive and Braking

35 Press and hold the function enable switch

on the proportional control handle.

36 Slowly move the proportional control

handle in the direction indicated by the

blue arrow on the control panel until the

machine begins to move, then return the

proportional control handle to the center

position.

⊙ Result:Themachineshouldmoveinthe

direction that the blue arrow points on the

control panel, then come to an abrupt stop.

37 Press and hold the function enable switch

on the proportional control handle.

38 Slowly move the proportional control

handle in the direction indicated by the

yellow arrow on the control panel until the

machine begins to move, then return the

proportional handle to the center position.

⊙ Result:Themachineshouldmoveinthe

direction that the yellow arrow points on the

control panel, then come to an abrupt stop.

Note: The brakes must be able to hold the

machine on any slope it is able to climb.

Test Limited Drive Speed

39 Press the lift function select button. Raise

the platform approximately 3.5 m from the

ground.

40 Press the drive function select button.

41 Press and hold the function enable switch

on the proportional control handle slowly

move the proportional control handle to the

full drive position.

⊙ Result: The maximum achievable drive

speed with the platform raised should not

exceed 12.5cm/s.

¤ Result: If the drive speed with the platform

raised exceeds 12.5cm/s, immediately tag

andremovethemachinefromservice.

Test the Tilt Sensor Operation

Note: Perform this test from the ground with

the platform controller. Do not stand in the

platform.

42 Fully lower the platform.

43 Drive both wheels on one side onto an

18cm block.

44 Raise the platform at least 3.5 m.

⊙ Result: The platform should stop and the tilt

alarm will sound. The indicator light on the

lift function select button will be red.

45 Press the drive function select button.

46 Move the proportional control handle in the

direction indicated by the blue arrow, then

move the proportional control handle in the

direction indicated by the yellow arrow.

⊙ Result: The drive function should not work

in either direction.

47 Press the lift function enable button.

48 Lower the platform and drive the machine

off the block.

Test the Oscillate System

Note: Perform this test from the ground with

the platform controller. Do not stand in the

24

OPERATOR’S MANUAL with Maintenance Information

Function Tests

platform.

49 Fully lower the platform.

50 Drive the Left front wheel onto an 18cm

block.

51 Raise the platform at least 3.5 m.

52 Press the drive function select button

53 Activate the proportional control handle in

the direction indicated by the yellow arrow

⊙ Result: The left front or right rear wheel

remains elevated in position off ground

54 Press the lift function enable button.

55 Lower the platform to stowed position,

activation drives forward and backward

moving machine.

⊙ Result: Lockout cylinders should release

and allow wheel to rest on ground

above 12 m unless the outriggers are

lowered.

63 Press the drive function select button.

Drive the machine forward.

⊙ Result: The drive function should operate.

64 Press the lift function select button.

65 Lower the platform. If the platform is higher

than 3.5 m from the ground, the outriggers

will not lower.

66 Lower the platform to the end.

67 Push and hold the auto level button.

68 Press and hold the function enable switch.

Activate the proportional control handle in

the direction indicated by the yellow arrow.

The outriggers will extend and level the

machine. A beep will sound when the

machine is level.

56 Drive the right front wheel onto an 18cm

block.

57 Raise the platform at least 3.5 m.

58 Press the drive function select button

59 Activate the proportional control handle in

the direction indicated by the yellow arrow

⊙ Result: The right front or left rear wheel

remains elevated in position off ground

60 Press the lift function enable button.

61 Lower the platform to stowed position,

activation drives forward and backward

moving machine.

⊙ Result: Lockout cylinders should release

and allow wheel to rest on ground

Test the Up Limit Switch and the

Outriggers

62 Push and hold the lift function enable

button. Raise the platform.

⊙ Result: The platform should rise to 12 m

and then stop. The platform should not rise

69 Raise the platform.

⊙ Result: The platform should rise to full

height.

70 Lower the platform.

Test Auxiliary Lowering

71 Push and hold the function enable button

and raise the platform approximately 60

cm.

72 Press the engine start/ flameout button to

engine off.

73 Push and hold the function enable button.

Activate the control handle in the direction

indicated by the yellow arrow.

⊙ Result: The platform should lower.

Test Platform Telescopic Functions

74 Push and hold the Platform retractable

enable button. Press and hold the function

enable switch. Activate the proportional

control handle in the direction indicated by

the blue arrow

25

OPERATOR’S MANUAL with Maintenance Information

Function Tests

⊙ Result: The platform should spread.

75 Push and hold the Platform retractable

enable button. Press and hold the function

enable switch. Activate the proportional

control handle in the direction indicated by

the yellow arrow.

⊙ Result: The platform should retract

26

OPERATOR’S MANUAL with Maintenance Information

Operating Instructions

Do Not Operate Unless:

√ You learn and practice the principles of

safe machine operation contained in this

operator's manual.

1 Avoid hazardous situations.

2 Always perform a pre-operation

inspection.

3 Inspect the workplace.

4 Always perform function tests prior to

use.

5 Only use the machine as it was

intended.

Fundamentals

This machine is a self-propelled hydraulic lift

equipped with a work platform on the scissor

mechanism. Vibrations emitted by these

machines are not hazardous to an operator in

the work platform. The machine can be used

to position personnel with their tools and

supplies at position above ground level and

can be used to reach work areas located

above and over machinery or equipment.

The Operating Instructions section provides

instructions for each aspect of machine

operation.

It is the operator's responsibility to follow all

the safety rules and instructions in the

operator's manual.

Using the machine for anything other than

lifting personnel, along with their tools and

materials, to an aerial work site is unsafe and

dangerous.

Only trained and authorized personnel should

be permitted to operate a machine. If more

than one operator is expected to use a

machine at different times in the same work

shift, they must all be qualified operators and

are all expected to follow all safety rules and

instructions in the operator's manual. That

means every new operator should perform a

pre-operation inspection, function tests, and a

workplace inspection before using the

machine.

A full and detailed implementation of EN ISO

13849-1/2 is correctly applied on our MEWP

design. SISTEMA, a software tool for PL

Calculation Tool, is also used to perform some

relatively straightforward calculations on

subsystem to determine the overall PL of the

system. Reliability data, diagnostic coverage

[DC], the system architecture [Category],

common cause failure and, where relevant,

requirements for software are used to assess

the PL to comply with PLr of SRP/CS in

Clause 5.11 of EN 280.

27

OPERATOR’S MANUAL with Maintenance Information

Operating Instructions

Emergency Stop

Push in the red Emergency Stop button to the

off position at the ground controls or the

platform controls to stop all machine functions

and turn the engine off.

Repair any function that operates when either

red Emergency Stop button is pushed in.

Starting the Engine

1 At the ground controls, turn the key switch

to the desired position.

2 Be sure both ground and platform control

red Emergency Stop buttons are pulled out

to the on position.

3

Press the engine start button.

When the temperature is too low, the engine

will be preheated automatically.

If the engine fails to start after 15 seconds of

cranking, determine the cause and repair any

malfunction. Wait 60 seconds before trying to

start again.

In cold conditions, -6°C and below, warm the

engine for 5 minutes before operating to

prevent hydraulic system damage.

In extreme cold conditions, -18°C and below,

machines should be equipped with optional

cold start kits. Attempting to start the engine

when temperatures are below -18°C may

require the use of a booster battery.

To Position Platform

1 Press the lift function enable button.

2 Press the platform up/down button to

activate the up function or the down

function.

Drive and steer functions are not available

from the ground controls.

Engine Idle Select

Select the engine idle (rpm) by press.

Operation from Platform

1 Turn the key switch to platform control.

2 Pull out the ground and platform red

Emergency Stop buttons to the on

position.

3 Start the engine.

To Position Platform

1 Press the lift function select button.

2 Press and hold the function enable switch

on the control handle.

3 Activate the proportional control handle in

the desired direction.

To Steer

1 Press the drive function select button.

2 Press and hold the function enable switch

on the control handle.

3 Push the steer mode select button for

steer mode (FS. AS CS)

Operation from Ground

1 Turn the key switch to ground control.

2 Pull out the platform red Emergency Stop

button to the on position.

3 Turn the red Emergency Stop button

clockwise to the on position.

4Starttheengine.

4 Turn the steer wheels with the thumb

rocker switch located on the top of the

control handle.

To Drive

1 Press the drive function select button.

2 Press and hold the function enable switch

on the control handle.

28

OPERATOR’S MANUAL with Maintenance Information

Operating Instructions

3 Increase speed: Slowly move the control

handle off center.

Decrease speed: Slowly move the control

handle toward center.

Stop: Return the control handle to center or

release the function enable switch.

Use the direction arrows on the platform

controls to identify the direction the machine

will travel.

Machine travel speed is restricted when the

platform is raised.

Drive Select Switch

The drive controls can operate in two different

drive speed modes. When the engine lower

speed idle select button light is on, slow drive

speed mode is active. When the engine high

speed idle select button light is on, fast drive

speedmodeisactive.

edge of the piece of wood and lift the end until

the piece of wood is level.

While holding the piece of wood level,

measure the distance from the bottom of the

piece of wood to the ground.

Divide the tape measure distance (rise) by the

length of the piece of wood (run) and multiply

by 100.

Example:

Run=3.6m

Rise = 0.3 m

0.3 m ÷ 3.6 m = 0.083 x 100 = 8.3%

If the slope exceeds the maximum slope or

side slope rating, the machine must be

winched or transported up or down the slope.

See Transport and Lifting section.

Driving on a slope

Determine the slope and side slope ratings for

the machine and determine the slope grade.

Maximum slope rating, stowed position 30%,

Maximum side slope rating, stowed position

25%

Note: Slope rating is subject to ground

conditions and adequate traction.

Press the drive speed select switch to the fast

drive speed mode.

To determine the slope grade

Measure the slope with a digital inclinometer

or use the following procedure.

You will need:

Carpenter’s level

Straight piece of wood, at least 1 m long

tape measure

To Extend and Retract Platform

1 Push and hold the platform spread button.

2 Push and hold the platform retracting

button.

Auxiliary Lowering

At the Ground Controls

Press and hold the lift function enable button.

Press and hold the platform down button.

At the Platform Controls

Press the lift function select button.

Push and hold the function enable button.

Activate the control handle in the direction

indicated by the yellow arrow.

Lay the piece of wood on the slope

At the downhill end, lay the level on the top

Operation from Ground with

29

OPERATOR’S MANUAL with Maintenance Information

Operating Instructions

Controller

Maintain safe distances between operator,

machine and fixed objects.

Be aware of the direction the machine will

travel when using the controller.

Outrigger Operation

1 Position the machine below the desired

work area.

Note: The engine must be running for the

outriggers to operate.

2 Push and hold the auto level button.

3 Press and hold the function enable switch.

Activate the proportional control handle in

the direction indicated by the yellow arrow.

The outriggers will extend and level the

machine. A beep will sound when the

machine is level.

How to use the Safety Arm

The safety arm on the left and on the right side

of the scissor system needs to be used for

maintenance work. This safety arm relief the

lifting cylinder and they hold the working

platform safe.

To put the safety arm into the retainer the

working platform has to be lifted. Afterwards

the screws can be released so that the safety

arm can be allinged downward.

When lowering the lifting system the safety

arm will be engage into the retainers among.

The lowering procedure will be interrupted

automatically if the safety arms are on block.

The indicator light on the lift function enable

button will turn on when one but not all

outriggers are down. All drive and lift functions

are disabled.

The indicator lights on the lift function enable

button and on the individual outrigger buttons

will turn off when all the outriggers are in firm

contact with the ground.

The drive function is disabled while the

outriggers are down.

To control individual outrigger

1 Push and hold one or more outrigger

buttons.

2 Press and hold the function enable switch.

Activate the proportional control handle in

the direction indicated by the yellow arrow.

The outriggers will extend and level the

machine.

Safety screw

Arm Retainer

30

OPERATOR’S MANUAL with Maintenance Information

Operating Instructions

Don’t engage the safety arm

unless unload the platform.

Using this safety arm is

necessary during operations near the scissor

system if the platform is lifted!

How to Fold Down the

Guardrails

The platform railing system consists of three

fold down rail section for the extension deck

and three sections for the main deck. All

sections are held in place by four latches.

2

○

3

○

4

○

5

○

6

○

1

○

1

○

Closed latch

Open latch

1 Fully lower the platform and retract the

platform extension.

2 Remove the platform controls.

3 Opening the latches in the corners the rails

have to be folded in correct order of the

numbering.

2

○

31

OPERATOR’S MANUAL with Maintenance Information

Operating Instructions

How to Raise the Guardrails

3

○

4

○

Follow the fold down instructions but in reverse

order.

Emergency operating with hand

pump

Emergency Lifting

1 Unplug the lever and put it into the hand

2 Press and hold the button(3).

3 Operate the hand pump with the lever, the

pump (1).

platform should rise.

5

○

6

○

Emergency Lowering

1 Unplug the lever and put it into the hand

pump (1).

2 Press and hold the button(2).

3 Operate the hand pump with the lever, the

platform should rise.

Retracting outriggers

1 Unplug the lever and

put it into the hand

pump (1).

2 Turn the knob (4) in

the direction of the

arrow.

3 Choose the outrigger which needs to

retract, turn the corresponding knob in the

direction of the arrow.

4 Operate the hand pump with the lever, the

outrigger emergency retract

Retracting Platform

1 Unplug the lever and put it into the hand

pump (1).

2 Turn the knob (6) in the direction of the

arrow.

32

OPERATOR’S MANUAL with Maintenance Information

Operating Instructions

3 Operate the hand pump with the lever, the

platform should rise.

Do not emergency lift/lower

the platform and retract outriggers simultaneity;

Reset the knob after all operations completed.

Emergency actuation of

outriggers only in normal position danger of

tipping!

After Each Use

1 Select a safe parking location - firm level

surface, clear of obstructions and traffic.

2 Lower the platform.

3 Turn the key switch to the off position and

remove the key to secure from

unauthorized use.

4 Chock the wheels.

1

2345678910

33

OPERATOR’S MANUAL with Maintenance Information

Transport and Lifting Instructions

Observe and Obey:

√ Common sense and planning must be

applied to control the movement of the

machine when lifting it with a crane or

forklift.

√ The transport vehicle must be parked on a

level surface.

√ The transport vehicle must be secured to

prevent rolling while the machine is being

loaded.

√ Be sure the vehicle capacity, loading

surfaces and chains or straps are sufficient

to withstand the machine weight. See the

serial label for the machine weight.

√ The machine must be on a level surface or

secured before releasing the brakes.

Free-wheel Configuration for

Winching

Chock the wheels to prevent the machine from

rolling.

Loosen nuts of screws provided for the

mechanical and manual release of the braking

units, and then move the nuts backwards by

approximately 8 mm.

√ Do not drive the machine on a slope that

exceeds the slope or side slope rating. See

Driving on a Slope in the Operating

Instructions section.

√ If the slope of the transport vehicle bed

exceeds the maximum slope rating, the

machine must be loaded and unloaded

using a winch as described.

Tighten screws so as to fasten them onto the

pressure plate.

Using a wrench, tighten the screws in an

alternate sequence by 1/4 turn at a time so as

to compress the Belleville washers and

disengage the braking disks

Before maintaining brakes,

whentheaxleisinstalledonthevehicle,follow

all safety instructions in the Original

Equipment Manufacturer (OEM) manual that

came with the vehicle.

Tighten maximum by one

turn.

34

Transport and Lifting Instructions

Securing to Truck or Trailer for

Transit

OPERATOR’S MANUAL with Maintenance Information

Always chock the machine wheels in

preparation for transport.

Retract and secure the extension deck(s).

Use the tie-down points on the chassis for

anchoring down to the transport surface.

Use a minimum of four chains or straps.

Use chains or straps of ample load capacity.

Turn the key switch to the off position and

remove the key before transporting.

Inspect the entire machine for loose or

unsecured items.

If the railings have been folded down, secure

them with straps before transporting.

35

OPERATOR’S MANUAL with Maintenance Information

Transport and Lifting Instructions

Observe and Obey:

√ Only qualified riggers should rig and lift the

machine.

√ Be sure the crane capacity, loading

surfaces and straps or lines are sufficient to

withstand the machine weight. See the

serial plate for the machine weight.

Lifting Instructions

Fully lower the platform. Be sure the extension

decks, controls and covers are secure.

Remove all loose items on the machine.

Determine the center of gravity of your

machine using the table and the picture on this

page.

Attach the rigging only to the designated lifting

points on the machine. There are two lifting

points on each end of the machine.

Adjust the rigging to prevent damage to the

machine and to keep the machine level.

Center of gravity X Axis Y Axis

JCPT2223RTA 1.7m 1.3m

Y Axis

X Axis

36

OPERATOR’S MANUAL with Maintenance Information

Maintenance

Observe and Obey:

√ Only routine maintenance items specified in

this manual shall be performed by the

operator.

√ Scheduled maintenance inspections shall

be completed by qualified service

technicians, according to the manufacturer's

specifications and the requirements

specified in this manual.

Maintenance Symbols Legend

The following symbols have

been used in this manual to help communicate

the intent of the instructions. When one or

more of the symbols appear at the beginning

of a maintenance procedure, it conveys the

meaning below.

Pre-delivery Preparation Report

The pre-delivery preparation report contains

checklists for each type of scheduled

inspection.

Make copies of the Pre-delivery Preparation

report to use for each inspection. Store

completed forms as required.

Maintenance Schedule

There are five types of maintenance

inspections that must be performed according

to a schedule— daily, quarterly, semi-annually,

annually, and two year. The Scheduled

Maintenance Procedures Section and the

Maintenance Inspection Report have been

divided into five subsections—A, B, C, D, and

E. Use the following chart to determine which

group(s) of procedures are required to perform

a scheduled inspection.

Indicates that tools will be required to

perform this procedure.

Indicates that new parts will be

required to perform this procedure.

Indicates that a cold engine is required

before performing this procedure.

Indicates that a warm engine will be

required to perform this procedure.

Indicates that dealer service will be

required to perform this procedure

Inspection Checklist

Daily or every 8 hours A

Quarterly or every 250 hours A+B

Semi-annually or every 500 hours A+B +C

Annually or every 1000 hours A+B +C +D

Two year or every 2000 hours A+B+C+D+E

Maintenance Inspection Report

The maintenance inspection report contains

checklists for each type of scheduled

inspection.

Make copies of the Maintenance Inspection

Report to use for each inspection. Maintain

completed forms for a minimum of 4 years or

in compliance with your employer, jobsite and

governmental regulations and requirements.

37

OPERATOR’S MANUAL with Maintenance Information

Maintenance

Pre-delivery Preparation

Report

Fundamentals

It is the responsibility of the dealer to perform

the Pre-delivery Preparation.

The Pre-delivery Preparation is performed

prior to each delivery. The inspection is

designed to discover if anything is apparently

wrong with a machine before it is put into

service.

A damaged or modified machine must never

be used. If damage or any variation from

factory delivered condition is discovered, the

machine must be tagged and removed from

service.

Repairs to the machine may only be made by

a qualified service technician, according to the

manufacturer’s specifications.

Instructions

Use the operator’s manual on your machine.

The Pre-delivery Preparation consists of

completing the Pre-operation Inspection, the

Maintenance items and the Function Tests.

Use this form to record the results. Place a

check in the appropriate box after each part is

completed. Follow the instructions in the

operator’s manual.

If any inspection receives an N, remove the

machine from service, repair and re-inspect it.

After repair, place a check in the R box.

Legend

Y = yes, completed

N = no, unable to complete

Scheduled maintenance inspections shall be

performed by qualified service technicians,

according to the manufacturer’s specifications

and the requirements listed in this manual.

R = repaired

Comments

Pre-Delivery Preparation Y N R

Pre-operation inspection

completed

Maintenance items

completed

Function tests completed

Model

Serial number

Date

Machine owner

Inspected by (print)

Inspector signature

Inspector title

Inspector company

38

Maintenance Inspection Report

OPERATOR’S MANUAL with Maintenance Information

Maintenance

Model

Serial number

Date

Hour meter

Machine owner

Inspected by (print)

Inspector signature

Inspector title

Inspector company

Instructions

• Make copies of this report to use for each

inspection.

• Select the appropriate checklist(s) for the type

of inspection to be performed.

Daily or 8 hours

□

Inspection:

Quarterly or 250 hours

□

Inspection:

Semi-annually or 500

□

hours Inspection:

Annually or 1000 hours

□

Inspection:

Two year or 2000 hours

□

Inspection:

• Place a check in the appropriate box after

each inspection procedure is completed.

• Use the step-by-step procedures in this

section to learn how to perform these

inspections.

• If any inspection receives an “N”, tag and

remove the machine from service, repair and

re-inspect it. After repair, place a check in the “R’

box.

Legend

Y = yes, acceptable

N = no, remove from service

R=repaired

ChecklistA Y N R

A-1 Manuals and decals

A-2 Pre-operation inspect

A-3 Check the Batteries

A-4 Check the Engine Oil Level

A-5ChecktheHydraulicOilLevel

A-6 Check the Engine Coolant Level

A-7 Function tests

A-8 Engine maintenance

A+B+C+D+E

A+ B

A+B+C

A+B+C+D

A-9 Drive Axle Maintenance

Perform after 40 hours:

A-10 30 day service

Perform after 50 hours:

A-11 Engine maintenance

Perform every 100 hours:

A-12 Drive Axle Maintenance

Checklist B Y N R

B-1 Battery

B-2 Electrical wiring

B-3 Exhaust system

B-4 Tires and wheels

B-5 Drive hub oil level

B-6 Key switch

B-7 Emergency Stop

B-8 Horn

A

B-9 Drive brakes

B-10 Drive speed - stowed

B-11 Drive speed - raised

B-12 Hydraulic oil analysis

B-13 Engine maintenance

B-14 Drive Axle Maintenance

Checklist C Y N R

C-1 Platform overload

C-2 Engine maintenance

C-3 Drive Axle Maintenance

Checklist D

D-1 Scissor arm wear pads

D-2 Free-wheel configuration

D-3 Replace the Drive Axle Oil

D-4 Engine maintenance

D-5 Drive Axle Maintenance

Checklist E Y N R

E-1 Test or replace hydraulic oil

Perform every 2000 hours:

E-2 Engine maintenance

Perform every 3000 hours:

E-3 Engine maintenance

Perform every 4000 hours:

E-4 Engine maintenance

Perform every 6000 hours:

E-4 Engine maintenance

Perform every 12,000 hours:

E-6 Engine maintenance

39

OPERATOR’S MANUAL with Maintenance Information

Maintenance

Checklist A Procedures

A-1

Inspect the Manuals and Decals

Maintaining the operator’s manual in good

condition is essential to safe machine

operation. Manuals are included with each

machine and should be stored in the container

provided in the platform. An illegible or missing

manual will not provide safety and operational

information necessary for a safe operating

condition.

In addition, maintaining all of the safety and

instructional decals in good condition is

mandatory for safe machine operation. Decals

alert operators and personnel to the many

possible hazards associated with using this

machine. They also provide users with

operation and maintenance information. An

illegible decal will fail to alert personnel of a

procedure or hazard and could result in unsafe

operating conditions.

1 Check to make sure that the operator’s

manual is present and complete in the

storage container on the platform.

⊙ Result: The machine is equipped with all

required decals, and all decals are legible and

in good condition.

¤ Result: The machine is not equipped with

all required decals, or one or more decals

are illegible or in poor condition. Remove

the machine from service until the decals

are replaced.

4 Always return the manual to the storage

container after use.

Note: Contact your authorized DINGLI

distributor or DINGLI Industries if replacement

manuals or decals are needed.

2 Examine the pages of manual to be sure

that they are legible and in good condition.

⊙ Result: The operator’s manual is

appropriate for the machine and the

manual are legible and in good condition.

¤ Result: The operator’s manual is not

appropriate for the machine or the manual

is not in good condition or is illegible.

Remove the machine from service until the

manual is replaced.

3 Open the operator’s manual to the decals

inspection section. Carefully and

thoroughly inspect all decals on the

machine for legibility and damage.

40

OPERATOR’S MANUAL with Maintenance Information

Maintenance

A-2

Perform Pre-operation Inspection

Completing a Pre-operation Inspection is

essential to safe machine operation. The

Pre-operation Inspection is a visual inspection

performed by the operator prior to each work

shift. The inspection is designed to discover if

anything is apparently wrong with a machine

before the operator performs the function tests.

The Pre-operation Inspection also serves to

determine if routine maintenance procedures

are required.

Complete information to perform this

procedure is available in the appropriate

operator’s manual. Refer to the Operator’s

Manual on your machine.

A-3

Check the Batteries

Proper battery condition is essential to good

engine performance and operational safety.

Improper fluid levels or damaged cables and

connections can result in engine component

damage and hazardous conditions.

Electrocution hazard. Contact

with hot or live circuits may result in death or

serious injury. Remove all rings, watches and

other jewelry.

Bodily injury hazard. Batteries

contain acid. Avoid spilling or contacting

battery acid. Neutralize battery acid spills with

baking soda and water.

1 Put on protective clothing and eye wear.

2 Be sure that the battery cable

connections are tight and free of

corrosion.

3 Be sure that the battery hold-down bars

are secure.

4 Remove the battery vent caps.

5 Check the battery acid level. If needed,

replenish with distilled water to the

bottom of the battery fill tube. Do not

overfill.

6 Install the vent caps.

41

OPERATOR’S MANUAL with Maintenance Information

Maintenance

A-4

Check the Engine Oil Level

Maintaining the proper engine oil level is

essential to good engine performance and

service life.

Operating the machine with an improper oil

level can damage engine components.

Check the oil level with the

engine off.

1 Open the engine cover

2 Release the latches on the engine tray and

fully rotate out

3 Check the oil level dipstick. Add oil as