Dinel ULM-53, ULS-53 Instruction Manual

Before the rst use of the level meter please read carefully the instructions provided in this User's Guide

and keep it for future use. The manufacturer reserves the right to make changes without previous notice.

INSTRUCTION MANUAL

Ultrasonic level Meters UlM – 53

Ultrasonic level sensors Uls – 53

TABLE OF CONTENTS

1. Safety .......................................................................................................................................4

2. Packing, transportation and storage ....................................................................................4

3. Measuring principle ................................................................................................................5

4. Range of application ..............................................................................................................5

5. Features of variants ................................................................................................................5

6. Dimensional drawings ............................................................................................................6

7. Installation and putting into operation .................................................................................6

8. Installation instructions .........................................................................................................7

9. Electrical connection ............................................................................................................ 11

10. Set-up elements ....................................................................................................................14

11. Status indication ...................................................................................................................15

12. Setting ....................................................................................................................................16

12.1. Setting procedure for level meters ULM-53 .................................................................17

12.2. Setting procedure for level sensors ULS-53 ................................................................19

13. Protocol Modbus...................................................................................................................21

14. Order code .............................................................................................................................21

15. Accessories ...........................................................................................................................22

16. Safety, protection, compatibility and explosion proof design .........................................22

17. Use, operation and maintenance ........................................................................................23

18. General conditions and warranty ........................................................................................23

19. Marking of labels ..................................................................................................................24

20. Specications .......................................................................................................................25

UL_–53 © Dinel, s.r.o.

4

Any operations described in this User's Guide may only be performed by trained personnel or by an authorized person. Warranty and post-warranty repairs shall be performed

exclusively on the manufacturer's site.

Improper use, installation or setting of the level meter may lead to crashes in the application

(overlling of the tank or damage to system components).

The manufacturer is not responsible for improper use , work losses resulting from direct

or indirect damage and expenses incurred during installation or use of the level meter.

1 .

SAFETy

USEd SymBOLS

In order to provide maximum safety of processes, we have dened the following safety and information instructions. Each of the instructions is marked with an icon.

Alert, warning, danger

This symbol informs about particularly important instructions for installation and operation

of the equipment or about dangerous situations that may occur during installation and operation. Failure to comply with the instructions may cause failures, damage or destruction

of the equipment, or may cause injuries to persons.

Information

This symbol informs about particularly important characteristics of the equipment.

2 .

PACkAgiNg, TrANSPOrT ANd STOrAgE

The ULM–53 or ULS-53 device is packed in a cardboard packaging and the whole shipment is

placed in a cardboard box. The cardboard box is suitably lled to prevent mechanical damage during transport.

Remove the device from the package just prior to its use to prevent possible damage.

Transport to the customer is provided by a forwarding company. Subject to prior arrangement, personal pick-up of the ordered goods is possible in the company's seat. Upon receipt, please check

whether the shipment is complete and corresponds to the extent of the order, or whether during the

transport the packaging and the device has not been damaged. Do not use a device apparently

damaged during transport and contact the manufacturer to resolve the situation.

If the device is transported further, it shall be wrapped in the original packaging and protected

against shocks and weather.

Store the device in its original packaging in a dry place, sheltered from weather, with humidity up

to 85% without the effects of chemically active substances. The range of storage temperature is

-20°C to +60°C.

Level meters (sensors) of variants ULM (ULS)–53_–01, 02, 06, 10 are tted with protective caps

to prevent damage to the ultrasonic transducer. Remove the caps before commissioning!

5

© Dinel, s.r.o. UL_–53

3 .

mEASUriNg PriNCiPLE

The ULM® ultrasonic level meters and the ULS® ultrasonic level sensors are compact measurement devices containing an electro-acoustic transducer and an electronic module. Using the

electro-acoustic transducer, level meters and level sensors transmit a series of ultrasonic puls-

es that spread towards the surface. The transducer then receives the reected acoustic wave,

which is subsequently processed in the electronic module. The current distance to the surface

level is calculated from the time of spread of individual pulses towards the surface and back and

the temperature measured in the tank. The output is then set on the basis of the surface height.

The outputs of the ULM level meter are current 4 -20 mA, voltage 0 - 10 V and industrial line RS-485

with Modbus RTU communication. The output of the ULS sensor consists of a PNP transistor with

an open collector and a two-state current switch 4 mA / 20 mA.

4 .

rANgE OF APPLiCATiON

Thanks to the proximity principle employed, the devices are suitable for continuous or limit measurement of the level of liquids, waste water, sludge, suspensions, adhesives, resins in various open

and closed vessels, sumps, open channels and drains. Applicability for measuring the surface level

of loose materials is limited, the range of measurement is shorter there. Setting is carried out either

using two buttons or a magnetic pen or by remote setting in case of Modbus RTU output. The device

is equipped with optical indication of its state (RUN) and the setting process (STATE). It is manufactured in designs for normal (N) and explosive atmospheres (Xi).

UL_–53_–01–_ measurement range 0.1 m to 1 m, all-plastic design, source

of PVDF (polyvinylidene uoride), mechanical connection

with thread G ¾.

UL_–53_–02–_ measurement range 0.20 m to 2 m, all-plastic design, source of PVDF,

mechanical connection with thread G 1''.

UL_–53_–06–_ measurement range 0.20 m to 6 m, all-plastic design, source of PVDF,

mechanical connection with thread G 1 ½".

UL_–53_–10– measurement range 0.4 m to 10 m, all-plastic case, source of PVDF,

mechanical connection with thread G 2 ¼“.

UL_–53_–20–_ measurement range 0.5 m to 20 m, all-plastic case, source of PVDF,

mechanical connection with ange of aluminium alloy.

5 .

FEATUrES OF vAriANTS

UL_–53 © Dinel, s.r.o.

6

6 .

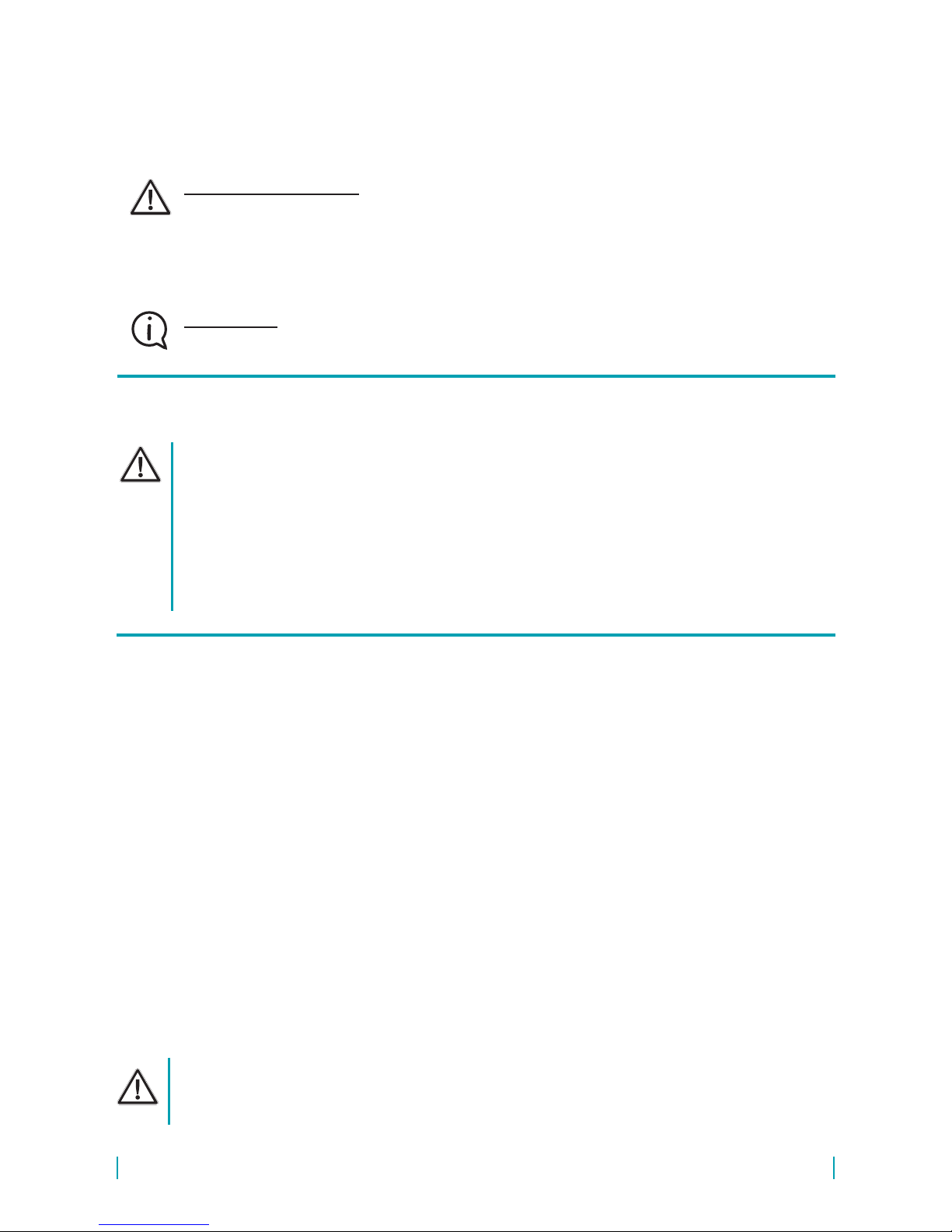

dimENSiONAL drAwiNgS

ground

terminal

UL_–53_–02–_

UL_–53_–06–_

UL_–53_–10–_

UL_–53_–20–_

Al alloy

This procedure includes the following three steps.

•

iNSTALLATiON

•

ELECTriC CONNECTiON

•

SETTiNg

7 .

iNSTALLATiON ANd PUTTiNg iNTO OPErATiON

UL_–53_–01–_

7

© Dinel, s.r.o. UL_–53

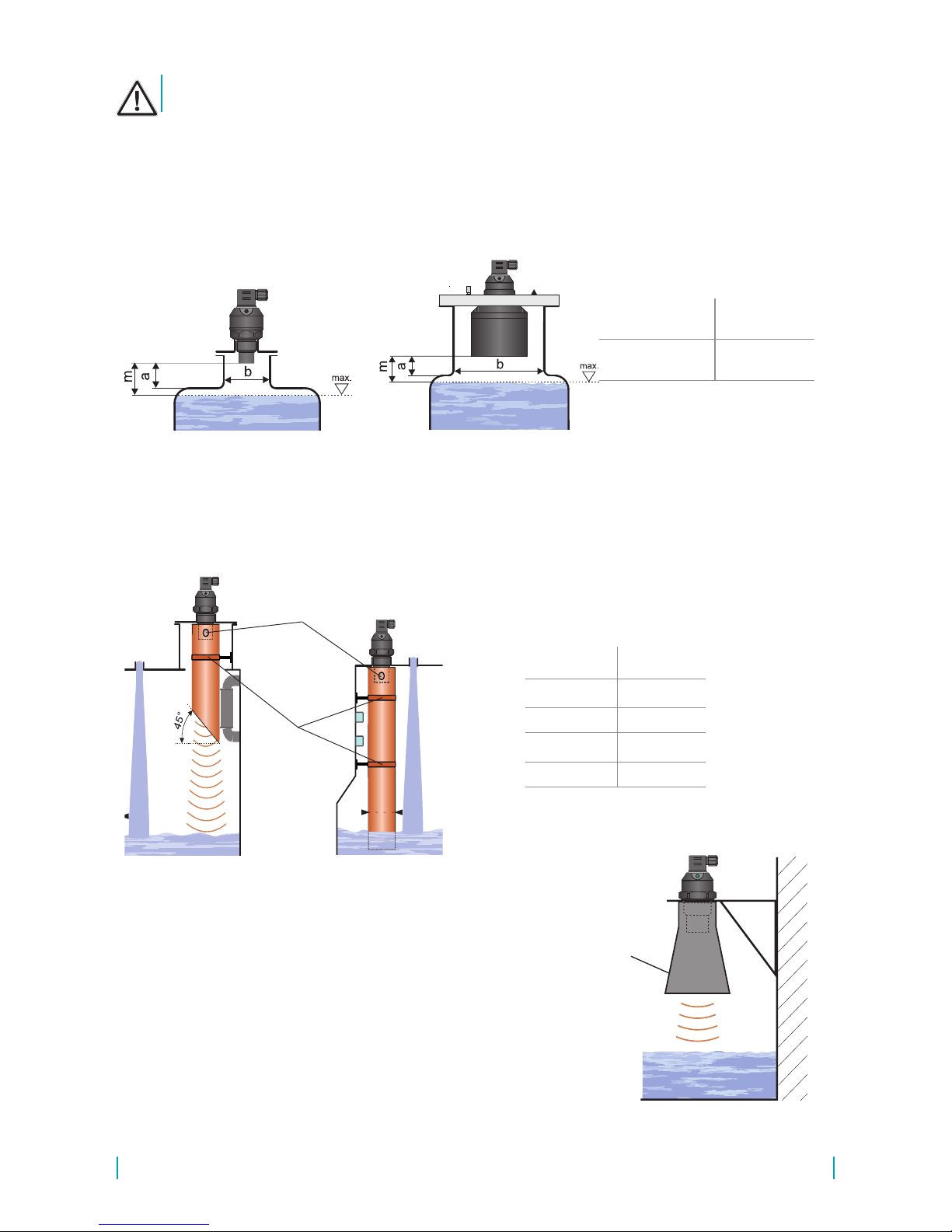

• The device is installed in a vertical position into the upper lid of the tank or reservoir using a

lug, a fastening nut or a ange in such a way that the axis of the device is perpendicular to the

surface level of the measured liquid (Fig. 1). Tightening

of the level meter in the welding ange (or. by the xing

nut) must be done only by hand *. The device shall be

installed in places with no risk of mechanical damage

to the front of the sensor.

• The minimum distance from the tank wall when installing

into the lid or the ceiling of the tank are listed in Fig. 3. In

the case of device installation close to smooth wall of the

tank it is not necessary to observe the minimum distance,

conversely it is suitable to shorten this distance.

• When installing in an open channel (sump, drain, etc.),

install the device onto a console as close as possible to

the expected maximum level.

• The reference plane for the measurement is the lower

edge of the transducer (Fig.2). In compliance with the

measuring principle, no signals reected in the area

directly below the device (dead zone) can be evaluated. The dead zone (Fig. 2) determines the minimum

distance possible between the device and the highest

level. The minimum distances to the medium are listed

in the chapter "Technical specications".

• The device shall be installed so that the surface does

not interfere with the dead zone when the tank is lled

to the maximum. If the measured surface interferes with

the dead zone, the device will not measure properly.

d – distance from tank wall

c – maximum reach of the device

m – dead zone

UL_–53–01 ; 02 ; 10

d > c/12

(min. 200 mm)

UL_–53–06

d > c/8

(min. 200 mm)

UL_–53–20

d > c/10

(min. 200 mm)

8 .

iNSTALLATiON iNSTrUCTiONS

Fig. 1: Correct installation of the sensor,

perpendicular to the liquid surface

Fig. 2: Dead zone of the device

Fig. 3: Distance of the device from

the tank wall

reference plane for

the measurement

*) To loosen the level meter can be used suitable wrenche.

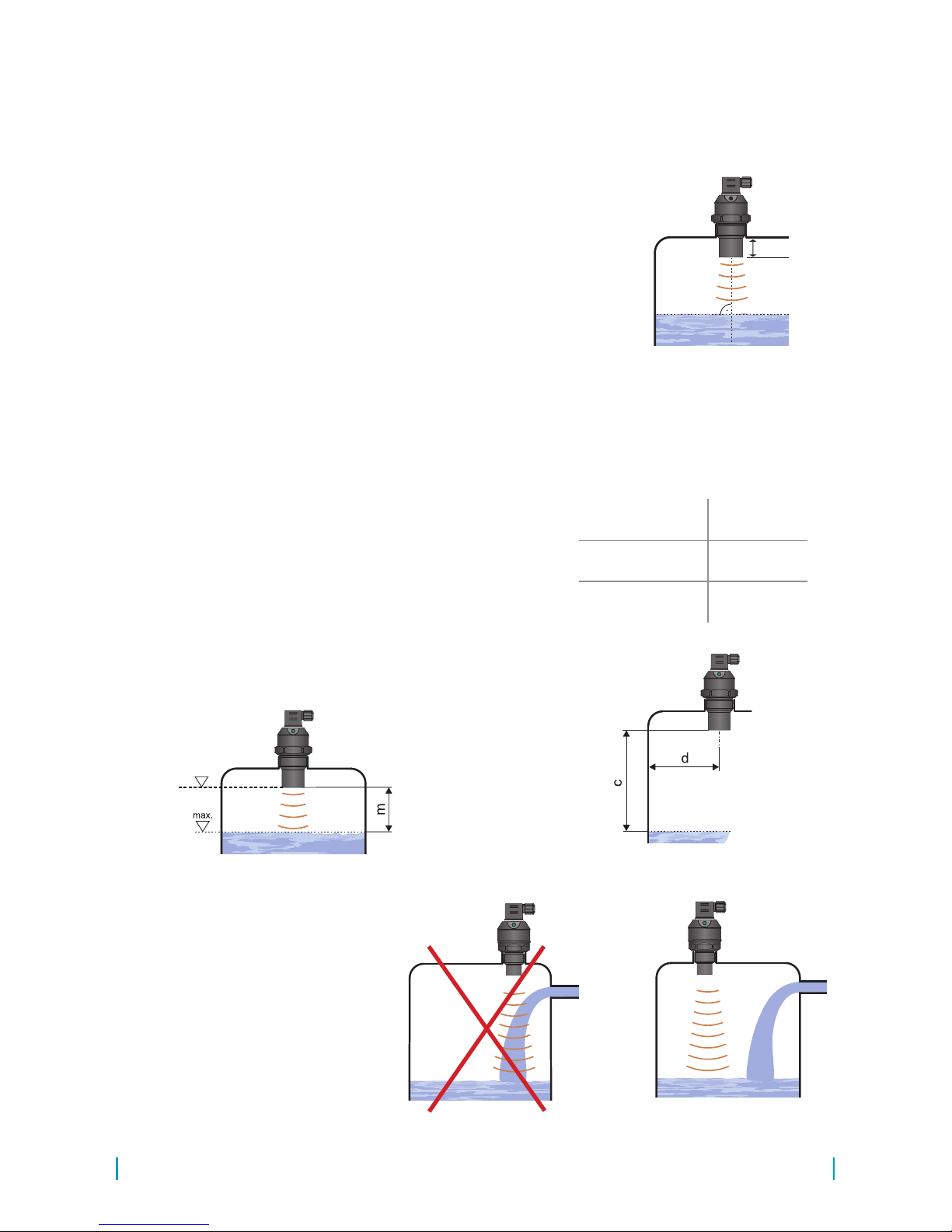

Fig. 4: Installation of the device out of reach of lling circulation

• Do not install the device in or

above the lling point (Fig.

4). The measurement could

be affected by the inowing

medium.

min. 10 mm

UL_–53 © Dinel, s.r.o.

8

It is recommended to avoid placing the sensor into a narrow inlet.

UL_–53–01; 02;

06; 10

a < 1.5 b

b > 100 mm

UL_–53– 20

a < 1.5 b

b > 150 mm

Fig. 5: Installation of the device in the installation neck

!

• If the level sensor is mounted to bottlenecks and places with barriers, or near uneven walls or the

lling area, where the transmission signal could be distorted, we recommend using a guide tube

(acoustic horn). The tube must be made from a single material with a smooth inner surface (see

image 6 a 7). The minimum tube diameter must have the dimension „h“ according to see to table

at image 7. The construction of the guide tube we recommend to consult with the manufacturer.

Fig. 6: Short guide

tube installation

ventilation holes

sleeves for

mounting

h

Fig. 7: Total guide

tube installation

Fig. 8: Horn adapter installation

Horn

adapter ST

• Horn adapter ST–G0,75 (for ULM–53_–01), ST–G1 (for

ULM–53_–02), ST–G1,5 (for ULM–53_-06) or ST–G2,25

(for ULM–53_–10) for improved reception of the transmitted

signal can be used in open channels, sumps, tanks, etc.

• Horn adapter ST increases the directivity of the emitted

acoustic waves, improves the reception of weak echoes

(unstable surface level, loose materials, foam on the level)

and reduces the risk of falsereections.

• The horn adapter is installed on the device via process

connection G3/4“ (ST–G0,75) or G1” (ST–G1) or G1½”

(ST–G1,5), or G 2 ¼“ (ST–G2,25).

a – neck height from source edge

b – neck width

m – dead zone

UL_–53–01 h ≥ 50 mm

UL_–53–02 h ≥ 70 mm

UL_–53–06 h ≥ 100 mm

UL_–53–10 h ≥ 150 mm

UL_–53– 20 h ≥ 200 mm

• Only if the maximum level in the tank gets into the dead zone, the device shall be mounted into

a higher installation neck. The tank can be then lled nearly up to the maximum volume. The

neck’s inner surface shall be even and smooth (without edges and welded joints), the inner

edge should be rounded in the spot where the ultrasonic wave leaves the pipe. Choose the

largest possible neck diameter, but keep the neck height as low as possible. The recommended

dimensions of the inlet neck are listed in Fig. 5.

9

© Dinel, s.r.o. UL_–53

• The ultrasonic signal can be scattered or attenuated if the

surface is moderately stirred or rippled (due to a mixer, inow

of liquid, etc.). This may result in reduction of the measurement range or unreliable operation of the device (Fig. 11).

For a rippled or swirling level, you can use the directional

horn to eliminate scattering of the ultrasonic signal.

!

Fig. 11: Moderately stirred surface

• The site for installing the level meter needs to be chosen so that the emitted acoustic signal is not

affected by nearby objects (reinforcements, supports, brackets, ladders, heating elements, mixers,

etc.). These obstacles may result in false rebounds, increasing measurement inaccuracy (Fig. 9).

x – distance from the edge of the longest

object

c – maximum reach of the level meter

UL_–53–01 ;02 ; 10

x > c/12

(min. 200 mm)

UL_–53–06

x > c/8

(min. 200 mm)

UL_–53–20

x > c/10

(min. 200 mm)

Fig. 9: Minimum distance from close objects in the tank

• Foam may be produced on the surface of the measured liquid

during lling, mixing and other processes. The thick foam

signicantly absorbs the ultrasound signal and may cause

malfunction of the device (Fig.10). In those cases it is necessary to test the device in advance or contact the manufacturer .

In case of a thin layer of foam, it is also possible to use

directional horn for improving receipt of the reected echo.

!

Fig. 10: Thick foam on the surface

!

Fig. 12: Strongly stirred

surface

Fig. 13: False reection from

mixer blades

• The device should not be installed in places

with the risk of falsereections of the ultra-

sonic signal from the mixer’s blades (Fig. 13).

• False surface reections of the ultrasonic

signal and unreliable operation of the device

might result from the mixer’s rotating blades

that ripple the surface level(Fig. 12).

Loading...

Loading...