Ultrasonic level meter ULM-55 - instructions

I. Description

The ULM-55 ultrasonic level meter is designed for continuous non-contact measurement of the level of liquids

and mushy and paste-like substances in open and closed vessels, reservoirs, sumps etc. Depending on the working

area, the N type can be applied in environments not exposed to the danger of explosion, whereas the Xi type is

intended for use in explosive environments.

Table 1 contains classifi cation of the environments.

The adjusting elements of the level meter are situated on the rear side of the sensor, under the cap nut (see

chapter V).

Table 1: Meter type and description of working areas (according to the Norms EN 60079-14, EN 60079-10)

ULM-55N non-explosive area

ULM-55Xi II 1/2G Ex ia IIBT5 with isolating repeater (e.g. IRU-420) complete level meter zone 1

front part of head zone 0

The level meter ULM-55 transmits by electro-acoustic transducer the series of ultrasonic pulses, which propagate towards to the level. Refl ected acoustic waves are received back by the transducer and processed in the

electronic module. The echos are traced in the fl oating time window, the time of the wawes fl ight are fi ltered and

averaged. Further is made the thermal compensation and the signalis transferred to the output current 4÷20 mA. If

continuing echo fault happens, the current of the level meter slowly falls down to the value <3,8 mA. When the level

is moving in the dead zone (see the catalogue’s data) the output current rises up to the alarm value >21 mA. This

value is kept, untill the level meter doesn´t register the continuous motion of the level away from the dead zone to

the nominal measuring range (jumping distance is evaluated as a permanent fault).

II. Assembly and disassembly

Level meters are installed in vertical position into the upper lid of a reservoir or a vessel, using welded-on piece,

nut or fl ange. The axis of the level meter must be perpendicular to the surface of the liquid being measured. The

installation point must be chosen in such way so that the emitted acoustic signal is not affected by near objects (reinforcements, ladders, mixing devices etc), liquid being poured inside, air fl ow etc. If in doubt, we advise to consult

it with the producer. The level meter housing need not to be grounded. Recommended dimensional parameters for

the level meter installation are shown in fi gure 1.

III. Installation

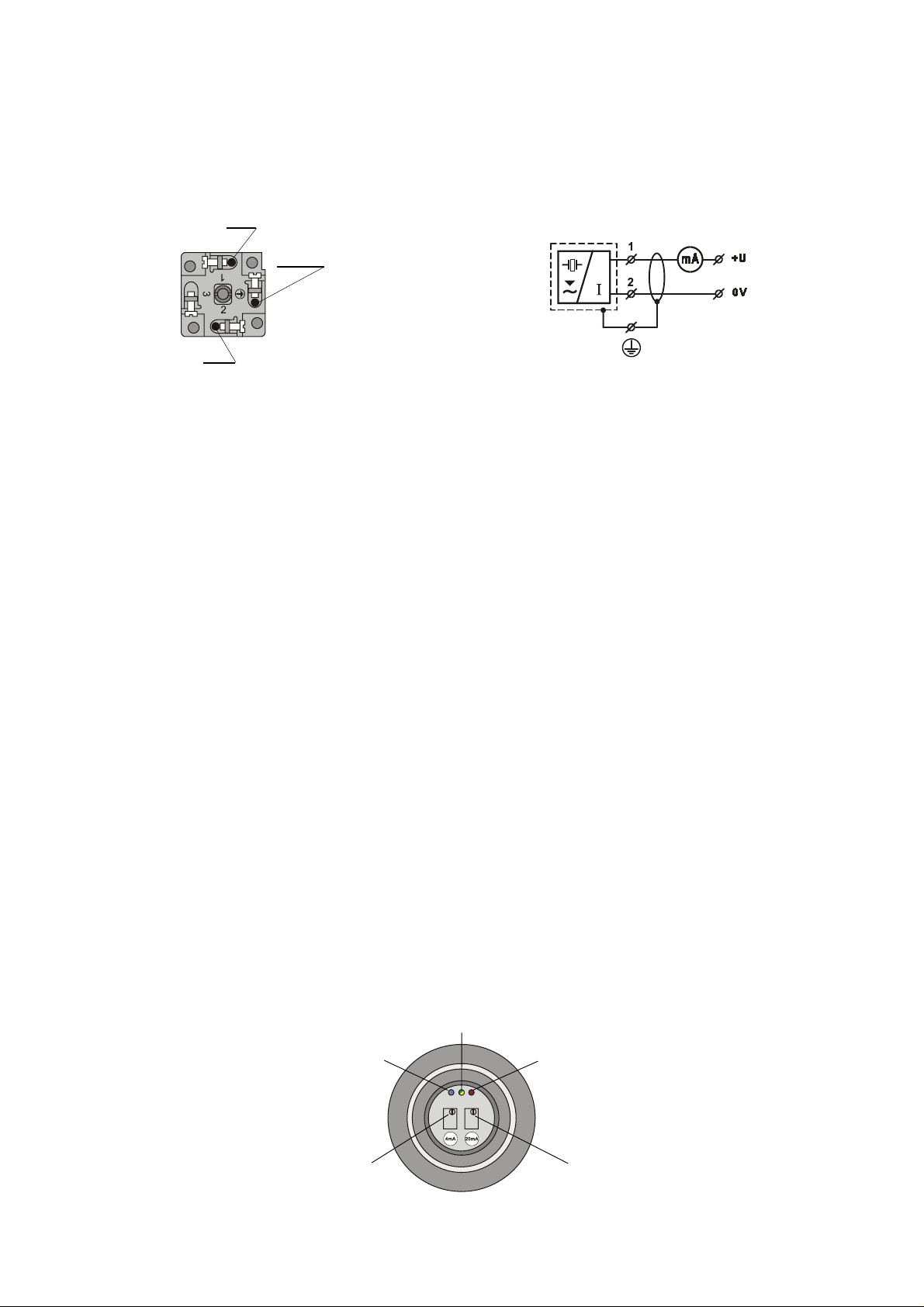

Terminals for electric connection are inside the dismountable GDM connector. Connect the positive pole (+)

ULM-55N-10

b > 100 mm

a / b < 1,5

c > 2000 mm

c / d < 8

ULM-55_-06

b > 100 mm

a / b < 3

c > 800 mm

c / d < 8

ULM-55_-02

b > 100 mm

a / b < 3

c > 500 mm

c / d < 8

Figure 1: Recommended dimensional parameters - dimension "a" must be as minimal as possible

ULM-nav-1.4

to terminal 1 and the negative pole (0 V) to terminal 2 – see fi gure 2 and 3. While making the connections the cable

must not be energised!

The level meter is connected to an evaluating device using a suitable two-core cable with an external diameter of

6-8 mm (recommended cross section of cores: 0,5 – 0,75 mm2). A shielded cable must only be used if the lead is

longer than 30 m or in the case of parallel lead togheter with power lines.

For supplying we advice a stabilized supply unit of safe voltage 12-30 VDC (SELV type), which can be part of the

connected evaluating device (for the ULM-55N type) or through an intrinsically-safe isolating repeater with supply

voltage 12-30 VDC, e.g. IRU-420 (for the ULM-55Xi type).

+U

shielding

0V

Figure 2: The inside of the GDM connector

Figure 3: Connection scheme

IV. Putting the unit into operation

The ULM-55N type: switch on the power supply (12-30 VDC).

The ULM-55Xi type: switch on the intrinsically safe isoating repeater (IRU-420).

V. Setting up

The level meter is set up by following steps. Use the adjusting elements located under the cap nut to set the

unit up – see fi gure 4.

Procedure:

1. Level meter is connected to the supply line via a miliampere meter (controller, etc.).

2. Disconnect the connector for access to adjusting elements and unscrew the cap nut (mind the internal wires).

Connect again the connector.

3. Empty the tank to the minimum level or put the level meter to the corresponding distance. Set the static current

by "4 mA" trimer to 4 mA.*

Turning to the right (clockwise) increases the current, while turning to the left decreases the current.

4. Fulfi ll the tank to the maximum level or put the level meter to the corresponding distance. Set the static current

by "20 mA" trimer to 20 mA.*

When it is impossible to fulfi ll the maximum level, then can be used any known (detectable) level and then set

appropriate current by next calculation:

I out = 4 + (0,16 x the level height in %) [mA]

5. To achieve maximum accuracy, it is advisable to re-check the setting of both limit values.

*

The trimmers do not have stop pieces – they can be turned approximately 15 times.

green-yellow wire

(shielding)

blue wire

(-)

trimer 4 mA

(minimum level

setting)

Figure 4: Adjusting elements

(top view of the internal electronic part)

ULM-nav-2.4

brown wire

(+)

trimmer 20 mA

(maximum level

setting)

Setting the level meter up inside the measured vessel (cesspit) is also possible and we recommend it especially:

- if accurate data of individual distances are not available

- if it is necessary to measure hot media (the meter must be tempered for about 1 hour before adjusting it;

the meter is equipped with temperature compensation)

- if it is necessary to measure a rippled surface (e.g. due to a nearby infl ow)

Note:

1) Set up the level meter is possible to proceed by simpler way outside of the measured tank. For example opposite a wall or opposite a fl at surface (sized aprox. 1 x 1m). Level meter must be perpendiculary targeted to

the measured surface (wall). While moving the level meter please avoid jumping distance changes (control

logic in ULM presuppose smooth level movement, jumping distance can be incorrectly evaluated).

2) If you don´t succeed in the level meter´s setting, or you don´t know at which distance the level meter is sett

then fi rst set the level meter to the basic stage by turning the trimer "20 mA" fully to the left (approximately 15

turn anti-clockwise).

3) If the level (refl ected surface) comes to the dead zone (see the catalogue’s data) during the setting, then the

current increases to the alarm value >21mA.

This value is kept, untill the level meter doesn´t register the continuous motion of the level away from the dead

zone to the nominal measuring range (jumping distance is evaluated as a permanent fault).

If the alarm signaling continues and it is impossible to put the current back by any motion of the level, then it

is necessary to make “Reset” of the level meter (disconnection and connection of the power supply).

The level meter makes level detection again.

4) Depending on the type, the level meter is set up by default for the following ranges:

ULM-55_-02 - 0,5 m (20 mA) to 2 m (4 mA)

ULM-55_-06 - 1 m (20 mA) to 4 m (4 mA)

ULM-55_-10 - 1 m (20 mA) to 8 m (4 mA)

VI. Usage, operation and maintenance

The level meter requires no operating personnel. In the case of operation, the optional local connected display

informs operating personnel about the measured level.

The maintenance of the unit includes a check-up on the good condition of the level meter and the supply cable.

Depending on the nature of the measured substance, we recommend to inspect the cleanliness of the emitting

surface at least once per year, and clean it if necessary, if detecting any visible damage. Contact the producer or

dealer immediately.

It is forbidden to modify or tamper in any way the ULM-55 unit without the approval of the producer. Repairs may

only be carried out by the producer or a service organisation authorised by the producer.

The ULM-55 unit must be assembled, installed, put into operation, operated and maintained in accordance

with these instructions, and the provisions of valid standards concerning electrical equipment installation must

complied with the ULM-55 features.

VII. Protection, safety, compatibility and non-explosiveness

The level meter is equipped with a protection against a reversal of polarity of supply voltage and against current

overload. Safety low voltage according to the Czech State Norm CSN 33 2000-4-41 protects against dangerous

touch. Electromagnetic compatibility is ensured in accordance with the Norms EN 55022/B, EN 61326-1, EN 610004-2, EN 61000-4-3, EN 61000-4-4, EN 61000-4-5, EN 61000-4-6. The non-explosiveness of the ULM-55Xi type is

certifi ed by FTZÚ-AO210 Ostrava-Radvanice, certifi cate number FTZÚ 02 ATEX 0263.

VIII. Labelling

The cap nut of the ULM-55N type contains the following information:

- Producer’s/ label and contact information

- Type of the level meter ULM-55N-_ _ (old version) or ULM-55N-_ _A (new version)

- Year of production (fi rst two digits) and serial number (remaining three digits) xx-xxx

- Supply voltage: U = 12÷30 VDC

- Range of output current I = 4÷20 mA

- Range of head working temperatures ta = - 30 … +70 °C (or ta= - 30 ... +60 °C for ULM-55N-10)

- Protection: IP65 / IP67

- CE labelling

- mark of electronic device waste (bin)

ULM-nav-3.4

ULM nav 4

.4

The cap nut of the ULM-55Xi type contains the following information:

- Producer’s label and contact information

- Type of the level meter ULM-55Xi-_ _ (old version) or ULM-55Xi-_ _A (new version)

- Year of production (fi rst two digits) and serial number (remaining three digits) xx-xxx

- Ex labelling in the hexagon

- rgerhgType II1/2GExiaIIBT5

- Number of the spark safety certifi cate

- Limit operating parameters U

= 30 VDC, Ii = 132 mA, Pi = 0,99 W, Ci = 370 nF, Li = 0,9 mH

i

- Range of head working temperatures ta = - 30 … +70 °C, ta = - 20 … +60 °C zone 0

- Protection: IP65 / IP67

- CE labelling

- Number of the authorised person inspecting the quality system

- mark of electronic device waste (bin)

IX. Standard accessories

For each sensor - 1 connecting GDM connector

For each delivery (per each 5 pieces)

- 1 adjusting screwdriver

For more detailed information about the product see www.dinel.cz

Dinel, s.r.o., U Tescomy 249, CZ - 760 01 Zlin - Priluky, Tel.: +420-577 002 003, fax: +420-577 002 007

E-mail: sale@dinel.cz Web: http://www.dinel.cz

05. 2007

Loading...

Loading...