General Information Agri NIR™ Analyzer Rev. A11

ENGLISH

1

INTRODUCTION

Some images included in this manual may differ from the real ones due a recent product updates. The

methods of use described are equally correct.

AgriNIR™ by

optical analyzer for fresh forages based on NIR

technology in order to measure humidity (dry

matter), crude protein, st arc h, ash, ADF a nd NDF of

the analyzed materials. Thanks to AgriNIR™ the

analysis of most relevant and variable ingredients

(forages!) used in your rati os can be performed j ust

in a few seconds on site, allowing to know in real

time its actual nutritional values.

AgriNIR™ is bas e d on NI R (Near Inf r a-Red) technology: it scans the sample with light and reads the

spectra absorbed by the sam ple in the NIR region.

Thanks to chemometrics techniques and

mathematical algorithms based on multivariate

analysis, the AgriNIR™ is able to provide

predictions on actual nutrients of the sample in a

real time.

This instrument structure is composed by :

• a microcomputer that manages the data, carries out mathematical operations applying complex

algorithms, providing the final results and the user interface devices: screen, keyboard and printer;

• an optica l group: the sam ple scanner and the NIR sensor, a trans ducer able to tr ansform the opt ical

signal in an electrical one.

is a portable

During the process of analysis there are the following main steps:

1. the light source emits light investing the sample inserted into the sample cup;

2. the sample absorb part of the light accordingly to its actual nutritional values;

3. the thermo-controlled NIR sensor collects spectra and measures the absorbance transforming the

optical in an electrical signal, then in numerical data;

4. the data are transf erred to the microcomputer able to apply all mathematical algorithm s in order

to predict the actual nutritional values for the sample.

General Information AgriNIR™ Analyzer Rev. A11

2

LICENCE AGREEMENT

IMPORTANT NOTICE: Acceptance and use of the enclosed NIR system (hereinafter

referred to as “Purchased Product”) constitutes your agreement to the following terms

and conditions. Please carefully read the following terms and conditions before using or

reselling the Purchased Product.

1. Limited License . Dinamica generale, an Italian company (“Owner”) is the owner of

the following Patents related to NIR solutions EP 2 377 392 / US 8 651 730 (“Patents”).

Owner hereby grants to the customer(“Customer”) a non-exclusive, non-transferable,

revocable, limited license to use the technology described in the Patents to use the

Purchased Product in the process covered by the Patents (“Licensed Product”), and to

sell and offer for sale other Licensed Product in accordance with the terms and

conditions set forth herein. Alternatively, Customer may resell the Purchased Product to

another entity for the purpose of that entity assembling the Licensed Product under a

permitted sublicense from the Customer with the same terms as this Agreement.

2. Acceptance of Terms and Conditions . Customer warrants that it has the authority

to enter into this binding agreement. If Customer does not accept the terms and

conditions, Customer shall not use the Purchased Product. Customer understands and

agrees that if it uses the Purchased Product as permitted herein, it will be deemed to

have accepted these terms and conditions and they shall become a binding agreement.

3. Limitations on Use

expressly authorized in this Agreement, and that any use not expressly authorized in

this Agreement is prohibited. Customer agrees that it will not: (i) loan, rent, lease,

assign, sublicense, distri bute

or otherwise transfer its rights under this Agreement to a third party, other than to resell

the Purchased Product to another entity for the purpose of that entity assembling the

Licensed Product; (ii)

copy or reproduce the Licensed Product; or (iii) grant any sublicenses other than to an

end user of the Licensed Product, or to another entity for the purpose of that entity

assembling the unit of a Licensed Pr od uct . C ust o mer agr ees to use r eason abl e e f for ts

to prevent any unauthorized

use or copying of the Licensed Product and will notify Owner immediately upon learning

of any such unauthorized use or copying.

Customer’s obligations under this section shall survive any termination of this

Agreement or the license granted hereunder. Any unauthorized use of the Licensed

Product will result in, among other things, the immediate termination of this license.

4. Ownership of Proprietary Rights . Customer acknowledges that the Licensed

Product is covered intellectual and/or proprietary rights, and that all such intellectual and

proprietary rights are owned by Owner. Customer hereby acknowledges that it has no

rights in the foregoing except as expressly granted herein.

. Customer agrees that it will use the Licensed Product only as

5. NO WARRANTY

and Customer acknowledges and agrees that Owner will not assume any product

liability or any other

liability for the Purchased Product or the Licensed Product. The Purchased Product is

furnished to Customer “AS IS.” Except as otherwise provided by separate

documentation, OWNER

MAKES NO WARRANTIES, EITHER EXPRESS OR IMPLIED, WITH RESPECT TO

THE PURCHASED

. Customer agrees to fully test and evaluate the Purchased Product

General Information Agri NIR™ Analyzer Rev. A11

ENGLISH

3

PRODUCT.

Customer agrees that Owner shall have no liability resulting from

Customer’s use of the Purchas ed Pro duct for any indirect damages includi ng

consequential, incidental or special

damages for loss of profit, good will or otherwise. Customer shall indemnify and hold

Owner harmless from any and all losses, expenses, damages, costs or expenses of any

kind,

including but not limited to reasonable attorneys’ fees, incurred by Owner resulting from

Customer’s use of the Purchased Product. NO ORAL OR WRITTEN STATEMENTS

MADE BY OWNER OR ITS EMPLOYEES INCLUDING BUT NOT LIMITED TO

STATEMENTS REGARDING CAPACITY,

SUITABILITY FOR USE, OR PERFORMANCE OF THE PURCHASED PRODUCT

SHALL BE DEEMED A WARRANTY OR REPRESENTATION BY OWNER FOR ANY

PURPOSE NOR GIVE RISE TO ANY LIABILITY OR OBLIGATION OF OWNER.

6. Remedies for Violations

. Owner reserves the right to seek all remedies available at

law and in equity for violations of this Agreement, including but not limited to the right to

recover the

Licensed Product.

7. Fees . In consideration for the rights granted under this Agreement, Customer has

paid a license fee that was included in the amount invoiced to the Customer for the sale

of the Purchased Product.

8. Entire Agreement . Except as expressly stated herein to the contrary, this Agreement

constitutes the entire agreement between the parties regarding the subject matter

hereof, and no verbal or written prior statements or representations of any sort made by

any party shall be effective or valid for any purpose whatsoever. This Agreement may

be amended only upon the mutual consent of all parties in writing.

9. Severability . If any provision of this Agreement shall be held to be invalid, illegal or

unenforceable, the validity, legality and enforceability of the remaining provisions shall

not in any way be affected or impaired thereby. The failure of any party to enforce any

provision of this Agreement shall not be considered a waiver thereof, nor shall such

failure prevent the future enforcement of any such provision.

10. Governing Law. This Agreement and the relationship between the parties shall be

governed in all respects by the laws of Italy. The parties consent to the jurisdiction and

venue of the Italian court of Bologna for resolution of any dispute under to this

Agreement.

Use or sale of the Licensed Product or of Purchased Product shall bind Customer

to all terms and conditions herein without the necessit y of signatures on this

Agreement.

General Information AgriNIR™ Analyzer Rev. A11

4

1.

2.

32 VDC

is not responsible for

3.

4.

5.

6.

clearing the

7.

ft and

8.

BEFORE USING

For a correct function ing of the device, it will be nec essary to put t he AgriNIR™ on a

horizontal surface allowing the user to move easily the fodder box containing the

sample to analyze.

The AgriNIR™ device must be supplied with a tension between 9,5 –

through the suitable connector put on the upper of the case. That can be done

through:

• Power Supply (output at 12 VDC) provided with the device;

• Supply cable (optional) with plug for car lighter supply.

In case other supply sources were used,

damages to people or the AgriNIR™ device.

For a correct functioning verify:

• In case of supplying through a 12 VDC s upplier, that the cable f or the supp lier is

If it is not the case,

If it is not the case, is not responsible for damages to the AgriNIR™.

connected to a tension between 100-240 VAC;

• In case of supplying through th e plu g f or car li ght er, that the battery has a tension

always higher then 9,5 Volts.

During delivery of the AgriNIR™ it is important:

• Not to put mobile and/or sharpened objects inside the case preventing the

electronic/optoelectr onic (graphical displa y, printer, communication cable , optical

fiber protected by a black sheath put at the bottom of the case) device from

being broken or wrongly hurt.

• To fasten the accessories (fodder box, accessories for the fodder box, power

supplier, supply cable, s up ply cable with plug for car lighter, c le arin g ac c ess or ies)

to prevent them from moving inside the case or the electronic/optoelectronic

device from being broken.

is not responsible for damages to the AgriNIR™.

DO NOT POWER the AgriNIR™ d evice ( b y suppl y power c able f or car ligh ter) du ring

transporting by car.

Disconnect the supply cable from the device before servicing and/or

AgriNIR™.

If it is not the case, is not responsible for da mages to people or to

the AgriNIR™.

To clean the AgriNIR™ correctly:

• for the upper part (display, keyboard, printer, reading glass) use a so

DO NOT use neither alcohol nor other solvents!

DO NOT wet with water!

If it is not the case,

If it is not the case, is not responsible for damages to the device.

slightly wet cloth;

• For the bottom (metal chassis of the f odder b ox and reading window of the R ead

NIR) use pressurized air or a soft and slightly wet cloth.

is not responsible for damages to the AgriNIR™.

For a correct function ing of the sampling fodder b ox, use a soft cloth or pressur ized

air or flowing water. DO use neither alcohol nor other solvents!

General Information Agri NIR™ Analyzer Rev. A11

ENGLISH

5

1.

2.

used. While working the

3.

4.

5.

6.

7.

8.

9.

CANNOT be consid ered responsible for damages to people or

10.

NOTES FOR THE USER

After switch ing ON the AgriNIR™, recomm ends strongly to wait

at least

the exercise temperature of the optoelectronic device.

For a correct func tioning of the o ptoelectronic device contained in the AgriNIR™, it’s

better to monitor the temperature of the place where it is

device mustn’t exceed the temperature range between 0°C and +40°C.

If it is not the case, is not responsible for damages to the AgriNIR™.

If ambient temperature is 3 5°C or upper, DO NOT keep the AgriNIR™ device turned

on for more than 2 hours time (

15 minutes before executing the analys is. That will allow the o ptimization of

IMPORTANT!

for machines HW rev. B3 or previous).

If it is not the case,

In case of use of the devic e outside, it SHOULD NOT

be exposed directly to climatic agents such as rain,

snow, hail ...

If it is not the case,

In case AgriNIR™ were supplied through the suitable supply cable (optional) with

plug for car lighter, disconnect this cable when the vehicle’s battery is being charged.

If it is not the cas e, is not responsibl e for damages to people or to

the AgriNIR™.

Disconnect the supply cable from the device before servicing and/or clearing the

AgriNIR™.

If it is not the case, is not responsible for da mages to people or to

the AgriNIR™.

For a correct functioning verify:

• In case of supplying through a 1 2 VDC supp lier, that t he cable f or the supp lier is

connected to a tension between 100-240 VAC;

• In case of supplying throug h th e plu g f or car li ght er, that the battery has a tension

always higher then 9,5 Volts.

is not responsible for damages to the AgriNIR™.

is not responsible for damages to the AgriNIR™.

DO NOT use USB extension cables LONGER than 1 meter to connect the USB

memory key to the USB connector available on the front unit of AgriNIR™ device.

things because of a misuse of the device.

DOES NOT assum e the responsibilit y for the result provide d by

AgriNIR™ in case there were not correspondence between the material analyzed and

the one declared by the system.

11. This marking on the product or on its pack aging illustrates that

this product may not be disposed of with normal household

waste. You are responsible for disposal of this equipment in a

correct way and in according to local regulatio ns .

General Information AgriNIR™ Analyzer Rev. A11

6

1 CONTENTS

INTRODUCTION ................................................................................................................... 1

LICENCE AGREEMENT ........................................................................................................ 2

BEFORE USING .................................................................................................................... 4

NOTES FOR THE USER ....................................................................................................... 5

1 CONTENTS .................................................................................................................. 6

2 TECHNICAL DATA & CONFIGURATION ..................................................................... 7

3 ACCESSORIES SUPPLIED .......................................................................................... 9

4 ELECTRIC CONNECTIONS ....................................................................................... 11

4.1 Supplying AgriNIR™ with the provided power supply ..................................................... 11

Supplying AgriNIR™ with the power cable for car lighter plug ........................................ 12

4.2

5 Description of the portable Analyzer AgriNIR™ ........................................................... 13

6 Use of the Portable AgriNIR™ Analysis System .......................................................... 16

6.1 NIR Parameters and NIR Families ................................................................................... 16

Correct Use of the Fodder Box for the Samples to Analyze ............................................ 18

6.2

Turning on the AgriNIR™ system .................................................................................... 21

6.3

States & Messaging of NIR analyzer internal system ...................................................... 23

6.4

Error Messaging of NIR analyzer internal system ........................................................... 25

6.5

Initial Optical Checking of the AgriNIR™ system ............................................................. 27

6.6

Analysis Samples Identifying ........................................................................................... 31

6.7

Analysis Exe cution with AgriNIR™ System ..................................................................... 34

6.8

Case of incorrect analysis ................................................................................................ 39

6.9

6.10 Analysis printing on tickets ............................................................................................... 40

Analysis saving on USB pen drive ................................................................................... 42

6.11

Analysis History – available only for AgriNIR W .............................................................. 44

6.12

Other Settings of AgriNIR™ System ................................................................................ 46

6.13

Calibration Updating of AgriNIR™ System ...................................................................... 47

6.14

Update Calibrations for AgriNIR W ....................................................................................... 48

6.14.1

LOADING OF NEW NIR DATA STRUCTURE (NIRDATA.BIN file) ................................ 50

6.15

Deleting Analysis on internal memory ............................................................................. 52

6.16

Deleting the initial message of FULL MEMORY .............................................................. 53

6.17

Printer Header Settings .................................................................................................... 55

6.18

7 CLEANING THE DEVICE ............................................................................................ 57

8 DEVICE SERVICING .................................................................................................. 58

8.1 Verification and Servicing of the Optical Group ............................................................... 58

Replacement of the Printer’s Paper ................................................................................. 59

8.2

9 RESPONSIBILITIES ................................................................................................... 60

10 CE CONFORMITY DECLARATION ............................................................................ 61

11 WARRANTY ................................................................................................................ 62

General Information Agri NIR™ Analyzer Rev. A11

ENGLISH

7

2 TECHNICAL DATA & CONFIGURATION

AgriNIR™ configurations

Code Machine Features

999-0228 AgriNIR Analyzer

999-0565 AgriNIR W Analyzer

999-0347 AgriNIR Analyzer with GSM/GPRS

Accuracy

[Note 2. at next page]

Working Temperature

[Note 1. at next page]

Power

Display

Dimensions 50 x 31 x 46 cm

Weight 20 Kg

standard machine

Worldwide version

with GSM/GPRS Quad-Band internal modem

[ see the tables at next page ]

0° ÷ +40°C

12 ÷ 18 VDC

60W max

LCD monochromatic

¼ VGA

Box ABS plastic

Protection Grade n. a.

Quad-Band GSM release 99

850/900/1800/1900 MHz

GMS / GPRS

internal modem

[only cod. 999-0347]

Paper Type

Paper width

Paper Type suggested

Roll diameter inner core

GPRS multi-slot class 12

Output power :

• Class 4 (2 W) for EGSM850

• Class 4 (2 W) for EGSM900

• Class 1 (1 W) for GSM1800

• Class 1 (1 W) for GSM1900

Thermal paper roll

(thermal side outside of the roll)

57 mm ±0.5 mm

from 55 g/m² to 70 g/m²

13 mm

Outer roll diameter max. Ø44mm

Soul type Cardboard or plastic

General Information AgriNIR™ Analyzer Rev. A11

8

NOTES FOR THE USER points N°

NIR

Families

NOTES.

If AgriNIR™ machine has Hardware revision B3 or p revious (the HW rev. is showed on yell ow

1.

label together machine S/N), the maximum working temperature recommended is 35°C.

For Hardware revision B4 or newer the maximum working temperature is 40°C.

Please DO NOT exceed the limits of temperature, according to

2 and 3 at page 3.

The percentage of Accuracy DOES NOT express the mathematical percentage of the error on

2.

analysis result, but it represents the maximum error in percentage points between the analysis

result (just expressed in pe rcent age points ) prov ided b y AgriNIR™ and the real analysis va lue, tha t

you can obtain by chemical analysis on the material in question.

Please see below the specific AgriNIR™ Accuracy values for each NIR family / parameters :

AgriNIR™

accuracy for

DG standard

calibrations package

CORN SILAGE

HAY

HIGH

MOISTURE

CORN

ALFALFA HAY

NIR Families

GRASS SILAGE

T.M.R.

SOYBEAN

FLOUR

NIR Chemical Parameters

Moisture

( Humidity )

Starch

Crude

Protein

ADF NDF Ash

±2,0% ±2,0% ±1,0% ±1,0% ±1,5% ±0,5% ±0,5%

±1,0% n.a. ±1,0% ±2,0% ±2,5% ±1,5% ±0,5%

±2,0% ±3,0% ±1,0% ±1,5% ±2,5% ±0,5% ±0,5%

±1,0% n.a. ±1,5% ±3,0% ±3,0% ±1,0% ±0,5%

±2,0% n.a. ±1,5% ±2,0% ±2,5% ±1,5% ±0,5%

±2,0% ±2,0% ±1,0% ±1,5% ±2,0% ±0,5% ±0,5%

±1,0% n.a. ±1,5% n.a. ±1,5% ±1,0% ±1,0%

Crude Fat

( Ether

Extract )

AgriNIR™

accuracy for

DG grains

calibrations package

[ optional ]

CORN GRAIN

WHEAT GRAIN

Moisture

( Humidity )

±1,0% ±1,0% ±1,0% n.a. ±1,0% ±1,0% ±1,0%

±1,0% ±1,0% ±1,0% n.a. ±1,0% ±1,0% ±1,0%

NIR Chemical Parameters

Starch

Crude

Protein

ADF NDF Ash

Crude Fat

( Ether

Extract )

General Information Agri NIR™ Analyzer Rev. A11

ENGLISH

9

3 ACCESSORIES SUPPLIED

Accessory Description

FODDER BOX

Tray with glass for fodder samples

and its pressure plate.

Also it presents special housing for

Check-Cell.

PRESSOR

The pressor with sponge is used for

grains or dry and chopped m att er.

The pressor without sponge is used

for forages of wet and voluminous

type.

General Information AgriNIR™ Analyzer Rev. A11

10

CHECK CELL

Special sample cell

acetyl resin for the

optics testing of

the machine.

POWER SUPPLY

AC input :

100-240V~2A, 50-60Hz

DC output :

12V, max 8A

and

AC power cable with SCHUKO plug

IEC320 connector.

Power cable for car lighter

plug

USB memory pen-drive

Roll of thermal paper for

printer

AgriNIR™ User Manual

Configuration AgriNIR™ Analyzer Rev. A11

ENGLISH

11

Power Connector

Power Supply

AgriNIR™ Analyzer

4 ELECTRIC CONNECTIONS

4.1 Supplying AgriNIR™ with t he pr ov ided power supply

IN : 100-240VAC – 2A

OUT : 12VDC – max 8A

Configuration AgriNIR™ Analyzer Rev. A11

12

Power Connector

AgriNIR™ Analyzer

4.2 Supplying AgriNIR™ with t he powe r cable for car lighter plug

Power cable for car lighter plug

Configuration AgriNIR™ Analyzer Rev. A11

ENGLISH

13

FODDER BOX

NIR OPTICAL UNIT

Knob and security

Communication

Printer

USB plug

PROG / DATA connector for

Screen and keypad

ELECTRONIC UNIT

GSM/GPRS

ON / OFF

5 Description of the portable Analyzer

AgriNIR™

In the following pictures it is explained how the system AgriNIR™ is composed:

modem led

available only for

AgriNIR 999-0347

for memory

pen drive

downloading data and

programming AgriNIR™

[ DG assistance only ]

for inserting the sample to analyze

hinge of NIR Unit

cable of NIR Unit

Configuration AgriNIR™ Analyzer Rev. A11

14

USB

Sample of forage

Measured Light

Optical Spectra Archive

DGNirManager

The portable Analyzer AgriNIR™ is composed by:

FODDER BOX → sampling box with screwed handles on presser, for the collection of the forage samples

that has to be analyzed with AgriNIR™.

NIR OPTICAL UNIT → optical unit for acquisition of light produced by the sample to be analyzed.

This unit consists of:

• Read NIR → O ptic a l rea di ng h ead that s ens es t h e lig ht s pec tra produced by the f eed c omponent

present in the fodder box inside AgriNIR™ system.

• Optical Fiber → transmits the light sensed by Read NIR head to NIR optical sensor.

• NIR sensor → optoe lectronic device that receives the light spectra sensed b y Read NIR head

on the feed component and transforms them in electrical signals.

ELECTRONIC UNIT → processing and control unit o f the AgriNIR™ system . With this unit the operator

can start the anal ysis on the feed com ponents put in t he fodder box, and get the anal ysis results sho wn

on display. These results can be printed on a paper or stored on a USB Pen Drive.

USB MEMORY PEN DRIVE → Memory unit that allows to store the results of the performed analysis and

to transfer them to PC through the management software DGNirManager.

Please see NOTES FOR THE USER point N° 8 at page 3.

The conceptual model that def ines the functioning of the por tab le a na l ysis s ystem AgriNIR™ is explained

in the following scheme :

Setting of :

NIR Families;

Chemical Parameters;

Calibration Curves.

AgriNIR™ Analyzer

key

NIR Families and

Chemical Parameters

NIR Calibrations

Data saving for :

analysis results;

optical spectra.

Spectra

Configuration AgriNIR™ Analyzer Rev. A11

ENGLISH

15

For the setting of the feed c omponents to an alyze and the st orage of the performed anal ysis on PC it is

used the management program DGNirManager produced by

This software product on PC allows the user to:

• set the Chemical Parameters for the analysis to be performed with the AgriNIR™ system;

• mark the feed components that will be analyzed with the AgriNIR™ system, b y means of NIR

Families components giving them proper theoretical reference values for the chemical

parameters that charac teri z e them; after having completed i ts own s et of f eed c omponents, this is

transferred to AgriNIR™ system through the USB memory key;

.

• store all the analysis p erformed with AgriNIR™ system and r elevant optical spectra sensed on

the analyzed components, previously stor ed o n U SB memory key; after having c ompleted its own

set of analysis, new Calibration Curves can be performed, i.e. new setting curves to be

transferred to the AgriNIR™ s ystem through the USB m emory key, in order to m ake AgriNIR™

analysis even more accurate.

Use AgriNIR™ Analyzer Rev. A11

16

NIR Parameters

all chemical parameters analyzable by an optical NIR analysis system

NIR Families

the categories or families of feed components analyzable by an optical NIR

6 Use of the Portable AgriNIR™ Analysis

System

6.1 NIR Parameters and NIR Families

In case of standard calibratio ns package, the portable anal ysis system AgriNIR™

can analyze till t o a max of

common use in cattle breeding.

In all NIR analysis systems produced by

defined:

For cattle feeding, the l ist of all chemical NIR parameters t hat can be analyzed for each NIR fam ily is

expressed in the following table:

7 chemical param eters for a max of 7 f eed components categor ies of most

and therefore also for AgriNIR™ it is

analysis system

NIR chemical

parameters that

can be analyzed in

every NIR Family

DG standard

calibrations package

CORN SILAGE

HAY

HIGH

MOISTURE

CORN

ALFALFA HAY

NIR Families

GRASS SILAGE

T.M.R.

SOYBEAN

FLOUR

NIR Chemical Parameters

Moisture

( Humidity )

Starch

YES YES YES YES YES YES YES

YES NO YES YES YES YES YES

YES YES YES YES YES YES YES

YES NO YES YES YES YES YES

YES NO YES YES YES YES YES

YES YES YES YES YES YES YES

YES NO YES NO YES YES YES

Crude

Protein

ADF NDF Ash

Crude Fat

( Ether

Extract )

It is necessary to keep this table in mind while defining with DGNirManager the feed components to

analyze.

• The a.m. definition of the NIR families and therefore of the feed components categories

analyzable by NIR systems, is subjected to market requests and intends to include all feed

components mostl y used in cattle breed ing. Moreover, depending on th e usage of the AgriNIR™

system (according to th e NIR Cal ibrations carried out by special ized labor atories) it is poss ible to

create NIR Families that are c ompletely different f rom those mentioned here (e. g. NIR family for

Olive Husk).

Use AgriNIR™ Analyzer Rev. A11

ENGLISH

17

NIR

Families

is an Optional Calibration

• For every NIR fam ily it is necess ary to set the suitable Theoretical Refer ence Values for each

NIR chemical param eter that can be analyzed (see table above). These reference values are

normally the result of laboratory chemical analysis performed on different samples of the NIR

family and allow to t he AgriNIR™ s ystem to m ake a “selection” of the optical analys is that result

incorrect (ex. due to a b ad optical reading, to a false position of the sample under the read ing

head Read NIR, to a too much damaged component, to external rests present, etc...).

In case of

portable analysis s ystem AgriNIR™ can an alyze following NIR grain families and a llows these chemical

NIR parameters :

grains calibrations package (optional calibrations for grains), the

NIR chemical

parameters that

can be analyzed in

every NIR Family

DG grains

calibrations package

[ optional ]

CORN GRAIN

WHEAT GRAIN

The of

package that the final customer can add, when he orders a new AgriNIR™ machine.

NIR Chemical Parameters

Moisture

( Humidity )

Starch

YES YES YES NO YES YES YES

YES YES YES NO YES YES YES

grains calibrations package

Crude

Protein

ADF NDF Ash

Crude Fat

( Ether

Extract )

Use AgriNIR™ Analyzer Rev. A11

18

6.2 Correct Use of the Fodder Box for the Sam ples to Analyze

Before going on with the real use of the Portable AgriNIR™ Analysis System, it is important to understand

the correct use of the fodder box containing the sample to analyze.

This fodder box (provided with the AgriNIR™) is composed by :

• an upper side with glass, to allow the optical scanning of the sample;

• a metallic frame able to maintain the sample properly (with the right pressure!) in front of the

scanning window glass.

To fill in the fodd er box with the food sample to an alyze, it is very IMPORTANT t o put in practice the

following simple rules:

• make sure the fodder box GLASS IS CLEAN, without residues of other samples;

• in case of very soft materials with long pieces, as hay, alfalfa, or grass silage, it is NECESSARY :

sampling m aterial usi ng a specia l Corer (strongl y suggested! ) and then cut the sa mple in

order to have parts with length equal to 2/3 cm;

press the sample in order to reduce its volume up to 1/2 or 1/3 of the original one;

• the sample must be put int o the fodder in order t o cover complete ly the scanning w indow (glass)

without open spaces. Be low you can see 2 d ifferent pictures reporting how th e sample has to be

putted inside the fodder: quantity, pressure…

• in the first picture below, you can see a sample well prepared and ready for analysis

OK!

good pressure without

air spaces.

• in the second p ictur e be low, a sam ple prep ared i n a wrong wa y: sam ple qua ntit y is wro ng an d its

pressure on the glass is too low

NO!

low pressure with air

spaces.

Use AgriNIR™ Analyzer Rev. A11

ENGLISH

19

• after the insertion of the metallic frame in the f odder for pressing the sam ple, it is necessary to

check that its upper handles do not exceed the fodder profile:

OK!

Upper handles are inside the

fodder profile.

NO!

Upper handles are over the

fodder profile, creating

mechanical interference

during the insertion of the

fodder inside the AgriNIR™

body for sample scanning.

As soon as the fodder is ready with sample inside, insert the fodder box (glass side up) into the

AgriNIR™ body using the hall on the right side (see picture below).

Use AgriNIR™ Analyzer Rev. A11

20

NO!

Just started the analysis (after press <ENTER>), it is required to perform the following actions :

• fodder has to be move d front and rear with a uniform speed spending about 2 seconds for a

complete scanning cycle: 1 sec to front and 1 sec to rear;

• the fodder profile has to be always inside the AgriNIR™ box.

OK!

The fodder box is completely inside

the AgriNIR™ body.

OK!

The fodder box is on the edge of the

AgriNIR™ body, but NOT outside.

NO!

The fodder box is partiall y outside f rom

the AgriNIR™ body.

Use AgriNIR™ Analyzer Rev. A11

ENGLISH

21

6.3 Turning on the AgriNIR™ system

Press key to turn ON the portable AgriNIR™ analyzer, the following screens will appear :

ONLY FOR AgriNIR W:

In this phase there is the in itializati on of AgriNIR™ system either from hardwar e or from software point of

view. During this initialization the device loads all the settings requested from the customer and previously

set.

After, ONLY FOR AgriNIR W, a screenshot with an initialization time of 5 minutes appears.

After all initialization p hases, the system autom atically proposes f ollowing screen, where it is possible to

set the :

CUSTOMER CODE identif ier num ber of th e custom er ( ex. the owner of the f orages sam ples) which

the AgriNIR™ system performs the analysis on the requested feed components.

Basically it represents the use mode of the machine on behalf of third parties.

Use AgriNIR™ Analyzer Rev. A11

22

NIR status icon

Current Date & Time

List of NIR

available on

AgriNIR™

Temperature of the internal NIR

Power supply voltage

GSM/GPRS signal level

Below in the display

Function Icons

After set the customer code, press <ENTER> to continue in the main screen :

sensor, controlled at 32°C

Available only for AgriNIR

Analyzer with GSM/GPRS

cod. 999-0347

families

analyzer

Name of the selected

NIR family

there are a set of

graphical icons.

Every function icon can

be activated by one key

Function Keys

on keyboard

corresponding of the 6

F-keys on the keypad.

Below in the disp lay can appear m aximum 6 function icons . In case of mor e function icon are av ailable

the following keys :

NEXT PAGE, to access to the next set of function icons

PREVIOUS PAGE, to return to the previous set of function icons

For example, if you press

if you press

ONLY FOR AgriNIR W:

in the main screen you can access to the next 4 function icon :

you can return to the 6 previous function icon :

Use AgriNIR™ Analyzer Rev. A11

ENGLISH

23

phase is

15

6.4 States & Messaging of NIR analyzer internal system

After turning on the AgriNIR™, before going on with the execution of the analysis it is better to wait

always at least

• the thermoregulation of the NIR optical sensor to reach the target temperature of 32°C;

• the necessary warming up of the internal lamp of the Read NIR reading head;

• one first calibration of the optical references of the internal NIR analysis system.

By the way, to help the user the AgriNIR™ system shows on the right t op of the sc reen an icon referr ing

to the contemporary state of the NIR system:

AgriNIR AgriNIR W Description of the icon

15 minute before starting to allow :

WARM-UP

the internal NIR system is executing the initial warm-up phase to reach the

target temperature of 32°C and to warm-up of the internal lamp.

OPTICAL CALIBRATION

the internal NIR system is executing the calibration phase of the optical

references.

READY

the AgriNIR™ system is ready for the analysis execution.

RUNNING ANALYSIS

the AgriNIR™ system is executing the analysis.

CONNECTION MISSING or ERROR STATUS

the NIR group is not connected to the electronic unit or there is an issue the

internal NIR system.

ERROR OF NIR CALIBRATION

After turning ON the machine BEFORE STARTING w ith t he a na l ysis executions, the AgriNIR™ system

executes automatically :

The system can’t performs the calibration.

1. the WARM-UP phase of the NIR group with status icon , to allow :

the thermoregulation of the NIR optical sensor to reach the target temperature of 32°C;

the necessary warming up of the internal lamp of the Read NIR head;

2. the CALIBRATION phase of the NIR group w ith status icon , to a llo w th e f irs t calibr at ion of

the optical references of the internal NIR analysis system;

3. after these first two phases the AgriNIR™ analyzer is READY, with status icon .

Although the WARM-UP takes less time and the CALIBRATION

already done, it’s STRONGLY RECOMMENDED to wait always at least

minutes before starting use the AgriNIR™ machine.

Please see NOTES FOR THE USER point N° 1 at page 3.

Use AgriNIR™ Analyzer Rev. A11

24

ne executes automatically

If you start the analysis execution during the WARM-UP phase, the AgriNIR™ system shows the

following message:

The status icon of the NIR system indicates

WARM-UP phase.

the

At the end of the calibration this message

disappears and the AgriNIR™ begins

automatically the CALIBRATION phase and its

message (see the next picture below).

If you start the a nalysis exec ution during the

following message :

CALIBRATION phase, th e AgriNIR™ system sho ws the

The status icon of the NIR system indicates

CALIBRATION phase.

the

At the end of the calibration this message

disappears and the AgriNIR™ begins

automatically the AN ALYSIS EXE CUTIO N of the

selected component.

During normal functioning, the AgriNIR™ machi

the optical calibration phase :

• every 5 minutes;

• just after every analysis execution.

For this reason it's possible :

the NIR status icon changes automatically to

to have the NIR calibration message during analysis execution.

;

Use AgriNIR™ Analyzer Rev. A11

ENGLISH

25

Error State

It’s NOT possible to detect the

6.5 Error Messaging of NIR analyzer internal system

After turning on the AgriNIR™, s et the Cus tomer Code to co ntinue in th e main s creen, if appear s (before

start the WARM-UP phase) :

TROUBLESHOOTING

1. Please check if a data c able is connected to the PR OG / DATA connector (please

see the picture at page 10). In th is case the intern al NIR system takes more time to

start the communication and to update NIR status icon and NIR temperature.

2. Please check if the communication cabl e from Electronic Un it (front control pa nel) is

connected to the NIR group inside the bottom box.

NIR system is in

temperature of the internal NIR

sensor

3. Please check if the communication cable from Electronic Unit to NIR group is not

damaged.

4. If is not the case 1 or 2, please contact the Customer Service.

During functioning of the AgriNIR™ machine, if appears this following messages :

the AgriNIR™ machine c annot communicate

with its internal NIR analyzer.

Use AgriNIR™ Analyzer Rev. A11

26

TROUBLESHOOTING

1. Please check if the communication cabl e from Electronic Un it (front control panel) is

connected to the NIR group inside the bottom box.

2. Please check if the communication cable from Electronic Unit to NIR group is not

damaged.

3. If is not the case 1 or 2, please contact the Customer Service.

During functioning of the AgriNIR™ machine, if appears this following messages :

the thermoregulation of the internal NIR

optical sensor CANNOT maintain the target

temperature of 32°C.

TROUBLESHOOTING

1. Verify if the environm ental temperature, where the AgriNIR™ machine is locat ed, is

out of the Working Temperature range. Please see Technical Data at page 5.

2. Remove completely the NIR group from the AgriNIR™ machine, then check if the

filter fan and the finned heat sink (visible on the back side where the shield is pierced)

are clean. Otherwise proceed to clean using a low flow of compressed air.

3. Verify if the fan on the c onnector side of t he NIR Group is working, ot herwise c ontact

the

Please IMMEDIATELY turn OFF the

AgriNIR™ m achine and leave it off for at

least

30 minute.

Customer Service for the spare part.

4. If is not the case 1, 2 or 3, please contact the Customer Service.

Use AgriNIR™ Analyzer Rev. A11

ENGLISH

27

back right angle corner

NO

6.6 Initial Optical Checking of t he AgriNIR™ system

Every day

recommend to execute the

BEFORE start using the AgriNIR™ analyzer,

OPTICS TEST using the CHECK-CELL accessory.

CHECK CELL special sample cell acetyl resin for the optics testing of the AgriNIR™ machine.

Follow the procedure below to perform the

1. Insert the CHECK-CEL L in the de dicat ed seat on t he u pper ed ges of t he fodder b ox, making s ure the

correct orientation :

OPTICAL TEST PROCEDURE.

beveled corner to match to the

seat of the fodder box

Use AgriNIR™ Analyzer Rev. A11

28

2. Insert completel y the fodder box and t he CHECK-CELL w ith its glass-face side up, inside the

AgriNIR™ box until the bottom :

3. In the main screen, pres s to access to the next 4 function icon , then pres s to enter

AGRINIR OPTICS TEST procedure :

on

the AgriNIR™ anal yzer shows instructions to

execute properly the

OPTIC S TEST.

Press <ENTER>

or <RESET>

to start optics test

to exit without testing.

Use AgriNIR™ Analyzer Rev. A11

ENGLISH

29

4. Press <ENTER> to start the automatic testing procedure :

WARNING!

DO NOT move the fodder box with the

CHECK-CELL inside during testing

execution.

If you move the fodder box, the CHECK-CELL

cannot be in front of the internal optical re ading

window (ReadNIR window, where is the lamp

light); consequentl y the CHECK-C ELL cann ot be

properly read.

Pressing <RESET>

testing execution is immediately aborted.

5. After 40 seconds, the AgriNIR™ analyzer shows the optical test result :

The AgriNIR™ internal optics is OK!

Now you can proceed to execute analysis.

Press <ENTER>

exit and continue.

or <RESET> to

6. If the testing exec u tio n t akes more than 4 0 sec o nds ( 2 minutes), the optics test could fail. In this case

the AgriNIR™ analyzer shows following message :

WARNING!

The AgriNIR™ internal optics is FAIL!

Consult the following troubleshooting procedure

to solve the issue.

Press <ENTER>

exit and continue.

In this case you can save t he optical spectra on

USB memory ke y pressing F-key

send data to the

Service for checking.

or <RESET> to

, then

Customer

Use AgriNIR™ Analyzer Rev. A11

30

TROUBLESHOOTING

1. Verify if the CHECK-CELL is properly inserte d inside the f odder box. Pleas e see the

pictures at page 23 point 1.

2. Verify if the fodd er box with CHECK-CELL is properly inserted inside the AgriNIR™

analyzer box. Please see the pictures at page 24 point 2.

3. Verify the cleaning of the CHECK-CELL glass or the ReadNIR glass insi de the NIR

group on the bottom side.

4. Verify if the CHEC K-CELL glass or the ReadNIR glass is broken, other wise contact

the

5. Verify if the lam p inside the NIR group is not on its correct position or its t ime life is

expiring (1 year) ; in second case, please contact the

Service for the spare part.

Customer Service for the spare parts.

Customer

6. Verify if the optic fiber terminal (visible inside the NIR group through t he g lass win do w

on the bottom side) is properly inserted on its brass fitting, otherwise if it's moved

please contact the

Customer Service.

7. If it's none of the previous cases, please s ave the optical spectra on U SB memory

key and contact the

Customer Service.

Use AgriNIR™ Analyzer Rev. A11

ENGLISH

31

6.7 Analysis Samples Identifying

Before starting the analysis on the forage sample, it’s possible to set the following identifiers.

If you press F-key

SAMPLE ID

is the current sample identifier number : this ID number will be automatically proposed

before starting the analysis on the sample and it will be printed on the tickets at the end of

analysis execution.

it’s possible to set :

SAMPLE ID, it allows to mark the parti-cular

physical sample to analyze.

Press the cursor keys

… to change the

Sample ID value.

Press <ENTER>

Press <RESET>

or the F-keys

to exit and save value.

to exit without saving.

LAST S AMPLE ID

is the previous sample identifier number used in the last analysis.

After every analysis the SAMPLE ID number is automatically increased by 1.

If you press F-key

it’s possible to set :

CUSTOMER CODE, it allows to give a

code number to the client who the analysis

sample belongs.

Press the cursor keys

… to change the

Customer Code value.

Press <ENTER>

or the F-keys

to exit and save value.

Press <RESET>

to exit without saving.

CUSTOMER CODE

this number will be printed on the tickets at the end of analysis execution.

Use AgriNIR™ Analyzer Rev. A11

32

If you press F-key it’s possible to set :

CLIENT INFORMATION, it allows to give

more details about the client who the physical

sample belongs.

Only the COMPANY name will be printed on the tickets at the end of analysis execution.

All the

Client’s data, when analysis is saved on USB memory key.

To modify the d ata in the

press keys

press F-key

CLIENT INFORMATIONs will be stored in the INFO.DAT file containing the

CLIENT INFORMATION window :

to move up / down the cursor and select the information;

to enter in edit mode on the selected information.

After pressed F-key

press keys

press

appear automatically the string icons on the bottom :

to move right / left the cursor “_“ ;

to insert a character at the beginning;

Use AgriNIR™ Analyzer Rev. A11

ENGLISH

33

press to select capital letters / small letters, numbers, symbols;

press

press

press

press

press <ENTER>

press <RESET>

press F-key

to insert a character at the cursor position;

to delete a character at the cursor position;

to delete all characters from the cursor position to the end on the right;

to insert a character at the end on the right;

to confirm the new data string;

to exit without modify the data string;

to save all data and quit

If you press F-key

memory.

If you press F-key

analyzer by

you can recall the Client Information previously stored on internal

you can recall the Client Information defaults provided on the AgriNIR™

:

Use AgriNIR™ Analyzer Rev. A11

34

Please take care to select the correct Component / NIR family before

feed components

6.8 Analysis Execution with AgriNIR™ System

After turned ON the AgriNIR™ system and performed following phases :

• WARM-UP (at least 15 minutes) and CALIBRATION please see at page 19 for more details;

• optics test with CHECK-CELL

• identification of the sample (using SAMPLE ID

(CUSTOMER CODE

it’s possible to prepare th e sample inside the fodder box (see at page 14 for more detai ls) and starts to

execute the analysis.

In the main screen it’s possible to select the component to analyze by pressing the keys

and CLIENT INFORMATION );

please see at page 23 for more details;

) and set the customer information

:

In case of

can analyze till to a max of

Moving the pointer you ca n c hoos e among 7 NIR families / components ( Corn S il age, Hay, High Moistur e

Corn, Alfalfa Hay, Gras s Silage, TMR, Soybean F lour) : every component t hat can be chosen in th is list

represents a feed components category (the NIR family) which the sample to analyze can belong.

Select a different com ponent / NI R families m eans select a different NIR c alibrati on inside the AgriNIR™

analyzer.

standard calibrations package, the portable analysis system AgriNIR™

7 NIR families (feed components categories) as mentioned at page 13.

starting the analysis on the forage sample.

The Component / NIR family selected represents the

category which the sample to analyze belong.

Use AgriNIR™ Analyzer Rev. A11

ENGLISH

35

Examples :

• Sample of HAY OF STEADY LAWN :

sample must be taken by the Corer (or shredded), then put it in the fodder box;

select the component (or NIR family) N° 2 HAY to execute the analysis.

• Sample of CORN SILAGE :

sample must be taken without grinding, then put it in the fodder box;

select the component (or NIR family) N° 1 CORN SILAGE to execute the analysis.

After selected the com ponent to anal yze, the AgriNIR™ system propose the Sam ple ID num ber to as sign

on the physical sample to be analyzed :

SAMPLE ID, it’s the actual number to assign to

the physical sample.

LAST SAMPLE ID, it’s the previous number

assigned to last physical sample analyzed.

Press <ENTER>

Press <RES ET>

where you can choice a different component.

If you press <ENTER>

two analysis execution modes :

to confirm the Sample ID and continue with analysis execution.

to quit immediatel y the anal ysis (without exec uting) an d return to the m ain scr een

to confirm, the AgriNIR™ s ystem gives the possibility to choos e between

Press the cursor keys

… to change the

Sample ID value.

or the F-keys

press <ENTER>

of you want choose the

MULTIPLE ANALYSIS mode;

press <RESET>

of you want choose the

SINGLE ANALYSIS mode;

Use AgriNIR™ Analyzer Rev. A11

36

INSTRUCTIONS FOR PROPER SELECTION OF ANALYSIS MODE

Case of SAMPLES HOMOGENEOUS and LOW QUANTITY

Case of SAMPLES NOT HOMOGENEOUS

Case of LARGE SAMPLE QUANTITY

The AgriNIR™ analyzer allows two analysis execution modes to satisfy following cases :

Examples : High Moisture Corn, Soybean Flour

1. If the sample is already grinded not more than 2/3 m m , it's poss ible to put direct ly

the sample inside the fodder box.

2. Select

Examples : Corn Silage, Hay, Alfalfa Hay, Grass Silage, TMR

1. Provide to shred the material to obtain pieces not longer than 2/3 cm, then put the

2. Select

3. Mix the sample inside the fodder box between a single analysis and the next.

Examples : bunker of Corn Silage, Grass Silage or TMR; bale of Hay or Alfalfa Hay

1. Collect enough samples that are r epresentative of the entire bunker front, or the

2. Provide to shred each samples to obtai n pieces not longer than 2/3 cm, then put

3. Select

4. After executed a single anal ysis, take next the sam ple and put it into t he fodder

SINGLE ANALYSIS mode to execute the analysis.

sample inside the fodder box.

MULTIPLE ANALYSIS mode, using at least 3 analysis.

entire bale, etc…

one sample inside the fodder box.

MULTIPLE ANALYSIS mode, using N° of analysis = N° of co llected

samples.

box.

In case of

SINGLE ANALYSIS execution mode (pressing <RESET> ) :

the AgriNIR™ system starts automatically with

the execution of a si ng le an alysis

component and therefore on the sample in the

fodder box.

Please start IMMEDIATELY to move the

fodder box as soon as you press

<RESET>

If you want to quit immediately the analysis, press<RESET>

on the selected

WARNING!

.

during the analysis execution.

Use AgriNIR™ Analyzer Rev. A11

ENGLISH

37

In case of MULTIPLE ANALYSIS execution mode (<ENTER> ) :

the AgriNIR™ system requests the number of

analysis to perform on the component in the

fodder box :

MAXIMUM 20 ANALYSIS

WARNING!

Please start IMMEDIATELY to move the

fodder box as soon as you press

<ENTER>

During the execution of the repeated analysis are shown screens like this :

Here it’s indicated the execution in progress of

the analysis N° 2 of the 5 total analysis.

Before starting ever y single anal ysis (of the tot al

N° scheduled), the AgriNIR™ system asks

always for a confirmation from the operator.

.

Use AgriNIR™ Analyzer Rev. A11

38

DRY MATTER

MOISTURE (Humidity)

Chemical Parameters on DM

Chemical Parameters on AsIs

At the end of the analysis executions (single or multiple) the AgriNIR™ system shows the results :

value of the

sample.

value of the sample :

calculated as 100% - Moisture.

the chemical values expressed on the

dry matter :

calculated as Param

values of the sample.

On display it is shown a table that reports the pred iction values of NIR chemical parameters obtained

from the analysis performed on the sample in the fodder box.

The values of the chemical parameters are always expressed in % and in 2 columns :

• in the left column are the prediction values expressed on AsIs, that is to say the total %

present in the sample just analyzed;

• in the right column are the prediction v alu es exp ressed o n t he D RY MATTER, that tot o say on

the sample part without water.

/ DM%

AsIs

NOTE. In case of MULTIPLE ANALYSIS the AgriNIR™ s ystem does not s how the r esults af ter ev ery

single analysis performed but only at the end of the execution of the last analysis.

The prediction va lues of the NIR chemic al parameters are the resu lt of the prediction AVERAGES of the

single analysis performed. In case of analysis not right performed, the AgriNIR™ system does not

consider them in the final average of the results.

In case a NIR chemical parameter following results :

n.a.

Parameter NOT AVAILAB LE

This chemical parameter hasn’t been defined for the NIR family chosen in analysis.

Parameter with WRONG RESULT

Err.

Out.

The AgriNIR™ analyzer cannot predict this chemical parameter.

Please check the sample in the fodder box, the NIR family chosen or the NIR calibration.

Parameter OUT OF RANGE

This chemical parameter prediction value is out of the acceptability range.

In this picture you can see :

STARCH is not available for GRASS SILAGE

PROTEIN is out of range

ADF, NDF are not possible to predict

Use AgriNIR™ Analyzer Rev. A11

ENGLISH

39

is broken, otherwise contact the

6.9 Case of incorrect analysis

In case of analysis (sing le or repeated) that are NOT correct, the AgriNIR™ s ystem shows the following

error message :

TROUBLESHOOTING

1. Verify if the sample is properly inserted inside the fodder box. Please see the

paragraph Correct Use of the Fodder Box for the Samples to Analyze at page 14.

2. Verify if the fodder box is properly moved d uring analysis execution. P lease see the

paragraph Correct Use of the Fodder Box for the Samples to Analyze at page 16.

If you press <ENTER>

system proposes again to execute the analysis

on the same component just selected.

If you press <RESET>

system quit the anal ysis execution phase o n the

selected component.

the AgriNIR™

the AgriNIR™

3. Verify if you have c h osen the correct NIR family / component before start the anal ysis

on the sample.

4. Verify the cleaning of the Fodder Box glass or the ReadNIR glass inside the NIR

group on the bottom side.

5. Verify if the Fodder Box glass or the R eadNIR glass

Customer Service for the spare parts.

6. Verify if the lam p inside the NIR group is not on its correc t position or its time lif e is

expiring (1 year) ; in second case, please contact the

Service for the spare part.

Customer

7. Verify if the optic fiber terminal (visible insi de the N IR g roup thr o ugh t he g las s w in do w

on the bottom side) is properly inserted on its brass fitting, otherwise if it's moved

please contact the

Customer Service.

8. If it' s none of the previous cas es, please contact the Customer

Service.

Use AgriNIR™ Analyzer Rev. A11

40

6.10 Analysis printing on tic ke t s

At the end of analysis execution, when the AgriNIR™ system shows the results table :

If you press the F-key

If you press the F-key

ticket (max. 99 copies) displaying the current number of printouts in a small box on the bottom of the

screen.

you can PRINT ON A TICKET the analysis results.

you can set th e PRINTOU T NUMBER i.e. the number of copies of the

Press the cursor keys

Then press <ENTER>

After setting the number of copies of the ticket, press the F-key

copies of the ticket of analysis results.

or the F-keys to change the PRINT N°.

to confirm the set copies of the ticket to print and exit.

to PRINTS all the requested

Use AgriNIR™ Analyzer Rev. A11

ENGLISH

41

Printer Header

NIR Family Identifier Number

Kind of Analyzed Component (NIR Family Name)

Identifier Number of the Analyzed Physical Sample

Customer Code and Company Name

AgriNIR machine serial number

The printout of the ticket after the analysis performed on a sample is :

[ see at page 48 how to set ]

who the particular sample belongs

Analysis Results of Chemical Parameters

(on AsIs and on the Dry Matter)

Time - Hour of the Analysis Execution

Use AgriNIR™ Analyzer Rev. A11

42

6.11 Analysis saving on USB pen drive

At the end of analysis execut ion, when the AgriNIR™ s ystem shows the results table, you can s tore the

results on the USB memory key :

Press F-key

On USB memory key a file folder is created with naming convention < Date Time >, which contains :

to SAVE THE DATA ON USB PEN DRIVE (on USB memory key).

analysis folders on USB key

one file .txt with naming convention < ID NIR Family _ progressive number > for each single

analysis just executed (1 file in Single Analysis mode, N file in Multiple Analysis mode);

single analysis mode multiple analysis mode

NOTE. These files .txt is used on ly associated with DGNirManager software to store the optica l

spectra of the analyzed samples, then to create new calibration curves.

Use AgriNIR™ Analyzer Rev. A11

ENGLISH

43

Sample ID

Name, value of

AgriNIR™

NIR family

the file INFO.DAT containing the Client ’s Data set on AgriNIR™ by Client Infor mation windows

(see at page 30) :

the file with nam ing con vention < DATE&T IME > containing the analys is results (show on displa y

at the end of analysis execution) :

Date & Time of

analysis execution

At the end of data saving on USB key, automatically :

• is PRINTED the number of ticket set previously;

• the following message is shown on the display :

chemical parameter

machine S/N

Machine S/N serial number of AgriNIR™

device used to make the analysis

Sample ID identifier number of the particular

physical sample just analyzed

NIR family identifier of the NIR family of the

analyzed component

Date date of the analysis execution

Time hour of the analysis execution

Use AgriNIR™ Analyzer Rev. A11

44

During the data store on USB Key, if the following error messages appear :

Fig. 1 Fig. 2

Error message in Fig. 1 the USB Key (Pen Drive) is not connected to the proper USB port on

AgriNIR™;

Error message in Fig. 2 the USB Key (Pen Drive) has been disconnected from USB port or

It’s necessary to erase a part of data stored on USB Key.

6.12 Analysis History – available only for AgriNIR W

The AgriNIR™ W save automatically the last 100 analysis executed inside an archive.

It is possible recall the analysis through this history in order to save it (on USB key), display it on the

screen, and eventually print it.

On the main page, press the

At this point, the follow screen will appear with the list of analysis executed:

key in order to switch to the next page and then press .

Use AgriNIR™ Analyzer Rev. A11

ENGLISH

45

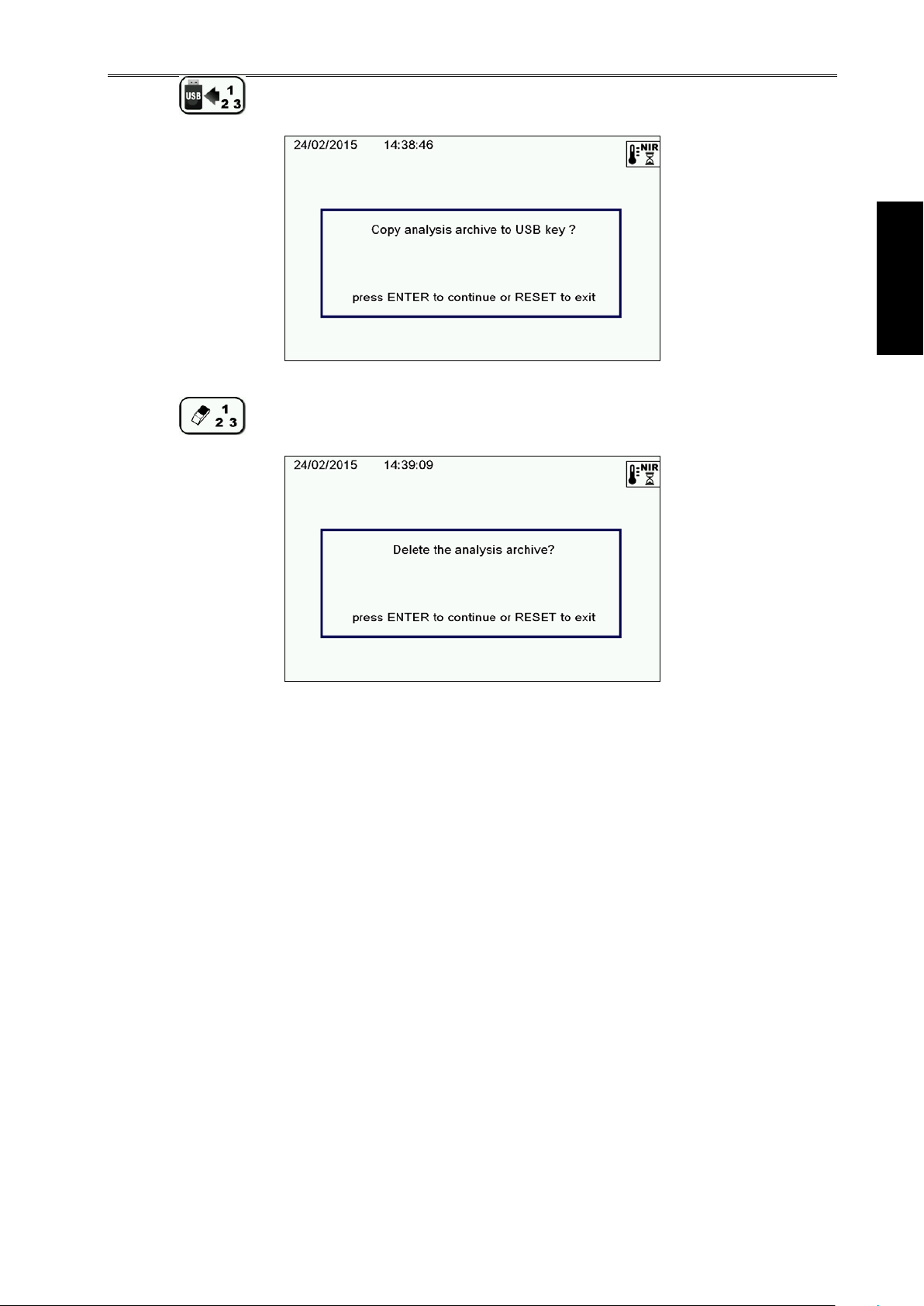

Press the key in order to copy the datas of analysis on the usb memory card.

Press the

key in order to delete the archive relative to the analysis.

Use AgriNIR™ Analyzer Rev. A11

46

6.13 Other Settings of AgriNIR™ System

In the main two screens, the AgriNIR™ system allows other simple setting commands :

buttons to go to the NEXT and PREVIOUS screen.

B&W DISPLAY INVERSION

with this command you can invert the

display from white background to black

background and vice versa.

CONTRAST ADJUSTMENT

with this command you can adjust the

display contrast.

DATE & TIME SETTING

with this command you can set the

current date and time of the AgriNIR™

system.

NOTE. This is important for a correct data

chronology.

Use AgriNIR™ Analyzer Rev. A11

ENGLISH

47

6.14 Calibration Updating of AgriNIR™ System

In the second main component selection screen, the AgriNIR™ system offers the following setting

commands :

CALIBRATION CURVES

UPDATING

With this command you can update the

calibration curves of the NIR families (available

on the main screen l ist) that can be analyzed by

the AgriNIR™ system.

To update the calibrations :

1. insert the USB memory key with the file

2. select the ID of the c omponent (see component list in t he main screen) where you wish to update

the calibration;

comp.a37 containing the new calibration curves;

3. press the special key

system.

to update the calibr ation in the interna l memor y of the AgriNIR™

NOTE. DO NOT remove the USB memory key until the message of ended calibration is displayed!

If the file

calibration curves IS NO T available on the USB

Key, the error message here shown on the left

appears.

comp.a37 that contains the new

Use AgriNIR™ Analyzer Rev. A11

48

6.14.1 Update Calibrations for AgriNIR W

Switch ON the AgriNIR-W machine keeping pressed both the

BOOTLOADER screen appears.

Press the F5 button to start loading the AgriNIR-W calibration upgrade.

+ buttons until the

Use AgriNIR™ Analyzer Rev. A11

ENGLISH

49

Press the F1 button to continue the AgriNIR-W calibration upgrade.

Wait the calibration loading (few seconds) until the GREEN SCREEN will appear.

Press the

button to switch OFF the AgriNIR-W machine.

Use AgriNIR™ Analyzer Rev. A11

50

AgriNIR

Chiavetta

nirdata.bin

6.15 LOADING O F NEW NIR DATA STRUCTURE (NIRDATA.BIN file)

USB

file

The NIR Data Structure contains the l ist of the NIR families an d chemical parameters available for the

analysis performed by the AgriNIR™ ana l yzer.

For NIR Data Structure upgrading is necessar y to reload the c onfiguration f ile nirdata.bin (prov ided by

dinamica generale or created by DGNirManager program). Please follow the steps below.

1. Copy nirdata.bin file into the USB key : please, don’t use any other existing folders!

2. Connect the USB key to the AgriNIR™ machine.

3. Turn ON the AgriNIR™ machine and press <ENTER>

Structure :

to accept the new NIR Data

Use AgriNIR™ Analyzer Rev. A11

ENGLISH

51

4. DO NOT remove the USB memory key while the file is being loaded!

5. Verify the new NIR Families list just loaded on the AgriNIR™ machine.

6. Execute an analysis to check the new Chemical Parameters now available on the AgriNIR™

machine.

Use AgriNIR™ Analyzer Rev. A11

52

6.16 Deleting Analysis on internal memory

DELETING ANALYSIS DATA FROM INTERNAL MEMORY

With this command you can permanently delete the data from the internal memory concerning the

analysis performed (either valid or wrong) and relevant optical spectra acquired from the analyzed

samples.

Pressing <ENTER> you start the deleting

procedure of the anal ysis data from the internal

memory of the AgriNIR™ system.

In this phase all data conc erning the CORRECT

ANALYSIS, i.e. wit h no errors, are deleted from

the internal memory.

In this phase all data concerning the WRONG

ANALYSIS, i.e. with errors or not successful

(“Analysis Error” is displayed), are deleted from

the internal memory

Use AgriNIR™ Analyzer Rev. A11

ENGLISH

53

6.17 Deleting the initial mes s a ge of FULL ME MO RY

After a certain num ber of analysis (approx. 60-70) per formed with the AgriNIR™ system , the following

message may appear when switching the system on :

When switching the system on, this mess age is

displayed to warn th at the space of the internal

memory for the Analysis Execution Log is

reaching its full capacity.

NOTE. This section of inte rnal mem ory is NO T acc essible to the user and m ay NOT be deleted with the

deleting function

To delete the section of internal memory for the Analysis Execution Log follow this procedure :

, as this function refers only to the memory area for the analysis data performed.

When switching the system on, when the

message “System Initialization” is displayed,

press <ENTER> for a few seconds until the

SYSTEM CONFIGU-RATION environment

appears.

Access the configuration menu 6 :

“Setup protected by pas sword”

Use AgriNIR™ Analyzer Rev. A11

54

Enter the password

procedure of the Analysis Execution Log in the

internal memory of the AgriNIR™ system.

Press <ENTER> to confirm the deleting

procedure of the Analysis Execution Log.

After a few seconds you get the message

informing that the deleting procedure of the

Analysis Execution Log was successful!

At the end you return to the main screen of SYSTEM CONFIGURATION :

1334 to access the deleting

press < RESET > for at least 1 SEC to exit and return to the use environment of the AgriNIR™

system.

Use AgriNIR™ Analyzer Rev. A11

ENGLISH

55

Printer Header

6.18 Printer Header Settings

It is possible to s et the Printer Header on tickets printed by the AgriNIR™ s ystem, with your preferred

data :

To set your Printer Header on the tickets, follow this procedure :

When switching the system on, when the

message “System Initialization” is displayed,

press <ENTER> for a few seconds until the

SYSTEM CONFIGURATION environment

appears.

Access the configuration menu 5 :

“Printer header”

Use AgriNIR™ Analyzer Rev. A11

56

press buttons to select data to modify;

press to recall the default printer

header (“Dinamica Generale …”).

press <ENTER> to edit the new data value

press buttons to insert a character;

press to move the cursor;

press to insert a character at the beginning;

press to select capital letters / small letters, numbers, symbols;

press to insert a character at the cursor position;

press to delete a character at the cursor position;

press to delete all characters from the cursor position to the end on the right;

press to insert a character at the end on the right.

press <ENTER> to confirm the new data value;

press <RESET> to exit without modify the data value.

You can use the SPECIAL CHARACTERS (not printable!) :

1¦ to set double width characters, on the printable string

2¦ to set double height characters, on the printable string

3¦ to set double width and double height characters, on the printable string

At the end, after set all data on the Printer Header :

press < RESET > to return to the main screen of SYSTEM CONFIGURATION;

press < RESET > for at least 1 SEC to exit and return to the use environment of the AgriNIR™

system.

Service AgriNIR™ Analyzer Rev. A11

ENGLISH

57

7 CLEANING THE DEVICE

It is important to clean thor oughl y and periodicall y the AgriNIR™ system, especially the lower m etal body

where the sample fodder box and the Read NIR module are positioned.

To clean the system correctly going on as follows:

• disconnect the connect or o f the elec tric ca ble an d loos en the sec uring k nob of the N IR Group, as

shown in pict. 6A;

• turn the securing bracket of the NIR Group by 90° anticlockwise, as shown in pict. 6B;

• raise the NIR Group up as sho wn in pict. 6C;

• clean with a soft lig htly wet cloth the Rea d NIR r ead ing hea d’s wind o w and el iminate the residues

around (see pict. 6C);

• clean with a soft wet cloth or even with pres suri zed air (a low press ure of 2/3 bar m ax) the fodder

box sliding site (see pict. 6C);

• it is possible discon nect the fan filter and c lean it with press urized air (a low press ure of 2/3 bar

max) (see pict. 6D).

It would be better to follow this procedure after executing analysis on samples with a high water

percentage (for example, corn silage).

Service AgriNIR™ Analyzer Rev. A11

58

8 DEVICE SERVICING

8.1 Verification and Servici ng of the O pti cal Gr oup

a) Remove the NIR Group from the metal support in the bottom of the case.

To do this :

• open the NIR Group (as indicated in section 6 pict. 6A and 6B);

• unhook the metal hinge supporting the NIR Group:

• remove the NIR Group from the metal bottom of the case.

b) Verify the protection glass of the Read NIR head.

If it is broken, get in touch with

c) Verify the communication state between NIR Group and Electronic Unit :

• a few seconds after s witching on the system, also th e lamp of the Read NIR reading h ead

must turn on (visible from the hole for inserting the fodder box on the right side of the case);

• after 2 minutes the ac tuator mus t move the optica l calibration door (just und er the Read NI R

reading head’s window see sect. 6 pict. 6C) towards the optical fiber, taking it in working

conditions after about 1 minute.

d) Verify the condition of the lamp: if during the checks made according to step C the lamp has not

turned on, check that the lamp is correc tly connected in the Re ad NIR head (open the door on the

side of the head unscrewing the 4 M4 self-locking nuts) and check that the lamp is not damaged.

To access the lamp:

• unscrew the 4 M4 self-locking nuts from the lamp cover on the NIR Group side

• CAREFULLY remove the cover with the lamp disconnecting the cable from the lamp socket;

Assistance Service.

If the lamp is broken or not correctly working, get in touch with

Service.

Assistance

Service AgriNIR™ Analyzer Rev. A11

ENGLISH

59

e) Verify the state of the linear actuator: if during the c hecks listed in st ep C the linear actuator h as not

moved the calibratio n door , c hec k the actuator’s c on ne c tion to the Re ad N IR ’s e lec tr onic b oar d (open

the door on the side of the head unscrewing the 4 M4 self-locking nuts and check the 4-wiredconnector).

If during the chec ks listed i n step C th e calibration door does n ot move f rom one side to the other of

the reading window, check that there are not mechanical obstacles.

f) Verify the optical fiber: ex ecute the analysis of the component. If AGRINIR™ continues s howing the

message “ANALYSIS ERROR!”, check that the extremity of the optical fiber inside the Read NIR

reading head’s window is clean.

WARNING! The optical fi ber is directly connected in side the NIR optical sensor and shows a little

glass fiber inside, that’s why:

• THE NIR GROUP SHOULD NOT BE OPENED (exc ept for the lamp cover as indicated in

step D and E);

• in case of faults, get in touch with

Assistance Service.

8.2 Replacement of the Printer’s Paper

a) Turn the AGRINIR™ off.

b) Open the front p anel of the print er by pres sing t he centr al green k ey (it lights up when th e AgriNIR™

system is switched on).

c) Pull out the empty paper plastic support.

d) Insert the new THERM IC PAPER roll, keeping attention to

insert correctly the paper through the printer site.

e) Hook again the front panel of the printer, ex erting a light pressure on the points show in the picture

below :

f) Turn the AGRINIR™ on.

g) Let the paper advanc e pus hing <FEED >

been inserted correctly.

on the printer. If the paper is block ed, check that it has

Rules AgriNIR™ Analyzer Rev. A11

60

9 RESPONSIBILITIES

The AgriNIR™ system is an analysis device that needs moving material in front of the

optical reading head Read NIR, to have a good scan of the sample in the fodder box

and obtain therefore a prediction in line with the expectations.

We remind that the AgriNIR™ system can have the GSM communication system, which

gives the possibility to :

• monitor the functionality of the AgriNIR™ system from a remote service centre;

• update the internal calibrations of NIR analy sis;

• send collected samples to analyze in a laboratory according to the “SAMPLES

COLLECTION HANDBOOK”.

All the analysis values performed by AgriNIR™ system are shown on display and stored

for future controls through the use of the special USB memory key (Pen Drive).

In particular the AgriNIR™ analysis results:

• are available directly on the screen or can be printed on a ticket at the end of the

analysis;

• can be transferred on PC, through the USB memory key (Pen Drive), to the

management program DGNirManager to store and use them for any updating of

the calibration curves of the NIR families analyzed by the AgriNIR™ system.

Rules AgriNIR™ Analyzer Rev. A11

ENGLISH

61

10 CE CONFORMITY DECL ARATION

Company’s name : Dinamica Generale s p a

Company’s address : Via Mondadori, 15

46025 Poggio Rusco (MN)

ITALY

WE DECLARE THAT THE PRODUCT:

Model : AgriNIR™ ANALYZER

Description : Portable Analysis System

Options : All configurations

is made in conformity with the following directives and standards required by European

2004/108/EC, respecting the following laws:

EMC generic standard for emission:

EN 61326-1

EN 55011 (1999) – A 1 (2000) – A2 (2003)

EMC generic standard for immunity:

EN 61000-4-2 (96) – A1 (99) – A2 (01)

EN 61000-4-3 (97) – A1 (02)

EN 61000-4-4 (96) – A1 (01) – A2 (01)

EN 61000-4-5 – (1997)

EN 61000-4-6 (97) – A1 (01)

EN 61000-4-8 (97) – A1 (01)

POGGIO RUSCO, 28/08/2006

This document is an exclusive property of Dinamica Generale spa

Even partial re production is forbidden.

Rules AgriNIR™ Analyzer Rev. A11