DINA SafeLine DNSL-ZM, SafeLine DNSL-ZMB, SafeLine DNSL-ZMA, SafeLine DNSL-ZMT, SafeLine DNSL-ZMR Product Information

...

SafeLine

Product information

Safety for men

and machines

DlNA Elektronik GmbH

Esslinger Straße 84, 72649 Wolfschlugen

Tel. 07022/95 17-0, Fax 07022/95 17-51

www.dinaelektronik.de,

info@dinaelektronik.de

Quality management system

DQS certificated according to

DIN EN ISO 9001: 2000

Reg.-Nr.67542-01

The direct path to safe automation

DIN EN 62061, SIL CL 3

Two-Hand-Control

according to EN 574: Type IIIC.

(BG-Nr: ET 06146)

IND.CONT.EQ

1 Z D 7

MTTFD: 25 years

DC

awg

: ≥≥≥≥ 99%

CCF according to EN 62061: 2005 85 points

CCF according to ISO 13849-1: 2006 95 points

PFHD = 6,24x10

-8

The total concept of the specified category must

be validated involving the whole control unit.

Variants management

FW

DESIGNER

V404.02x V404.03x

V1.13 x

V1.20 Customer-specific

V1.31 x

V1.32 Customer-specific

V1.38 x

SafeLine DESIGNER Version 1.38B5

SafeLine modules

Central module DNSL-ZM

6 safe digital inputs

4 safe positive switching outputs

2 positive switching outputs, free configurable

1 positive switching output, system ready

V24 interface

Central module DNSL-ZMB

16 safe digital inputs

2 safe positive switching outputs

1 relay output with 2 safe contacts

1 positive switching output, system ready

V24 interface

Dual motion and standstill monitoring

Central module DNSL-ZMT

11 safe digital inputs

5 safe analogue inputs

2 safe positive switching outputs

1 relay output with 2 safe contacts

1 positive switching output, system ready

V24 interface

Dual motion and standstill monitoring

Central module DNSL-ZMR

16 safe digital inputs

4 safe positive switching outputs

2 positive switching outputs, free configurable

1 positive switching output, system ready

Control for the relay outputs module DNSL-KM

V24 interface

Dual motion and standstill monitoring

Central module DNSL-ZMK

6 safe digital inputs

2 safe positive switching outputs

1 relay output with 2 safe contacts

1 positive switching output, system ready

V24 interface

Central module DNSL-ZMA

6 safe digital inputs

1 analogue input

2 safe positive switching outputs

1 positive switching output, system ready

V24 interface

Function modules

Dual standstill, motion and direction monitor

module DNSL-DS, DNSL-DR

8 digital inputs

2 Encoder inputs

4 positive switching semiconductor outputs

DNSL-DR only outputs

Input module DNSL-IN

16 digital inputs

4 positive switching semiconductor outputs

Input / output module

8 digital inputs

10 positive switching semiconductor outputs

Relay module DNSL-RM, DNSL-RM 230

4 relay outputs

8 NO contacts

2 NC contacts only with DNSL-RM

Relay module DNSL-KM

4 safe relay outputs every with 2 safe NO contacts

4 signal contacts

Field busses

Profibus DP DNSL-DP

Interface, 24 byte input and output data,

for diagnostic purpose only

Ether CAT DNSL-EC

Interface, 24 byte input and output data,

for diagnostic purpose only

Product information

Products: safety technology SafeLine redaction 11 date 10.04.09 page 4 from 48

Contents Page

Safety regulations

Intended usage

5

SafeLine: Product description 6

SafeLine DESIGNER 7

DNSL-ZM: Central module 10

DNSL-ZM input usage 10

Outputs usage 11

Special functions RTDS Pulse generator via IF1 11

DNCO Function: Parameter mask

12

Position monitoring of axis with DNSL-DS

12

DNSL-ZMB, DNSL-ZMT: Central modules 13

Inputs usage 13

DNSL-ZMB, DNSL-ZMT: Standstill and motion monitoring 14

DNSL-ZMB, DNSL-ZMT: Output usage RTDS Pulse generator via IF1

DNSL-ZMT: usage of inputs I16 to I20 for safety shutdown mats 15

Parameter mask DNSL-ZMB 15

Parameter mask DNSL-ZMT Memory of application 16

DNSL-ZMR: Central module 17

Inputs usage Inputs usage for standstill and motion monitoring 17

Outputs usage Special functions Description of the wiring layer 17

Parameter mask Memory of application 18

DNSL-PR: Programming device for user application 18

DNSL-KM Relay module 19

Parameter mask Description of wiring layer 19

DNSL-ZMK Central module 20

Inputs usage Outputs usage 20

Special functions Parameter mask 20

DNSL-ZMA: Central module 21

Inputs usage Outputs usage Special functions 21

Parameter mask DNCO Function with „Teach function“ 21

Central modules: Software elements 22

SafeLine settings Password setting SafeLine diagnostic 23

DNSL-DS and DNSL-DR: Standstill, motion and direction monitoring 25

DNSL-DS, DNSL-DR inputs usage 25

DNSL-DS and DNSL-DR: Function of standstill, motion and direction monitoring 26

Monitoring of the drive break 26

DNSL-DS and DNSL-DR: Measuring system (encoder) requirements for speed monitoring. 26

Input frequency at the resolver input. 26

DNSL-DS, DNSL-DR: DNCO function Input selection for DNCO Function Usage of DNCO function 27

Usage of the outputs Mask of parameter 28

DNSL-IN: Input module Inputs usage 29

Output usage Parameter mask 30

DNSL-IO: Input/ output module Inputs usage 31

Outputs usage 32

Parameter mask 33

DNSL-RM, DNSL-RM 230: Relay modules 34

Outputs usage Parameter mask 34

Field BUS: DNSL-DP Profibus DP and DNSL-EC Ether CAT 35

Field BUS parameter mask Spindle activation and deactivation: 35

Virtual wiring Example: Field BUS virtual wiring of input data bit to the field bus Master 36

Field bus: Virtual wiring of output data from field bus Master Field BUS communication 37

Dimension diagram and assembling 38

General technical data 39

DNSL-ZM 39

DNSL-ZMB, DNSL-ZMT DNSL-ZMA, DNSL-ZMK DNSL-ZMR 40

DNSL-DS, DNSL-DR DNSL-IN DNSL-IO 41

DNSL-RM DNSL-RM 230 DNSL-KM 42

Error massage DESIGNER 44

Certificate 46

Product information

Products: safety technology SafeLine redaction 11 date 10.04.09 page 5 from 48

Safety regulations

• The unit may only be installed and operated by those who are qualified electrical engineers or have received sufficient

training and are familiar with both these instructions and the current regulations for safety at work and accident prevention.

Follow VDE, EN as well as local regulations especially as regards preventative measures!

• Ignoring the safety regulations can lead to death, serious injury or cause considerable damage!

• In emergency stop applications use the internal function “Speed output restart disable” or a higher level control unit must

ensure that the machine cannot start up again automatically!

• Transport, storage and operating conditions should all conform to EN 60068-2-1, 2-2. See technical details

• Any guarantee is void following unauthorised modifications. This can lead to death, serious injury or cause considerable

damage!

• The unit should be cabinet mounted, otherwise dampness or dust could lead to functional impairment.

• Adequate fuse protection must be provided on all output contacts especially with capacitive and

inductive loads.

• The unit must be installed following the specification of DIN EN 50274, VDE 0660-514 regarding the required distances.

• During operation, parts of the electronic switchgear carry high voltage.

• DANGER! During operation the protective covers must not be removed from the electronic switchgear!

• The device must always be replaced after the first malfunction!

• The unit must be disposed of properly when it reaches the end of it service life.

• Keep the operating instructions!

Intended usage

The SAFELINE series is a product with safety-relevant functions for machines and equipments.

With this product the most diverse functions at machinery can be supervised and/or steered.

Testing basis:

• 2006/95/EWG „guidelines of low voltage usage"

• 2004/108/EG „EMC-guidelines“, EN55011+A1, EN61000-6-2

EN 61496-1-2, VDE 0113-201 non contact protection device „BWS- interference immunity"

GS-ET-20: Principles for testing and certification of relay safety combinations"

DIN EN 62061 „Safety of machinery”, (VDE 0113-50)

DIN EN 61508-part3 „Principles for computers in safety systems “

The safety outputs correspond to DIN EN 62061, SIL CL 3, VDE 0113-50

As a motion monitor according to EN 60 204-1 /VDE 0113 part 1 corresponding to DIN EN 62061, SIL CL 3, VDE 0113-50.

As a standstill monitor according to EN 60 204-1/ VDE 0113 Part 1 corresponding to DIN EN 62061, SIL CL 3, VDE 0113-

50.

As logic unit for two-hand control function according to EN 574: Type III C (BG No.: ET 06146).

The analogue inputs (I16 to I20) are also used with a safety shutdown mat, only type TS/ W1 and TS/ BK1/ Fa. Mayser

The products are according to the requirements of the updated standards, which are listed in this document.

Product information

Products: safety technology SafeLine redaction 11 date 10.04.09 page 6 from 48

SafeLine: Product description

SafeLine is housed in a metal rack type enclosure. It can be mounted by spring fasteners to a DIN rail. The individual functional modules are pluggable. The equipment is available in different housing sizes, depending on the

number of functional modules to be used. Up to 15 functional modules may be used. Racks with 3, 5, 7, 9, 13

and15 slots are available. Unused slots are covered with a blind cover. (Article No. 10BD00) All modules are

plugged into the redundant backplane bus system. The device is programmed using the SafeLine DESIGNER program on a PC.

To cover the requirements of a wide range of applications, different function modules are available.

The status of all I/O clamps and supply voltages is indicated by corresponding LED.

Central module Rack Function modules

DNSL-ZMR Rack DNSL-DS DNSL-DP DNSL-IN DNSL-IO DNSL-RM DNSL-KM

Central modules Function modules

DNSL-ZMB-DP DNSL-ZMT DNSL-ZM DNSL-ZMA DNSL-ZMK DNSL-DR DNSL-RM 230

DNSL-ZMB, ZMT and ZMR optional with PROFIBUS

The central module will always be put into slot 1. (Leftmost slot in the rack) The PROFIBUS module DNSL-DP must

be placed next. All other modules may be placed in any order.

The module DNSL-ZMB, ZMT and ZMR require 2 slots.

DNSL-ZMB, ZMT and ZMR are available with integrated PROFIBUS module DNSL-DP.

See picture of ZMB, ZMT on the left!

The relay module DNSL-KM can only be used by central module DNSL-ZMR and must be placed next.

Interfaces

The COM PORT interface is used to transfer data between the PC SafeLine Designer Program and SafeLine.

The used connection cable has to be V24 (1:1). Pin 2, 3 and 5 in the cable are important.

The PROFIBUS interface DNSL-DP is used to transfer data between the PROFIBUS DP Master and SafeLine.

Indicators

The middle LED at the black LED-Block indicates the supply voltage is present, the left and right LED indicate that

the module is ready.

Product information

Products: safety technology SafeLine redaction 11 date 10.04.09 page 7 from 48

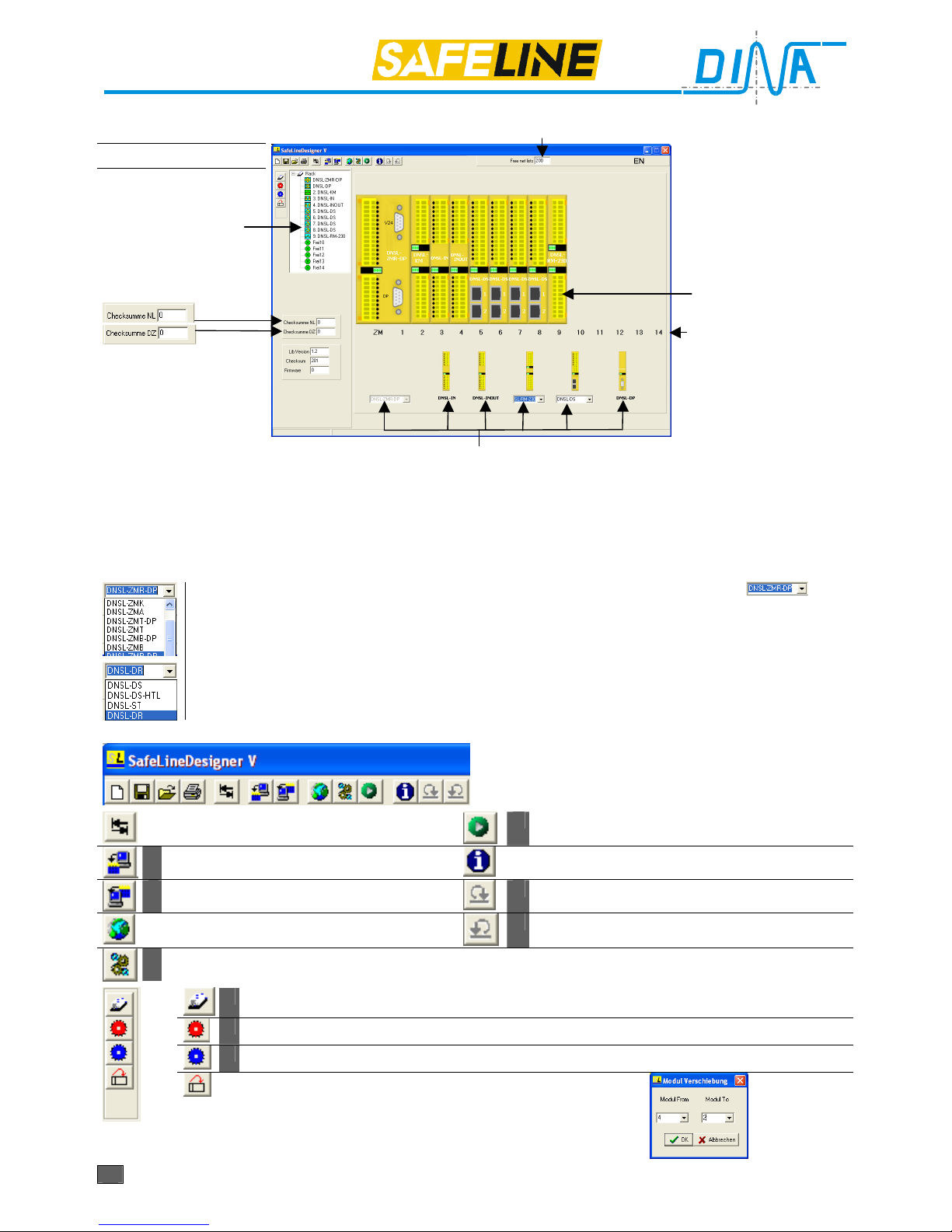

SafeLine DESIGNER

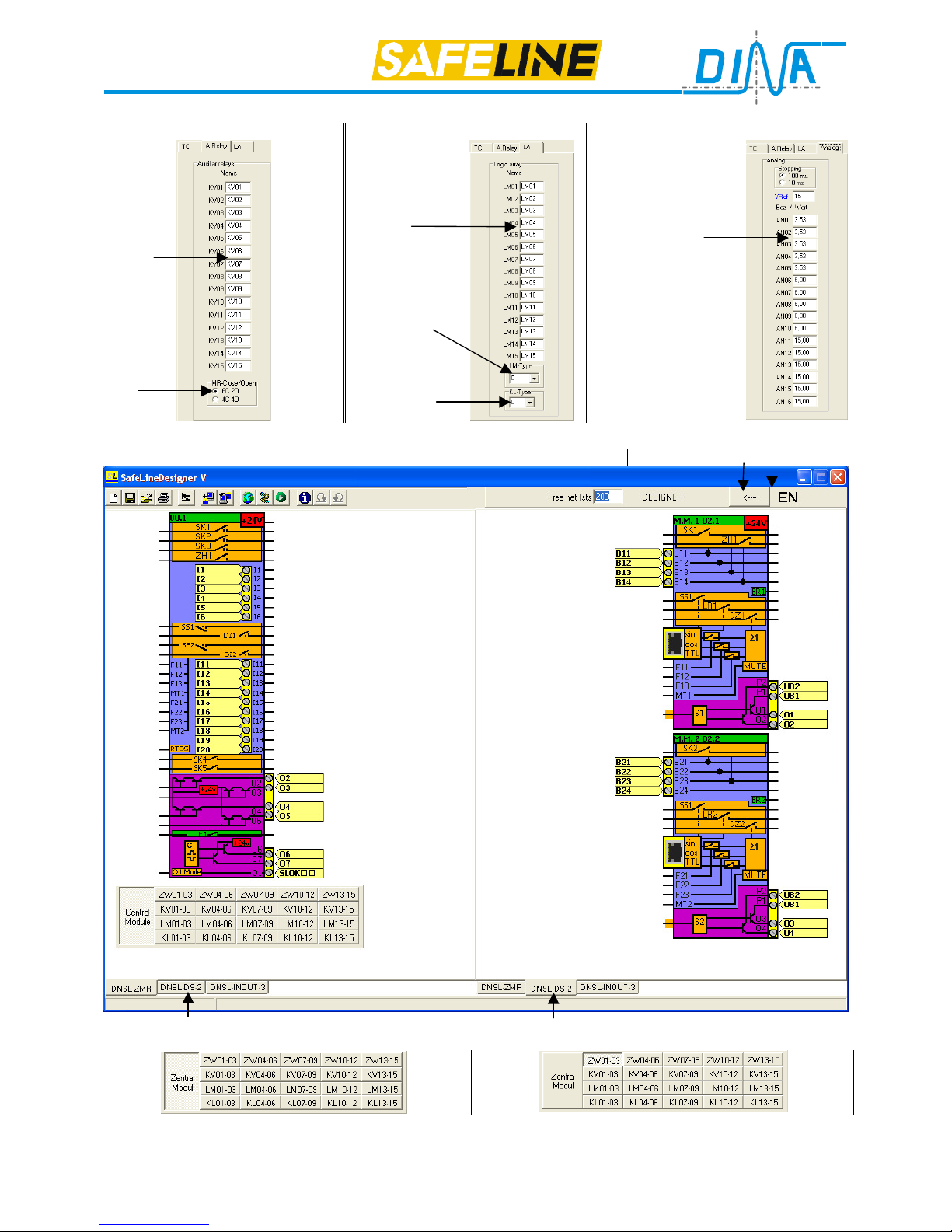

1. layer: Module layer

Free circuit

Selection Menu

used modules

net list

motion control

parameter

Layer 2 (parameter

mask) will be displayed

by right click with

mouse on the individual

module.

Position of modules

Module selection

The central module will always be put at slot ZM. The field bus module DNSL-DP or DNSL-EC must be placed

next. All other modules may be placed in any order. Only one central module and one PROFIBUS module can be

used. Function modules can be several.

The central module DNSL-ZMB, ZMT and ZMR need 2 slot. If one of them will be selected, the next slot will be

barred.

To place the module DNSL-IN, INOUT and DP: move the mouse to the module. Press the left mouse-button and

hold it down, than move the mouse to the wished position at the area above left and release the mouse-button.

Module with variants: Modules with different variants show a selection area(example ).

Click the downward arrow button with the left mouse-button. The variants will be displayed. Select the

wished variant with a click.

After a selection of a variant of central module an other window will be displayed. Click OK. The module will be automatically placed at slot position 0.

After a selection of a function module the module will be placed above the selection area. move the

mouse to the module. Press the left mouse-button and hold it down, than move the mouse to the

wished position at the area above left and release the mouse-button.

Menu description

To change between module and wiring

layer

To change to layer diagnostic

Transfer of data from PC to SafeLine

Information of DESIGNER and Firmware

Transfer of data from SafeLine to PC

Export of net list from SafeLine and PROFIBUS

Language selection

Import of net list from SafeLine and PROFIBUS

To change to layer 2 (parameter layer)

Parameter file history

Actual error list

saved error list

To change module position

Click at arrow left to select the actual position.

Click at arrow right to select the new position.

After click OK.

The function of these buttons is only possible, if there is a connection for data transfer to SafeLine.

Product information

Products: safety technology SafeLine redaction 11 date 10.04.09 page 8 from 48

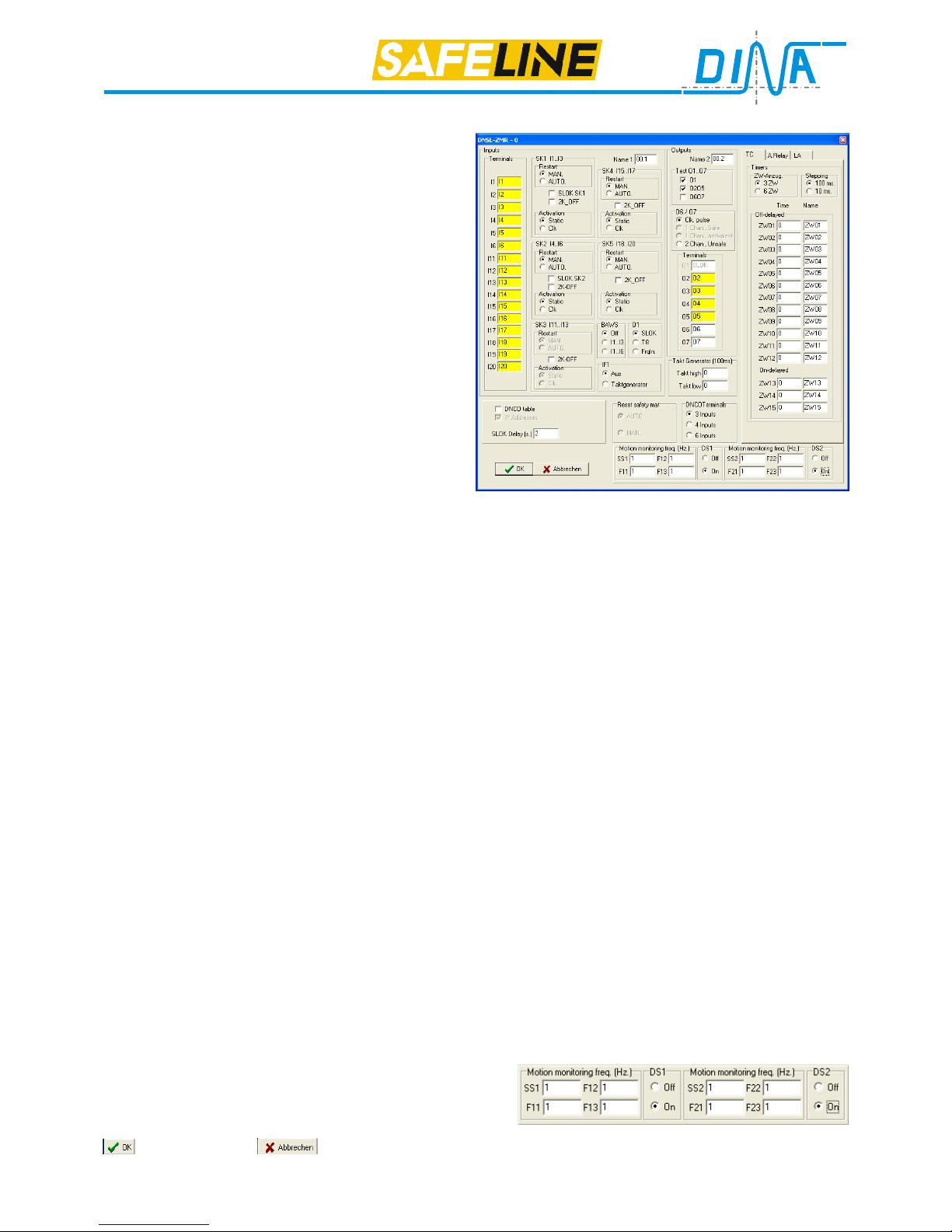

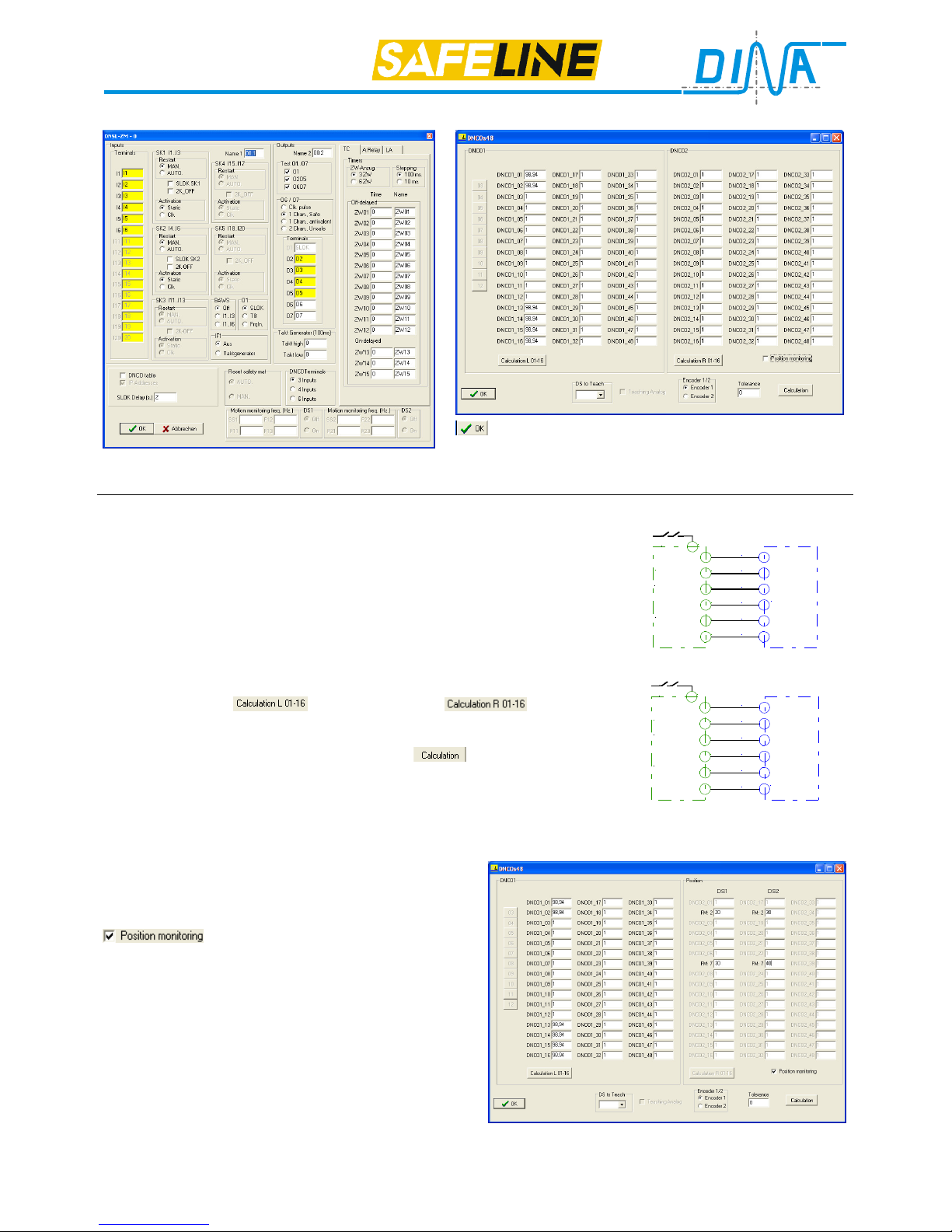

2. layer: Parameter mask

Selection timer(TC)

Central module parameter mask

Inputs, terminal: labelling of inputs I1 to I20

SK1 I1..I3, SK2 I4..I6, Restart: SK*-Restart „manually“

by activating Q or „Auto.“ automatically

SLOK SK1, SLOK SK2: the function SLOK SK1 and

SLOK SK2 is only important, if:

1. SK1 I1..I3 or SK2 I4..I6 as Emergency stop safety

circuit is used.

2. an external sensor or internal SafeLine error is

existed.

After SafeLine forces an emergency stop function like

the actuating of the emergency-stop button.

The forced emergency stop stopped the plant.

SafeLine works normally till the end of the SLOK Delay

time. After all outputs of SafeLine will be turned off.

The SLOK Delay time has to be selected such so long,

that the plant will be stopped safety.

2K_OFF: If it is activated and Restart AUTO is selected, no switch off/on of the circuit contact is necessary for test after power off/on. By Restart MAN a quit

signal is necessary.

If 2K_OFF is not activated a switch off/on of the contact is necessary after power off/on. By Restart MAN a quit

signal is necessary.

SK Activation: Safety circuit via static or clock signal (cross-circuiting detection)

Name 1: Labelling of the inputs

BAWS: Operation mode 3 or 6 switch positions via 3 or 6 inputs

O1: SLOK: Output of operating state, T8: semiconductor output

FrqIn: frequency input for motion control only possible with DNSL-ZMT, ZMB, ZMR and field bus module

Test O1..O7: The internal check of the outputs O1, O2 till O5 and O6, O7 can be turned off and on.

The function „check turned off“ the outputs will not tested.

This feature is possible for all semiconductor outputs at all central modules.

TC, A. Relay, LA: Change between time delay relays, auxiliary relays and logic modules. See below.

Timers, ZW-Anzug: selection 3 or 6 on-delayed timers

Timers, Stepping: „100ms“ time domain 100ms to 999,9s „10ms“time domain 10ms to 99,9s

Off-delayed, on-delayed:

Fields left: Entry of time value, 10 = 1s with selection 100ms, 10 = 100ms with selection 10ms

Fields right: Entry of the name of time delay.

Terminals O2 to O7: fields for entry the name of the outputs.

DNCO Table: If this function will be selected, a mask with two tables for frequency values will be appear. Every

table includes fields for 48 values. The frequency values assign the motions, that have be monitored.

See DNSL-DS.

DNCO Terminals: The number of the monitored motions defines the necessary inputs at the central module or

DNSL-DS. Eight motions need 3 inputs, 16 motions need four inputs and 48 motions need 6 inputs.

IF1: With the selection „ON” the function of a pulse generator (Takt Generator) is possible via the virtual contact

IF1. IF1 can be used to control an hardware output.

Takt Generator(100ms): The time of the signal „High“ and the signal „Low“ can be defined. The stepping is

100ms. 1 = 100ms, 10 = 1s etc.

SLOK Delay [s]: If there is a defect in SafeLine or in the sensor system of SafeLine the output 01 will be turn off.

After an adjustable delay time 0 to 25s all outputs at SafeLine will be turn off. For the time length please take care

for the function SLOK SK1 or SLOK SK2

DS1, DS2: With the central module there are two motion and standstill controls for two drives possible.

The sensors for the motion and standstill controls can be proximity switches. For a motion control there are two

proximity switches with 24V signals necessary. With the selection is this function available.

The input IN11 to IN14 are used for this function at the central module DNSL-ZMB, ZMT and ZMR.

Motion monitoring freq. [Hz];

SS1, SS2: Entry the frequency value for standstill

F11, F21: Entry the frequency value for tool setting mode

F12, F22: Entry the frequency value for semiautomatic mode

F13, F23: Entry the frequency value for automatic mode

: save and close. : close without saving.

*)SK: Safety circuit

Product information

Products: safety technology SafeLine redaction 11 date 10.04.09 page 9 from 48

Central module: selection A. relay, LM or Analogue

Selection A. Relay, Contactor relay Selection (LM), logic modules Selection Analogue only with ZMT/ZMA

Fields for

labelling

Contact

definition

Fields for

labelling

Selection of

logic module

type

Selection of

custom logic

module

Vref: Reference voltage 15V,

produced in

SafeLine.

Fields to enter the

voltage value

Trigger points at ZMT,

Tension values at

ZMA

3. layer: Wiring layer

Graphic to lift side language

Button to select the modules at the wiring layer. The module can be selected left or right, depending from the used button

The cipher at the end of the button is the position number in the rack.

Button to select the time delay relay (ZW), contactor relay (KV) or logic modules (LM) at the wiring layer, if the central

module is chosen. The module can be selected left or right, depending from the used button.

Product information

Products: safety technology SafeLine redaction 11 date 10.04.09 page 10 from 48

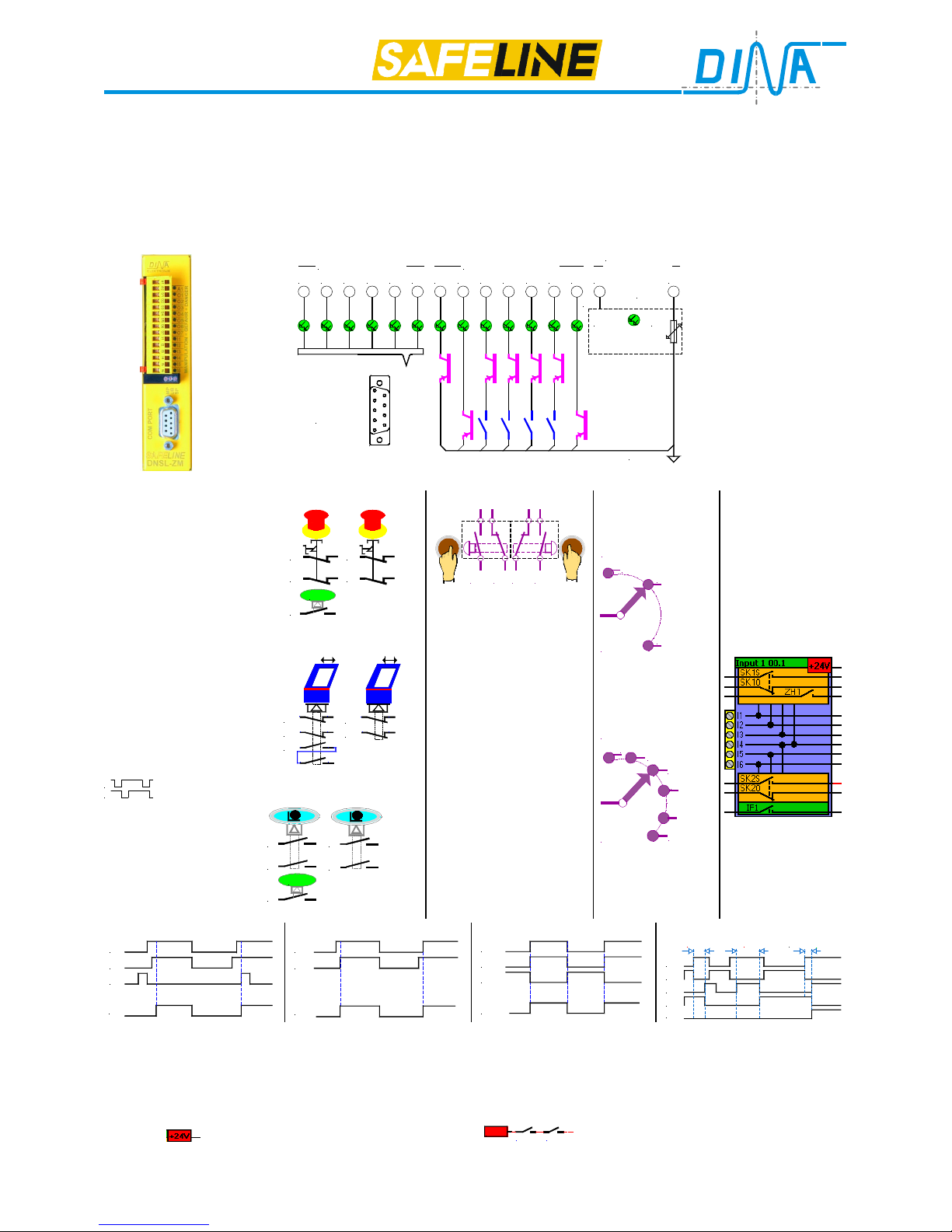

DNSL-ZM: Central module

Every unit contains only one central module.

The number of function modules is dependent on the application.

Programming of the SafeLine unit is accomplished with the SafeLine Designer program on a PC. The completed

program is transferred via the COM interface to the Safeline unit.

The SafeLine DESIGNER is special software developed by DINA Elektronik.

The operation voltage (24V DC) is supplied to the clamps A1 und A2.

DNSL-ZM Connection scheme DNSL-ZM

O5

V24

COM PORT

Netzteil

Power supply

UB = 24V DC

I1I2I3I4I5I6 O1O2O3O4O6O7 A2 A1

0V

24V intern

6A

Eingänge / Inputs Ausgänge / Outputs

24V DC

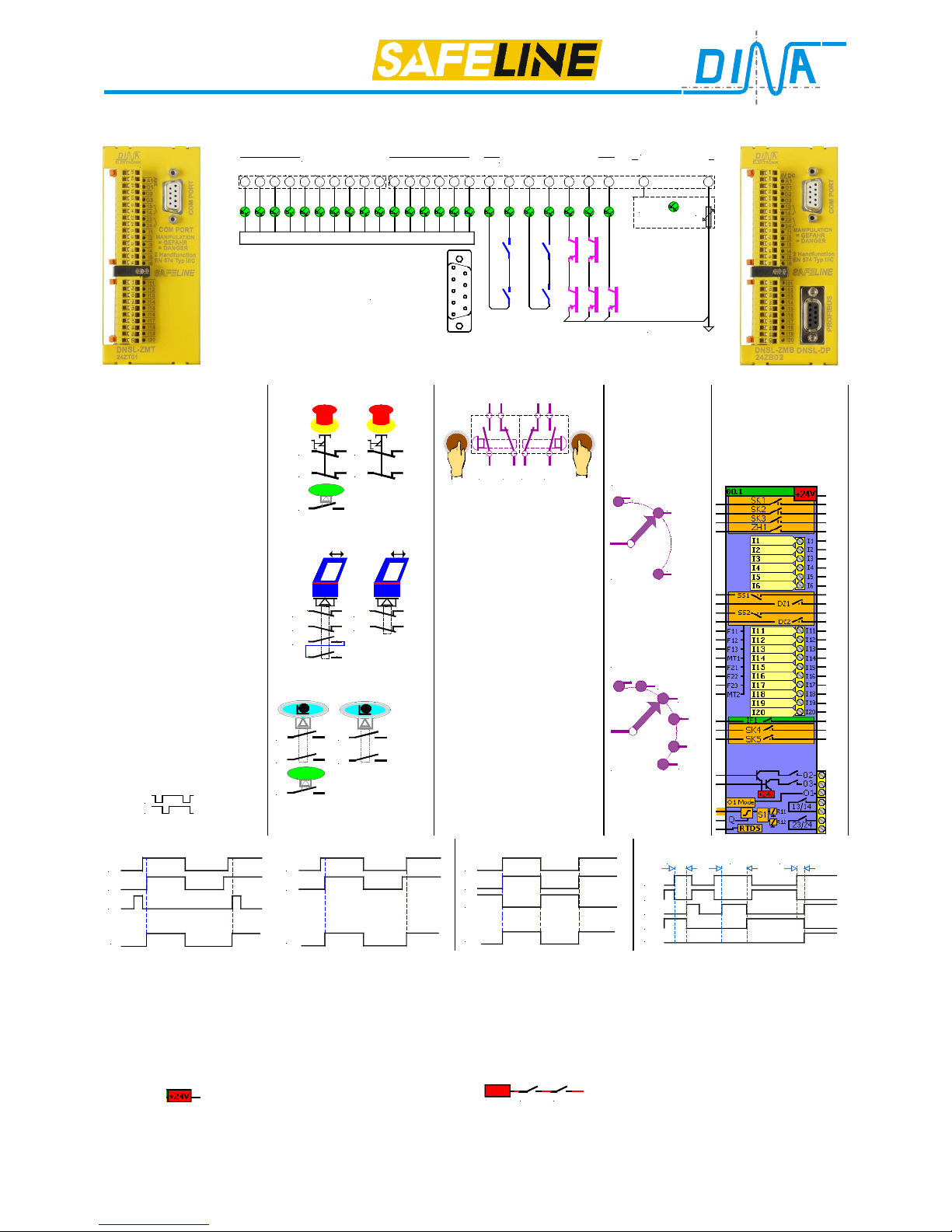

DNSL-ZM input usage

Safety circuit 1 (SK1)

E1⇒I1

E2⇒I2 and

Q ⇒I3

control SK1S and

SK1Ö

Safety circuit 2 (SK2)

E1⇒I4

E2⇒I5 and

Q ⇒I6

control SK2S und

SK2Ö

E1 and E2 may be

used in static or

clocked mode.

E1

E2

All inputs may be used

for optional functions.

Emergency Stop

E1

E2

E1

E2

Q

Quit

manually automatic

Protection cover function

E1

E2

11 12

21 22

E1

E2

Q

11 12

21 22

13 14

23 24

automatic

Permission function

Q

E2

E1

Quit

E2

E1

manually automatic

Two-hand function

Q1E1Q2

E2

only by

E1⇒I1

Q1⇒I2

E2⇒I3

Q2⇒I4

control ZH1

Static input signal only

According EN 574:

Type IIIC

Operation mode

Switch (BAWS)

One from three

24V

DC

BA/ Mode

1

2

3

I1 to I3

One from six

24V

DC

BA / Mode

2

3

4

5

6

1

I1 to I6

DNCO Function

See page 12

and DNSL-DS

Wiring Layer

manually

automatic

Protection cover function

Two-hand function

E1

E2

Q

SK1S, 2S

E1

E2

SK1S, 2S

Q

E1

E2

SK1S, S2

Q2

E1

E2

ZH1

Q1

>500ms Q2

OK

<500ms

The static/ clocked and manually / automatic operation mode of SK1 and SK2 are defined in the parameter

mask. In manual mode, restart is only possible using Q.

Note: „automatic“ should be selected in the DESIGNER, if protection cover switch with quit contact is used. The

quit contact has to be connected to I3 respectively I6. “automatic“ should be selected in the DESIGNER, if there

are safety circuits without quit contact. I3 respectively I6 has to be connected to 24V DC.

SK1S, SK2S will be wired into the safety chain with the DESIGNER. The left side of the 1st contact must be con-

nected to

, the right side connects to the next contact.

SK1

SK2

+24V

. SK1S, SK1Ö, SK2S, SK2Ö and ZH1 are

virtual redundant Contacts. Two safety circuits or one Two-hand-function are possible.

The inputs may also be used as general-purpose inputs.

Product information

Products: safety technology SafeLine redaction 11 date 10.04.09 page 11 from 48

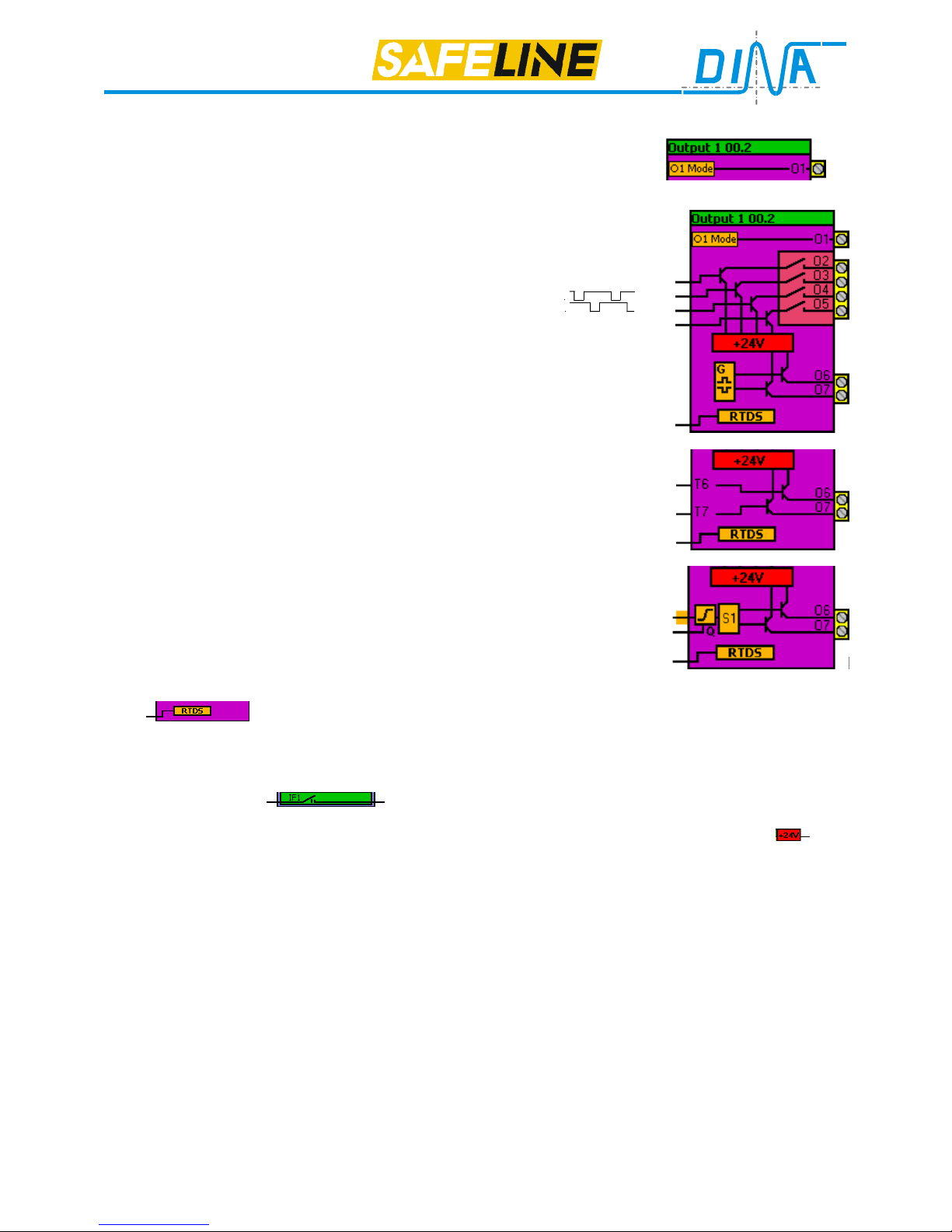

Outputs usage

1. Output O1 function may be defined in the parameter layer to one of the following:

SLOK: Output indicating System Ready

T8: Semi conductor switch

2. FrqIn: possible only with DNSL-ZMB, ZMT and ZMR

3. O2, O3, O4 and O5 are redundant outputs made of a positive switching semiconductor and a relay contact. These outputs may be activated directly by external inputs or by virtual connections from NC, NO, Logic-elements, time delay relays etc. The wiring is done by the virtual control inputs in the DESIGNER.

4. O6 and O7 are free usable outputs. The usage may be defined in the parameter

layer to the following:

Clock output supply for cross-circuiting detection in safety circuits,

E1

E2

No virtual wiring possible

Single outputs individually activated by T6, T7

Note: T6 and T7 only visible, if this mode is selected in the

parameter layer.

Paired output Safe output to duplicate dual channel contacts.

Activated by S1 and Q

Q may be wired to virtual 24V directly or can be used from an external input.

S1 and Q are only visible, if this mode is selected in the parameter layer.

The 24 V supply for the outputs O1 – O7 is from the A1 input clamp.

Note: All semiconductor outputs will be monitored constantly for wrong behaviour

independent of the function. If an error is detected on one of the outputs, all outputs

will be switched off after an adjustable time delay (0-25s).

Wiring layer

Special functions

RTDS

Virtual input to reset the interlock of the virtual contacts of the motion control module DNSL-DS, and DNSL-DR

after the actual values are below the limit values. The virtual input RTDS must be held at 24V for more then 500ms.

For this function a hardware input or virtual output can be used.

Pulse generator via IF1

With the selection „ON” via the parameter mask the function of a pulse generator (Takt Generator) is possible via

the virtual contact IF1. The right connection can be used to control an hardware output, the left to virtual

The time of the signal „High“ and the signal „Low“ can be defined. The stepping is 100ms. 1 = 100ms, 10 = 1s etc.

Note: in the SAFELINE unit all digital inputs are processed by both channels and checked for Plausibility. There

is no single channel processing.

Malfunctions

Behavior: Output O1 switched off. LED- for O1 not illuminated.

Left LED at ZM Block not on. Right LED at Block blinks sequence short/long.

Correction: Check of the wiring

Check of the configuration (wrong assembly of the rack or wrong project planning.)

Reset stored errors by switching 24V supply OFF and ON.

Product information

Products: safety technology SafeLine redaction 11 date 10.04.09 page 12 from 48

Parameter mask DNCO Parameter mask

: Mask save and close.

Selecting DNCO mask is available in every central module mask.

Description of the parameter mask: See page 8 and 9.

DNCO function: Parameter mask

Two frequency tables containing up to 48 values each.

These values define the maximum monitored speeds. This frequency values

are the frequencies of the encoder of the drive measurement system by the

corresponding speed.

Monitoring 8, 16 or 48 speed’s is possible and can be selected via the central

module mask “DNCO Terminals”. The necessary inputs to select one from 8,

16 or 48 speeds can be used at the central module or at the motion monitoring

module DNSL-DS. For 8 value there are 3 input necessary, for 16 value 4

inputs and for 48 value 6 inputs.

A frequency value has to be entered in every field of the selected table.

With the selection 16 the frequency value 01 to 15 can be automatically calculated, if the maximal value in field DNCO1_16 is entered.

After this the button for the left table and for the right

have to be activated.

A %-value (0 to 20%) can be sum up to all value in the table, if in the field

“Tolerance” a value was entered and the button

will be activated.

For every frequency table the encoder input at motion monitoring equipment

has to be defined. The selection has to be done vie Encoder1/2.

DS to Teach: For this function see DNSL-ZMA.

Example:

DNCO1 table via DNSL-DS

D1

B11

D2

D3

D4

D5

D6

B12

B13

B14

B21

B22

DNSL-DS

DNCO1

SH-K

TK

Steuergerät

Control

device

DNCO2 table via central module

D1

I1

D2

D3

D4

D5

D6

I2

I3

I4

I5

I6

DNSL-ZM

ZMB

ZMT

ZMA

ZMK

ZMR

DNCO1

SH-K

TK

Steuergerät

Control

device

Position monitoring of axis with DNSL-DS

Usage DNCO mask for the configuration

The right side of the mask is used for the position monitoring.

The motion control DNSL-DS, DR is able to monitor the

position of axis. This function has to be selected with

. After the message “DNCO Data will be

cleared. continue?” It has to be confirmed with yes or no.

The DESIGNER sense the rack position of the function

modules (FM) DNSL-DS or DNSL-DR. 14 function modules are possible.

Every motion control has two position monitorings. In the

fields beside FM the increments number of the encoder

can be written.

Always if no function modes are selected and the axis

stop, DNSL-DS, DR record this position as the new monitored position.

The monitored axis can oscillate lift and right but not more than these predetermined increments. If it decrease, the

virtual contact SS1 or SS2 in the wiring layer opens.

Notice: If position is monitored, no standstill monitoring is possible.

Product information

Products: safety technology SafeLine redaction 11 date 10.04.09 page 13 from 48

Central modules DNSL-ZMB, DNSL-ZMT

DNSL-ZMT

Schematic

14

V24

COM PORT

Netzteil

Power supply

24V DC

I1I2I3I4I5I20 O1O2O3132324 A2 A1

0V

24V intern

6A

I19 I18 I17 I16 I15 I14 I13 I12 I11 I6

Eingänge / Inputs

Ausgänge / Outputs

UB = 24V DC

DNSL-ZMB and ZMT can be ordered with an integrated field bus, Profibus or Ether cat

module. Type with Profibus: DNSL-ZMB-DP, type with Ether cat: DNSL-ZMB-EC

DNSL-ZMB-DP

DNSL-ZMB, DNSL-ZMT: Inputs usage

Safety circuit 1 (SK1)

E1⇒I1

E2⇒I2

Q ⇒I3 controls SK1

Safety circuit 2 (SK2)

E1⇒I4

E2⇒I5

Q ⇒I6 controls SK2

Safety circuit 3 (SK3)

E1⇒I11

E2⇒I12

Q ⇒I13 controls SK3

Only at ZMB

Safety circuit 4 (SK4)

E1⇒I15

E2⇒I16

Q ⇒I17 controls SK4

Safety circuit 5 (SK5)

E1⇒I18

E2⇒I19

Q ⇒I20 controls SK5

E1 and E2 may be used

in static or clocked

mode.

E1

E2

Emergency Stop

E1

E2

E1

E2

Q

Quit

manually automatic

Protection cover function.

E1

E2

11 12

21 22

E1

E2

Q

11 12

21 22

13 14

23 24

automatic

Permission function

Q

E2

E1

Quit

E2

E1

manually automatic

Two-hand function

Q1E1Q2

E2

Only by

E1⇒I1

Q1⇒I2

E2⇒I3

Q2⇒I4

control ZH1

Static input signal only

According EN 574:

Type IIIC

Operation

mode Switch

(BAWS)

One from

three

24V

DC

BA/ Mode

1

2

3

I1 to I3

One from six

24V

DC

BA / Mode

2

3

4

5

6

1

I1 to I6

DNCO function

See page 27

or click here

DNSL-DS

Programming Layer

manually automatic

Protection cover function

Two-hand function

Q

E1

E2

SK1-5

E1

E2

SK1-5

Q

E1

E2

SK1-5

Q2

E1

E2

ZH1

Q1

>500ms Q2

OK

<500ms

The static/ clocked and manually / automatic operation mode are defined in the parameter mask. In manual

mode, restart is only possible using Q.

Note: „automatic“ should be selected in the DESIGNER, if protection cover switch with quit contact is used. The

quit contact has to be connected to I3, I6, I13, I17 respectively I20.

“automatic“ should be selected in the DESIGNER, if there are safety circuits without quit contact. I3, I6, I13, I17

respectively I20 has to be connected to 24V DC.

All inputs may be used for optional functions.

SK1 to SK5 will be wired into the safety chain with the DESIGNER. The left side of the 1st contact must be con-

nected to

, the right side connects to the next contact.

SK1

SK2

+24V

. SK1 to SK5 and ZH1 are virtual redun-

dant contacts. Five safety circuits or one Two-hand function and three safety circuits are possible.

These inputs may also be used as general-purpose inputs.

Product information

Products: safety technology SafeLine redaction 11 date 10.04.09 page 14 from 48

DNSL-ZMB, DNSL-ZMT: Standstill and motion monitoring

The Central module DNSL-ZMB may be used to monitor two motions for safe standstill and safe speed. For speed

sensing at a motion two proximity switches could be used. This Function is also with DNSL-ZMR available.

Inputs

Operation mode Virtual

Inputs

Examples

Wiring layer

Monitoring 1

Sensor (S1)⇒I11

Sensor (S2)⇒I12

Monitoring 2

Sensor (S3)⇒I13

Sensor (S4)⇒I14

Tool setting mode BA2

Semi automatic mode BA3

Automatic mode BA1

Not-monitored BA1

Tool setting mode BA2

Semi automatic mode BA3

Automatic mode BA1

Not monitored BA1

F11⇒

F12⇒

F13⇒

MT1⇒

F21⇒

F22⇒

F23⇒

MT1⇒

Tip contact

Permission contact

Protection cover contact

Protection cover contact

Tip contact

Permission contact

Protection cover contact

Protection cover contact

S1

S2

S3

S4

Zahnrad

Gear

Zahnrad

Gear

Monitoring 1

Monitoring 2

SS1 virtual contact for standstill: closed if standstill, open if

νννν

act >

νννν

standstill

DZ1 virtual contact for

νννν

max: closed if

νννν

act <

νννν

max , open if

νννν

act > νmax

SS2 virtual contact for standstill: closed if standstill, open if

νννν

act >

νννν

standstill

DZ2 virtual contact for

νννν

max: closed if

νννν

act <

νννν

max , open if

νννν

act > νmax

To use motion monitoring the function DS1 and/or DS2 in the SafeLine DESIGNER must be selected.

I11, I12 and I13 are not available for safety circuits in this case.

Selection of the individual speeds is accomplished by entering the corresponding frequency in Hz into the parameter fields. The maximum Input-frequency for I11 – I14 is 1200Hz.

Proximity switches requirements:

2 signals with 180° phase offset. One switch at the cog the an other at the gap. Positive switched to 24V DC (PNP)

DNSL-ZMB, DNSL-ZMT: Output usage

Output O1 function may be defined in the parameter layer to one of the following:

SLOK: Output indicating system ready

T8: Semi conductor switch

FrqIn: Frequency input (maximal 1200Hz) single channel motion control.

The output O1 can be redefined as frequency input in the parameter layer to function

as a one-channel not safe motion control. As impulse device a proximity switch may

be used.

Setting the value for the motion control will be done using the PROFIBUS.

The proceeding of programming is received by DINA Elektronik.

SS2 virtual contact is closed at standstill and opened at

νννν

act >

νννν

standstill

DZ2 virtual contact is closed at

νννν

act <

νννν

max and opened at

νννν

act > νmax

To reset the contact DZ2 the maximum of the speed has to be decreased more than

10% a the virtual input RTDS has to be switched to virtual 24V.

Programming Layer

O2 and O3 are redundant outputs made of two positive switching semiconductors. These outputs may be activated

directly by external inputs or by virtual connections from NC, NO, logic elements, time relays etc.

R13/R14, R23/R24 are 2 relay outputs and they are configurable to the following:

a) two independent NO contacts, safety category 2, activated by K1, K2

b) two redundant NO contacts, safety category 4, activated by S1 and Q.

Q may be connected to or connected via an external input. S1 and Q are displayed in the programming layer

only in this mode.

Version a and b will be factory-made. The factory-made configuration has to be selected via the parameter mask.

Note: All outputs will be monitored constantly for wrong behavior independent of the function. If an error is detected on one of the outputs, all outputs will be switched off.

Special function:

RTDS: Virtual input to reset the interlock of the virtual contacts of the motion control at the central mod-

ule and DNSL-DS, DR after the actual values are below the limit values. This virtual input can be also used to reset

safety shutdown mat. The virtual input RTDS must be held at virtual 24V for more then 500ms. For this function a

hardware input I1-I6, I11, I12 rather a hardware input at a function module or virtual output can be used.

Pulse generator via IF1:

With the selection „ON” via the parameter mask the function of a pulse generator (Takt Generator) is possible via

the virtual contact IF1. The right connection can be used to control an hardware output, the left to virtual

The time of the signal „High“ and the signal „Low“ can be defined. The stepping is 100ms. 1 = 100ms, 10 = 1s etc.

Product information

Products: safety technology SafeLine redaction 11 date 10.04.09 page 15 from 48

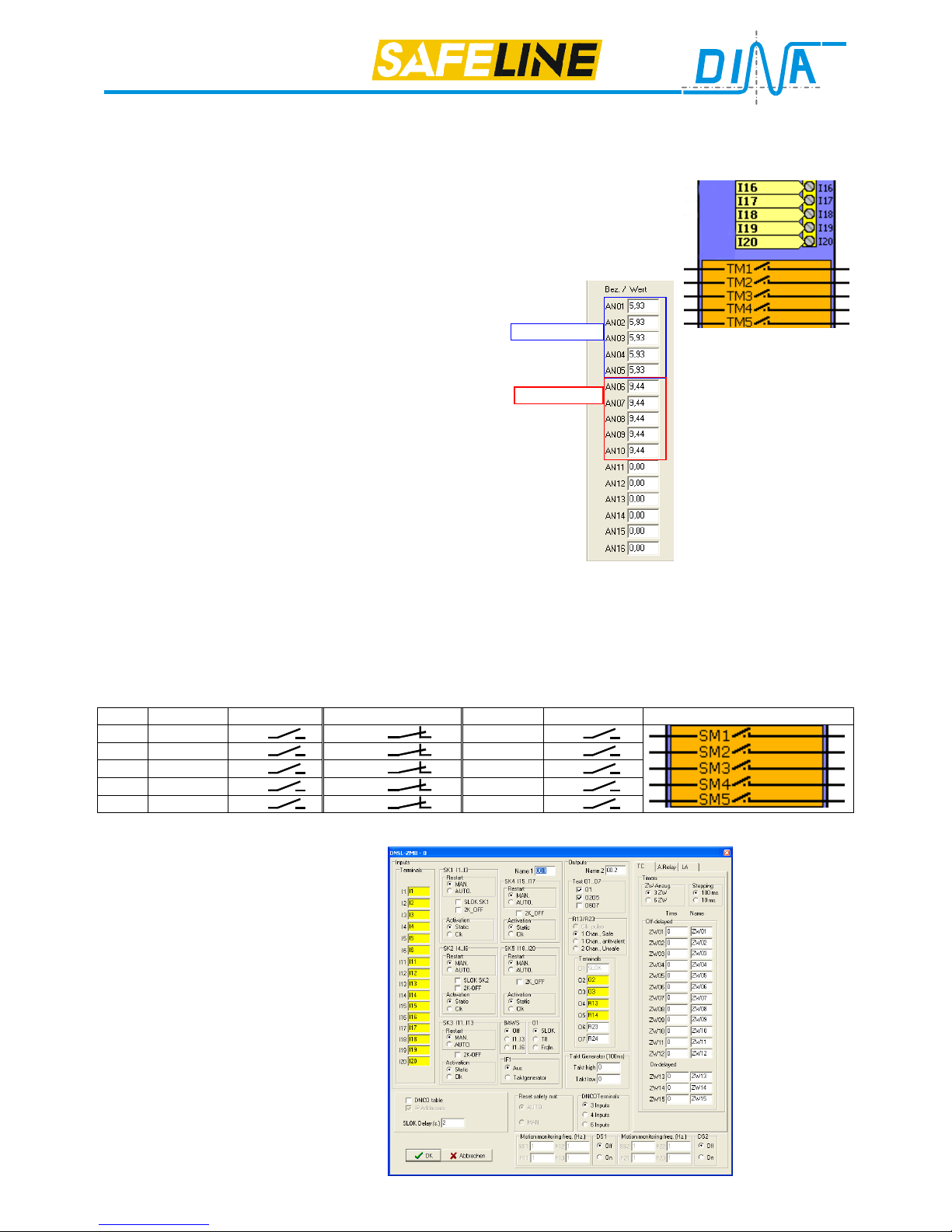

DNSL-ZMT: usage of inputs I16 to I20 for safety shutdown mats

For working with safety shutdown mats (max. 5) virtual redundant contacts TM1 to TM5 are provided. If the safety

shutdown mats is OK and not activated the corresponding

contacts TM1 to TM5 are closed. Stepping on the safety

shutdown mat or an internal malfunction of the mat will open

the corresponding contact. Contact closes again if no one is

on the mat.

A manual reset must be programmed using the logic module

in the DESIGNER.

The status of TM1 to TM5 may be monitored using the

Profibus.

The values for the analogue edges will be set using:

AN01 to AN05 for lower level

AN06 to AN10 for upper level

AN01/ AN06, AN02/ AN07, AN03/ AN08, AN04/ AN09 and

AN05/ AN10 are paired values.

Note for initial start-up:

At the clamp the measured voltage against 0V is 8,5V with a

free mat.

Additional parameters are not necessary.

Unused clamps I16-I20 may be left unconnected.

Note: Digital inputs and analogue safety mat inputs will be

processed in two channel mode and tested for plausibility on

the Central – and all Function modules. There is no single

channel processing.

SAFELINE DESIGNER

Parameter mask

Programming mask

The tension values

shown in the left picture

are for a safety mat with

shorting outputs using an

external 8,2Kohm Reference resistor.

For different reference

resistor values, contact

DINA Elektronik.

DNSL-ZMT: usage of inputs I16 to I20 for current source monitoring (4 to 20mA)

This inputs can be used to monitor the current value with an internal resistance of 500Ohm. The switching thresholds can be defined as for shutdown mats. Lower value and upper value must be entered. The interpretation will be

done via the virtual contacts SM1 to SM5. It may be to control outputs with right connection of the contacts. The left

connection can be linked with virtual +24V or with another software elements.

0V potential of the current source has to be connected with A2 of the central module.

Interrelationship between hardware inputs, voltage respectively current values and virtual contacts

Input min. value < min. value > min.,< max. value max. value > max. value Virtual contacts

I16 AN01 SM1 SM1 AN06 SM1

I17 AN02 SM2 SM2 AN07 SM2

I18 AN03 SM3 SM3 AN08 SM3

I19 AN04 SM4 SM4 AN09 SM4

I20 AN05 SM5 SM5 AN10 SM5

Parameter mask DNSL-ZMB

Description of the parameter mask: See

page 8 and 9.

The terminals O4-O5 and O6-O7

are two redundant NO contacts

Lower value

Upper value

Loading...

Loading...