Page 1

Service Manual

Model

VF2927L

VFA2927

VF5452L

UL Part Number

6909410210

6909410110

6909680110

IMPORTANT SAFETY INFORMATION: Always read this manual rst before attempting to service this replace. For your

safety, always comply with all warnings and safety instructions contained in this manual to prevent personal injury or property damage.

Dimplex North America Limited

1367 Industrial Road Cambridge ON Canada N3H 4W3

1-888-346-7539 www.dimplex.com

In keeping with our policy of continuous product development, we reserve the right to make changes without notice.

© 2016 Dimplex North America Limited

REV PCN DATE

00 - 25-SEP-14

01 - 3-MAY-16

7400850000R01

Page 2

TABLE OF CONTENTS

OPERATION .................................................................... 3

MAINTENANCE ................................................................. 4

EXPLODED PARTS DIAGRAM - SINGLE ............................................. 5

EXPLODED PARTS DIAGRAM - DOUBLE ............................................ 6

WIRING DIAGRAM- SINGLE ....................................................... 7

WIRING DIAGRAM - DOUBLE ...................................................... 7

FRONT GLASS REPLACEMENT ................................................... 8

BOTTOM LOGSET REPLACEMENT ................................................. 8

TOP LOGSET REPLACEMENT ..................................................... 8

LED CONTROLLER REPLACEMENT ................................................ 8

LED LIGHT ASSEMBLY REPLACEMENT ............................................. 9

LED SCREEN REPLACEMENT .................................................... 9

TROUBLESHOOTING GUIDE ..................................................... 11

Always use a qualied technician or service agency to repair this replace.

!

NOTE: Procedures and techniques that are considered important enough to emphasize.

CAUTION: Procedures and techniques which, if not carefully followed, will result in damage to the equipment.

WARNING: Procedures and techniques which, if not carefully followed, will expose the user to the risk of re,

serious injury, or death.

2 www.dimplex.com

Page 3

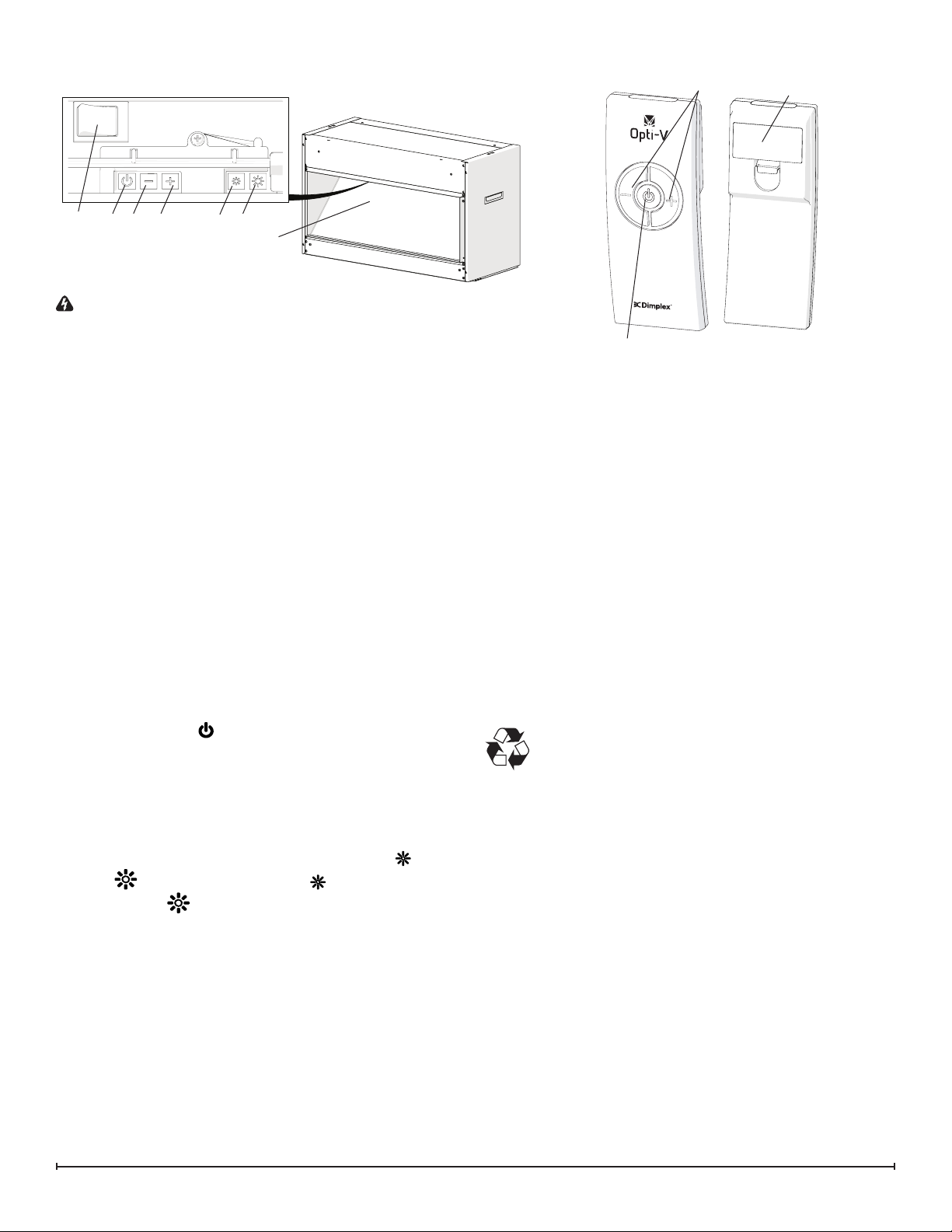

OPERATION

Figure 1

Figure 2

Volume

Controls

Battery

Cover

A

WARNING: This electric rebox must be properly in-

stalled before it is used.

The power switch (Figure 2A) must rst be switched “I” to

operate the appliance.

An ‘Opti-V’ logo will appear on the screen for about 3 sec-

onds before the ame picture starts .

!

NOTE: The user may notice a blank screen for approximately 5 seconds, every 30 minutes. This is normal

and should not be a cause for concern.

Manual Operation

The manual controls for the screen are located at the inner

top left hand side of the appliance above the glass.(Figure

2).

The mains (power) switch (Figure 2A) may be used to

switch the appliance Off (“O”) when it is not required, for

example, overnight or for long periods, to avoid unnecessary energy use.

!

NOTE: Ensure that the mains (power) switch shall

remain readily operable.

DC

IR Remote Sensor

F

EB

Standby

Button

Remote Control Operation

The remote control may be operated once the appliance is

switched to the ON “I” position (Figure 2A).

Aim the remote control at the IR remote sensor located on

the left of the re display (Figure 2). The volume may be

adjusted up or down by pressing the volume control but-

tons ( + and -).

Battery Replacement

!

NOTE: The remote control is packed separately in the

carton.

1. Slide battery cover open on the remote control (Figure

3).

2. Correctly install 2 1.5 Volt (AAA) battery in the battery

holder.

3. Close the battery cover.

The standby button “ ” (Figure 2B) is located just below

the power switch. A red light will indicate when the unit is in

standby mode. (Figure 2)

The volume of the wood re sound effects may be adjusted

up or down by pressing the volume control buttons (Figure

2C & 2D).

The screen brightness can be adjusted using the (Figure

2E) and (Figure 2F) buttons. The button darkens the

screen and the button brightens the screen.

!

NOTE:On the VF5452L there are brightness controls

for each LED screen. The brightness controls for the right

screen are located in the center of the unit.

Battery must be recycled or disposed of properly.

Check with your Local Authority or Retailer for recycling advice in your area.

3

Page 4

MAINTENANCE

WARNING: Disconnect power before attempting any

maintenance or cleaning to reduce the risk of re, electric

shock or damage to persons.

Glass Cleaning

The glass is cleaned in the factory during the assembly

operation. During shipment, installation, handling, etc., the

front glass may collect dust particles, these can be removed by dusting lightly with a clean dry cloth.

To remove ngerprints or other marks, the glass can be

cleaned with a dry cloth. The glass should be completely

dried with a lint free cloth to prevent water spots. To

prevent scratching, do not use abrasive cleaners or spray

liquids on the glass surface.

Fireplace Surface Cleaning

To remove ngerprints or other marks, the exterior nish

can be cleaned with a damp cloth with a mild detergent.

The surface should be completely dried with a lint free cloth

to prevent water spots.

Servicing

Except for installation and cleaning described in this manual, an authorized service representative should perform any

other servicing.

4 www.dimplex.com

Page 5

EXPLODED PARTS DIAGRAM - SINGLE

9

5

3

1

6

2

8

7

Replacement Parts List - Single

1. LED Light Strip ........................9600880100RP

2. LED Light Controller ....................9600930100RP

3. Opti-V Remote Control. . . . . . . . . . . . . . . . . .9600950100RP

4. Power Supply Wire Harness .............9600980100RP

5. Electrical Connector ....................9601030100RP

6. Single LED Screen Assembly (see note)* 9600890100RP

7. Glass*. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9600910100RP

8. Lower Logset Assembly* ................9600900100RP

Lower Coral Assembly ..................9601400200RP

9. Upper Logset Assembly (see note) ........9600940100RP

Upper Coral Assembly ..................9601390200RP

10. 8mm Socket .........................9601170100RP

!

NOTE: Send out Socket when sending out upper logs

and Screen Assembly.

* Group items that include suction cups.

5

Page 6

EXPLODED PARTS DIAGRAM - DOUBLE

3

5

11

1

10

6

2

4

2

7

9

8

Replacement Parts List - Double

1. LED Light Strip (2 per unit). . . . . . . . . . . . . . . 9600880100RP

2. LED Light Controller (2 per unit)* . . . . . . . . . . 9600930100RP

3. Opti-V Remote Control. . . . . . . . . . . . . . . . . .9600950100RP

4. Power Supply Wire Harness .............9600980100RP

5. Electrical Connector ....................9601030100RP

6. Double LED Screen Assembly (see note)* 9600970100RP

7. Double Glass* ........................9601000100RP

8. Right Lower Logset Assembly*. . . . . . . . . . . .9600990100RP

9. Left Lower Logset Assembly*. . . . . . . . . . . . . 9601010100RP

10. Right Upper Logset Assembly (see note) ....9600960100RP

11. Left Upper Logset Assembly (see note). . . . .9601020100RP

6 www.dimplex.com

12. 8mm Socket .........................9601170100RP

!

NOTE: Send out Socket when sending out upper logs

and Screen Assembly.

* Group items that include suction cups.

Page 7

WIRING DIAGRAM- SINGLE

Supply

LED Strip

LED Driver

Logbed - TOP LED

Logbed - BOTTOM LED

WIRING DIAGRAM - DOUBLE

LED Strip

LED Screen Assembly

LED Strip

L

N

E

Mains

LH Logbed

TOP LED

LH Logbed

BOTTOM LED

LED Driver

Mains

Supply

LED Driver

Power Supply Wire Harness

L

N

E

RH Logbed

TOP LED

Double LED Screen

RH Logbed

BOTTOM LED

7

Page 8

FRONT GLASS REPLACEMENT

WARNING: Disconnect power before attempting any

maintenance or cleaning to reduce the risk of electric

shock or damage to persons.

Tools required: Phillips head screwdriver

Suction Cups

1. Locate the glass retention strip at the top of the front

glass (Figure 3).

2. Remove the securing screws on either side of the

retention strip.

3. Apply the suction cups to the glass at a comfortable

distance to allow for easily removing the front glass.

Figure 3

Securing Screws

4. Gently tilt the glass forward, lift up and lift the glass out

of the unit.

5. Reassembly in the revers order.

BOTTOM LOGSET REPLACEMENT

WARNING: Disconnect power before attempting any

maintenance or cleaning to reduce the risk of electric

shock or damage to persons.

Tools required: Phillips head screwdriver

Suction Cups

1. Locate the glass retention strip at the top of the front

glass (Figure 3).

2. Remove the securing screws on either side of the

retention strip.

3. Apply the suction cups to the glass at a comfortable

distance to allow for easily removing the front glass.

4. Gently tilt the glass forward, lift up and lift the glass out

of the unit.

5. Locate the 4 screws that secure the logset to the bot-

tom of the unit (Figure 4) and remove the logset(s).

!

NOTE: The screws are recessed slightly into the em-

ber bed of the logset.

6. Disconnect the logset LED’s from the LED controller

board.

7. Replace connection with new logset LED wire.

8. Reassembe in the revers order.

TOP LOGSET REPLACEMENT

WARNING: Disconnect power before attempting any

maintenance or cleaning to reduce the risk of electric

shock or damage to persons.

Tools required: Phillips head screwdriver

5/16” (8 mm) socket wrench

Suction Cups

1. Locate the glass retention strip at the top of the front

glass (Figure 3).

2. Remove the securing screws on either side of the

retention strip.

3. Apply the suction cups to the glass at a comfortable

distance to allow for easily removing the front glass.

4. Gently tilt the glass forward, lift up and lift the glass out

of the unit.

5. Remove the bottom logset (only the corresponding logset to the side that needs to be repaired on the double

unit). Locate the 4 screws that secure the logset to the

bottom of the unit (Figure 4) and remove the logset.

!

NOTE: The screws are recessed slightly into the em-

ber bed of the logset.

6. On the top front surface of the rebox there are a sec-

ond set of logs that reect on to the glass. Locate the

nuts that secure the logset to the rebox - single units,

there is one on either end, double units there are three,

two on each end and one in the middle.

!

NOTE: The nuts are recessed slightly into the ember

bed of the logset.

7. Using a 5/16” (M8) socket wrench remove the nuts to

remove the logset. There is a slight ledge at the top of

the front opening that will help hold the logset from falling while the screws are being removed.

8. The wiring for the logset is connected to the LED con-

troller located on the botton panel of the rebox below

the bottom logset. Disconnect the LED connector for

the top logset from the LED controller and attach a

peice of string to the end that can be led through the

corner to pull the new LED connector back through.

9. Replace the top logset.

10. Reassemble in the reverse order.

LED CONTROLLER REPLACEMENT

WARNING: Disconnect power before attempting any

maintenance or cleaning to reduce the risk of electric

shock or damage to persons.

Tools required: Phillips head screwdriver

Suction Cups

8 www.dimplex.com

Page 9

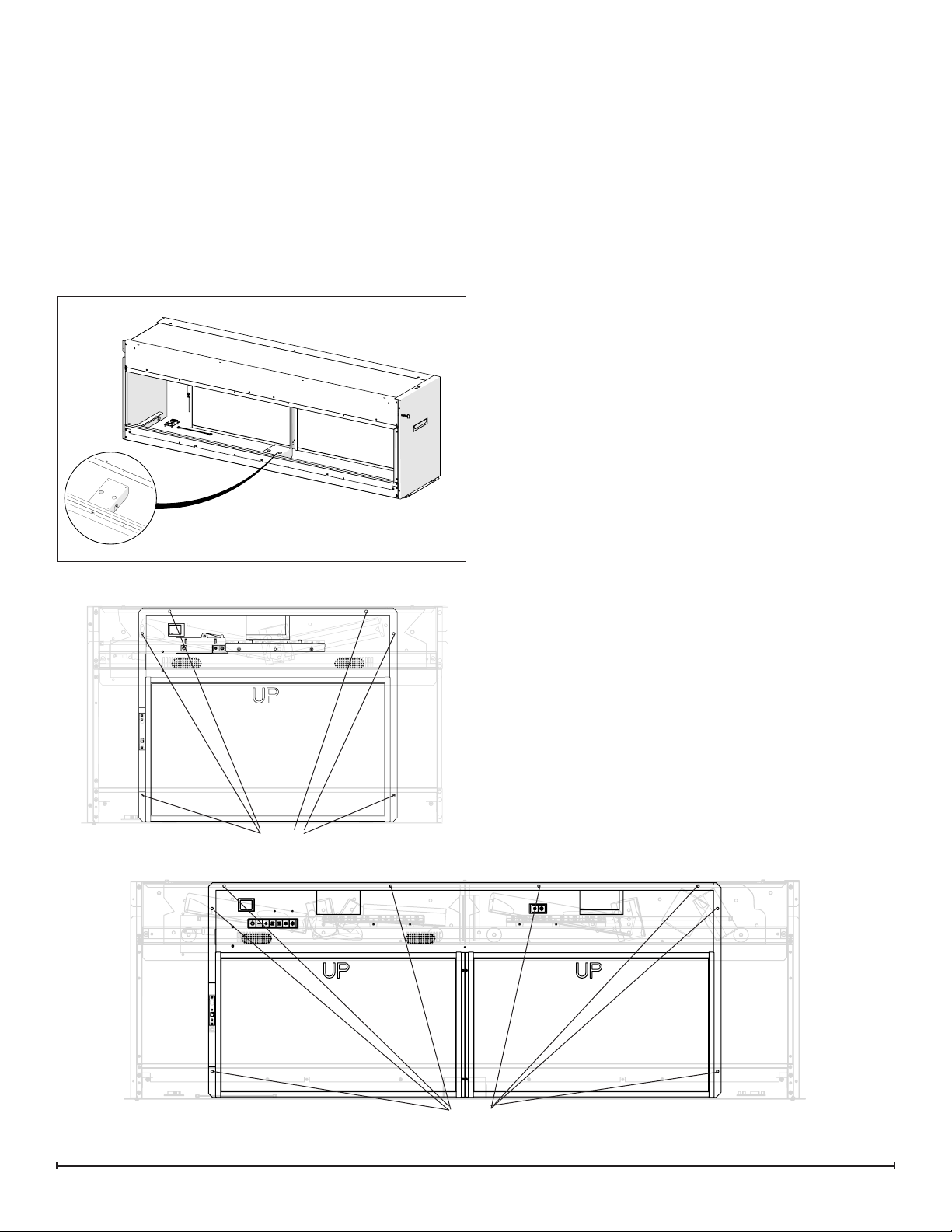

Figure 4

Approximate locations

of securing screws

(RH Double)

remove the logset.

!

NOTE: The screws are recessed slightly into the em-

ber bed of the logset.

Double units - Depending on which side is not working

correctly, remove the corresponding logset to access

the LED controller, i.e. the left logs and lights are not

working remove the bottom left logs.

Approximate locations

of securing screws

(Single & LH Double)

1. Locate the glass retention strip at the top of the front

glass (Figure 3).

2. Remove the securing screws on either side of the

retention strip.

3. Apply the suction cups to the glass at a comfortable

distance to allow for easily removing the front glass.

4. Gently tilt the glass forward, lift up and lift the glass out

of the unit.

5. Single units - Locate the 4 screws that secure the log-

set to the bottom of the unit (Figure 4) and remove the

logset.

!

NOTE: The screws are recessed slightly into the em-

ber bed of the logset.

Double units - Depending on which side is not working

correctly, remove the corresponding logset to access

the LED controller, i.e. the left logs and lights are not

working remove the bottom left logs.

6. Locate the LED controller and disconnect the wiring

connections noting their original locations.

7. Remove the LED controller and install the new one.

8. Reassemble in the reverse order.

6. The wiring for the light assembly is connected to the

LED controller located on the botton panel of the rebox below the bottom logset. Disconnect the LED connector for the light assembly from the LED controller

and attach a peice of string to the end that can be led

through the corner to pull the new LED light assembly

cord through.

7. Remove the light assembly by removing the two screws

located below the assembly and replace with new light

assembly.

8. Reassemble in the reverse order.

LED SCREEN REPLACEMENT

WARNING: Disconnect power before attempting any

maintenance or cleaning to reduce the risk of electric

shock or damage to persons.

Tools required: Phillips head screwdriver

5/16” (8 mm) socket wrench

Suction Cups

1. Locate the glass retention strip at the top of the front

glass (Figure 3).

2. Remove the securing screws on either side of the

retention strip.

3. Apply the suction cups to the glass at a comfortable

distance to allow for easily removing the front glass.

4. Gently tilt the glass forward, lift up and lift the glass out

of the unit.

LED LIGHT ASSEMBLY REPLACEMENT

WARNING: Disconnect power before attempting any

maintenance or cleaning to reduce the risk of electric

shock or damage to persons.

Tools required: Phillips head screwdriver

Suction Cups

1. Locate the glass retention strip at the top of the front

glass (Figure 3).

2. Remove the securing screws on either side of the

retention strip.

3. Apply the suction cups to the glass at a comfortable

distance to allow for easily removing the front glass.

4. Gently tilt the glass forward, lift up and lift the glass out

of the unit.

5. Single units - Locate the 4 screws that secure the

logset to the bottom of the unit (2 on either end) and

5. Remove the electrical plug from the left hand side of

the unit ensuring that it cannot fall out of the back of the

unit (Figure 5)

6. Locate the 4 screws that secure the logset to the bot-

Figure 5

9

Page 10

tom of the unit (2 on either end) and remove the logset.

For the double units remove both logsets, taking note

of the left and right.

!

NOTE: The screws are recessed slightly into the em-

ber bed of the logset.

7. Disconnect the logset LED’s from the LED controller

board and set in a safe place.

8. Remove the power supply wireharness that runs from

one LED controller board to the other.

9. On the top front surface of the rebox there are a sec-

Figure 6

ond set of logs that reect on to the glass. Locate the

nuts that secure the logset to the rebox - single units,

there is one on either end, double units there are three,

two on each end and one in the middle.

!

NOTE: The nuts are recessed slightly into the ember

bed of the logset.

10. Using a 5/16” (M8) socket wrench remove the nuts to

remove the logset. There is a slight ledge at the top of

the front opening that will help hold the logset from falling while the screws are being removed.

11. Remove the two screws securing the center bracket to

the unit (double unit only) (Figure 6).

12. Remove the top panel of the unit by removing the 3

screws along the top back portion of the unit, start with

the outter two then remove the center one last.

13. Slide the top panel towards the back the let the front

drop down and pull out the front opening.

14. Locate the securing screws of the LED Screen (Figure

7) and remove the LED Screen.

15. Reassemble in the reverse order.

Figure 7

Securing Screws

Securing Screws

10 www.dimplex.com

Page 11

TROUBLESHOOTING GUIDE

PROBLEM CAUSE SOLUTION PART NUMBER

General

Circuit breaker trips or fuse

blows when unit is turned

on

Appearance

Fireplace does not turn on

Manually

Fireplace does not turn on

using the Remote Control

Backlight on screen is On,

with sound but no picture

Dark screen and no sound Loose wiring Check wiring connections

Screen is blue with “No

memory card” displayed in

the top left hand corner

Logset is not lighting up Loose wiring Check wiring connections

Both top and bottom logset

are not lighting up

Flame Frozen Loose wiring Check wiring connections

Noise

No sound Improper operation Refer to Operation Section

Short in unit wiring. Trace wiring in unit.

Improper circuit current rating Additional appliances may exceed the

current rating of the circuit breaker or fuse.

Plug unit into another outlet or install unit on

a dedicated 15 amp circuit.

Improper operation Refer to Operation Section

No incoming power from the

electrical wall socket

Loose wiring Check wiring connections

Defective LED screen Replace LED screen Single - 9600890100RP

Improper operation Refer to Operation Section

Remote Control not working Install new battery into the Remote Control.

Loose wiring Check wiring connections

SD Card not working Switch the two SD Cards to ensure the

Defective LED screen Replace LED screen Single - 9600890100RP

Defective LED screen Replace LED screen Single - 9600890100RP

Defective LED controller Replace LED controller 9600930100RP

Loose SD Card Ensure that the SD card is fully inserted

Defective logset Replace logset Refer to RP list for

Loose wiring Check wiring connections

Defective LED controller Replace LED controller 9600930100RP

Defective LED screen Replace LED screen Single - 9600890100RP

Defective LED screen Replace LED screen Single - 9600890100RP

Check fuse/breaker panel

Initialize Remote Control where necessary

Replace Remote Control 9600950100RP

digital input has been saved correctly

(located at the top of the unit, just above the

LED light assembly)

Double - 9600970100RP

Contact Customer

Service

Double - 9600970100RP

Double - 9600970100RP

specic part numbers

Double - 9600970100RP

Double - 9600970100RP

11

Loading...

Loading...