Page 1

SV8000

Professional steam & vacuum cleaning machine

User instructions

Warning

instructions. Always keep the instructions attached to the appliance or readily

available at the appliance storage site.

Do not operate this appliance before reading and understanding these

Page 2

Technical specification

Congratulations

Boiler capacity (continuous fill) 3.3 litres

Water tank capacity 5 litres

Chemical tank capacity 2.5 litres

Steam pressure (max) 8 bar

Steam temperature (max) 180ºC

Maximum power 3000W

Vacuum motor 850W

Heating element 2000+1000W

switched

Hose length 4m

Voltage 240V

Low voltage controls 5V

• Stainless steel construction

• Steam output control

• Vacuum control

• Water filtration vacuum

• Air purifier

We would like to thank you for your

choice of the combined steam vacuum

cleaner, the SV8000 is manufactured in

Ireland to the highest quality standards.

This instruction manual contains all of the

necessary information to operate and

maintain this machine. Please read this

instruction manual carefully before you start

using or carrying out any maintenance on the

machine.

If used correctly as stated in this

Instruction Manual this machine will fulfil

your steam cleaning needs.

To ensure the best results

• Operate the machine in accordance with

the instruction manual.

• Maintain the machine in accordance with

the instruction manual.

• Use only parts supplied by approved

distributors.

• Use only approved detergents and

cleaning products in the solution tank.

Keep this manual in a safe place

for future reference and ordering of

spare parts.

Operation

This machine is intended for use in a

commercial cleaning environment.

• If you do not follow the instructions

contained in this manual situations may

arise which will be dangerous or harmful

to the machine or the person operating

the machine.

• Read this manual carefully so that you

will know when such situations can arise.

• Ensure that all operators of this machine

are fully trained on how it works.

• Report any problems or damage to the

machine immediately to the supplier of

this product.

If something is missing fr

•

do not operate it.

2

om the machine

Page 3

Warnings

This machine has been designed with

your safety in mind, however it is important

that you observe the following points for

safe operation

• To obtain best results from your steam

cleaner please read the instructions

carefully.

• This appliance is for indoor use only.

• If the electrical cable becomes damaged

the complete cable must be replaced.

Do not attempt this task yourself contact

the supplier of this product.

• If the Hose Assembly becomes

damaged the complete assembly must

be replaced. Do not attempt this task

yourself contact the supplier of this

product.

• Do not discharge steam towards people,

danger of scalding.

• Never allow children to play with this

appliance.

• Always unplug the machine when:

- The machine is not in use

- Cleaning the machine

• When using the machine keep it

horizontal.

• Do not use the machine for other

purposes that it was built for.

• Steam must not be dir

equipment containing electrical

components.

• Do not use any chemicals, detergents,

perfumes, alcohol etc in the clean water

tank.

• Unapproved chemicals may damage the

connectors, seals etc. in your machine.

To ensure your safety use only approved

chemicals and use only in the solution

tank.

• When changing the accessory heads

during use, please note these are hot.

• Never touch the plug or power cable

with wet hands.

• If an extension cord is used the plug and

socket must be of watertight

construction. Inadequate extension

ds can be danger

cor

• Please remember that the steam cleaner

operates at temperatures in excess of

170ºC. Never use it on objects which

ected towards

ous.

cannot resist the temperature (delicate

materials, fabrics, plastics, wood etc).

Where any doubt exists check carefully

on a part of the material where minor

marks will not matter.

• Electrical connection and supply:

- THIS MACHINE MUST ONLY BE USED

ON AN EARTHED SUPPLY.

- Check that the supply voltage details

on the rating label are in accordance

with your electrical supply

• This machine is fitted with the following

safety devices:

- Electrical pressure switch with

mechanical over pressure release.

- Electronic temperature switch with

over temperature fuse.

- Mechanical temperaure switch.

- Two independent boiler water level

detectors.

- Cold water level detection.

- Shutdown after 30 minutes unattended

when cold water level alarm sounds.

• Do not operate the machine or carry out

any maintenance on it

- Unless you are trained and authorised

to do so

- Unless you have read and thoroughly

understand this instruction manual.

3

Page 4

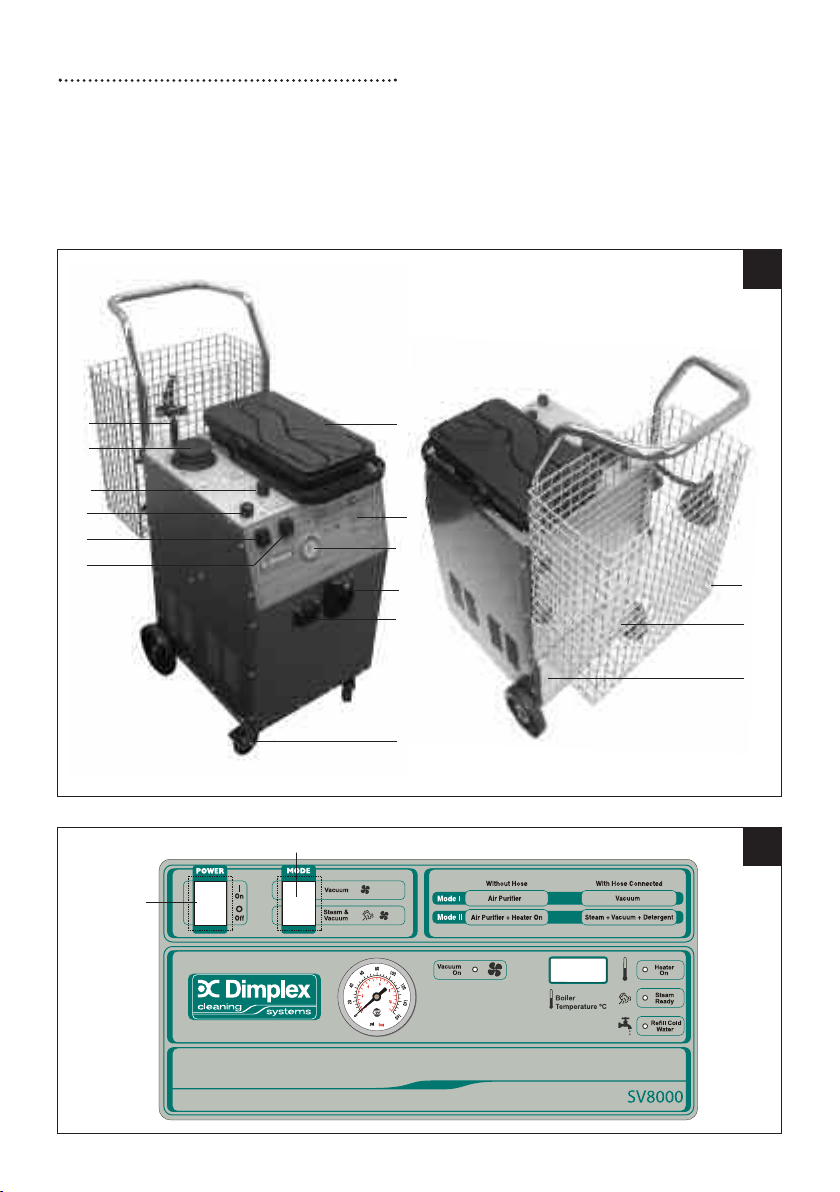

Components

⁄ Solution tank connection point

¤ Cold water tank

‹ Steam control

› Vacuum control

fi On/Off switch

fl Mode switch

‡ Collection tank

· Temperature display LED

‚ Pressure gauge

„ Vacuum hose connection

‰ Steam hose connection

Castors with brake

Ê Accessory basket

Á Rating label

Ë Filter panel

A

⁄

¤

‹

›

fi

fl

fi

fl

‡

·

‚

„

‰

Â

Ê

Á

Ë

B

170

4

Page 5

Accessories

È 2 x extension tubes

Í Floor tool

Î Floor squeegee 400mm

Ï Carpet strip 400mm

Ì Floor brush 400mm

Ó Detail nylon brush

Ú

Ò

Ô Detail wire brush

Window squeegee

Ò Steam lance short

Ú Steam lance long

Û Upholstery tool

Ù 4m hose complete with handle controls

C

Í

È

Î

Ï

Ì

Ù

Ó

Ô

Û

5

Page 6

Steam vacuum

operating procedure

1 Switch mode switch fl to position II.

• Mode 2 switches on the boiler heater

and enables the handle control (i.e.

steam, vacuum and detergent switches).

2 Remove the top cover of the collection

tank ‡ and pour clean cold water into

the tank up to the white mark (approx 1

litre).

3 Replace top cover on the collection

tank.

4 Fill the Cold water tank ¤ with clean

water.

5 Connect the Solution tank hose to the

chemical point ⁄ on top of the machine

if required.

• Fill the Solution tank with the

recommended detergent as required.

6 Connect vacuum hose and steam hose

to the front of the machine.

• Ensure both parts are locked in position.

• To release the vacuum hose slide back

the red button.

• To release the steam hose lift the steam

flap before pulling out the hose.

7 Plug in machine cord to socket.

8 Ensure steam mode II is selected on

mode switch fl.

9 Switch on power switch fi, "Heater On"

light will illuminate.

10 Allow approximately 10 minutes for the

boiler to heat the water

11 When the "Steam Ready" LED

illuminates the operator can commence

steam cleaning.

12 The handle controls are active and the

operator can switch on and off the

steam, vacuum and detergent supply

• Depressing the large button under the

handle will release the steam. This

button can only be locked in the off

position - slide the red button across to

lock.

• Pressing the left hand switch (with fan

symbol) located on the top of the handle

will activate the vacuum.

• Pressing the right hand momentry

switch located on the top of the handle

will activate the deter

.

.

gent pump. Hold

the switch for as long as you need to

dispense the detergent. Releasing the

switch will stop the detergent supply.

Note: steam and detergent cannot be

used at the same time.

13 The steam output can be adjusted by

the Steam Control knob ‹ on the top of

the machine.

14 The vacuum power can be adjusted by

the Vacuum Control knob › on the top

of the machine.

15 Choose and fit the required accessory to

the hose handle. Lock the accessory in

place by turning the accessory locking

clip.

During use

Cold Water Tank empty

Refill the cold water tank when the

1

"Cold Water Refill" LED is illuminated, a

buzzer sounds and steam no longer

comes out of the nozzle when the steam

switch on the handle is pressed.

2 Always empty the collection tank

each time the cold water tank is

refilled.

3

Pour cold water in to the collection tank

to fill up to the white mark.

4 The pumps and vacuum will not operate

if the cold water tank is empty.

5 Once the "Cold Water Refill" LED is

activated the boiler heater will remain on

for 30 minutes. If the cold water tank is

efilled within 30 minutes and the

not r

machine is left powered ON the boiler

heater will switch off.

Solution Tank empty

If the detergent does not come out of

the nozzle when the detergent switch on

the handle is pressed - refill the "Solution"

tank.

Collection Tank full

1 The collection tank must be

emptied each time the cold water

tank is refilled

2

The pitch of the motor noise changes

and there is no suction at the nozzle -

indicates the collection tank is full and

needs emptying.

6

Page 7

3 Switch off the machine, empty the

collection tank and rinse clean

4 Pour cold water in to the collection tank

to fill up to the white mark and

recommence cleaning.

Maintenance

Warning: Disconnect machine from the

mains before cleaning or maintenance.

Daily maintenance

To be carried out every day or every 10

hours of operation.

1 Wash the hose by sucking one or two

litres of water from a basin into the

recovery tank.

2 Unplug the machine and wipe down with

a clean cloth.

3 Empty the collection tank, rinse and

wipe down.

4 If chemical or detergent has been used

clean the detergent tank and pump by

putting 1 litre of clean water in the

chemical tank and pump this out using

the detergent switch on the handle.

5 Remove the foam filter and the collection

tank foam panel, wash in water and refit.

• Take care not to damage the foam or filter

mesh. If either becomes torn DO NOT use

the machine and replace damaged parts

immediately.

6 Wipe down the inside of the underside of

the machine head.

7 Always wash the cleaning attachments in

hot soapy water.

Do not immerse the machine or the

hose assembly in water.

8

Wrap the cable ar

storage.

Weekly maintenance

ound the handle before

2 Inspect the Hose Assembly for any signs

of damage. If damaged do not repair,

contact the supplier of this product. Do

not use until repaired.

3 Inspect wheels and castors to ensure all

securing bolts are fully tightened.

Air purification/filtration

1 Always ensure the machine is switched

off prior to selecting the air purification

mode.

2 Remove the top cover of the collection

tank ‡ and pour clean cold water into

the collection tank up to the white mark in

the base of the tank.

3 Add in the correct quantity of fragrance to

the water in the collection tank.

4 Replace top cover.

5 Do not connect the hose assembly to the

machine.

6 Position the machine in the room to be

purified.

7 Ensure vacuum mode 1 is selected on

mode switch.

8 Plug in the machine power cord.

9 Set the vacuum power using the "Vacuum

Control" knob on top of the machine.

10 Switch on power (without fixing the hose

assembly), the "Vacuum On" light will

illuminate and "Pur" will be displayed on

the temperature display showing that you

have selected the air purification mode.

11 Leave the machine to r

the room.

12 On completion of the air purification

empty the collection tank and rinse clean.

ecirculate the air in

Cleaning altro, vinyl, tiled

and stone floors

To be carried out every week or every 50

hours of operation.

As for daily maintenance plus the

following:

1 Inspect the power cord for any signs of

damage. If damaged do not repair,

contact the supplier of this pr

not use until r

epair

ed.

oduct. Do

1 It is advisable to vacuum the floors using

a tub vacuum prior to steam cleaning.

2 Fit the extension tubes to the hose

assembly and lock in place.

3 Fit the multi-function nozzle to the tubes.

4 When cleaning tiles or stone floors fit the

universal brush fitting to the multi function

nozzle.

7

Page 8

5 When cleaning carpet fit the carpet

cleaning insert.

6 When cleaning Altro or vinyl floors fit the

squeegee insert.

7 Steam and vacuum the floor by

following the machine operating

instructions.

Service

If you require service contact your local

authorised Dimplex Cleaning Systems

distributor or call Dimplex Cleaning

Systems direct on

Detailed cleaning

1 Fit the detail nozzle to the handle

locking it in place.

2 Fit the round plastic bristle brush to the

detail nozzle.

3 After cleaning fit the floor tool and

vacuum away the liquid.

Safety precautions

This machine is to be used by trained

operatives only.

Do

1

Check the cable and plug are safe and

intact before plugging the machine in.

Place cleaning in progress signs where

necessary.

2 Wear protective gloves and goggles.

3 Point the steam nozzle away from your

body during use.

4 Disconnect machine from the mains

before cleaning or maintaining.

5 Check surfaces to be cleaned for their

reaction (e.g. colour fastness of carpets).

6 Empty the collection tank each time the

cold water tank is refilled.

7 Empty and clean the machine after each

use.

Do not

1

Use the machine near people, children

or animals.

2 Point the steam at electrical apparatus.

3 Use the machine to clean the machine

down.

4 Leave the machine unattended.

5 Pour anything other than water into the

cold water tank.

6 Do not use on velvet, satin or leather.

7 Do not pick up boiling water with the

vacuum

In Ireland 1890 327327

Outside Ireland 00353 66 7121444

Important note for service

engineers

Removal of pressurised components

• When removing parts from a pressurised

vessel (ie boiler) ensure the pressure

vessel is at room temperature before any

parts are removed.

Guarantee

Dimplex Cleaning Systems guarantees

that if within twelve months from the date of

purchase this appliance, or any part thereof,

is proved to be defective by reason of faulty

workmanship or materials, we will at our

option repair or replace the same free of

charge for labour and materials, provided

that:

• The appliance has been installed and

used in accordance with our operating

and servicing instructions.

• lf the appliance has been serviced,

maintained, repaired, modified taken

apart or tampered with by any person

not authorised by us, then we will not be

liable under this guarantee for any fault

arising from their defective

workmanship.

• We shall not be liable under this

guarantee for any fault in the appliance

arising from the use of spare parts not

supplied and recommended by us.

• Excluded from this guarantee are parts

that need replacement due to normal

wear and tear such as hoses, nozzles

and accessories.

8

Page 9

Troubleshooting

Symptom Possible Cause Action

No power Not connected / Faulty socket Check connection to wall socket

On/Off switch not on Press On/Off switch which will

Fuse Blown Replace fuse with approved 13A

Unknown Call for service

No steam Steam Control turned Turn the control to half way

down fully clockwise

Steamer not ready Wait for the "Ready to Steam"

Clean water tank is low Pour water into the clean water

(beeping sound & tank until the beeper stops. The

“Refill” light is lit) steam handle will work again

Unknown Call for service

No steam, just water Steamer not ready Wait for the "Ready to Steam"

Boiler at pressure and not Hold the steam switch on for

heating (temperature less approximately one minute, even if

than 110ºC) just water is coming out. This will

Unknown Call for service

Vacuum power low Vacuum operation has been Operate any of the handle controls

selected after the machine was which will reset the motor power

previously used as an air purifier to full. Continue vacuuming

High pitch motor noise Switch the machine off and empty

Unknown Call for service

No detergent Solution tank empty Pour cleaning solution diluted in

Unknown Call for service

The machine has Cold water supply interrupted Switch off the machine.

stopped working and Check cold water tank is full of

the temperature LED water. Check the filter on the end

displays “HOT”

Unknown Call service engineer

and socket switch. Try in another

wall socket

illuminate when on

fuse

light to illuminate

light to illuminate

result in the heater coming back

on

the collection tank. Refill the

collection tank with clean water

to the mark and recommence work

accordance with the manufacturers

instructions into the solution tank

of the pipe in the cold water tank is

not blocked. Leave the machine to

cool for 30 minutes and switch on

again

9

Page 10

10

Page 11

11

Page 12

Clash Industrial Estate

Tralee

Co. Kerry

Ireland

T 00353 66 7121444

F 00353 66 7193380

E sales@dimplexcleaning.com

W www.dimplexcleaning.com

16RM00030 Rev 1 11/04

Loading...

Loading...