Dimplex SUTP Mid Range, SUTP30, SUTP50, SUTP75 Installation Manual

SUTP Mid Range

Unvented Hot Water Heaters

Installation Manual

30,50 & 75 Litres

Important -This Manual Should Be Left With The Unit After Installation

Table of Contents

1. Introduction.......................................................................................................................................2

2. Component Check List .....................................................................................................................3

3. General requirements........................................................................................................................3

4. Plumbing Installation........................................................................................................................5

7. Electrical installation.........................................................................................................................9

8. Filling and commissioning- ............................................................................................................10

9. Servicing and maintenance. ............................................................................................................11

10. Fault finding..................................................................................................................................12

11. Users instructions..........................................................................................................................13

12. Warranty........................................................................................................................................13

13. Installation, Commissioning and Service Record.........................................................................14

1. Introduction

The “SUTP Mid Range” is a high quality unvented stainless steel domestic hot water cylinder

suitable for domestic hot water systems where the cold mains water supply is between 3bar and 12bar.

Reduced performance is available at lower pressures but the units are not suitable for pressures lower

than 1.5bar and flow rate of 20 litres per minute. The unit comes complete with all the necessary safety

equipment to comply with legislation governing the installation of such systems.

2

Technical Specification

Model Number SUTP30 SUTP50 SUTP75

Storage capacity (litres)

30 50 75

depth (mm)

400 400 400

width (mm)

400 400 400

Overall height incl t&p valve

665 860 1175

Height excl t&p valve

586 781 1093

Weight when full (kg)

47 71 100

Cold feed/hot draw off connections (mm)

22 22 22

Maximum water supply pressure (bar)

12 12 12

System operating pressure (pre-set) (bar)

333

Expansion vessel charge pressure (bar)

333

Expansion relief valve set pressure (bar)

666

Temperature and pressure relief valve settings:

Lift pressure (bar)

777

Lift temperature (ºC)

90 90 90

Package includes*:

Expansion vessel ltr

555

3bar pressure reducing valve, non return valve, 6 bar expansion relief valve,

tundish

•••

T/P valve 7bar 90degC factory fitted

•

•

•

15mm to 22mm Tundish

•

•

•

Cylinder with 3kW immersion, thermostat, and manual reset thermal cut-out

•••

Installation Manual

•

•

•

Performance:

Heat up time 15 to 65 ºC (min)

36 55 85

Reheat time for 70% of contents (min)

25 38 60

2. Component Check List

The SUTP water heater comes complete with all necessary safety equipment, please check through the

components supplied and ensure that all parts are present:

a. Water Heater

b. 5 litre Expansion Vessel

c. Pressure reducing valve

d. Expansion relief valve

e. Isolation valve

f. Tundish

g. Expansion vessel bracket

Please contact our customer service department immediately should any part be missing.

3. General requirements

3.1. The “SUTP Mid Range” domestic hot water cylinder MUST be installed by a competent person

in accordance with section G3 of the current Building Regulations.

3.2. Important - It is important that the installer reads and understands these instructions, unpacks and

familiarises themselves with the equipment before commencing the installation. Failure to observe

these installation instructions could invalidate the warranty.

3

3.3. Water supply – The water supply to the cylinder should be potable water direct from a public

mains water supply with any water treatment equipment functioning correctly.

For optimum performance the unit should be fed via a 15 mm diameter supply pipe direct from the

mains water entry point to the property with supplies between 3bar and 12bar, however, the the unit

can operate with a minimum supply pressure of 1.5 bar and a flow rate of at least 20 litres per minute,

but flow from the outlets will be low if several outlets are used simultaneously. The cylinder control

equipment is factory set to limit the system operating pressure to 3 bar. The maximum supply pressure

into the pressure-reducing valve is 12 bar.

3.4. Taps and fittings - All taps and fittings incorporated in the unvented system should have a rated

operating pressure of 7 bar or above.

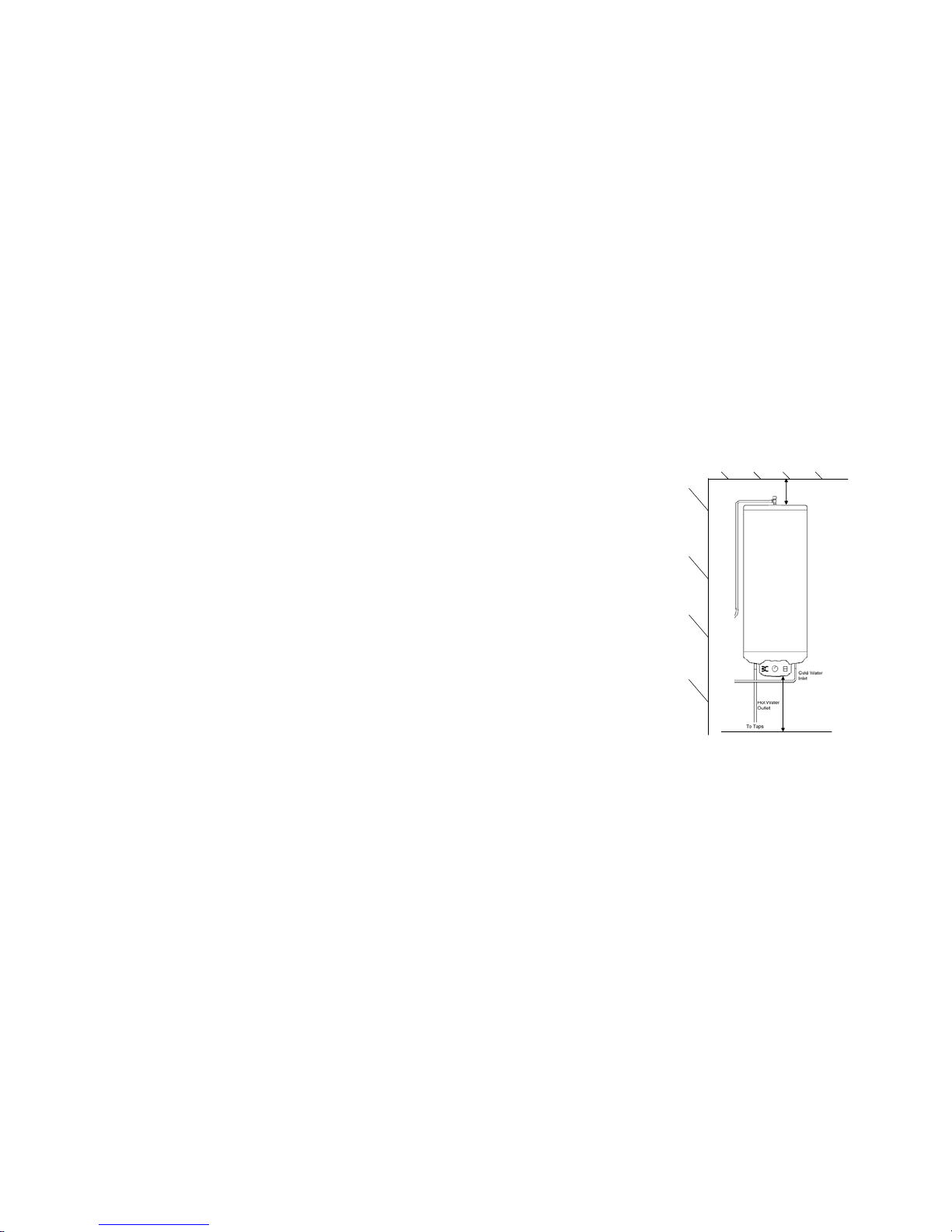

3.5. Location – The unit is designed to be vertically wall mounted, indoors, in a frost-free

environment. When choosing a suitable location for the cylinder, consideration should be given to the

routing of the discharge pipe to a convenient point and also the availability of an adequate power

supply for connecting the immersion heater.

The wall onto which the cylinder is mounted should be of good sound masonry construction capable of

holding the weight of the cylinder when full of water (See Technical specifications for weights).

min 300mm

min 100mm

Unit should be mounted on or near external wall

The position of the cylinder should be such that easy access is provided for servicing the controls and

replacing the immersion heater should the need arise.

Pipe runs should be made as short as possible and lagged to prevent heat loss.

To allow for servicing and repairs the unit must be mounted at least 300mm

above any surface or object, so that access can be gained to electric

connectors and the heating element may be removed.

The unit should be mounted close to an external wall so that the discharge

pipe D2 can be routed to a safe visible place.

The tundish should be mounted in a visible location so that it may easily be

inspected.

3.6. Storage and handling – If the cylinder is not being installed immediately, it should remain in its

carton with all pipe end protective caps in situ to prevent damage. We recommend that the cylinder be

transported to its installation position with the outer carton in place.

3.7. Pipework connections – All Pipework connections to the cylinder MUST be made in accordance

with Fig1.

4

4. Plumbing Installation

4.1. Connections. Connections MUST be made to the cylinder in accordance with Fig 1, and Fig 2.

A drain cock (not supplied) should be fitted in the position shown in Fig 1 to facilitate draining of the

cylinder.

4.2. Cold water supply – For best results, the cylinder should be fed by an uninterrupted 15mm

supply pipe into the pressure reducing valve (PRV) with a supply pressure of between 3 and 12 bar

maximum. The cylinder should not be used on any system with a supply pressure below 1.5 bar and a

flow rate of less than 20 litres per minute.

4.3. Temperature and pressure relief valve – The temperature and pressure relief valve (T&P Valve)

is supplied factory fitted to the cylinder. The T&P Valve must not be removed from the cylinder or

tampered with in any way. The valve is pre calibrated to lift at 7 bar or 90 degrees centigrade and any

attempt to adjust it will invalidate the warranty and could affect the safety performance of the unit.

The outlet of the T&P valve should be routed in 15mm copper piping in a downward direction

alongside the water heating unit to the tundish. The outlet of the expansion relief valve must be T’d

into this pipe before the tundish so that any water exiting either valve can be seen draining through the

tundish– see fig 2

4.4. Pressure Reducing Valve – The pressure relief valve should be installed in the cold water supply

to the water heating unit with the arrow pointing in the direction of water flow as shown in figure 5.

This can be connected to a supply pressure of between 1.5 and 12 bar.

4.5 Expansion Relief Valve this must be installed between the pressure reducing valve and the water

heating unit in accordance with Figure 1. No other valve should be fitted between this valve and the

cylinder. The expansion relief valve contains a non return valve.

4.6. Expansion vessel – A suitable expansion vessel with a pre-charge pressure of 3 bar is supplied for

fitting to all water heating units in the range. The expansion vessel MUST be fitted between the

expansion relief valve and the cylinder. The expansion vessel MUST be positioned with the entry

point at the bottom.

IMPORTANT: Regular checks must be carried out to ensure that the expansion vessel is correctly

pressurised to 3 bar at all times. The expansion vessel should be installed using a standard t-connector

between the expansion relief valve and the cylinder – see Figure 1.

4.7. Tundish – The tundish must not be positioned above or in close proximity of any electrical

current carrying devices or wiring. The installation should conform with the requirements of item 7

below.

5

Loading...

Loading...