Page 1

SOLAR

Technical Manual

Complete guide to Dimplex Solar

Page 1 of 72

ST0133 – A 02/09

Page 2

Technical manual

SOLAR

1 Contents

1 CONTENTS 2

2 BEFORE YOU START 4

G

ENERAL 4

3 SOLAR THERMAL 4

3.1

INTRODUCTION 4

3.2

SOLAR RADIATION 4

3.1.1 Available solar radiation 4

3.1.2 Orientation 6

3.3

SOLAR THERMAL SYSTEM 8

3.3.1 Components of a solar thermal system 8

3.3.2 Function of a solar thermal system 10

4 DIMPLEX SOLAR PRODUCTS 11

4.1

DIMPLEX SOLAR COLLECTOR SOLC220 11

4.1.1 General description 11

4.1.2 Hydraulic collector connection 13

4.1.3 Roof fixing kits 17

4.1.4 Space requirement 22

4.1.4 Technical data 24

4.2

DIMPLEX SOLAR CONTROL UNIT SOLCU1/2/3 24

4.2.1 General description 24

4.2.2 Temperature sensors 25

4.2.3 Technical data 26

4.3

DIMPLEX SOLAR PUMP UNIT SOLPU1/2 26

4.3.1 General description 26

4.3.2 Pump connection 30

4.3.3 Technical data 31

4.4

DIMPLEX SOLAR EXPANSION VESSELS SOLEV 32

4.4.1 General description 32

4.4.2 Expansion vessel sizing 32

4.4.3 Technical data 35

4.5

DIMPLEX EXPANSION VESSEL FIXING KIT SOLVK1 35

4.5.1 General description 35

4.5.2 Technical data 36

4.6

DIMPLEX HEAT TRANSFER MEDIUM SOLHT20 36

4.6.1 General description 36

4.6.2 Technical data 37

4.7

DIMPLEX SOLAR CYLINDERS SCX 37

4.7.1 General description 37

4.7.2 Wiring integration Dimplex solar cylinders SCx 39

4.7.3 Hydraulic integration Dimplex solar cylinders SCx 42

4.7.4 Technical data 43

Page 2 of 72

ST0133 – A 02/09

Page 3

Technical manual

SOLAR

4.8 DIMPLEX SOLAR ACCESSORIES 44

4.8.1 General description 44

4.8.2 Corrugated flexible pipe SOLFH10/15 45

4.8.3 Feed through tiles SOLFTT and SOLFTM 46

5 SYSTEM SIZING 47

5.1

REQUIRED INFORMATION 47

5.2

SIZING GUIDE 47

6 PIPE WORK 49

6.1

TYPE OF PIPE WORK 49

6.2

PIPE WORK SIZING 49

6.3

PIPE WORK PRESSURE DROP 50

6.4

PIPE WORK LIQUID CONTENT 50

6.5

PIPE WORK FIXATION 51

6.6

PIPE WORK INSULATION 51

7 COMMISSIONING 52

8 OPERATION 53

8.1

CONTROL UNIT 53

8.2

PUMP UNIT 55

9 MAINTENANCE 55

10 PRODUCT AND KIT LISTINGS 58

10.1

DIMPLEX SOLAR KITS 58

10.2

DIMPLEX SOLAR COMPONENTS 58

11 DIMPLEX LITERATURE STRUCTURE 60

12 APPENDIX 61

12.1

ON SITE QUESTIONNAIRE 61

12.2

ON SITE INSPECTION 62

12.3

DIMPLEX SOLAR SYSTEM DIRECT – OVERALL VIEW 65

DIMPLEX SOLAR SYSTEM INDIRECT – OVERALL VIEW 66

12.4

12.5

EXAMPLE DIMPLEX SOLAR SIMULATION REPORT 67

13 NOTES AND SKETCHES 72

Page 3 of 72

ST0133 – A 02/09

Page 4

Technical manual

SOLAR

2 Before you start

General

Thank you for your interest in Dimplex Solar products. We trust this manual will give

you all the answers to the questions that you might have regarding the products. Although every care was taken to ensure the content of this manual is correct we do not

accept any liability for claims resulting directly or indirectly from the application of the

information contained in this manual.

This manual is written specifically for the Dimples Solar product range. Any information

contained therein must not be applied generally to any other solar products.

Should you require any further assistance please do not hesitate to contact us.

3 Solar thermal

3.1 Introduction

The sun supplies every day a multiple of the required world wide daily energy demand

to the earth. The energy of the sun is available in various forms such as:

- direct, diffuse and reflected solar radiation

- wind

- waves

- the ground and in other forms.

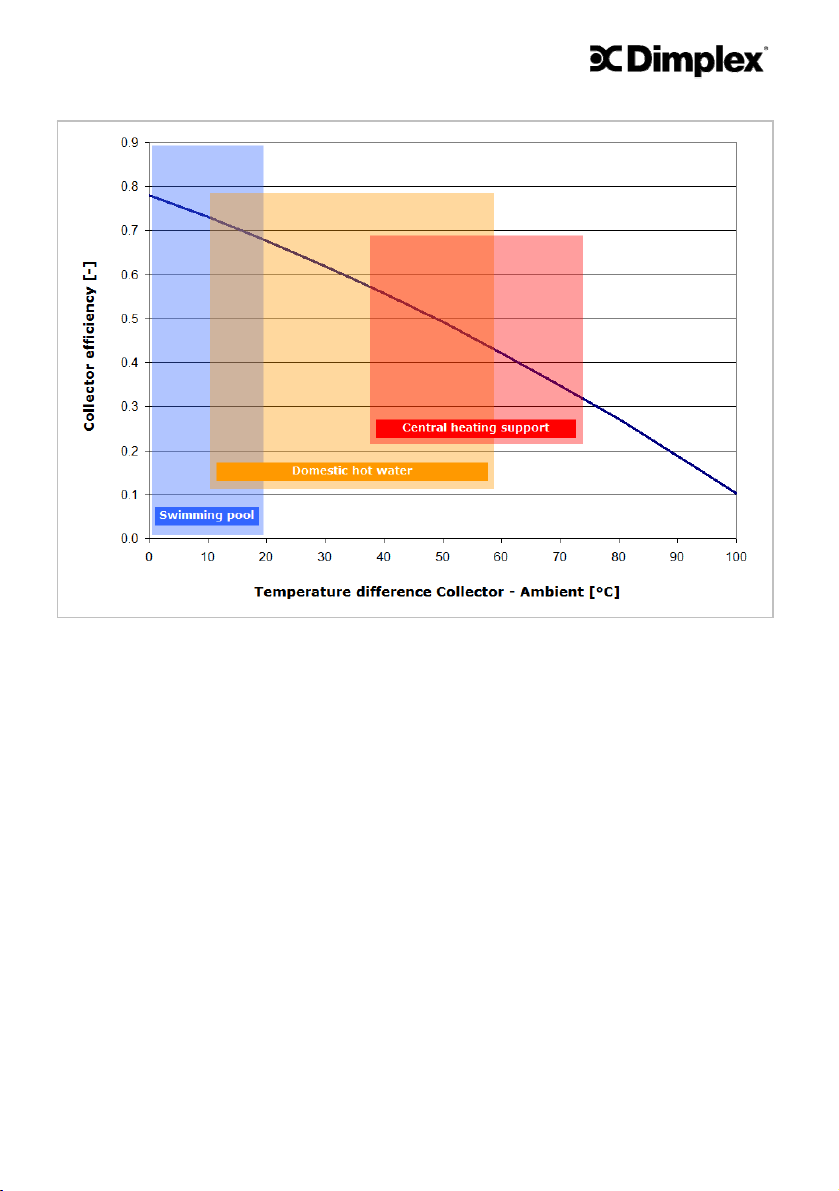

Solar thermal systems convert the energy incident from the sun on an absorber surface

into sensible heat in form of hot water. Depending on the temperature required and

achieved, this hot water can be used for a whole range of applications as summarised in

Figure 1.

Figure 1 – Approximate temperature ranges of some solar thermal applications

3.2 Solar radiation

3.1.1 Available solar radiation

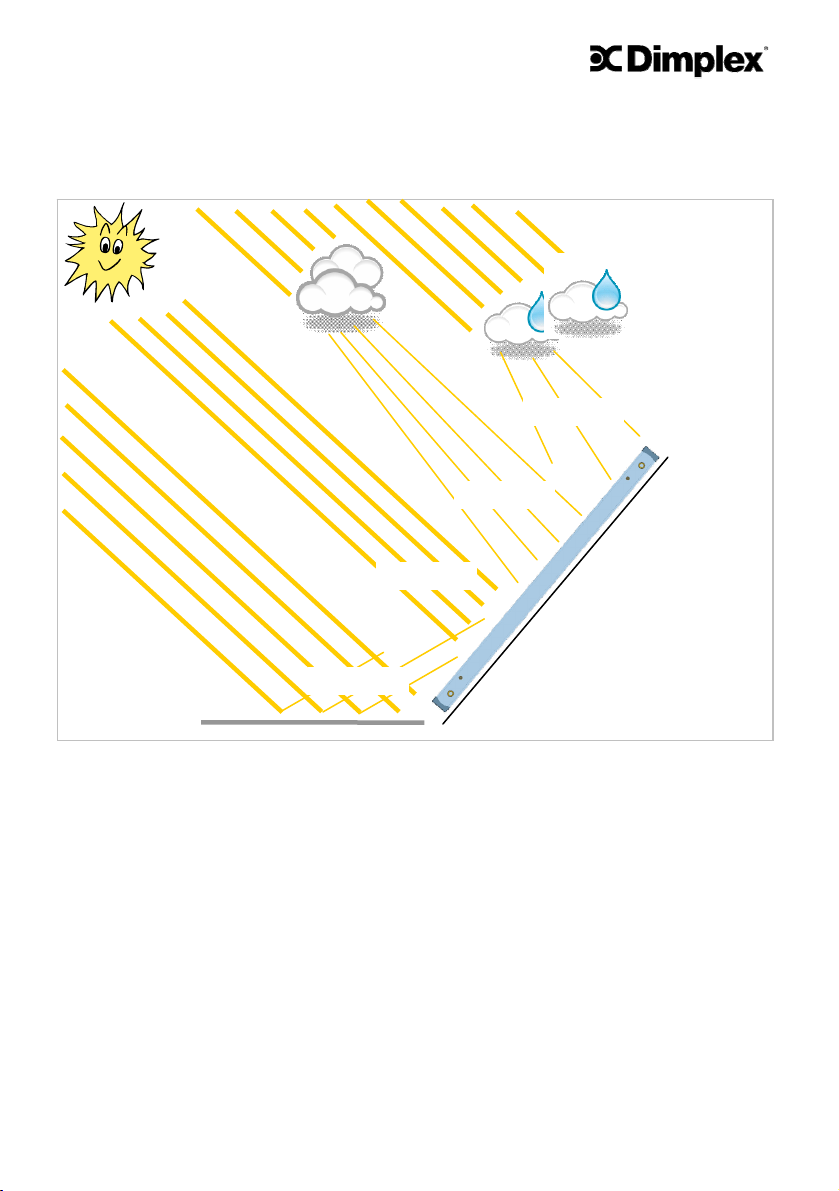

Solar thermal systems can only utilise the energy from the sun in form of solar radiation.

The solar radiation can be incident on the solar panels in various forms which are shown

Page 4 of 72

ST0133 – A 02/09

Page 5

Technical manual

SOLAR

in Figure 2, namely direct, reflected and diffuse radiation. The various types of radiation

can occur in isolation but in most cases the radiation incident on a solar thermal collector is a combination thereof.

<200 W/m²

<600 W/m²

<1000 W/m²

<1200 W/m²

Figure 2 – Forms of incident solar radiation

direct + reflected

strong

diffuse

diffuse

direct

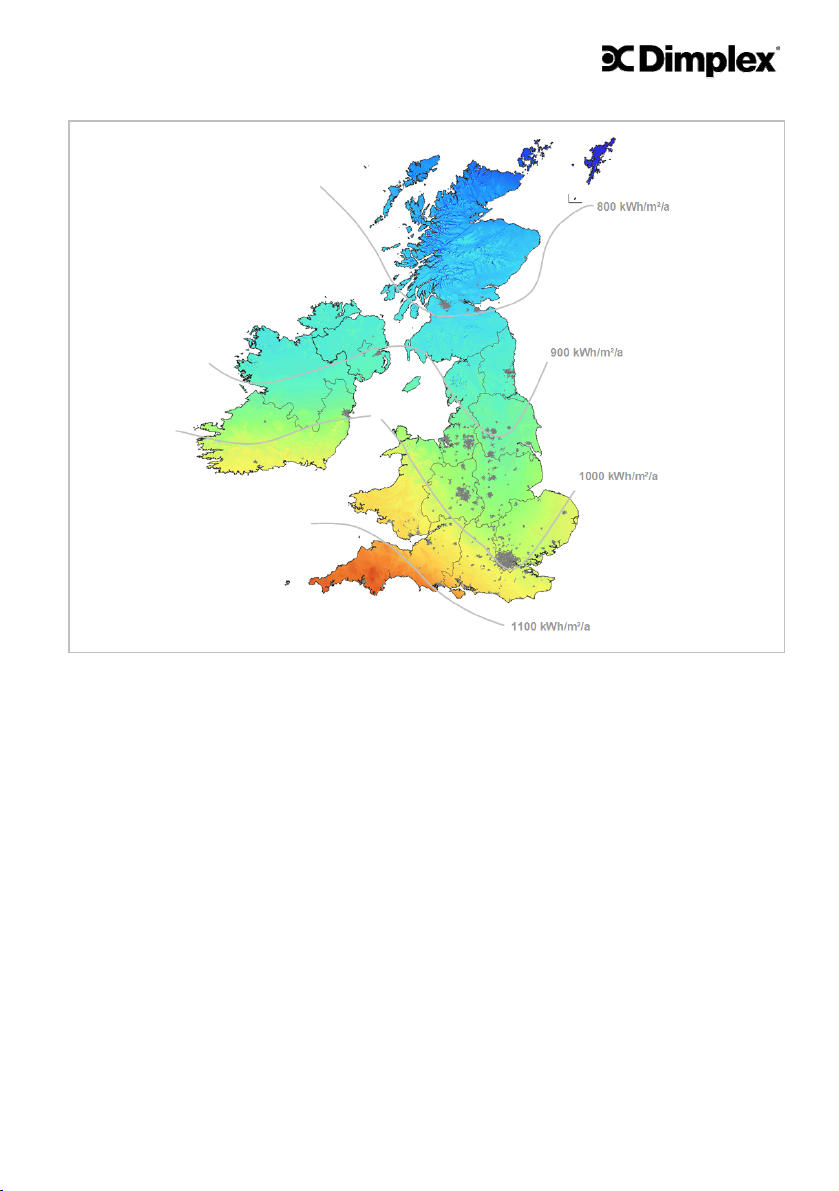

The solar radiation available outside the earth’s atmosphere, the so called extraterrestrial radiation, has a density of 1367 W/m². Depending on:

- the location of the solar system

- the time of day and year

- the “obstacles” in the atmosphere such as cloud cover and pollution

- and the inclination of the solar system in relation to the sun

this value varies strongly. A map of the United Kingdom and Ireland is shown in Figure

3, indicating average annual solar energy gains on the horizontal surface.

Page 5 of 72

ST0133 – A 02/09

Page 6

Technical manual

SOLAR

Figure 3 – UK and Ireland irradiation map (horizontal surface)

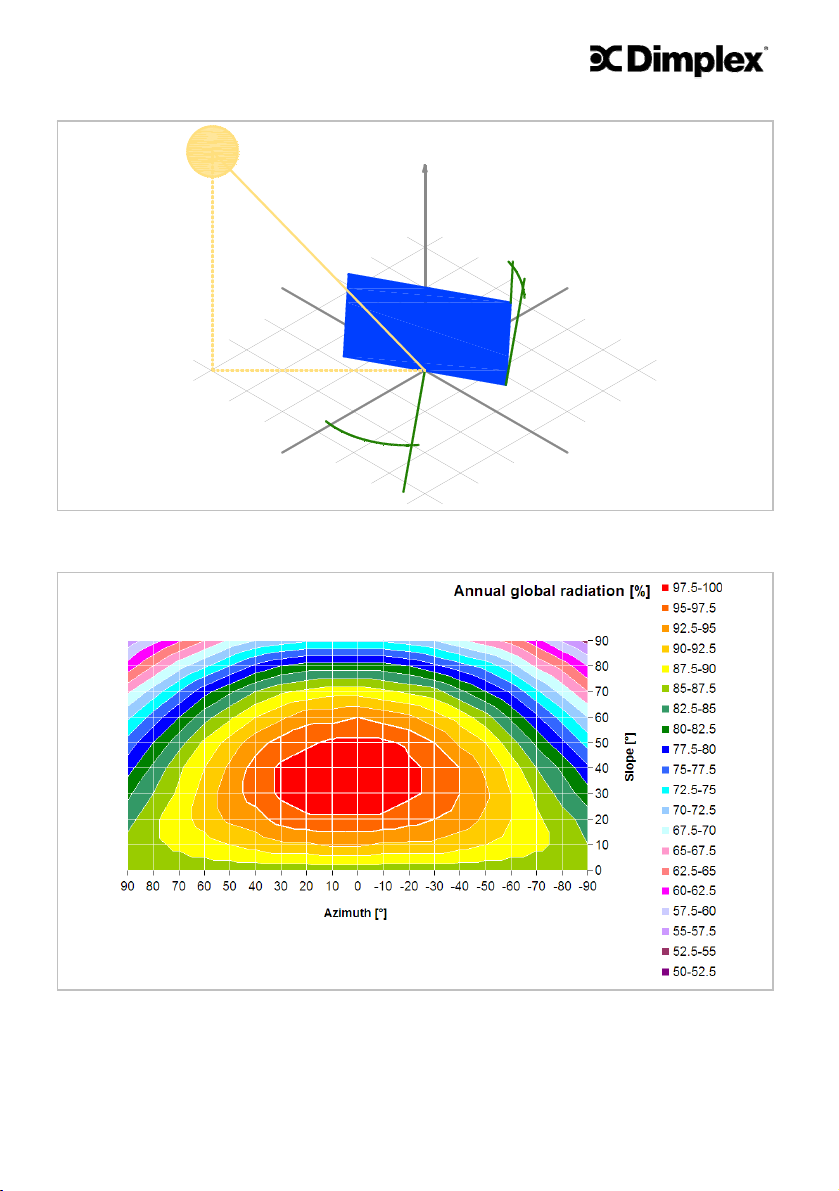

3.1.2 Orientation

The solar irradiance shown in Figure 3 is an average value incident on the horizontal

surface. As mentioned above, depending on the orientation and inclination of the solar

collector the incident radiation onto the collector surface can vary although it might be

in the same location.

The terminology used to describe the exact location and orientation of a solar collector

is described in Figure 4. The terms indicate:

- longitude: geographic coordinate for East/West measurement

- latitude: geographic coordinate North or South of the equator

- slope: angle between the horizontal and the collector plane

- azimuth: angle between South and the perpendicular to the collector pane (West

+90°, South =0°, East -90°)

Page 6 of 72

ST0133 – A 02/09

Page 7

Technical manual

SOLAR

S U N

W

L

a

t

i

t

u

Zenith

d

e

Slope

N

e

d

u

t

i

g

n

o

L

Azimuth

S

Figure 4 – Terminology to describe location and orientation of solar thermal panel

E

Figure 5 – Effect of orientation on incident radiation levels

Page 7 of 72

ST0133 – A 02/09

Page 8

Technical manual

SOLAR

Although the location of the solar thermal system can be described using the longitude

and latitude of the installation, in practise the locality is being used to determine the

location of the system.

The effect of the orientation on the incident solar radiation levels can be seen from Figure 5.

3.3 Solar thermal system

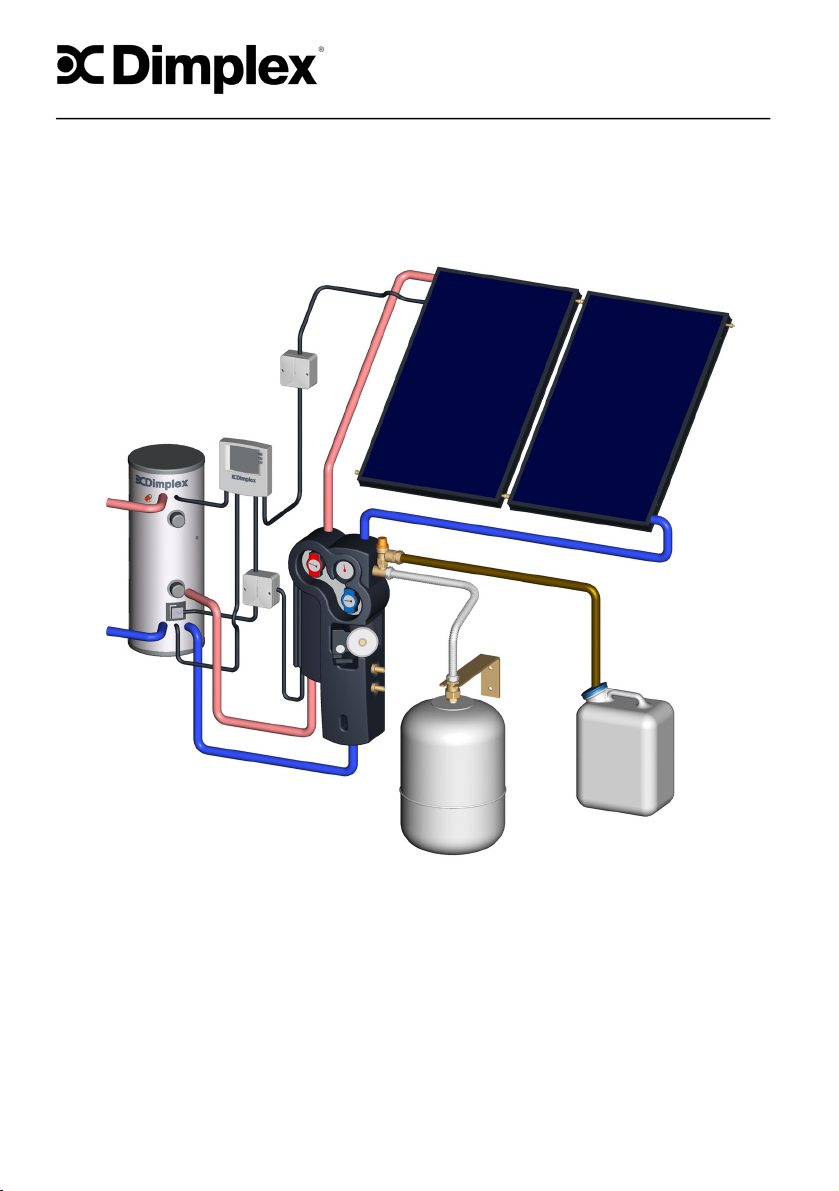

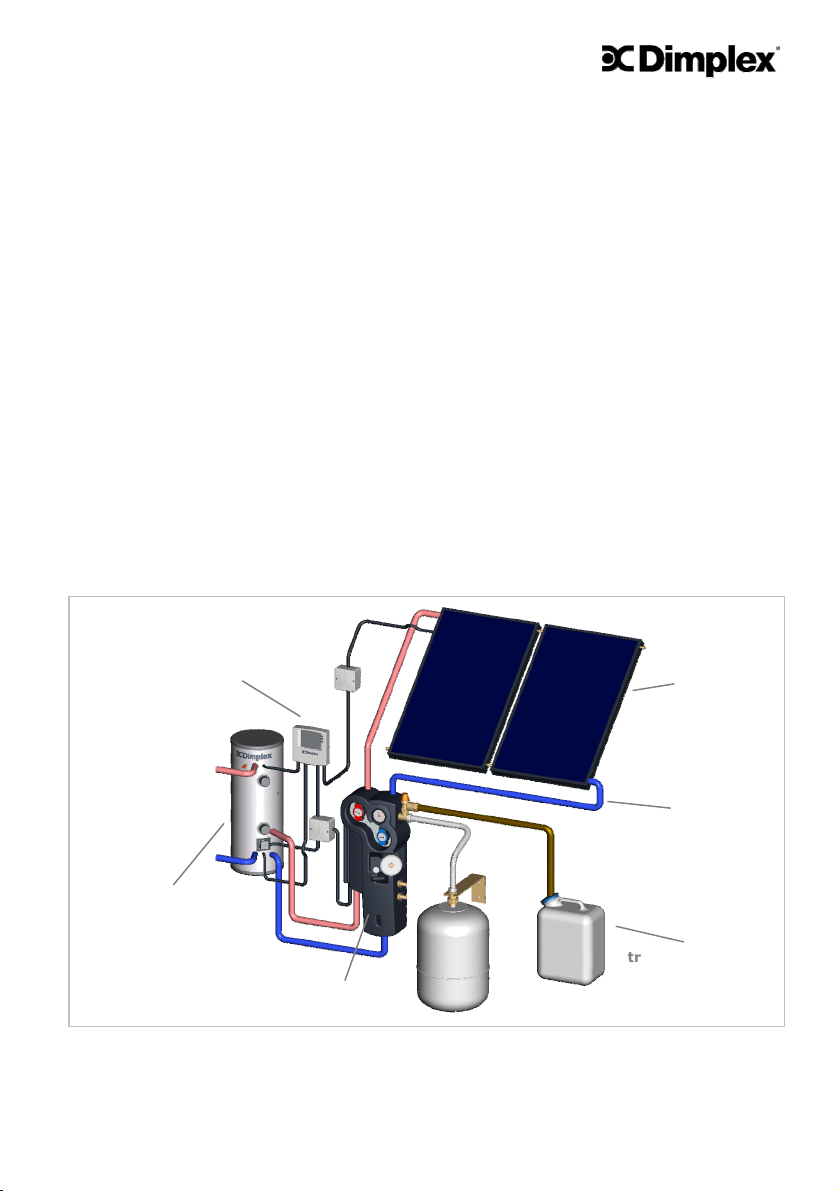

3.3.1 Components of a solar thermal system

Although solar thermal systems cover a whole range of applications, see Figure 1, the

basic components used are in principle the same. A solar thermal system consists of:

- solar collector

- heat transfer medium

- pipe work

- pump and safety equipment

- heat exchanger

- storage facility

- control unit

- user

Applying the above to a domestic hot water system, the individual components are

identified in Figure 6.

control

storage cylinder

with build in

heat exchanger

transfer medium

pump and safety

equipment

solar

collector

pipe

work

heat

Figure 6 – Solar system components overall view

Page 8 of 72

ST0133 – A 02/09

Page 9

Technical manual

SOLAR

Each component in the solar thermal system fulfils a specific function which is described

below:

Solar thermal collector

The solar thermal collector receives the solar radiation, converts it into thermal energy

and passes it on to the heat transfer fluid.

Heat transfer fluid

The heat transfer fluid circulates through the solar collector, the pipe work and the heat

exchanger. It transfers the energy gained by the collector into the storage device. The

heat transfer fluid has additional properties such as frost protection and anti-corrosion

inhibitors to ensure a long and reliable operation of the solar thermal system.

Pipe work

The pipe work connects the various components of the solar thermal system to allow

the heat transfer medium to transport the energy from the collector to the storage device. The pipe work must be insulated and both, the pipe work and the insulation must

be of appropriate material for solar thermal applications.

Pump and safety equipment

The pump and safety equipment are combined in the pump unit. Beside the actual circulation pump the pump unit contains a flow meter, flush and fill point, air separator,

non return valves, manual thermometers, isolating valves, pressure relief valve, pressure gauge and the connection point for the expansion vessel.

Heat exchanger

The heat exchanger allows a hydraulic separation of systems but allows the transfer of

energy between the two systems, i.e. the solar circuit and the wholesome water. In a

domestic solar thermal hot water system the heat exchanger is usually in form of a coil

immersed in the wholesome water inside the hot water cylinder.

To ensure the solar thermal system works at its optimum efficiency, the heat exchanger

has to be sufficiently sized and positioned correctly within the hot water cylinder.

Storage facility

The storage facility is most likely to be a domestic hot water cylinder or a buffer vessel.

As the solar thermal system will not always be able to supply all of the required energy,

it is important that an auxiliary heating system is available to boost the system as and

when required.

The storage facility should be of such design that all energy sources can work independent of each other without compromising each others efficiencies, giving solar thermal the priority to allow for maximum energy gain.

Control unit

The control unit has the primary function of switching the circulation pump on and off

ensuring that the maximum amount of energy is being transferred from the solar thermal collector into the storage facility.

The control unit is usually also the user interface with the system and has therefore a

display and additional functions to ease the operation, maintenance and control of the

system.

Page 9 of 72

ST0133 – A 02/09

Page 10

Technical manual

T2

SOLAR

User

The user varies from installation to installation but has a big influence on the operation

of the solar thermal system. However, the system has all components to ensure the

provision of the comfort levels that the user expects.

3.3.2 Function of a solar thermal system

Bearing in mind the function of the individual components, the function of a solar thermal system is in principle very simple. Based on two measured temperatures, one in

the hottest (T1) and one in the coldest (T2) part of the system, the control unit

switches the pump either on or off depending on the temperature difference between T1

and T2 and the temperature reached in the storage device. The location of the temperature sensors is indicated in Figure 7.

T1

Figure 7 – Location of temperature sensors in solar thermal system

If T1 is greater than T2 plus an additional temperature differential (called ΔT ‘delta T’),

the circulation pump is being switched on by the control unit to transfer the energy

from the collector into the storage device. As soon as this on condition is not given, the

pump is being switched off.

The solar control unit also ensures that the water in the cylinder is not being heated

above a set temperature which can be freely chosen and is measured by the temperature sensor T2.

Page 10 of 72

ST0133 – A 02/09

Page 11

Technical manual

A more detailed description of the function of the individual components follows in

Chapter 4, Dimplex solar products.

SOLAR

4 Dimplex solar products

The following section details the product features and relevant technical data of the

components of the Dimplex solar offering. Where applicable a general description of the

component’s function is given.

4.1 Dimplex solar collector SOLC220

4.1.1 General description

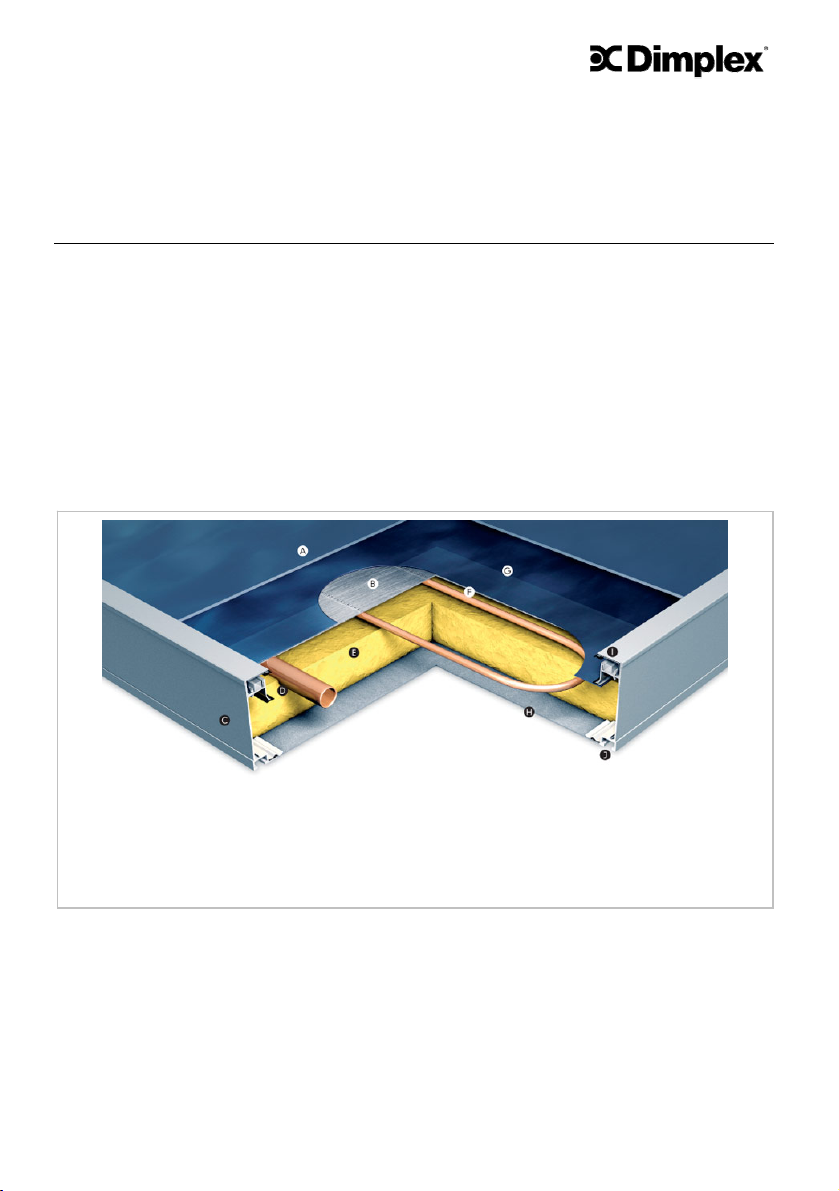

The Dimplex solar collector SOLC220 is a solar thermal flat plate collector. A cross sectional drawing of the Dimplex SOLC220 is given in Figure 8 detailing the individual collector components.

(A) Collector cover (glass)

(B) Absorber plate (aluminium)

(C) Powder coated frame (aluminium)

(D) Manifold pipe (copper)

(E) Collector insulation (mineral wool)

Figure 8 – Flat plate collector components

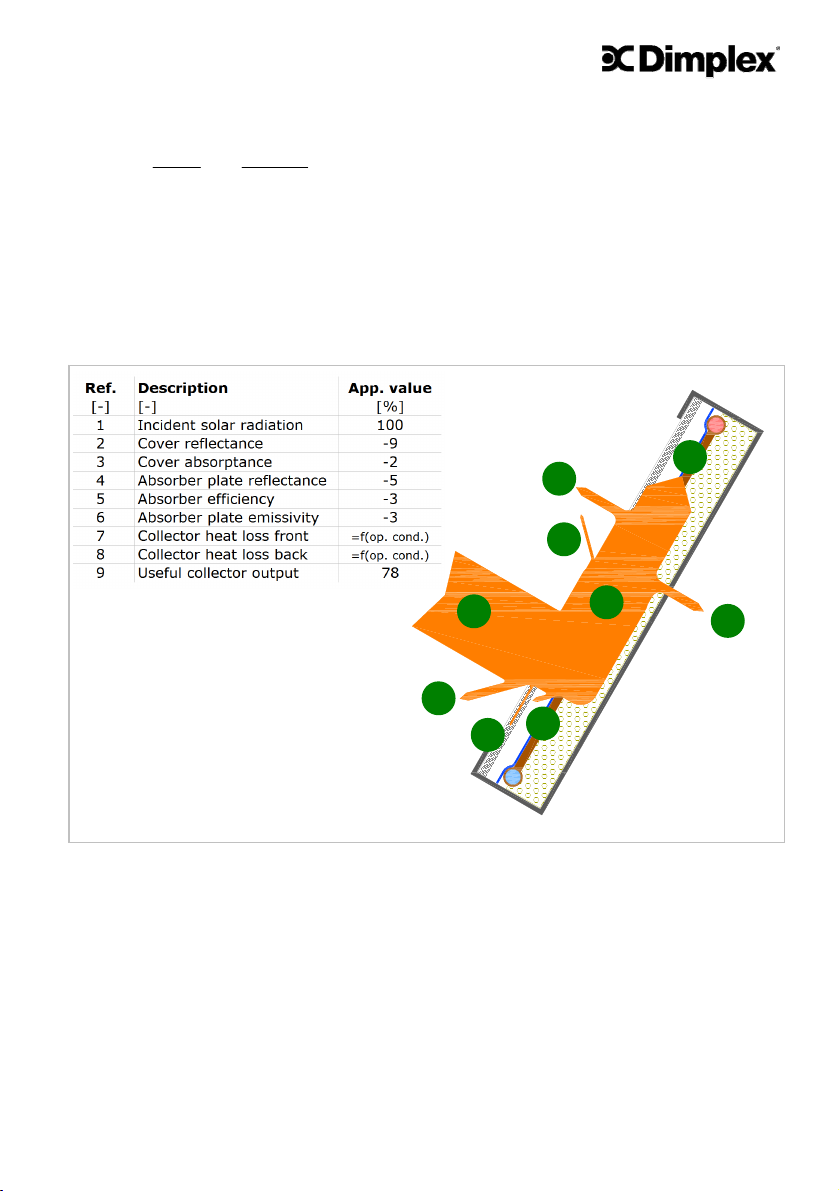

Due to its construction, a flat plate collector is subject to conduction, convection and

radiation heat losses. The sum of these heat losses and the design and production quality are summarised in the thermal collector efficiency which is empirically determined

through independent third party testing and expressed in Equation 1. The heat loss

modes of a flat plate collector are shown in Figure 9.

(F) Meander pipe (copper)

(G) High selective absorber coating

(H) Back plate (aluminium)

(I) Secure cover fixation

(J) Continuous mounting channel

Page 11 of 72

ST0133 – A 02/09

Page 12

Technical manual

2 3 4

7

5

2

()

−

ηη

tt

⋅−=

a

G

−

tt

amam

⋅−

a

210

[1]

G

Where:

a

a

η [-] thermal collector efficiency

η

[-] optical collector efficiency/zero loss coefficient

0

[W/m²/K] linear heat loss coefficient

1

[W/m²/K²] squared heat loss coefficient

2

G [W/m²] global incident radiation

t

t

[°C] collector middle temperature

m

[°C] collector ambient temperature

a

6

SOLAR

9

1

8

Figure 9 – SOLC220 heat loss modes

The collector heat loss front (7) and collector heat loss back (8) are dependant on the

operating conditions of the solar thermal collector, i.e. primarily on the temperature

difference between the collector module and the ambient air and wind speed. Applying

equation 1 to the Dimplex SOLC220 collector the graph shown in Figure 10 can be derived.

Page 12 of 72

ST0133 – A 02/09

Page 13

Technical manual

SOLAR

Figure 10 – Thermal efficiency curve Dimplex SOLC220 flat plate collector

Figure 10 shows that the higher the temperature difference between the collector module and the ambient is, the lower is the efficiency of the product. Due to the required

operating conditions of various applications (see Figure 1) the collector has to operate

at varying efficiencies.

In general central heating support applications are not recommended with solar thermal

except if the whole system is especially designed for the application offering all the required features such as collector orientation, storage, heating operating temperatures,

heating demand and others.

Beside the thermal efficiency of the solar collector various other parameters are of importance for the correct application thereof. All of these parameters are determined in

accordance with EN12975 and some of them are detailed in Figure 25, Technical details

Dimplex SOLC220.

4.1.2 Hydraulic collector connection

The hydraulic integration of the solar thermal collector in the overall system is critical to

ensure the most efficient and reliable operation of the installation. When integrating the

collector, the following aspects have to be considered:

- installation space availability

Page 13 of 72

ST0133 – A 02/09

Page 14

Technical manual

D A B

SOLAR

- collector design

- collector pressure drop

- flow rate

- required system output

Figure 11 shows the Dimplex SOLC220 collector with the pipe work attached to the absorber plate indicated.

C

Figure 11 – Absorber pipe work Dimplex SOLC220 collector

From Figure 11 it can be seen that the collector has 4 connections which can be used to

connect the flow and return pipes of the installation and to connect the collectors between each other. The 4 connections offer the following features:

- one collector for small or large installations

- left hand or right hand side connection of single collector installations

- up to 10 collectors directly connected together

- collectors connected in parallel to each other, thus low overall pressure drop of array

- same collector for vertical or horizontal installations

The sensor pockets to connect the collector sensor T1 from the control unit are always

on the side with the connections marked (A) and (C). It is important to ensure that all

of the pipe work within the collector is being utilised:

- for single collector installations, the flow and return pipes must be installed on connections (B) and (D).

- for multiple collector installations the sensor pockets must always face outwards.

Page 14 of 72

ST0133 – A 02/09

Page 15

Technical manual

SOLAR

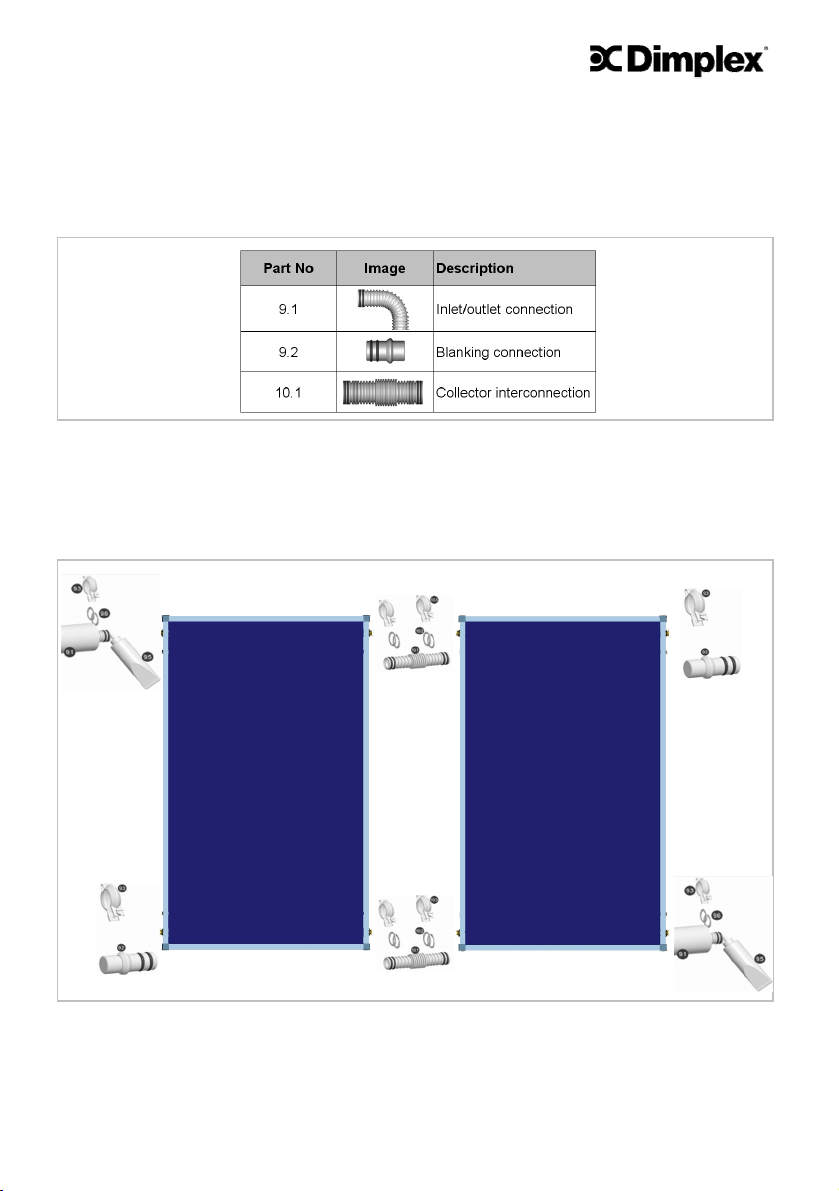

The flow and return of the collector are connected using a 800mm long insulated corrugated stainless steel flexible hose (9.1). The interconnections consist of short flexible

bellows (10.1). The remaining connections are to be blanked off using the blanking

pieces (9.2). The connections components are depicted in Figure 12 using the same

references as in the installation manuals.

Figure 12 – Connection components Dimplex SOLC220 collector

An overall view of the application of the individual connection components is given in

Figure 13 (two collectors, flow left hand side, return right hand side). Note: the sensor

pockets on both collectors face outwards.

Figure 13 – Typical connection of Dimplex SOLC220 collector

Page 15 of 72

ST0133 – A 02/09

Page 16

Technical manual

SOLAR

An overall view of possible collector connections is given in Figure 14 detailing also the

pressure drop at nominal low-flow and high-flow flow rates.

No. of collectors

Flow rate

[l/min]

Pres. drop

[mbar]

1

2

3

4

5

6

7

8

1

2

2

4

3

6

4

8

5

10

6

12

7

14

8

16

150

325

150

330

150

330

160

340

160

340

170

350

185

385

195

400

10

9

9

18

10

20

200

420

210

500

Figure 14 – Collector connection options, flow rates and pressure drop

Page 16 of 72

ST0133 – A 02/09

Page 17

Technical manual

SOLAR

Although only the vertical collector orientation is shown, the same principles can be

applied to the horizontal collector installation. The same applies for the positioning of

the flow and return, it can be changed from left to right hand side as long as the sensor

(indicated by dot) is moved accordingly.

Note: Up to 5 collectors can also be connected single sided with the orientation of the

individual collectors as shown in Figure 14 and the sensor placed in the sensor

pocket on the collector flow.

4.1.3 Roof fixing kits

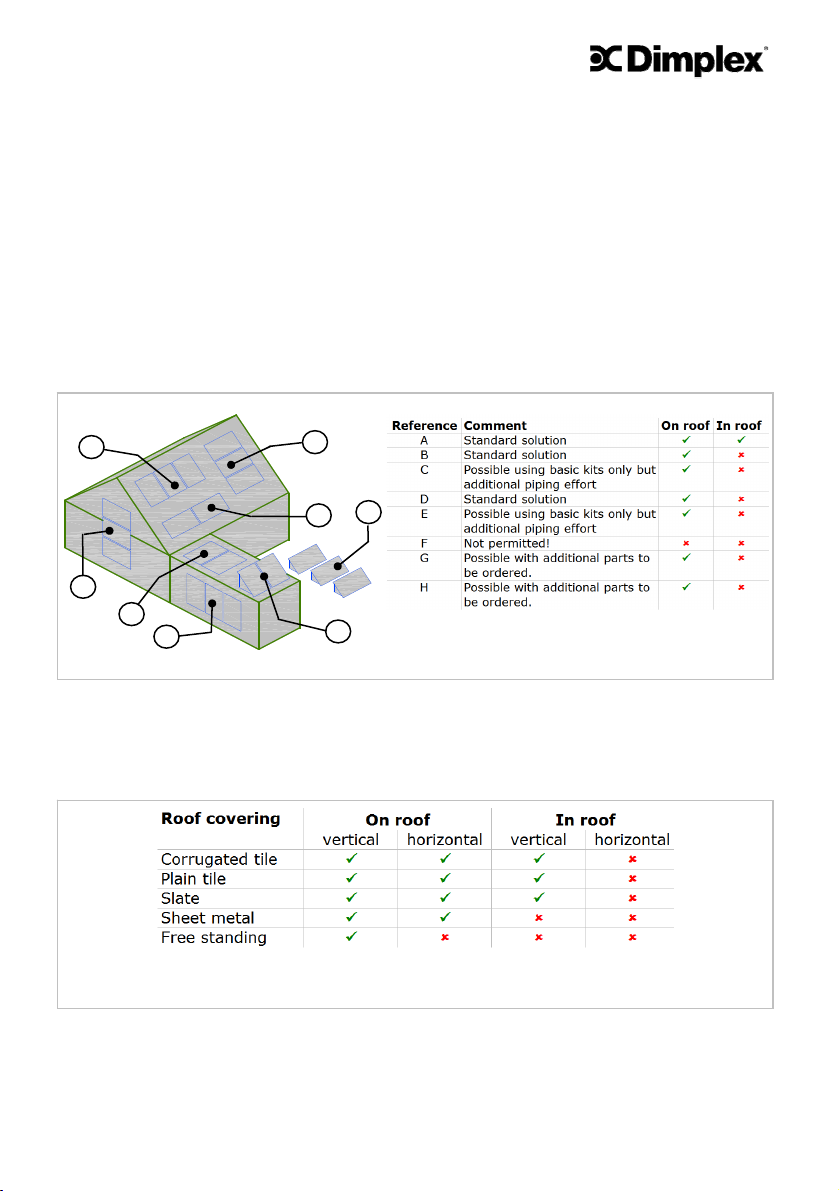

The Dimplex solar collectors SOLC220 can be installed in most situations on or near a

building. An overall view of the installation options is shown in Figure 15.

A

B

E

C

H

F

G

Figure 15 – Dimplex Solar collector installation options

D

Dimplex offers a wide range of roof fixing kits for the installation of the SOLC220 solar

collector. The available roof fixing kits are summarised in Figure 16.

Flashing kits are available as accessory for the integrated roof kits to cover the sides, bottom

and the gap between the collectors.

Figure 16 – Dimplex solar roof fixing kits overall view

Page 17 of 72

ST0133 – A 02/09

Page 18

Technical manual

SOLAR

On roof kits

The on roof kits come as basic and extension kit. The basic kit has to be ordered for

each first collector of a collector field, the extension kit for each additional collector in

the installation.

Corrugated

tile

Plain tile

Slate

Figure 17 – On roof mounting options

Sheet metal

As detailed in Figure 16 the on roof kits suit various types of roof coverings. The different mounting methods for the various tiles are shown in Figure 17 differing only in the

design of the bracket/fixation of the collector support rail to the roof structure.

In roof kits

The in roof kits are only available for vertical collector installation and vary for tile roof

coverings and slate covering only. Additional flashing kits are available to complement

the integrated roof kits, covering the pipe work on the side of the collector, the fixing

brackets at the bottom and the gap between the collectors.

The in roof kits and flashing kits are not sold as basic and extension kits but come as

complete kits for 2, 4 and 6m² installations. Should a larger collector field be installed,

further extension kits are available.

Page 18 of 72

ST0133 – A 02/09

Page 19

Technical manual

SOLAR

Integrated roof kit

without flashings fitted

Figure 18 – Dimplex SOLC220 integrated roof kit without and with flashing kit fitted

Integrated roof kit

with flashings fitted

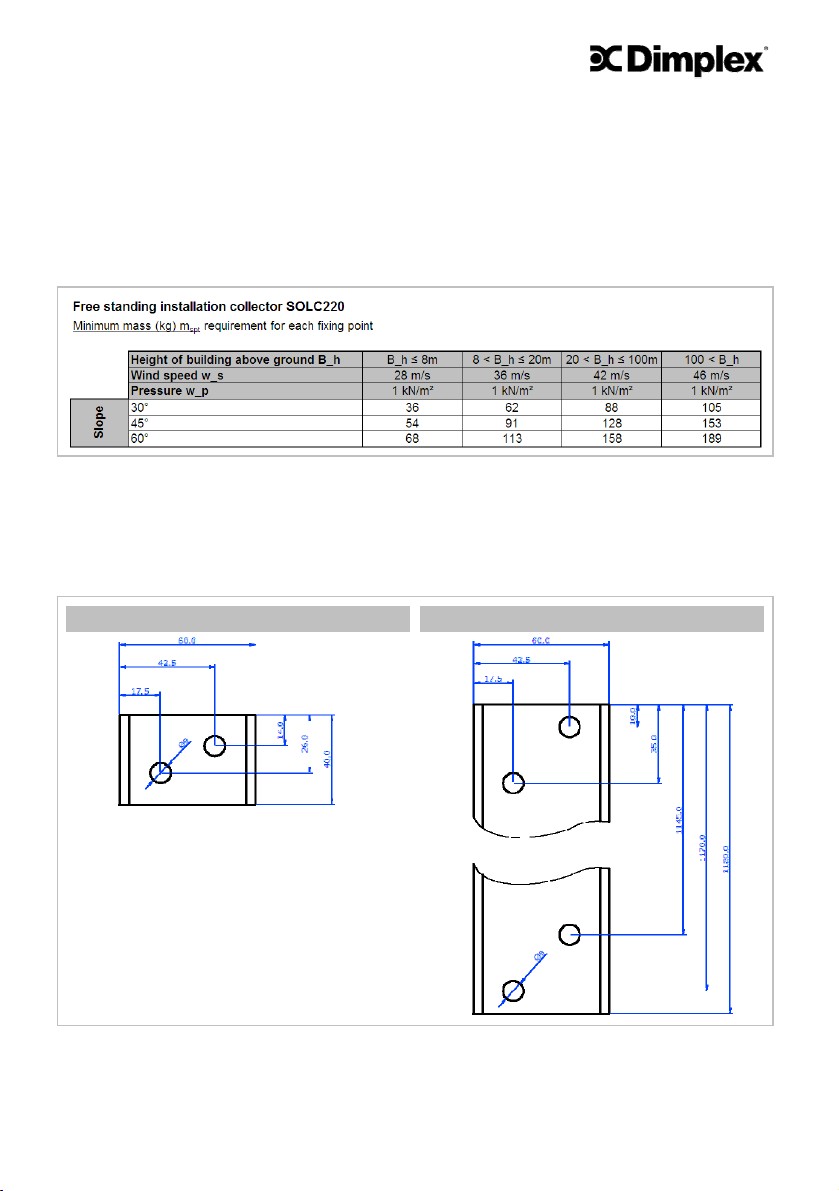

Free standing kits

The free standing kit is designed for the vertical installation of the solar collector on

even ground with a slope of 45° to 60°. For lower sloping angles shorted support struts

can be ordered, allowing the collector to slope between 30° and 40°.

As shown in Figure 24, the free standing mounting kit is usually fixed at 4 individual

points. Alternatively a U – section rail is available as accessory aiding on uneven ground

or for suspended installation.

When more than one row of solar collectors is being installed it is important to minimise

the impact of shading of one row to the other. Equation 2 can be used to calculate the

optimum row spacing to avoid shading at solar noon on the least favourable day of the

year, i.e. 21

st

December.

180sin1870

_

mm

=

cp

sin

α

αβ

+−°⋅

()()

s

s

[2]

Where: p_c [mm] pitch between collector rows

β [°] sloping angle of solar collector

α

[°] solar altitude angle

s

The solar altitude angle can be calculated applying Equation 3 or approximating it from

Figure 19.

s

φφα

)45.23sinsin45.23cos(cos90 °⋅+°⋅−°=

[3]

Where:

α

[°] solar altitude angle

s

φ [°] latitude of installation

Page 19 of 72

ST0133 – A 02/09

Page 20

Technical manual

SOLAR

Figure 19 – Free standing kit row distance calculation details

In addition to the row distance the fixation of the free standing kit to the mounting surface has to be considered carefully. Due to the shape of the flat plate collector considerable wind forces can act on the free standing kit installation.

Ideally the free standing kit is bolted to a fixed structure. However, this is not always

practicable, especially when the roof surface must not be penetrated for water tightness reasons.

Equation 4 is to be used to calculated the required mass to securely locate the free

standing kit. The required parameters can be found in Figure 20.

Note: the stated parameters are only valid for the wind speeds stated in Figure 20. It is

the responsibility of the installer/mechanical engineer to validate these figures for the

individual installation. Dimplex does not accept any liability for damage to material,

buildings or persons resulting from free standing installations not being sufficiently supported.

Page 20 of 72

ST0133 – A 02/09

Page 21

Technical manual

r

SOLAR

mnmnm ⋅−⋅= [4]

colcolsptspttot

Where: m

n

m

n

m

[kg] minimum mass required

tot

[-] number of supports in installation

spt

[kg] mass for each support (see Figure 20)

spt

[-] number of collectors in installation

col

[kg] mass of collector (SOLC220 = 34.5 kg)

col

Figure 20 – Free standing kit support weight calculation details

In some cases it might be required to prepare the load baring structure in advance to

accept the fittings of the Dimplex solar free standing kit. Figure 21 details the support

feet (4x for each collector) and the free standing bottom bar (2x for each collector).

Support feet Free standing bottom ba

Figure 21 – Fixation details Dimplex solar free standing kit

Page 21 of 72

ST0133 – A 02/09

Page 22

Technical manual

SOLAR

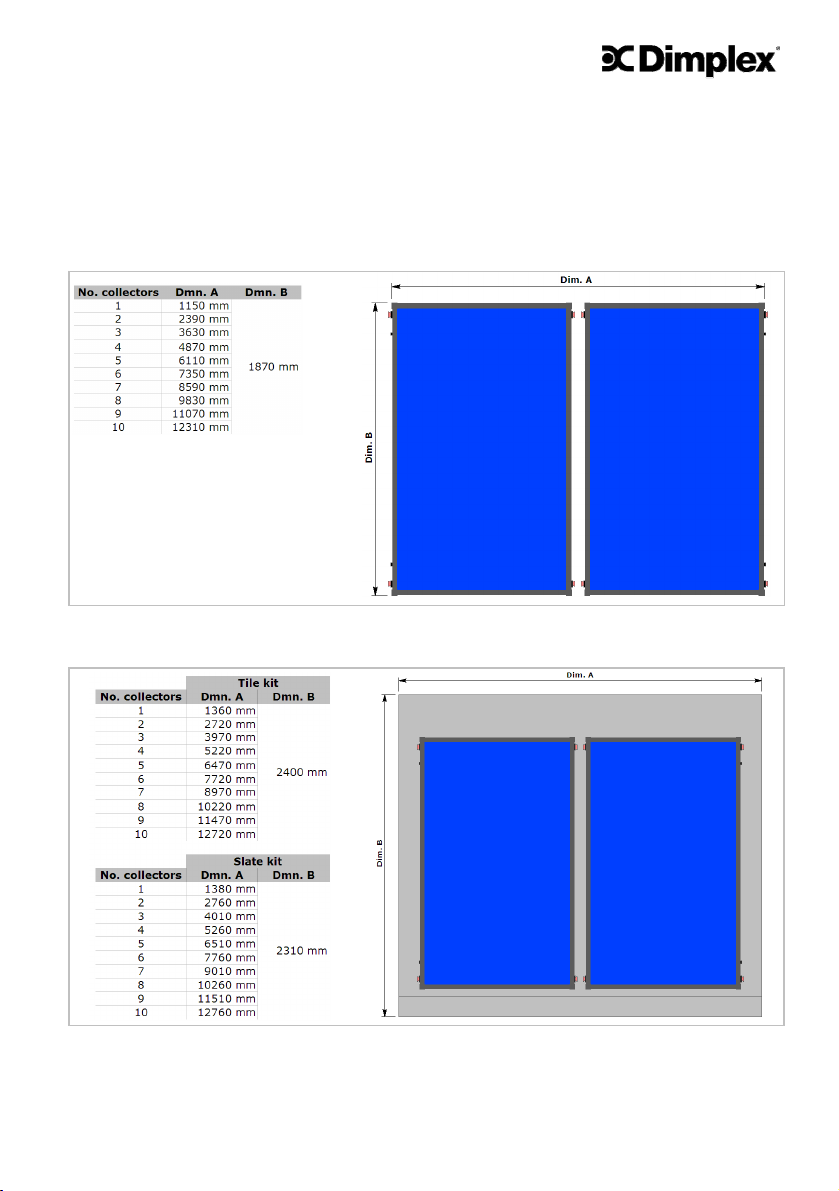

4.1.4 Space requirement

Depending on the mounting method the foot print required by the solar collector installation varies. The dimension for the on roof and free standing mounting kits do not include the space required to fit the connection pipes as these vary depending on the pipe

feed through chosen. The dimensions provided for the integrated roof kits include the

pipe work as the pipe feed through is part of the integrated roof kit.

Figure 22 – Space requirement Dimplex SOLC220 on roof installation

Figure 23 – Space requirement Dimplex SOLC200 in roof installation

Page 22 of 72

ST0133 – A 02/09

Page 23

Technical manual

SOLAR

Figure 24 – Space requirement Dimplex SOLC220 free standing installation

Page 23 of 72

ST0133 – A 02/09

Page 24

Technical manual

SOLAR

4.1.4 Technical data

Figure 25 summarises the key technical data of the Dimplex SOLC220 solar thermal

collector.

Figure 25 – Technical data Dimplex SOLC220 collector

4.2 Dimplex solar control unit SOLCU1/2/3

4.2.1 General description

Dimplex solar offer a range of solar control units with differing input and output options

and functionality. All control units operate on the basic principles described in chapter

3.3.2. Figure 26 shows the SOLCU1 control unit detailing the main components which

are common to all Dimplex solar control units.

LCD display

- animated

- backlit

- controller operation

and system settings

Operating switch

× ON

- AUTO

Ø OFF

SOLCU1

Operating buttons

- scroll up

- SET

scroll down

-

Connections

- mains supply

- relay output(s)

sensor inputs

-

Figure 26 – Dimplex solar control unit overall view

Page 24 of 72

ST0133 – A 02/09

Page 25

Technical manual

r

r

SOLAR

A detailed description of the individual operation and function of the control units can be

found in the respective installation and operating instructions.

4.2.2 Temperature sensors

All Dimplex solar control units come with three PT1000 temperature sensors which can

be extended as required. The polarity of the sensor contacts is not important.

The length of the sensors delivered with each control unit is:

- collector sensor: 1.5m

- cylinder sensors (x2): 3.0m

When extending the collector sensor, the overvoltage protection box is to be used to

protect the control unit from voltage surges caused by lightening (see Figure 27). The

overvoltage protection box is part of the pump unit delivery.

The cable used for the extension of any of the sensors should meet the following minimum requirements:

- 0.75mm² up to 50m long

- 1.50mm² up to 100m long

Note: Sensor and mains cables must not be routed or ducted together. A minimum

separation of 100mm or equivalent shielding must be observed.

To controlle

From Collecto

Figure 27 – Connection of collector temperature sensor to overvoltage protection box (included with

Dimplex solar pump unit SOLPU1/2)

ST0133 – A 02/09

Page 25 of 72

Page 26

Technical manual

SOLAR

4.2.3 Technical data

The main features of the Dimplex solar control units SOLCU1/2/3 are summarised in

Figure 28.

Figure 28 – Technical data overall view Dimplex solar control units SOLCU1/2/3

4.3 Dimplex solar pump unit SOLPU1/2

4.3.1 General description

The Dimplex solar pump units SOLPU1 and SOLPU2 comprise a number of features aiding in the installation, commissioning, operation and maintenance of the solar thermal

installation. The components of the pump unit are depicted in Figure 29 followed by a

brief description of their function.

Page 26 of 72

ST0133 – A 02/09

Page 27

Technical manual

01

16

02

SOLAR

03

15

14

13

04

05

06

12

07

11

08

09

10

Figure 29 – Components of Dimplex solar pump unit SOLPU1 and SOLPU2

Pump unit connections (1, 2, 10 and 13)

The SOLPU1 pump unit connections can be utilised in three different ways:

- 3/4” flat seal at the end of corrugated stainless steel pipe

- 3/4”F x 22mm straight connection

- 15mm reducing set

The 15mm reducing set is included in the delivery of the SOLPU1 pump unit, the ¾” flat

seal is part of the delivery of the Dimplex solar flexible hose SOLFH10/15. The ¾”F x

22mm straight connection has to be provided by the installer.

The SOLPU2 pump unit connections follow the same principle as those of the SOLPU1

except that the connection diameters are increased:

- 1” flat seal at the end of corrugated stainless steel pipe

- 1”F x 22mm or 1”F x 28mm straight connection

- 22mm reducing set

The 22mm reducing set is included in the delivery of the SOLPU2 pump unit, the 1” flat

seal should be part of a DN20 corrugated stainless steel hose. Note, the Dimplex solar

Page 27 of 72

ST0133 – A 02/09

Page 28

Technical manual

SOLAR

flexible hose SOLFH10/15 is DN16 and only provides ¾” connections. Should this product be applied to the SOLPU2 a 1” to ¾” reducer has to be provided with sufficient sealing surface for the flat seal to sit against. The 1”F x 22mm or 1”F x 28mm straight connection has to be provided by the installer.

6 bar pressure relief valve (3)

The 6 bar pressure relief valve is part of the safety components in the solar circuit. Its

correct application is therefore important. The discharge pipe from the relief valve must

be:

- 22mm copper pipe

- with no more than 2 bends

- terminating safely (it is recommended to end the discharge pipe in a suitable vessel

and not to discharge to drain)

Should the pressure relief valve open and discharge fluid, this is a clear sign that the

system is malfunctioning. The malfunction can be caused by:

- cold fill pressure of system too high

- expansion vessel too small

- expansion vessel pre-charge not adjusted correctly

- expansion vessel faulty

- solar collector array considerably oversized

Pressure gauge (4)

The pressure gauge indicates the current pressure inside the solar thermal loop. In a

properly designed, installed, commissioned and operated system the pressure indicated

by the pressure gauge should remain constant in all operating conditions.

Non return ball valve, temperature gauge (5 and 16)

The non return valve is critical in a solar thermal system to avoid gravity circulation at

times when the cylinder is warmer than the collector as during night time hours. The

non return valves avoid unwanted gravity circulation from the cylinder to the collector,

thus losing energy from the system. As both the flow and the return path of the

SOLPU1/2 pump units have a non return valve the circulation of flow from the collector

to the cylinder can be eliminated when the pump is switched off.

The non return valves have an integrated ball valve which can be closed by turning the

handle with the integrated manual thermometer by 90°. This allows the temporarily

isolation of certain parts of the system for maintenance purposes. The non return valves

can be opened for venting or draining purposes by turning the handles to 45°.

Circulation pump (6)

Two different circulation pumps are being utilised in the SOLPU1 and the SOLPU2 pump

station to increase the capacity of the range. The characteristic pump curves for the

pumps used are shown in Figure 30 along side the pressure drop of each pump unit.

Flush and fill point (7)

The flush and fill point allows the connection of the Dimplex solar flush and fill pump

SOLFFP110/240 for the flushing and filling of the solar loop. Should a hand pump being

used it is also to be connected at this point but not all three valves are being made use

of during the filling process.

Page 28 of 72

ST0133 – A 02/09

Page 29

Technical manual

SOLAR

The centre valve of the flush and fill point is being used to adjust the flow rate if required.

Figure 30 - Pump characteristics and pump unit pressure drop SOLPU1 and SOLPU2

Expansion vessel fixing kit (8)

The expansion vessel fixing kit is not part of the scope of delivery of the pump units but

is part of the standard Dimplex solar kits and is suitable for expansion vessels of up to

24 litre contents. It simplifies the expansion vessel installation and reduces the maintenance effort.

Flow meter (9)

The flow meter indicates the flow rate of the solar loop. It aids during the commissioning process to adjust the flow rate correctly and assists during operation, maintenance

and troubleshooting to identify eventual problems.

Air purger and related components (11, 14 and 15)

The heat transfer medium used has a high affinity to air, thus the air does not readily

separate from the medium while the medium is cold. At the beginning of the operation

of a solar thermal system therefore the heat transfer medium will release air into the

system which would without the presence of a collection and separation device eventually cause the system to stop functioning.

The air purger collects the dissolved air and it can be conveniently vented from the

manual bleed valve. The flexible bleed valve discharge tube ensures that the venting

process can be done safely.

Page 29 of 72

ST0133 – A 02/09

Page 30

Technical manual

SOLAR

Insulation cover (12)

The insulation cover avoids unnecessary heat loss from the solar loop and gives the

pump unit its aesthetically pleasing appearance.

4.3.2 Pump connection

The connection of the circulation pump to the control unit has to be considered in its

application for:

- open vented hot water systems

- closed unvented hot water systems

When installing the solar thermal system in conjunction with an open vented system,

the pump can be directly wired into the control unit as shown in the control unit manual.

When using an unvented hot water system, the pump has to be wired through the twin

thermostat at the cylinder. Figure 31 shows the wiring schematic utilising the 4-way

wiring centre provided with the pump unit.

Control Unit

Solar pump

L

N

Twin tank

thermostat

Figure 31 – Wiring of solar circulation pump to control unit utilising 4-way wiring centre

C

1

2

C

2

1

The use of a motorised two port valve is not required as long as:

- the pump unit has a non return valve in flow and return

- the circulation pump is connected using the twin thermostat mounted to the cylinder

- the cylinder is situated lower in the property than the lowest part of the solar collector

Page 30 of 72

ST0133 – A 02/09

Page 31

Technical manual

SOLAR

Should the above conditions not be given, the motorised two port valve has to be installed in series to the twin thermostat.

4.3.3 Technical data

Figure 32 – Technical data Dimplex solar pump unit SOLPU1 and SOLPU2

Page 31 of 72

ST0133 – A 02/09

Page 32

Technical manual

(

)

(

SOLAR

4.4 Dimplex solar expansion vessels SOLEV

4.4.1 General description

Dimplex solar offer an extensive range of expansion vessels from 18 to 80 litres. All

expansion vessels are particularly suited for the application in solar thermal systems

with a high temperature resistant membrane which has also excellent diffusion barrier

characteristics in conjunction with the heat transfer medium used in solar thermal systems.

In solar thermal systems the expansion vessels has a number of functions to ensure the

safe and reliable operation of the system:

- absorption of additional system volume when system is heating up during normal operation

- absorption of steam volume of system when installation enters stagnation

- holding of medium reserve when system temperature drops below fill temperature

4.4.2 Expansion vessel sizing

A number of parameters have to be considered when sizing the expansion vessel. The

parameters to be considered are:

- total system volume

- static height of system

- expansion coefficient of heat transfer medium

- opening pressure of pressure relief valve

- required pressure in highest system point

- number of collectors installed

- fluid content of each collector

Applying the above system parameters, Equation 5 can be used to calculate the expansion vessel size V

pressure of the expansion vessel.

=

V

EV

Where: V

V

V

n [-] number of collectors connected to expansion vessel

V

p

p

Equation 6 is to be applied to determine the expansion vessel pre-charge volume V

Where: V

V

, the cold fill pressure of the system and the membrane pre-charge

EV

)

1⋅−+⋅⋅++

pVnVV

rvcoleppc

[5]

6.0)(

pp

pcrv

[l] minimum expansion vessel volume

EV

[l] pre-charge volume

pc

[l] system expansion volume

ep

[l] collector volume (SOLC220 = 1.7 litre)

col

[bar] relief valve pressure

rv

[bar] cold fill pressure

pc

.

pc

litreVV

3005.0 ≥⋅= [6]

syspc

[l] pre-charge volume

pc

[l] total system volume

sys

Page 32 of 72

ST0133 – A 02/09

Page 33

Technical manual

SOLAR

The expansion volume of the system Vep can be calculated using Equation 7.

β

⋅=

VV [7]

sysep

Where: V

V

[l] system expansion volume

ep

[l] total system volume

sys

β [-] heat transfer medium expansion coefficient (0.00085)

The pressure relief valve pressure p

can as first approximation be used as 6 bar. How-

rv

ever, to allow for some tolerance it is recommended to calculate the pressure relief

valve pressure p

in accordance with Equation 8.

rv

pp [8]

oprv

Where: p

p

)1.01( −⋅=

[bar] relief valve pressure

rv

[l] opening pressure of relief valve (6 bar)

op

The last parameter to be calculated for use in Equation 5 is the cold fill pressure p

the system. The cold fill pressure p

thermal system and the required pressure in the highest system point p

tion of the static height h

is depicted in Figure 33.

stat

depends on the static height h

pc

of the solar

stat

. The defini-

min

pc

of

h

stat

Figure 33 – Definition of static height of solar system

The pressure in the highest system point p

cold fill pressure p

can therefore be calculated as shown in Equation 9.

pc

should be between 1 and 1.5 bar. The

min

bar

hpp ⋅+= 1.0

[9]

pc

min

Where: p

p

h

stat

m

[bar] cold fill pressure

pc

[bar] pressure in highest system point

min

[m] static height of system

stat

Equation 9 concludes the calculation of parameters required for Equation 4 to calculate

the expansion vessel volume V

membrane pre-charge pressure p

. To be able to commission the expansion vessel, the

EV

has to be calculated as shown in Equation 10.

mp

Page 33 of 72

ST0133 – A 02/09

Page 34

Technical manual

SOLAR

VVpp−

⋅=

pcmp

Where: p

p

V

V

pcEV

[10]

V

EV

[bar] membrane pressure

mp

[bar] cold fill pressure

pc

[l] expansion vessel volume

EV

[l] pre-charge volume

pc

The expansion vessel membrane pressure p

has to be adjusted before the system is

mp

being filled and pressurised. Once the theoretical expansion vessel volume has been

calculated, the next larger available vessel is to be chosen.

A sizing guide of the expansion vessel under the stated conditions is given in Figure 34.

Please note that the calculation should be carried out in the case that the assumptions

shown in Figure 34 do not apply.

Figure 34 – Expansion vessel sizing chart applying Equations 5 to 10

Page 34 of 72

ST0133 – A 02/09

Page 35

Technical manual

SOLAR

4.4.3 Technical data

Figure 35 – Technical data Dimplex SOLEV expansion vessels

4.5 Dimplex expansion vessel fixing kit SOLVK1

4.5.1 General description

The expansion vessel fixing kit SOLVK1 aids with the installation, maintenance and decommissioning of the solar thermal system. The product consists of (see Figure 36):

- expansion vessel wall bracket (suitable for vessels of up to 440mm)

- 500mm corrugated stainless steel hose with ¾” flat seal connections

- quick fit connection

01

02

03

Figure 36 – Components Dimplex solar expansion vessel fixing kit SOLVK1

Page 35 of 72

ST0133 – A 02/09

Page 36

Technical manual

It is not recommended to fit vessels larger than 24 litres using the expansion vessel

fixing kit as faulty vessels gain considerably in weight and the wall bracket would not

support the additional weight.

The 500mm corrugated stainless steel hose allows the expansion vessel to be directly

connected to the expansion vessel connection port of the Dimplex solar pump units

SOLPU1 and SOLPU2.

The quick fit connection is a combined retainer and vessel connection. The vessel connection incorporates a fast acting two way valve operating always in the direction of

lower pressure. Should the vessel need maintained or replaced, the fitting eliminates

the need for the system to be drained down as it will close as soon as the vessel disconnects from the circuit.

Once the vessel is maintained or replaced the same fitting can be used to reconnect the

vessel to the system.

SOLAR

4.5.2 Technical data

Figure 37 – Technical data Dimplex expansion vessel fixing kit SOLVK1

4.6 Dimplex heat transfer medium SOLHT20

4.6.1 General description

The Dimplex solar heat transfer medium SOLHT20 is a ready to use 1.2-polypropylene

glycol fluid for solar thermal installations. The product has particularly good characteristics at higher temperatures where the liquid inhibitors resolve more readily back into

the solution than solid inhibitors.

This increases the useable life of the product, reduces the acidity of the medium when

at high temperatures and ensures the frost protection function is not being lost. In addition the inhibitors will not solidify inside the solar system and block ducts with small

diameters.

The heat transfer medium is ready mixed and must not be diluted on site. When replacement of lost medium is required it is important to ensure that only the same medium is being used.

Dimplex provide a test kit, SOLHTTK, to monitor the condition of the medium over the

course of its life.

Page 36 of 72

ST0133 – A 02/09

Page 37

Technical manual

SOLAR

4.6.2 Technical data

Figure 38 – Technical data Dimplex solar heat transfer medium SOLHT20

4.7 Dimplex solar cylinders SCx

4.7.1 General description

Dimplex offer a range of direct electric and indirect heated solar cylinders from 175 litre

to 305 litre overall volume. An overall view of the products is given in Figure 39 and a

summary of the key features is given in Figure 40.

The inlet and outlet pipe routing of the cylinders is in such a way that during water draw

offs the stratification of the stored hot water is effected as little as possible, ensuring

the maximum amount possible to be drawn at high water temperatures.

In addition, the sloped outlet pipe of the cylinder minimises the required installation

height and reduces the heat losses from the unit to a minimum.

The corrugated stainless steel solar coil ensures high heat transfer rates and minimises

the risk of lime build up. The position of the solar coil ensures maximum usage of the

available cylinder volume without compromising the comfort of sufficient auxiliary volume available.

Page 37 of 72

ST0133 – A 02/09

Page 38

Technical manual

02 03

05

09

11 12 13 14 15

17

01 02 03 04 05 07 12 13

15

17 06

SCx175/215/255/305sd

18

16

SOLAR

SCx175/215/255/305si

14

18

01

04

16

08

10

07

Figure 39 – Overall view Dimplex solar SCx unvented stainless steel cylinders

Page 38 of 72

ST0133 – A 02/09

Page 39

Technical manual

SOLAR

Figure 40 – Key features Dimplex solar cylinders SCx

4.7.2 Wiring integration Dimplex solar cylinders SCx

There are several ways to integrate the Dimplex solar cylinders into an existing or a

new central heating system. The principle plumbing and wiring schematics are shown

for two systems in Figures 41 and 42. Please note that these illustrations do not show

all the required components to ensure a safe and reliable operation of the systems.

Figure 41 shows the integration using 2x two port motorised valves. The advantage of

this system is that the provision of space heating and the provision of domestic hot water can be carried out independently.

Figure 42 shows the application of a three way diverter valve allowing the provision of

hot water and central heating at the same time. However, to comply with the regulative

requirements the fitting of a motorised two port valve to the cylinder is still required.

Page 39 of 72

ST0133 – A 02/09

Page 40

Technical manual

SOLAR

Figure 41 – Auxiliary loop integration 2x motorised two port valve

Page 40 of 72

ST0133 – A 02/09

Page 41

Technical manual

SOLAR

Figure 42 - Auxiliary loop integration 1x motorised two port valve and mid-position valve

Page 41 of 72

ST0133 – A 02/09

Page 42

Technical manual

SOLAR

The integration of the solar thermal control and pump unit independent from manufacturer nomenclature is shown in Figure 43.

Figure 43 – Solar loop integration

4.7.3 Hydraulic integration Dimplex solar cylinders SCx

Should the cylinder range of 175 to 305 litres not be sufficient, any number of cylinders

can be connected in parallel or in series to achieve higher storage volumes. The following should be observed when connecting the cylinders:

- each cylinder must be equipped with its own safety equipment as part of the scope of

delivery

- each cylinder must have its own save discharge in accordance with building regulations

- connect the cylinders on the potable and energy supply side in series when an even

demand is required over a period of time

- connect the cylinders on the potable and energy supply side in parallel when peak

demands are expected exceeding the capacity of an individual cylinder with its supply

- when installing larger systems ensure a risk assessment is carried out in accordance

with approved code of practise L8 from the HSE

- ensure each cylinder is accessible for maintenance and replacement work as required

- ensure the hydraulic circuit from the solar loop is balanced, i.e. the correct flow rate is

achieved through each coil

Page 42 of 72

ST0133 – A 02/09

Page 43

Technical manual

L

4.7.4 Technical data

F

E

D/N

M

K

A

O

J

B

C

P

H

SOLAR

G

I

Figure 44 – Technical data Dimplex solar cylinder SCx

Page 43 of 72

ST0133 – A 02/09

Page 44

Technical manual

Figure 45 – Pressure drop Dimplex solar SCx cylinder coils

4.8 Dimplex solar accessories

SOLAR

4.8.1 General description

To aid in the installation, commissioning, maintenance and the realisation of more complex systems Dimplex offer a range of accessories as summarised in Figure 46.

Figure 46 – Dimplex solar accessories

Page 44 of 72

ST0133 – A 02/09

Page 45

Technical manual

SOLAR

4.8.2 Corrugated flexible pipe SOLFH10/15

The Dimplex solar flexible corrugated stainless steel pipe includes:

- high temperature and weather resistant insulation

- integrated 2 core sensor cable

- wall fixings

- connection fittings from the collector to the pump unit and from the pump unit to the

cylinder

- 10m or 15m length.

The SOLFH10/15 pipe work reduces the installation time considerably by reducing the

number of joints to be performed, insulation of the pipe work separately, laying the

sensor cable and ensuring the leak tightness along its installation.

The technical data of the SOLFH10/15 pipe work is summarised in Figure 47.

~100mm

~45mm

Figure 47 – Technical data Dimplex flexible hose SOLFH10/15

Page 45 of 72

ST0133 – A 02/09

Page 46

Technical manual

SOLAR

4.8.3 Feed through tiles SOLFTT and SOLFTM

The Dimplex solar feed through tiles are suitable for corrugated and plain tiles, slate

roof coverings and sheet metal coverings depending on the type chosen:

- SOLFTT: corrugated and plain tile, slate roof covering

- SOLFTM: sheet metal roof covering, plain or corrugated

For each pipe feed through one tile of the appropriate type is required. The product

allows pipes and cables from 0 to 35mm to be fed securely into the roof. The feed

through tiles are suitable for plain copper tubing and for corrugated stainless steel hose.

An overall view of the two types of feed through tiles and the technical data are given in

Figure 48.

SOLFTT

SOLFTM

Figure 48 – Overall view feed through tiles SOLFTT and SOLFTM

Page 46 of 72

ST0133 – A 02/09

Page 47

Technical manual

SOLAR

5 System sizing

5.1 Required information

The sizing of solar thermal systems depends on a number of factors which require the

use of solar simulation software to allow reliable solar fraction predictions. The information required to reliably specify a domestic solar thermal hot water system is shown in

Figure 49.

Figure 49 – Required information for domestic solar thermal hot water system sizing

It can be seen from Figure 49 that the suitability of solar thermal depends primarily on

the user and the local conditions.

5.2 Sizing guide

Page 47 of 72

ST0133 – A 02/09

Page 48

Technical manual

SOLAR

Figure 50 – Dimplex solar initial sizing guide

Page 48 of 72

ST0133 – A 02/09

Page 49

Technical manual

SOLAR

For an initial assessment the following sizing guide (Figure 50) can be used to discuss

the feasibility of solar. It is however recommended, following the completion of the sizing guide to complete the On Site Questionnaire as shown in Figure 49 and Appendix

11.1 to validate the initial sizing with a detailed solar fraction simulation.

The solar fraction achieved using the sizing guide shown in Figure 50 will vary depending on the location of the installation within the UK (see Figure 3), its orientation (see

Figure 5) and the actual hot water demand.

6 Pipe work

For installation where the Dimplex solar corrugated stainless hose SOLFH10/15 is not

suitable, it is required to specify the correct pipe work for the installation.

6.1 Type of pipe work

Only full metal pipe work must be used in solar thermal installations. Plastic or composite materials are not suitable due to the high temperatures that can occur in solar thermal installations and the compatibility with the heat transfer medium.

Due to its ease of use and the readily available fittings it is recommended to use copper

as pipe material. Steel pipe work can also be used when it is ensured that it always

terminates into a brass fitting before getting in contact with copper.

The joints of the pipe work must be carried out in such a way that they are suitable for

the pressure and the temperatures present in the solar thermal system. For copper pipe

work it is recommended to work with brass compression fittings with brass olives.

6.2 Pipe work sizing

The size of the pipe work depends primarily on the flow rate circulating through the pipe

work. As discussed in Chapter 4.1.2 each collector requires a specified flow rate to ensure optimum operation and efficiency.

Equation 11 can be used to calculate the minimum required inner pipe diameter ID_min

in mm:

&

ID

min

Where: ID

4.6 [-] unit conversion factor

V [l/min] flow rate through pipe

w [m/s] flow velocity through pipe

Due to the higher viscosity of the heat transfer medium in comparison to water the flow

velocity w should not exceed 0.5 to 0.7m/s. A number of typical pipe diameters for

various collector field sizes are given in Figure 51 with a flow velocity of 0.5 and 0.7m/s.

V

⋅= 6.4

[9]

w

[mm] minimum required pipe diameter

min

Page 49 of 72

ST0133 – A 02/09

Page 50

Technical manual

SOLAR

Figure 51 – Suitable pipe diameters for various collector field sizes

6.3 Pipe work pressure drop

To be able to determine the suitability of the circulation pump it is important to be able

to calculate the pressure drop of the pipe work. Figure 52 summarises the approximate

pressure drop

pressure drop is 30% higher than that of water.

Δp_pipe in 1m of pipe work at 0.5 and 0.7m/s assuming that the glycol

Figure 52 – Pressure drop copper pipe per metre

6.4 Pipe work liquid content

To be able to reliably determine the liquid content of the system when specifying the

required amount of heat transfer medium and when sizing the expansion vessel, Figure

53 summarises the liquid content for the above selection of copper pipe.

Figure 53 – Liquid volume of copper pipe for 1 metre length

Page 50 of 72

ST0133 – A 02/09

Page 51

Technical manual

SOLAR

6.5 Pipe work fixation

When fixing the pipe work to the building structure a number of points should be considered before choosing the fixation method:

- temperature of liquid carried in pipes

- sound transfer from pipe work into building structure

- thermal expansion and contraction of pipe work due to large temperature changes

- safe securing of pipe work to building structure

- fire safety

It is important that the pipe work is secured to the building structure in a safe and

proper manner. Only wall/floor fixings that are suitable for the given conditions should

be used. When routing the pipe work on the outside of the building also the aesthetic

impact of the pipe work on the building should be considered.

The recommended distance between fixation points for various copper pipe sizes are

shown in Figure 54.

Figure 54 – Distance between fixation points of copper pipe work

6.6 Pipe work insulation

Additional requirements are in place for insulation used in solar thermal installations

compared with conventional heating and hot water systems. When choosing a suitable

insulation the following should be considered:

- the heat transfer medium in the pipe work can reach +150°C

- the insulation has to be UV and weather resistant

- the insulation should be at least 100% of the inner pipe diameter (e.g. a 22mm pipe

should be insulated with at least 19mm of insulation).

The Dimplex solar connection hoses which are delivered with the various roof fixing kits

and the 10m and 15m flexible pipes SOLFH10/15 are insulated with the appropriate

material.

Page 51 of 72

ST0133 – A 02/09

Page 52

Technical manual

SOLAR

7 Commissioning

The commissioning of a Dimplex solar thermal system is a simple procedure as outlined

in Figure 55.

Figure 55 – Dimplex commissioning procedure Part 1

Page 52 of 72

ST0133 – A 02/09

Page 53

Technical manual

SOLAR

Figure 55 – Dimplex commissioning procedure Part 2

8 Operation

8.1 Control unit

In general the operation of the Dimplex solar thermal system is fully automatic and

does not require any user intervention to ensure its efficient, safe and reliable operation.

However, the solar control unit offers a number of useful information that might be of

interest to the user.

In addition, the following settings and functions can be altered and activated or deactivated as applicable (see Figure 56):

- cylinder temperature setting

- temperature unit °F/°C

Page 53 of 72

ST0133 – A 02/09

Page 54

Technical manual

- holiday and frost protection function

- variable speed control of circulating pump

SOLAR

Figure 56 – Display information and menu structure SOLCU1

Page 54 of 72

ST0133 – A 02/09

Page 55

Technical manual

D:

p

B:

SOLAR

8.2 Pump unit

As for the whole system no manual intervention is required on the pump unit when the

system is operating normally. However, the pump unit offers some useful information

detailing the operational status of the solar system (see Figure 57):

A: current flow rate: to be seen on flow meter

B: flow and return temperature: approximate values on flow and return ball valves

C: operating pressure: pressure gauge

D: air – separation: to be carried out on air purger without having to access the roof

A:

C:

B:

Note: thermometers shown in

“open” position. During normal

operation the handles are to be

u

-right.

Figure 57 – Operational information provided by Dimplex solar pump unit SOLPU1/2

9 Maintenance

The maintenance effort for the Dimplex solar system is minimal and can ideally be executed when carrying out the mandatory checks on the unvented hot water installation.

Figure 58 details the schedule of the maintenance to be carried out.

It is recommended to check the function of the system after the 1

and then carry out a bi-annual maintenance check. Not all steps have to be undertaken

every two years as detailed in Figure 58. All the values measured during the maintenance procedure are to be recorded in the appropriate fields in the maintenance schedule. The following steps are part of the system maintenance:

Check system pressure

The original system pressure can be found on the system commissioning sheet contained in the on site guide. Should the pressure have reduced considerably, the cause is

to be investigated.

Check pipe work for leaks

This step is only required if the system pressure dropped considerably. Where readily

accessible joints should be checked for signs of small leaks.

st

year of operation

Page 55 of 72

ST0133 – A 02/09

Page 56

Technical manual

SOLAR

Check content discharge vessel

Should any heat transfer medium be deposited in the discharge vessel which was not

there from the beginning, the cause is to be established.

Check roof feed-through for leaks

The points at which the pipe work penetrates the primary and secondary protection

layer are to be inspected if accessible. No leakage must be found at these points.

Check condition of pipe insulation

As detailed in Chapter 6.6 the pipe work insulation in solar thermal systems must fulfil

certain criteria. However, damage due to system overheating, animal and mechanical

influences are always possible. Damaged insulation is to be replaced.

Check collector fixations

This work must be carried out with safe access only.

Check electrical connections

This check must only be carried out in a safe manner and by a qualified person.

Check pump function

This check can be carried out by moving the switch on the side of the control unit to its

ON position. A flow should be registered on the flow meter in the system. Remember to

return the control unit into AUTO when testing is complete.

Check sensor readings

The sensor readings can be checked in the display of the control unit by pressing the up

and down buttons. Should any doubt exist about the correct reading, the sensor should

be exchanged against another sensor in the system for reference and replaced if required.

Check frost protection and pH value of heat transfer medium

The SOLHTTK test kit is to be used to ensure the heat transfer medium retained its

properties. To access the heat transfer medium in the system slacken the bleed screw

of the circulating pump and allow 1 or 2 drops of liquid to escape to carry out the testing.

Check charge pressure expansion vessel

This can only be carried out when the expansion vessel is hydraulically disconnected

from the solar loop. It must therefore not be undertaken when the system is hot or will

heat up in the foreseeable future. This check must only be carried out when any doubt

exists that the charge pressure has reduced such as reduced fill pressure, pressure fluctuation between cold and hot system.

At the end of the maintenance routine it is imperative to ensure the system is back in

its automatic operation and that the user is informed of what has been undertaken.

Page 56 of 72

ST0133 – A 02/09

Page 57

Technical manual

SOLAR

Figure 58 – Overall view Dimplex solar maintenance procedure

Page 57 of 72

ST0133 – A 02/09

Page 58

Technical manual

SOLAR

10 Product and kit listings

The Dimplex solar product range is offered as kit or as individual components. The following listings detail all the kits and the individual components available.

10.1 Dimplex solar kits

The Dimplex solar kits are packaged in such a way that all the required components are

contained in the kit. Optional components are available but are not contained in the

standard kits. Furthermore, the kits are structured to allow a 1

tion should the installation be done in stages such as in new build situations.

The cylinders are to be ordered separately as they differ in type, direct and indirect

auxiliary heating, and the size of cylinder relative to the collector area can vary. The

kits are summarised in Figure 59, the cylinders are listed in Figure 60 along side the

individual solar kit components.

st

fix and 2nd fix installa-

Figure 59 – Dimplex solar kits overall view

10.2 Dimplex solar components

For systems larger than 6.6 m² (3 collectors) or should additional components be required the individual components can be chosen from Figure 60.

Page 58 of 72

ST0133 – A 02/09

Page 59

Technical manual

SOLAR

Figure 60 – Dimplex solar components overall view

Page 59 of 72

ST0133 – A 02/09

Page 60

Technical manual

SOLAR

11 Dimplex literature structure

Dimplex solar offers a range of literature to provide relevant information at all stages of

the product life cycle from planning and design, installation and maintenance to operation and troubleshooting. Figure 61 summarises the available documents and their relevance at the various stages of the product’s application.

Product implementation stage

Planning, sizing and

system design

- Technical Manual

Installation, commis-

sioning and mainte-

nance

- On Site Guide

- Installation manuals

Collector and roof kit man-

ual

Control unit manual

Pump unit manual

Exp. ves. fixing kit

Accessories

Figure 61 – Dimplex solar literature structure

- On Site Guide

- Installation manuals

Pump unit manual

Operation and trou-

bleshooting

Control unit manual

Page 60 of 72

ST0133 – A 02/09

Page 61

Technical manual

12 Appendix

12.1 On site questionnaire

SOLAR

Page 61 of 72

ST0133 – A 02/09

Page 62

Technical manual

12.2 On site inspection

SOLAR

Page 62 of 72

ST0133 – A 02/09

Page 63

Technical manual

SOLAR

Page 63 of 72

ST0133 – A 02/09

Page 64

Technical manual

SOLAR

Page 64 of 72

ST0133 – A 02/09

Page 65

Technical manual

12.3 Dimplex solar system direct – overall view

SOLAR

Page 65 of 72

ST0133 – A 02/09

Page 66

Technical manual

12.4 Dimplex solar system indirect – overall view

SOLAR

Page 66 of 72

ST0133 – A 02/09

Page 67

Technical manual

12.5 Example Dimplex solar simulation report

SOLAR

Page 67 of 72

ST0133 – A 02/09

Page 68

Technical manual

SOLAR

Page 68 of 72

ST0133 – A 02/09

Page 69

Technical manual

SOLAR

Page 69 of 72

ST0133 – A 02/09

Page 70

Technical manual

SOLAR

Page 70 of 72

ST0133 – A 02/09

Page 71

Technical manual

SOLAR

Page 71 of 72

ST0133 – A 02/09

Page 72

Technical manual

13 Notes and sketches

SOLAR

Page 72 of 72

ST0133 – A 02/09

Loading...

Loading...