Page 1

(SP4) SP420

(SP5) SP520

(SP9) SP920

08/19222/6 (UK) - Issue 6

Products comply with the European Safety Standard: EN 60335-2-30 and the European Standards for Electromagetic Compatibility (EMC)

EN55014-1 / A2: 2002 and EN55014-2:2003 which cover the essential requirements of EEC directives 73/23 and 89/336

Page 2

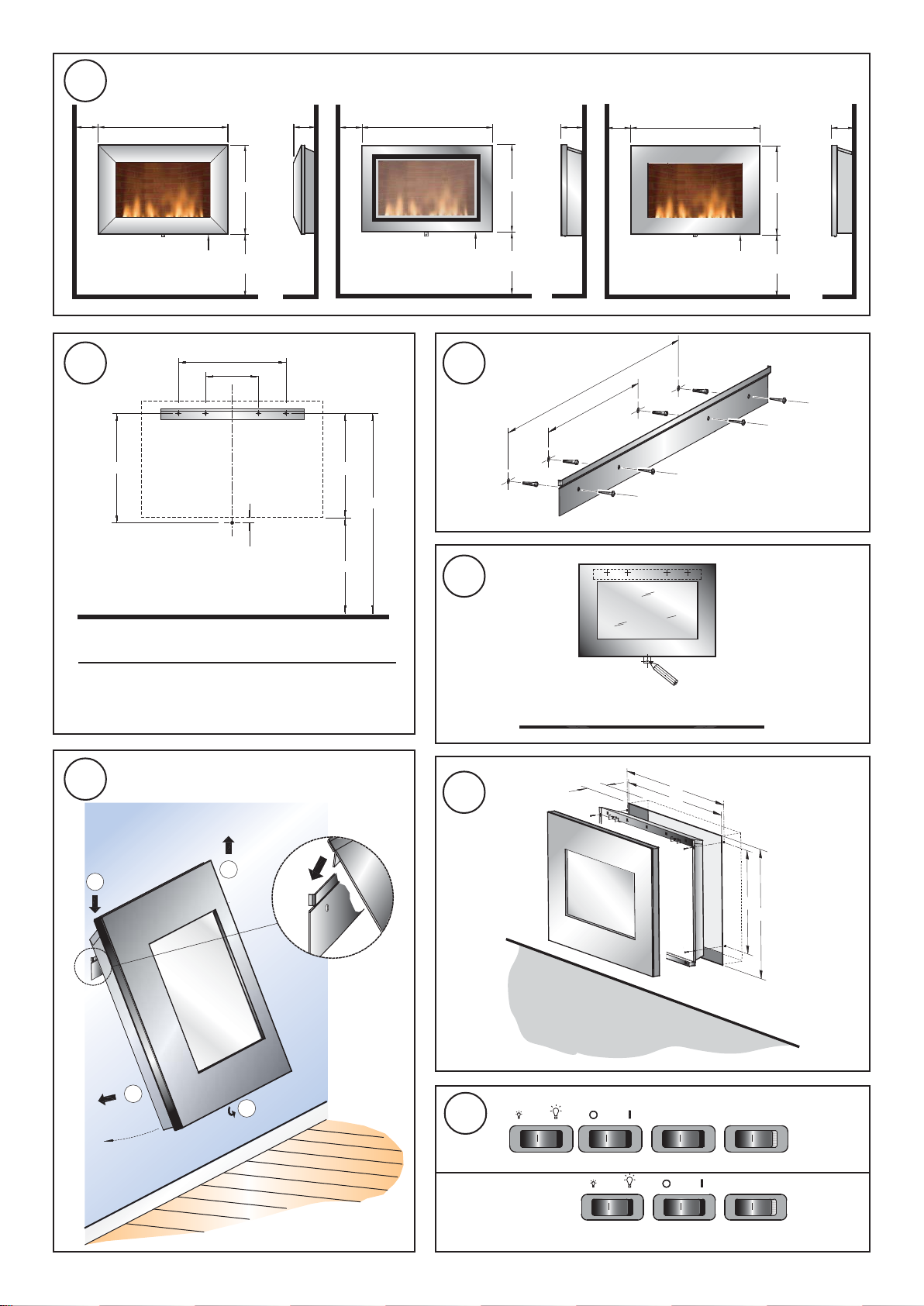

1

SP420 SP920

SP520

100

min.

2

964

664

'a'

300 min.

(600 recommended)

A

B

170

100

min.

1200

'a'

(600 recommended)

3

650

300 min.

182

100 1010

min.

A

696

'a'

300 min.

(600 recommended)

168

B

C

8

D

E

600

5

A B C D E

SP420 480 240 566 558 1158

SP520 840 280 554 546 1146

SP920 480 240 566 558 1158

4

a

b

'X'

'X'

d

c

5a

6

S4

Z

MAN

A

X

B

Y

OFFAUTO

ON

SP420

SP920

S3

S2

ON

S1

OFF

SP520

S3

S2

S1

Page 3

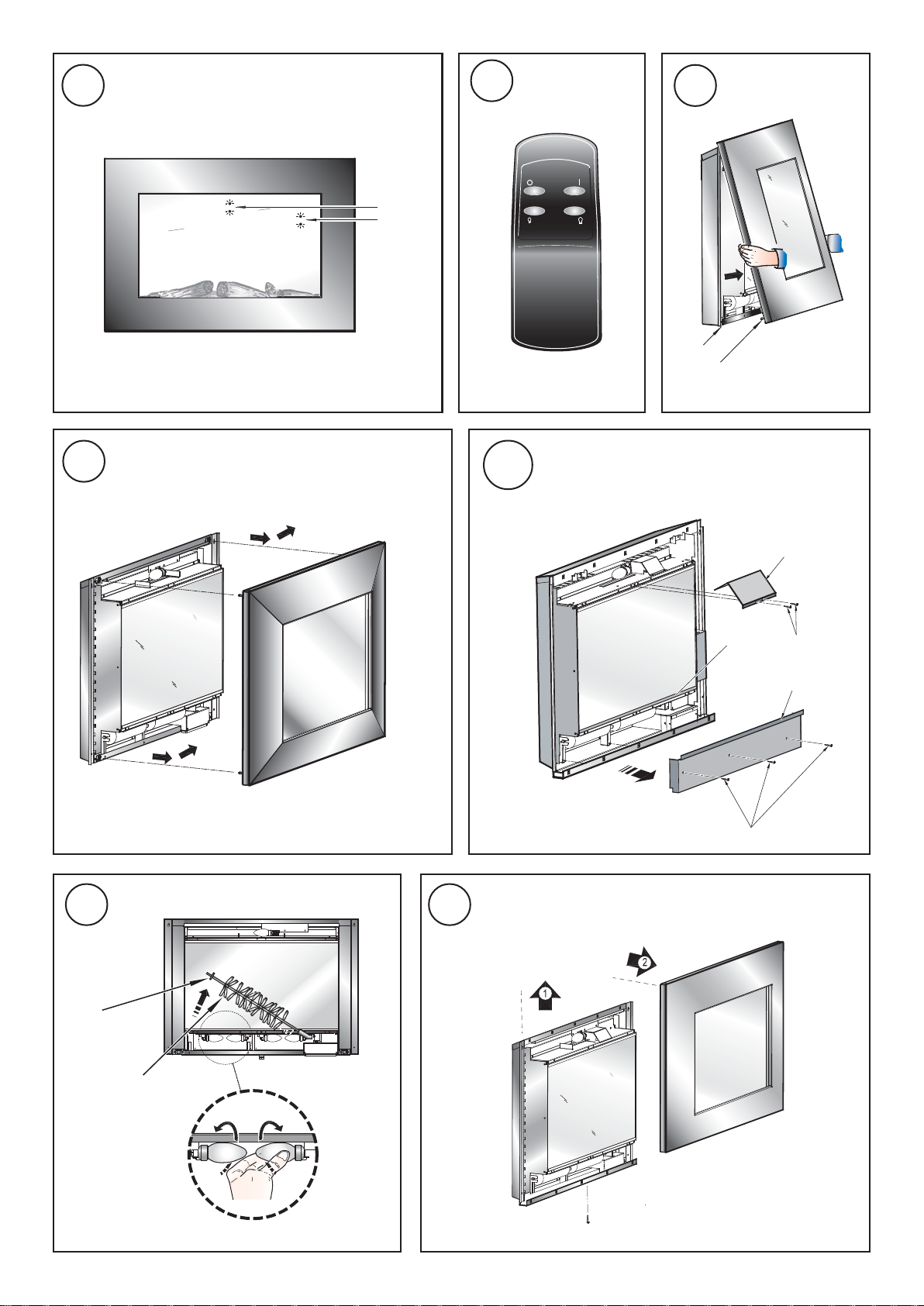

7

SP520

SP420

SP920

8

9

b

a

10

SP420

11 12

10a

SP520 & SP920

SP520 & SP920

X

C

A

Y

B

b

a

Page 4

Wall Fires Models: SP420, SP520 & SP920

IMPORTANT: THESE INSTRUCTIONS SHOULD BE READ CAREFULLY AND RETAINED FOR FUTURE REFERENCE

Important Safety Advice

When using electrical appliances, basic precautions

should be followed to reduce the risk of fire, electric

shock, and injury to persons, including the following:

If the appliance is damaged, check immediately with

the supplier before installation and operation.

Do not use this heater in the immediate surroundings

of a bath, shower or swimming pool.

Do not use outdoors.

Do not cover or obstruct the heater in any way.

Overheating will result if it is accidentally covered.

In the event of a fault unplug the heater.

Unplug the heater when not required for long periods.

The supply cord is recommended to be placed on the

right hand side of the heater. The heater can also be

HARD wired - this is recommended if the heater is

recessed - see ‘Recessed Installation’.

This appliance is not intended for use by children or

other persons without assistance or supervision if their

physical, sensory or mental capabilities prevent them

from using it safely. Children should be supervised to

ensure that they do not play with the appliance.

If the supply cord is damaged it must be replaced by

the manufacturer or service agent or similarly qualified

person in order to avoid a hazard.

Electrical

WARNING – THIS APPLIANCE MUST BE EARTHED

This heater must be used on an AC ~ supply only and the

voltage marked on the heater must correspond to the supply

voltage.

Do not switch the appliance on until properly installed. Please

read all the safety warnings and operating instructions.

General

Unpack the heater carefully and retain the packaging for

possible future use, in the event of moving or returning the

fire to your supplier.

Contents of Carton

• Heater.

• Wall fixing bracket.

• Fixing screws and wall plugs.

• Remote control and batteries

• Spare bulb.

Do not connect the heater to an electricity supply until it is

installed on a wall correctly - see ‘Installation’.

SP420 & SP920 - When in operation there is a 300 watt heat

output from the fuel effect, and an additional 120 watt output

when the heated glass panel is in operation.

SP520 - When in operation there is a 300 watt heat output

from the fuel effect, and an additional 200 watt output when

the heated glass panel is in operation.

The heater can be used remotely or manually - see ‘Operation’.

(AAA’s type).

General features of remote control are:

• Activate/Deactivate heated glass panel.

• The illumination of fuel effect can be increased or

decreased.

Please note: Used in an environment where background

noise is very low, it may be possible to hear the motor which

operates the flame effect. This is normal and should not be

a cause for concern.

Installation

Do not connect appliance until properly fixed to the wall

and the Instruction leaflet is read fully.

The minimum distances must be observed.

For installation of the appliance, care must be taken not to

damage concealed cables.

Please be careful while drilling the holes.

This model is designed to be permanently fixed to a wall at a

minimum height of 300mm. The wall bracket must be fitted

horizontally and the cable routed to the bottom right of the

heater as in Fig. 1.

A height of 600mm from bottom of heater to floor is

recommended for optimum viewing of fuel bed (see Fig. 2 for

recommended fixing dimensions).

For optimum viewing mark the top four screw fixing positions

on wall in accordance with the recommended fixing dimensions

- see Fig. 2. Drill holes with a 6mm drill bit.

Fix the wall bracket using the plugs and screws provided see Fig. 3.

Carefully lift the heater up ensuring that the top rear ledge of

heater engages the wall bracket and is sitting centrally

positioned. - see Fig. 4 (b).

Rotate the bottom fixing bracket down. - see Fig. 4 (c).

Gently bring the heater level with the wall. - see Fig. 4 (d).

Mark the bottom hole position (see Fig. 5), remove the heater

ensuring that the bottom fixing bracket is rotated up.

Drill and fit wall plug.

Refit the heater to the wall fixing bracket (i.e. follow steps as

in Fig. 4 a, b, c and d) and rotate the bottom fixing bracket

down again and use the screw provided to permanently fix

the heater in place.

The heater should not be connected until the instruction leaflet

is read fully.

Recessed Installation

Please note that this appliance can also be wall-mounted so

that it is recessed. This can be installed in a large fireplace

opening or a purpose built wall. See Table 1 for size of recess

required and hole fixing dimensions and Fig. 5a. This fireplace

insert does NOT require venting.

In order to ensure it’s future safety in use, it is essential

that this fire is securely fixed to the wall.

IT IS IMPORTANT THAT THE FIXING DEVICE CHOSEN IS

APPROPRIATE TO THE WALL MATERIAL TO WHICH THE

FIRE IS BEING FIXED. SOME MODERN INTERNAL

BUILDING MATERIALS ARE VERY LOW DENSITY BLOCK

AND REQUIRE SPECIALIZED FIXING DEVICES TO

PROVIDE A SAFE,SECURE INSTALLA TION.

The installation of this fire should be carried out by a competent

person. If in doubt please consult your local builder.

Page 5

This section provides step by step instructions for selecting

a location and preparing the site to install the fireplace into

the following:

Existing Fireplace

1. Make sure that the fire is located on a flat surface.

2. Seal all draughts and vents to prevent chimney debris

from falling onto the Fireplace Insert. Do not install into an

existing fireplace that is prone to dampness.

3. Remove the fire front panel by following the steps as

outlined in ‘Lamp Replacement’ sections.

4. Locate the 4 fixing holes, position the fire accordingly,

and firmly fix the appliance to the wall using the appropriate

screws - see Fig. 5a.

5. Replace the front panel.

New Support Structure Construction

When planning where to position your purpose built support

structure the following steps must be observed:

1. Place the fire in the desired location to see how it will

look in the room.

2. Mark the desired location for the new support structure

in the room and store the fire in a safe, dry and dust free

location.

3. Using timber studs to support the fire, devise and

construct a suitable means of supporting the product within

the wall partition and provide electrical power for the fire to

be HARD wired. For recommended sizes of height, width

and depth of opening for recess and hole fixing dimensions

for each model - see Table 1 and Fig. 5a.

4. When the structure is complete, remove the front panel

of the fire by following the steps as outlined in ‘Lamp

Replacement’ sections.

5. Locate the 4 fixing holes, position the fire accordingly,

and firmly fix using the appropriate screws.

6. Replace the front panel.

TABLE 1

Models A B X Y Z

SP420 871 570 847 646 115

SP520 1160 560 1143 640 146

SP920 914 565 895 676 150

NOTE: The appliance should be HARD wired to an electrical

power outlet when placed in a recessed installation.

Please consult a qualified electrician for appropriate wiring

requirements.

Manual Operation - SP420 & SP920

The switches are located at the bottom right side of the heater.

The Standby Switch (Switch S1) must be first turned ‘ON’ and

the AUTO/MAN (Switch S2) switch set to ‘MANUAL ’ to operate

the manual controls - see Fig. 6.

Note : When the fire is put in Manual mode the first time the

flame effect will come on indicated by the Bottom neon coming

on for 3 seconds - see Fig. 7.

Manual & Remote Operation

Setting Operation Setting

Flame Effect only Press the ‘ I ’ button (Switch 3) Top Neon

Flame Effect & Heat On Press the ‘ I ’ button again (Switch 3) Bottom Neon

The Standby switch must first be turned ‘ON’ to operate the

heater manually or by remote control.

Note: It takes some time for the receiver to respond to the

transmitter. DO NOT PRESS the buttons more than once within

two seconds for correct operation.

To go to the previous settings press the O button.

Pressing the O button on the remote turns off the light & heat

settings. To resume press the I button until the desired setting

is reached - see Fig. 8.

To increase or decrease the brightness of the flames, use the

dimmer button or the

button on the Remote Control. The

heat setting will remain the same.

T o turn off the power the S tandby Switch must be turned ‘OFF’.

Lamp Replacement - SP420

WARNING – ALWAYS DISCONNECT FROM THE POWER

SUPPLY BEFORE REMOVING LAMPS.

Warning - The lamps reach high temperatures during

operation. For this reason, allow the lamps to cool down after

switching off the appliance.

The

front panel will need to be removed in order to change

lamps –see Fig. 10.

Warning - The front panel is heavy and easily damaged.

The

front panel is fixed with 4 spring loaded pins (see ‘a’ in

Fig. 9) and is supported at the top by the chassis.

To gain access to lamps please apply the following

procedure:

While holding the

carefully pull forwards the panel at the bottom until the pins

detach from the clips - see Fig. 9.

When the bottom holding pins are undone, carefully pull

forwards at the top until the top pins detach and then lift the

front panel up and out (see Fig. 10).

T o gain access to the bulbs remove the screws at ‘A ’ to remove

the cover bracket ‘X’ - see Fig. 10a.

For access to the bottom bulbs, carefully slide the flexible

rotisserie (see ‘a’ in Fig. 11) to one side ensuring that the

rubber grommet is not lost (see ‘b’ in Fig. 11).

Remove the defective lamp by unscrewing it (see Fig. 11).

Replace with a 60W E14 SES Clear Candle bulb, rotating it.

Take care not to over-tighten the lamp.

Steps for reassembling the heater

1. Refit the rotisserie making sure that the rubber grommet

is carefully pushed into the slotted hole on the axial bracket.

2. Replace the cover bracket ‘X’ - see Fig. 10a.

3. Replace the front by aligning the slots on the front frame

and making sure that it catches fully on the support brackets.

front panel by its sides with both hands,

Manual Operation - SP520

The switches are located at the bottom right side of the heater

- see Fig. 6.

Remote Operation

The standby switch (S1) must first be turned ‘ON’ (and the

‘AUTO/MAN’ Switch turned to ‘AUTO’ - SP420 & SP920).

Note: It takes some time for the receiver to respond to the

transmitter. DO NOT PRESS the buttons more than once

within two seconds for correct operation.

Page 6

Lamp Replacement – SP520 & SP920

WARNING – ALWAYS DISCONNECT FROM THE POWER

SUPPL Y BEFORE REMOVING LAMPS.

Warning - The lamps reach high temperatures during

operation. For this reason, allow the lamps to cool down

after switching off the appliance.

The front panel will need to be removed in order to change

lamps – see Fig. 12.

Warning - The front panel is heavy and easily damaged.

The front panel is supported at the top by the chassis and

held tight by magnets at the top and bottom on the SP520

model. On the SP920 the front panel is held at the bottom by

a fixing screw.

To gain access to lamps please apply the following

procedure:

Remove the fixing screw from the base of the front frame on

the SP920 - see Fig. 12.

While holding the front panel by its sides with both hands,

carefully tilt the bottom of the frame outwards until free and

then lift the panel up (1) and then away (2) from the main

body - see Fig. 12.

T o gain access to the bulbs remove the screws at ‘A ’ to remove

the cover bracket ‘X’ and the screws at ‘B’ to remove the

cover bracket ‘Y’ - see Fig. 10a.

For access to the bottom bulbs, carefully slide the flexible

rotisserie (see ‘a’ in Fig. 11) to one side ensuring that the

rubber grommet is not lost (see ‘b’ in Fig. 11).

Remove the defective lamp by unscrewing it (see Fig. 11).

Replace with a 60W E14 SES Clear Candle bulb, rotating it.

Take care not to over-tighten the lamp.

Steps for reassembling the heater

1.Refit the rotisserie making sure that the rubber grommet

is carefully pushed into the slotted hole on the axial bracket.

2.Replace the cover brackets ‘X’ and ‘Y’ - see Fig. 10a.

3.Replace the front by aligning the slots on the front frame

and making sure that it catches fully on the support

brackets.

The magnets on the chassis will hold the front flush to the

main body (SP520).

4. Replace the fixing screw on the base of the front frame

(SP920).

Page 7

Cleaning

WARNING – ALWAYS DISCONNECT FROM THE POWER

SUPPL Y BEFORE CLEANING THE HEATER.

For general cleaning use a soft clean duster – never use

abrasive cleaners. The glass viewing screen should be

cleaned carefully with a soft cloth. DO NOT use proprietary

glass cleaners.

Recycling

For electrical products sold within the European Community.

At the end of the electrical products useful life it

should not be disposed of with household waste.

Please recycle where facilities exist. Check with

your Local Authority or retailer for recycling advice

in your country.

After Sales Service

Your product is guaranteed for one year from the date of

purchase.

Within this period, we undertake to repair or exchange this

product free of charge (excluding lamps & subject to

availability) provided it has been installed and operated in

accordance with these instructions.

Y our rights under this guarantee are additional to your statutory

rights, which in turn are not affected by this guarantee.

Should you require after sales service you should contact our

customer services help desk on 0845 600 5111. It would

assist us if you can quote the model number, series, date of

purchase, and nature of the fault at the time of your call. The

customer services help desk will also be able to advise you

should you need to purchase any spares.

Please do not return a faulty product to us in the first instance

as this may result in loss or damage and delay in providing

you with a satisfactory service.

Please retain your receipt as proof of purchase.

Page 8

Dimplex UK Limited

Millbrook House

Grange Drive

Hedge End

Southampton

Hampshire. SO30 2DF

[c] Dimplex UK Limited

All rights reserved. Material contained in this publication may not be reproduced in whole or in part, without prior permission in writing of Dimplex UK Limited.

UK customer help line 8.00am–5.00pm Mon-Fri and 8:30am-1.00pm Sat (October-March)

Technical Services: Tel. 0845 600 5111

Fax. 01489 773053

e-mail technical.services@dimplex.co.uk

Republic of Ireland Tel. 01 8424833

Loading...

Loading...