Page 1

SERVICE POLICY/GUARANTEE

Shower User Guide

Before telephoning the Dimplex Customer Service Department you should

ensure that you have the model number, power rating, serial number and

date of purchase.

If the product is no longer covered by the Guarantee, a charge will be made

for the site visit and for any parts supplied.

A charge will be made where a call under the terms of the guarantee has

been booked and a failure was not product related, or an engineer arrives

and is not able to gain access.

If a service call is booked, you or a representative must be present during the

Engineers visit.

The Dimplex Customer Service Department will be able to inform you whether

the fault can be rectified by the provision of a replacement part or an on site

visit by a Qualified Service Engineer.

In the event of you needing to contact the Dimplex Customer Service Department,

the following procedure should be followed:-

Glen Dimplex Limited guarantee this product for a period of two years, from date of purchase,

against mechanical and electrical defects arising from faulty materials or manufacturing defects,

providing the product has been installed by a competent person in accordance with the

fitting instructions.

Glen Dimplex Limited undertake to repair or replace, at their discretion, without charge,

provided the product has been properly maintained and operated in accordance with the

operating instructions. Any component found to be defective during this period, as the result

of misuse or damage, or the effects of scaling, will not be covered by this guarantee.

This product must not be modified, repaired or taken apart except by a person authorised by

Glen Dimplex Limited.

This Guarantee is only valid within the United Kingdom and does not cover product used commercially.

This Guarantee does not affect your statutory rights.

Glen Dimplex UK Limited, Millbrook House, Grange Drive, Hedge End, Southampton SO30 2DF.

Tel 0870 077 7117 Fax 0870 727 0109

Customer Services Tel 0870 240 9402

1

2

3

4

5

GUARANTEE

Dimp13292-Shower inst aX4 5/5/04 2:08 pm Page 1

Page 2

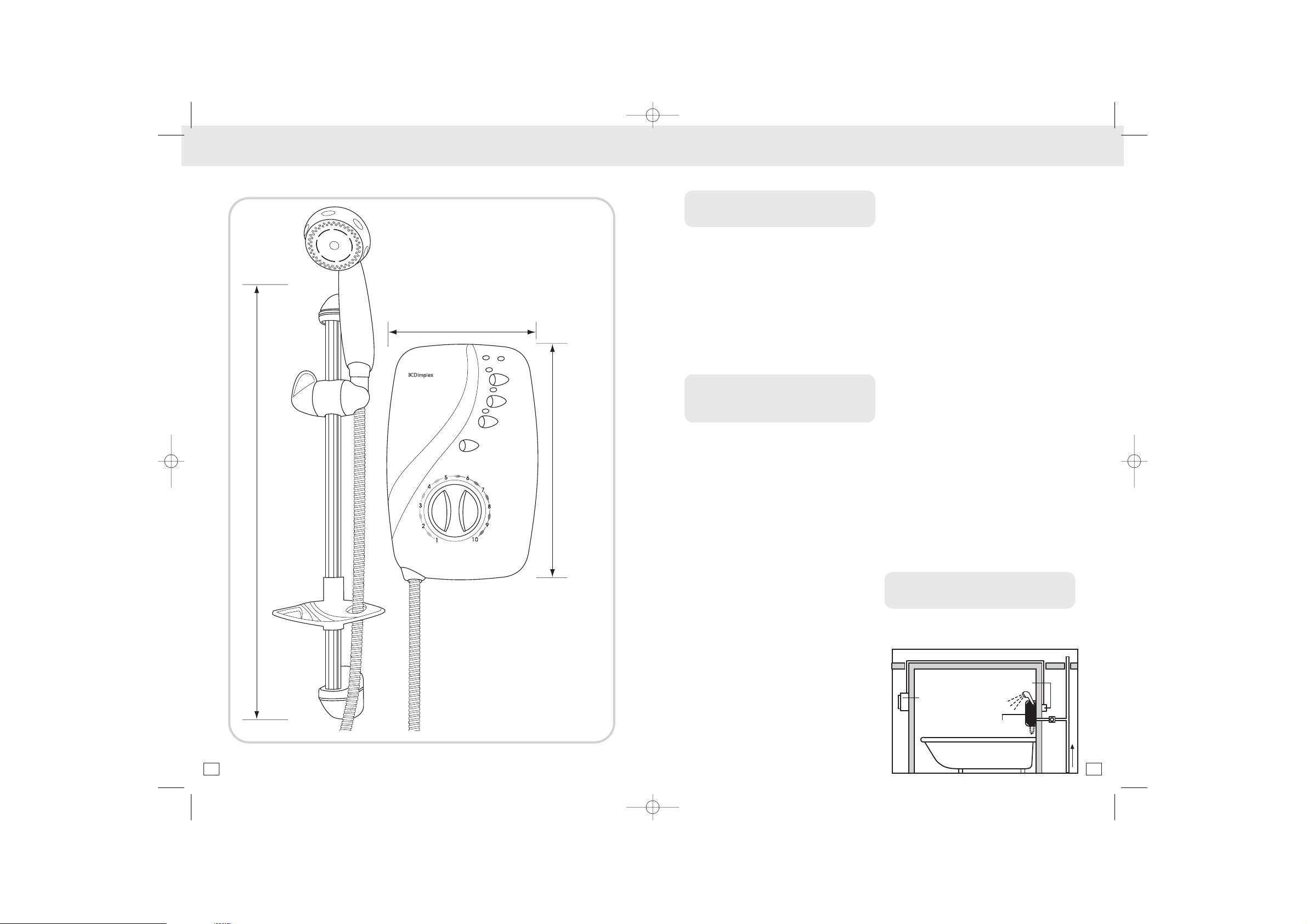

SECTION 1

Unpacking and important notices

Contents

1 x Shower Unit

1 x Showerhead

1 x Flexible Hose

1 x Slider Rail Tube

1 x Slider Rail Brackets

1 x Height adjuster

1 x Screw pack

1 x Soap dish

1 x Showerhead key

IMPORTANT NOTICES

PLEASE READ BEFORE ATTEMPTING

TO INSTALL THE SHOWER UNIT

1) The shower unit must be installed by a

suitably qualified person and conform

to IEE Regulations and National Water

Council Bylaws.

2) The shower must only be connected

to a 15mm mains cold water supply.

Do not connect the unit to the cold

water supply of a header tank.

3) The minimum recommended running

water pressure to which the shower

heater may be connected is 15lb/sq in

(1bar); running pressure of 8 litres/minute;

maximum static pressure recommended

150lb/sq in (10 bar).

4) The shower unit must not be fitted

where it may be exposed to frost, for

example in an outdoor shower area. The

shower must not be used if suspected of

being frozen. Please note: Frost damage

is not covered by the guarantee.

5) Do not use Plumbers jointing compound.

Use of plumbers jointing compounds

invalidates the guarantee.

Complete all plumbing connections

before making any electrical connections.

The outlet of the shower unit must only be

connected to the hose and showerhead

supplied with the unit. Use of other

components will invalidate the warranty.

Always switch off at the isolating switch

when the shower is not in use.

To comply with National Water Council

bylaws a double check valve must be

fitted where it is possible that the showerhead may come into contact with used

water e.g. in the shower tray or bath.

Do not operate power tools in a wet environment. It is recommended that any power

tools operated in the bath or shower area are

supplied via a Residual Current Device (RCD).

WARNING! THIS APPLIANCE MUST BE EARTHED.

This shower is for connection to a

230V-240V/50Hz mains electricity supply.

SECTION 2

Installation

Typical instantaneous electric shower

installation

DIMENSIONS UNPACKING AND IMPORTANT NOTICES / INSTALLATION

HIGH

LOW

COLD

LOW

PRESSURE

AUTO

RESET

TEMPERATURE

S

T

O

P

610mm

218mm

339mm

2 3

Dimp13292-Shower inst aX4 5/5/04 2:08 pm Page 3

Double pole heater switch wall mounted in

accordance with local authority regulations

Seperate permanently

connected supply

from consumer unit

Dimplex electric

water heater

Isolating

stop tap

Cold

water

mains

supply

Page 3

Planning the installation

The shower should be located in a position

where walls are protected from water and

sufficient drainage is provided.

1) Consideration should be given to the

location of the nearest cold mains

water supply and the routing of this

to the shower. The shower will accept

a mains supply from the bottom,

back or top of the unit. Remove the

appropriate plastic plate from the

back plate before commencing

installation.

2) Avoid connecting the shower unit

where it will be affected by water

drawn off by other appliances, e.g.

from the mains feed to the W.C. This

may cause a drop in pressure too low

for the shower unit to work correctly.

General

1) Fit an isolating valve to the mains

water supply so that the shower can

be serviced.

2) The shower unit is best placed to the

right hand side of the riser rail and

placed so that the top of the unit sits

alongside the middle to top of the riser

rail. This reduces the amount of water

falling on the unit.

The top of the riser rail should be sited

to coincide with the height of the tallest

person using the shower.

Before drilling any holes check that

there are no hidden cables or pipes

below the surface to be drilled.

To avoid loss of small parts cover any

drainage holes.

3) The shower unit should be positioned

so that the showerhead cannot be

immersed in the bath or shower tray

when hanging down.

Where holes are to be drilled into a

tiled surface a suitable tile or glass drill

bit should be used to make a hole

through the tile only. The hole made

through the tile should be 0.5mm larger

than the hole in the wall.

These installation instructions assume

mounting onto a solid masonry wall.

For other types of structure please

amend the procedure accordingly.

Plumbing

1) Remove the front cover of the shower

unit complete with the two control knobs

by removing the two screws securing it to

the back plate. Remove the ‘trim plate’ at

the bottom right-hand side of unit to

allow easy access for the plumbing work.

2) Position the shower unit on the wall in

the desired place and mark the location

of the fixing holes.

3) Determine the direction of the inlet water

supply: bottom (rising), top (falling) or

back inlet. The shower unit is supplied

with a swivelling push-fit inlet elbow. This

elbow should be rotated to match the

desired direction of water supply entry to

the unit. Carefully remove the appropriate

plastic break-out from the unit’s back

plate so that the mains water supply

pipe can be routed into the unit.

4) Carefully drill the holes using a 5.5mm

masonry drill (note when drilling though

tiles first use a glass or tile drill bit of 6mm

diameter to drill a hole through the tile).

5) Insert the plugs provided through the

hole in the tile and fix the unit to the

wall using the screws supplied. Do not

tighten the screws fully at this stage.

6) Turn off the water supply at the isolating

stop tap.

7) Bring the mains water supply using

15mm copper or stainless steel pipe to

the shower unit so that it enters through

the hole in the back plate.

8) Before connecting the shower unit, flush

out any debris in the new pipework by

connecting a hose to the end of the

mains supply pipe and running the mains

water until all the debris has cleared.

9) After flushing out, turn off the

water supply and connect

the pipe to the shower inlet.

Having inserted the inlet

pipe into the elbow, secure

the joint by finger tightening

the locking device, rotating

in a clockwise direction.

10)Make sure that the shower unit is

positioned squarely on the wall and

tighten the fixing screws. Tighten all

plumbing joints and turn on the water

supply to check for leaks. With the unit

firmly fixed to the wall and the pipework

free from leaks, dry the shower area in

preparation for the electrical

installation.

INSTALLATION INSTALLATION

4 5

Dimp13292-Shower inst aX4 5/5/04 2:08 pm Page 5

Product Positioning Guide

LOW

AUTO

PRESSURE

RESET

COLD

LOW

HIGH

P

O

T

S

TEMPERATURE

Page 4

Riser rail

Part the mounting bracket

assembly so that the fixing plate

is separate from the cover.

Establish the best position for the

riser rail, and mark the wall for

the lower mounting bracket.

Make allowances for the tallest person likely to

use the shower regularly.

When drilling through tiles use a

suitable glass or tile drill of 6mm

diameter to drill through the tile

only. Use a no 10/5.5mm masonry

drill to make a hole 35mm deep,

and fit the wall plug. (NB some

wall constructions may require the use of

different types of wall fixings to those supplied).

Screw the lower bracket base to the wall.

Locate the crimped end of

the riser rail (Figure 4) into the

mounting bracket, then fit

the upper bracket to the rail.

Ensure the rail is vertical, then

mark the wall for the fixing.

NOTE if it is necessary to

shorten the rail, use a junior

hacksaw to cut the excess

material from the plain end

of the rail (the uncrimped

end).

Insert the end pieces of the

height adjuster into the body

section matching the letters A

and B (moulded into the ends

of each piece) and twist so the

pieces lock together.

With the shower head holder in

the upright position (widest

opening at the top) and the

lever in the open position, slide

the assembly onto the rail.

Tighten the height adjuster to

the rail by twisting the lever.

Insert the rail into the bottom

and top brackets and screw

the upper mounting bracket

in place. Clip the end caps

onto the mounting brackets.

Electrical

Switch off the water supply at the isolating

valve before connecting the wiring to the

unit.

The shower unit must be permanently

connected to the electricity supply, direct

from the consumer unit via a double pole

linked switch with a minimum contact gap

of 3mm.

It is recommended that the switch be a

cord operated type with neon on/off

indicator, otherwise the switch should be

readily accessible, clearly identifiable and

out of reach of any person using the shower.

The wiring to the switch must be done

without the use of a plug or socket outlet.

The cable used must be of a diameter

suitable for the power rating of the

shower selected. The table below may

be used as a guide to the cable

requirements. If in doubt consult a

qualified electrician.

kW rating Minimum Fuse rating Max cable length

Isolating switch (Amps) (Amps) Consumer unit to

shower (m)

6mm cable 10mm cable

7.5 40 40 27 44

8.5 40 40 23 38

9.5 40 40 21 32

10.5 45 45 18 30

2

3

4

5

6

1

7

INSTALLATION INSTALLATION / FINAL ASSEMBLY AND COMMISSIONING

The cable should be routed to the shower

unit from either the top, bottom or back

of the shower unit. This cable should be

hidden from view.

Connect the brown live wire to the terminal

marked L

Connect the blue neutral wire to the terminal

marked N

Connect the yellow and green earth

wire to the terminal marked E on the

backplate.

IMPORTANT – ensure the terminal block

screws are fully tightened and that no

insulation enters the terminal block,

preventing a good electrical connection.

To conform to IEE regulations the earth

continuity conductor of the electrical

installation must be effectively connected

to all exposed metal parts of other

appliances and services in the room in

which the shower unit is installed.

WARNING! Do not attempt to operate

the shower unit until the installation is

fully complete.

SECTION 3

Final assembly and commissioning

With the unit wired and plumbed correctly

the front cover may now be refitted.

1) Place the cover lightly over the shower

unit and turn the knobs so that they

engage correctly with the spindles.

The front cover may then be pressed

lightly into place and secured using the

two fixing screws.

2) Fit the flexible hose to the shower unit

and remove the showerhead.

3) Turn the temperature control knob at

the bottom of the unit fully

anti-clockwise.

4) Turn on the power at the isolating

switch.

5) Start the shower by pressing the cold

power selector button. The water

should now begin to flow through the

shower.

Warning do not attempt to select any other

setting other than Cold at this stage.

6) Once a steady stream of water is

achieved from the outlet of the shower

unit stop the shower by pressing the

STOP button.

7) Pass the hose through the hole in the

soap dish and refit the shower head.

8) Fit the handset into the height adjuster

and clip the soap dish onto the riser

rail.

The unit is now ready for commissioning.

Commissioning the shower

Important: The shower unit must be full of

water before power (heat) settings are used.

1) With the water supply to the unit turned

on, turn the bottom temperature

control knob anti-clockwise to the full

cold position. No water should exit the

shower either from the handset or from

any other part of the shower unit.

6 7

Dimp13292-Shower inst aX4 5/5/04 2:08 pm Page 7

Page 5

2) Switch on the electrical supply at the

double pole isolating switch, the power

neon on this switch should light.

3) Start the shower by pressing the ‘Cold’

power selector button. Water should

start to flow from the handset within a

few seconds. The water will be at full

force and will run cold.

4) Now press the ‘Low’ power selector

button. Allow a few seconds for the

warmer temperature to reach the

showerhead – this shows that the ‘Low’

power is operating correctly.

5) N

ow press the ‘High’ power selector

button. The temperature at the shower

head will rise further – this shows that

the full power setting is operating

correctly.

6) Turn the bottom temperature control

knob clockwise for hotter water and

anti-clockwise for cooler water. Allow

a few seconds between selections for

the temperature change to reach the

showerhead. Note that selecting a

hotter setting in the temperature

control reduces the flow of water.

7) Press the STOP button to stop the water

flow. Water should continue to flow,

eventually running cool before

switching off.

A small amount of water may continue to

drip from the unit as water drains from the

pipe-work. This should stop within a few

minutes.

The commissioning procedure is now

complete.

SECTION 4

Operation

‘Power indicator’:

The power indicator on the shower unit

will light when the shower is switched

on and water is flowing on one of the

two heat settings. The indicator does

not light on the cold setting.

‘Auto Reset Indicator’

The Auto Reset Indicator will illuminate if

an overheat temperature is sensed

during operation. Once activated the

electricity supply to the elements is

switched off until the unit has cooled

sufficiently, where upon power to the

elements will be restored.

‘Low Pressure Indicator’

The low pressure indicator will

illuminate if the mains water supply

pressure falls below the minimum

level. The heat settings will be

disabled until normal operating

pressure is restored.

1) Switch on using the pull-cord or wall

mounted switch.

2) To start the shower, turn the temperature

dial to the desired number and press

the desired power button, upon which

water will start to run through the

shower.

3) The shower has three positions

‘Cold’, ‘Low’ power and ‘High’ power.

‘Cold’ setting:

Adjustment of the flow control on this

setting will only alter the flow of water

not the temperature.

FINAL ASSEMBLY AND COMMISSIONING / OPERATION OPERATION / LOOKING AFTER YOUR SHOWER

‘Low’ setting:

This is the low power setting for economy

during warmer months or when a

cool shower is required.

‘High’ setting:

This is the full power setting.

4) If necessary turn the bottom ‘temperature’

control knob slowly to obtain the desired

showering temperature. Waiting a few

seconds after each adjustment for the

temperature to stabilise.

To increase the shower temperature

Turn the temperature control knob

clockwise, this will decrease the flow

of water and increase the shower

temperature.

To decrease the shower temperature

Turn the temperature control knob

anti-clockwise, this will increase the flow

of water and decrease the shower

temperature.

5) To stop the shower press the STOP button.

Allow the water to run until it stops

automatically

6) Switch off the electricity supply using

the pull-cord or wall mounted switch.

SECTION 5

Looking after your shower

The showerhead should be cleaned

periodically to remove limescale or other

particles which will reduce the performance

of the shower. The frequency of cleaning

will vary according to the local water

quality. In hard water areas cleaning will

be needed more often than in soft water

areas. A liquid non-abrasive bathroom

HIGH

LOW

COLD

LOW

PRESSURE

AUTO

RESET

TEMPERATURE

S

T

O

P

Cooler Warmer

TEMPERATURE TEMPERATURE

8 9

Dimp13292-Shower inst aX4 5/5/04 2:08 pm Page 9

LOW

PRESSURE

COLD

AUTO

RESET

LOW

HIGH

P

O

T

S

Page 6

cleaner may be used on external surfaces

of the handset. Rub-clean showerheads

may be rubbed lightly to remove scale as

required. Over time build-up of limescale

requires the showerhead to be cleaned

more thoroughly, as follows.

1) Use a liquid non-abrasive bathroom

cleaner on external surfaces of the

handset.

2) Engage the key into the spray cartridge

recesses and turn anti-clockwise to

unscrew.

3) Remove the two small black ‘O’ rings

from the rear of the spray cartridge,

and rinse the ‘O’ rings clean.

4) Brush the spray plate with a stiff bristled

brush, if necessary immerse and soak

the spray plate for several hours in a

proprietary limescale remover. Rinse off

all traces of limescale and limescale

remover from the showerhead.

5) Replace the two black ‘O’ rings on the

rear of the spray cartridge and refit the

cartridge to the showerhead tightening

with the key.'

SECTION 6

Trouble shooting

Before calling our customer service

department please use the table to

determine likely causes of the problem:

NOTE Under normal operation the shower

heats the water as it passes through the

unit. The temperature of the water is

affected by the temperature of the water

in the mains cold water supply and the

speed with which the water flows through

the unit. It is therefore normal for the water

coming out of the shower to change

temperature through summer and winter

months where the mains water

temperature changes. It is also normal

for the water temperature to vary when

other water appliances are being use in

the home as these vary the water flow to

the shower unit. Do not under any

circumstances cover the showerhead

or prevent or restrict water leaving the

showerhead or unit. It is important to keep

the showerhead clean, removing all lime

scale and any other dirt blocking the

holes of the showerhead. The showerhead

must be cleaned as described in section

5 ‘looking after your shower’.

SECTION 7

Maintenance

Disconnect from mains electricity supply

before removing front cover.

All maintenance should only be carried

out by a qualified service engineer.

LOOKING AFTER YOUR SHOWER / TROUBLESHOOTING / MAINTENANCE TROUBLESHOOTING

SYMPTOM

No hot water

Power indicator is

not lit

Water too hot

Water too cool or cold

Water flow is poor

Water continues to

drip from the handset

when switched off.

Pressure relief device

has operated

(water ejecting from

Pressure Relief tube).

POSSIBLE CAUSE

Power setting is at Cold.

Low Water Pressure.

The thermal cut-out

has operated.

The power setting is on cold.

Water pressure below minimum required.

Not enough water flowing through the

shower.

Blockage in supply.

Increase in ambient water

temperature.

Wate r flow too high.

Water pressure below minimum

required (See rating label).

Reduction in ambient water

temperature.

Shower head is blocked

The temperature control knob is

set at its hottest setting.

Water is draining from the shower unit,

after use.

Blocked spray head.

Twisted/blocked flexible shower hose.

ACTION

Select a heat setting

The water supply has dropped below the

minimum operating pressure. Switch off other

cold water devices and retry.

Clean the showerhead, and restart the shower.

If no hot water is produced call the Dimplex

Service Centre.

Select a heat setting and the indicator should

light.

Check if water mains stop valve is fully open.

Increase flow rate via temperature control.

Blocked spray head - clean or replace blocked

spray plate in spray head.

Check if stop valves are fully open. Check for

blockage in inlet filter.

Re-adjust flow rate to give increased flow.

Select ‘Low’ power.

Reduce flow rate via temperature control.

Select ‘High’ power.

Clean the showerhead. Ensure showerhead is as

specified by manufactured.

Increase the power setting by selecting hot and

increase the flow using the temperature control

knob.

This is normal, no action required. Should

water continue to drip after a few minutes

contact Dimplex Service Centre.

Remove handset and run water through the

shower and hose to remove any dirt that may

be trapped in the system. Clean or, if possible,

replace the spray plate in the spray head and

then fit a new Pressure Relief Device.

Check the hose is not restricted anywhere along

its length. Replace the hose if necessary and fit

a new Pressure Relief Device.

10 11

Dimp13292-Shower inst aX4 5/5/04 2:08 pm Page 11

Loading...

Loading...