Dimplex SCxn175si, SCxn215sd, SCxn215si, SCxn255si, SCxn305si Installation And Operating Instructions Manual

...Page 1

Page 1 of 28

ST0109 – C 05/09

WATER

Unvented hot water cylinder – SCxn…d/i, SCxn…sd/si

Installation and operating instructions

Page 2

Unvented hot water cylinder – SCxn…d/i, SCxn…sd/si

Page 2 of 28

ST0109 – C 05/09

WATER

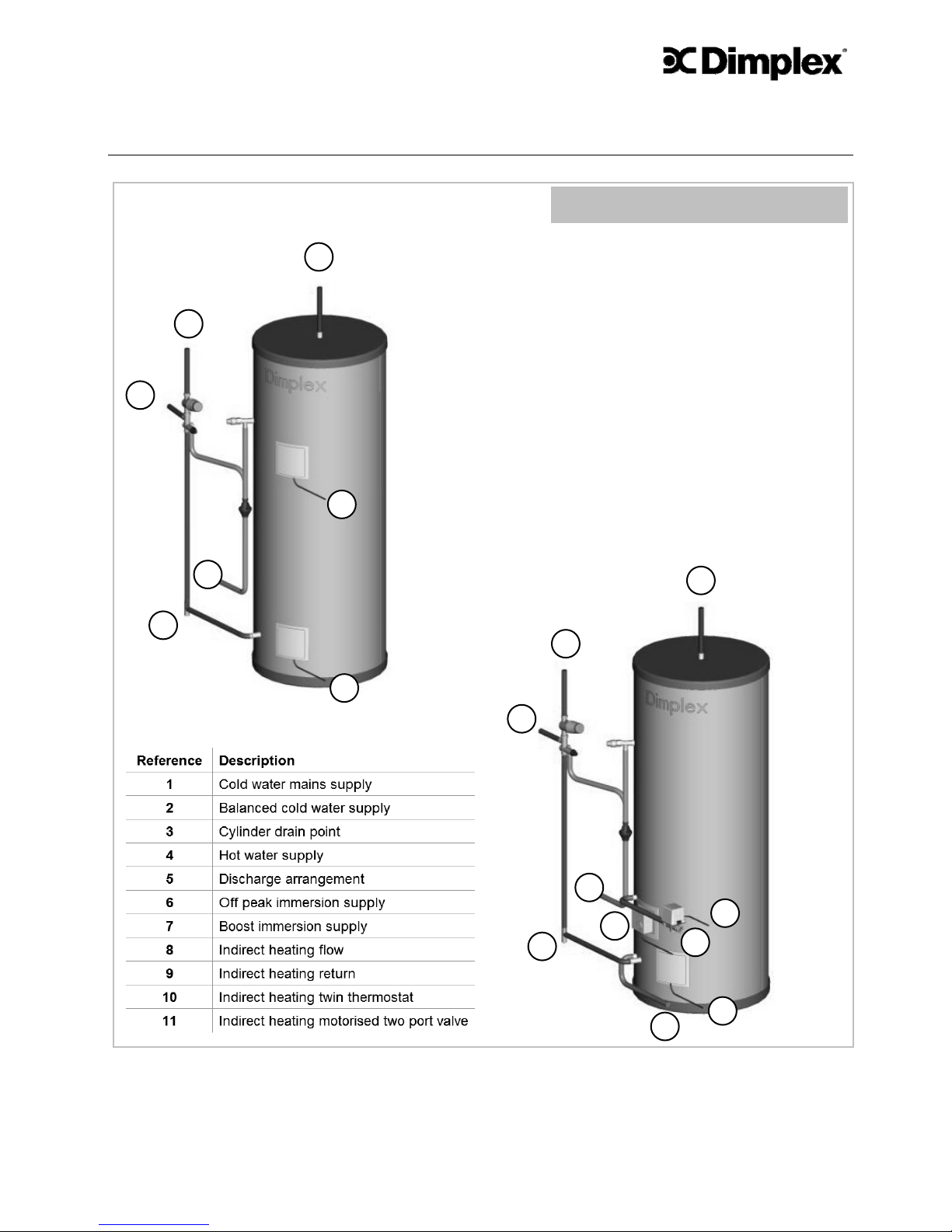

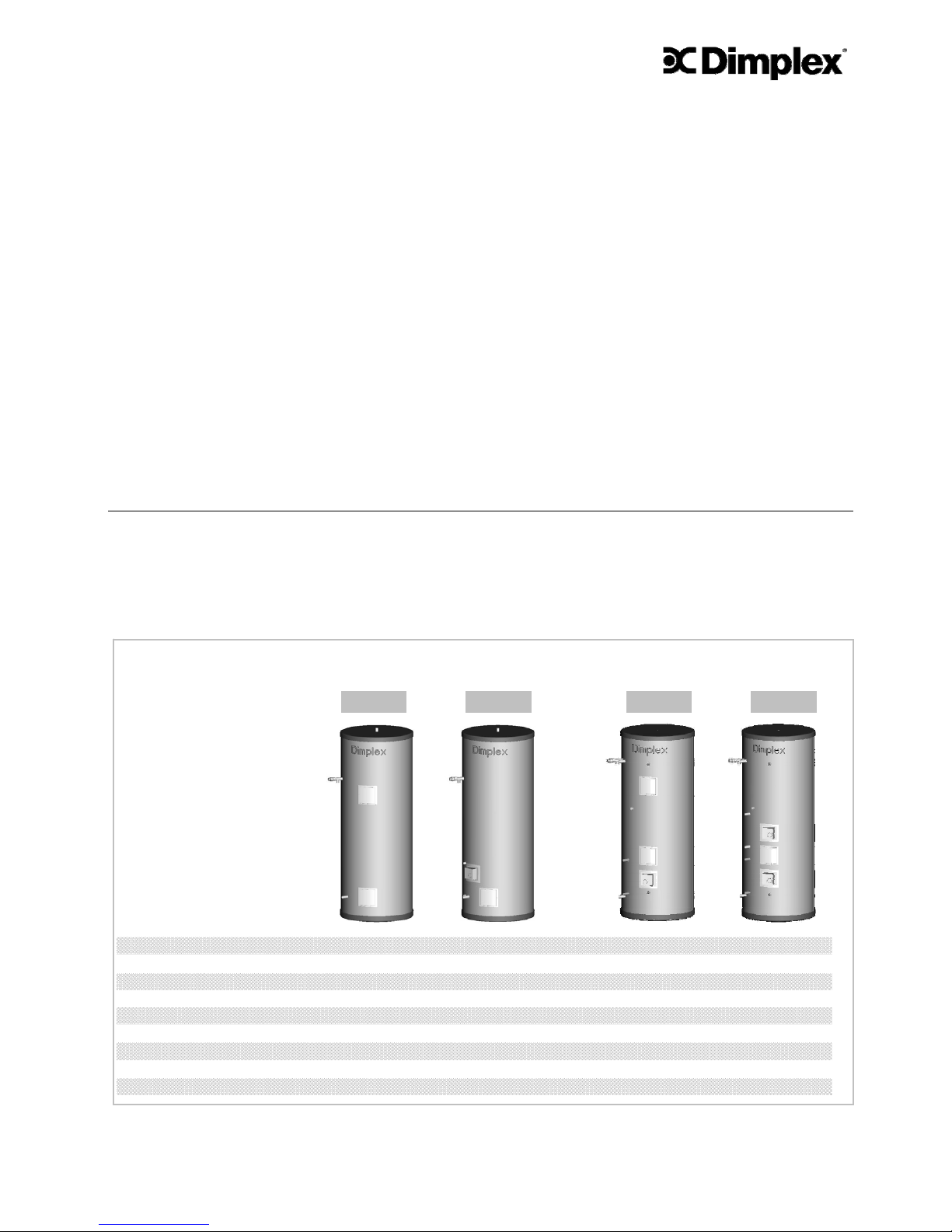

0 Overall view

Figure 1 – Overall view of proposed installation sequence SCxn…d/i

SCxn80/130/150/175/215/255/305d

01

02

03

04

05

06

07

SCxn80/130/150/175/215/255/305i

11

08

Standard SCxn cylinder

01

02

03

04

05

07

09

10

Page 3

Unvented hot water cylinder – SCxn…d/i, SCxn…sd/si

Page 3 of 28

ST0109 – C 05/09

WATER

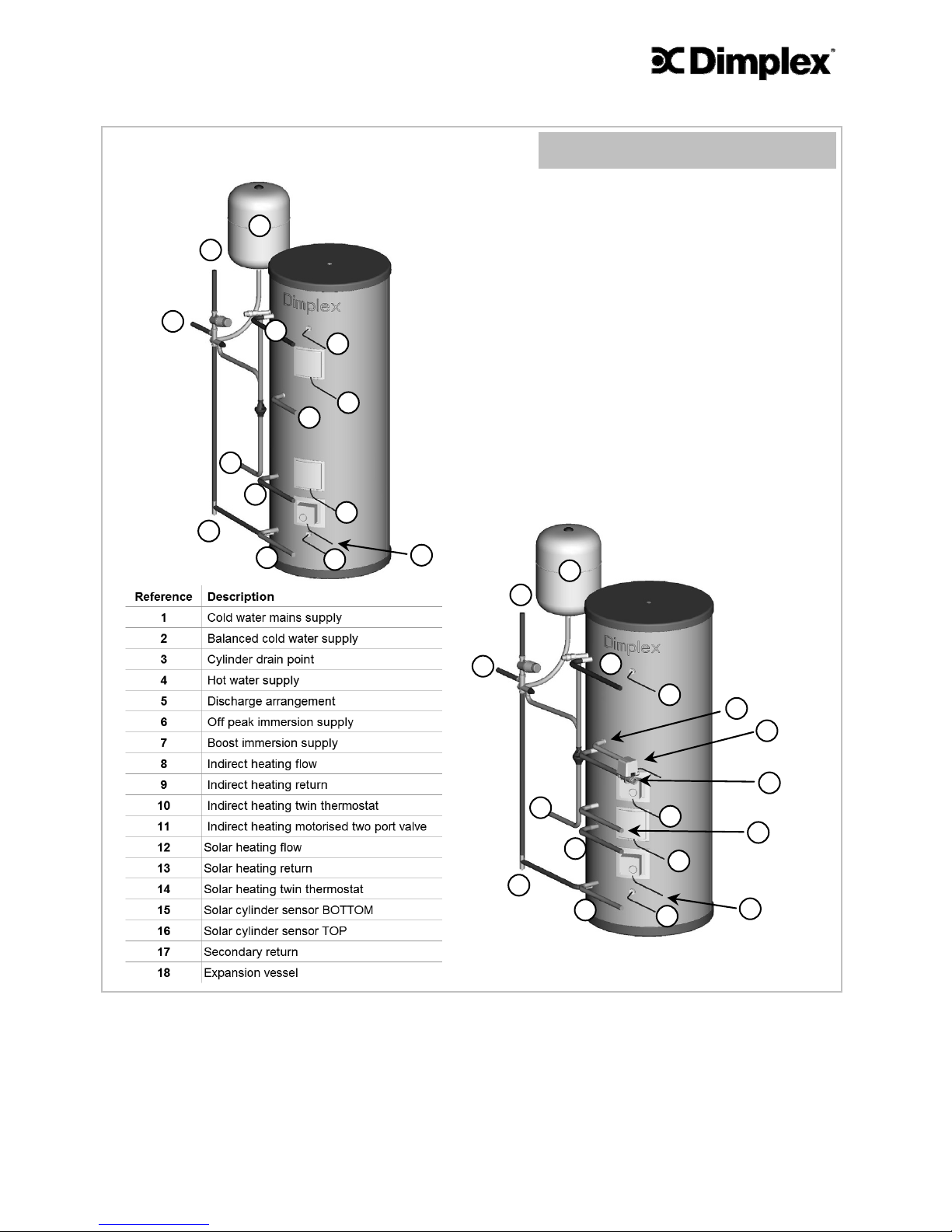

Figure 2 – Overall view of proposed installation sequence SCxn…sd/si

SCxn175/215/255/305sd

SCxn175/215/255/305si

18

01 02 03 04 05 07 08 09 10 11 12 13 14 15 16 17 18 01 02 03 04 05 07 12 13 14 15 16 17 06

Solar SCxn cylinder

Page 4

Unvented hot water cylinder – SCxn…d/i, SCxn…sd/si

Page 4 of 28

ST0109 – C 05/09

WATER

1 Contents

0 OVERALL VIEW 2

1 CONTENTS 4

2 BEFORE YOU START 5

G

ENERAL 5

C

OMPETENCE 5

H

EALTH AND SAFETY 5

R

ISK ASSESSMENT 6

3 SCOPE OF DELIVERY 6

4 PRODUCT FEATURES AND DESCRIPTIONS 7

5 INSTALLATION 9

5.1

GENERAL ADVICE 9

5.2

SITING CONSIDERATIONS 10

5.3

COLD WATER SUPPLY AND DISCHARGE PIPE WORK 10

5.4

HOT WATER OUTLET 12

5.5

IMMERSION HEATER 12

5.6

INDIRECT HEATING LOOP 13

5.7

SOLAR LOOP 14

5.8

SECONDARY RETURN 15

5.10

INSTALLATION EXPANSION VESSEL 15

5.11

WIRING SCHEMATIC AUXILIARY LOOP 16

5.12

WIRING SCHEMATIC SOLAR LOOP 19

5.13

SOLAR SENSOR INSTALLATION 19

6 COMMISSIONING 21

6.1

SCXN … D/I RANGE 21

6.2

SCXN … SD/SI RANGE 21

7 OPERATION 22

7.1

WATER TEMPERATURE DIRECT ELECTRIC HEATING 22

7.2

WATER TEMPERATURE AUXILIARY HEATING 23

8 MAINTENANCE 23

9 TROUBLESHOOTING 24

10 TECHNICAL DATA 25

10.1

SCXN … D/I 25

10.2

SCXN … SD/SI 26

Page 5

Unvented hot water cylinder – SCxn…d/i, SCxn…sd/si

Page 5 of 28

ST0109 – C 05/09

WATER

2 Before you start

General

Thank you for choosing a Dimplex product. We ensure you that every effort was made

at design, manufacture and delivery stages of this product to meet your expectations.

We ensure you of our best possible support throughout the product’s lifespan.

As part of ongoing product development and improvement Dimplex reserves the right to

undertake changes to the product without prior notice. Great care has been taken to

ensure this manual was correct at the time of print. Should you however discover any

issues with the information contained therein please do not hesitate to contact your

vendor.

We strongly recommend you read the whole contents of this manual before commencing the work.

Competence

Dimplex products have been designed and manufactured to the current relevant standards and under stringent quality control. It is therefore imperative that the product is

only installed by a:

- trained and

- competent

person as defined in the relevant regulations. Dimplex does not accept any liability for

damage done to persons or property resulting from undue handling and usage of this

product.

All regulations current at the time of installation are to be considered alongside the content of this manual as they form the code of best practice.

The guarantee of this product is linked to the ability of proving that the product was

installed, commissioned and maintained:

- by a competent person

- in accordance with Dimplex instructions and the current relevant regulations and legislation

- the product being registered with Dimplex at the time of installation using the form in

the Dimplex On Site Guide

- records showing the date of maintenance in accordance with the maintenance schedule as detailed in the On Site Guide

Health and Safety

The installation of this product is subject to the Health and Safety at Work Act. It is

your responsibility to ensure that the transport, storage, installation and operation of

the product is carried out in a safe manner.

Dimplex will not accept any liability due to damage caused to people or property resulting from negligence or not adhering to the relevant Health and Safety practises.

Page 6

Unvented hot water cylinder – SCxn…d/i, SCxn…sd/si

Page 6 of 28

ST0109 – C 05/09

WATER

Risk assessment

The compilation of a risk assessment is strongly recommended before installing the

product. The following areas require particular consideration in addition to the information required by the Health and Safety at Work Act.

- scalding: where appropriate or required by law a thermostatic mixing valve is to be

fitted to the hot water outlet of the cylinder

- explosion: the unit is fully equipped with all relevant safety equipment to comply with

current regulations. The correct design and function has been verified by independent

third party testing. The correct application thereof is the responsibility of the competent installer.

- water borne organisms (i.e. Legionella): if applicable a risk assessment should be

carried out following the recommendations outlined in the Approved Code of Practise

L8.

- the user preference must be considered when commissioning the system, in particular

when adjusting the solar and auxiliary system temperature and timer settings.

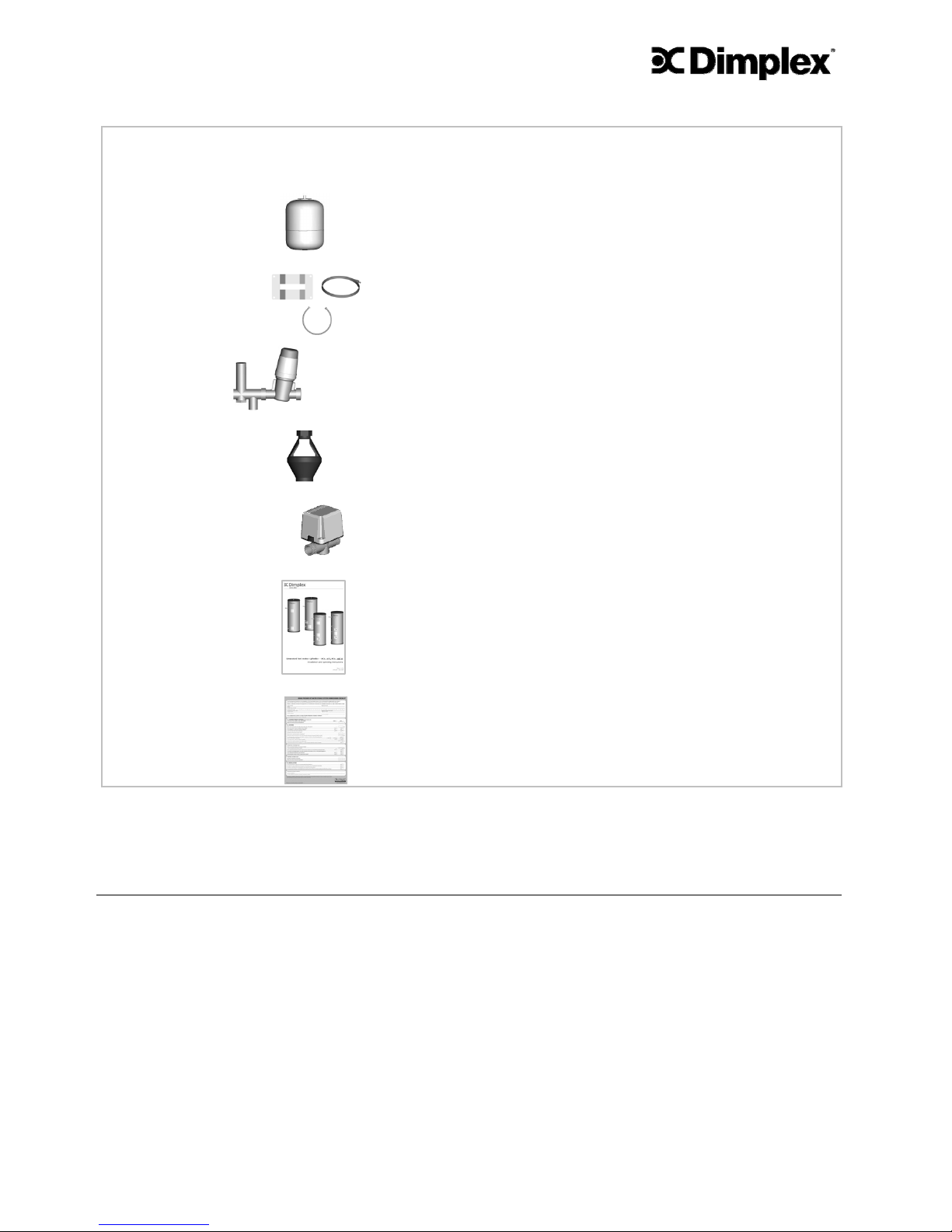

3 Scope of delivery

Please check the contents and condition of your delivery before signing the delivery

documentation. Contact your supplier immediately for any missing or damaged components. Claims for missing or damaged parts after signing for the delivery will not be

accepted.

SCxn

175/215/255/305

SCxn

80/150/175/215/255/305

d i sd si

Unvented stainless steel

cylinder including:

- cold water inlet

- hot water outlet

- ½” sensor pockets

- ½” secondary return

- auxiliary heating coil

- solar coil

- twin thermostat

- 3kW immersion

- T&P Valve

x1

x1

-

-

-

-

-

x1(SCxn80)/x2

x1

x1

x1

-

-

x1

-

x1

x1 x1

x1

x1 x2 x1

-

x1

x1 x2 x1

x1

x1 x2 x1 x1 x1 x2 x1 x1

Page 7

Unvented hot water cylinder – SCxn…d/i, SCxn…sd/si

Page 7 of 28

ST0109 – C 05/09

WATER

Figure 3 – Scope of delivery

4 Product features and descriptions

The Dimplex® unvented stainless steel cylinder range incorporates many features to

ensure the highest level of comfort in providing hot water while minimising energy requirements and environmental impact during manufacturing, operation and disposal.

The range covers storage volumes from 80 litres to 305 litres in various designs from

direct electric heated units, indirect units to a range of units allowing the use of renewable energy sources such as solar thermal.

A complete list of features provided by the whole range of cylinders is given in Figure 4.

Expansion vessel:

18 l: 175 l, 215 l

24 l: 255 l, 305 l

-

-

-

-

x1

x1

Expansion vessel

fixing kit

-

- x1

x1

Inlet control

group

2ba

r

6bar

2ba

r

6bar

3ba

r

6bar

3ba

r

6bar

Tundish

15mm – 22mm

x1

x1 x1 x1

Two port motorised valve 22mm

-

x1 - x1

Instructions x1

x1 x1 x1

Benchmark card x1

x1 x1 x1

SCxn…d

SCxn…i

SCxn…sd

SCxn…si

Pres. red.

Pres. rel.

Page 8

Unvented hot water cylinder – SCxn…d/i, SCxn…sd/si

Page 8 of 28

ST0109 – C 05/09

WATER

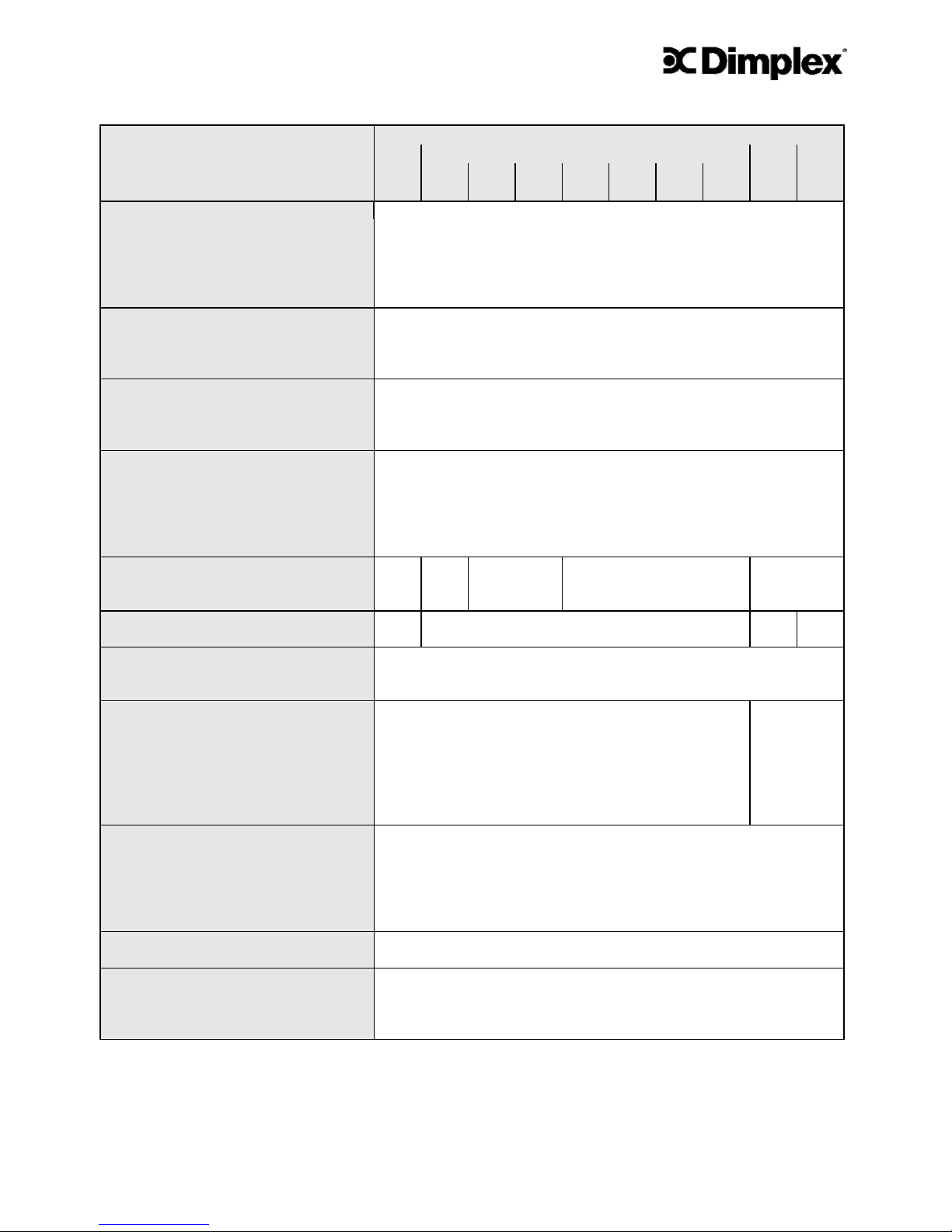

Feature

SCxn

d i si

sd

80

-

305

80 130 150 175 215 255 305

175

-

305

175

-

305

Materials

- inner cylinder

- outer cylinder

- inlet/outlet

- coils

- insulation

Duplex stainless steel

Dove grey leather grain coated steel

Stainless steel

Corrugated stainless steel

60mm PU foam (GWP=1, ODP=0)

Maximum operating conditions

- potable water temperature

- heating water temperature

- operating pressure

70°C

95°C

6bar

Cold water supply

- minimum dynamic pressure

- maximum pressure

- minimum flow rate

1.5bar

25bar

15 l/min

Connections

- cold water inlet

- hot water outlet

- secondary return

- coil flow and return

- sensor pocket

22mm stainless steel

22mm stainless steel

½”F BSP

22mm stainless steel

½”F BSP

Coil specification

- surface area [m²]

- rating [kW]

-

-

0.3

7

0.5

14

0.75

17

0.75/1.1

17/-

Immersion heater 1/

2

1 1 2

Thermostatic control

- direct input

- indirect input

- integral immersion heater thermostat and cut out

- external twin thermostat and cut out

Safety components

- pressure reducing valve and

strainer

- expansion relief valve

- temperature and pressure relief

valve

- factory pressure test

2bar

6bar

7bar / 90°C

10bar

3bar

6bar

7bar /

90°C

10bar

Other features Water inlet diffuser – prevents cold and hot water from mix-

ing

Water outlet sloped – improves stratification during draw off

and reduces heat loss

Light weight – easy handling

No anode – reduced service requirements

Approvals KIWA

BBA

Guarantee

- inner cylinder

- immersion heaters

- other components

25 years

2 years – excluding the effects of lime scale

5 years – excluding expansion vessel membrane pressure

Figure 4 – Product features

Page 9

Unvented hot water cylinder – SCxn…d/i, SCxn…sd/si

Page 9 of 28

ST0109 – C 05/09

WATER

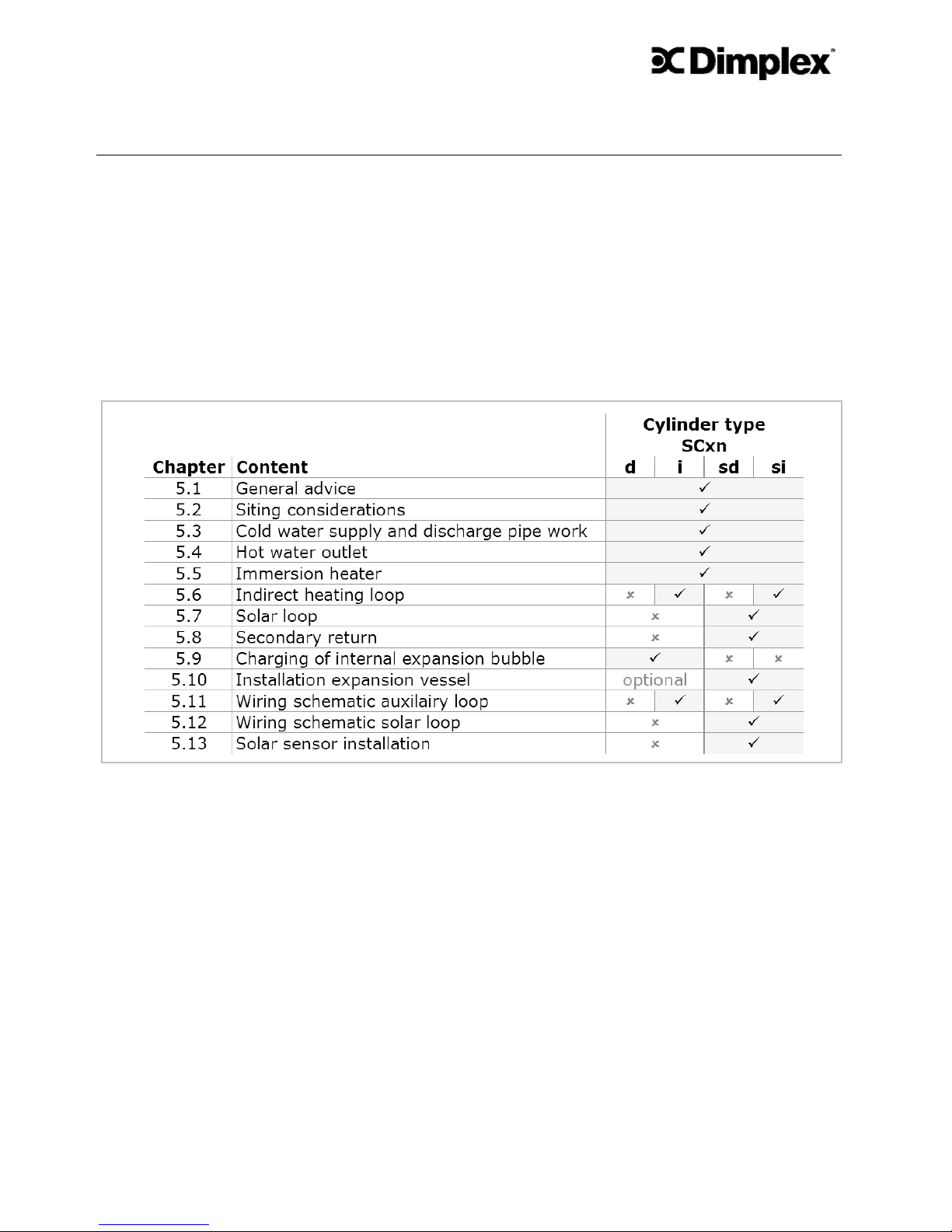

5 Installation

5.1 General advice

Please read the following section carefully before commencing installation. If in any

doubt, please call the appropriate help desk. Disregarding the instructions given in this

manual in its entirety and any relevant regulations, standards and codes of practice will

void the guarantee of this product.

Please note: the following instructions are structured in such a way that individual steps

are described. Not all steps will apply to all products. Figure 5 shows which steps apply

to which cylinder types.

Figure 5 – Chapter reference

Handling – depending on the size of the unit and access to its installation location consideration must be given to the handling of the unit. Please note that handling, installation and use of this product is subject to the Health and Safety at Work Act.

If the unit is not installed immediately, it should remain in its protective packaging with

all pipe protectors/end caps applied to prevent damage and dirt deposit inside the cylinder and the coils.

Pipe work – the pipe runs should be executed as short as possible, unused pipe work

should be removed and all remaining pipe work should be lagged in accordance with

regulatory requirements to prevent heat loss and the formation of condensation.

Taps and fittings – all taps and fittings incorporated in the unvented system should

have a rated operating pressure of 6 bar or above.

Page 10

Unvented hot water cylinder – SCxn…d/i, SCxn…sd/si

Page 10 of 28

ST0109 – C 05/09

WATER

5.2 Siting considerations

When choosing a suitable location for the cylinder the following aspects should be considered:

- structural integrity

- access for installation, operation, maintenance and replacement

- routing of discharge pipe work

- access to water mains supply, hot and cold water distribution pipe work

- access to suitable electricity supply

- location in relation to remaining system components such as auxiliary and solar heating system

- frost protection

The Dimplex SCxn cylinder range is designed to be floor standing, vertically mounted,

indoors and in a frost free environment. The cylinder may be located on any flat and

level surface, provided it is sufficiently robust to support the weight of the cylinder

when full of water (see chapter 10).

The position and orientation of the cylinder should be such that easy access is provided

for servicing the controls and replacing the immersion heater should the need arise.

Ensure that no pipe work hinders any work to be carried out on the various cylinder

components.

Particular care must be taken when placing the cylinder in a garage or outbuilding. All

exposed pipe work must be correctly insulated to avoid frost damage. If required the

occurrence of frost has to be avoided by means of heating the space in which the cylinder is located.

5.3 Cold water supply and discharge pipe work

The required operating conditions of the Dimplex SCxn cylinder range are summarised

in Figure 4. The following instructions have to be followed when installing the cold water

mains supply to the cylinder.

1 The cold water supply to the cylinder must come directly from the cold water mains

after the mains stop valve to the property.

2 The inlet group supplied with the cylinder contains a line strainer, pressure reducing

valve, pressure relief valve, check valves, balanced cold water supply port and a

connection point for the expansion vessel (required for SCxn solar only).

3 The cold water inlet pipe work should have at least an inside diameter of 19mm and

meeting the requirements of the water regulations for the supply of wholesome water.

4 The discharge pipe work from the expansion relief valve must be installed constantly

falling to an open point of discharge. It is recommended to combine it with the discharge of the temperature and pressure relief valve as illustrated in Figure 6.

When completing the installation of the discharge pipe work ensure the valve itself is

secured by tightening the screw on the side of the assembly. Loosening the screw

allows the best possible orientation of the valve.

Page 11

Unvented hot water cylinder – SCxn…d/i, SCxn…sd/si

Page 11 of 28

ST0109 – C 05/09

WATER

5 It is recommended to install a drain valve in the lowest point of the cold water feed

to the cylinder. This allows the cylinder to be drained in a controlled manner should

this become necessary.

Note: Between the inlet group and the cold water inlet on the cylinder NO

isolating

device should be fitted as by doing so important safety devices could be isolated!

6 The temperature and pressure relief valve must be discharged into the tundish. The

sizing of the discharge pipe work is regulated through building regulation G3. An extract is shown in Figure 6.

01

02 03 04 05

Discharge pipe constantly

falling to safe discharge

location.

max. 500mm

06

min. 300mm

Page 12

Unvented hot water cylinder – SCxn…d/i, SCxn…sd/si

Page 12 of 28

ST0109 – C 05/09

WATER

Figure 6 – Cold water supply and discharge pipe work installation

5.4 Hot water outlet

The hot water pipe work is to be directly connected to the how water outlet connections

of the cylinder as indicated in Figures 1 and 2.

Should a thermostatic mixing valve be required the valve is to be installed following the

manufacturers instructions. When fitting the thermostatic mixing valve ensure that

none of the safety relevant devices of the unit can be isolated (see 5.3).

It is recommended to insulate the hot water pipe work from the cylinder to the outlets

to reduce the energy requirements for providing hot water.

5.5 Immersion heater

The immersion heater has to be connected in accordance with IEE Wiring Regulations

and the installer carrying out the work has to be suitably qualified. It must be connected through a double pole isolating switch or suitable controller which must have a

contact separation of at least 3mm in all poles. The wiring diagram for the immersion

heater is shown in Figure 7. For further details please see instructions provided with

immersion heater.

The immersion heater incorporates an independent non-self resetting over temperature

cut-out. Should the over temperature cut-out operate, the rest pin will be pushed upwards, and become level or slightly proud of the cover at the position marked “Safety”.

Use a suitable sized implement to reset the pin by pushing it hard into its original position.

Figure 7 – Wiring diagram immersion heater

Page 13

Unvented hot water cylinder – SCxn…d/i, SCxn…sd/si

Page 13 of 28

ST0109 – C 05/09

WATER

Note: The cylinder must be filled with water before switching on the immersion

heater. Failure to do so will damage the element and void any guarantee on the

product.

5.6 Indirect heating loop

The indirect heating source can be connected to the cylinder in various ways as described by the chosen control system supplier. The wiring and installation principles for

two typical integration methods are detailed in chapter 5.11.

Figure 8 – indirect heating loop installation

To conform with building regulations it is imperative that the motorised two port valve

is installed in the indirect heating loop and connected into the control circuit as required.

08

SCxn…i

SCxn…si

09

11 10 08 09 11 10

Page 14

Unvented hot water cylinder – SCxn…d/i, SCxn…sd/si

Page 14 of 28

ST0109 – C 05/09

WATER

The port connections for the indirect heating flow and return are identified in Figure 1

for the SCxn…i range and in Figure 2 for the SCxn…si range.

Should the flow connection be the highest point in the indirect heating loop an adequate

device for de-aeration has to be installed. Equally, should the return connection be the

lowest point in the indirect heating loop, a suitable drain device should be installed in

the lowest point.

When installing the motorised two port valve ensure the direction of flow is adhered to

as marked on the body of the device. Connecting the control loop ensure the correct

thermostat on the cylinder is chosen for the respective loop.

The fittings used to connect to the cylinder must be suitable for stainless steel. Not all

push fit fittings can be used – please check with your supplier. Should compression fittings be used ensure that the connection is not being over-tightened, always countering

the force with a second spanner.

5.7 Solar loop

The solar loop has to be completely installed:

- in metal pipe work

- insulated with high temperature insulation

- connected with compression fittings only (or other means which are suitable for solar)

Figure 9 – Solar loop installation

13

SCxn…sd / SCxn…si

12

14

Page 15

Unvented hot water cylinder – SCxn…d/i, SCxn…sd/si

Page 15 of 28

ST0109 – C 05/09

WATER

The wiring schematic for the solar loop is detailed in chapter 5.12. Please note: the solar loop does not require a motorised two port valve as long as:

- the Dimplex SOLPU1/2 pump unit is being used (non return valves in flow and return)

- the cylinder is located lower than the solar panels

- all other connection requirements in this manual are being adhered to

To conform with building regulations it is imperative that the solar circulation pump is

installed in the solar loop through the twin thermostat and not directly from the solar

control unit.

The port connections for the solar flow and return connections are identified in Figure 2

for the SCxn…sd and the SCxn…si range.

Should the flow connection be the highest point in the solar loop an adequate device for

de-aeration has to be installed should the system not be commissioned using a flush a

fill pump. Equally, should the return connection be the lowest point in the solar loop, a

suitable drain device should be installed in the lowest point.

5.8 Secondary return

A ½” boss is provided on the SCxn…sd/si cylinder range to connect a secondary return

loop to avoid:

- stagnant water in long pipe runs

- long waiting times at draw off point for hot water

- undue water wastage

To minimise the energy consumption of the secondary return circuit and to ensure reliable operation it is important to consider:

- the control of the circulation pump to be time and temperature controlled

- the secondary return circuit pipe work to be insulated

- the secondary return pump to be of suitable material

The location of the secondary return connection on the cylinder is highlighted in Figure

2.

5.10 Installation expansion vessel

Optional for standard SCxn d/i cylinders, mandatory for solar SCxn d/I cylinders.

The expansion vessel can be connected directly to the cold water inlet group utilising

the flexible hose supplied with the vessel. It is important not to install any isolating devices between the vessel and the cold water inlet group.

Further it is recommended to mount the vessel higher than the cylinder to avoid having

to drain the cylinder when maintaining and replacing the expansion vessel. The connection of the expansion vessel to the inlet group is shown in Figure 10.

Page 16

Unvented hot water cylinder – SCxn…d/i, SCxn…sd/si

Page 16 of 28

ST0109 – C 05/09

WATER

Figure 10 – Installation expansion vessel

(optional for standard SCxn d/i cylinders, mandatory for solar SCxn d/I cylinders)

It is important to check the pre-charge pressure of the expansion vessel membrane before filling the cylinder. The pre-charge should be >2bar.

5.11 Wiring schematic auxiliary loop

The auxiliary heating system can be interfaced with the Dimplex SCxn cylinder in various. Two common examples are given in Figures 11 and 12.

Before adapting one of the proposed systems ensure the system is compatible

with the remaining control equipment installed in the system.

Page 17

Unvented hot water cylinder – SCxn…d/i, SCxn…sd/si

Page 17 of 28

ST0109 – C 05/09

WATER

Figure 11 – Auxiliary loop integration 2x motorised two port valve

Page 18

Unvented hot water cylinder – SCxn…d/i, SCxn…sd/si

Page 18 of 28

ST0109 – C 05/09

WATER

Figure 12 - Auxiliary loop integration 1x motorised two port valve and mid-position valve

Page 19

Unvented hot water cylinder – SCxn…d/i, SCxn…sd/si

Page 19 of 28

ST0109 – C 05/09

WATER

5.12 Wiring schematic solar loop

The integration of the Dimplex solar SCxn cylinder is shown in Figures 11 and 12. The

wiring schematic for the solar loop is shown in Figure 13.

Figure 13 – Solar loop integration

5.13 Solar sensor installation

The Dimplex solar SCxn range cylinders allow for the installation of two sensors. The

lower sensor is required to control the solar circulation pump. The upper sensor is for

information only to indicate the actual available hot water temperature.

Two ½” sensor pockets are supplied with the pump unit. The sensor pockets are to be

used to install the sensors in the cylinders.

The location of the sensor bosses is indicated in Figure 14, also showing the methodology of installing the sensor into the sensor pocket. A suitable sealant is to be used such

as Loctite 577.

Page 20

Unvented hot water cylinder – SCxn…d/i, SCxn…sd/si

Page 20 of 28

ST0109 – C 05/09

WATER

Figure 14 – Solar sensor boss positions and sensor installation

01

02 03

Page 21

Unvented hot water cylinder – SCxn…d/i, SCxn…sd/si

Page 21 of 28

ST0109 – C 05/09

WATER

6 Commissioning

The following commissioning procedure only details the required steps to be taken for

the potable water loop and not for the direct heating, auxiliary or solar loops. Please

refer to relevant manuals for these operations.

6.1 SCxn … d/i range

1 Check all connections and joints to ensure they have been tightened and se-

cured correctly.

2 Before turning on the mains supply to the cylinder a hot water tap should be

opened, preferable on the same floor or the floor below where the cylinder is

located.

3 Turn on the supply to the cylinder and fill until water runs from the open hot

water tap.

4 Turn off the mains supply to the cylinder and wait for the water to stop run-

ning from the hot water tap.

5 Operate the temperature and pressure relief valve until water stops flowing.

6 Close the hot water tap and temperature and pressure relief valve.

7 Connect an air pump to the Schrader valve (valve with blue cap) located on

the pressure reducing valve (inlet group).

8 Pump air into the Schrader valve until a pressure of 1 bar is reached.

9 Remove the pump and replace the blue cap.

10 Turn the mains supply back on and bring the cylinder up to working pressure.

11 Check all joints for leaks, even those not having been altered especially when

replacing a vented cylinder.

12 Open temperature and pressure relief valve to ensure proper discharge and

check after closing that valve is not dripping.

13 Open pressure relief valve to ensure proper discharge and check after closing

that valve is not dripping.

14 Check all shower outlets, toilet cisterns and other draw off points for leaks or

dripping (especially when replacing a vented unit).

15 Open all water outlets to purge air from pipe work and ensure proper opera-

tion.

16 Adjust timer programmer and cylinder thermostat settings in accordance with

client requirements.

17 Instruct user in the operation of the unit and hand over manuals and bench-

mark card, advising the owner of annual service requirement.

6.2 SCxn … sd/si range

1 Check all connections and joints to ensure they have been tightened and se-

cured correctly.

2 Before turning on the mains supply to the cylinder a hot water tap should be

opened, preferable on the same floor or the floor below where the cylinder is

located.

3 Check the pre-charge in the expansion vessel and ensure it is at least 2bar.

Note actual pressure on label on expansion vessel.

Page 22

Unvented hot water cylinder – SCxn…d/i, SCxn…sd/si

Page 22 of 28

ST0109 – C 05/09

WATER

4 Turn on the supply to the cylinder and fill until water runs from the open hot

water tap.

5 Close the hot water tap.

6 Check all joints for leaks, even those not having been altered especially when

replacing a vented cylinder.

7 Open temperature and pressure relief valve to ensure proper discharge and

check after closing that valve is not dripping.

8 Open pressure relief valve to ensure proper discharge and check after closing

that valve is not dripping.

9 Check all shower outlets, toiler cisterns and other draw off points for leaks or

dripping (especially when replacing a vented unit).

10 Open all water outlets to purge air from pipe work and ensure proper opera-

tion.

11 Adjust timer programmer and cylinder thermostat settings in accordance with

client requirements.

12 Instruct user in the operation of the unit and hand over manuals and bench-

mark card, advising the owner of annual service requirement.

7 Operation

Once the system has been fully commissioned, no user interference should be required

to fully enjoy the comfort and benefits of the Dimplex SCxn hot water cylinder.

The hot water temperature can be set to various requirements. Ideally it should be

around 60°C. Higher temperature can cause tripping of the high limit thermostat, introduces more heat loss from the unit and increases the risk of scalding significantly.

When turning on a hot tap for the first time after a heat up period there might be a

short surge of water. This is normal in unvented systems and does not constitute a fault.

Sometimes the water may appear milky – this is due to very fine air bubbles in the water which will clear quickly.

7.1 Water temperature direct electric heating

Before removing the cover from immersion heater isolate appliance on isolating

switch! Danger of electrical shock! Never enter immersion heater housing with

blank metal objects!

Figure 15 – Adjustment water temperature direct electric heating element

Dial to adjust water temperature.

Page 23

Unvented hot water cylinder – SCxn…d/i, SCxn…sd/si

Page 23 of 28

ST0109 – C 05/09

WATER

The hot water temperature achieved by the direct electric heating element can be adjusted by removing the cover from the immersion heater and adjusting the dial up or

down as indicated in Figure 15.

7.2 Water temperature auxiliary heating

The water temperature achieved by the auxiliary heating system depends on the setting

of the thermostat on:

- the cylinder AND

- the auxiliary heating source.

The adjustment at the cylinder is being carried out on the twin thermostat fitted to the

cylinder as shown in Figure 16. The manual high limit re-set is behind the black screw.

Figure 16 – Adjustment water temperature auxiliary source

8 Maintenance

The maintenance of this appliance must be carried out by a suitably qualified

person only.

Isolate all electrical supplies from the unit before commencing work. Danger of

electrical shock!

1 Draw some water from cold water tap and retain in container.

2 Isolate cold water mains supply from cylinder.

3 Briefly open temperature and pressure relief valve, assure safe discharge and

check that valve is not dripping when closed.

4 Briefly open pressure relief valve, assure safe discharge and check that valve

is not dripping when closed.

5 Open hot water tap and release remaining pressure from unit.

6 Note the set pressure of pressure reducing valve. Remove cartridge and

clean strainer in water provided in container. Re-assemble pressure reducing

valve ensuring the correct pressure is set.

7 Periodically the immersion heaters should be removed, cleaned and the unit

flushed out. The immersion heater seal should be replaced when fitting the

element to the cylinder.

8 Check electrical wiring connections and the condition of the cable of the im-

mersion heater and the thermostat.

9 Re-commission unit.

Dial to adjust water temperature.

Page 24

Unvented hot water cylinder – SCxn…d/i, SCxn…sd/si

Page 24 of 28

ST0109 – C 05/09

WATER

9 Troubleshooting

Fault Cause Solution

A No water

from hot

water taps

A.1 Stop valve closed

A.2 Strainer blocked

A.3 Pressure reducing valve fitted

against flow

A.1 Open stop valve

A.2 Turn water supply off,

clean strainer and recommission

A.3 Re-fit with arrow showing

in direction of flow

B No hot water B.1 Timer/Programmer not set

correctly

B.2 Auxiliary heating mal function

B.3 Direct heating mal function

B.4 Auxiliary/direct heating high

limit thermostat has tripped

B.1 Set timer/programmer

correctly

B.2 Consult auxiliary heating

system instructions

B.3 Call for qualified person

to check immersion

heater

B.4 Reset limit thermostat(s)

C Intermittent

water discharge

through tundish on

warm-up

C.1 Bubble depleted

C.2 Expansion vessel lost charge

C.1 See commissioning for

creation of bubble

C.2 Check expansion vessel

(see commissioning/maintenance), top up

or replace

D Continuous

discharge

D.1 Pressure reducing valve not

working

D.2 Pressure relief or T&P valve

not seating correctly

D.3 Mal function of high limit

thermostat or appliance

D.1 Check pressure after

valve and replace if

faulty

D.2 Manually lift valve once

or twice to clear debris,

otherwise replace

D.3 Check function of ther-

mostats and appliances

E Leakage from

casing

E.1 Compression/threaded joints

not formed correctly

E.1 Re-seal joints with care

F Hot water

from cold tap

F.1 Hot pipe work being routed

adjacent to cold pipe work

F.2 Leaking seal in mixer tap

F.1 Insulate hot pipe work or

re-route

F.2 Replace seals in mixer

tap

G Metallic noise

from system

G.1 Pipe work not sufficiently

supported

G.1 Add extra pipe work fix-

ings

Page 25

Unvented hot water cylinder – SCxn…d/i, SCxn…sd/si

Page 25 of 28

ST0109 – C 05/09

WATER

10 Technical data

10.1 SCxn … d/i

SCxn

Capacity 80

130

150

175

215

255

305

Weight

[kg]

d 27

30 32 37 43 50

59

i 29

32 35 40 48 55

65

Heat loss

[kWh]

d/i 1.12 1.50 1.82 2.10 2.59 2.73 2.88

Heat up

[mns]

d 64

115

138

167

212

263

313

i 33

28 33 27 35 42

50

Re-heat

[mns]

d 53

90

104

124

153

184

220

i 23

21 24 24 30 35

42

A [mm] d/i 182

B [mm] d/i 196

C [mm] d -

570

648

753

821

1269

1526

D [mm] d/i 356

626

745

891

1116

1365

1620

E [mm] d/i 645

958

1086

1243

1485

1753

2029

F [mm] d/i 574

G [mm] i 339

380

369

H [mm] i 445

I [mm] i 182

B

F

F

A/I

D

E

G

E

A

C

D

B

H

Page 26

Unvented hot water cylinder – SCxn…d/i, SCxn…sd/si

Page 26 of 28

ST0109 – C 05/09

WATER

10.2 SCxn … sd/si

SCxn

Capacity 175

215

255

305

Weight [kg] sd

44

52 59

69 si 48

56 63

73

Heat loss [kWh] sd/si

1.78

2.19 2.31

2.51

Heat up [mns] sd

20

24 29

34 si 18

22 25

30

Re-heat [mns] sd

14

17 20

24 si 13

18 19

22

A [mm] sd/si

182

B [mm] sd/si

531/589

C [mm] sd

846

1087 1355

1631

D/N/P [mm] sd/si

1017

1259 1527

1804

E [mm] sd/si

1243

1485 1753

2029

F [mm] sd/si

574

G [mm] si

711

H [mm] si

842

I [mm] si

580

J [mm] sd/si

346

K [mm] sd/si

480

L/0 [mm] sd/si

213

M [mm] sd

803

879 1057

1196

si

774

1116 1029

1167

Aux. vol. [l] sd

90

130 170

220

si 80

120 160

210

A

K

M

D/N

E

F

O

J

B

C

P

I

G

H

Page 27

Unvented hot water cylinder – SCxn…d/i, SCxn…sd/si

Page 27 of 28

ST0109 – C 05/09

WATER

Page 28

Unvented hot water cylinder – SCxn…d/i, SCxn…sd/si

Page 28 of 28

ST0109 – C 05/09

WATER

Dimplex UK Limited

Millbrook House Grange Drive, Hedge End, Southampton SO30 2DF

Te.: 01489 773 052, Fax.: 01489 773 061

e-mail: customer.services@dimplex.co.uk

www.dimplex.co.uk

Loading...

Loading...