Page 1

Service Manual

Model

RLG20

RLG20BR

RLG20FC

RLG25

RLG25BR

RLG25FC

Part Number

6909740159

6909740400

6909740500

6909760159

6909760200

6909760300

IMPORTANT SAFETY INFORMATION: Always read this manual rst before attempting to service this log grate. For your

safety, always comply with all warnings and safety instructions contained in this manual to prevent personal injury or property damage.

7400950000R01

Page 2

TABLE OF CONTENTS

Operation ...........................................................3

RLG20, RLG20BR, RLG20FC, RLG25BR, RLG25FC .....................3

RLG25 ..........................................................4

Maintenance .........................................................5

Exploded Parts Diagrams

RLG20, RLG20BR, RLG20FC .......................................6

RLG25 ..........................................................7

RLG25BR, RLG25FC ..............................................8

Wiring Diagram ......................................................9

RLG20 ..........................................................9

RLG25 ..........................................................9

RLG20BR, RLG20FC .............................................10

RLG25BR, RLG25FC .............................................10

Back Log Replacement ...............................................11

Log Set Replacement ................................................11

Flame LED Strip and Coloured LED Strip Replacement ....................12

Back Light Assembly Replacement .....................................12

Main Control Board Replacement ......................................12

Power Supply Replacement ...........................................13

IR Key Board Replacement. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Power Cord Replacement .............................................13

Flicker Motor Replacement. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Heater Assembly Replacement ........................................14

Troubleshooting Guide ...............................................16

Always use a qualied technician or service agency to repair this log grate.

!

NOTE: Procedures and techniques that are considered important enough to emphasize.

CAUTION: Procedures and techniques which, if not carefully followed, will result in damage to the equipment.

WARNING: Procedures and techniques which, if not carefully followed, will expose the user to the risk of re, serious

injury, or death.

2 www.dimplex.com

Page 3

Operation

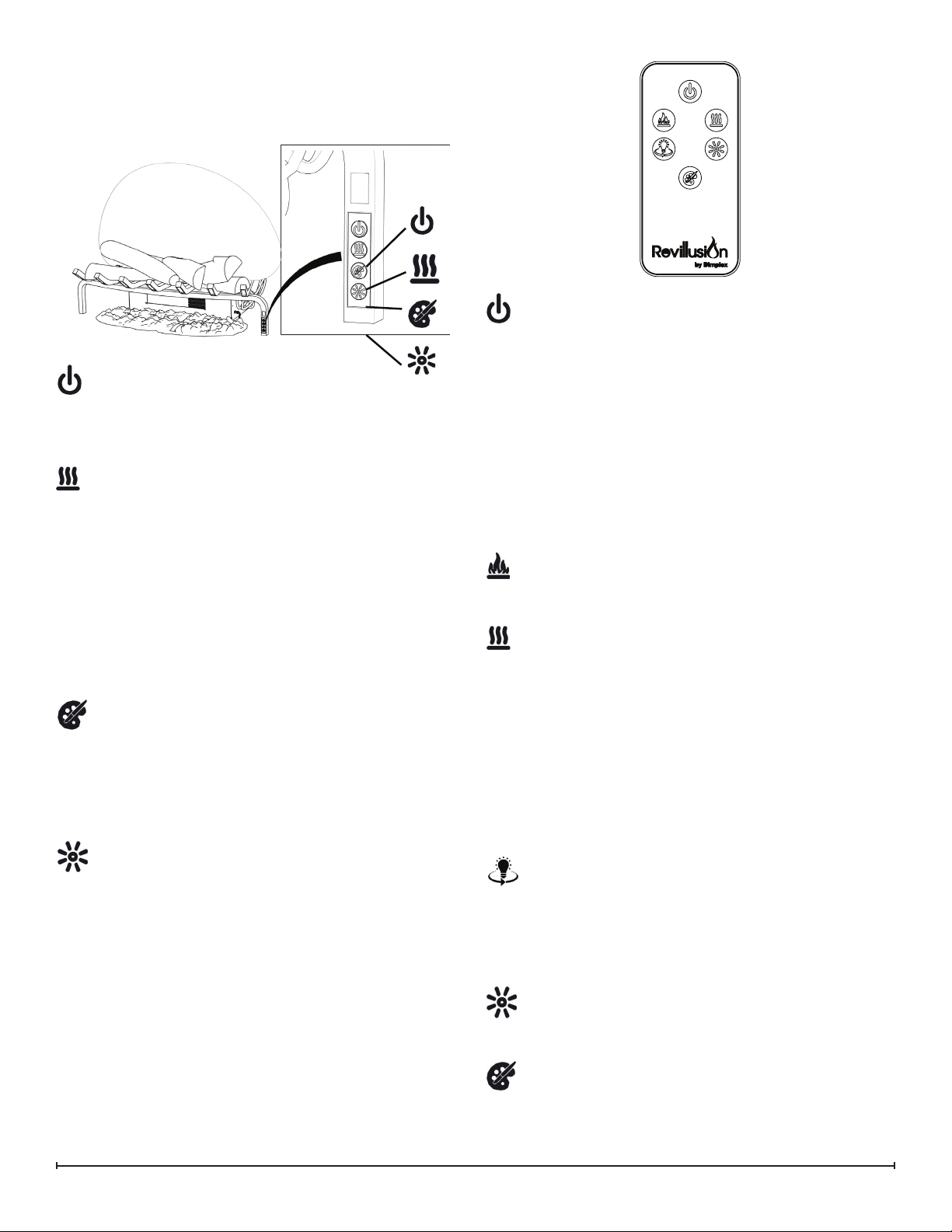

RLG20

Manual Control

The manual controls for the Revillusion are located on the

right-front leg of the log grate.

Power

Press to turn the ame eect on and activate the

previous heat setting (O, Low, or High). Press again

to put the unit in standby mode.

Heat

• Heat On

Press to set the heat to Low (indicated by 1 short

beep). Press again to set the heat to High (indicated

by 2 short beeps).

• Heat O

Press to turn heat O (indicated by 1 long beep).

NOTE: After the heater is switched o, the fan will

!

continue on for 60 seconds before turning o. The

log LEDs remain On when the heater is ON and the

ame eect is O.

360o Light

Press multiple times to change the LEDs on the

sides and back of the unit from white ickering to

white solid to O. (This feature is active only when

the ame eect is On.)

Power

Press to activate the current standby state (On/O).

• Standby State On

Press to turn everything O. Press again to active the

previous ame eect state.

• Standby State O

Press to activate the previous ame eect state.

- If the ame eect was On, the previous heat setting

will be activated (High, Low, or O).

- If the ame eect was O, the previous heat setting

will be activated (High or Low).

Press again to turn everything O.

Flame

Press to light the back log, grate log, and ember mat

(optional), and start the ame eect.

Heat

• Heat On

Press to set the heat to Low (indicated by 1 short

beep). Press again to set the heat to High (indicated

by 2 short beeps).

• Heat O

Brightness

Press multiple times to toggle the log set LEDs

through its four brightness settings.

Remote Control

The replace is supplied with a multi-function remote control.

The remote control has a range of approximately 30 ft (9

m). To operate correctly, the remote control must be pointed

toward the front of the unit.

Press to turn heat O (indicated by 1 long beep).

NOTE: After the heater is switched o, the fan will

!

continue on for 60 seconds before turning o. The log

LEDs remain On when the heater is ON and the ame

eect is O.

360o Light

Press multiple times to change the LEDs on the

sides and back of the unit from white ickering to

white solid to O. (This feature is active only when

the ame eect is On.)

Brightness

Press multiple times to toggle the log set LEDs

3

Page 4

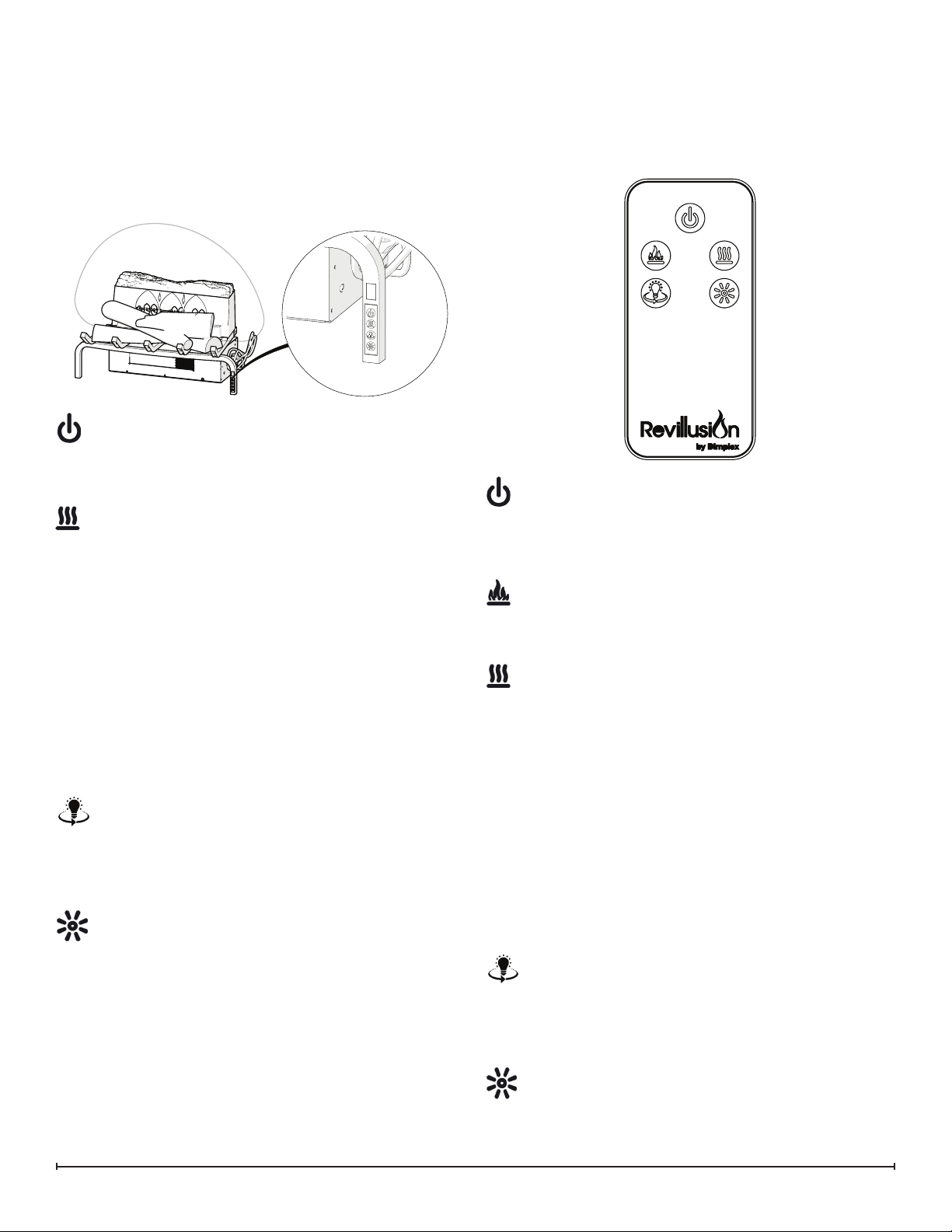

RLG25

Manual Control

The manual controls for the Revillusion are located on the

right-front leg of the log grate.

Power

Press to turn the ame eect on and activate the

previous heat setting (O, Low, or High). Press again

to put the unit in standby mode.

Heat

• Heat On

Press to set the heat to Low (indicated by 1 short

beep). Press again to set the heat to High (indicated

by 2 short beeps).

• Heat O

Press to turn heat O (indicated by 1 long beep).

NOTE: After the heater is switched o, the fan will

!

continue on for 60 seconds before turning o. The

log LEDs remain On when the heater is ON and the

ame eect is O.

Color Themes

Press multiple times to change the LED lights from:

ame base yellow, ame base blue, ame base

yellow with yellow 360 LEDs, ame base blue with

360 LEDs. (Feature is active only when the ame

eect is On.)

Brightness

Press multiple times to toggle the log set LEDs

through its four brightness settings.

Remote Control

The replace is supplied with a multi-function remote control.

The remote control has a range of approximately 30ft (9m).

To operate correctly, the remote control must be pointed

toward the front of the unit.

Power

Press to activate the current standby state (On/O).

• Standby State On

Press to turn everything O. Press again to active the

previous ame eect state.

• Standby State O

Press to activate the previous ame eect state.

- If the ame eect was On, the previous heat setting

will be activated (High, Low, or O).

- If the ame eect was O, the previous heat setting

will be activated (High or Low).

Press again to turn everything O.

Flame

Press to light the back log, grate log, and ember mat,

and start the ame eect.

Heat

Heat On

Press to set the heat to Low (indicated by 1 short

beep). Press again to set the heat to High (indicated

by 2 short beeps).

• Heat O

Press to turn heat O (indicated by 1 long beep).

NOTE: After the heater is switched o, the fan will

!

continue on for 60 seconds before turning o. The

log LEDs remain On when the heater is ON and the

ame eect is O.

360o Light

Press multiple times to change the LEDs on the

sides and back of the unit from natural yellow

ickering to yellow solid to white ickering to white

solid to O. (Feature is active only when the ame

eect is On.)

Brightness

Press multiple times to toggle the log set LEDs

through its four brightness settings.

Color Themes

Press multiple times to change the ame base colors

from Yellow to Blue to O. (Feature is active only

when the ame eect is On.)

4 www.dimplex.com

Page 5

Operation

RLG20BR, RLG20FC, RLG25BR,

RLG25FC

Manual Control

The manual controls for the Revillusion are located on the

right-front leg of the log grate.

Power

Press to turn the ame eect on and activate the

previous heat setting (O, Low, or High). Press again

to put the unit in standby mode.

Heat

• Heat On

Press to set the heat to Low (indicated by 1 short

beep). Press again to set the heat to High (indicated

by 2 short beeps).

• Heat O

Press to turn heat O (indicated by 1 long beep).

NOTE: After the heater is switched o, the fan will

!

continue on for 60 seconds before turning o. The

log LEDs remain On when the heater is ON and the

ame eect is O.

NOTE: The heater will only turn on when the ame

!

eect is on.

360o Light

Press multiple times to change the LEDs on the

sides and back of the unit from white ickering to

white solid to O. (This feature is active only when

the ame eect is On.)

Brightness

Press multiple times to toggle the log set LEDs

through its four brightness settings.

Remote Control

The replace is supplied with a multi-function remote control.

The remote control has a range of approximately 30 ft (9

m). To operate correctly, the remote control must be pointed

toward the front of the unit.

Power

Press to turn the ame eect on and activate the

previous heat setting (O, Low, or High). Press again

to put the unit in standby mode.

Flame

Press to light the back log, grate log, and ember mat,

and start the ame eect.

Heat

• Heat On

Press to set the heat to Low (indicated by 1 short

beep). Press again to set the heat to High (indicated

by 2 short beeps).

• Heat O

Press to turn heat O (indicated by 1 long beep).

NOTE: After the heater is switched o, the fan will

!

continue on for 60 seconds before turning o. The

log LEDs remain On when the heater is ON and the

ame eect is O.

NOTE: The heater will only turn on when the ame

!

eect is on.

360o Light

Press multiple times to change the LEDs on the

sides and back of the unit from white ickering to

white solid to O. (This feature is active only when

the ame eect is On.)

Brightness

Press multiple times to toggle the log set LEDs

through its four brightness settings.

5

Page 6

Maintenance

General Maintenance

Inspect the log set regularly, depending upon conditions,

and at a minimum yearly intervals. Remove dust and clean

the logs, mat, grate, and base as required.

Except for installation and cleaning described in this manual, an authorized service representative should perform any

other servicing.

WARNING: Disconnect power and allow heater to cool

before attempting any maintenance or cleaning to reduce

the risk of fire, electric shock, or injury.

Clean Logs and Base

The log set should not be operated with an accumulation of

dust or dirt on or in the unit, as this can cause a build up of

heat and eventual damage.

Dust and vacuum the log set as needed. Use a damp cloth

and a mild detergent to clean painted surfaces of the fireplace. Never use abrasive cleaners.

Clean Mirage™ Flame Panel

The Mirage™ Flame Panel is cleaned in the factory during

the assembly operation. During shipment, installation, handling, etc., the screen may collect dust particles; these can

be removed by dusting lightly with a clean dry cloth.

To remove fingerprints or other marks, clean the Mirage™

Flame Panel reflector screen with a damp cloth. Never use

abrasive cleaners. Dry the screen completely with a lint free

cloth to prevent water spots.

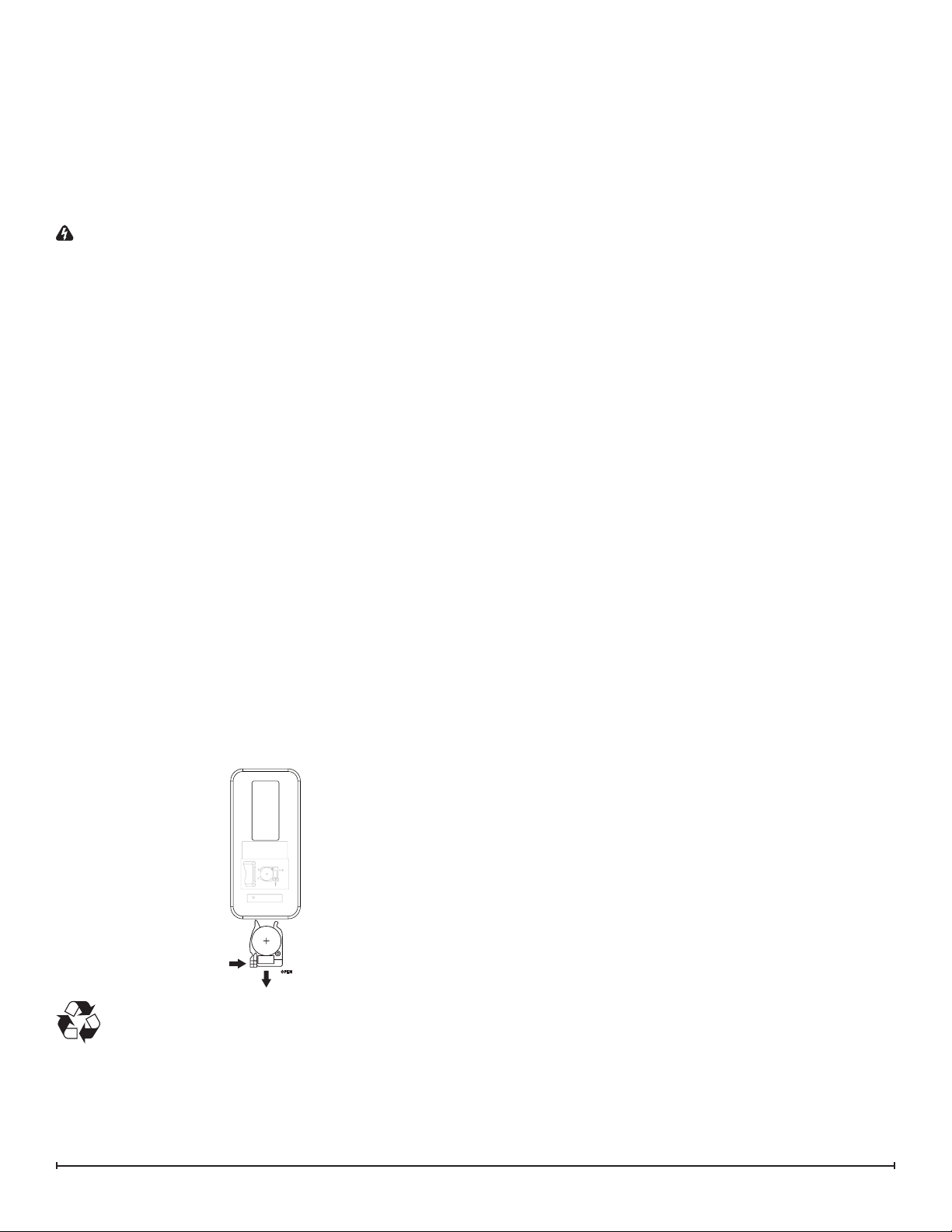

Battery Replacement

To replace the battery:

1. Push the release tab toward the center and slide the

battery cover open.

2. Install 3V Lithium battery in the battery holder. The

positive (+) side of the battery faces up.

3. Close the battery cover.

OPEN ---- OUVRIR

PUSH ---- POUSSER

RELEASE ---- DÉGAGER

Lithium Battery--Batterie au lithium

CR2025/2032

OPEN

RELEASE

PUSH

Battery must be recycled or disposed of properly.

Check with your Local Authority or Retailer for

recycling advice in your area.

6 www.dimplex.com

Page 7

Exploded Parts Diagram - RLG20, RLG20BR, RLG20FC

4

6

2

3

5

7

1

12

Replacement Parts List - RLG20, RLG20BR, RLG20FC

1. Logset RLG20 ........................0441910100RP

RLG20BR. . . . . . . . . . . . . . . . . . . . . . 0442780100RP

RLG20FC . . . . . . . . . . . . . . . . . . . . . . 0442770100RP

2. Flame LED Strip RLG20. . . . . . . . . . . . . . . . . 3001760100RP

3. Back Log RLG 20. . . . . . . . . . . . . . . . . . . . . . 0441920100RP

RLG20BR .....................0442740100RP

RLG20FC .................... 0442730100RP

4. Mirage™ Flame Panel ..................5902930100RP

5. Flicker Motor. . . . . . . . . . . . . . . . . . . . . . . . . . 2000500900RP

6. Back Light Assembly ...................3001770100RP

7. Heater-Blower Assy with Cutout. . . . . . . . . . . 2203730100RP

8. Main Control Board ....................3001740100RP

RLG20BR & RLG20FC ...........3001740300RP

9. IR Key Board .........................3001750100RP

10. Power Supply . . . . . . . . . . . . . . . . . . . . . . . . . 2100250100RP

11. Cordset, 3-prong ......................4100190300RP

12. Remote Control .......................6700580100RP

13. Ash Mat (RLG20BR & RLG20FC) ..............REM-KIT

Accessory

14. Ash Mat ..................................REM-KIT

10

8

9

11

7

Page 8

Exploded Parts Diagram - RLG25

4

1

3

2

7

5

6

14

13

Replacement Parts List - RLG25

12

8

11

9

10

1. Logset. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 0441940100RP

2. Flame LEDs, 4x1W ....................3001760200RP

3. Back Log ............................0441950100RP

4. Mirage™ Flame Panel ..................5902880100RP

5. Flicker Motor, 18RPM, CCW .............2000500900RP

6. Back Light Assembly ...................3001780100RP

7. Coloured Light Assembly (RLG25 only) .....3001570400RP

8. Heater-Blower Assy with Cutout ...........2203730100RP

9. Main Control Board ....................3001740200RP

10. IR Key Board .........................3001750100RP

11. Power Supply .........................2100250100RP

12. Cordset, 3-prong ......................4100190300RP

13. Remote Control .......................6700580200RP

14. Ash Mat ..................................REM-KIT

8 www.dimplex.com

Page 9

Exploded Parts Diagram RLG25BR, RLG25FC

4

3

12

13

1

2

7

8

10

5

6

11

9

Replacement Parts List - RLG25BR, RLG25FC

1. Logset RLG25BR ......................0442610100RP

RLG25FC ......................0442600100RP

2. Flame LEDs, 4x1W ....................3001760200RP

3. Back Log RLG25BR ....................0442760100RP

RLG25FC ....................0442750100RP

4. Mirage™ Flame Panel ..................5902880100RP

5. Flicker Motor, 18RPM, CCW .............2000500900RP

6. Back Light Assembly ...................3001770100RP

7. Heater-Blower Assy with Cutout ...........2203730100RP

8. Main Control Board ....................3001740400RP

9. IR Key Board .........................3001750100RP

10. Power Supply .........................2100250100RP

11. Cordset, 3-prong ......................4100190300RP

12. Remote Control .......................6700580100RP

13. Ash Mat ..................................REM-KIT

9

Page 10

Wiring Diagram

RLG20

L

RLG25

120V / 12V

~

AC / DC

CUTOUT

CONTROL BOARD

N

+T°+T°

BLOWER

M

MOTOR

FLICKER

MOTOR

M

FLAME LIGHTS

3 x 1W LEDs

LOGSET ASSEMBLY

ASH MAT ASSEMBLY

360 LIGHTS

REMOTE

4-7 x 0.20mA LED STRIP

4 PIECES

4-7 x 0.20mA LED STRIP

2 PIECES

IR EYE/KEY BOARD

6 x 0.20mA LEDs

120V / 12V

~

AC / DC

CUTOUT

+T°

+T°

CONTROL BOARD

M

BLOWER

MOTOR

REMOTE

FLICKER

MOTOR

M

FLAME LIGHTS

LOGSET ASSEMBLY

ASH MAT ASSEMBLY

360° COLOUR LIGHTS

4 x 1W LEDs

4-7 x 0.20mA LED STRIP

4 PIECES

FLAME BASE COLOUR LIGHTS

4 x 0.20mA RGB STRIP

4-7 x 0.20mA LED STRIP

2 PIECES

6 x 0.20mA RGB HARNESS

IR EYE/KEY BOARD

L

N

10 www.dimplex.com

Page 11

RLG20BR, RLG20FC

L

CUTOUT

+T°

120V / 12V

~

AC / DC

CONTROL BOARD

RLG25BR, RLG25FC

+T°

M

REMOTE

FLICKER

MOTOR

M

FLAME LIGHTS

ASH MAT ASSEMBLY

360 LIGHTS

3 x 1W LEDs

4-7 x 0.20mA LED STRIP

2 PIECES

IR EYE/KEY BOARD

N

6 x 0.20mA LEDs

120V / 12V

~

AC / DC

CUTOUT

+T°

+T°

CONTROL BOARD

M

BLOWER

MOTOR

REMOTE

FLICKER

MOTOR

M

FLAME LIGHTS

ASH MAT ASSEMBLY

360° LIGHTS

4 x 1W LEDs

4-7 x 0.20mA LED STRIP

2 PIECES

IR EYE/KEY BOARD

L

N

6 x 0.20mA LEDs

11

Page 12

Back Log Replacement

Tools Required: Philips head screwdriver

WARNING: If the log grate was operating prior to ser-

vicing, allow at least 10 minutes for the heating elements to

cool o to avoid accidental burning of skin.

WARNING: Disconnect power before attempting any

maintenance to reduce the risk of electric shock or damage

to persons.

1. Lift the ame panel from the unit and put it aside in a

safe place.

2. Remove the ember mat by disconnecting it from the

right side of the unit (if applicable).

3. Remove the two screws at the front of the back log.

(Figure 3)

4. Install the replacement log and secure with the two

screws that were previously removed.

5. Reinstall the ame panel.

6. Re-assemble the remainder of the log grate in reverse

order from the instructions above.

WARNING: Ensure wires do not come in contact with

moving parts by securing wires in wiring tie wraps.

Figure 5

Power Supply

Blower

Assembly

Main Control

Board

Log Set Replacement

Tools Required: Philips head screwdriver

WARNING: If the log grate was operating prior to ser-

vicing, allow at least 10 minutes for the heating elements to

cool o to avoid accidental burning of skin.

Figure 3

Figure 4

Back Log

WARNING: Disconnect power before attempting any

maintenance to reduce the risk of electric shock or damage

to persons.

1. Lift the ame panel from the unit and put it aside in a

safe place.

2. Remove the ember mat by disconnecting it from the

right side of the unit.

3. Remove the 3 screws along the bottom of the front and

back of the bottom assembly and the four screws from

each corner on both ends. (Figure 4)

4. Gently tilt the unit onto the back and lower the bottom

assembly so that the electrcial can be easily accessed.

5. Remove the two screws in the bottom of the second

and fourth prongs of the grate to release the logs.

6. Trace the wire from the logs to the main control board

and disconnect the wire, noting the location on the

board.

7. Run the wire from the new logs, following the same

path as the wire that was removed. Attach the new wire

to the board.

8. Install the replacement logs and secure with the two

screws that were previously removed.

9. Re-assemble the remainder of the log grate in reverse

order from the instructions above.

WARNING: Ensure wires do not come in contact with

moving parts by securing wires in wiring tie wraps.

Bottom Assembly

12 www.dimplex.com

Page 13

Flame LED Strip and Coloured LED Strip Replacement

Tools Required: Philips head screwdriver

WARNING: If the log grate was operating prior to ser-

vicing, allow at least 10 minutes for the heating elements to

cool o to avoid accidental burning of skin.

WARNING: Disconnect power before attempting any

maintenance to reduce the risk of electric shock or damage

to persons.

1. Lift the ame panel from the unit and put it aside in a

safe place.

2. Remove the ember mat by disconnecting it from the

right side of the unit (if applicable).

3. Remove the two screws at the front of the back log.

(Figure 3)

4. Place the back log to the side, trying not to strain the

wires (if applicable).

5. Lift the LED strip out of the holder.

6. Gently pull the connector at the end of the strip out of

the plug.

7. Connect the new LED strip to the connector and rein-

stall.

8. Re-assemble the remainder of the log grate in reverse

order from the instructions above.

WARNING: Ensure wires do not come in contact with

moving parts by securing wires in wiring tie wraps.

Figure 6

Back Light Assembly Replacement

Tools Required: Philips head screwdriver

WARNING: If the log grate was operating prior to ser-

vicing, allow at least 10 minutes for the heating elements to

cool o to avoid accidental burning of skin.

WARNING: Disconnect power before attempting any

maintenance to reduce the risk of electric shock or damage

to persons.

1. Lift the ame panel from the unit and put it aside in a

safe place.

2. Remove the ember mat by disconnecting it from the

right side of the unit (if applicable).

3. Locate the three sections of lights that are located

along the bottom edge of the grate. (Figure 6)

4. Depress each of the tabs and gently pull the light strips

forward and down to remove them from the unit.

5. Gently pull the connector at the end of the strip out of

the plug.

6. Connect the new LED strip to the connector and rein-

stall.

7. Re-assemble the remainder of the log grate in reverse

order from the instructions above.

WARNING: Ensure wires do not come in contact with

moving parts by securing wires in wiring tie wraps.

Main Control Board Replacement

Tools Required: Philips head screwdriver

Needle-nose pliers

Flat Head Screwdriver

Flame LED

Strip

Back Light

Assembly

Coloured LED Strip

(RLG25 only)

WARNING: If the log grate was operating prior to servicing, allow at least 10 minutes for the heating elements to

cool o to avoid accidental burning of skin.

WARNING: Disconnect power before attempting any

maintenance to reduce the risk of electric shock or damage

to persons.

1. Lift the ame panel from the unit and put it aside in a

safe place.

2. Remove the ember mat by disconnecting it from the

right side of the unit.

3. Remove the 3 screws along the bottom of the front and

back of the bottom assembly and the four screws from

each corner on both ends. (Figure 4)

4. Gently tilt the unit onto the back and lower the bottom

assembly so that the electrcial can be easily accessed.

5. Transfer the wire connectors from the terminals on the

original board to the same location on the replacement

board.

!

NOTE: Use a at head screwdriver to gently pry

between the end of the connector and the remote control

receiver to release the wires.

6. Squeeze the mounting tabs located on the corners of

13

Page 14

the board with the needle-nose pliers, to release the

tabs and lift the board o.

7. Position the new board over the tabs and gently press

down to engage the tabs.

8. Re-assemble the remainder of the log grate in reverse

order from the instructions above.

WARNING: Ensure wires do not come in contact with

moving parts by securing wires in wiring tie wraps.

Power Supply Replacement

Tools Required: Philips head screwdriver

WARNING: If the log grate was operating prior to ser-

vicing, allow at least 10 minutes for the heating elements to

cool o to avoid accidental burning of skin.

WARNING: Disconnect power before attempting any

maintenance to reduce the risk of electric shock or damage

to persons.

1. Lift the ame panel from the unit and put it aside in a

safe place.

2. Remove the ember mat by disconnecting it from the

right side of the unit.

3. Remove the 3 screws along the bottom of the front and

back of the bottom assembly and the four screws from

each corner on both ends. (Figure 4)

4. Gently tilt the unit onto the back and lower the bottom

assembly so that the electrcial can be easily accessed.

5. Remove the four remaining screws from the right end

pane to release the bracket that supports the power

supply.

6. Trace the wires to the main control board and the wire

nuts and replace the old connections with the new connections.

7. Reinstall the support bracket over the new power sup-

ply.

8. Re-assemble the remainder of the log grate in reverse

order from the instructions above.

WARNING: Ensure wires do not come in contact with

moving parts by securing wires in wiring tie wraps.

IR Key Board Replacement

Tools Required: Philips head screwdriver

WARNING: If the log grate was operating prior to ser-

vicing, allow at least 10 minutes for the heating elements to

cool o to avoid accidental burning of skin.

WARNING: Disconnect power before attempting any

maintenance to reduce the risk of electric shock or damage

to persons.

1. Lift the ame panel from the unit and put it aside in a

safe place.

2. Remove the ember mat by disconnecting it from the

right side of the unit.

3. Remove the two screws securing the IR key board to

the back side of the right leg. (Figure 7)

4. Remove the 3 screws along the bottom of the front and

back of the bottom assembly and the four screws from

each corner on both ends. (Figure 4)

5. Gently tilt the unit onto the back and lower the bottom

assembly so that the electrcial can be easily accessed.

6. Trace the wire from the IR key board to the main con-

trol board and disconnect the wire, noting the location

on the board.

7. Run the wire from the IR key board, following the same

path as the wire that was removed. Attach the new wire

to the board.

8. Install the replacement key board and secure with the

two screws that were previously removed.

9. Re-assemble the remainder of the log grate in reverse

order from the instructions above.

WARNING: Ensure wires do not come in contact with

moving parts by securing wires in wiring tie wraps.

Figure 7

IR Key Board

14 www.dimplex.com

Page 15

Power Cord Replacement

Tools Required: Philips head screwdriver

Needle-nose pliers

Flat Head Screwdriver

WARNING: If the log grate was operating prior to servicing, allow at least 10 minutes for the heating elements to

cool o to avoid accidental burning of skin.

WARNING: Disconnect power before attempting any

maintenance to reduce the risk of electric shock or damage

to persons.

1. Lift the ame panel from the unit and put it aside in a

safe place.

2. Remove the ember mat by disconnecting it from the

right side of the unit.

3. Remove the 3 screws along the bottom of the front and

back of the bottom assembly and the four screws from

each corner on both ends. (Figure 4)

4. Gently tilt the unit onto the back and lower the bottom

assembly so that the electrcial can be easily accessed.

5. Follow the wiring from the power cord to the wire nuts,

removing any tie wraps and remove the connections,

taking note of the original locations.

6. Disconnect the ground wire from the screw on the bot-

tom pane.

7. With needle nosed pliers, squeeze and push the grom-

met securing the power cord out of the casing.

8. Insert the new power cord and grommet, reattaching

the wire with new tie wraps.

9. Reconnect the wires according in their original congu-

ration.

10. Re-assemble the remainder of the log grate in reverse

order from the instructions above.

Flicker Motor Replacement

Tools Required: Philips head screwdriver

WARNING: If the log grate was operating prior to ser-

vicing, allow at least 10 minutes for the heating elements to

cool o to avoid accidental burning of skin.

WARNING: Disconnect power before attempting any

maintenance to reduce the risk of electric shock or damage

to persons.

1. Lift the ame panel from the unit and put it aside in a

safe place.

2. Remove the ember mat by disconnecting it from the

right side of the unit (if applicable).

3. Remove the two screws at the front of the back log and

set it aside, ensuring that the wires are not strained (if

applicable). (Figure 3)

4. IRemove the 3 screws along the bottom of the front

and back of the bottom assembly and the four screws

from each corner on both ends. (Figure 4)

5. Gently tilt the unit onto the back and lower the bottom

assembly so that the electrcial can be easily accessed.

6. Remove the two screws that secure the motor support

to the base of the grate (verticle). (Figure 8)

7. Disconnect the icker rod and rubber grommet from the

icker motor.

8. Remove the two screws that secure the motor from the

motor support (horizontal). (Figure 8)

9. Trace the wires from the motor to the main control

board and disconnect the wire, noting the location on

the board.

10. Run the wire from the new motor, following the same

path as the wire that was removed. Attach the new wire

to the board.

11. Re-assemble the remainder of the log grate in reverse

order from the instructions above.

WARNING: Ensure wires do not come in contact with

moving parts by securing wires in wiring tie wraps.

Figure 8

Flicker Motor

Flicker Rod

15

Page 16

Heater Assembly Replacement

Tools Required: Philips head screwdriver

Flat Head Screwdriver

WARNING: If the log grate was operating prior to servicing, allow at least 10 minutes for the heating elements to

cool o to avoid accidental burning of skin.

WARNING: Disconnect power before attempting any

maintenance to reduce the risk of electric shock or damage

to persons.

1. Lift the ame panel from the unit and put it aside in a

safe place.

2. Remove the ember mat by disconnecting it from the

right side of the unit.

3. Remove the 3 screws along the bottom of the front and

back of the bottom assembly and the four screws from

each corner on both ends. (Figure 4)

4. Gently tilt the unit onto the back and lower the bottom

assembly so that the electrcial can be easily accessed.

5. Remove the four screws in the top assembly - two on

either end of the heater.

6. Turn the logs and log grate on its side, to the right, to

access the four screws that secure the heater assembly to the top assembly.

7. On the heater assembly, there is a plastic spacer that

channels the air from the heater assembly out of the

unit, remove the two screws on either end that hold the

plastic spacer to the heater. (Figure 9)

8. Install the plastic spacer to the new heater, transfer the

wires from the old heater to the new heater and re-assemble the remainder of the log grate in reverse order

from the instructions above.

!

NOTE: Use a at head screwdriver to gently pry

between the end of the connector and the heater assembly to release the wires.

WARNING: Ensure wires do not come in contact with

moving parts by securing wires in wiring tie wraps.

Figure 9

Connecting

Screws

Plastic

Spacer

16 www.dimplex.com

Page 17

Troubleshooting Guide

PROBLEM CAUSE SOLUTION

General

Short in unit wiring. Trace wiring in unit.

Circuit breaker trips or fuse

blows when unit is turned on

Lights dim in room while the unit

is on

Power cord gets warm

Appearance

Log grate does not turn on in

Manual Mode

Log grate does not turn on in

Remote Mode

One or all logs in log set dim, not

glowing (only applicable for the

RLG20 & RLG25)

Ash mat dim or not glowing

Flame dim or not appearing

Flame Frozen

Flame Shudder Defective Flicker Motor Replace icker motor

Back lighting dim or not

appearing

Colour themes dim or not appearing (only applicable for the

RLG25)

Improper circuit current rating

Unit is drawing close to circuit current

rating

Normal Operation

Defective power cord Replace power cord if cord gets hot to the touch.

Improper operation Refer to cperation section

No incoming power from the electrical

wall socket

Defective IR key board Replace IR key board

Defective main control board Replace main control board.

Improper operation Refer to operation section

Loose wiring Check wiring connections

Remote Control not working

Defective main control board Replace main control board.

Loose connection Check wiring connections

Defective log set wiring Replace log set assembly

Loose connection of ash mat Check wiring connections

Defective ash mat Replace ash mat

Defective main control board Replace main control board

Improper operation Refer to operation section

Loose connection of ame LEDs Check wiring connections

Defective ame LED wiring Replace ame LED assembly

Defective main control board Replace main control board.

Loose wiring Check wiring connections

Defective Flicker Motor Replace icker motor

Improper operation Refer to operation section

Loose connection of back light LEDs Check wiring connections

Defective back light LED wiring Replace back light LED assembly

Defective main control board Replace main control board.

Improper operation Refer to operation section

Loose connection of coloured LEDs Check wiring connections

Defective coloured LED wiring Replace coloured LED assembly

Defective main control board Replace main control board.

Additional appliances may exceed the current rating

of the circuit breaker or fuse. Plug unit into another

outlet or install unit on a dedicated 15 amp circuit.

Move the unit to another outlet or install unit on a dedicated 15 amp circuit

The power cord may get slightly warm to the touch

when the heater is on

Check fuse/breaker panel

Install new battery into the remote control. Reinitialize

remote control where necessary

17

Page 18

PROBLEM CAUSE SOLUTION

Heater

Heater is not turning O

Heater is not turning On

Heater is turning o after a

couple of minutes of operation

Heater emits an odor

Heater fan turns on but heater

lacks heat

Heating element is glowing red

Heater fan runs continuously

Noise

Excessive noise with the heater

on

Improper operation Refer to operation section

Defective main control board Replace main control board.

Improper operation Refer to operation section

Loose wiring Check wiring connections

Defective heater assembly Replace heater assembly

Build up of dirt/dust in heater assembly

Ensure that exterior intake louvers and log grate cavity

are free of dirt/dust.

Defective Heater Assembly Replace heater assembly

Normal operation is when the heater emits an odor

Normal Operation

for a brief period after the heater is initially turned on.

The heater is burning o any dust accumulated during

manufacturing or operation.

Defective heater assembly Replace heater assembly

Improper operation Refer to operation section

Loose wiring Trace wiring in unit

Defective heater assembly Replace heater assembly

Normal Operation

Small glowing sections of the element are considered

normal.

If larger glowing sections are causing the heater to trip

Defective heater assembly

the thermal cutout, unplug unit, discontinue use and

replace heater assembly.

Loose wiring Trace wiring in unit

Defective heater assembly Replace heater assembly

Dirty heater assembly

Ensure that exterior intake louvers and log grate cavity

are free of dirt/dust.

Defective heater assembly Replace heater assembly

REV PCN DATE

00 - 19-OCT-16

01 15450 17-JUL-19

1-888-346-7539 | www.dimplex.com

In keeping with our policy of continuous product improvement,

we reserve the right to make changes without notice.

© 2019 Glen Dimplex Americas

18 www.dimplex.com

Loading...

Loading...