Dimplex RFI815D31-KIT, RFI820D31W-KIT, RFI815D31W-KIT, RFI820D31-KIT, RFI820D41-KIT Installation Instructions Manual

...Page 1

Forced Air Heater

RFI Series

IMPORTANT INSTRUCTIONS

When using electrical appliances, basic precautions should

always be followed to reduce the risk of re, electric shock

and injury to person, including the following:

Read all instructions before using this heater.1.

A heater has hot and arcing or sparking parts inside. Do 2.

not use it in areas where gasoline, paint or ammable

liquids are used or stored.

This heater is hot when in use. To avoid burns, do not let 3.

bare skin touch hot surfaces. If provided, use handles

when moving this heater. Keep combustible materials

such as: furniture, pillows, bedding, papers, clothes and

curtains away from heater.

To prevent a possible re, do not block air intakes or 4.

exhaust in any manner. Do not use on soft surfaces like

a bed where openings may become blocked.

Do not insert or allow foreign objects to enter any venti-5.

lation or exhaust opening as this may cause an electric

shock or re, or damage the heater.

SAVE THESE INSTRUCTIONS

Installation Instructions

WARNING: Wiring procedures and connections should

be in accordance with the National Electric code (NEC &

CEC) and local codes.

!

NOTE: Each heater comes as two packages: the main

heater assembly and the associated grille kit.

CAUTION: Do not operate heater without the Grille

installed.

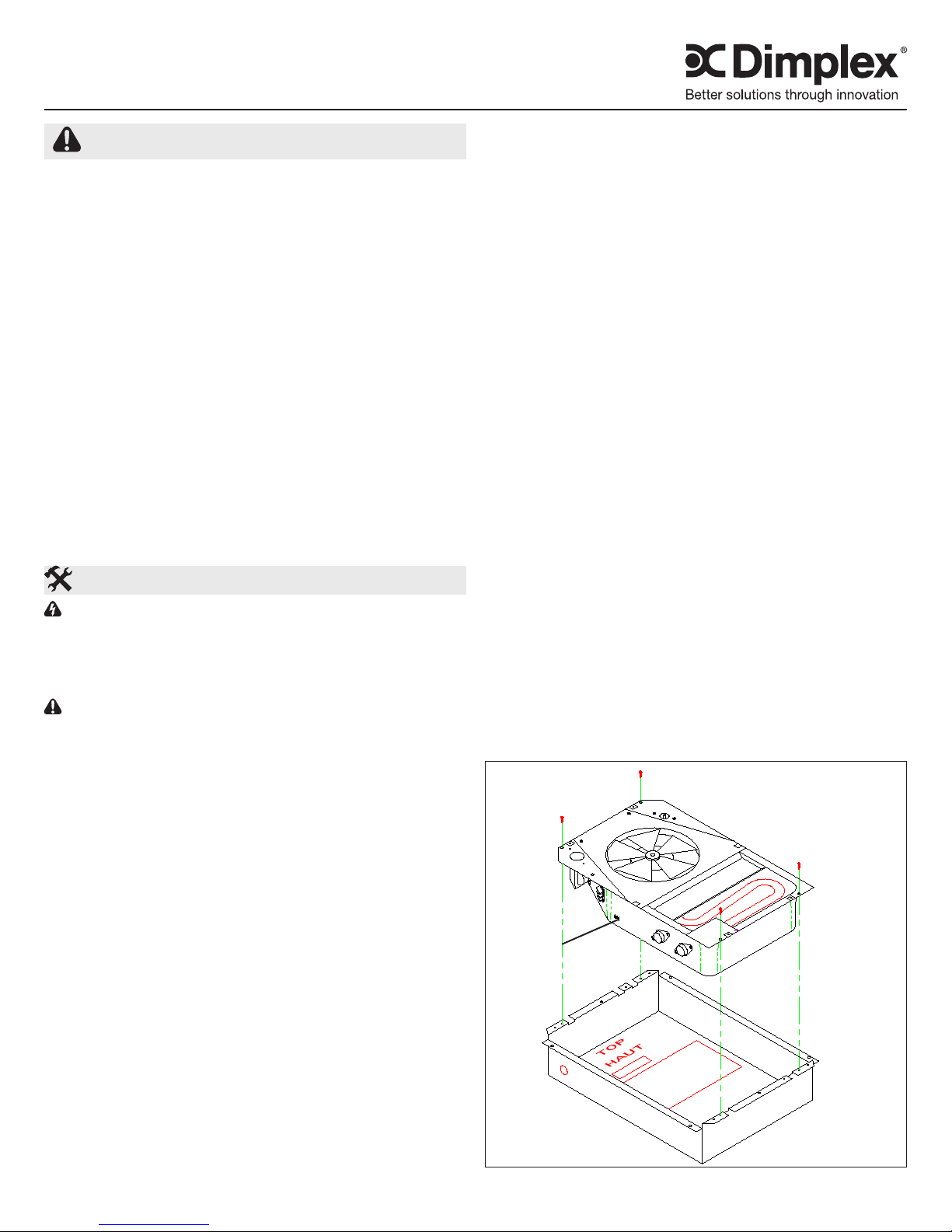

Remove the main heater assembly from the carton. Re-1.

move the screws securing heater assembly and retaining

brackets to the recess box and separate. (Figure 1) .

!

NOTE: Mount the heater a minimum of 12” (30.5cm)

from the nished oor, and a minimum of 6” (15cm) from any

vertical surface if installed in the ceiling.

Recessed Installation

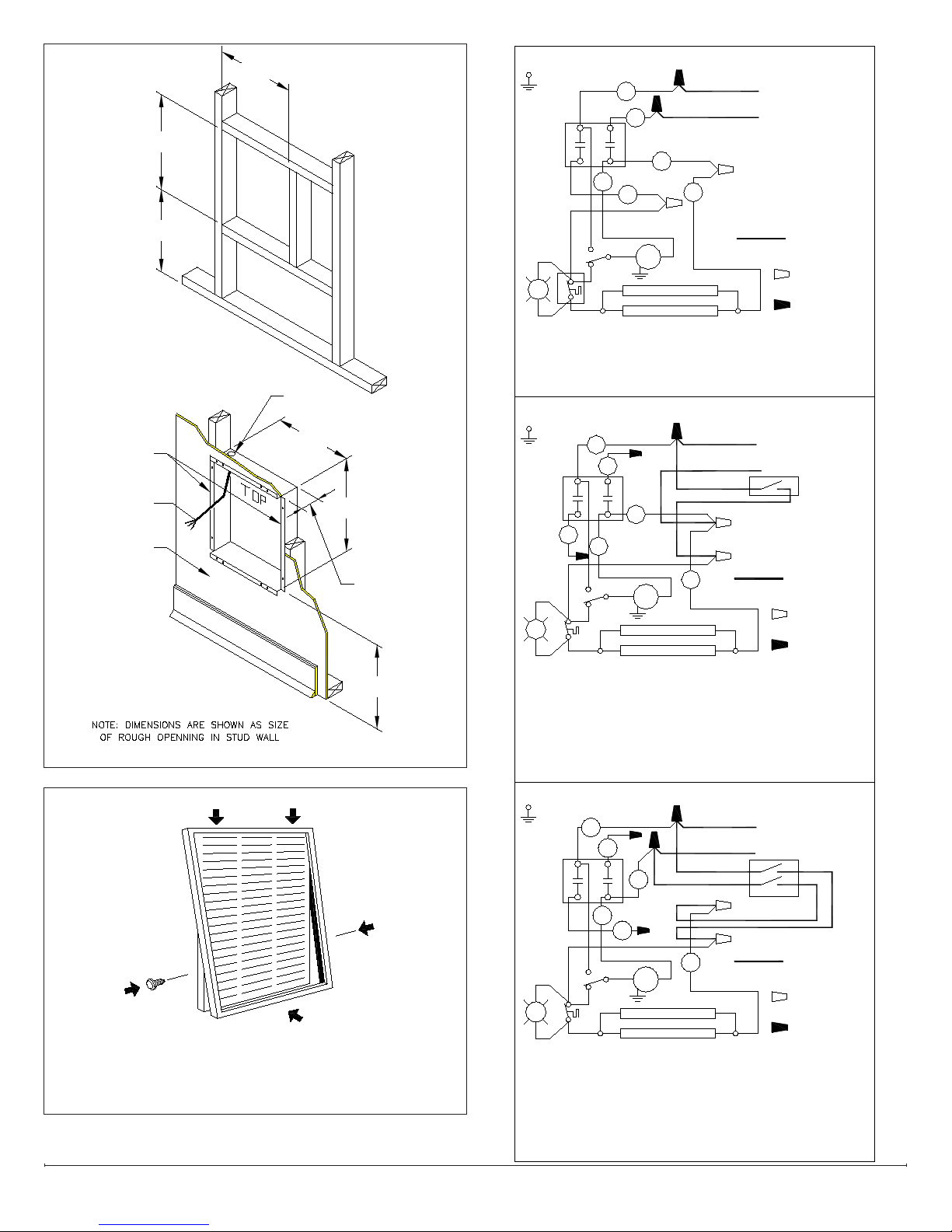

The recess box provided with the heater is designed for 2.

attachment between studs placed on 16” (40.6cm) centres. If different spacing exists, construct frame to suit

the box in order to avoid any vibration and noise caused

by loose mounting (Figure 2a).

Note the orientation of box (“TOP” shown on recess 3.

box) and secure to studs using four holes provided on

side anges, ensuring these anges are ush with nished surface of wall or ceiling (Figure 2b).

Surface Installation

2. Secure optional surface mount box (Part No. RFP8D)

by angling screws through holes provided in rear of

surface box into studs or nished surface.

3. Position recess box into surface box and secure with

four screws provided in parts bag of surface box.

Supply Wiring and Heater Installation

Insert approximately 15” (38cm) of supply wire into 4.

recess box through knockout provided in upper left hand

corner (Figure 2b). Wire should be rated for a minimum

of 75°C (167°F)

Connect power supply to terminals provided marked L1 5.

and L2. Ground wire should be secured to green ground

screw provided on side of heater assembly (Figure 1).

All units are factory prewired for operation with built-in 6.

thermostat. If remote thermostat operation is required

follow appropriate wiring diagram located on inside of

recess box.

!

NOTE: It is recommended that for ceiling mount applications a remote thermostat be used in order to provide superior temperature control.

!

NOTE: All wiring must comply with National Electrical

Code and local codes.

Secure heater assembly into recess box using the four 7.

M4 screws previously removed.

Front Panel Installation

Remove trim frame and front panel (grille) from the 8.

carton.

If tamper proof built-in or remote thermostat operation 9.

is required, secure the louvered door to the front panel

using 2 M3 screws (not included) through the holes provided. The knob can then be removed and adjustment

of the thermostat can be made using needle nose pliers

through the front panel.

Install the front panel on the heater assembly. Check to 10.

see that the fan blade is free to turn and that no residue

remains in the unit. Front panel can then be secured to

assembly using four M4.8 x 37 screws provided.

Follow the steps as shown in Figure 3.11.

Figure 1

HEATER

ASSEMBLY

GROUND

SCREW

RECESS BOX

7211900100R00

Page 2

FINISHED WALL

SURFACE

SIDE FLANGES

15"

[38cm]

min. 12"

[30.5cm]

3 5/8"

[9cm]

14 1/4"

[36cm]

19 3/4"

[50cm]

7/8"[22mm] DIA

KNOCKOUT

FINISH FLOOR

19 3/4"

[50cm]

14 1/4"

[36cm]

min. 12"

[30.5cm]

Figure 2

L

L

L

WIRING

CUSTOMER

SUPPLY

BUILT-IN THERMOSTAT (FACTORY WIRED)

OFF

CYCLE

GRND.

UNIT

THERMOSTAT

L1L2

3

2

1

M

UNIT

GRND.

S.P. "LINE" VOLTAGE REMOTE THERMOSTAT

D.P. "LINE" VOLTAGE REMOTE THERMOSTAT

GRND.

UNIT

L2

L1

A

B

FACTORY

SUPPLIED

SUPPLIED

CUSTOMER

CUSTOMER

SUPPLIED

SUPPLIED

FACTORY

B

A

L1

L2

M

1

2

3

L2 L1

THERMOSTAT

CYCLE

OFF

SUPPLY

CUSTOMER

WIRING

REMOTE

SP STAT

DP STAT

REMOTE

WIRING

CUSTOMER

SUPPLY

OFF

CYCLE

THERMOSTAT

L1L2

3

2

1

M

L2

L1

A

B

FACTORY

SUPPLIED

SUPPLIED

CUSTOMER

NOTE:

THIS WIRING REPRESENTS THE UNIT AS FACTORY WIRED.

PLEASE CONSULT THE OTHER DIAGRAMS SHOWN AS TO

WHAT OPTION IS REQUIRED. PLEASE ASSURE THAT ALL

1. MARR/TAPE WIRE LABELLED "L1" FROM THERMOSTAT

AS SHOWN.

2. DISCONNECT WIRE "B" FROM MARR CONNECTOR "B",

REMOVE FROM THERMOSTAT CONNECTOR AND DISCARD.

3. CONNECT INCOMING SUPPLY "L1" TO CONNECTOR "A"

4. CONNECT LOAD SIDE OF REMOTE LINE VOLTAGE

THERMOSTAT TO MARR CONNECTOR "B" AS SHOWN.

5. CONNECT INCOMING POWER WIRE "L2" TO BOTH THE LINE

1. MARR/TAPE WIRE LABELLED "L1" FROM THERMOSTAT

AS SHOWN.

2. DISCONNECT WIRE "B" FROM MARR CONNECTOR "B",

REMOVE FROM THERMOSTAT CONNECTOR AND DISCARD.

3. CONNECT LOAD SIDES OF REMOTE WALL THERMOSTAT TO

MARR CONNECTORS "A" AND "B" AS SHOWN IN DIAGRAM.

CONNECTIONS MADE ARE SECURE AND THAT ALL ELECTRICAL

CLEARANCES ARE MET.

A

B

C

B

A

C

D

B

C

L1

L2

L2

L1

L1

L2

SIDE OF REMOTE WALL THERMOSTAT AND WIRE ATTACHED

TO BUILT IN THERMOSTAT WIRE LABELLED "L2" AS SHOWN.

4. CONNECT WIRE "A" TO INCOMING SUPPLY "L1".

5. CONNECT THE OTHER INCOMING POWER SUPPLY LINE TO

THE OTHER LINE SIDE OF REMOTE WALL THERMOSTAT

AS SHOWN.

D

A

D

B

C

C

A

A

B

Figure 3

(A) Place frame over top of tabs.

(B) Push in at bottom until frame is ush with front panel.

(C) Insert two screws to hold frame in place.

www.dimplex.com2

Page 3

Operation and Maintenance

Set thermostat to desired temperature and both fan and 1.

heat should come on. Note that when desired temperature is reached the fan operation will continue for a short

period after the elements have de-energized in order to

remove residual heat from the unit.

The fan motor is permanently lubricated, sealed at the 2.

factory and is maintenance free.

It is suggested that at the beginning of each season the 3.

front panel is removed and the wire connection condition

is checked and the unit is cleaned of dust and dirt with a

vacuum cleaner.

!

NOTE: Always open the circuit breaker to disconnect

power to the unit prior to performing any maintenance or

service operation.

WARNING: Should the Over Temp light come on, discon-

nect power to the heater or turn down the thermostat fully

counterclockwise and call a licensed electrician. DO NOT

USE HEATER UNTIL THE CAUSE OF THE PROBLEM IS

DETERMINED AND FIXED.

Warranty

The Manufacturer warrants the heating elements and components

of the enclosed product against any defect in material or

workmanship for a period of one year from the date of purchase. In

full satisfaction of any claims under this Warranty the Manufacturer

will repair or replace without charge, in its factory or in the eld as it

alone may decide, any parts which in its opinion are defective.

The Manufacturer shall not be responsible for any transportation

or shipping costs in relation to such repair or replacement except

as specically assumed by it. Misuse of this product or repairs by

persons other than the Manufacturer’s authorized personnel without

the Manufacturer’s written approval, will void this Warranty.

This Warranty is in lieu of all other warranties or conditions

whether express or implied including but not limited to those of

merchantability or tness for purpose and shall constitute the sole

remedy of the Purchaser and the sole liability of the Manufacturer in

respect of the sale of the product, whether in the nature of breach or

breach of fundamental term, or of negligence or otherwise.

The Manufacturer shall not be liable for any special, indirect or

consequential damages or for any damages resulting from removal

or replacement of a heater subject to warranty claim without the

Manufacturer’s authorization.

This Warranty is transferable by the original consumer purchaser

of the product. Any claims under this Warranty must be submitted

in writing to the Service Manager, Dimplex North America Ltd., 1367

Industrial Rd., Cambridge, Ontario N1R 7G8, Canada.

Replacement Parts

Fan Blade . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 00010034RP

Cut Out . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 00009112RP

Thermostat . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13678001RP

Thermostat Knob ............................. 13691001RP

CATALOGUE

NO.

RFI815D31-KIT

RFI815D31W-KIT RPIFPW

RFI820D31-KIT

RFI820D31W-KIT RPIFPW

RFI820D41-KIT

RFI820D41W-KIT RPIFPW

RFI830D31-KIT

RFI830D31W-KIT RPIFPW

RFI830D41-KIT

RFI830D41W-KIT RPIFPW

RFI840D21-KIT

RFI840D21W-KIT RPIFPW

RFI840D31-KIT

RFI840D31W-KIT RPIFPW

RFI840D41-KIT

RFI840D41W-KIT RPIFPW

RFI848D31-KIT

RFI848D31W-KIT RPIFPW

MOTOR CAPACITOR ELEMENT FAN DELAY

00013004RP

2000260600RP 3200070100RP

00013002RP

2000260200RP 3200070400RP 00013008RP 00033002RP

2000260600RP 3200070100RP 00013004RP 00033001RP

2000260200RP 3200070400RP 00013007RP 00033002RP

00013001RP

2000260600RP 3200070100RP

00013002RP

2000260200RP 3200070400RP 00013008RP 00033002RP

2000260600RP 3200070100RP 00013005RP 00033001RP

00033001RP

00033001RP

FRONT PANEL

KIT

RFIFPA

RFIFPA

RFIFPA

RFIFPA

RFIFPA

RFIFPA

RFIFPA

RFIFPA

RFIFPA

1367 Industrial Road Cambridge ON Canada N1R 7G8

1-888-346-7539 www.dimplex.com

In keeping with our policy of continuous product improvement, we reserve the right to make changes without notice.

© 2012 Dimplex North America Limited

3

Loading...

Loading...