Page 1

ELECTRICAIRE

WARM AIR HEATING SYSTEM

Models: R7 - 7kW / 46kWh, R8 - 8kW / 57kWh, R10 - 10kW / 69kWh,

R12 - 12kW / 80kWh, R15 - 15kW / 103kWh

INSTALLATION INSTRUCTIONS

IMPORTANT

PLEASE READ THIS LEAFLET CAREFULLY AND RETAIN FOR

FURTHER USE. NOTE ALSO THE INFORMATION GIVEN ON THE HEATER

IMPORTANT - IN EVERY CASE THE UNIT MUST BE FITTED ON

TOP OF A PLENUM CHAMBER FOR CORRECT OPERATION

• The installation must be carried out by trained personnel.

• A means for disconnection must be incorporated in the fi xed wiring in accordance with the wiring rules.

• The heater must not be installed immediately below a socket outlet.

• The heater is not suitable for connectin to a 30A ring circuit.

• Do not position the heater under windows where curtains can contact the heater casing.

• WARNING - THE SURFACES ON THIS HEATER CAN BE HOT.

• This heater meets BS 3456 safety requirements. However, any heater type becomes hot in normal operation. Care

must be taken to ensure that prolonged skin contact with the heater does not occur.

WHERE YOUNG CHILDREN, INFIRM PERSONS, OR THE AGED ARE LIKELY TO BE LEFT UNSUPERVISED

IN THE VICINITY OF THE HEATER WE RECOMMEND THAT A GUARD IS FITTED. Contact your installer or the

manufacturer for further advice.

This appliance is not intended for use by persons (including children) with reduced physical, sensory or mental

capabilities, or lack of experience and knowledge, unless they have been given supervision or instruction concerning

use of the appliance by a person responsible for their safety.

Children should be supervised to ensure that they do not play with the appliance.

• THIS APPLIANCE IS EXTREMELY HEAVY. THE FLOOR MUST BE CHECKED TO ENSURE THAT IT IS CAPABLE

OF BEARING THE WEIGHT OF THE UNIT, UP TO 750KG (¾ TON). DO NOT UNDER ANY CIRCUMSTANCES

ATTEMPT TO MOVE OR REPOSITION THIS HEATER WITHOUT SEEKING EXPERT ADVICE.

• To maintain stability, it is essential that the heater is placed on a level surface.

• The heater must be installed where it is impossible for switches and other controls to be touched by a person using

a bath or shower.

• IMPORTANT - Due to the newness of materials the heater will produce a slight smell for the fi rst few days of

operation. ROOMS MUST BE WELL VENTILATED AND YOUNG CHILDREN, CAGED BIRDS, OR PERSONS

WITH RESPIRATORY COMPLAINTS MUST NOT REMAIN IN CLOSE PROXIMITY TO THE HEATER DURING

THE FIRST 48 HOURS OF THE COMMISSIONING PERIOD.

• IF, DURING ANY REASSEMBLY OF THE HEATER, A PART OF THE THERMAL INSULATION SHOWS DAMAGE

OR DETERIORATION WHICH MAY IMPAIR SAFETY, IT SHOULD BE REPLACED BY AN IDENTICAL PART.

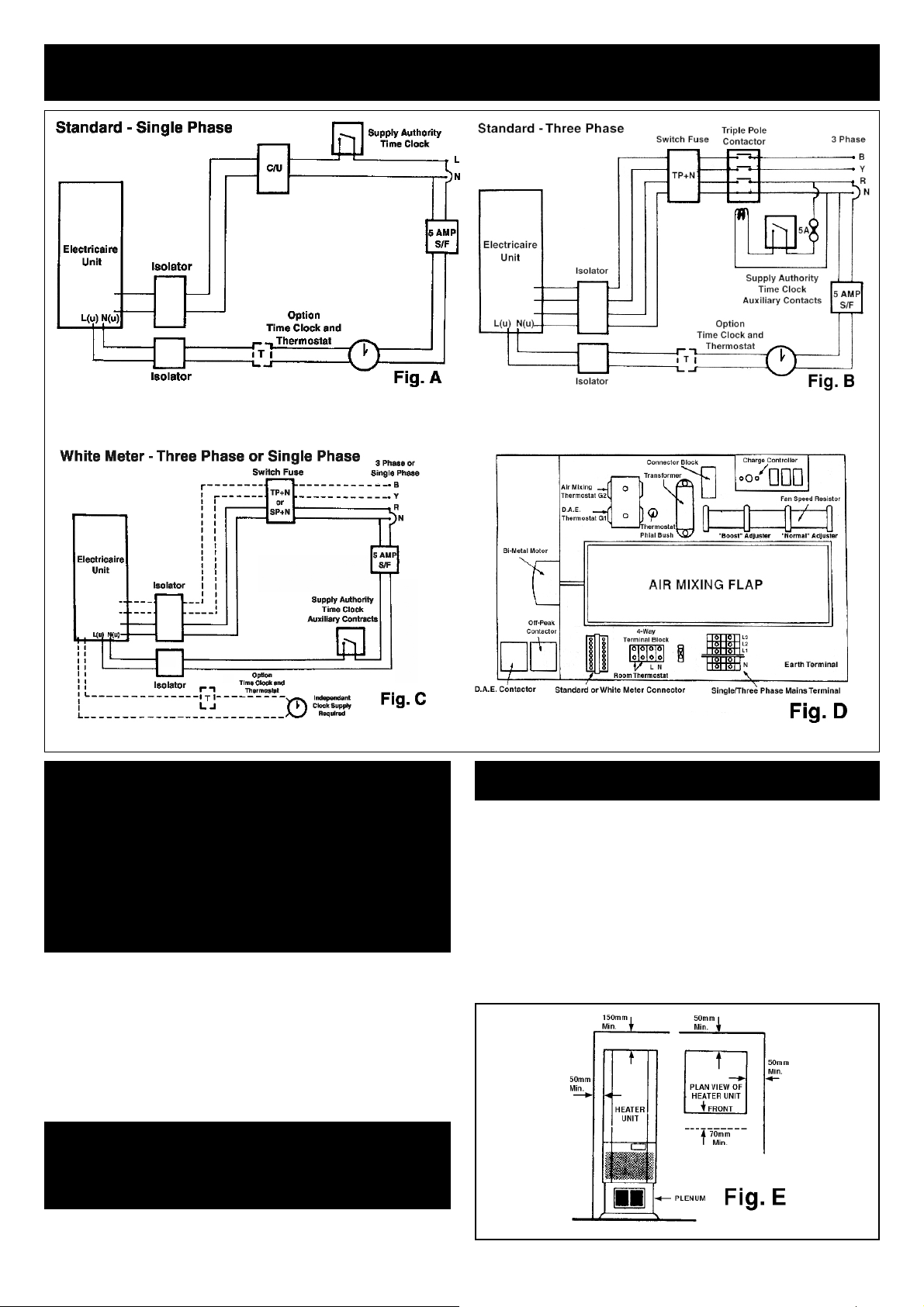

• The heater must stand at least 50mm clear of any walls and 150mm below ceilings.

Page 2

INSTALLATION INSTRUCTIONS

PREPARATION

The heater will arrive separately from its storage

bricks, the following bricks will be required.

R 7 / 8 / 10 - 40 bricks

R12 - 48 bricks

R15 - 64 bricks

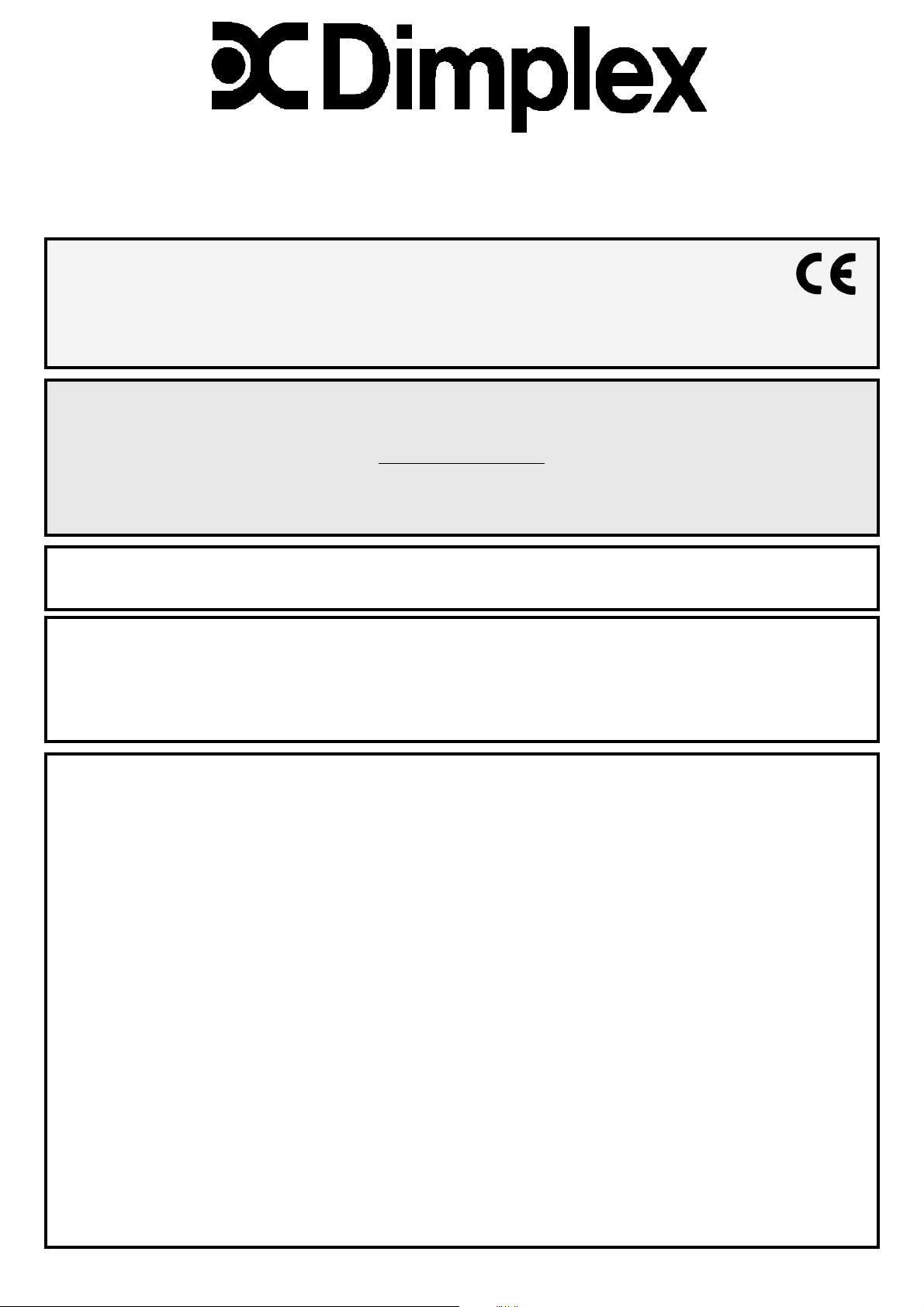

Electrical Supply

Two supplies are required for the operation of this heater -

for ‘on-peak’ and ‘off-peak’ supply. Both supplies should be

connected through isolator switches. A time clock / thermostat

control circuit may be required.

WARNING - This appliance

must be earthed

Only heat resisting cable (min. rating T85) should be used.

POSITIONING

Important - In every case the unit must be fi tted on top of a

plenum chamber for correct operation.

The unit can be installed free standing or in a suitable cupboard.

For minimum clearances all around the heater refer to Fig. E. The

fl oor must be checked to ensure that it is capable of bearing the

weight of the unit, see warning on front cover. Also the fl oor should

be fl at and level. A concrete plinth measuring 700x700mm can be

constructed. The plenum should be insulated from the fl oor or plinth

by at least 13mm of non-compressible insulation material.

Page 3

VENTILATION & DUCTING

INSTALLATION

Cupboard Ventilation - When the heater is installed in a cupboard,

two return grilles should be provided in the cupboard door or wall.

The top of the high level grille should be approximately 50mm

below the top of the cupboard and the bottom of the low level grille

approximately 25mm above the plenum top.

Return air grilles should be a minimum of 400mmx250mm. Grilles

must be positioned to return air from the heated areas.

Ducting will be required if the heater is positioned in a cupboard

and also in free standing installations if adjacent rooms are also to

be heated.

Holes to the required dimensions (to suit airducts used) should be

cut in the sides of the plenum chamber prior to siting. Holes should

not be cut closer than 30mm to either sides, top or bottom of the

plenum - see Fig F. The chamber can then be placed in position.

The ductwork can now be fi rmly attached to the plenum internally,

be means of ‘bent over’ fl anges or externally by pop rivets. Ensure

that all joints are sealed by 50mm wide tape.

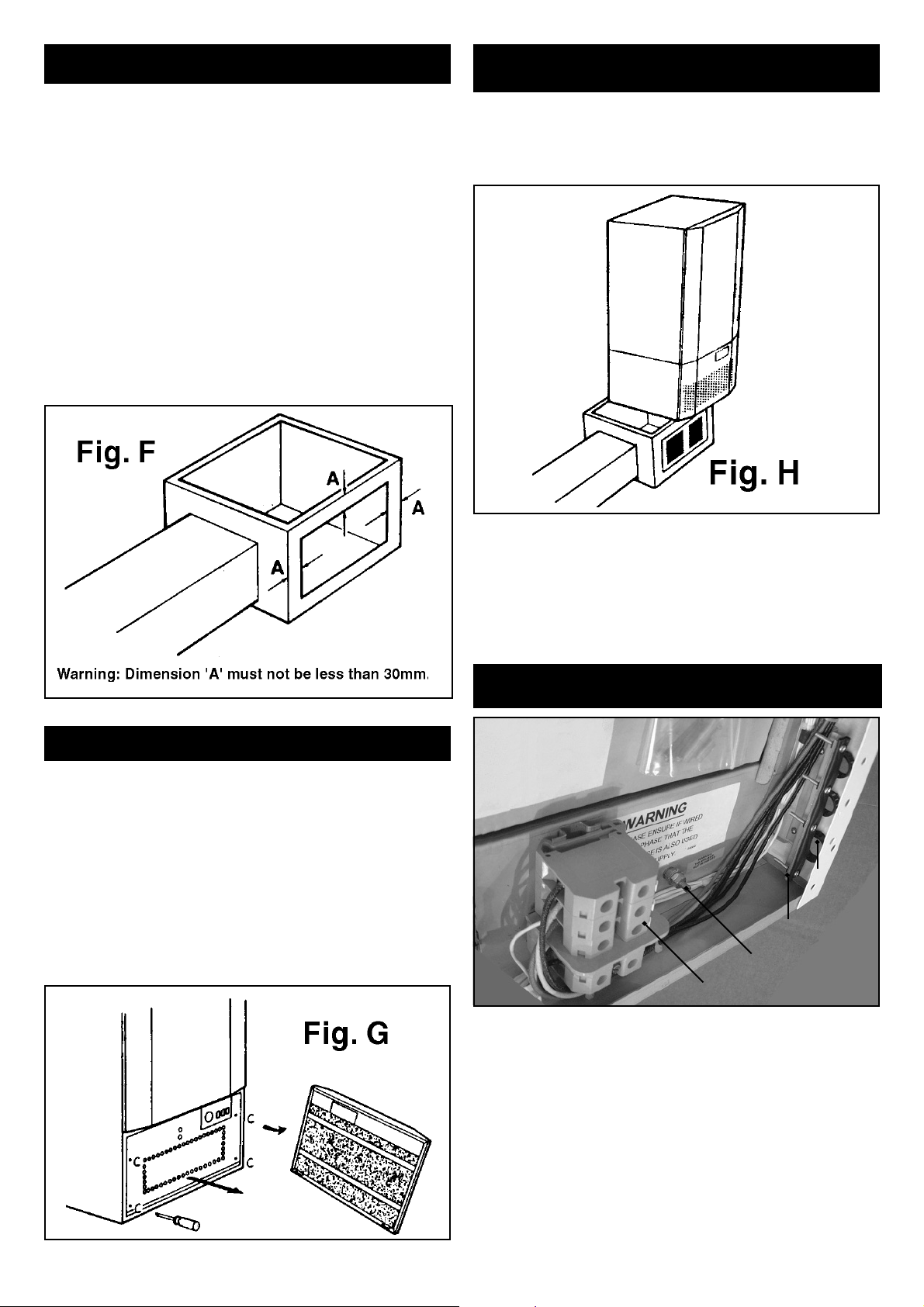

1. Lift the heater onto the plenum and work it gently backwards

to its correct location, see Fig. H. Position the heater exactly over

the plenum with sides and rear fl ush to ensure stability. If fi tted in

a cupboard please ensure that the heater is facing the cupboard

door to allow for ease of access.

2. CONNECTION OF THE MAINS CABLE

Cable entry to the unit is at the bottom right hand corner when viewed

from the front. See Fig. I. Conductors are to be fed through bushings

and the clamping bar before being terminated in the terminal blocks

on the lower wiring panel. Several blanking plugs are provided for

any cable entry bushings that are not used.

Important - All mains supplies have to be installed with

independent isolators.

WARNING - This appliance must be earthed

INSPECTION BEFORE INSTALLATION

Having removed the heater from its packing inspect it for possible

damage caused in transit. Note - two sheets of mica insulation will

be found underneath the heater. Retain these in a safe place, see

Section 6. An inspection of the core bricks should also be made

at this stage.

Remove the fi lter panel by pulling the top end away from the heater,

and lift out of location hooks - see Fig G.

Remove the grille mesh by fi rst unscrewing the fi xing screws, then

spring out one end - the grille should now lift clear.

Check that all wiring connections are secure and that the fan rotates

freely.

Fig. I

Bushing

Clamping Bar

Earth

Terminal Block

Main element supplies can be provided from either single phase or

3 phase supplies.

If 3 phase is chosen, the switching circuit must use the red

phase.

An auxiliary or pilot circuit is also required, see Point 3. Control of

the fan operation by a time clock or thermostat is also an option.

Use wiring diagrams for more detail - Figs. A, B and C.

Important

Clarify if the day energy provided by the main heating element is

required. See Point 4.

Carry out the following instructions with care.

Page 4

Main Element Supply - Single Phase

Connect the live (coloured red or brown) of the main supply cable (i.e.

that cable supplying the heating elements) to the D.I.N. connector

block marked ‘L1’ and the neutral lead (coloured blue or black)

to the neutral terminal marked ‘N’. Connect all earth leads (bare

conductors or coloured green or green and yellow) to the earth

terminal marked with the symbol ah. All bare earth conductors must

be sleeved with earth sleeving.

Fit the D.I.N. connector linking bar assembly, see Fig. J, across

D.I.N. connectors marked L1, L2, L3. The linking bar assembly

drops into the centre groove in the top of the connector blocks once

the transit screws, where fi tted, are removed. It is essential that all

screws are fi tted and tightened securely.

Where centre control of the fan is required with the day energy option

the fan supply from the D.I.N. connectors will need to be removed.

Another circuit is required.

Important

Ensure that all cables are routed neatly to the cable clamp, that

no excess wire is left inside the heater and that no wire is left so

that it can ‘foul’ the air mixing fl ap. Tighten the clamp fi rmly on all

incoming cables.

b) Day Energy

The installation design may require the use of the day energy facility

provided by the main heating elements. This facility can be easily

selected using the 8 way snap connectors on the left hand corner

of the lower wiring panel, see Fig. L and Fig. D.

Main Element Supply - Three Phase Connection

Connect each phase of the incoming mains supply cable to the

respective live terminal in the D.I.N. connector blocks i.e. red phase

to L1, yellow phase to L2, blue phase to L3. (Note that the internal

wiring is colour coded red, yellow, blue). Connect the neutral of the

incoming mains supply, coloured black, to the terminal marked ‘N’

on the D.I.N. connector blocks.

Connect all earth leads (bare conductor or coloured green or green

and yellow) to the earth terminal marked with the symbol E. All

bare conductors must be sleeved with earth sleeving.

3. CONNECTION OF AUXILIARY SUPPLY

(FAN OR PILOT)

Connect the live lead of the fan or pilot supply (if day energy is

required, see Point 4), coloured red or brown to the terminal marked

L(u) and likewise the neutral coloured blue or black to the terminal

marked N(u). These terminals are located in the four-way connector

block placed in the centre of the bottom wiring panel. See Fig. K.

and Fig. D

i) Day Energy Operation - If the day energy facility is required the

supply to the mains block will have to be permanently live.

Locate the 8-way connector block and position the two strips so that

the ‘W’s stamped on the strips line up.

ii) Standard Operation - For standard operation position the 8-way

connector so that the ‘S’s stamped on the strips line up.

NOTE: The heater is normally shipped set up for Day Energy

Operation.

5. PREPARATION FOR CORE ASSEMBLY -

i) Remove two screws securing bottom of outer front panel and

lift upwards to withdraw. The ceramic tube for the phial of the

input controller will be taped to a vertical terminal panel - Fig.

M. Remove and keep in a safe place as it will be required when

reassembling the heater - see section 8(e).

Fusible Link

Inner Front

Ceramic Tube

Capillary

of Charge

Controller

4. OPTIONS -

a) Time Clock / Thermostat

Remove the loop of wire from the terminals in the four-way

connector block adjacent to the pilot supply terminal block, see

Fig. K. Remake this connection with the leads from the time clock

and/or thermostat.

Fig. M

ii) Remove the fusible links located halfway up the inner front

panel.

iii) Bend the capillary back to ensure that the inner front panel can

be removed without damaging either capillary or phial.

Page 5

iv) Remove the inner front panel by removing the securing screws.

This panel can now be pulled forward and then withdrawn by tilting

the top outwards and lifting.

v) Note carefully the correct location of the hole in the next layer

of insulation and remove. Check that the interior insulation has not

been disturbed in transit.

vi) Raise the plastic spacers separating the moulded air passages

slightly and remove packs containing elements and sealing strips.

Do not remove spacers until bricks have been built up to same level

as this helps to keep insulation in place - Fig. N.

Ensure both pieces of base insulation have not be disturbed

in transit.

The fi rst layer is constructed from 4 bricks running front to back and

the grooves on top as shown in Fig. S (a). Ensure these sit fi rmly

on the base and locate neatly between the moulded air ducts.

Handle the element with great care. Carefully locate each leg of

the element in a groove of the brick. The second layer can now

be positioned with the brick running from side to side as layer b.

(Except R15 Models - see Fig. T).

Refer to the table and sketch - see Fig. T and fi t the brick exactly as

shown. Element positions are indicated by the numbers.

IMPORTANT - Mica insulation sheets are provided to insulate

between phases. These must be fi tted between the brick layers at

the points indicated on the diagram. Additional labels are also fi tted

to the terminal panels of the heater.

Fig. N

Sealing

Strips

Box

containing

Elements

Spacers

7. CONNECTING THE ELEMENTS

It is important that no part of the bare element wire is exposed or is

close to the brick. The elements are insulated with porcelain fi sh-

spine beads and can be pushed over the wire to ensure there are no

gaps. Locate each element tail in the appropriate groove and route it

round against the side and thread it through the ceramic bush in the

vertical terminal panel. Connect the end of the tail to the appropriate

terminal block. See Fig. O. Note: there is a maximum of two element

tails per terminal block. Check the wiring at this stage for electrical

continuity and insulation resistance. To ensure that the elements are

correctly tightened into the terminal block it is imperative to tighten

it again. This should be done at least three times.

Fig. O

Ensure base

insulation has

not moved during

transit.

Do not cover air inlet

and outlet holes.

vii) Inspect each element and the charge controller for damage

during transit.

6. CORE ASSEMBLY - see Fig. T

NOTE: It is essential that the thermal insulation, especially

the moulded air passages, are not damaged during assembly.

Follow these instructions carefully.

Care must be taken to ensure that the bricks, when fi tted, do not

intrude into the space allowed for air passages around the core. Air

inlet and outlet holes in the bottom of the core must not be covered.

Avoid excess gaps in the core by placing the bricks as close as

possible during assembly.

Follow the instructions below and refer to Fig. T to ensure safe

installation.

Each layer uses 4 double sized bricks. Build the core a layer at a

time and include the elements at the appropriate position as shown

by the number indicated in Fig. T.

Page 6

8. REASSEMBLY OF THE UNIT

i) Fit side insulation strips on each side between the cold tails and

the inner front panel - Fig. P.

ii) Replace inner front insulation. Ensure that when insulation is

fi tted the hole for the charge controller lines up with the grooves in

the second and third layer of bricks down from

the top. In the R15/104 unit only, the charge

controller is entered in grooves between the

fourth and fi fth layers from the top - Fig. Q

Fig.P

Sealing

Strip

Fig. Q

Inner Front

Insulation

iii) Replace inner front panel and secure with screws. Ensure that

hole for charge controller in this panel lines up with that in the inner

front insulation.

iv) Reconnect the fusible links and check for electrical continuity.

Ensure that the fusible links fi t properly into the support bracket.

v) A special ceramic tube houses the phial of the input controller.

Fit the ceramic tube by inserting it through the hole in the safe door

pushing it in the full length - Fig. R.

vi) Fit the input controller phial into the ceramic tube until the end

of the phial bottoms in the tube. About 150mm of the capillary also

goes into this tube. Secure the remainder of the capillary to the

safe door using the clips provided.

9. COMMISSIONING THE UNIT

When the heater has been completely assembled it will be necessary

to commission the unit. This entails checking that the unit is functioning

properly, that the airfl ow delivered is correct for the installation and

that the outlet air temperatures are acceptable.

Fan speeds and outlet temperatures are factory preset but the fan

speed can be adjusted by following the points below;

i) Switch on the heater with the charge controller set at Max and

allow to charge up overnight.

ii) Switch ‘on’ the fan at ‘Boost’ speed and run for fi fteen minutes.

iii) Check the airfl ow delivered and if incorrect adjust as follows;

Switch off mains supplies (both restricted and unrestricted).

Remove fi lter panel. Remove grille. Loosen the fi rst moveable

band from the left on the fan speed resistor (see Fig. D) and move

towards the left-hand end to increase the fan speed, towards the

right-hand end to decrease the fan speed. Tighten up the band on

the resistor and reassemble the heater. Switch on and check the

airfl ow. Repeat the adjustment if necessary.

iv) Switch the fan on to normal speed. After 15 minutes check the

airfl ow delivered, if it is incorrect adjust as above, but in this case it

is the second moveable band from the left which alters the speed.

Ceramic Phial

Holder

Clip

Capillary

Tube

Fig. R

vii) Replace the outer front panel.

viii) Replace the grille mesh.

ix) Replace the fi lter panel.

IMPORTANT - Recheck all electrical connections

for tightness.

Page 7

SPECIAL INSTRUCTIONS FOR CONVERSION FROM R10 TO R7 / R8 HEATER

Follow these instructions carefully to ensure the Electricaire units operate safely and reliably.

The build of the storage core for models R7, R8 and R10 is identical (see diagram Model No. R7/8/10). Elements must only be fi tted

as indicated below.

MODEL R7

Only four elements must be used for this specifi cation. Install elements in positions 3, 4, 5 and 6 only. See diagram Model No.

R7/8/10.

MODEL R8

Only fi ve elements are to be used for this specifi cation. Fit elements into positions 2, 3, 4, 5 and 6 only. See diagram Model No.

R7/8/10.

MODEL R10

All 6 elements are installed as per diagram Model No. R7/8/10.

Important

Self adhesive rating labels are supplied. Please ensure the correct rating label, identifying the correct model,

is fi tted. The rating label is fi xed to the mesh panel behind the detachable fi lter.

Page 8

Installer Note: Please ensure that the USER INSTRUCTIONS are handed

to the User when you have completed the installation if applicable, or left with the

heater if the building is unoccupied when the installation is carried out.

RECYCLING

For electrical products sold within the European Community. At the end of the electrical products useful life

it should not be disposed of with household waste. Please recycle where facilities exist. Check with your Local

Authority or retailer for recycling advice in your country.

ELECTRICAIRE

Customer Help Line 0845 600 5111

Mon–Thurs 08.30-17.00 and Fri 08.30-16.00 (Sept-April)

Mon–Thurs 08.30-17.00 and Fri 08.30-15.00 (May to August)

Fax 01489 773 050

Web-site www.dimplex.co.uk

e-mail technical.services@dimplex.co.uk

Republic of Ireland 01 842 4833

Dimplex UK Ltd,

Millbrook House,

Grange Drive,

Hedge End,

Southampton,

Hampshire,

SO30 2DF

© Dimplex UK Limited

All rights reserved. Material contained in this publication may not be reproduced in whole or part, without prior permission in writing from Dimplex UK Limited.

71186 Issue 8 : 02.09

Loading...

Loading...