Page 1

Service Manual

26” Self Trimming Fireplace

Model Number:

DF2608

DF2622

NBDF2608

UL Part Number

6904400359

IMPORTANT SAFETY INFORMATION: Always read this manual rst before attempting to service this

replace. For your safety, always comply with all warnings and safety instructions contained in this

manual to prevent personal injury or property damage.

Dimplex North America Limited

1367 Industrial Road

1-888-346-7539 www.dimplex.com

In keeping with our policy of continuous product development, we reserve the right to make changes without notice.

© 2011 Dimplex North America Limited

Cambridge ON Canada N1R 7G8

REV PCN DATE

00 11527 Jul 20, 09

01 11658 Oct 13, 09

02 11879 Feb 12, 10

03 Jan 3.12

7400200000R03

Page 2

Table of Contents

Operation .....................................................................3

Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Exploded Parts Diagram - DF2608/NBDF2608 ........................................5

Wiring Diagram - DF2608 / NBDF2608 ..............................................6

Exploded Parts Diagram - DF2622 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Wiring Diagram - DF2622 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Front Glass Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Partially Reective Glass Replacement. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

3-Position Switch Replacement ....................................................9

Heater Switch Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Light Dimmer Replacement ......................................................10

Flame Speed Control Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Flicker Motor/Flicker Rod Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Thermostat Control Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Remote Control Replacement ....................................................14

Log Driver Controller Replacement (DF2608 only) ....................................14

Lower Light Harness Replacement ................................................15

Heater Assembly Replacement ...................................................15

Power Cord Replacement .......................................................16

Troubleshooting Guide . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Always use a qualied technician or service agency to repair this replace.

!

NOTE: Procedures and techniques that are considered important enough to emphasize.

CAUTION: Procedures and techniques which, if not carefully followed, will result in damage to the

equipment.

WARNING: Procedures and techniques which, if not carefully followed, will expose the user to the

risk of re, serious injury, or death.

2

Page 3

Operation

This section will explain the function of each convenient

control (Figure 2).

To access the controls, ip open the control panel cover

towards the bottom of the replace (Figure 1).

Figure 1

when rst used. This odor is a normal condition caused

by initial heating of internal heater parts and will not

occur again.

Resetting The Temperature Cutoff Switch

This unit is equipped with a thermostat which controls the

temperature of the room. It does this by turning the heater

on and off. The heater is protected with a safety device

to prevent overheating. Should the heater overheat, an

automatic cut out will turn the heater off and it will not come

back on without being reset. It can be reset by switching

the 3-Position Switch to Off (“ o ”)and waiting ve (5)

minutes before switching the unit back on.

CAUTION: If you need to continuously reset the heater,

unplug the unit and call Technical Support at

1-888-346-7539. Please have your model and serial

number ready when calling.

Figure 2

A EC DB

A. 3-Position Switch

The switch has two (2) On positions marked with “ I ” and

“ II ”. The “ I ” position is for manual operation. In this

position the built-in remote control is bypassed. The “ II ”

position is for operating the unit with the provided remote

control. When in “ II ” position the unit is operated with

the ON and OFF buttons of the remote control. When the

switch is in the center “ o ” position the unit is off.

B. Flame Speed Control

Turn the Flame Speed Control knob to adjust the ame

speed to the desired level.

C. Light Dimmer Control

Turn the Light Dimmer Control knob to increase or

decrease the brightness of the interior of the replace.

D. Heater Switch

The Heater Switch supplies power to the heating unit when

the 3-Position Switch (A) is on (“ I ” or “ II ” positions).

E. Thermostat Control

To adjust the temperature to your individual requirements,

turn the thermostat control clockwise all the way to

turn on the heater. When the room reaches the desired

temperature, turn the thermostat knob counter clockwise

until you hear a click. Leave in this position to maintain the

room temperature at its setting. For additional heat, turn

clockwise until you hear the click again and the heater will

turn on. To turn the heater off, rotate the knob fully counter

clockwise.

!

NOTE: The heater may emit a slight, harmless odor

Remote Control

The replace is supplied with an

integrated on/off remote control.

!

NOTE: Ensure that the 3-Position

Switch on the replace is set to

the remote control setting (“II”

position).

To operate, push the ON button to

turn the replace on, push the OFF

button to turn the replace off.

Battery Replacement (Figure 3)

To replace the battery:

• Slide battery cover open on the

hand held transmitter.

• Correctly install one (1) 12 Volt

(A23) battery in the battery holder.

• Close the battery cover.

Remote Initialization/Reprogram

Follow these steps for remote control

initialization and if required,

reinitialization:

1. Disconnect power to replace.

2. Set the 3-Position Switch to the Remote position (Figure

2A).

3. Wait a minimum of ve (5) seconds and then reacquire

power to replace.

4. Within 10 seconds of reacquiring power, press the ON

button located on the remote control.

!

NOTE: You will have only 10 seconds to perform this last

step. Failure to do so will result in these steps needing

to be followed again.

Figure 3

OFF

Button

ON

Button

Battery

Cover

3

Page 4

Maintenance

WARNING: Disconnect power before attempting any

maintenance or cleaning to reduce the risk of re, electric

shock or damage to persons.

Light Bulb Replacement

Allow at least ve (5) minutes for the light bulbs to cool

before touching them to avoid accidental burning of the skin.

The light bulbs need to be replaced when you notice a dark

section of the ame or when the clarity and detail of the

log ember bed exterior reduces. There are three (3) bulbs

under the Log Set Assembly, which generate the ames

and embers, and two (2) bulbs above that illuminate the log

exterior.

Lower Light Bulb Requirements: Quantity of three (3) clear

chandelier or candelabra bulbs with an E-12 (small) socket

base, 60 Watt rating. Example: GE 60BC or Philips 60CTC.

Do not exceed 60 Watts per bulb.

Helpful Hints: It is a good idea to replace all light bulbs at

one time if they are close to the end of their rated life. Group

replacement will reduce the number of times you need to

open the unit to replace light bulbs. Care must be taken

when removing the Log set assembly as it contains LED’s

and wires (DF2608 only).

Slide replace out of mantel.1.

Lay unit on it’s back for safe removal of front glass.2.

Remove three (3) Phillips screws from the right side of 3.

trim.

Remove trim.4.

Slide glass to right side of replace to remove (Figure 3).5.

Pull the front edge of the plastic ember bed or plastic 6.

grate up and forward until the rear tab releases from

the ledge located at the bottom of the partially reective

glass (Figure 4).

!

IMPORTANT: Only handle the log set assembly by the

ember bed or plastic grate.

!

NOTE: Log set assembly ts tightly into rebox, some

force may be necessary to remove.

Set log set assembly in front of replace.7.

Remove icker rod by pulling rod to the right, towards the 8.

icker motor. Bend the icker rod enough to clear the

bracket on the left, lift out and pull icker rod off of icker

motor shaft (Figure 5).

Remove four (4) Phillips screws (two (2) per side) which 9.

attach light lter bracket for easier access to light bulbs

(Figure 5).

Unscrew bulbs counter clockwise to remove.10.

Figure 3

Trim

Figure 4

Back

Ledge

Log

Ember Bed

Figure 5

Flicker Rod

Light Block

Light Filter

Bracket screws (2)

Lower Light

Bulbs (3)

Light Block screws (4)

Insert new bulbs and screw in clockwise.11.

Replace light lter bracket and icker rod.12.

Install the log set assembly by placing the front, bottom 13.

edge of the ember bed in the track behind the control

panel. Once in place, push down on the back edge of

the ember bed until the rear tab snaps into place under

the mirror (Figure 4).

!

NOTE: Ensure the log set Assembly is installed tightly

under the bottom edge of the mirror to prevent light leakage.

Lay unit on it’s back and slide Front Glass back into 14.

position and attach trim.

Upper Light Bulb Requirements: Quantity of two (2) clear

chandelier or candelabra bulbs with an E-12 (small) socket

base, 15 Watt rating.

Do not exceed 25 Watts per bulb.

To access the upper light bulb area:

Slide replace out of mantel.1.

Lay unit on it’s back for safe removal of front glass.2.

Remove three (3) Phillips screws from right side of trim.3.

Remove trim.4.

Slide glass to the right side of the replace to remove 5.

(Figure 3).

Upper bulbs are located in the upper left and upper 6.

right corners of replace, behind the light block bracket

(Figure 5).

Remove the four (4) Phillips screws that attach the light 7.

block to the rebox (Figure 5).

Unscrew bulbs counter clockwise.8.

Insert new bulbs and screw in clockwise.9.

Re-attach light block bracket.10.

Lay unit on it’s back, slide front glass back into position 11.

and attach Trim.

Glass Cleaning

The glass is cleaned in the factory during the assembly

operation. During shipment, installation, handling, etc.,

the clear door may collect dust particles, these can be

removed by dusting lightly with a clean dry cloth.

To remove ngerprints or other marks, the clear door can

be cleaned with a damp cloth.

Log Set

Assembly

Front

Glass

Rear

Tab

Side Section

Fireplace Surface Cleaning

Use a cloth dampened with warm water only to clean

Front

painted surfaces of the electric replace. Do not use

Edge

abrasive cleaners.

4

Page 5

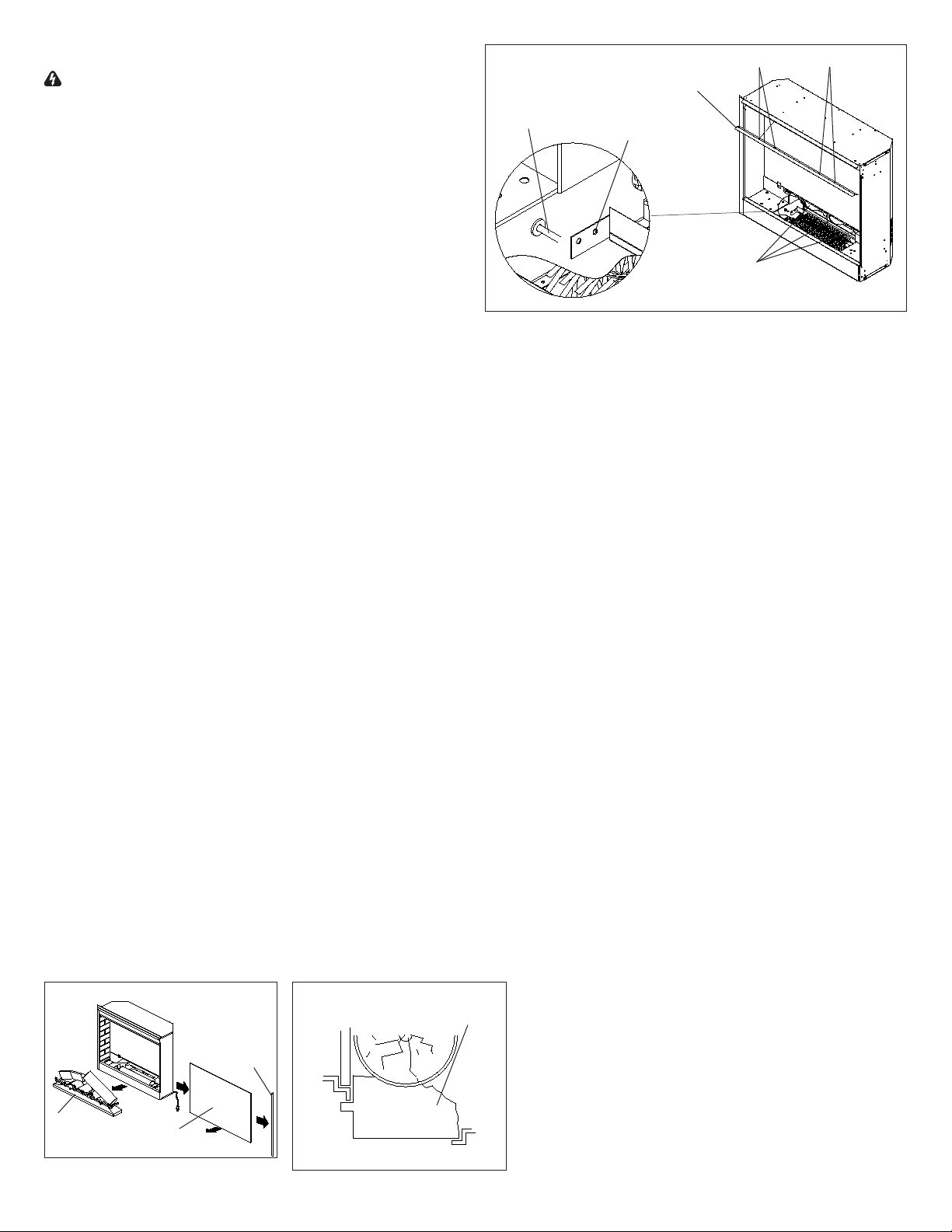

Exploded Parts Diagram - DF2608/NBDF2608

4

14

18

10

12

13

7

8

9

19

16

1

11

3

1

Replacement Parts List

Part Number 6904400359

Replacement Part:

Log Set1. . . . . . . . . . . . . . . . . . . . . . . . . 0439560100RP

Log Driver Controller2. .............. 3000390100RP

Flicker Motor 3. . . . . . . . . . . . . . . . . . . . 3000240200KIT

Heater Assembly (with cutout) 4. ...... 2000330100RP

Thermostat 5. . . . . . . . . . . . . . . . . . . . . . 2300150100RP*

Heater Switch 6. . . . . . . . . . . . . . . . . . . . 2800210500RP

3-Position Switch 7. . . . . . . . . . . . . . . . . 2800210100RP

Flame Speed Control 8. . . . . . . . . . . . . . 3000240500RP

Light Dimmer Control 9. . . . . . . . . . . . . . 3000250100RP

Power Cord 10. . . . . . . . . . . . . . . . . . . . . 4100040200RP

15

5

6

Single Light Holder11. . . . . . . . . . . . . . . . 2500150300RP

Double Light Harness 12. . . . . . . . . . . . . 2500400300RP

Partially Reective Glass 13. .......... 5901210200RP

Partially Reective Glass (NBDF2608) 5901450100RP

Front Glass 14. . . . . . . . . . . . . . . . . . . . . 5901220100RP

Control Knob (3 on unit)15. . . . . . . . . . . . 8800000200RP

Remote Control 16. . . . . . . . . . . . . . . . . . 3000370500RP

Remote Control Receiver 17. ..........3000380200RP

Terminal Block 18. . . . . . . . . . . . . . . . . . . 4000070100RP

Flicker Rod 19. . . . . . . . . . . . . . . . . . . . . . 5901250100RP

17

2

5

Page 6

Wiring Diagram - DF2608 / NBDF2608

Remote Control

Receiver

Heater

Switch

3-Position

Switch

Power

Cord

Light Dimmer

Control

Log Set

Driver

Heater

Assembly

Thermostat

Flame Speed

Control

6

Page 7

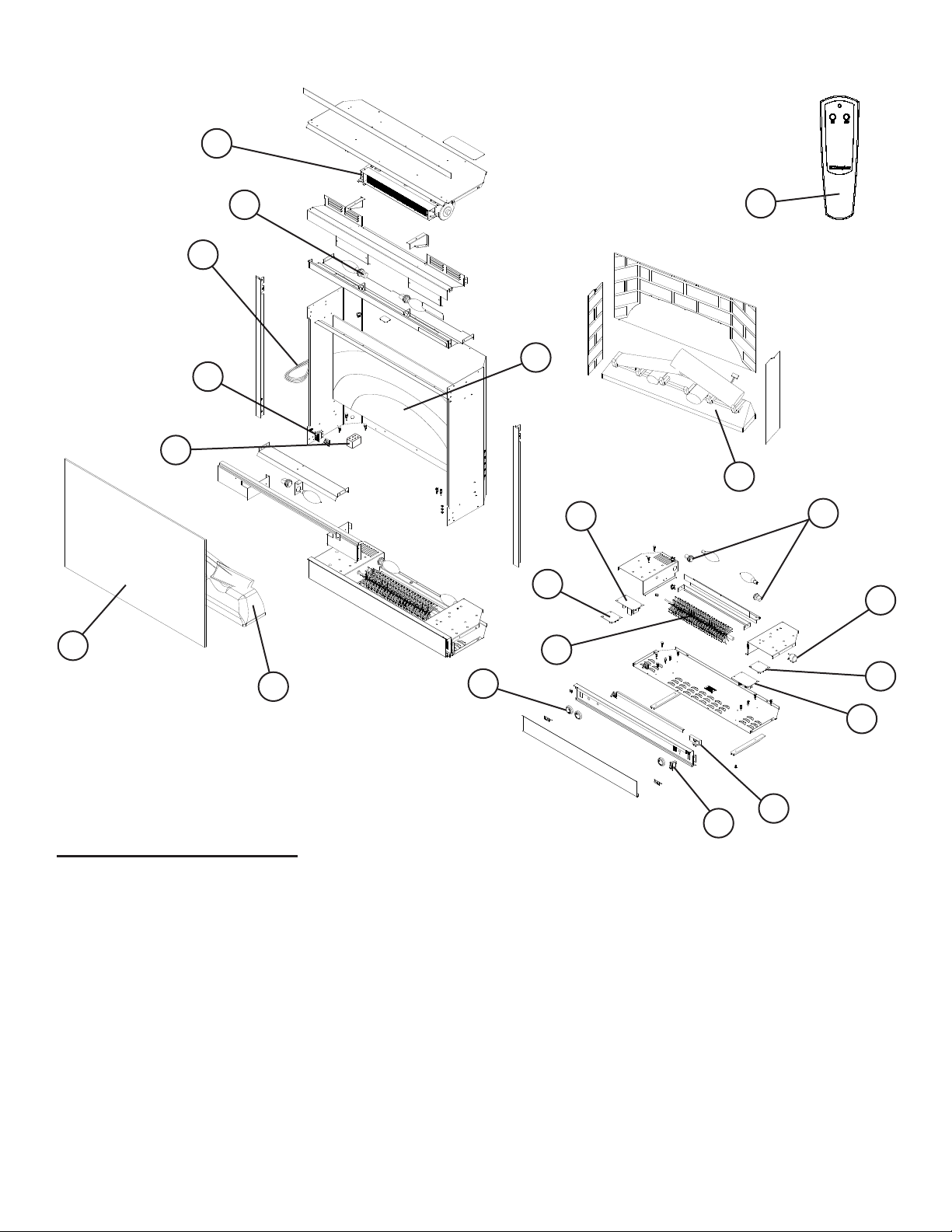

Exploded Parts Diagram - DF2622

3

11

9

22

6

20

15

12

17

13

1

Replacement Parts List

Part Number 6904400659

Replacement Part:

Log Set1. . . . . . . . . . . . . . . . . . . . . . . . 0439560200RP

Flicker Motor 2. . . . . . . . . . . . . . . . . . . 3000240200KIT

Heater Assembly (with cutout) 3. .....2000330100RP

Thermostat 4. . . . . . . . . . . . . . . . . . . . . 2300150100RP*

Heater Switch 5. . . . . . . . . . . . . . . . . . . 2800210100RP

3-Position Switch 6. . . . . . . . . . . . . . . . 2800210500RP

Flame Speed Control 7. . . . . . . . . . . . . 3000240500RP

Light Dimmer Control 8. . . . . . . . . . . . . 3000250100RP

Power Cord 9. . . . . . . . . . . . . . . . . . . . 4100040200RP

Single Light Holder 10. . . . . . . . . . . . . . . 2500150300RP

Double Light Harness 11. . . . . . . . . . . . 2500400300RP

Partially Reective Glass 12. .........5901450100RP

21

7

8

18

14

19

4

5

Front Glass 13. . . . . . . . . . . . . . . . . . . . 5901220100RP

Control Knob (3 on unit)14. . . . . . . . . . . 8800000200RP

Remote Control 15. . . . . . . . . . . . . . . . . 3000370500RP

Remote Control Receiver 16. .........3000380200RP

Terminal Block 17. . . . . . . . . . . . . . . . . . 4000070100RP

Flicker Rod 18. . . . . . . . . . . . . . . . . . . . . 5901250100RP

Stainless Steel Replacement Parts for DF2622SS

Stainless Steel Control Cover19. . . . . . . 1018760180RP

Stainless Steel Top Trim20. . . . . . . . . . . 1018830180RP

Stainless Steel Right Side Trim21. .....1018840180RP

Stainless Steel Left Side Trim22. . . . . . . 1018830280RP

10

2

16

7

Page 8

Wiring Diagram - DF2622

Remote Control

3-Position

Switch

Receiver

Power Cord

Light Dimmer

Control

Heater

Switch

Heater

Assembly

Thermostat

8

Page 9

Front Glass Replacement

CAUTION: If unit was operating prior to servicing allow

at least 10 minutes for lights, heating elements and top

panel to cool off to avoid accidental burning of skin.

WARNING: Disconnect power before attempting any

maintenance to reduce the risk of electric shock or damage

to persons.

Slide rebox out of mantel.1.

Lay unit on it’s back for safe removal of Front Glass.2.

Remove three (3) Phillips screws from right side of Trim.3.

Remove Trim.4.

Slide glass to the right side of the rebox to remove 5.

(Figure 6).

Reassemble using replacement Front Glass in reverse 6.

order as described above.

CAUTION: Even though the glass is safety glass it

may break if bumped, struck or dropped. Care must be

taken when handling the glass.

Reective Glass.

!

IMPORTANT: Only handle the Log Set Assembly by

the Ember Bed or plastic grate.

!

NOTE: Log Set Assembly ts tightly into rebox, some

force may be necessary to remove.

Loosen but do not remove the two (2) Philips screws 7.

that clamp the Partially Reective Glass in place, and

swivel down so that the clamp clears the edge of the

Partially Reective Glass (Figure 7).

Push the Partially Reective Glass out from behind to 8.

clear the frame and remove.

Insert replacement Partially Reective Glass top end 9.

rst and lay the bottom end gently in the bottom track

of the frame.

Tighten clamps back into place and reassemble rebox 10.

in reverse order as described above.

Figure 7

Figure 6

Trim

Log Set

Assembly

Front Glass

Partially Reective Glass Replacement

CAUTION: If unit was operating prior to servicing allow

at least 10 minutes for lights, heating elements and top

panel to cool off to avoid accidental burning of skin.

WARNING: Disconnect power before attempting any

maintenance to reduce the risk of electric shock or damage

to persons.

Slide rebox out of mantel.1.

Lay unit on it’s back for safe removal of Front Glass.2.

Remove three (3) Phillips screws from the right side of 3.

Trim.

Remove Trim.4.

Slide glass to right side of replace to remove (Figure 5.

6).

CAUTION: Even though the glass is safety glass it

may break if bumped, struck of dropped. Care must be

taken when handling the glass.

Pull the front edge of the plastic Ember Bed or plastic 6.

grate up and forward until the rear tab releases

from the ledge located at the bottom of the Partially

Partially Reective

Glass

Clamp

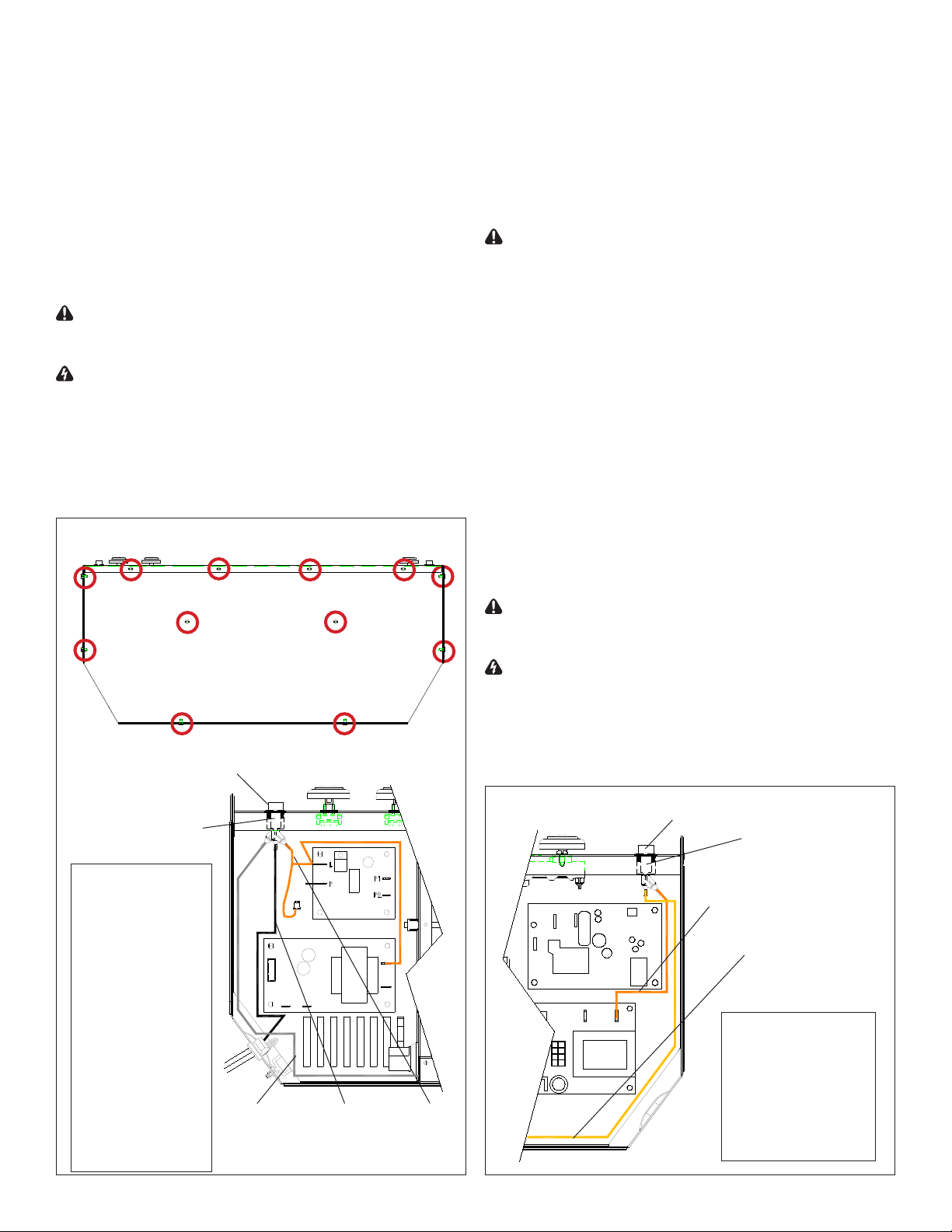

3-Position Switch Replacement

CAUTION: If unit was operating prior to servicing allow

at least 10 minutes for lights, heating elements and top

panel to cool off to avoid accidental burning of skin.

WARNING: Disconnect power before attempting any

maintenance to reduce the risk of electric shock or damage

to persons.

Remove the rebox from the mantel.1.

Lay unit on its back.2.

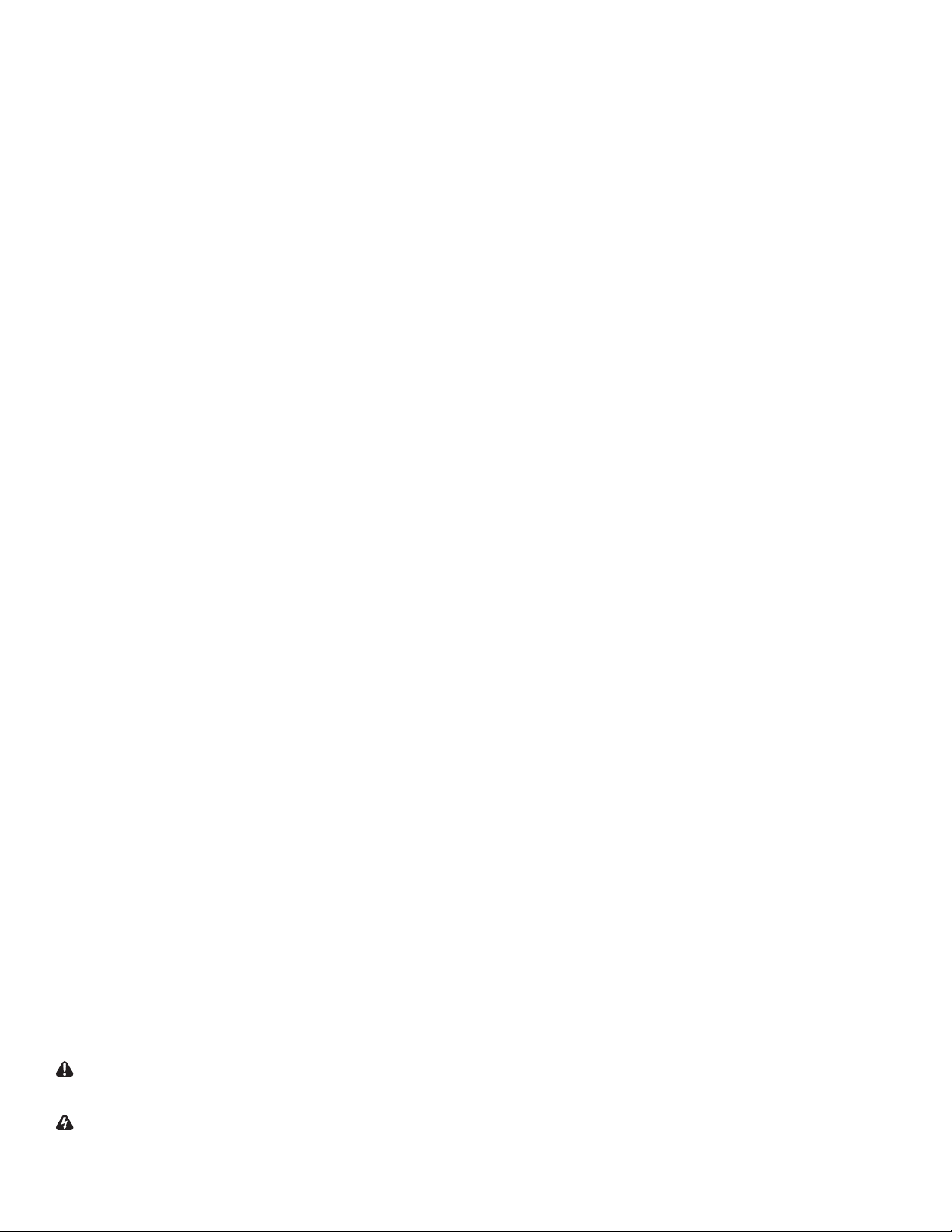

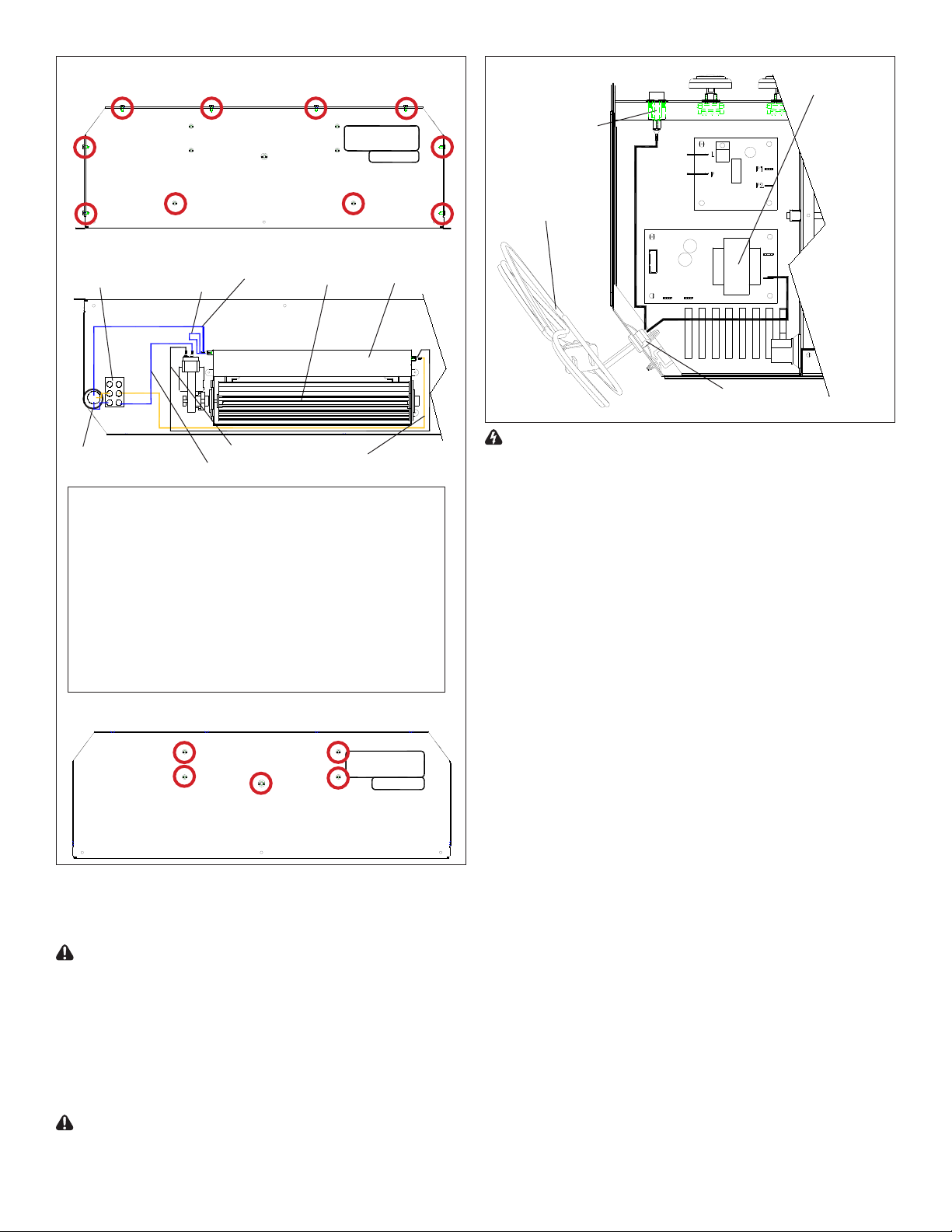

Remove the 12 Philips screws that fasten the bottom 3.

cover to the rest of the rebox. There are: two (2)

screws on each side; two (2) screws on the back panel

(you may have to tip the bottom of the rebox up if it is

laying on its back), four (4) screws in the front directly

under the control panel; and two (2) screws on the

bottom of the rebox (see Figure 8). The bottom panel

is now free to be removed.

Locate the 3-Position Switch mounted on the control 4.

panel on the left side (Figure 9) and disconnect the

three (3) wiring clips noting their original locations.

CAUTION: Internal wire colors may not be the same

within the unit being serviced as those shown. To avoid

damage to the unit, damage to property or personal injury,

ensure wires are reconnected to match their original

locations.

Depress the two (2) retainer clips on the top and 5.

9

Page 10

bottom of the switch and push the switch out the front

panel.

Properly orient the new switch and reconnect all of the 6.

wiring clips and connections as before.

Push the switch through the front control panel until 7.

the Retainer Clips snap the switch into place, then

reassemble the rebox in reverse order as above.

!

NOTE: When placing bottom panel back onto unit,

position the metal lip from under the control panel between

the rubber spacers (attached to the bottom panel) and the

sheet metal of the bottom panel.

Heater Switch Replacement

CAUTION: If unit was operating prior to servicing allow

at least 10 minutes for lights, heating elements and top

panel to cool off to avoid accidental burning of skin.

WARNING: Disconnect power before attempting any

maintenance to reduce the risk of electric shock or damage

to persons.

Remove the rebox from the mantel.1.

Lay unit on its back.2.

Remove the 12 Philips screws that fasten the bottom 3.

cover to the rest of the rebox. There are: two (2)

Figure 8

Screws To Remove

screws on each side; two (2) screws on the back panel

(you may have to tip the bottom of the rebox up if it is

laying on its back), four (4) screws in the front directly

under the control panel; and two (2) screws on the

bottom of the rebox (Figure 8). The bottom panel is

now free to be removed.

Locate the Heater Switch mounted on the control panel 4.

on the right side (Figure 10, page 11) and disconnect

the two (2) wiring clips noting their original locations.

CAUTION: Internal wire colors may not be the same

within the unit being serviced as those shown. To avoid

damage to the unit, damage to property or personal injury,

ensure wires are reconnected to match their original

locations.

Depress the two (2) retainer clips on the top and 5.

bottom of the switch and push the switch out the front

of the rebox.

Properly orient the new switch and reconnect all of the 6.

wiring clips and connections as before.

Push the switch through the front control panel until 7.

the Retainer Clips snap the switch into place, then

reassemble the rebox in reverse order as above.

!

NOTE: When placing bottom panel back onto unit,

position the metal lip from under the control panel

between the rubber spacers (attached to the bottom

panel) and the sheet metal of the bottom panel.

Figure 9

3-Position Switch

Retainer Clips

(One top, one bottom)

Wire 1: Dark orange

piggy-back wire

from bottom

terminal of switch

to: top, left terminal

of Dimmer Control

and; to one of 3

wire connectors.

Wire 2: Black,

smooth edged wire

from power cord to

middle terminal of

switch.

Wire 3: Grey wire

from top terminal

of switch to

opposite side of

rebox.

Light Dimmer Replacement

CAUTION: If unit was operating prior to servicing allow

at least 10 minutes for lights, heating elements and top

panel to cool off to avoid accidental burning of skin.

WARNING: Disconnect power before attempting any

maintenance to reduce the risk of electric shock or damage

to persons.

Remove the rebox from the mantel.1.

Lay unit on its back.2.

Remove the 12 Philips screws that fasten the bottom 3.

Figure 10

Wire 1Wire 2Wire 3

Heater Switch

Retainer Clips

(One top, one bottom)

Wire 1

Wire 2

Wire 1: Dark orange

wire from bottom

terminal of switch to

top, right terminal of

Log Driver (DF2608).

Wire 2: Yellow wire

from top terminal of

switch to other side of

rebox.

10

Page 11

cover to the rest of the rebox. There are: two (2)

screws on each side; two (2) screws on the back panel

(you may have to tip the bottom of the rebox up if it is

laying on its back), four (4) screws in the front directly

under the control panel; and two (2) screws on the

bottom of the rebox (Figure 8). The bottom panel is

now free to be removed.

Locate the Light Dimmer Control Board and 4.

Potentiometer mounted on the left side (Figure 11).

Pull off the Light Dimmer Control knob and unscrew 5.

the retaining nut (Figure 11). The Potentiometer

can now be removed from the panel by pushing the

potentiometer through the front panel and removed

from inside the rebox.

The Light Dimmer Control board is fastened to the 6.

underside of the Ember Bed support by four (4)

mounting studs, one in each corner (Figure 11).

Squeeze each mounting stud’s clasp to release the

circuit board from the rebox.

!

NOTE: If mounting studs are damaged, replacement

mounting studs will need to be inserted from underneath

Log Set Assembly. Follow steps 1 - 6 of Partially Reective

Glass Replacement procedure on page 9 to do this. It

is recommended to attempt to release the control board

without cutting mounting studs.

Properly orient the replacement Light Dimmer Control 7.

board and push it onto the four (4) mounting studs

(running the connecting Potentiometer wires under the

board) until the clasps of the mounting studs snap the

control board into place.

Properly orient the Potentiometer attached to the 8.

replacement control board, push it through the front

control panel and anchor it in place using the retaining

Figure 11

Retaining

Nut

Potentiometer

Light Dimmer

Control Board

Mounting Studs (4)

Wire 2Wire 1

Wire 1: White wire from bottom, left terminal of board to

cable sheath leading to upper rebox area.

Wire 2: Dark orange piggy-back wire from top, left terminal

of board to: top, right terminal of Flame Speed Control

board and; bottom terminal of 3-Position Switch.

nut removed in step 5.

Disconnect one of the two (2) wire leads from the 9.

original control board (which are still connected to

parts within the rebox) and immediately connect it to

the new control board’s terminal, matching its position.

Continue with the remaining wire using the same

procedure.

CAUTION: Internal wiring and colors may not be the

same within the unit being serviced as those shown. To

avoid damage to the unit, damage to property or personal

injury, ensure wires are reconnected to match their original

locations.

Follow steps 1 through 3 in reverse order to 10.

reassemble the rebox.

!

NOTE: When placing bottom panel back onto unit,

position the metal lip from under the control panel

between the rubber spacers (attached to the bottom

panel) and the sheet metal of the bottom panel.

Flame Speed Control Replacement

CAUTION: If unit was operating prior to servicing allow

at least 10 minutes for lights, heating elements and top

panel to cool off to avoid accidental burning of skin.

WARNING: Disconnect power before attempting any

maintenance to reduce the risk of electric shock or damage

to persons.

Remove the rebox from the mantel.1.

Lay unit on its back.2.

Remove the 12 Philips screws that fasten the bottom 3.

cover to the rest of the rebox. There are: two (2)

screws on each side; two (2) screws on the back panel

(you may have to tip the bottom of the rebox up if it is

laying on its back), four (4) screws in the front directly

under the control panel; and two (2) screws on the

bottom of the rebox (Figure 8). The bottom panel is

now free to be removed.

Locate the Flame Speed Control and Potentiometer 4.

mounted on the left hand side (Figure 12).

Pull off the Flame Speed Control knob and unscrew 5.

the retaining nut (Figure 12). The Potentiometer

can now be removed from the panel by pushing the

Potentiometer through the front panel and remove from

inside the rebox.

The Flame Speed Control board is fastened to the 6.

underside of the Ember Bed support by four (4)

mounting studs, one in each corner (Figure 12).

Squeeze each mounting stud’s clasp to release the

circuit board from the rebox.

!

NOTE: If mounting studs are damaged, replacement

mounting studs will need to be inserted from underneath

Log Set Assembly. Follow steps 1 - 6 of Partially

Reective Glass Replacement procedure to do this. It

is recommended to attempt to release the control board

without cutting mounting studs.

Properly orient the replacement Flame Speed Control 7.

board and push it onto the four (4) mounting studs

(running the connecting Potentiometer wires under the

11

Page 12

Figure 12

Potentiometer

Flame Speed

Control Board

Wire 1

Mounting Studs (4)

Wire 2

Cable connector

for Flicker Motor

Wire 1: Dark orange piggy-back wire from top, right

terminal of Flame Speed Control board to: top, right

terminal of Light Dimmer board and; other side of rebox.

Wire 2: Blue wire from bottom, right terminal of Flame

Speed Control board to one of 3 wire connectors.

Wire 3: Black wire from bottom, right terminal of Flame

Speed Control board to power cord.

Wire 3

Retaining

Nut

board where possible) until the clasps of the mounting

studs snap the control board into place.

Properly orient the Potentiometer attached to the 8.

replacement control board, push it through the front

control panel and anchor it in place using the retaining

nut removed in step 5.

Disconnect one of the wire leads from the original 9.

control board (which are still connected to parts

within the rebox) and immediately connect it to the

new control board’s terminal, matching its position.

Continue with the remaining wires (there are four (4)

wires which are piggy-backed together in pairs, and the

cable connector which leads to the Flicker Motor) using

the same procedure.

CAUTION: Internal wiring and colors may not be the

same within the unit being serviced as those shown. To

avoid damage to the unit, damage to property or personal

injury, ensure wires are reconnected to match their original

locations.

Follow steps 1 through 3 in reverse order to 10.

reassemble the rebox.

!

NOTE: When placing bottom panel back onto unit,

position the metal lip from under the control panel between

the rubber spacers (attached to the bottom panel) and the

sheet metal of the bottom panel.

maintenance to reduce the risk of electric shock or damage

to persons.

Remove the rebox from the mantel.1.

Lay unit on its back.2.

Remove the 12 Philips screws that fasten the bottom 3.

cover to the rest of the rebox. There are: two (2)

screws on each side; two (2) screws on the back panel

(you may have to tip the bottom of the rebox up if it is

laying on its back), four (4) screws in the front directly

under the control panel; and two (2) screws on the

bottom of the rebox (Figure 8). The bottom panel is

now free to be removed.

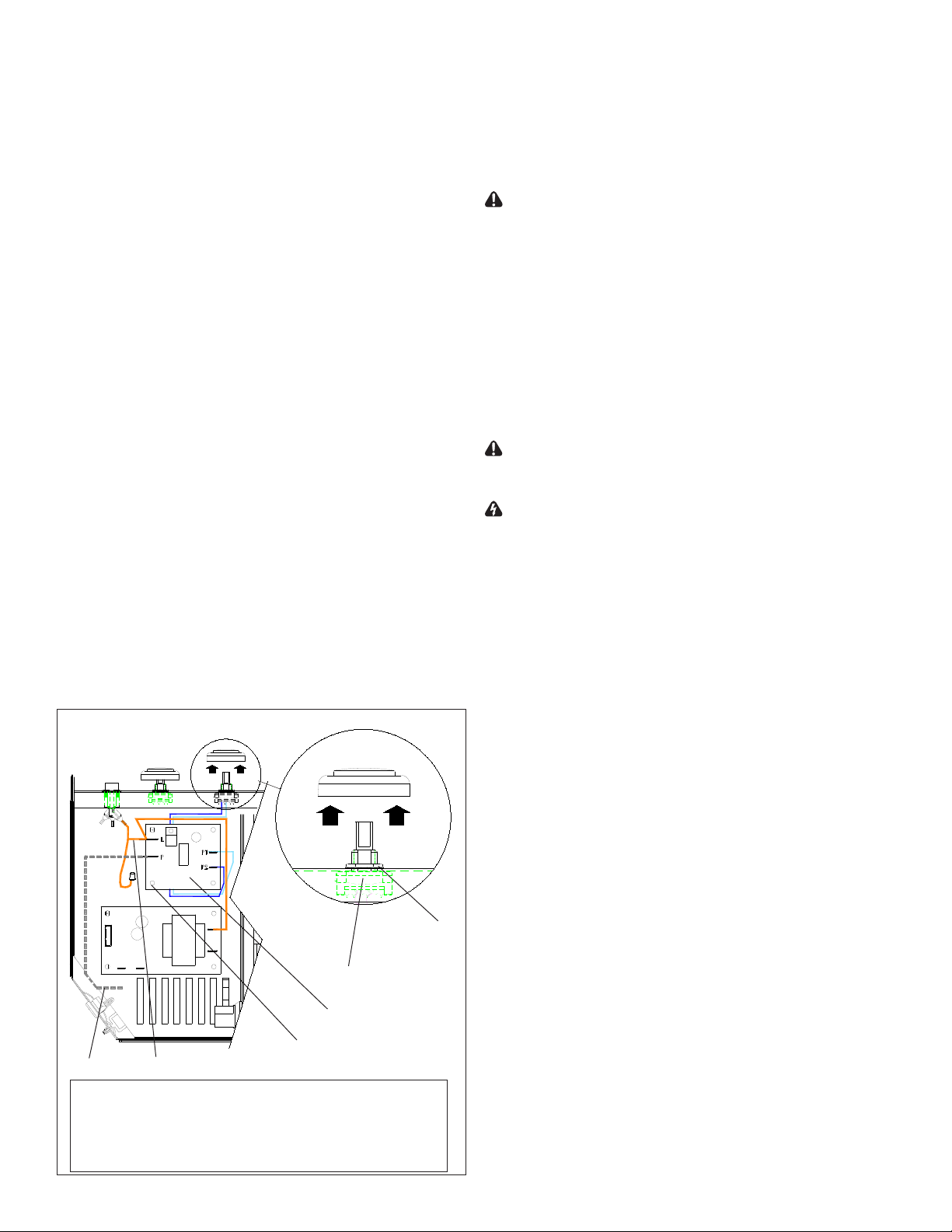

Locate Flicker Rod and Flicker Motor in the base 4.

assembly (Figure 13).

Gently pull the Flicker Rod to the right as far as 5.

possible into the rubber bushing (Figure 13).

!

NOTE: When removing the Flicker Rod, damage may

occur if bent excessively. If the Flicker Rod is damaged,

replace to insure proper operation.

Cautiously bend the Flicker Rod enough so that the 6.

remaining end of the Flicker Rod clears the plastic

bushing on the left (Figure 14).

Remove the Flicker Rod by pulling it free from the 7.

rubber bushing on the motor shaft (Figure 14).

Before removing the Flicker Motor, cut the Flicker Motor 8.

Figure 13

Figure 14

5 Color

Cable

Flicker

Rod

Flicker

Motor

Mounting

Screw

Rubber

Bushing

Flicker

Motor

Flicker Motor/Flicker Rod Replacement

CAUTION: If unit was operating prior to servicing allow

at least 10 minutes for lights, heating elements and top

panel to cool off to avoid accidental burning of skin.

WARNING: Disconnect power before attempting any

Mounting

Screw

12

Page 13

wires (ve (5) in total) as close to the Flicker Motor as

possible.

Remove the rubber bushing from the motor shaft by 9.

applying needle nose pliers to the motor shaft and twist

the rubber bushing off of the motor shaft.

Remove the two (2) motor mounting screws and 10.

remove Flicker Motor from the mounting bracket

(Figure 14).

Discard old Flicker Motor.11.

Pick up new Flicker Motor and cut wire leads to 3 ½ 12.

inch long with wire cutters.

Using one of the supplied wire connectors from the 13.

Replacement Part Kit, place one (1) yellow wire from

the new Flicker Motor and the yellow wire cut in step 8

into each terminal.

Secure the wire connector by crimping the 3M symbol 14.

with pliers.

Pull on end of wires to ensure a strong connection.15.

Repeat the process for the four (4) remaining wires. 16.

Ensure that all wires are paired by color in each

connector.

!

NOTE: In the event that multiple Flicker Motors were

already replaced within unit, or if required wiring has been

cut too short, it may be necessary to replace Flicker Motor

and the attached cable as a whole.

To do so:

i) Follow steps 1 through 7 and step 9.

ii) Unplug the cable connector from the Flame Speed

Control board on the left side of the rebox (Figure 12,

page 12).

iii) Cut all cable ties that bind the Flicker Motor Cable

and other wires together (wires and cable run behind

the lower bulbs).

iv) Follow steps 10 and 11 to remove defective Flicker

Motor.

v) Follow steps 17 through 19 to install new Flicker

Motor.

vi) Run Flicker Motor Cable along channel behind

lower bulbs and bind together with other wires using

cable ties.

vii) Plug cable connector into Flame Speed Control

board (Figure 12).

viii) Reassemble rebox and replace in mantel.

Properly orient and secure the replacement Flicker 17.

Motor to the bracket with screws removed in step 10.

Replace rubber bushing on motor shaft.18.

Replace Flicker Rod.19.

Reassemble rebox and replace in mantel.20.

!

NOTE: When placing bottom panel back onto unit,

position the metal lip from under the control panel

between the rubber spacers (attached to the bottom

panel) and the sheet metal of the bottom panel.

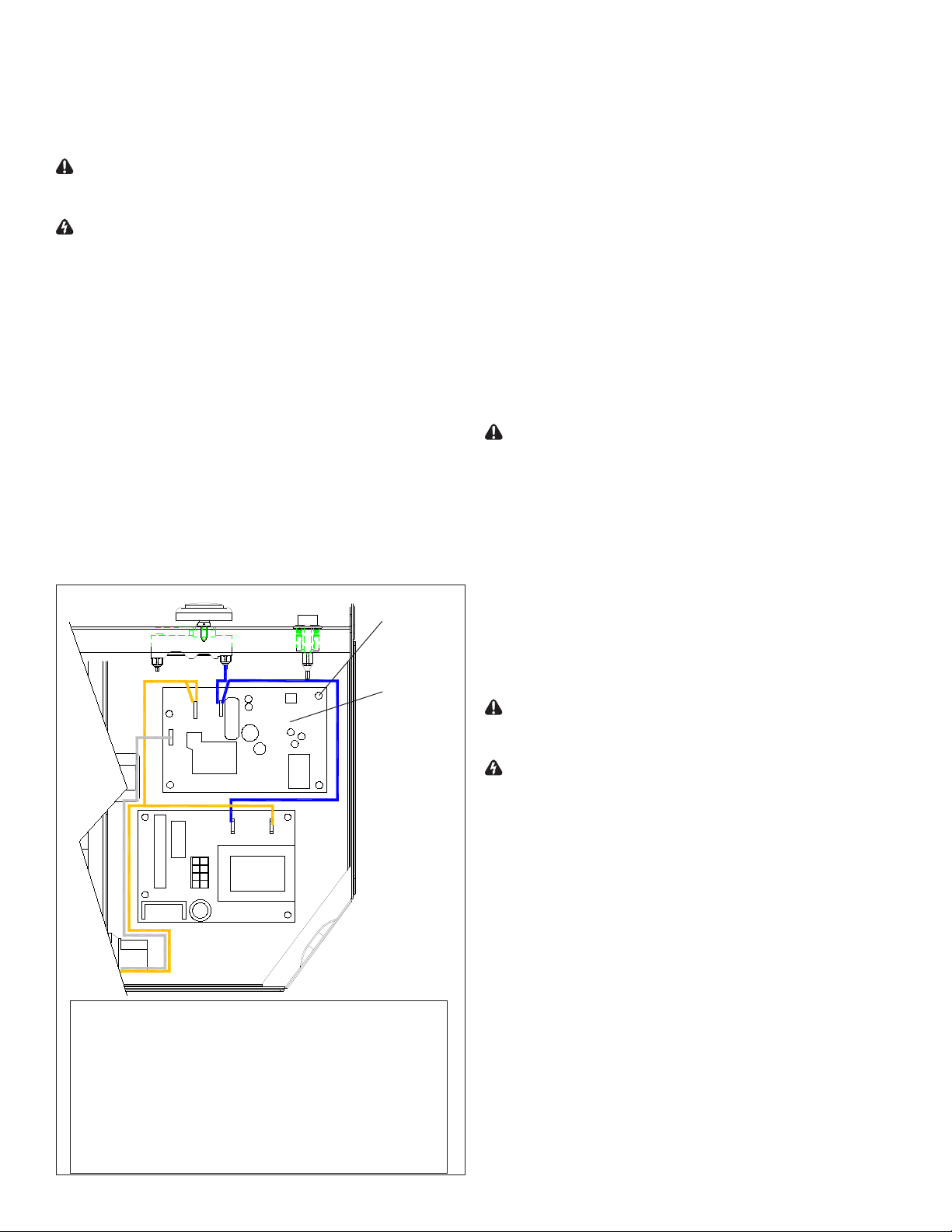

Thermostat Control Replacement

CAUTION: If unit was operating prior to servicing allow

at least 10 minutes for lights, heating elements and top

panel to cool off to avoid accidental burning of skin.

WARNING: Disconnect power before attempting any

maintenance to reduce the risk of electric shock or damage

to persons.

Remove the rebox from the mantel.1.

Lay unit on its back.2.

Remove the 12 Philips screws that fasten the bottom 3.

cover to the rest of the rebox. There are: two (2)

screws on each side; two (2) screws on the back panel

(you may have to tip the bottom of the rebox up if it is

laying on its back), four (4) screws in the front directly

under the control panel; and two (2) screws on the

bottom of the rebox (Figure 8). The bottom panel is

now free to be removed.

Locate the Thermostat Control mounted on the control 4.

panel on the right hand side (Figure 15) and disconnect

the two (2) wiring clips noting their original locations.

CAUTION: Internal wiring and colors may not be the

same within the unit being serviced as those shown. To

avoid damage to the unit, damage to property or personal

injury, ensure wires are reconnected to match their original

locations.

Pull off the thermostat control knob to expose the two 5.

(2) Philips mounting screws (Figure 15).

Remove the mounting screws and remove the 6.

thermostat controller from inside the control panel.

Properly orient the new Thermostat Control and 7.

reconnect the wiring connections.

Reassemble in the reverse order as above.8.

!

NOTE: When placing bottom panel back onto unit,

position the metal lip from under the control panel

between the rubber spacers (attached to the bottom

panel) and the sheet metal of the bottom panel.

Figure 15

Thermostat

Wire 1

Wire 2

Wire 1: Blue wire from right terminal of thermostat to top,

right terminal of Remote Control Receiver.

Wire 2: Blue wire from left terminal of thermostat to

opposite side of rebox and up to Heater Assembly.

Screw

13

Page 14

Remote Control Replacement

Remote Control require no replacement procedure

however, a reinitialization procedure may need to be

followed. Refer to Page 1 for the Remote Initialization/

Reprogram procedure.

CAUTION: If unit was operating prior to servicing allow

at least 10 minutes for lights, heating elements and top

panel to cool off to avoid accidental burning of skin.

WARNING: Disconnect power before attempting any

maintenance to reduce the risk of electric shock or damage

to persons.

Remove the rebox from the mantel.1.

Lay unit on its back.2.

Remove the 12 Philips screws that fasten the bottom 3.

cover to the rest of the rebox. There are: two (2)

screws on each side; two (2) screws on the back panel

(you may have to tip the bottom of the rebox up if it is

laying on its back), four (4) screws in the front directly

under the control panel; and two (2) screws on the

bottom of the rebox (Figure 8). The bottom panel is

now free to be removed.

Locate the Remote Control Receiver mounted on the 4.

right hand side (Figure 16).

The Remote Control Receiver is fastened to the 5.

underside of the Ember Bed support by four (4)

mounting studs, one in each corner (Figure 15).

Figure 16

Mounting

Studs (4)

Squeeze each mounting stud’s clasp to release the

circuit board from the rebox.

!

NOTE: If mounting studs are damaged, replacement

mounting studs will need to be inserted from underneath

the Log Set Assembly. Follow steps 1 - 6 of Partially

Reective Glass Replacement procedure on page 9 to do

this. It is recommended to attempt to release the control

board without cutting mounting studs.

Properly orient the replacement Remote Control 6.

Receiver board and push it onto the four (4) mounting

studs until the clasps of the mounting studs snap the

control board into place.

Disconnect one of the wire leads from the original 7.

control board (which are still connected to parts

within the rebox) and immediately connect it to the

new control board’s terminal, matching its position.

Continue with the remaining wires (there are four (4)

wires which are piggy-backed together in pairs, and a

single grey wire) using the same procedure.

CAUTION: Internal wiring and colors may not be the

same within the unit being serviced as those shown. To

avoid damage to the unit, damage to property or personal

injury, ensure wires are reconnected to match their original

locations.

Follow steps 1 through 3 in reverse order to re-8.

assemble the rebox.

!

NOTE: When placing bottom panel back onto unit,

position the metal lip from under the control panel

between the rubber spacers (attached to the bottom

panel) and the sheet metal of the bottom panel.

Remote

Control

Receiver

Blue piggy-back: • From top, right terminal of Remote

Control Receiver to 1) right terminal of thermostat and 1)

to left terminal of Log Driver board.

Orange piggy-back:• From top, left terminal of Remote

Control Receiver to 1) right terminal of Log Driver board

and 1) to opposite side of rebox and to top terminal of

Flame Speed Control board.

Grey:• From left side terminal of Remote Control

Receiver to opposite side of rebox, leading to Heater

Assembly.

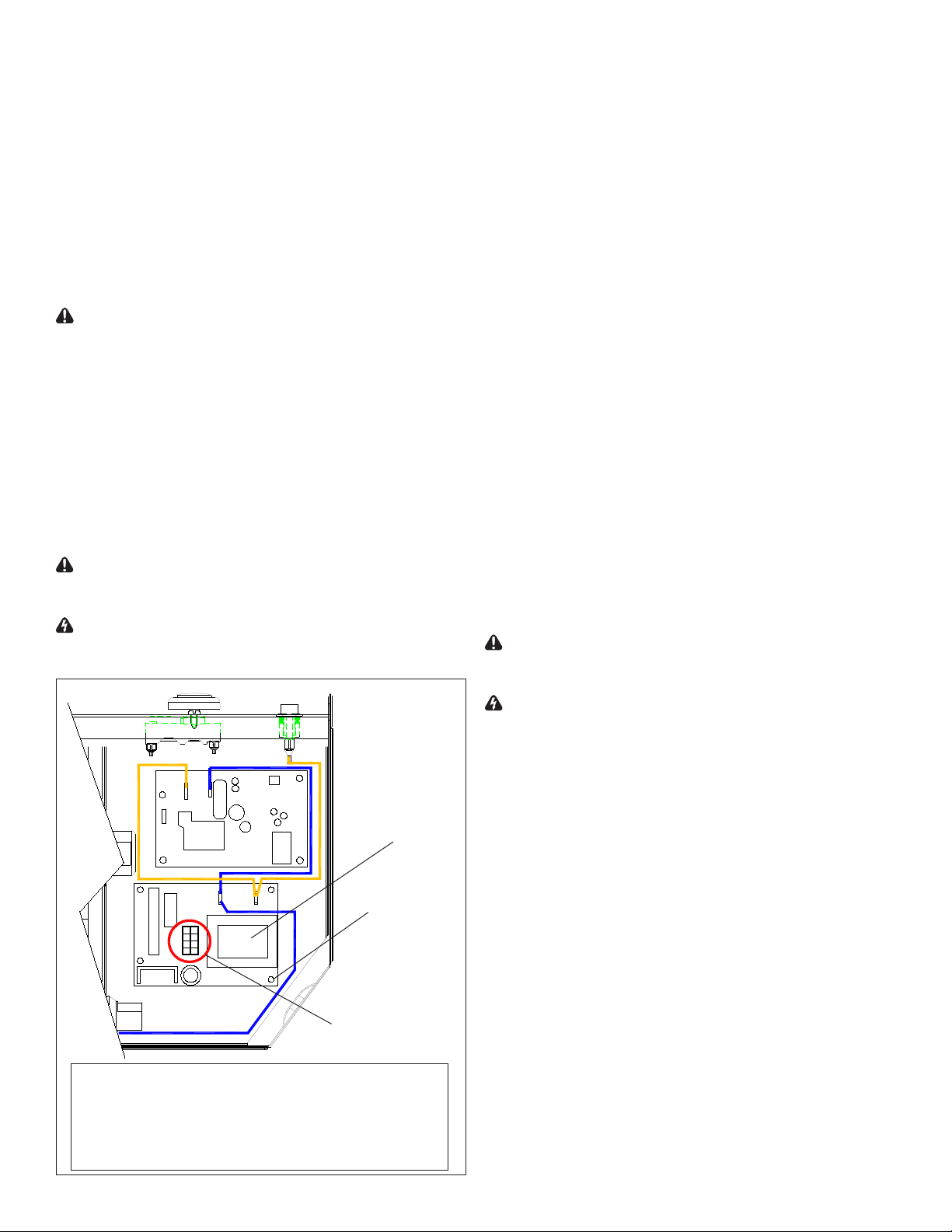

Log Driver Controller Replacement (DF2608 only)

CAUTION: If unit was operating prior to servicing allow

at least 10 minutes for lights, heating elements and top

panel to cool off to avoid accidental burning of skin.

WARNING: Disconnect power before attempting any

maintenance to reduce the risk of electric shock or damage

to persons.

Remove the rebox from the mantel.1.

Lay unit on its back.2.

Remove the 12 Philips screws that fasten the bottom 3.

cover to the rest of the rebox. There are: two (2)

screws on each side; two (2) screws on the back panel

(you may have to tip the bottom of the rebox up if it is

laying on its back), four (4) screws in the front directly

under the control panel; and two (2) screws on the

bottom of the rebox (Figure 8). The bottom panel is

now free to be removed.

The Log Driver Control Board is fastened to the 4.

underside of the Ember Bed support by four (4)

mounting studs, one in each corner (Figure 17).

Squeeze each mounting stud’s clasp to release the

circuit board from the rebox.

!

NOTE: If mounting studs are damaged, replacement

mounting studs will need to be inserted from underneath

the Log Set Assembly. Follow steps 1 - 6 of Partially

14

Page 15

Reective Glass Replacement procedure on page 9 to do

this. It is recommended to attempt to release the control

board without cutting mounting studs.

Properly orient the replacement Log Driver board and 5.

push it onto the four (4) mounting studs until the clasps

of the mounting studs snap the control board into place.

Disconnect one of the wire leads from the original 6.

control board (which are still connected to parts

within the rebox) and immediately connect it to the

new control board’s terminal, matching its position.

Continue with the remaining wires (there are four (4)

wires which are piggy-backed together in pairs, and a

single grey wire) using the same procedure.

CAUTION: Internal wiring and colors may not be the

same within the unit being serviced as those shown. To

avoid damage to the unit, damage to property or personal

injury, ensure wires are reconnected to match their original

locations.

Follow steps 1 through 3 in reverse order to re-7.

assemble the rebox.

!

NOTE: When placing bottom panel back onto unit,

position the metal lip from under the control panel

between the rubber spacers (attached to the bottom

panel) and the sheet metal of the bottom panel.

Lower Light Harness Replacement

CAUTION: If unit was operating prior to servicing allow

at least 10 minutes for lights, heating elements and top

panel to cool off to avoid accidental burning of skin.

WARNING: Disconnect power before attempting any

maintenance to reduce the risk of electric shock or damage

to persons.

Figure 17

Log Driver

Control

Board

Mounting

Studs (4)

Multicolored LED

Wire Harness

Blue piggy-back: • From left terminal of Log Driver board

to 1) right terminal of Remote Receiver board and 1) to

other side of rebox and connecting to wire nut.

Orange piggy-back:• From right terminal of Log Driver

board to 1) bottom terminal of Heat Switch and 1) left

terminal of Remote Receiver board.

Remove the rebox from the mantel.1.

Lay unit on its back.2.

Remove the 12 Philips screws that fasten the bottom 3.

cover to the rest of the rebox. There are: two (2)

screws on each side; two (2) screws on the back panel

(you may have to tip the bottom of the rebox up if it is

laying on its back), four (4) screws in the front directly

under the control panel; and two (2) screws on the

bottom of the rebox (Figure 8). The bottom panel is

now free to be removed.

Locate the three (3) light sockets, in the middle of the 4.

rebox.

Remove the lightbulbs and place in a safe location.5.

Trace the light socket wires by cutting the tie wraps 6.

and removing the wire covering. Disconnect the wire

connectors that are attached to the sockets that are

being replaced, noting the associated connection for

each wire.

Remove the retaining ring from the light sockets and 7.

replace sockets with new sockets.

Replace associated wire connectors.8.

Follow steps 1 through 6 in reverse order to 9.

reassemble the rebox.

!

NOTE: When placing bottom panel back onto unit,

position the metal lip from under the control panel

between the rubber spacers (attached to the bottom

panel) and the sheet metal of the bottom panel.

Heater Assembly Replacement

CAUTION: If unit was operating prior to servicing allow

at least 10 minutes for lights, heating elements and top

panel to cool off to avoid accidental burning of skin.

WARNING: Disconnect power before attempting any

maintenance to reduce the risk of electric shock or damage

to persons.

Remove the rebox from the mantel.1.

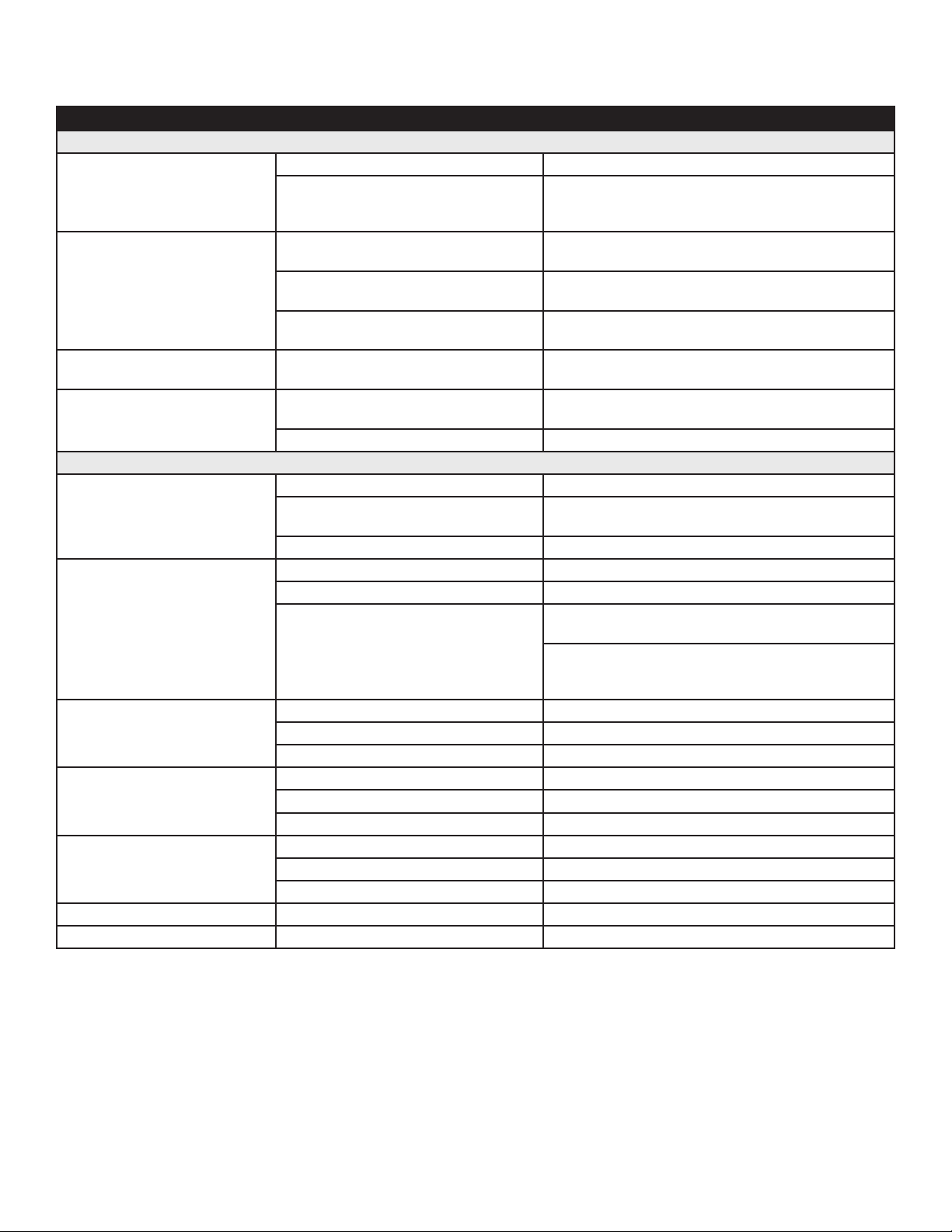

Remove the 10 Philips screws that fasten the top cover 2.

to the rest of the rebox. There are: (four) 4 screws at

the back of the rebox, along the top; two (2) screws

on each side and at the top of the rebox; and two (2)

screws on the top of the rebox (Figure 18).

Flip the top panel over and place upside down on the 3.

top of the unit. You may experience some resistance

as the Heater Assembly is mounted to the top panel

and may be a snug t inside the rebox. Orient

yourself with the placement of the Heater Assembly

and wiring as shown in Figure 19.

Turn the top panel over and, while supporting the 4.

Heater Assembly and panel in one hand, remove the

ve (5) Phillips heater mounting screws, noting the

center screw is of a larger diameter (Figure 20).

Separate the Heater Assembly from the top panel.5.

Properly orient the new Heater Assembly and attach it 6.

to the top panel using the screws removed in step 5.

Disconnect one of the wire leads from the original 7.

Heater Assembly (which are still connected to parts

15

Page 16

Figure 18

Screws to Remove

Figure 21

3-Position

Switch

Power Cord

Flame Speed

Control

Figure 19

Terminal Block

Wires leading to

bottom assembly

Wire 1: • Blue wire connecting top and bottom terminal of

Heater Element on left side.

Wire 2:• Blue wire from top, left terminal of Heater

Element through to lower part of rebox.

Wire 3: • Blue wire connecting inside terminal of Motor to

Terminal Block, matched with blue wire from Terminal

Block to lower part of rebox.

Wire 4:• Black wire from outside terminal of Motor to

bottom terminal of Heater Element on right side.

Wire 5:• Yellow wire from top terminal of Heater Element

on right side to Terminal Block, matched to yellow wire

leading to lower part of rebox.

Wire 1

Wire 2

Wire 4

Wire 3

Heater

Assembly

Wire 5

Heating

Element

Figure 20

within the rebox) and immediately connect it to the

new Heater Assembly’s terminal, matching its position.

Continue with the remaining wires using the same

procedure.

CAUTION: Internal wiring and colors may not be the

same within the unit being serviced as those shown. To

avoid damage to the unit, damage to property or personal

injury, ensure wires are reconnected to match their original

locations.

Fit Heater Assembly into top of rebox and re-assemble 8.

rebox using screws removed in step 2.

Wire Clamp

WARNING: Disconnect power before attempting any

maintenance to reduce the risk of electric shock or damage

to persons.

Remove the rebox from the mantel.1.

Lay unit on its back.2.

Remove the 12 Philips screws that fasten the bottom 3.

cover to the rest of the rebox. There are: two (2)

screws on each side; two (2) screws on the back panel

(you may have to tip the bottom of the rebox up if it is

laying on its back), four (4) screws in the front directly

under the control panel; and two (2) screws on the

bottom of the rebox (Figure 8). The bottom panel is

now free to be removed.

Locate and disconnect the two (2) power cord wire 4.

connections. The smooth edged wire leading from the

narrow blade of the power plug connects to the middle

of the three (3) terminals on the 3-Position Switch; the

side of the power cord leading from the wide blade of

the plug, and has ridges along its edge leads to the

bottom, right terminal of the Flame Speed Control

board (Figure 21).

Using pliers, squeeze the sides of the plastic wire 5.

clamp on the Power Cord from inside the chassis and

push it through the sheet metal.

Release clamp from the Power Cord and remove 6.

Power Cord from the rebox.

Run replacement Power Cord through the rebox as 7.

above and connect wire ends as described in step 4.

Leave two (2) inches of slack in cord and secure in 8.

place with clamp.

Follow steps 1 through 3 in reverse order to 9.

reassemble the rebox.

Power Cord Replacement

CAUTION: If unit was operating prior to servicing allow

at least 10 minutes for lights, heating elements and top

panel to cool off to avoid accidental burning of skin.

16

Page 17

Troubleshooting Guide

PROBLEM CAUSE SOLUTION

General

Circuit breaker trips or fuse

blows when unit is turned on

Unit turns on or off by itself Remote Control has a similar frequency

Lights dim in room while the unit

is on

Power cord gets warm Normal Operation The power cord may get slightly warm to the touch

Appearance

Fireplace does not turn on Manually

Fireplace does not turn on using

the Remote Control

Flame Frozen Loose wiring Check wiring connections

Flame not bright or ame not

visible

Log set dim, not glowing

(DF2608 Only)

Flame Shutter Defective Flicker Motor Replace Flicker Motor

Light leaking around the log set Log set not positioned properly Check log set for proper t

Short in unit wiring. Trace wiring in unit.

Improper circuit current rating Additional appliances may exceed the current rating

of the circuit breaker or fuse. Plug unit into another

outlet or install unit on a dedicated 15 amp circuit.

Replace Remote Control. Initialize to Remote Control

to other remotes in the area.

Radio frequency disturbance from outside sources.

Defective Remote Control Receiver Replace Remote Control Receiver. Initialize Remote

Unit is drawing close to circuit current

rating

Defective Power Cord Replace Power Cord if cord gets hot to the touch.

Improper operation Refer to Operation Section

No incoming power from the electrical

wall socket

Defective 3-Position Switch Replace 3-Position Switch

Improper operation Refer to Operation Section

Remote Control not initialized to replace Initialize the Remote Control

Remote Control not working Install new battery into the Remote Control. Initialize

Defective Flicker Motor Replace Flicker Motor

Defective Flame Speed Control Replace Flame Speed Control Components

Burnt out light bulbs Replace light bulbs

Loose wiring Check wiring connections

Defective Light Harness Replace Light Harness

Loose wiring Check wiring connections

Defective Log Driver Controller Replace Log Driver Controller

Defective Log Set Replace Log Set

Receiver.

Replace Remote Control. Initialize Remote Control

and Receiver.

Control and Receiver.

Move the unit to another outlet or install unit on a dedicated 15 amp circuit

when the heater is on

Check fuse/breaker panel

Remote Control.

Replace Remote Control Receiver or Remote Control, where necessary. Initialize Remote Control and

Remote Control Receiver.

17

Page 18

PROBLEM CAUSE SOLUTION

Heater

Heater is not turning off Improper operation Refer to Operation Section

Defective Heater Switch Replace Heater Switch

Defective Thermostat Replace Thermostat

Heater is not turning on Improper operation Refer to Operation Section

Loose wiring Trace wiring in unit

Defective Heater Switch Replace Heater Switch

Defective Thermostat Replace Thermostat

Defective Heater Assembly Replace Heater Assembly

Heater is turning off after a

couple of minutes of operation

Heater emits an odor Normal Operation Normal operation is when the heater emits an odor

Heater fan turns on but heater

lacks heat

Heating element is glowing red Normal Operation Small glowing sections of the element are considered

Noise

Excessive noise with the heater onDirty Heater Assembly Ensure that exterior intake louvers and rebox cavity

Grinding or excessive noise with

the heater off

Buzzing noise from control panel Defective Flame Speed Controller Replace Flame Speed Controller

Build up of dirt/dust in Heater Assembly Ensure that exterior intake louvers and rebox cavity

are free of dirt/dust.

Defective Heater Assembly Replace Heater Assembly

for a brief period after the heater is initially turned on.

The heater is burning off any dust accumulated during

manufacturing or operation.

Defective Heater Assembly Replace Heater Assembly

Improper operation Refer to Operation Section

Loose wiring Trace wiring in unit

Defective Thermostat Replace Thermostat

Defective Heater Assembly Replace Heater Assembly

normal.

Defective heater assembly If larger glowing sections are causing the heater to trip

the thermal cutout, unplug unit, discontinue use and

replace Heater Assembly.

are free of dirt/dust.

Defective Heater Assembly Replace Heater Assembly

Flicker rod hitting or rubbing against

internal components

Defective Flicker motor Replace Flicker motor

Ensure rod is straight and mounted properly in the

bracket, spinning freely away from other components.

Replace if necessary.

18

Loading...

Loading...