Page 1

ContactDetails

Pleasenotethatsomeofthecontactdetailson

thisPDFdocumentmaynotbecurrent.

Pleaseusethefollowingdetailsifyouneedto

contactus:

Telephone:08448793588

Email:customer.services@gdcgroup.co.uk

Thecustomersupportsectionofourwebsitealsofeaturesawide

rangeofinformationwhichmaybeofusetoyouandisavailable

24hoursaday.Itincludes:

• Operatingandinstallationinstructions

• Easy‘Howtouse’guidesforstorageheaters

• Serviceandrepairs

• Where

tobuyourproducts

• Literaturedownloads

• Heatingrequirementcalculator

Visit‐www.dimplex.co.uk/support

A division of GDC Group Ltd

Millbr ook House Grange Drive Hedge End Sout hampton SO30 2DF

ww w.d implex.co.uk

Registered No: 1313016 England

VAT GB 287 1315 50004

EEE Producer Registration Numb er –

WEE/ GE0057TS

Paper f rom sustainabl e sources

Page 2

LA 6 MI

LA 9 MI

LA 12 MI

LA 16 MI

Inverter air to water heat pump for

outdoor installation

Technical planning manual

08/60393/0

Page 3

Page 2

Supporting documents

The following documents are available to aid in the planning, installation, operation and maintenance of the Air-eau heat

pumps:

Technical manuals

Contains the necessary information required during the planning stages.

Air-eau inverter heat pumps packages (this document)

SmartRad

Installation instructions

Contains the necessary information required during the installation.

Air-eau inverter air-to water heat pump system packages

LA MI settings function & programming overview

EC-eau cylinders

SmartRad

User guides

Contains the necessary information for the user for operation and maintenance of the system

Air-eau heat pumps (Pack 1 and 2 – standard heating and DHW) for standard users

Air-eau heat pumps (Pack 1 and 2 – standard heating and DHW) for sheltered housing

Horstmann wall mounted room thermostat

The installation of an Air-eau heat pump should only be carried out by a suitably trained and

competent person who is approved by Dimplex. All installations should be in accordance

with this planning manual to ensure efficient operation.

Page 4

Page 3

Contents

Supporting documents ......................................................................................................................................................... 2

Section 1: Introduction ............................................................................................................................................................. 6

What are the benefits of a heat pump? ................................................................................................................................ 6

How a heat pump works ....................................................................................................................................................... 6

Intended Use ........................................................................................................................................................................ 6

Air as a heat source ............................................................................................................................................................. 6

Advantages of inverter compressors .................................................................................................................................... 6

Advantages of fixed speed compressors .............................................................................................................................. 7

Heat pump labelling .............................................................................................................................................................. 7

Comparison of the LA MS and LA MI ranges ....................................................................................................................... 7

Section 2: Selection and sizing of the heat pump ..................................................................................................................... 8

Process to select a heat pump ............................................................................................................................................. 8

Mono energy operation......................................................................................................................................................... 8

Accurately determining the building‟s heat loss .................................................................................................................... 8

Estimating the building‟s heat loss ....................................................................................................................................... 9

Dimplex design service......................................................................................................................................................... 9

Drying-out of buildings .......................................................................................................................................................... 9

Sizing example 1 ................................................................................................................................................................ 10

Sizing example 2 ................................................................................................................................................................ 10

Section 3: System controls in a domestic setting .................................................................................................................... 11

Boiler inter lock ................................................................................................................................................................... 11

Horstmann PRT thermostat ................................................................................................................................................ 11

Heat Pump Controller ......................................................................................................................................................... 11

Weather compensation....................................................................................................................................................... 11

Section 4: Selection of heat emitters and flow temperatures .................................................................................................. 12

Minimising the flow temperature ......................................................................................................................................... 12

Considerations for fan convectors ...................................................................................................................................... 12

Section 5: DHW preparation with inverter heat pumps ........................................................................................................... 13

Dimplex EC-Eau cylinder range ......................................................................................................................................... 13

Dimplex ECS Combination DHW and Buffer Cylinders ...................................................................................................... 13

Heat pump power for hot water preparation ....................................................................................................................... 13

Selecting a DHW cylinder ................................................................................................................................................... 13

Cylinder volume and reheat ................................................................................................................................................ 14

Cylinder replacement ......................................................................................................................................................... 14

Selecting and controlling the DHW temperature ................................................................................................................. 14

Sterilisation ......................................................................................................................................................................... 15

Secondary circulation pipes ................................................................................................................................................ 15

Section 6: Installation considerations ...................................................................................................................................... 16

Physical location ................................................................................................................................................................. 16

Fixing of the heat pump ...................................................................................................................................................... 16

Wall mounting ..................................................................................................................................................................... 16

Ventilation ........................................................................................................................................................................... 17

Page 5

Page 4

Minimum maintenance clearances ..................................................................................................................................... 17

Sound insulation measures ................................................................................................................................................ 17

Air quality ............................................................................................................................................................................ 18

Local planning regulation.................................................................................................................................................... 18

MCS Planning Standard ..................................................................................................................................................... 18

Town and Country planning, England ................................................................................................................................ 18

Planning in Wales and Northern Ireland ............................................................................................................................. 19

Town and Country planning, Scotland ................................................................................................................................ 20

Section 7: Heating System Connection .................................................................................................................................. 21

External pipe work .............................................................................................................................................................. 21

Minimum water volume....................................................................................................................................................... 21

Buffer tank .......................................................................................................................................................................... 21

Minimum heating water flow rate ........................................................................................................................................ 21

Taconova flow checker ....................................................................................................................................................... 21

Plumbing connections ........................................................................................................................................................ 22

Frost protection .................................................................................................................................................................. 22

Condensate ........................................................................................................................................................................ 22

Flushing the system ........................................................................................................................................................... 22

Filter ................................................................................................................................................................................... 23

Filling the system ................................................................................................................................................................ 23

De-aeration ......................................................................................................................................................................... 23

Adjusting the water flow rate .............................................................................................................................................. 23

Expansion vessel sizing ..................................................................................................................................................... 23

2 port valves ....................................................................................................................................................................... 24

Controlling DHW temperature ............................................................................................................................................ 24

Section 8: Electrical Connection ............................................................................................................................................. 25

Routing of cables within the heat pump .............................................................................................................................. 25

Ducting cables .................................................................................................................................................................... 25

Connection of the power supply to the Heat pump ............................................................................................................. 26

Main power supply cable .................................................................................................................................................... 26

Inline flow boiler .................................................................................................................................................................. 28

Domestic hot water immersion ........................................................................................................................................... 28

Controller cable .................................................................................................................................................................. 29

Connection with the system ................................................................................................................................................ 30

Installation of the controller ................................................................................................................................................. 30

Section 9: System Health checks ........................................................................................................................................... 31

Heat pump .......................................................................................................................................................................... 31

Electrical ............................................................................................................................................................................. 31

Hydraulic ............................................................................................................................................................................ 31

Cylinder .............................................................................................................................................................................. 31

Wall mounted thermostat.................................................................................................................................................... 31

Heat pump controller .......................................................................................................................................................... 31

Section 10: Standard packages .............................................................................................................................................. 31

Package 1 and 2 ................................................................................................................................................................ 31

Page 6

Page 5

Package 1 and 2 – Plumbing Schematic ............................................................................................................................ 34

Package 1 and 2 – Micro wiring schematic (option 1 – immersion controlled direct) .......................................................... 35

Section 11: Technical specification of the LA MI range .......................................................................................................... 36

Approvals ........................................................................................................................................................................... 37

Performance Data .............................................................................................................................................................. 37

Performance Data .............................................................................................................................................................. 38

CE declaration of conformity .............................................................................................................................................. 39

LA 6 MI performance .......................................................................................................................................................... 40

LA 9 MI performance .......................................................................................................................................................... 42

LA 9 MI performance (continued) ....................................................................................................................................... 43

LA 12 MI performance ........................................................................................................................................................ 44

LA 16 MI performance ........................................................................................................................................................ 46

Product Dimensions LA 6 MI and LA 9 MI .......................................................................................................................... 48

Product Dimensions LA 12 MI and LA 16 MI ...................................................................................................................... 49

LA 6 MI and LA 9 MI Spare parts ....................................................................................................................................... 50

LA 12 MI and LA 16 MI Spare parts ................................................................................................................................... 55

Information for DHW cylinder with buffer - ECS125HP-580 .................................................................................................... 60

Information for DHW cylinder with buffer - ECS150HP/75-580 ............................................................................................... 61

Information for DHW cylinder with buffer - ECS210HP/75-580 ............................................................................................... 62

Page 7

Page 6

Section 1: Introduction

What are the benefits of a heat pump?

Large quantities of pollutants, such as carbon dioxide,

sulphur dioxide and nitrogen oxide are released from gas

or oil boilers used to heat our homes. A large percentage

of our energy supply comes from fossil fuels which have a

serious effect on our environment. Fuel security is also an

issue as our oil and gas reserves are limited and often

from volatile counties around the world. The way electrical

energy is generated will change in the future to favour

more renewable generation methods. A heat pump uses

electrical power that could come from a variety of sources

and it uses very efficiently.

How a heat pump works

A heat pump converts low grade heat from the

environment to high grade heat for space and DHW

heating using a refrigeration cycle. Surrounding air is

drawn in by the fan and passed over the evaporator. The

evaporator cools the air, i.e. it extracts heat from it. This

extracted heat is then raised in temperature via the

refrigeration cycle and then transferred to the condenser.

The heat is “pumped” to a higher temperature level by

increasing its pressure with the aid of an electrically driven

compressor.

Because the energy extracted from the air is transferred to

the heating water, this type of device is called an air-towater heat pump. The air-to-water heat pump consists of

the main components evaporator, fan and expansion

valve, as well as the low noise compressor, condenser

and electrical control system.

At low ambient temperatures, humidity accumulates on the

evaporator in the form of frost reducing the transfer of

heat. The evaporator is defrosted automatically by the

heat pump as required.

The refrigerant circuit is hermetically sealed. It contains

the Kyoto protocol approved refrigerant R410 with a GWP

value of 1725. It is CFC-free, does not deplete ozone and

is non-flammable.

Intended Use

This device is only intended for use as specified by

Dimplex as detailed within this technical manual. The airto-water heat pump is to be used exclusively for the

heating of heating water in a closed circuit. Any other use

beyond that intended by the manufacturer is prohibited.

Persons, especially children, who are not capable of

operating the device safely due to their physical, sensory

or mental abilities or due to their inexperience or lack of

knowledge, must not operate this device without

supervision or instruction by the person in charge.

Air as a heat source

The decision whether to install either an air source heat

pump or a ground source heat pump depends on the

following factors:

Investment costs:

In addition to the costs for the heat pump and the

heat emitter system (radiators and circulation pump),

the investment costs are heavily influenced by the

costs of tapping the heat source. Air is the easiest

heat source to tap as the heat pump is relatively

easy to position outside. Tapping the ground as a

heat source is more difficult. If the land area is

available horizontal loops are the most cost effective

way to install the ground collector. If boreholes are

used, due to the cost of mobilising the plant,

experience has shown that installations with less

than 10 boreholes are not economical.

Operating costs:

The seasonal performance factors of the heat pump

influences the operating cost. These are primarily

affected by the type of heat pump, the average heat

source temperature and the required heating flow

temperatures. Ground source heat pumps have

higher SPF‟s compared to air source heat pumps.

Advantages of inverter compressors

An inverter heat pump is able to modulate its‟ heat output

over a set range. The inverter compressor modulates its

output to keep the return temperature constant. If demand

increases the output of the compressor can increase to

keep the flow temperature constant. If the demand

decreases beyond the minimum setting of the compressor

it will turn off until the heating circuit temperature reduces.

A fix speed compressor will run at a constant speed until

the set temperature is reached. When the set point is

reached the compressor will turn off until the temperature

in the heating circuit drops to a hysteresis value. When

this value is reached the compressor will restart. The

compressor will cycle on and off to maintain the correct

temperature. If demand increases the fixed speed

compressor will be on more often.

Even though an inverter compressor cycles less, to ensure

optimum life expectancy an inverter compressor should

always be installed with a buffer tank to increase run times

and store energy for the defrost.

Correct selection of the heat pump, heat

emitters and circulation system is essential for

efficient operation of the entire system.

Page 8

Page 7

An inverter compressor starts gently ramping up to its

maximum speed over a couple of minutes meaning the

current increase is very gradual. The fixed speed

compressor has a larger starting current because it

doesn‟t turn on gradually. The starting current is smoothed

by an inbuilt soft-starter to keep it within acceptable limits.

The starting current does not cause any problems

because an in-built randomised time delay that ensures

multiple heat pumps to not turn on at the same time.

An inverter heat pump is able to modulate down its output

as the external temperature increases. A fixed speed heat

pump will run at a constant speed meaning that its output

increases with rising temperature. This means that an

inverter compressor could achieve slightly higher cylinder

temperatures for the same size coil although in practice

both types of compressor can achieve suitable cylinder

temperatures.

Advantages of fixed speed compressors

A fixed speed compressor is designed to work at the

optimum performance level all of the time. An inverter

compressor does not always work in the optimum zone

because it modulates its output to match the heat demand.

The „over-driving‟ of an inverter compressor causes it

efficiency to drop.

Since the output of both the fixed and inverter

compressors drop with decreasing temperature, there

becomes a point when a secondary heat source is

required to match the properties heat demand, known as

the Bivalent point. At lower temperatures an inverter

compressor and a fixed speed compressor are equally as

efficient despite the inverter needing more immersion

support.

Heat pump labelling

The product code for the inverter range of heat pumps

continues the same convention as the rest of Dimplex‟s

heat pump range.

Letter

Meaning

L

Luft (German for air)

A

Aus (German for outside)

##

Nominal kW rating

M

Mono (German for single phase)

I

Inverter

Table 1: Product coding convention

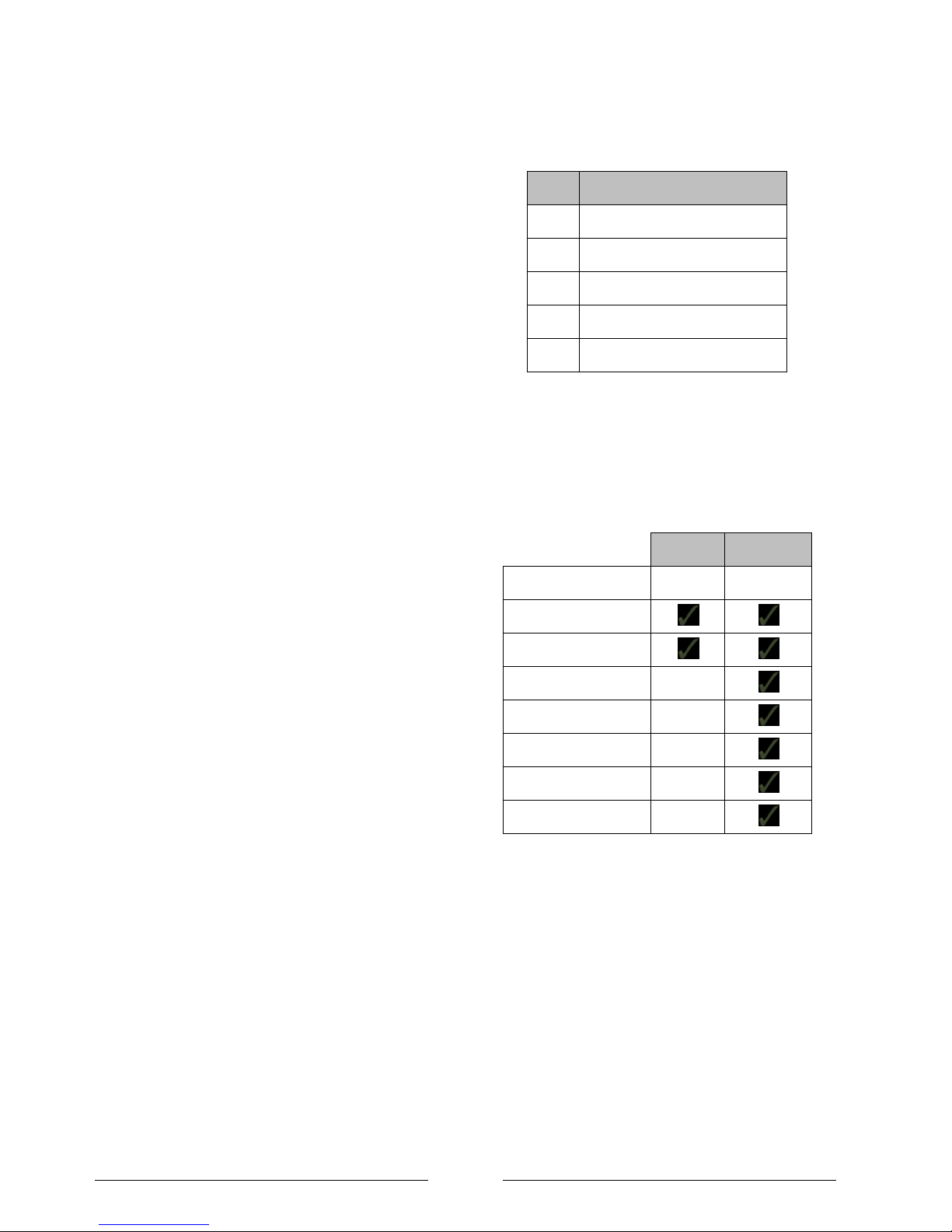

Comparison of the LA MS and LA MI ranges

The LA MI and LA MS range of heat pumps are ideal for

providing DHW and space heating. In addition, the MS

range of heat pumps also has a sophisticated controller

capable of controlling more complicated systems.

MI range

MS range

Compressor speed

Variable

Fixed

Heating only

Heating & DHW

Mixed heating circuits

Swimming pool

Solar Thermal

Boiler integration

Multiple heat pump

Table 2: Comparison of WPM and MI Range

Page 9

Page 8

Section 2: Selection and sizing of the heat pump

Process to select a heat pump

1. Confirm the building is suitable for a heat pump

installation as out lined in Section 6: Installation

considerations.

2. Accurately determine the buildings heat loss to EN

15316.

3. Decide on the maximum flow temperature.

4. Select the model of heat pump using the output

curves to EN14511

Mono energy operation

As the weather gets colder, the heat demand of the

building increases and the output of the heat pump

decreases. There becomes a tipping point where it is so

cold outside the output of the heat pump is not able to

heat the building alone. The LA MI range of heat pumps

are monoenergy heating devices. i.e. in the event of very

low external temperatures an electrically operated inline

flow boiler will automatically be activated to provide

additional heat and keep the building warm.

The heat pump should fully meet the heat consumption

down to a certain external temperature as specified by the

NHBC and summarised in Table 3. The MIS 3005 also

standard states outside design temperatures for different

locations in the UK. To comply with both pieces of advice

the system should be designed to operate to the lower of

the two design temperatures. If this is not the case, the

electrical inline flow boiler will operate more frequently and

increase the running costs.

External

temperature

England and Wales

-3C

Scotland

-5C

Table 3: External design temperatures (bivalent point) stated

by NHBC

Bivalent operation is when an additional heat source other

that electricity is used to supplement the heat load.

Integration of another boiler such as gas, oil or LPG is not

possible with the LA MI but is possible with Dimplex‟s

WPM range.

Accurately determining the building’s heat loss

It is essential to accurately calculate the buildings heat

loss to ensure the heat pump is correctly sized. The heat

loss of a building is calculated using details of the

buildings construction, individual room sizes, room

temperatures and air change rates.

Dimplex recommend calculating the buildings heat loss to

the standards defined in EN15316, this is also stipulated in

MIS 3005 which is required if the installation is going to be

MCS approved.

The total heat loss is made of two components; the fabric

losses and the ventilation heat losses. Fabric heat losses

are due to the transmission of heat by conduction though

the buildings structure such as windows, walls, roof and

floor. Ventilation heat losses are due to warm air escaping

the building and being replaced by cold air.

Total heat loss = Fabric losses + Ventilation losses

Fabric heat loss (W) = U x A x T

Where: U = U value (w/m2 C)

A = Area of the wall, window, ceiling or floor (m2)

T = Temperature difference on either side of the

insulation (C)

Typical U values

New build

Walls

0.35

Windows

2.00

Roof

0.18

Floor

0.25

Table 4: Example U values for Fabric heat loss calculation.

Further details can be found in Dom 8 - Design of total

heating systems.

Ventilation heat loss (W) = V x R x T x F

Where: V = Room volume (m3)

R = Air change rate per hour

T = Temperature difference of air in and out (C)

F = Ventilation Factor (W / m3 C)

It is beyond the scope of this document to give

all the necessary values to calculate the

buildings total heat loss. This section intends

to outline the process to remind the system

designer to find the necessary information.

Page 10

Page 9

Typical room

temperatures

Air

changes

per hour

Ventilation

factor

Living room

21

1

0.33

Dining room

Study

Kitchen

18

2

0.67

Bathroom

22

2

0.67

W.C

Bedroom

18

½

0.17

Hall

18

1 ½

0.50

Landing

18

1 ½

0.50

Table 5: Example of values used in the ventilation heat loss

calculation. For full details see BS 5449:1990

Estimating the building’s heat loss

The existing boiler cannot be used as a guide to determine

the actual heat consumption because boilers are often

over sized.

However, an approximate estimate can be made on the

basis of the existing energy consumption of the living

space to be heated and the specific heat consumption.

For early budgeting purposes a buildings heat loss can be

estimated based upon the floor area.

Estimated heat loss(W) = A x E

Where: A = Floor area (m2)

E = Estimated heat loss (W/m2)

Estimated

heat loss

per m2

High insulation new build

30 W/m2

New build (2002 regulations)

50 W/m2

1970‟s

80 W/m2

1930‟s

100 W/m2

Older than 1930‟s

120 W/m2

Older than 1930‟s with high

ceilings

150 W/m2

Table 6: Typical building heat loss per m2 used to estimate a

buildings heat loss

Dimplex design service

Dimplex offer a free of charge service to calculate a

buildings heat loss along with a full product and accessory

specification. Providing we receive the information below,

turnaround is usually 7-10 working days.

To request this service a form can be downloaded from

our website that should be sent in with the following

information:

Plan and elevation drawings [scale 1:50 or 1:100]

Construction U values

Type of scheme ie: domestic, commercial or

industrial

Internal and external design temperatures

required

Details of any special requirements or unusual

aspects to the building

Alternatively the form and CAD drawings can be

emailed to

Drying-out of buildings

When a house is being built, large quantities of water are

normally used for mortar, rendering, plaster and wall

paper, which only evaporates very slowly from the

building. In addition, rain can decisively increase the

humidity in the building's structure. This increased

humidity in the entire structure causes an increase in the

heat consumption of the house during the first two heating

periods. For this reason, buildings should be dried out

using specially designed dehumidifiers.

The heat pump is not designed for the

increased heat consumption required when a

building is being dried out. Some additional

heat is available in the form of an inline flow

preinstalled in the product. If a building is to

be dried out in autumn or winter, we

recommend installing an additional

temporary heating.

For further information about our design

service please visit:

http://www.dimplex.co.uk/products/renewable

_solutions/heating_design_service

Rules of thumb and estimates are suitable for

budget purposes but are not accurate enough

to calculate the building‟s heat loss in order to

select a heat pump.

Page 11

Page 10

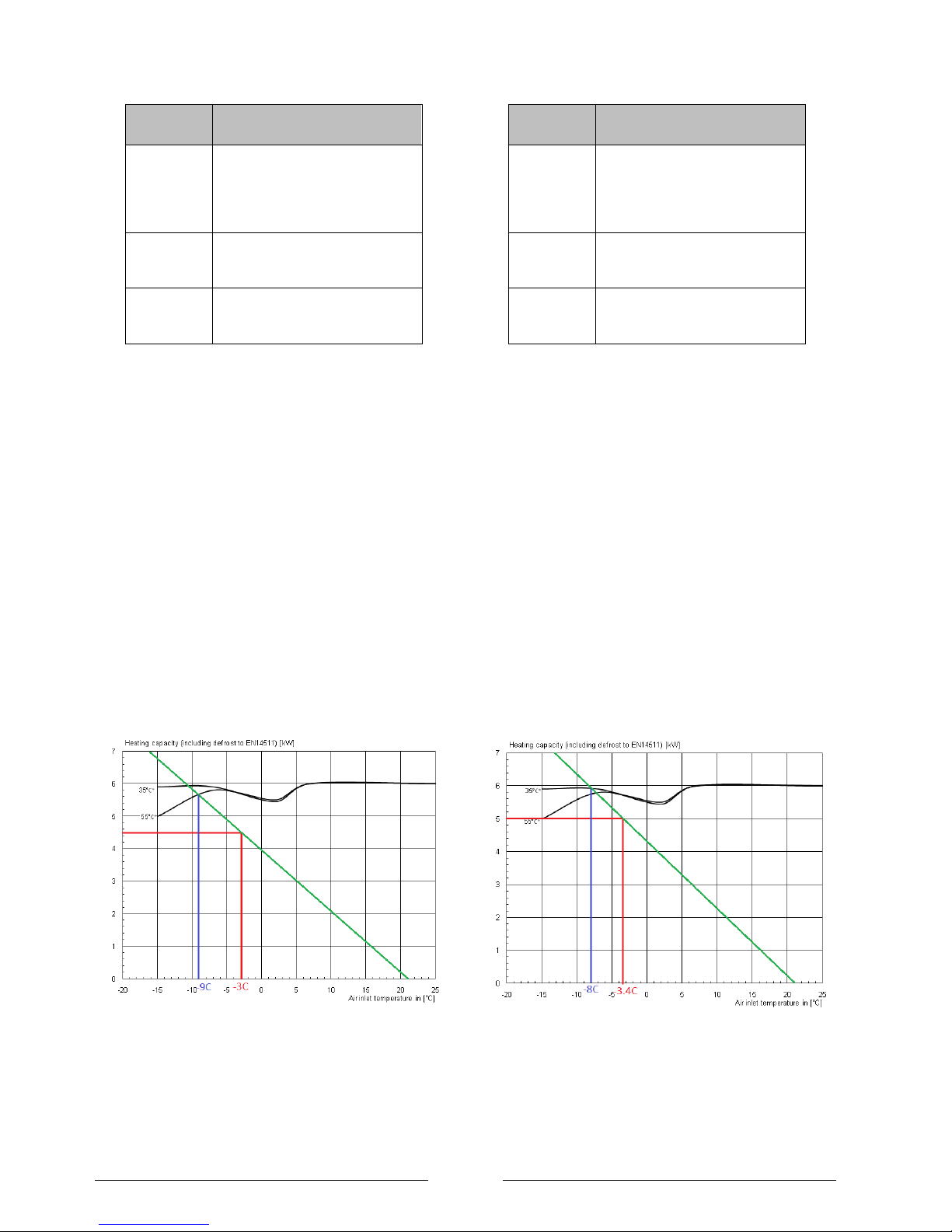

Sizing example 1

Design

temperature

The property is in Manchester,

England – NHBC recommend 3C and CIBSE recommend -

2.2C. The design temperature is

therefore -3C.

Building

heat loss

The properties heat loss is

calculated to be 4.5kW at the

design temperature.

Flow

temperature

Has been selected at 55C as

radiators are going to be

installed.

The heat pump is dimensioned on the heat consumption

of the building at the design temperature as shown in

green in Figure 1.

Step 1: The building's heat loss is plotted based upon the

0kW @ 21C and the building‟s calculated heat loss at the

design temperature i.e. 4.5kW @ -3C as shown by the

green line.

Step 2: At the point where the green line crosses the

performance line of the heat pump the blue line can be

drawn to show the external temperature that the heat

pump will be able to match the heat load of the property

which in Figure 1 is -9C.

Step 3: Below external temperatures of -9C the property

will require additional heat. The factory fitted 3kW inline

flow boiler in addition to the 6kW heat pump to gives 9kW

which will support the properties heat load down to the

operating limit of the heat pump which is -20C.

Figure 1: Example heat output curves to EN14511

for the LA 6 MI for a heat loss of 4.5kW at a design

temperature of -3

C.

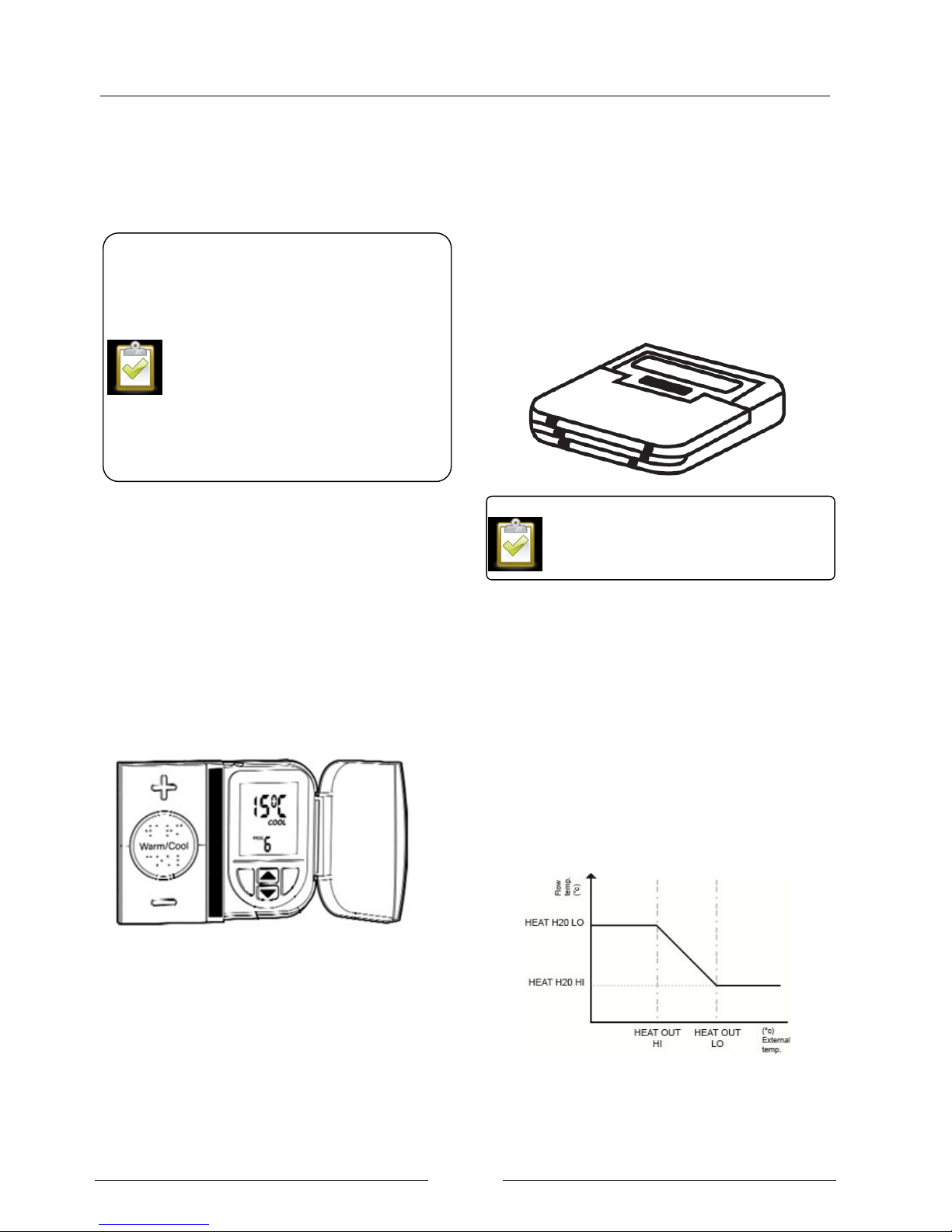

Sizing example 2

Design

temperature

The property is in Birmingham,

England – NHBC recommend

3C and MIS 3005 recommend -

3.4C. The design temperature is

therefore -3.4C.

Building

heat loss

The properties heat loss is

calculated to be 5kW at the

design temperature.

Flow

temperature

Has been selected at 35C as

under floor heating is going to be

used.

The heat pump is dimensioned on the heat consumption

of the building at the design temperature as shown in

green in Figure 2.

Step 1: The building's heat loss is plotted based upon the

0kW @ 21C and the building‟s calculated heat loss at the

design temperature i.e. 5kW @ -3.4C as shown by the

green line.

Step 2: At the point where the green line crosses the

performance line of the heat pump the blue line can be

drawn to show the external temperature that the heat

pump will be able to match the heat load of the property

which is also 5.9kW at –8C.

Step 3: Below external temperatures of -8C the property

will require additional heat. The factory fitted 3kW inline

flow boiler in addition to the 6kW heat pump to gives 9kW

which will support the properties heat load down to the

operating limit of the heat pump which is -20C.

Figure 2: Example heat output curves for the LA 6 M for a

heat loss of 5.0kW at a design temperature of -1.8C and a the

building heat loading being met down to -15C.

Page 12

Page 11

Section 3: System controls in a domestic setting

Boiler inter lock

The Domestic heating compliance guide sets out the best

practise for preventing energy wastage by preventing

unnecessary running of the circulation pump and heat

pump.

Figure 3: Extract from Domestic Heating compliance guide,

V1 April 2006

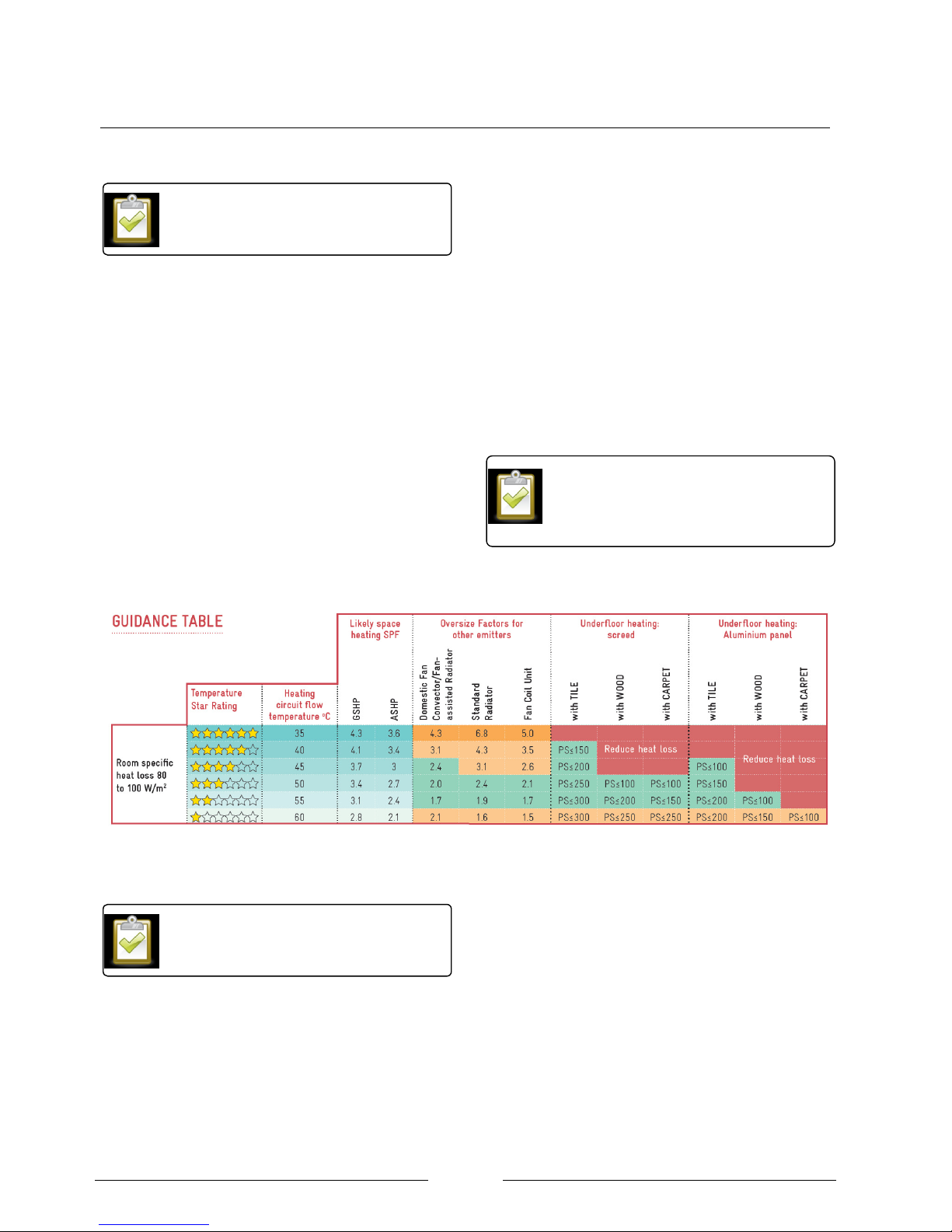

Horstmann PRT thermostat

The LA MI range of heat pumps achieves boiler interlock

using the PRT thermostat.

Supplied by Horstmann, the mains powered thermostat is

designed to provide an economical but comfortable

pattern of heating without the need for complex

adjustments by the user. With built in minimum room

temperature protection this thermostat is ideal for use with

heat pumps because it maintains a base level of heat.

For day-to-day use only the 3 large buttons on the front of

the thermostat are required. The centre „WARM/COOL‟

button, complete with Braille markings, changes the

temperature state and the „+‟ and „-„ buttons provide fine

user adjustment as well as audible feedback. Each user

adjustment is immediately reflected in changes to the

bright red and blue LED display.

Using a variety of pre-installed heating profiles that can be

easily set up by the installer, and a minimum cool setting

of 15C, the ThermoPlus aims to provide maximum

comfort to the user and prevent hypothermia and keep a

level of background heat. Under the flap the blue standby

button will put the control into „frost protection‟ mode until

reactivated.

Heat Pump Controller

The heat pump‟s safe and efficient operation is regulated

by the built in controller. The remote panel can be

connected via the 15m cable meaning allowing the user to

adjust the heat pump settings.

Weather compensation

The highest flow temperatures are only required during the

coldest weather. As the external temperature increases,

the heat loss of the build decreases which means that the

heat emitters no longer have to work at their maximum

output in order to keep the building at the correct

temperature.

The LA MI is fitted with a weather compensation curve as

shown in Figure 4. The curve can be adjusted depending

on the system characteristics. By activating weather

compensation it ensures the heat pump is always

operating at the minimum flow temperature and therefore

the maximum efficiency.

Figure 4: Weather compensation curve on the LA MI

Recommended controller settings can be

found in the installation instructions. An

explanation of how to set the controller can be

found in the programming overview document.

External controls should include:

Room thermostat to regulate the space

temperature and interlocked with the heat

pump unit operation.

Timer to optimise operation of the heat

pump

An interlock is defined as “controls which are

wired so that when there is no demand for

either space heating or hot water, the boiler

and pump are switched off.

The use of Thermostatic radiator valves

alone does not provide interlock.

Page 13

Page 12

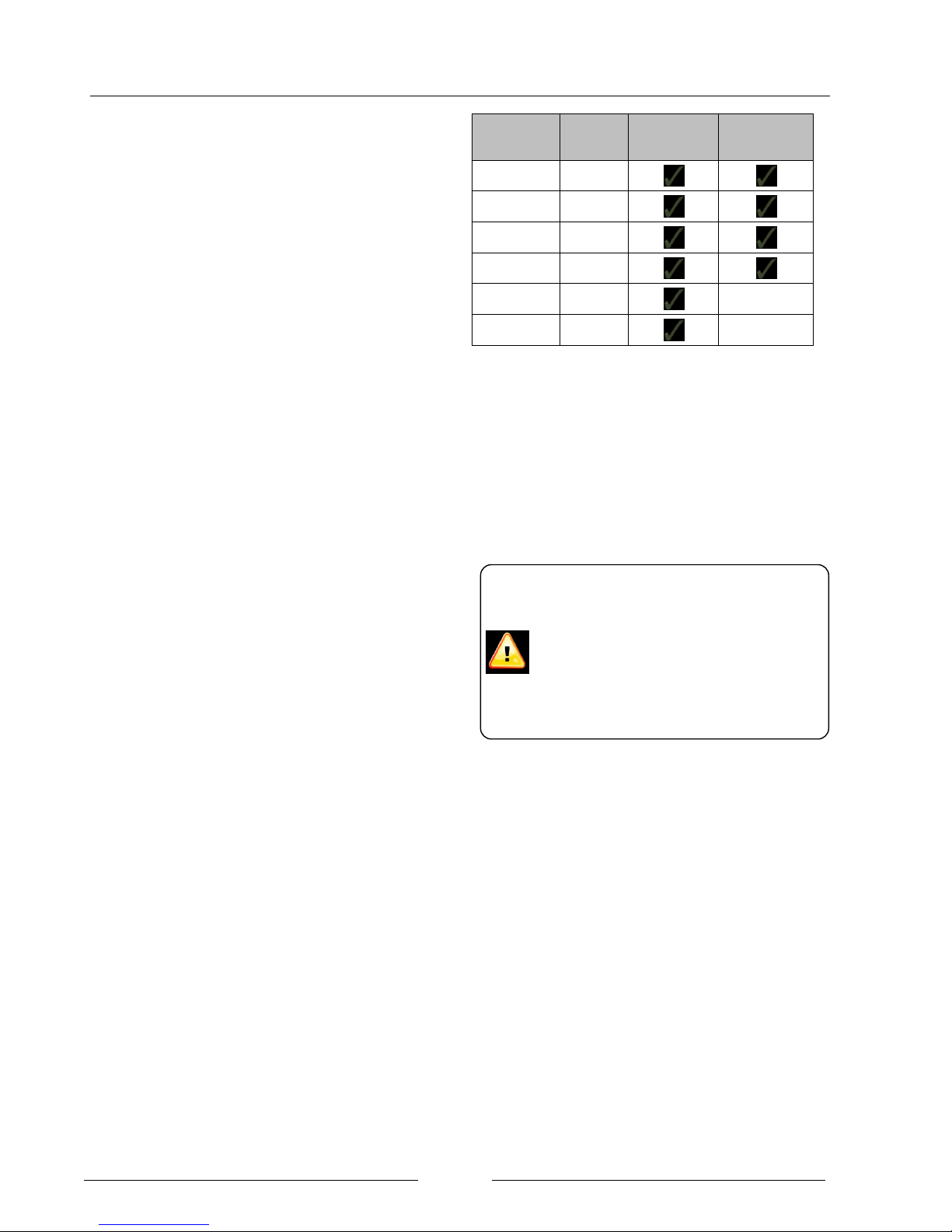

Section 4: Selection of heat emitters and flow temperatures

Minimising the flow temperature

In most oil and gas boiler systems the efficiency doesn‟t

vary greatly with flow temperature, therefore the flow

temperature is set to around 70°C to 75°C. The high

temperatures are not always required as downstream

regulator such as mixing and thermostat valves, prevent

the building from overheating.

To design the most efficient heat pump system it is

essential to minimise the flow temperature. When using

low flow temperatures the choice of heat emitter is critical

to ensure enough heat can be emitted into the room. A

number of industry stakeholders have produced a guide to

selecting the correct heat emitter, an extract of which is

shown in Figure 5. The full guide is available for download

from HHIC website. The guide shows that systems with

lower flow temperature achieve the highest SPF‟s which

would reduce running costs and carbon emissions.

Green areas show suitable heat emitters

Example: a domestic fan convector such as a

SmartRad can be installed with a flow temperature of

45C.

Orange areas show that extra caution is advised

Example: standard radiators should not be installed

with a flow temperature of 60C as a flow

temperature of 50C would give the necessary output

without causing the radiator to become excessively

large.

Red areas show that this technology is not suitable

Example: under floor heating on a screed floor with a

wood covering would not emit enough heat into the

room with a flow temperature of 45C.

Figure 5: Extract from the HHIC's guide to heat emitter selection for a heat loss of 80W/m2

Considerations for fan convectors

The benefits of installing SmartRad with a heat pump

system are well known and explained in the SmartRad

planning manual. This selection deals with connecting

SmartRad with the LA MI range of heat pumps.

When connecting the SmartRad the same principles

should be followed as for any other heat emitter. The

minimum flow rate for the heat pump should be observed.

The heating circuit should be designed in such away to

maintain the flow to the heat pump even when the part of

the circuit is shut off by motorised valves or the heating

circulation pump is off.

For full details about connecting SmartRad

to an inverter air source heat pump see the

SmartRad planning manual.

The Heat Emitter Guide is widely available to

download on the internet. Hard copies are

available upon request by contacting the

MarComs team at Dimplex.

As a rule of thumb, by lowering the flow

temperature by one degree, the system

performance will improve by 2%.

Page 14

Page 13

Section 5: DHW preparation with inverter heat pumps

Dimplex EC-Eau cylinder range

EC-Eau, the new range of unvented stainless steel

cylinders from Dimplex can supply all the hot water

required for the modern home, providing rapid fill baths

and invigorating showers to en-suite bathrooms and

other domestic appliances simultaneously. Offering low

running costs, reliable hot water and fantastic flow

rates, EC-Eau cylinders are available in a range of

capacities, so there is size to suit even the most

demanding household.

EC-Eau heat pump cylinders are specified with large,

high surface area heat exchangers, specifically sized to

match the requirements of Dimplex heat pumps,

optimising heat pump efficiency and reducing running

costs. The diameter of the EC-eau range has been

specifically picked for the UK market with a diameter or

580mm unlike many other cylinders available.

Supplied with an external expansion vessel for

improved reliability and reduced cylinder height, ECEau standard cylinders are flexible to site and easy to

install.

Environmental sensitivity and efficient performance are

key attributes across the EC-Eau range, which boasts

60mm of low GWP insulation foam and innovative

measures such as recessed immersions and

thermostats to reduce energy wastage. This combined

with the use of 100% recyclable stainless steel inner

components and a sleek black, hard wearing outer shell

manufactured from completely recycled materials

ensures the EC-Eau range looks as good as it

performs.

Dimplex ECS Combination DHW and Buffer

Cylinders

In addition to all the benefits of the standard cylinder

Dimplex can also offer a combination cylinder with a

DHW cylinder and buffer cylinder. This makes is easy

to retrofit a heat pump as the new combination cylinder

takes up the same space as the old cylinder.

The EC-eau range of combined buffer and DHW

cylinders have the buffer cylinder on top which gives

the following benefits:

The buffer acts as an excellent air separator,

and putting at the top of the cylinder means it

is likely to be one of the highest points in the

system allowing air to easily be removed.

The heat loss is reduced from the combination

cylinder because there is less of a temperature

gradient between the cylinder/buffer compared

to the cylinder/ambient air.

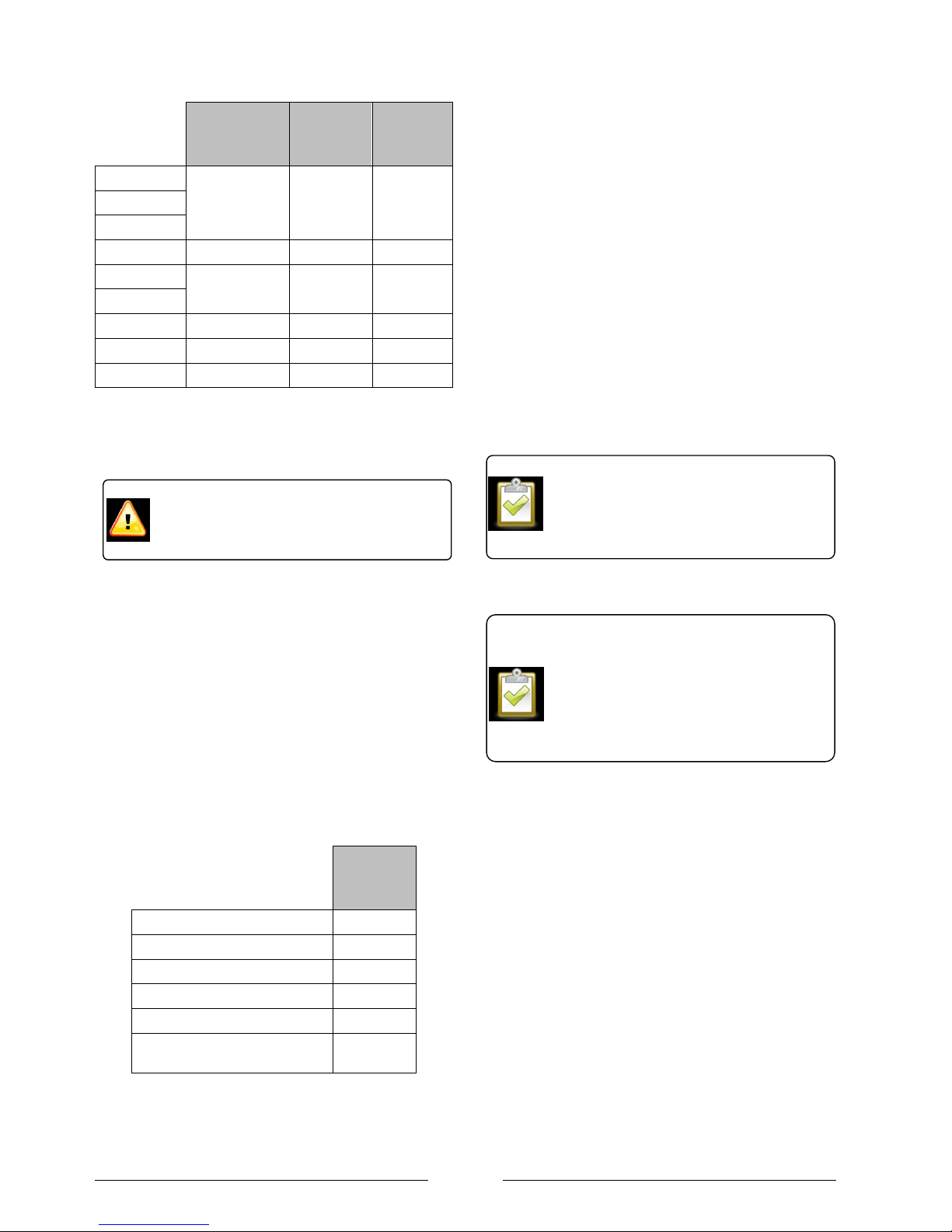

Volume

Outer

diameter

Cylinder

only

Combined

buffer and

cylinder

125

580mm

150

580mm

175

580mm

210

580mm

250

580mm

300

580mm

Table 7: EC-eau cylinders for use with the LA MI range

Heat pump power for hot water preparation

In addition to the space heating, the demand placed on

the heat pump for hot water production must be taken

into account when selecting the heat pump.

To meet normal comfort requirements, a peak hot water

consumption of approximately 60-70 litres per person,

per day, should be allowed, based on a hot water

temperature of 45°C.

Selecting a DHW cylinder

A standard DHW cylinder is not suitable for use with

heat pumps due to the small coil size. A heat pump

provides lower hot water temperatures compared to a

boiler. For this reason a heat pump cylinder needs a

larger coil to ensure that the heat can be transferred

from the heat pump in to the water within cylinder as

efficiently as possible.

For all heat pumps, the achievable cylinder temperature

is affected by the maximum flow temperature and also

the kW output of the heat pump. Since the kW heat

output of an inverter air source heat pump does not rise

with air temperature the LA MI heat pump can achieve

45°C in all of the cylinders shown in Table 8.

If a different cylinder temperature is required the

following must be taken into account. For each of

Dimplex‟s heat pump cylinders, a graph of kW input vs

The sizing should be based on the worst

day, with the coldest possible weather and

the maximum possible number of persons

using DHW. If this sizing method is not

suitable because it causes over sizing of the

heat pump, the end user should be made

aware that they may sometimes need to use

the immersion DHW boost which can be

activated from the wall mountable heat pump

controller.

Page 15

Page 14

attainable cylinder is published. In conjunction with the

published information of the minimum output at

A25/W55 for each heat pump the attainable cylinder

temperature can be found.

The flow rate though the cylinder coil is an important

factor in determining the achievable cylinder

temperature. The hydraulic resistance of the coil and

connecting pipe work must be checked to ensure that

the circulation pump pre-installed in the LA MI is able to

achieve the necessary flow rate.

Heat Pump

Cylinder model

45C achievable

with correct flow

rate

LA 6 MI

(Flow rate 1.0m3/h)

ECS125HP-580

Yes

ECS150HP-580

Yes

ECS175HP-580

Yes

ECS210HP-580

Yes

ECS250HP-580

Yes

ECS300HP-580

Yes

LA 9 MI

(Flow rate 1.6m3/h)

ECS125HP-580

Yes

ECS150HP-580

Yes

ECS175HP-580

Yes

ECS210HP-580

Yes

ECS250HP-580

Yes

ECS300HP-580

Yes

LA 12 MI

(Flow rate 2.1m3/h)

ECS125HP-580

Yes

ECS150HP-580

Yes

ECS175HP-580

Yes

ECS210HP-580

Yes

ECS250HP-580

Yes

ECS300HP-580

Yes

LA 16 MI

(Flow rate 2.8m3/h)

ECS125HP-580

Yes

ECS150HP-580

Yes

ECS175HP-580

Yes

ECS210HP-580

Yes

ECS250HP-580

Yes

ECS300HP-580

Yes

Table 8: Cylinders suitable for use with the LA MI range

with an external temperature up to 25°C.

Cylinder volume and reheat

The amount of stored hot water should be adequate to

meet the demands of the property. The installer should

gauge the likely hot water use depending upon the type

of showers, baths and taps installed within a short time

and select an appropriately sized cylinder.

It should be noted that the cylinder reheat times will be

longer with a heat pump compared to a typical gas

boiler. This is because a gas boiler is often drastically

oversized compared to the space heating requirement

whereas a heat pump is sized much closer to the heat

pump. For this reason, it may be necessary for a heat

pump cylinder to be larger than a cylinder installed with

a gas boiler.

Heat pump output

6kW

9kW

12kW

16kW

ECS125HP-580

44

29

22

16

ECS150HP-580

52

35

26

20

ECS175HP-580

61

41

31

23

ECS210HP-580

73

49

37

27

ECS250HP-580

87

58

44

33

ECS300HP-580

105

70

52

39

Table 9: Calculated cylinder reheat time with different heat

pumps

Cylinder replacement

In addition to the instructions supplied with the cylinder,

when planning on replacing an old vented cylinder for a

new unvented stainless steel cylinder it is important

check the following:

The water main is capable of supply adequate

pressure and flow rate at all times of the day.

The fittings such as taps and valves are

suitable for the new higher pressure system.

Selecting and controlling the DHW

temperature

The heat pump controller monitors the temperature in

the DHW cylinder via a sensor and decides when to

work in hot water mode. The user can set the time of

DHW production and also the temperature of DHW

product using the wall mountable controller.

It is important that the customer understands

that the maximum flow temperature out of the

heat pump is higher than the maximum

attainable temperature in the cylinder.

If a heat pump is being installed on to an

existing property it is likely that the old hot

water cylinder will have to be replaced with a

new one with a larger coil.

Page 16

Page 15

For efficient operation the DHW temperature should be

set to 45°C. Experience has found that this is more

than hot enough for showering and bathing.

If required, the hot water temperature can be set up to

75ºC although this will utilise the immersion heater for

some of the heating period. By raising the storage

temperature, the volume of usable water is increased

which is useful is properties where a larger cylinder

can‟t physically be fitted.

The maximum temperature that the compressor can

achieve before the immersion needs to finish the

demand is variable based upon a number of factors. In

practice the LA MI heat pump is able to reduce its kW

output using the inverter compressor and can also

maintain its output above 55ºC for a short period of

time.

It is therefore, not uncommon for the LA MI to achieve

cylinder temperatures of 50ºC using only the

compressor. It should however be noted that other

factors within the system can reduce the attainable

cylinder temperature so the customer expectation

should be managed to expect their hot water to be

stored at 45ºC.

The adjustable dial on the cylinder thermostat is not

wired in or used because the temperature of the

cylinder is controlled by a sensor. A notice such as that

shown in Figure 6 should be attached next to the

cylinder thermostat.

Figure 6: Notice to be fixed next to cylinder thermostat

Note that the manually resettable high temperature cutout in the cylinder thermostat is wired back to the heat

pump for G3 protection.

Sterilisation

For Domestic properties there is no official guidance on

the correct storage temperature or if thermal

sterilisation is required. There is a theoretical risk of

legionella growth, although no cases have yet been

reported in a domestic hot water system.

There is a trade off between maximising system

efficiency by reducing energy consumption and

minimising the theoretical risk of legionella growth. The

risk of legionella growth can be minimised by ensuring

that the cylinder does not remain stagnant for long

period of time. If the property is not occupied for a long

period, upon reoccupation, it would be prudent to raise

the cylinder temperature to 60°C and open the water

outlets to allow the connecting pipe work and outlets to

be sterilised.

For private domestic properties, Dimplex recommend

that the cylinder is raised to 60°C once per week

although the ultimate decision lies with the householder

to weight up the risk with the energy saving benefits.

For commercial properties the legislation requires for

the water to be stored at 60C.

Secondary circulation pipes

A secondary circulation pipes is used to continuously

pump hot water around a closed loop, so that there is

not a long period of time from the taps opening to the

hot water being available. All of the EC-eau range of

cylinders larger than 210L feature a boss for connection

of a secondary return.

Heat consumption for a circulation pipe can be

considerable. The increase in consumption depends on

both the length of the circulation line and the quality of

the pipe insulation and on a large system should be

taken into account to ensure the heat pump is suitably

sized.

To maximise the efficiency of the system, if a circulation

system cannot be dispensed with because of long pipe

runs, the circulation pump should operate on a timed

basis.

The water drawn off immediately after

sterilisation will be much hotter than usual.

Consideration should be given to installing

a temperature limiting device at the outlets

to prevent scolding.

The schedule for sterilisation should be

determined by the installer to comply with

the necessary regulations.

TEMPERTURE ADJUSTMENT

The temperature of the hot water in this

cylinder is set using the wall mounted heat

pump controller. The setting shown on this

thermostat does not affect the hot water

temperature.

Setting the hot water temperature higher

than the heat pump alone can do with the

compressor would cause the immersion to

It is important to explain to an end user about

the correct cylinder temperature for economic

operation of the heat pump. They may have

previously been used to scolding hot

temperature that they mixed with cold water.

Page 17

Page 16

Section 6: Installation considerations

When deciding the location to install the heat pump the

items contained within this chapter should be considered.

Physical location

The heat pump is for outdoor installation only. It should

also be installed in a place where:

The condensate can easily be drained away.

Hydraulic connections can easily be made to the

heating system and the DHW cylinder.

There is no risk of a flammable gas leak or any

outlets vents from any other system.

The wiring lengths come within reasonable

ranges particularly taking note of the 15m

controller cable.

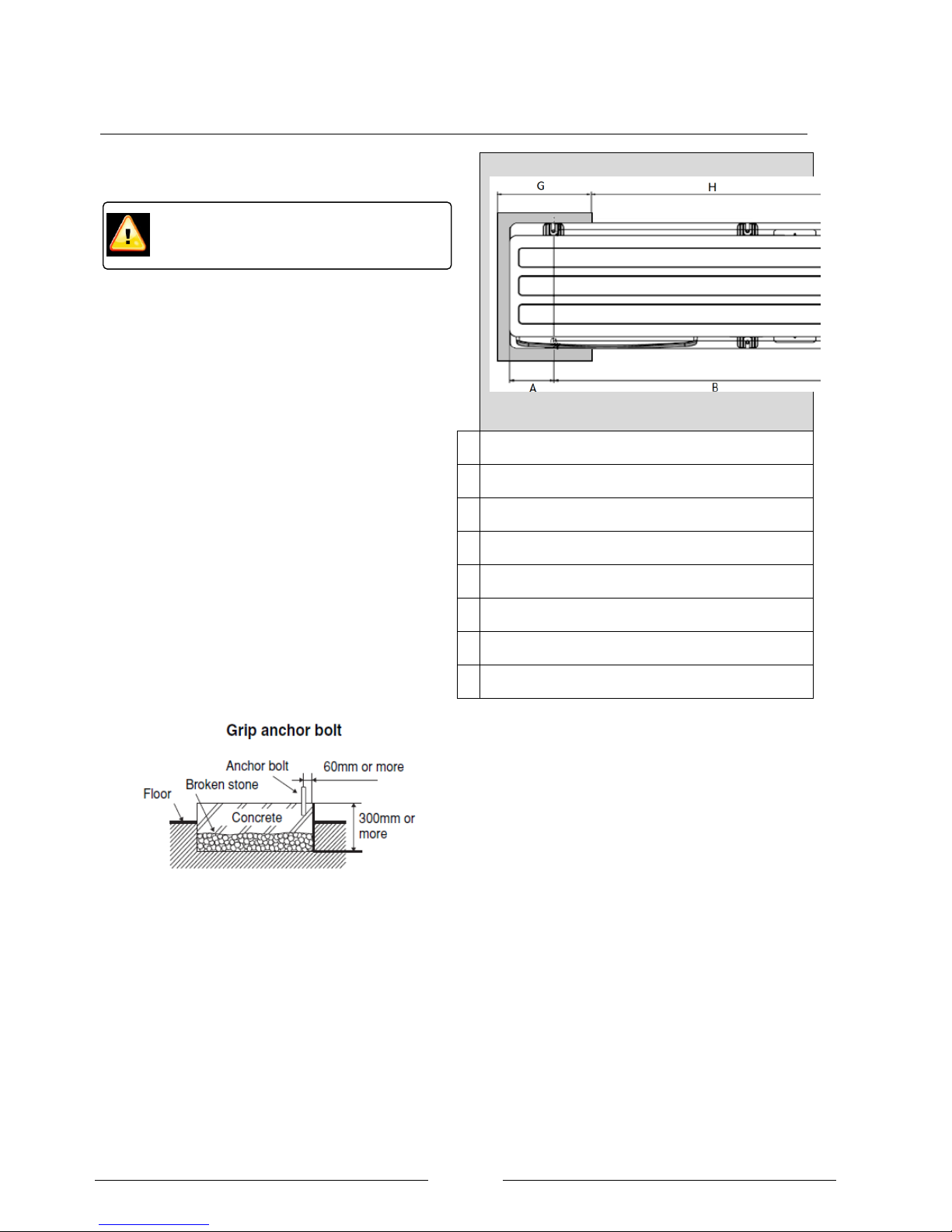

Fixing of the heat pump

The heat pump should be fixed on two flat, horizontal and

solid hard surfaces such as concrete pads that are

capable of taking the unit‟s weight and draining the

condensate.

To prevent tipping, the heat pump must be suitably fixed.

The fixing should be strong enough to prevent the unit

from tipping over if the base becomes unlevel over time.

Suggested dimensions of concrete pads as shown in

Figure 7.

A

152 B 1002

C

300

D

356 E 400 F 520 G 400

H

600

When installing the product in a place where it will be

affected by strong wind such as wind blowing between

buildings or on a rooftop an overturn prevention wire

supplied by the installer may be necessary.

Wall mounting

If the heat pump is to be wall mounted a condensate

collection tray (supplied by the installer) should be fixed

under the heat pump. The pipe from the tray to a suitable

drain should be heated so that it can‟t freeze and become

blocked.

The installation of an air source heat pump

should be carried out by a Dimplex Accredited

installer.

Page 18

Page 17

Figure 7: Top view of two concrete mounting blocks that allow the condensate to drain away via a gravel soak away.

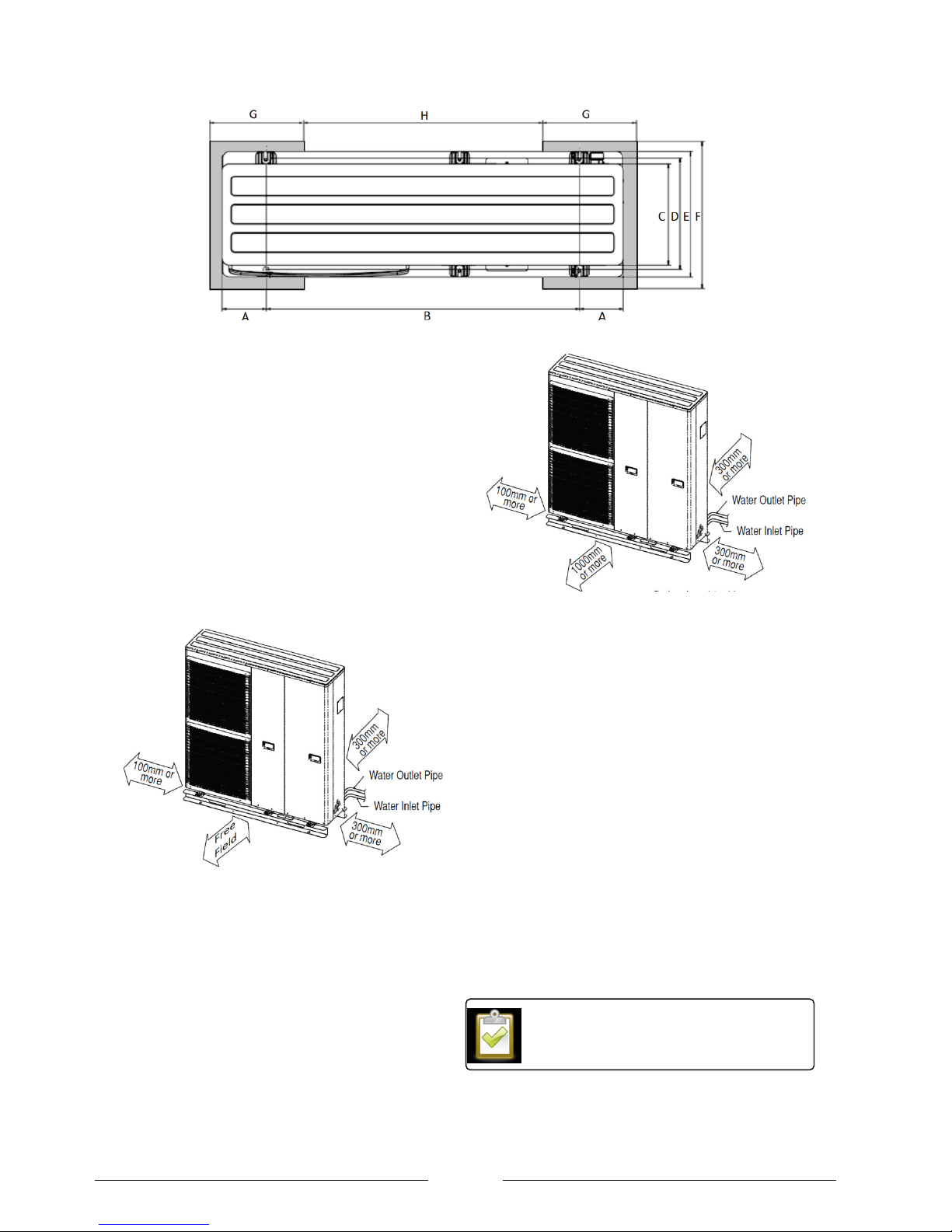

Ventilation

The installation site must be an open location clear of any

obstacles which may cause a short circuiting of the

discharged air or increased resistance due to blocking of

the inlet or outlet. This includes walls and fences as well

as locations prone to blocking debris such as leaves or

snow.

Avoid installing the heat pump in a location where suction

side of the fan may be exposed directly to wind. If the

location is in open ground, the heat pump should be set

up so that the air outlet direction of the fan is

perpendicular to the main wind direction to allow

unrestricted defrosting of the evaporator.

Figure 8: Minimum distances to objects to ensure adequate

ventilation

Minimum maintenance clearances

It must be possible to carry out maintenance work without

hindrance the displayed in Figure 9 should be observed.

For example if the unit is installed on a balcony there must

be a space measuring 1000mm in front of the unit of

maintenance.

Figure 9: Minimum clearances for maintenance (not

including clearance for air circulation)

Sound insulation measures

The installation may also have to comply with the MCS

020 standard as detailed in the section on the next page.

Furthermore, the heat pumps should be installed in a

location considering the following:

the occupant‟s enjoyment of the garden and

outside spaces.

any windows that open close to the heat pump.

The effect on neighbouring properties.

The lowest noise emissions are achieved if an area of 35m surrounding the heat pump does not have any hard

surfaces that can reverberate the sound. Additionally, the

foundation can be covered up to the level of sledge on the

heat pump with sound-absorbing material such as bark,

plants or grass. These must not affect the air flow or and

care must be taken so they don‟t get sucked into the fan.

If the heat pump is installed above inhabited

rooms, measures to prevent solid-borne

sound should be considered.

Page 19

Page 18

Air quality

If heat pump is subject to any of the following substances

in the air its‟ life span will be shortened and the guarantee

may not be valid. If the air contains any of the following,

please contact Dimplex for further information:

Sulphur i.e. Near a busy congested road.

Oil i.e. a workshop.

Ammonia i.e. animal stables

Salt i.e. near the sea.

The above conditions will affect all the exposed

components within the heat pump, but especially the

evaporator. Dimplex offer an extra service to coat the

evaporator with a protective coating. This additional

service adds a week to the delivery times. For more

details contact the Dimplex technical team.

Local planning regulation

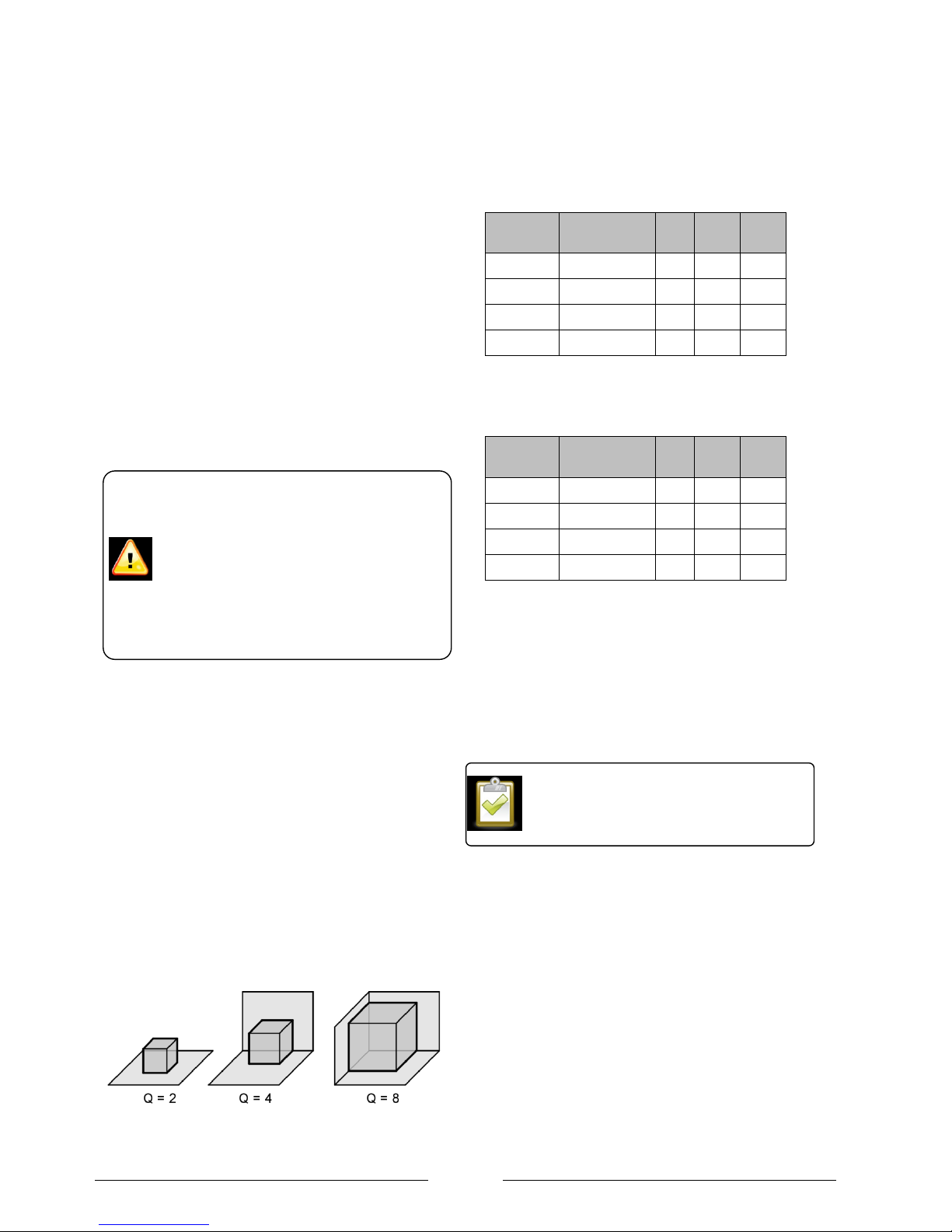

MCS Planning Standard

The MCS planning standard sets out the method by which

to calculate if the installation would meet the noise limit of

42bB. If the assessed noise level is greater than 42dB the

installation may only still go ahead if planning permission

is granted by the local authority. The value of the noise

level at the assessment position is affected by:

The A weighted sound power level of the heat

pump as given in the technical information

The directivity Q factor as determined by the

number of walls as shown in Figure 10.

The effect of solid barriers between the heat

pump and the assessment position.

The back ground noise level.

Figure 10: Q factors for different surfaces within 1 meter of

the LA MI.

Table 10 and Table 11 show the minimum distance to

achieve the 42bB at the assessment position in the MCS

020 calculation.

A weighted

sound power

level

Q2

Q4

Q8

LA 6 MI

58.0dB(A)

2m

2m

3m

LA 9 MI

61.5 dB(A)

2m

3m

4m

LA 12 MI

62.0dB(A)

2m

3m

4m

LA 16 MI

64.0dB(A)

3m

4m

5m

Table 10: Minimum distances to achieve 42dB if there is a

wall between the heat pump and assessment position

A weighted

sound power

level

Q2

Q4

Q8

LA 6 MI

58.0dB(A)

4m

6m

8m

LA 9 MI

61.5 dB(A)

8m

10m

15m

LA 12 MI

62.0dB(A)

8m

10m

15m

LA 16 MI

64.0dB(A)

8m

12m

20m

Table 11: Minimum distances to achieve 42dB if there is NOT

a wall between the heat pump and assessment position

Compliance with the MCS Planning Standard on its own

does not bestow permitted development rights – there are

a number of other conditions and limitations which must

be complied with for an installation to be permitted

development, some of which are detailed below.

Town and Country planning, England

The following is a summary of the main points for an Air

source heat pump under the Town and country planning

act. The installer should consult the original document for

further clarification and a full list of points. The act states

that planning permission would be required if the:

Installation doesn‟t comply with the MCS

planning standard.

Installation would result in more than one air

source heat pump on or within the grounds of

the building.

Site already has a wind turbine.

For further information see the MCS document

020, “MCS Planning Standards For permitted

development installations of wind turbines and

air source heat pumps on domestic premises.”

Every effort has been made to give accurate

advice on local planning regulations for

England, Wales and Scotland. The following

information is provided with the intension of

making the installer aware that such

regulations exist rather than a definitive guide.

It is essential that the installer verifies the

regulations with the local planning office

before proceeding with the installation.

Page 20

Page 19

Heat pump will be within 1m of the property

boundary.

Heat pump is installed on a pitched roof or 1m

from the edge of a flat roof.

Proposed site is a scheduled monument, listed

building, conservation area or world heritage

site.

Installed on a wall or roof which fronts the

highway

Heat pump ss closer to the road than the

property

The heat pump is installed above the level of the

ground storey.

The heat pump is used solely for heating

purposes.

external unit is greater than 0.6 m3 in size (all LA

MI units pass this test)

Planning in Wales and Northern Ireland

Air source heat pump installations in Wales and Northern

Ireland require planning permission as there are no

permitted development regulations.

For further information see the “Town and

Country Planning (General Permitted

Development) (Amendment) (England) Order

2011, No. 2056”

Page 21

Page 20

Town and Country planning, Scotland

A domestic installation of an air source heat pump in

Scotland will be classed as a Permitted Development,

unless:

It would result in the presence within the curtilage

of a dwelling of more than one air source heat

pump

The air source heat pump would be situated less

than 100 metres from the curtilage of another

dwelling

The air source heat pump is visible from the road

in a conservation area or would be within a World

Heritage Site or the curtilage of a listed building.

In addition, before beginning the development the

developer must apply to the planning authority to:

determine whether the prior approval of the

authority will be required for the siting and

external appearance of the air source heat pump

Find out if the application needs to be

accompanied by a range of other information and

a if any number of other conditions apply.

For further information see the “The Town and

Country Planning (General Permitted

Development) (Domestic Microgeneration)

(Scotland) Amendment Order 2010, No. 27.”

Page 22

Page 21

Section 7: Heating System Connection

External pipe work

The pipe work running from the heat pump into the

property should be sufficiently insulated to minimise

the heat loss and consideration should be given to

using the correct material.

Minimum water volume

The minimum water volume of the system is 50 litres

which must always be available when in heating mode

even if all of the zone valves are closed and additional

circulation pumps are off. This is typically achieved by

installation of a buffer cylinder. If a buffer cylinder is

not present there may be problems during a defrost,

namely the heating distribution system going cold and

electric immersion being required to bring it up to

temperature.

The internal volume of the heat pump is 5L.

Buffer tank

The integration of an air-to-water heat pump requires a

buffer tank connected in series to ensure that the

evaporator (finned heat exchanger) is defrosted by

means of reverse circulation. Installation of a buffer

tank connected in series also lengthens the runtimes

of the heat pump during periods of reduced heating

demand.

Minimum heating water flow rate

performance data table‟ must be observed. The

following factors should be considered:

Hydraulic resistance of the pipe work. Special

attention should to given to ensure the correct

pipe diameter is chosen considering the

required flow rates.

As a rule of thumb 28mm pipe work should be

used although the sizing of the pipe work

remains the responsibility of the installer.

To minimise energy consumption the pump

should run of the lowest speed possible whilst

still achieving the correct flow rate. The

resistance of all the pipe fittings, filter, heat

emitters and condenser must be taken into

account.

Failure to observe the minimum water throughput will

cause the heat pump not to work due to operation of

the flow switch alarm (H62).

The maximum water throughput is 20% more than the

stated minimum water throughput. Exceeding the

maximum flow rate would result in an inefficient

system operation due to increased pumping losses.

For systems in which the heating water flow can be

shut off via actuators or thermostatic valves an

overflow bypass valve must be installed to guaranteed

to minimum water flow rate.

Taconova flow checker

The Taconova flow checker is provided in every

system package to provide a simple way to verifying

that the flow rate is correct. The flow rate is read on

the bottom of the spinner as shown in

Figure 11: Correct reading of flow rate on the taconova

flow checker

The flow checker should be installed in a visible

location inside the property and as close to the heat

pump flow as possible. In order given an accurate

reading the pipe installation distances shown in Figure

12 should be observed as well as the flow direction as

shown in Figure 13.

When connecting the heating system, all

applicable regulations must also be adhered

to including all relevant European and

national regulations (including EN61770), and

local building regulation codes.

Work that requires the covers to be removed

must only be carried out under supervision of

qualified contractor, installation engineer or

service person.

The installation of an air source heat pump

must be carried out by a Dimplex Qualified

installer.

Page 23

Page 22

It is important to install the flow checker on the flow

pipe so it is protected from impurities within in the

system via the filter on the heat pump return.

Figure 12: Minimum straight pipe distance before entrace

to Taconova unit

Figure 13: Ensure the flow rate through the Taconova is

in the same direction as the arrow

Plumbing connections

Model

Fitting size

Torque

LA 6 MI

1 ¼” male flat face

118 Nm

LA 9 MI

LA 12 MI

LA 16 MI

Table 12: Water connections on LA MI

Frost protection

So long as the heat pump is connected to the mains

electrical supply the automatic antifreeze function will

prevent the water in the pipes freezing during cold

weather.

In case of a prolonged power supply failure or a

circulation pump failure the system must be drained

using the screws on the flow and return connections.

When water is idle inside the system, freezing up is

very likely to happen which could damage the system

beyond economic repair.

The installer should conduct a risk assessment to

determine the likelihood of water freezing in the heat

pump and interconnecting pipe work in the event of a

power failure during cold weather. The heating circuit

should be dosed with suitable antifreeze if heat pump

system is in a building where a power failure cannot be

detected or the occupants would be unable to drain

the system. If antifreeze is used the concentration

should be large enough to prevent freezing for the

coldest local temperature and the installer should

ensure the glycol is vented to a suitable place to

prevent contamination of the environment or sewage

system in the event the pressure relief valve activating.

Condensate

During normal operation the heat pump will remove

water vapour from the air. The condensate will run

down the evaporator into the condensate tray where it

will drain out of the unit. Defrosting takes place up to

16 times per day, with up to 3 litres of condensed

water being produced each time.

Condensed water that forms during operation must be

drained off frost-free. The heat pump must be mounted

on a level surface to guarantee proper drainage. The

condensate such drain onto a surface such as gravel.

If a tray is used to funnel the condensate, the drainage

pipe must have a minimum diameter of 50mm and

should be fed into a frost free trap and then a sewer for

rain water to ensure that large quantities of water can

be drained off.

Flushing the system

It is advisable to fit specific connections for flushing

and filling as shown in the plumbing schematics.

Before connecting the heating water system to the

heat pump, the heating system must be flushed to

remove any impurities and residue from sealants, etc.

Any accumulation of deposits in the condenser could

reduce the heat pumps performance. Do not use worn

out piping that may have become blocked over time.

Ensure that impurities are not flushed though

the heat pump since they could block the

channels in the condenser.

The condensate must drain on to an surface

that is freely draining. It must not drain on to

footpaths or patios as it could refreeze and

become a hazard.

Page 24

Page 23

Filter

It is essential to install a filter immediately before the

water inlet to the heat pump. Not installing this filter

would invalidate the warranty of the heat pump as

debris can easily block the condenser channels.

The MFK114 isolation valve as shown in Figure 14 is

included in the heat pump packages. The valve can be

closed and the filter removed and checked without

having to drain the system.

Figure 14: Isolation valve and filter supplied in LA MI

packages to be fitted to the heat pump return.

Figure 15: Isolation valve supplied in package to be fitted

to the heat pump flow.

Filling the system

The system should be filled with potable water. The

system water should be treated with standard central

heating inhibitors.

The cold fill gauge pressure on the heat pump should

be between 0.8 and 1.5 bar (0.08-0.15MPa). This will

rise during normal operation.

De-aeration

Air trapped in the system causes air locks which in turn

cause poor water flow around the system. Every high

point in the system should have a means of bleeding

out air which is supplied by the installer.

The pressure relief valve shown in Figure 17 can be

used to purge the air from the heat pump during filling.

Figure 16: Location of pressure relief valve

Figure 17: Pressure relief valve

Adjusting the water flow rate