Page 1

CE

INSTALLATION and OPERATING

INSTRUCTIONS

Air-to-Water Heat Pump

for Outdoor installation

LA 6MR LA 12TR

LA 8MR LA 16TR

LA 10MR

Order No.: 452159.67.07 FD 8602

Page 2

CONTENTS

1 READ IMMEDIATELY 3

1.1 Important Information

1.2 Legal Provisions and Guidelines

1.3 Energy-Efficient Use of the Heat Pump

2 PURPOSE OF HEAT PUMP 4

2.1 Field of Application

2.2 Principle of Operation

3 SCOPE OF DELIVERY 4

3.1 Baseline Unit

3.2 Control Box

4 TRANSPORT 5

5 INSTALLATION 5

5.1 General

5.2 Condensate Line

6 MOUNTING 6

6.1 General

6.2 Heating-Side Connection

6.3 Electrical Connection

7 COMMISSIONING 7

7.1 General

7.2 Preparatory Steps

7.3 Procedure

8 FUNCTIONAL DESCRIPTION 8/9

8.1 Heat Pump Remote Control Unit

8.2 Control Board

8.3 Heating Function

8.4 Cooling Function

8.5 Domestic Hot Water Function

9 CLEANING / CARE 9/10

9.1 Care

9.2 Cleaning of Heating Side

9.3 Cleaning of Air Side

10 MALFUNCTIONS / TROUBLE-

SHOOTING 10

11 DECOMMISSIONING 10

11.1 End-of-Life Decommissioning / Disposal

12 APPENDIX FF

2

Page 3

READ IMMEDIATELY

READ IMMEDIATELY

1

1.1 Important Information

CAUTION!

electrical circuits have been disconnected from the

power supply.

CAUTION!

not be tilted more than 45° (in either direction).

CAUTION!

only connected by the packaging film.

CAUTION!

openings must neither be constricted nor

obstructed.

CAUTION!

case of multiphase units) must be observed: Damage

to the compressor may be incurred if it is operated

in the wrong sense of rotation.

CAUTION!

containing sand, soda, acid or chloride as these may

damage the surface.

CAUTION!

is imperative that the water circuits be neutralized

after cleaning using appropriate agents.

Do not open the unit unless all

During transport, the heat pump must

Heat pump and transport pallet are

The air intake and discharge

Clockwise phase sequence (in the

Do not use any cleaning agents

To prevent consequential damage it

1.2 Legal Provisions and Guidelines

This heat pump was designed and built in

compliance with all relevant EU directives, DIN and

VDE regulations (see CE Declaration of Conformity).

The electrical connection of the heat pump must be

performed according to and conforming with all relevant VDE, EN and IEC standards. Beyond that, all

technical connection requirements of the local

electrical utility company have to be adhered to.

On connecting the heating system, all relevant

regulations have to be heeded.

1.3 Energy-Efficient Use of the Heat

Pump

By purchasing this heat pump you contribute to the

protection of the environment. A prerequisite for

energy-efficient operation is the proper design of the

heat source system and the heat utilization system.

One of the most important factors of heat pump

efficiency is keeping the temperature difference

between the heating water and the heat source as

small as possible. It is therefore strongly

recommended that the design of both the heat

source system and the heat distribution system be

carried out with great care. A 1 Kelvin (1°C) higher

temperature difference corresponds to an

increase in power consumption of approx. 2.5%.

When designing the heating system care must be

taken that special applications such as domestic

water heating are taken into consideration and

dimensioned for low temperature operation. Heat

pumps are optimally suited for underfloor heating

(surface/radiant heating) applications due to the

low supply temperatures (30 °C to 40 °C).

During operation it is essential that the heat

exchangers are not contaminated as this would

increase the temperature difference resulting in a

lower coefficient of performance.

CAUTION!

with a frequency converter.

CAUTION!

be performed by qualified persons only.

The unit is not suitable for operation

Work on the refrigeration circuit may

3

Page 4

PURPOSE OF HEAT PUMP

SCOPE OF DELIVERY

PURPOSE OF HEAT

23

PUMP

SCOPE OF DELIVERY

3.1 Baseline Unit

2.1 Field of Application

The air-to-water heat pump is intended for use in

existing or newly built heating systems.

The heat pump is designed for the cooling or heating

of water for heating purposes and the supply of

domestic hot water!

The heat pump is suitable for mono-energetic and

bivalent operation.

During heating mode, a heating water return

temperature of more than 18 °C must be maintained

in order to assure proper defrosting of the

evaporator.

The heat pump is generally not designed for

satisfying any increased heat demand during the

drying phase of new buildings. The additional heat

demand must therefore be met by special appliances

to be supplied on site. For the structural drying of

new buildings during autumn and winter, its is

recommended that an additional electric heating

element (available as an accessory) be installed.

The heat pump is deliverd as a compact unit

containing the components listed below.

The refrigerant used is R407C.

123

4

CAUTION!

with a frequency converter.

The unit is not suited for operation

2.2 Principle of Operation

Ambient air is drawn in by the fan and passed over a

finned heat exchanger, which extracts heat from the

air in the heating mode or gives off heat to the air in

the cooling mode. This energy difference is

transferred to the working fluid (refrigerant) in the

heat exchanger.

With the aid of an electrically driven compressor, the

absorbed heat is "pumped" to a higher temperature

level through pressure increase and - depending

on the particular application (cooling or heating) - is

given off to the heating water or the waste air via the

heat exchanger.

During heating mode, electrical energy is used to

raise the heat of the environment to a higher

temperature level. Due to the fact that the energy

extracted from the air is transferred to the heating

water, this type of appliance is referred to as air-towater heat pump.

The air-to-water heat pump consists of the following

main components: evaporator, fan and expansion

valve as well as the low-noise compressor, a

condenser and the electric control unit.

In the case of low ambient temperatures in the

heating mode, moisture contained in the air may

accumulate on the evaporator in the form of frost

thus impairing the heat transfer. The evaporator is

automatically defrosted by the heat pump, if required.

Vapour pluming may occur at the air outlet depending

on the weather conditions.

98 7 6 5

1) Evaporator 6) Receiver/

2) Control box filter drier

3) Fan 7) Circulat. pump

4) Pressostats 8) Electric heater

5) Expansion vessel 9) Compressor

3.2 Control Box

The control box is integrated in the heat pump. It is

accessible after removal of the cover panel (the

fastening screw holes of the cover panels are

capped).

The control box houses the mains terminals, the

power contactors, the soft start unit as well as the

terminals for the remote control.

The control of the heat pump is effected via the

remote control included in the scope of delivery (see

also section 8.).

4

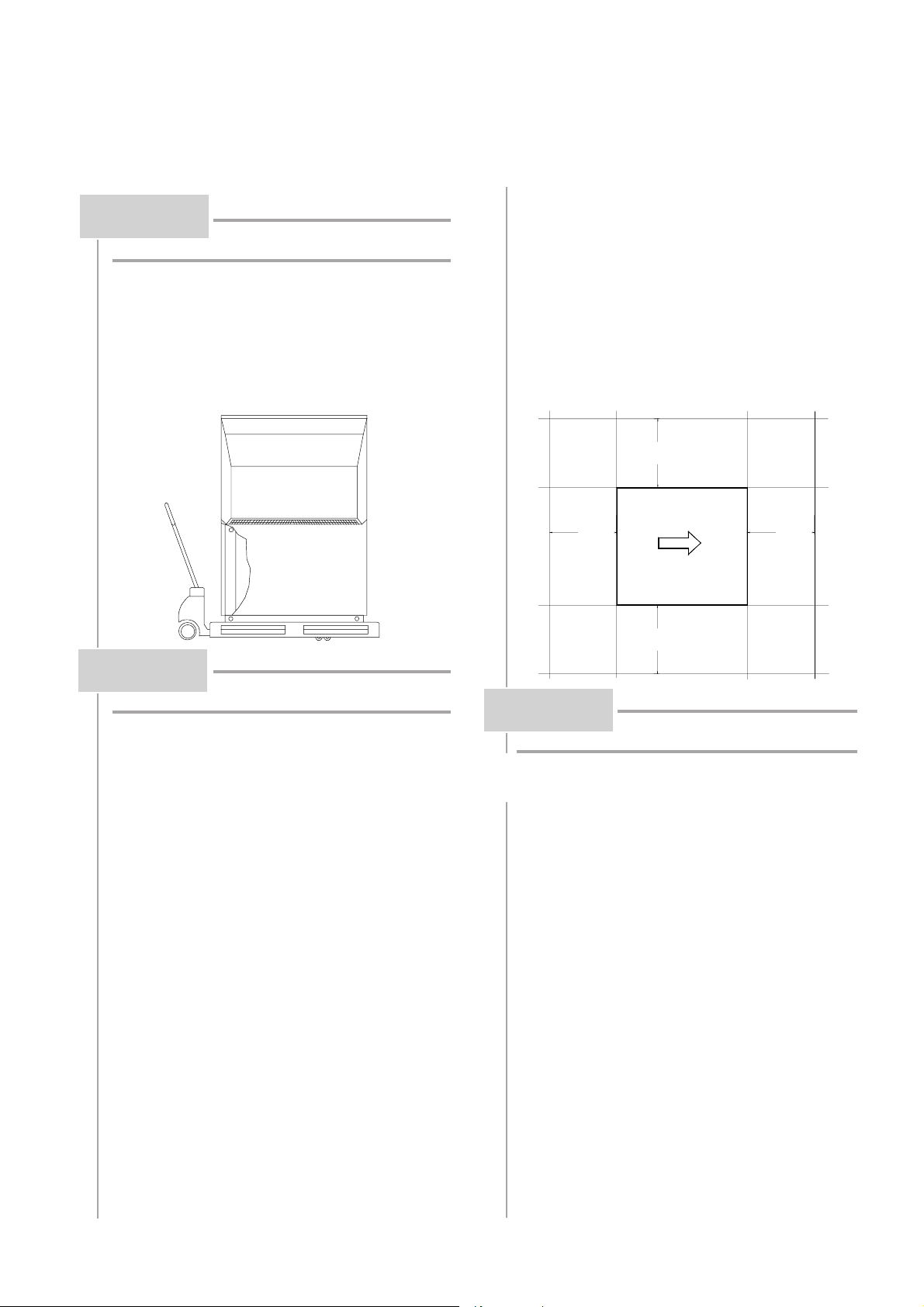

Page 5

TRANSPORT

INSTALLATION

TRANSPORT

4

CAUTION!

must not be tilted more than 45° (in either direction).

The unit should be transported to the final

installation site on a wooden pallet. The heat pump

can be transported either by means of a lift truck or

using 3/4" pipes to be passed through the openings

provided in the base plate or in the frame.

During transport, the heat pump

INSTALLATION

5

5.1 General

The unit should always be installed on a

permanently level, smooth and horizontal floor. The

base frame (with its contact surfaces) should make

close contact with the floor in order to prevent any

structure-borne noise from being transmitted. If this

is not possible, additional sound-absorbing

measures might become necessary. It must be

possible to carry out servicing activities without any

problems. This is assured if a clearance of 1.2m is

maintained all around the unit.

1,2 m

1,2 m1,2 m

CAUTION!

are only connected by the packaging film.

When using 3/4" carrying pipes, be sure to secure

them against shifting so as to avoid injuries (to your

hands) during transport!

When slipping the carrying pipes through the frame,

care must be taken that no components (in particular

the plastic condensate pan or the drain pipe socket)

are damaged.

The heat pump and transport pallet

1,2 m

CAUTION!

openings must not be restricted nor obstructed.

The air intake and discharge

5.2 Condensate Line

The condensation water that may collect during

operation must be drained in a place protected from

frost. The heat pump must be positioned horizontally

so that proper discharge can be ensured. The

condensation water pipe must have a minimum

diameter of 50 mm and should be discharged to the

sewer drain in a frost-proof location.

The condensate pipe has to be placed centered

unterneath the drain pipe fitting of the condensate pan

(see also dimensioned drawing in the Appendix). Alternative condensate discharge options have to be

agreed with the manufacturer.

Do not discharge the condensate directly into

septic pits or cesspools as the evaporator is likely

to be destroyed by the aggressive vapours

generated there.

5

Page 6

MOUNTING

MOUNTING

6

6.1 General

The following connections need to be established

on the heat pump:

- supply/return lines of the heating system

- condensate drain

- control lead to the remote control

- power supply

6.2 Heating-Side Connection

The connections on the heating side of the heat

pump are provided with 1"external thread (flat

sealing). When making the connections to the heat

pump, use a wrench to counterhold at the transitions.

Before completing the heat pump connections on

the heating water side, the heating installation must

be flushed in order to remove any impurities that

may be present, as well as any residues of sealing

material, and the like. Any accumulation of deposits

in the condenser may result in a total failure of the

heat pump. On systems equipped with heating water

flow shut-off devices such as radiator or thermostat

valves, an overflow valve, to be provided by the

customer, needs to be installed at the outlet of the

heat pump in a heating system bypass. This assures

a minimum heating water flow through the heat

pump and thus prevents any malfunctions from

occurring.

Once the installation on the heating side has been

completed, the heating system must be filled, deaerated and pressure-tested..

Heating water minimum flow rate

The heating water minimum flow rate through the heat

pump must be assured in all operating states of the

heating system. This can be accomplished, for example,

by installing a differential pressure-free manifold or an

overflow valve. The procedure for setting an overflow

valve is described in the Chapter Commissioning.

Frost Protection

On heat pumps installed in a location prone to frost,

a manual drain valve (see "Hydraulic Block Diagrams"

in the Appendix) should be provided. Properly installed

appliances feature an internal frost protection feature.

If the heat pump is taken out of service or in the event

of a power failure, the system must be drained. In

heat pump installations where a power failure cannot

be readily detected (e.g. holiday houses), the heating

circuit must contain a suitable antifreeze product.

6.3 Electrical Connection

The power connection of the heat pump is effected

via a standard 3-core (for 1-phase units) or a 5-core

(for 3-phase units) cable.

In the case of the 1-phase units, an additional 3-core

cable must be installed for the electric back-up heater.

The cable(s) has (have) to be supplied by the client;

the cross-sectional area is to be selected in

accordance with the power consumption of the heat

pump (see Equipment Data in the appendix) as well

as all relevant VDE (EN) and VNB regulations.

The power supply of the heat pump must be equipped

with an all-pole disconnecting device with a contact

gap of at least 3 mm (e.g. utility company shut-off

contactor, power contactor) as well as a 3-pole circuit

breaker, with simultaneous tripping of all external

conductors (tripping current as stated in the Equipment Data).

- optionally, an additional three-core cable is

required for the domestic hot water supply.

When connecting multiphase units the clockwise

phase sequence of the motor electrical supply must

be assured.

Phase sequence: L1, L2, L3.

CAUTION!

case of multiphase units) must be ensured: Operating

the compressor in the wrong sense of rotation, may

result in damage to the compressor. An incorrect

phase sequence causes the fan to operate in the

wrong sense of rotation leading to a significant

reduction in performance.

The control voltage for the remote control is provided

by the power supply of the unit.

The connecting lead (control lead) from the remote

control to the heat pump (not included in the scope of

delivery) must be suitable for 230 V mains power

supply. The lead must have (at least) 6 cores and the

cross-section of the single cores must be at least 0.5

mm2.

The power supply of the heat pump must be as

specified in the Technical Data of the applicance, i.e.

230 V AC 50 Hz or 3-L/N/PE 400 V.

The connection inside the heat pump is to be effected

using the terminal strips in the control box. For

detailed information refer to the Wiring Diagrams in

the Appendix.

Clockwise phase sequence (in the

6

Page 7

COMMISSIONING

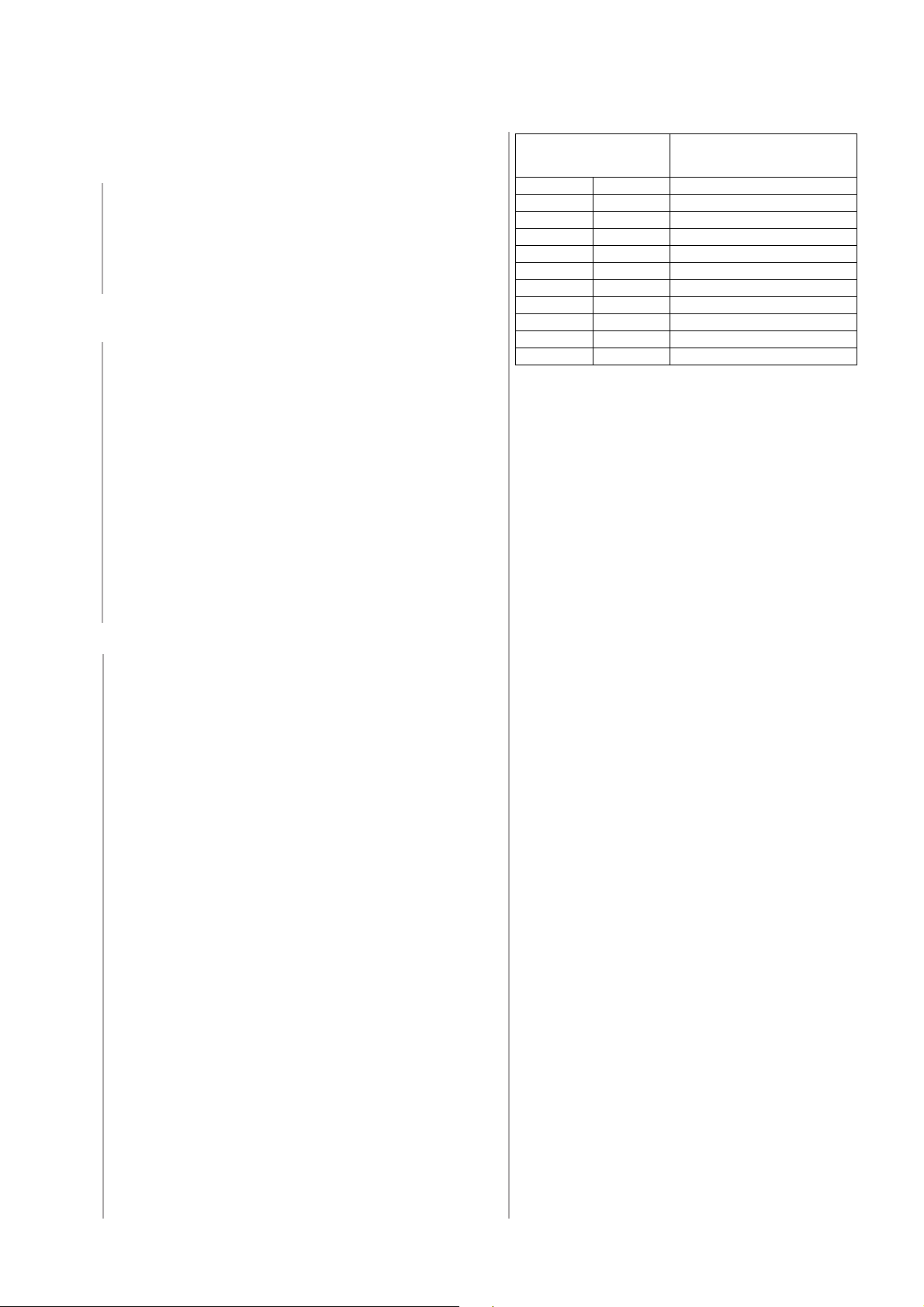

Heat source temperature

from to

max. difference betwe en

heating water supply and

return temperature

-20 °C -15 °C 4 K

-14 °C -10 °C 5 K

-9 °C -5 °C 6 K

-4 °C 0 °C 7 K

1 °C 5 °C 8 K

6 °C 10 °C 9 K

11 °C 15 °C 10 K

16 °C 20 °C 11 K

21 °C 25 °C 12 K

26 °C 30 °C 13 K

31 °C 35 °C 14 K

7

7.1 General

To ensure proper commissioning it should be

carried out by an after-sales service authorized by

the manufacturer. Only then can an extended

warranty period of 3 years in total be granted (cf.

Warranty service).

7.2 Preparatory Steps

Prior to commissioning, the following items need to

be checked:

- All connections of the heat pump must have been

made as described in Chapter 6.

- In the heating circuit all valves that could impair

the proper heating water flow must be open.

- The air intake/discharge path must be

unobstructed.

- The sense of rotation of the fan must correspond

to the direction of the arrow.

- An operating mode must have been set on the

remote control.

- Proper condensate drainage must be ensured.

7.3 Procedure

The start-up of the heat pump is effected via the

remote control.

Where an overflow valve is fitted to assure the minimum

heating water flow rate, the valve must be set in

accordance with the specific requirements of the heating

installation. An incorrect setting may result in various

error symptoms and an increased electric power

consumption. To correctly set the overflow valve, the

following procedure is recommended for the "heating

mode":

Close all of the heating circuits that may also be closed

during operation (depending on the type of heat pump

usage) so that the least favourable operating state with respect to the water flow rate - is achieved.

Typically these are the heating circuits of the rooms

on the building's south and west sides. At least one

heating circuit must remain open (e.g. bathroom).

The overflow valve is to be opened to such an extent

that based on the current heat source temperature

the maximum temperature spread between heating

supply and return flow temperature is obtained, as

indicated in the table that follows. The temperature

spread should be measured as closely to the heat

pump as possible. In mono-energetic systems, the

electric heating element is to be deactivated.

COMMISSIONING

The following procedure must be observed so that

the commissioning activities can be carried out

without any problems:

a) Close all heating circuits.

b) Open the overflow valve all the way.

c) Wait until the buffer tank has reached a

temperature of approx. 25 °C.

d) Subsequently, slowly reopen the valves of the

heating circuits, one after the other, in such a

way that the heating water flow rate is

continually increased by slightly opening the

related heating circuit. When so doing, the

heating water temperature in the buffer tank

must not fall below 20 °C so that the heat pump

can be defrosted at any time.

e) Once all heating circuit are fully open and a

heating water temperature of approx. 20 °C is

maintained in the buffer tank, the minimum flow

rate must be set on the overflow valve and the

heating circulating pump.

7

Page 8

FUNCTIONAL DESCRIPTION

654321

12

11

78910

FUNCTIONAL

8

DESCRIPTION

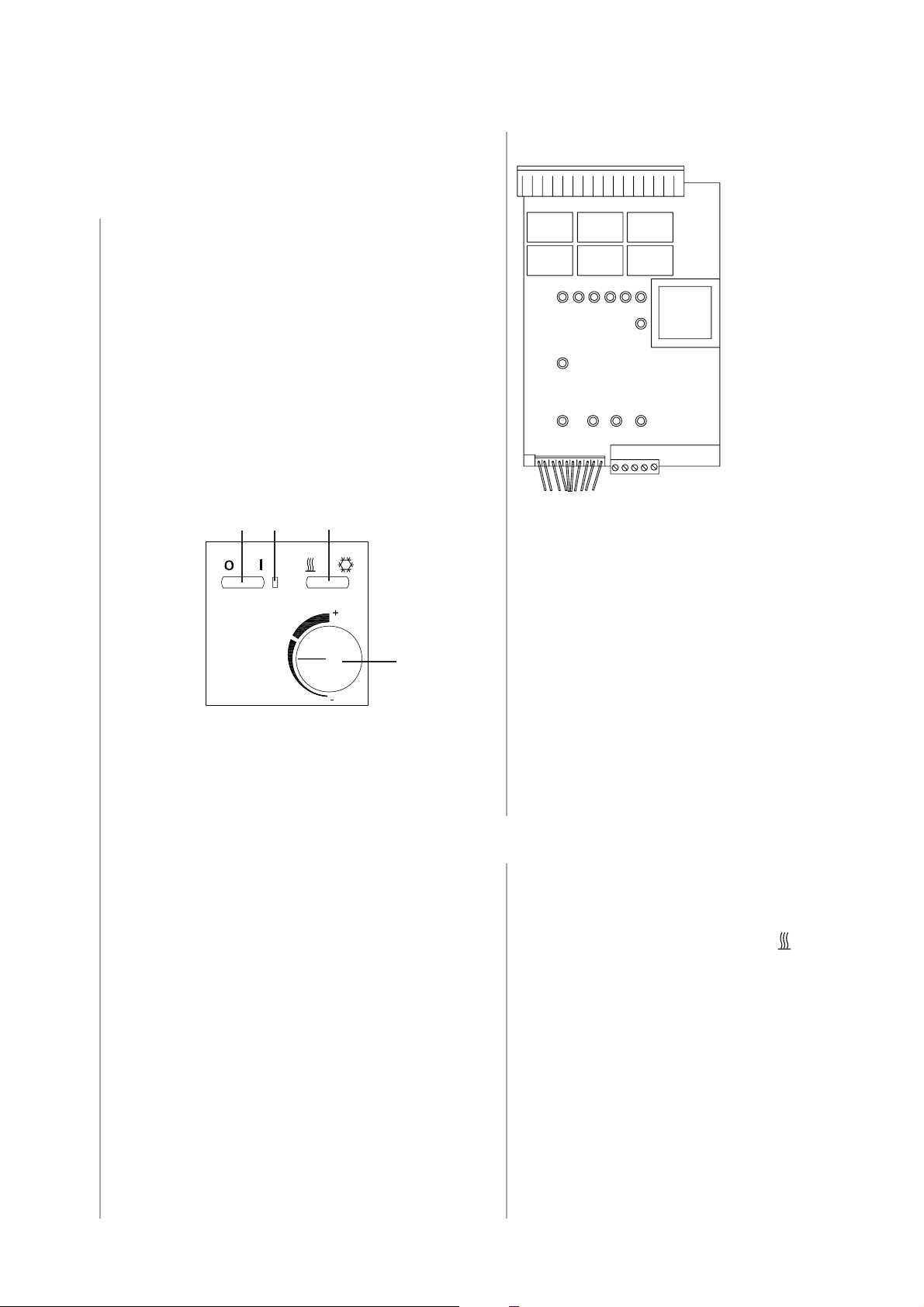

8.1 Heat Pump Remote Control Unit

The heat pump can be switched on and off by means

of the remote control positioned inside the building.

Switching off in this case means switching to a

"standby" function, i.e. as long as the heat pump is

supplied with mains power, the frost protection

function of the heat pump remains active. If the water

temperature is too low, first the heating circulating

pump, and if this is not enough, also the compressor

must be put in operation. The remote control allows

you to set the heating or cooling operating mode

(the switchover delay from the heating to the cooling

mode, or vice-versa, is 10 min.) as well as the

temperature level of the heating water.

1) Switch On/Standby

2) LED (green) is illuminated regardless of the

3) Switch "Heating" (left side depressed)

4) Dial for selecting heating water setpoint

12 3

switch position (indicates operational readiness of heat pump)

Switch "Cooling" (right side depressed)

temperature

8.2 Control Board

1) on = compressor is operating

2) on = fan is operating

3) off = reversing valve set to "Heating"

on = reversing valve set to "Cooling" or

"Defrost"

4) on = heating circulating pump is operating

5) off = output backup heater off

6) on = call for frost protection, HP is heating

4

off = call for frost protection off

7) on = low pressure pressostat okay

8) off = defrost process in progress or

"Heating mode"

on = defrost process is terminated or

"Cooling mode"

9) not used

10) not used

11) flashing during operation

12) flashing in the event of a malfunction

8.3 Heating Function

Set switch (1) to position On (I) to put heat pump

into operation. The heating mode can be preselected

by placing switch (3) to the Heating ( ) position.

The desired return temperature can be set using

selector dial (4), the relevant call for heat is

controlled by the potentiometer and lies within a

range of min. 10 °C and max. 55 °C. If the preset

temperature is reached, the heat pump switches off.

Once the return temperature drops below the preset

temperature by 4 Kelvin, the heat pump switches

back on. In the event that the preset return

temperature cannot be reached, the output for the

back-up heater cuts in after approx. 1 hour. The heat

pump cannot be restarted until a minimum time delay

of 5 minutes has elapsed. At a supply temperature

of approx. 60 °C or if the air temperature is too low,

the heat pump switches off.

8

Page 9

FUNCTIONAL DESCRIPTION

CLEANING / CARE

8.4 Cooling Function

Place switch (1) in position On (I) to put heat pump

into operation. The cooling mode can be

preselected by placing switch (2) to the Cooling

(

) position. The desired return temperature can

be set using selector dial (4), the relevant call for

heat is controlled by the potentiometer and lies

within a range of min. 12 °C and max. 25 °C. When

the preset temperature is reached, the heat pump

switches off. Once the return temperature exceeds

the preset value by 4 Kelvin, the heat pump

switches back on. The heat pump cannot be

restarted until a minimum time delay of 5 minutes

has elapsed. At a supply temperature of below

7 °C, the heat pump switches off.

To prevent condensate from forming on the

system in the case of surface cooling systems, it

is recommended that dew point monitors be

installed at critical places of the cold distribution

system and connected in lieu of jumper A1. In the

event that condensation should form, the cooling

operation of the system will be interrupted.

8.5 Domestic Hot Water Function

This heat pump can also be used for heating domestic

water.

The call for domestic water heating (and the domestic

water temperature) is controlled by terminal "X2-7"

by means of a thermostat to be provided by the client.

This thermostat connects phase (L) to terminal "X27" and controls a reversing valve which is part of the

hot water switch group "N13".

A suitable thermostat is available as an accessory.

The call for domestic water heating may also occur if

no call for space heating exists. On a call for heat,

the control unit switches off the heating circulating

pump and the setpoint is set to maximum.

The water temperature is now controlled by the

external thermostat. After the domestic hot water

preparation has been terminated, the system

returns to the same function that was active before

the call.

CLEANING / CARE

9

9.1 Care

To protect the paint finish, avoid placing objects

against or on the unit. The external parts of the heat

pump can be wiped with a damp cloth and

commercially available cleaning agents.

CAUTION!

containing sand, soda, acid or chloride as these may

damage the surface.

To prevent malfunctions due to dirt deposits in the

plate heat exchanger of the heat pump, care must

be taken that the heat exchanger cannot become

contaminated in the heating installation. In the event

that operating malfunctions due to contamination

occur nevertheless, the system should be cleaned

as described below. (Caution: The fins of the finned

heat exchanger have sharp edges -> risk of cutting

injuries!)

9.2 Cleaning of Heating Side

The ingress of oxygen into the heating water may

result in the formation of oxidation products. An additional contamination of the heating water caused

by residues of lubricating and sealing agents occurs

in many cases.

Both of the above causes may lead to a reduction in

the performance of the plate heat exchanger of the

heat pumps. In such cases, the installer must clean

the heat exchanger concerned. Based on information

known to date we recommend cleaning with a 5%

phosphoric acid solution or, in the case that cleaning

needs to be performed more frequently, with a 5%

formic acid solution. In both cases the cleaning fluid

should be at room temperature. Thorough flushing

is necessary to ensure that all cleaning agent

residues are removed from the system. It is

recommended that the heat exchanger be cleaned

in the direction opposite to the normal flow direction.

Owing to their acid content, flushing agents must be

used with caution. To prevent acidic flushing agents

from entering the heating installation when cleaning

the condenser, we recommend that the flushing

device be mounted directly to the supply and return

line of the heat pump. The regulations of the trade

associations must be adhered to. If in doubt, contact

the manufacturers of the chemicals!

Do not use any cleaning agents

CAUTION!

is imperative that the water circuit be neutralized

after cleaning using appropriate agents.

To prevent consequential damage it

9

Page 10

CLEANING / CARE

MALFUNCTIONS / TROUBLESHOOTING

DECOMMISSIONING

Caution - Heating Contractors

Depending on the water quality and quantity, in

particular in the case of mixed installations and

plastic pipes, mineral deposits (rust sludge, lime)

may form impairing the proper functioning of the

heating installation. A cause of this is the water

hardness as well as oxygen dissolved in the filling

water as well as additional oxygen from the air which

may penetrate via valves, fittings and plastic pipes

(oxygen diffusion). As a preventive measure it is

recommended that a physical water conditioner such

as ELYSATOR be used.

9.3 Cleaning of Air Side

Finned heat exchangers, fan and condensate drain

should be cleaned of debris (leaves, branches, etc.)

prior to the start of the heating season. Contamination

of this nature can be removed manually using

compressed air or by washing off with clear water.

The appliance cover and the air intake grille may have

to be removed for this purpose.

CAUTION!

ensured that all electrical circuits are disconnected

from the power supply.

When cleaning do not use any sharp or hard objects

so as to prevent any damage to the evaporator and

the condensate pan.

Extreme weather conditions (e.g. heavy snow) may

in some cases result in ice build-up on the inlet and

outlet grilles. To assure a minimum air flow rate, clear

the inlet and discharge areas of snow and ice, if

needed.

Prior to opening the unit it must be

The preset temperature level cannot be reached!

Please check whether

- the permissible operating conditions of the heat

pump are complied with (air temperatures too high

or too low).

- the air inlet or outlet areas are neither covered,

obstructed nor severely contaminated.

- valves or stop-cocks in the water lines (heating

lines) are closed.

- the water temperature in the buffer tank is

sufficiently high.

If you cannot eliminate the malfunction yourself,

please contact your customer service in charge (see

Warranty Certificate).

CAUTION!

only by an authorized and qualified customer service.

Work on the heat pump may be done

DECOMMISSIONING

11

11.1 End-of-Life Decommissioning /

Disposal

Before removing the heat pump, disconnect the

appliance from the power supply and close all valves.

Environment-relevant requirements regarding the

recovery, recycling and disposal of service fuels and

components in accordance with all relevant

standards must be adhered to. In this context,

particular attention must be paid to the proper

disposal of refrigerants and refrigeration oils.

10

MALFUNCTIONS /

TROUBLESHOOTING

This heat pump is a quality product and is designed

for troublefree and maintenance-free operation. In

the event that a malfunction occurs nevertheless,

you will be able to correct the problem easily yourself

in the majority of cases.

Heat pump does not run!

Please check that:

- there is no problem with the power supply (blown

fuse, power failure).

- the power switch on the remote control is switched

on and the correct operating mode is selected, as

well as that the correct setpoint temperature is set.

10

Page 11

12

APPENDIX

APPENDIX

12.1 DIMENSIONED DRAWING 12

12.2 EQUIPMENT DATA 13

12.3 SCHEMATICS

12.3.1 Heating mode LA 6MR 14

12.3.2 Cooling mode LA 6MR 15

12.3.3 Heating mode LA 8MR 16

12.3.4 Cooling mode LA 8MR 17

12.3.5 Heating mode LA 10MR 18

12.3.6 Cooling mode LA 10MR 19

12.3.7 Heating mode LA 12TR 20

12.3.8 Cooling mode LA 12TR 21

12.3.9 Heating mode LA 16TR 22

12.3.10 Cooling mode LA 16TR 23

12.4 WIRING DIAGRAMS

12.4.1 Control LA 6MR-LA 10MR 24

12.4.2 Load LA 6MR-LA 10MR 25

12.4.3 Terminal Diagram LA 6MR-LA 10MR 26

12.4.4 Legend LA 6MR-LA 10MR 27

12.4.5 Control LA 12TR-LA 16TR 28

12.4.6 Load LA 12TR-LA 16TR 29

12.4.7 Terminal Diagram LA 12TR-LA 16TR 30

12.4.8 Legend LA 12TR-LA 16TR 31

12.5 HYDRAULIC

BLOCK DIAGRAMS

12.5.1 Mono-energetic system 32

12.5.2 Mono-energetic system and

domestic hot water function 33

12.6 EC DECLARATION OF

CONFORMITY 34

11

Page 12

APPENDIX: 12.1 DIMENSIONED DRAWING

Dimensioned Drawing

Heating water

Supply

G 1” external thread

Heating water

Return

G 1” external thread

Feed-through

Electric lines

Condensate pan

Condensate drain

Appliance contact surfaces

(stainless steel)

( Base frame )

Soil

to sewer

Condensate tube

(plastic)

Direction of air flow

35 (circumferential)

Condensate drain

Air discharge end

Electr.

connection box

(inspection side)

12

Page 13

.

Equipment Data

EQUIPMENT DATA for air-to-water heat pumps for heating

APPENDIX: 12.2 EQUIPMENT DATA

1

2

2.1 Type

TYPE AND COMMERCIAL DESCRIPTION LA06MRN LA08MRN LA10MRN LA12TRN LA16TRN

MODEL

reversible reversible reversible reversible reversible

2.2 Enclosure type acc. to EN 60 529 for compact unit and/or heating element IP 24 IP 24 IP 24 IP 24 IP 24

2.3 Installation site outdoors outdoors outdoors outdoors outdoors

3

PERFORMANCE DATA

3.1 Operating temperature limits:

Heating water supply / return °C / °C max.60/min.18 max.60/min.18 max.60/min.18 max.60/min.18 max.60/min.18

Cooling, flow °C +7 to +20 +7 to +20 +7 to +20 +7 to +20 +7 to +20

Air (heating)

Air (cooling)

3.2 Heating capacity / coeff. of perform. at A7 / W35

1)

at A7 / W45

1)

°C -20 to +35 -20 to +35 -20 to +35 -20 to +35 -20 to +35

°C +15 to +45 +15 to +45 +15 to +45 +15 to +45 +15 to +40

kW / --- 6.1 / 3.3 7.4 / 3.3 8.5 / 3.4 11.9 / 3.3 15.3 / 3.3

kW / --- 6.1 / 2.7 7.3 / 2.7 8.4 / 2.8 11.6 / 2.7 14.9 / 2.8

3.3 Cooling capacity / coeff. of perform. at A35 / W18 kW / --- 7.9 / 3.2 9.4 / 3.3 11.1 / 3.3 15.8 / 3.3 18.5 / 3.3

at A35 / W7 kW / --- 6.4 / 2.7 7.7 / 2.9 9.0 / 2.9 13.6 / 3.0 16.1 / 3.0

3.4 Sound power level dB(A) 70 71 71 72 72

3.5 Sound pressure level at 10 m distance (discharge side) dB(A) 45 46 46 47 47

3.6 Heating water flow rate m³/h 1.1 1.3 1.5 1.7 1.9

3.7 Free pressure, heating circulating pump (max. stage) Pa 34800 35600 33800 32700 58900

3.8 Refrigerant; total charge weight type / kg R407C / 1.5 R407C / 2.3 R407C / 2.3 R407C / 3.4 R407C / 3.7

3.9 Rating electric heating element (back-up heater) max. kW 66666

4

DIMENSIONS; CONNECTIONS AND WEIGHT

4.1 Equipment dimensions H x W x L cm 86 x 127 x 67 86 x 127 x 67 86 x 127 x 67 86 x 127 x 67 86 x 127 x 67

4.2 Equipment connections for heating inch G 1'' external G 1'' external G 1'' external G 1'' external G 1'' external

4.3 Weight of transport unit(s) incl. packaging kg 159 165 170 185 196

5

ELECTRICAL CONNECTION

5.1 Nominal voltage; fusing V / A 230 / 20 230 / 20 230 / 25 400 / 20 400 / 25

5.2 Fuse protection, electric heating element (only 230V units) A

30

4)

30

4)

30

4)

--

5.3 Nominal power consumption 1) A2 W35 kW 1.9 2.3 2.5 3.6 4.6

5.4 Starting current with soft starter A 26 32 38 26 27

5.5

6

7

Nominal current A2 W35 / cos ϕ

COMPLIES WITH EUROPEAN SAFETY REGULATIONS

OTHER DESIGN CHARACTERISTICS

A / --- 10.3 12.5 13.6 6.5 8.3

3) 3) 3) 3) 3)

7.1 Defrosting automatic automatic automatic automatic automatic

Defrost type cycle reversal cycle reversal cycle reversal cycle reversal cycle reversal

Defrost pan available yes (heated) yes (heated) yes (heated) yes (heated) yes (heated)

7.2 Heating water inside unit protected against freezing yes 2) yes 2) yes 2) yes 2) yes 2)

7.3 Performance settings 11111

1)

2) The heating circulating pump and the controller of the heat pump must be on standby at all times.

3) See EC Declaration of Conformity

4) For the electr. connection of the electric heating element, a separate load line with its own fuse protection is required

These data characterize the size and performance of the system. For economic and energetic

considerations, additional factors such as defrosting behaviour, bivalence point and control need to be taken

into account. Abbreviations have the following meaning: e.g. A7 / W35: outside temperature 7 °C and

heating water supply temperature 35 °C.

Subject to change without notice Issued: 02.03.2006

13

Page 14

APPENDIX: 12.3 SCHEMATICS

12.3.1 Heating mode LA 6MR

Heating capacity in [kW]

Heizleistung in [kW]

11

Water outlet temperature in [°C]

Wasseraustrittstemperatur in [°C]

10

Bedingungen:

9

Conditions:

Heating water flow rate 1.1 m3/h

Heizwasserdurchsatz 1,1 m³/h

35

50

8

7

6

5

4

40

3

2

1

0

-20-100 10203040

Lufteintrittstemperatur in [°C]

Air inlet temperature in [°C]

Power consumption (incl. power input to pump)

Leistungsaufnahme (incl. Pumpenleistungsanteil)

3

2

40

50

35

20000

18000

16000

Pressure loss in [Pa]

Druckverlust in [Pa]

Condenser

Verflüssiger

1

14000

0

-20-100 10203040

Lufteintrittstemperatur in [°C]

Air inlet temperature in [°C]

Coefficient of performance (incl. power input to pump)

6

Leistungszahl (incl. Pumpenleistungsanteil)

35

5

4

50

3

2

40

1

0

-20-100 10203040

Air inlet temperature in [°C]

Lufteintrittstemperatur in [°C]

14

12000

10000

8000

6000

4000

2000

0

0 0,5 1 1,5

00,511,5

Heizwasserdurchsatz in [m³/h]

Heating water flow rate in [m3/h]

Page 15

12.3.2 Cooling mode LA 6MR

Cooling capacity in [kW]

Kühlleistung in [kW]

14

APPENDIX: 12.3 SCHEMATICS

Wasseraustrittstemperatur in [°C]

Water outlet temperature in [°C]

12

Bedingungen:

Conditions:

Water flow rate 1.1 m3/h

Wasserdurchsatz 1,1 m³/h

10

8

6

18

8

4

2

0

10 15 20 25 30 35 40 45 50

Lufteintrittstemperatur in [°C]

Air inlet temperature in [°C]

Power consumption (incl. power input to pump)

Leistungsaufnahme (incl. Pumpenleistungsanteil)

4

3

18

20000

18000

8

Pressure loss in [Pa]

Druckverlust in [Pa]

2

1

0

10 15 20 25 30 35 40 45 50

Lufteintrittstemperatur in [°C]

Air inlet temperature in [°C]

Leistungszahl (incl. Pumpenleistungsanteil)

Coefficient of performance (incl. power input to pump)

7

6

5

4

3

2

18

8

1

0

10 15 20 25 30 35 40 45 50

Lufteintrittstemperatur in [°C]

Air inlet temperature in [°C]

16000

14000

12000

10000

8000

6000

4000

2000

0

Verflüssiger

Condenser

0 0,5 1 1,5

00,511,5

Heizwasserdurchsatz in [m³/h]

Heating water flow rate in [m3/h]

15

Page 16

APPENDIX: 12.3 SCHEMATICS

12.3.3 Heating mode LA 8MR

Water outlet temperature in [°C]

Heating capacity in [kW]

Heizleistung in [kW]

13

12

11

10

Bedingungen:

Conditions:

Heating water flow rate 1.3 m3/h

Heizwasserdurchsatz 1,3 m³/h

9

8

7

6

5

4

40

3

2

1

0

-20-100 10203040

Wasseraustrittstemperatur in [°C]

35

50

Air inlet temperature in [°C]

Lufteintrittstemperatur in [°C]

Power consumption (incl. power input to pump)

Leistungsaufnahme (incl. Pumpenleistungsanteil)

4

3

40

2

50

35

1

0

-20-100 10203040

Air inlet temperature in [°C]

Lufteintrittstemperatur in [°C]

Leistungszahl (incl. Pumpenleistungsanteil)

Coefficient of performance (incl. power input to pump)

6

5

4

35

50

3

2

40

1

0

-20-10 0 10203040

Air inlet temperature in [°C]

Lufteintrittstemperatur in [°C]

Pressure loss in [Pa]

18000

16000

14000

12000

10000

8000

6000

4000

2000

Druckverlust in [Pa]

Condenser

Verflüssiger

0

0 0,5 1 1,5 2

00,511,52

Heizwasserdurchsatz in [m³/h]

Heating water flow rate in [m3/h]

16

Page 17

12.3.4 Cooling mode LA 8MR

Cooling capacity in [kW]

Kühlleistung in [kW]

18

APPENDIX: 12.3 SCHEMATICS

Wasseraustrittstemperatur in [°C]

Water outlet temperature in [°C]

16

Bedingungen:

Conditions:

Water flow rate 1.3 m3/h

14

Wasserdurchsatz 1,3 m³/h

12

10

8

6

18

8

4

2

0

10 15 20 25 30 35 40 45 50

Lufteintrittstemperatur in [°C]

Air inlet temperature in [°C]

Druckverlust in [Pa]

Power consumption (incl. power input to pump)

Leistungsaufnahme (incl. Pumpenleistungsanteil)

4

Pressure loss in [Pa]

18000

18

3

8

16000

2

1

0

10 15 20 25 30 35 40 45 50

Air inlet temperature in [°C]

Lufteintrittstemperatur in [°C]

Coefficient of performance (incl. power input to pump)

Leistungszahl (incl. Pumpenleistungsanteil)

7

6

5

4

3

2

18

8

1

0

10 15 20 25 30 35 40 45 50

Air inlet temperature in [°C]

Lufteintrittstemperatur in [°C]

Verflüssiger

14000

12000

10000

8000

6000

4000

2000

0

Condenser

0 0,5 1 1,5 2

00,511,52

Heizwasserdurchsatz in [m³/h]

Heating water flow rate in [m3/h]

17

Page 18

APPENDIX: 12.3 SCHEMATICS

12.3.5 Heating mode LA 10MR

Heating capacity in [kW]

Heizleistung in [kW]

16

Water outlet temperature in [°C]

Wasseraustrittstemperatur in [°C]

14

12

Bedingungen:

Conditions:

Heating water flow rate 1.5 m3/h

Heizwasserdurchsatz 1,5 m³/h

35

50

10

8

6

40

4

2

0

-20-100 10203040

Air inlet temperature in [°C]

Lufteintrittstemperatur in [°C]

Power consumption (incl. power input to pump)

Leistungsaufnahme (incl. Pumpenleistungsanteil)

4

3

40

50

18000

16000

Pressure loss in [Pa]

Druckverlust in [Pa]

35

2

14000

Condenser

Verflüssiger

1

0

-20-100 10203040

Air inlet temperature in [°C]

Lufteintrittstemperatur in [°C]

Leistungszahl (incl. Pumpenleistungsanteil)

Coefficient of performance (incl. power input to pump)

7

6

5

4

35

50

3

2

1

40

0

-20-10 0 10203040

Air inlet temperature in [°C]

Lufteintrittstemperatur in [°C]

12000

10000

8000

6000

4000

2000

0

0 0,5 1 1,5 2 2,5

0 0,5 1 1,5 2 2,5

Heizwasserdurchsatz in [m³/h]

Heating water flow rate in [m3/h]

18

Page 19

12.3.6 Cooling mode LA 10MR

Cooling capacity in [kW]

Kühlleistung in [kW]

22

20

Bedingungen:

18

16

14

12

Conditions:

Water flow rate 1.5 m3/h

Wasserdurchsatz 1,5 m³/h

APPENDIX: 12.3 SCHEMATICS

Water outlet temperature in [°C]

Wasseraustrittstemperatur in [°C]

10

8

18

8

6

4

2

0

10 15 20 25 30 35 40 45 50

Lufteintrittstemperatur in [°C]

Air inlet temperature in [°C]

Pressure loss in [Pa]

Power consumption (incl. power input to pump)

Leistungsaufnahme (incl. Pumpenleistungsanteil)

5

18000

Druckverlust in [Pa]

18

4

8

16000

3

Condenser

2

1

14000

12000

Verflüssiger

0

10 15 20 25 30 35 40 45 50

Lufteintrittstemperatur in [°C]

Air inlet temperature in [°C]

10000

Coefficient of performance (incl. power input to pump)

Leistungszahl (incl. Pumpenleistungsanteil)

7

6

5

4

3

2

18

8

1

0

10 15 20 25 30 35 40 45 50

Air inlet temperature in [°C]

Lufteintrittstemperatur in [°C]

19

8000

6000

4000

2000

0

0 0,5 1 1,5 2 2,5

0 0,5 1 1,5 2 2,5

Heizwasserdurchsatz in [m³/h]

Heating water flow rate in [m3/h]

Page 20

APPENDIX: 12.3 SCHEMATICS

12.3.7 Heating mode LA 12TR

Heating capacity in [kW]

Heizleistung in [kW]

22

20

Bedingungen:

18

16

14

12

10

8

Conditions:

Heizwasserdurchsatz 1,7 m³/h

Heating water flow rate 1.7 m3/h

Water outlet temperature in [°C]

Wasseraustrittstemperatur in [°C]

35

50

6

40

4

2

0

-20-10 0 10203040

Lufteintrittstemperatur in [°C]

Air inlet temperature in [°C]

Leistungsaufnahme (incl. Pumpenleistungsanteil)

Power consumption (incl. power input to pump)

5

4

40

50

35

18000

16000

Druckverlust in [Pa]

Pressure loss in [Pa]

3

Verflüssiger

2

1

14000

12000

Condenser

0

35

50

10000

8000

6000

4000

-20-10 0 10203040

Air inlet temperature in [°C]

Lufteintrittstemperatur in [°C]

Leistungszahl (incl. Pumpenleistungsanteil)

Coefficient of performance (incl. power input to pump)

6

5

4

3

2

1

40

2000

0

-20-10 0 10203040

Air inlet temperature in [°C]

Lufteintrittstemperatur in [°C]

0

0 0,5 1 1,5 2 2,5 3

00,511,522,53

Heizwasserdurchsatz in [m³/h]

Heating water flow rate in [m3/h]

20

Page 21

12.3.8 Cooling mode LA 12TR

Cooling capacity in [kW]

Kühlleistung in [kW]

30

Bedingungen:

25

20

Conditions:

Water flow rate 1.7 m

Wasserdurchsatz 1,7 m³/h

APPENDIX: 12.3 SCHEMATICS

Water outlet temperature in [°C]

Wasseraustrittstemperatur in [°C]

3

/h

15

10

18

8

5

0

10 15 20 25 30 35 40 45 50

Air inlet temperature in [°C]

Lufteintrittstemperatur in [°C]

Pressure loss in [Pa]

Leistungsaufnahme (incl. Pumpenleistungsanteil)

Power consumption (incl. power input to pump)

7

6

5

18

18000

8

16000

Druckverlust in [Pa]

4

Condenser

3

14000

Verflüssiger

2

1

12000

0

10 15 20 25 30 35 40 45 50

Lufteintrittstemperatur in [°C]

Air inlet temperature in [°C]

10000

Leistungszahl (incl. Pumpenleistungsanteil)

Coefficient of performance (incl. power input to pump)

7

6

5

4

3

2

18

8

1

0

10 15 20 25 30 35 40 45 50

Air inlet temperature in [°C]

Lufteintrittstemperatur in [°C]

21

8000

6000

4000

2000

0

0 0,5 1 1,5 2 2,5 3

00,511,522,53

Heizwasserdurchsatz in [m³/h]

Heating water flow rate in [m3/h]

Page 22

APPENDIX: 12.3 SCHEMATICS

12.3.9 Heating mode LA 16TR

Water outlet temperature in [°C]

Heating capacity in [kW]

Heizleistung in [kW]

28

26

24

22

Bedingungen:

Conditions:

Heizwasserdurchsatz 1,9 m³/h

Heating water flow rate 1.9 m3/h

20

18

16

14

12

10

8

40

6

4

2

0

-20-100 10203040

Wasseraustrittstemperatur in [°C]

35

50

Lufteintrittstemperatur in [°C]

Air inlet temperature in [°C]

Power consumption (incl. power input to pump)

Leistungsaufnahme (incl. Pumpenleistungsanteil)

7

6

5

40

50

35

4

3

2

1

0

-20-100 10203040

Lufteintrittstemperatur in [°C]

Air inlet temperature in [°C]

Coefficient of performance (incl. power input to pump)

Leistungszahl (incl. Pumpenleistungsanteil)

6

5

4

35

50

3

2

1

40

0

-20-10 0 10203040

Air inlet temperature in [°C]

Lufteintrittstemperatur in [°C]

Pressure loss in [Pa]

14000

12000

10000

8000

6000

4000

2000

Druckverlust in [Pa]

Condenser

Verflüssiger

0

0 0,5 1 1,5 2 2,5 3

00,511,522,53

Heizwasserdurchsatz in [m³/h]

Heating water flow rate in [m3/h]

22

Page 23

12.3.10 Cooling mode LA 16TR

Cooling capacity in [kW]

Kühlleistung in [kW]

35

APPENDIX: 12.3 SCHEMATICS

Water outlet temperature in [°C]

Wasseraustrittstemperatur in [°C]

30

Bedingungen:

Conditions:

Water flow rate 1.9 m3/h

Wasserdurchsatz 1,9 m³/h

25

20

18

15

8

10

5

0

10 15 20 25 30 35 40 45 50

Lufteintrittstemperatur in [°C]

Air inlet temperature in [°C]

Pressure loss in [Pa]

Power consumption (incl. power input to pump)

Leistungsaufnahme (incl. Pumpenleistungsanteil)

8

7

6

5

4

18

14000

8

12000

Druckverlust in [Pa]

Condenser

Verflüssiger

3

2

10000

1

0

10 15 20 25 30 35 40 45 50

Lufteintrittstemperatur in [°C]

Air inlet temperature in [°C]

8000

Coefficient of performance (incl. power input to pump)

Leistungszahl (incl. Pumpenleistungsanteil)

8

7

6

5

4

3

2

18

8

1

0

10 15 20 25 30 35 40 45 50

Lufteintrittstemperatur in [°C]

Air inlet temperature in [°C]

23

6000

4000

2000

0

0 0,5 1 1,5 2 2,5 3

00,511,522,53

Heizwasserdurchsatz in [m³/h]

Heating water flow rate in [m3/h]

Page 24

APPENDIX: 12.4 WIRING DIAGRAMS

12.4.1 Control LA 6MR-LA 10MR

Coding

Call

Heating/cooling

Fan

Copressor

Supply sensor

External sensor

Attention! Low voltage

Reversing valve

Back-up heater

FSK sensor

Setpoint

Setpoint

On/Off

Cooling

Heating circulating pump

ON/OFF

24

Page 25

12.4.2 Load LA 6MR-LA 10MR

APPENDIX: 12.4 WIRING DIAGRAMS

Jumper 4kW

Jumper 6kW

Back-up heater

Mains supply

Mains supply

25

Page 26

APPENDIX: 12.4 WIRING DIAGRAMS

12.4.3 Terminal Diagram LA 6MR-LA 10MR

Switch box LA 6-10

Jumper 4kW

Jumper 6kW

ye/gn

ye/gn

Connecting lead

Connecting lead

Mains supply

Mains supply for back-up heater

26

Page 27

APPENDIX: 12.4 WIRING DIAGRAMS

12.4.4 Legend LA 06MR-LA10MR

A1 Wire jumper: The jumper must be removed for external control (via potential-free contact)

or when a dew point monitor (via potential-free contact) is used.

B3* Thermostat, hot water

B5 Control thermostat, back-up heater

C1 Operating capacitor, compressor

C3 Operating capacitor, fan

E3 Pressostat, defrost end

E4 Nozzle ring heater

E10 Back-up heater

F1 Control fuse

F4 Pressostat, high pressure

F5 Pressostat, low pressure

F17 Safety temperature limiter, back-up heater

H1** LED, ready for operation

K2 Contactor, fan

K20 Contactor, back-up heater

K24 Relay, call for hot water

M1 Compressor

M2 Fan

M13 Heating circulating pump

N5* Dew point monitor

N7 Soft starter

N10 Remote control

N12 Control board

N13* Switch group, hot water

R1 External sensor

R2 Return sensor

R7 Coding resistor

R10* Moisture sensor

R12 Frost protection sensor, cooling mode (water)

R14** Setpoint potentiometer

R15 Flow sensor

S1** Control switch HP ON/OFF

S2** Change-over switch HEATING/COOLING

X1 Terminal strip, mains L/N/PE - 230 V AC / 50 Hz

X2 Terminal strip, external components

X3 Terminal strip, back-up heater

X4 Terminal strip, compressor

X5 Terminal strip, internal wiring

Y1 4-way reversing valve heating/cooling

Y5* 3-way reversing valve for domestic hot water preparation

* Parts to be provided by the client

** Parts are integrated into the remote control

27

Page 28

APPENDIX: 12.4 WIRING DIAGRAMS

12.4.5 Control LA 12TR-LA 16TR

Setpoint

Cooling

Coding

Call

Heating/cooling

Fan

Copressor

Supply sensor

External sensor

Attention! Low voltage

Reversing valve

Back-up heater

Heating circulating pump

FSK sensor

Setpoint

28

Page 29

12.4.6 Load LA 12TR-LA 16TR

APPENDIX: 12.4 WIRING DIAGRAMS

Mains supply - load

29

Page 30

APPENDIX: 12.4 WIRING DIAGRAMS

12.4.7 Terminal Diagram LA 12TR-LA 16TR

Switch box LA 12-16

ye/gn

Connecting lead

Mains supply

30

Page 31

APPENDIX: 12.4 WIRING DIAGRAMS

12.4.8 Legend LA 12TR-LA 16TR

A1 Wire jumper: For external control (via potential-free contact)

or use of a dew point monitor (via potential-free contact)

the jumper must be removed.

B3* Hot water thermostat

B5 Control thermostat, back-up heater

E3 Pressostat defrost end

E4 Nozzle ring heater

E10 Back-up heater

F1 Control-circuit fuse

F4 Pressostat, high pressure

F5 Pressostat, low pressure

F17 Safety temperatur limiter, back-up heater

F23 Bimetal contact, fan

H1** LED, ready for operation

K1 Contactor, compressor

K2 Contactor, fan

K20 Contactor, back-up heater

K24 Relay, call for domestic hot water

M1 Compressor

M2 Fan

M13 Heating circulating pump

N5* Dew point monitor

N7 Soft starter

N10 Remote control

N12 Control board

N13* Schaltgruppe, hot water

R1 External sensor

R2 Return sensor

R7 Coding resistor

R10* Moisture sensor

R12 Frost protection sensor, cooling mode (water)

R14** Setpoint potentiometer

R15 Flow sensor

S1** Control switch HP ON/OFF

S2** Change-over switch HEATING/COOLING

X1 Terminal strip, mains L/N/PE - 230 V AC / 50 Hz

X2 Terminal strip, external components

X5 Terminal strip, internal wiring

Y1 4-way reversing valve heating/cooling

Y5* 3-way reversing valve for domestic hot water preparation

* Parts to be provided by the client

** Parts are integrated into the remote control

31

Page 32

APPENDIX: 12.5 HYDRAULIC BLOCK DIAGRAMS

12.5.1 Mono-energetic system

Temperature sensor

Flexible connecting hose

Electric distribution

Electric heating element

Heating system circulating pump

Remote control

External sensor

Return sensor

Supply sensor

Air-to-water heat pump

Buffer tank

Overflow valve

Safety assembly

Circulating pump

Expansion vessel

Thermostat/manual valve

Shut-off valve with drain

Heat consumers

32

Page 33

APPENDIX: 12.5 HYDRAULIC BLOCK DIAGRAMS

12.5.2 Mono-energetic systems and domestic hot water function

Temperature sensor

Flexible connecting hose

Electric distribution

Cold water

Hot water

Electric heating element

Hot water thermostat

Heating system circulating pump

Remote control

Switch group, hot water

External sensor

Return sensor

Supply sensor

Three-way valve

Branching box

Overflow valve

Safety assembly

Circulating pump

Expansion vessel

Thermostat/manual valve

Three-way valve

Shut-off valve with drain

Heat consumers

Air-to-water heat pump

Buffer tank

Hot water tank

33

Page 34

APPENDIX: 12.6 EC DECLARATION OF CONFORMITY

EC Declaration of Conformity

Declaration of Conformity

The undersigned

Glen Dimplex Deutschland GmbH

Division Dimplex

Am Goldenen Feld 18

D-95326 Kulmbach

hereby confirm that the design and construction of the product(s) listed below, in the version(s) placed

on the market by us, conform to the relevant requirements of the applicable EC directives.

This declaration becomes invalidated if any modifications are made to the product(s) without our

prior authorization.

Designation of the product(s): EC Directives:

Air-to-water heat pumps EC Directive for Low Voltage

for outdoor installation (73/23/EEC)

containing R407C EC Directive for Electromagnetic Compatibility (EMC)

(89/336/EEC)

Pressure Equipment Directive

(97/23/EEC)

Type(s): Harmonized EN Standards:

LA 6MR

LA 8MR

LA 10MR

LA 12TR

LA 16TR

Requirements of category II

Order No.: National Standard/Directives:

350 790

350 800

350 810

350 820

350 830

Kulmbach, 01.06.2005

General Manager Technical Director

34

Page 35

Notes

35

Page 36

Glen Dimplex Deutschland GmbH Subject to technical modifications

Division Dimplex Telefax (0 92 21) 709-589

Am Goldenen Feld 18 www.dimplex.de

D-95326 Kulmbach

Loading...

Loading...