Page 1

Installation and Operating Manual

Heat Pump for Cooling of Domestic Water

with Airduct Connection

KWP 300

451902.67.39 FD8411

Page 2

2

TABLE OF CONTENTS

Page

1. Regulations / Safety Notices 3

2. Description 4

2.1 Refrigeration Cycle 4

2.2 Water Circuit 4

2.3 Safety and Control Devices 5

3. Storage / Transport 6

3.1 General Requirements 6

4. Installation 6

4.1 Installation Site 6

4.2 Installation 7

5. Mounting 7

5.1 Connection of Water Piping 7

5.2 Electrical Connection 8

6. Commissioning 8

6.1 Domestic Water Circuit 8

6.2 Operation of the Heat Pump for Cooling of Domestic Water 9

7. Maintenance / Service 10

7.1 Water Circuit 10

7.2 Air Circuit 10

7.3 Sacrificial Anode 11

8. Malfunctions / Troubleshooting 12

9. Decommissioning 12

10. Environmental Requirements 12

11. APPENDIX

11.1 Refrigeration Cycle with Legend 13

11.2 Hydraulic Plumbing Diagram 14

11.3 Circuit Diagram 15

11.4 Technical Data 16

(

HPCDW = abbreviation used in the following for Heat Pump for Cooling of Domestic Water

)

Page 3

3

1. Regulations / Safety Notices

(

This installation and operating manual must be read prior to starting up the unit !

)

¾¾¾¾####

The heat pump for cooling of domestic water (short: HPCDW) is designed exclusively for the cooling (in part

also for the heating) of domestic or potable water within the specified operating temperature limits! The cooling

(or heating) of liquids other than drinking water is not permissible. The technical regulations for the drinking

water installation (DIN 1988) must be adhered to.

¾¾¾¾####

The air supplied to the unit should not exceed a temperature of +45 °C. The energy-efficient operation of the

heat pump decreases as the air temperature increases.

¾¾¾¾####

The following is not permitted:

- operation using exhaust air posing an explosion hazard or containing solvents

- use of exhaust waste air laden with grease, dust or sticking aerosols

- connection of exhauster hoods to the ventilation system

¾¾¾¾####

The unit must not be installed:

- outdoors

- in rooms with a danger of freezing

- in wet rooms (e.g. bathrooms)

- in room with an explosion hazard due to gases, vapours or dust

¾¾¾¾####

The operation of the unit is not permitted:

- with empty storage tank

- during the construction phase

¾¾¾¾

In the design and construction of the HPCDW all relevant EC directives were complied with. (See also EC

Declaration of Conformity.)

¾¾¾¾

The qualified expert must ensure that prior to the commencement of any maintenance/repair activities on

refrigerant-carrying parts, the refrigerant has been removed to such an extent as necessary for the safe

performance of this work. The refrigerant must be handled and disposed of in accordance with applicable

regulations and must not be released into the atmosphere! (Refrigerant R134a is CFC-free, non-flammable

and has no ozone-depleting properties.)

¾¾¾¾####

When working on the HPCDW, the unit must always be disconnected from the power source.

¾¾¾¾####

The electrical connection of the HPCDW must be performed according to and conforming with all relevant

VDE, EN and IEC standards. Beyond that, the technical connection requirements of the local utility company

have to be observed.

Caution!

Any work on the cooling/domestic water heat pump may only be performed by qualified persons! All

relevant accident prevention regulations have to be observed !

Page 4

4

2. Description

The

HPCDW

is a domestic water cooling unit ready for connection and essentially consists of a domestic water

tank, the components of the refrigeration, air and water circuits as well as all control, regulating and monitoring

devices required for automatic operation.

In accordance with the heat pump's principle of operation, unwanted heat is extracted from the domestic water and

then transferred to the discharged outlet air.

The unit is equipped as standard with an electric immersion heater (1.5 kW) which enables domestic water to be

heated (up to a temperature of max. 85 °C) (heating function).

2.1 Refrigeration Cycle

(Heat Pump Principle of Function)

The refrigeration cycle is a closed system in which the refrigerant R134a circulates as an energy carrier. In a

tubular evaporator wrapped around the domestic water tank, heat is extracted from the domestic water at a low

evaporation temperature and transferred to the refrigerant. The vaporous refrigerant is drawn in by an electrically

driven compressor and compressed to a higher pressure/temperature level and then passed to the condenser (fintype heat exchanger), where the heat that is absorbed in the tubular evaporator and part of the heat of the

compressor motor is transferred to the drawn-in exhaust air. Subsequently, the high condensing pressure is

reduced by means of a throttling device (expansion valve) to the level of the evaporating pressure, and the

refrigerant can again absorb heat from the domestic water tank via the tubular evaporator.

2.2 Water Circuit

The water circuits of the

HPCDW

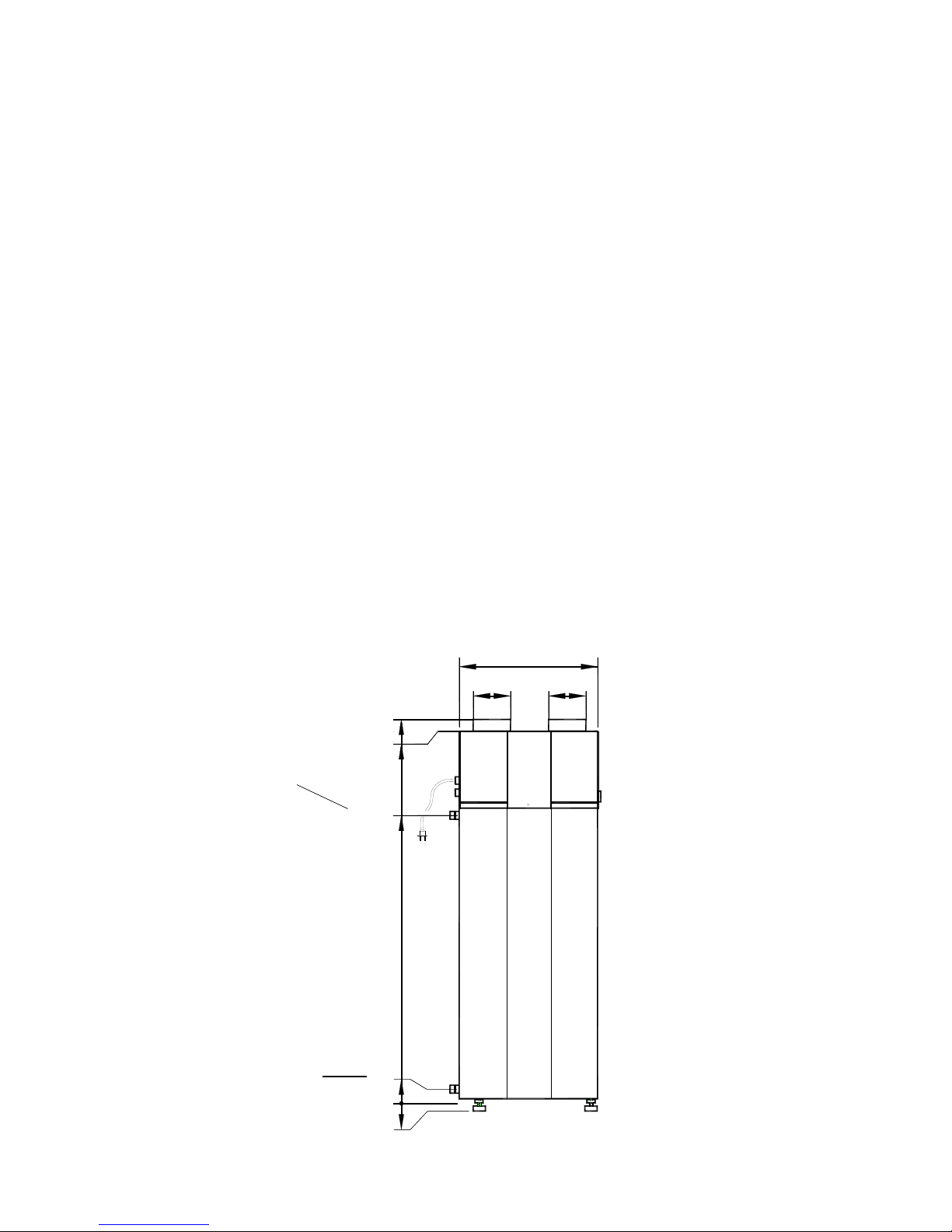

are to be field-installed (by the customer). The water connections (Fig. 1) are

located at the rear of the unit.

Fig. 1: Water connections

Brauchwasserzulauf

R1" Außengewinde

Brauchwasserentnahme

R1" Außengewinde

20 - 35

0

1226

55

1620

1660

Ø

160

Ø

160

660

Domestic water supply

external thread R1“

Domestic water outlet tap

external thread R1“

Page 5

5

2.3 Safety and Control Devices

The HPCDW is equipped with the following safety features:

2.3.1 High-pressure pressostat (HD)

The high-pressure pressostat protects the heat pump from excessive operating pressures in the refrigeration cycle.

In the case of a malfunction, the pressostat switches off the heat pump; the heat pump is restarted automatically as

soon as the pressure in the refrigeration cycle has dropped to an acceptable level.

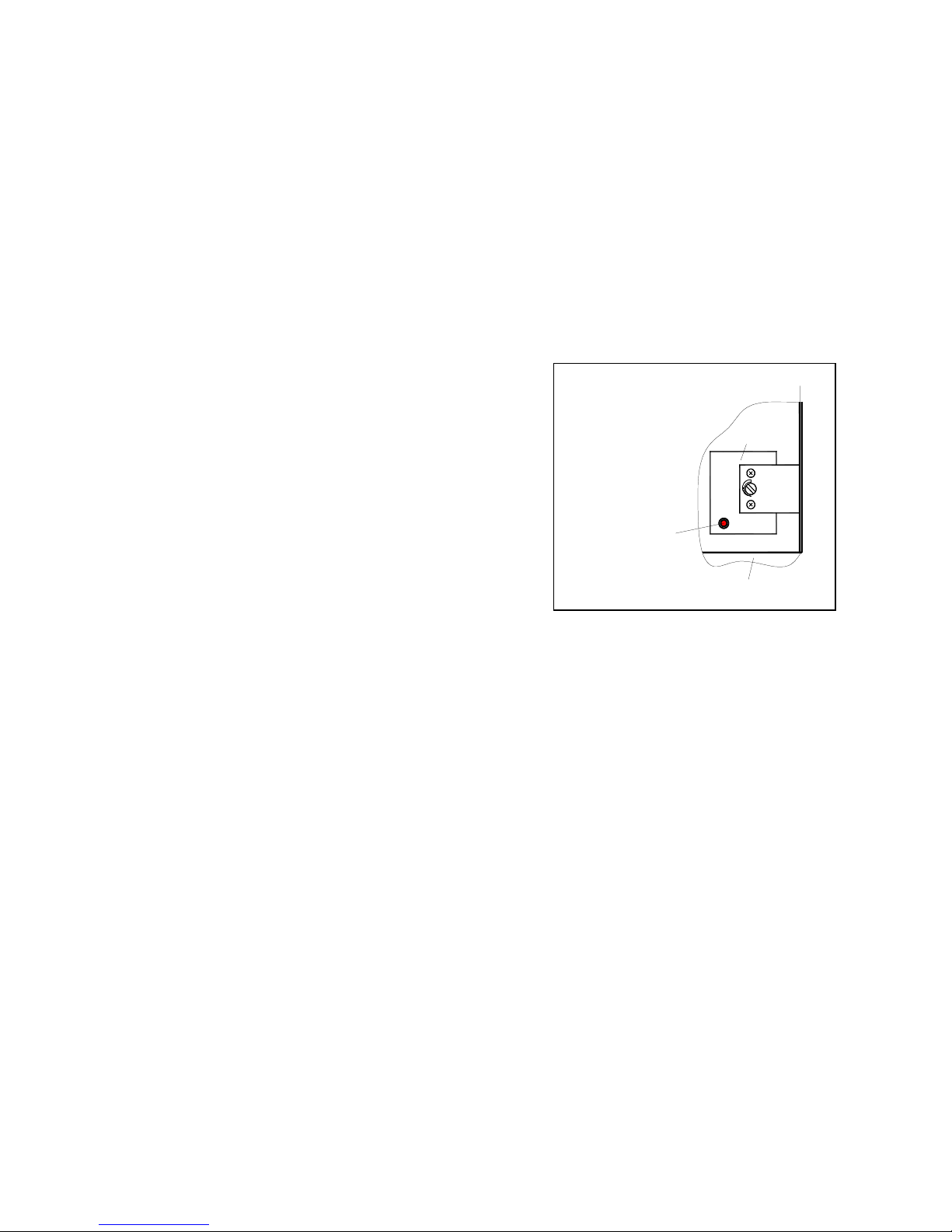

2.3.2 Safety temperature limiter for immersion heater (STL)

The STB protects the hot water installation from

excessive temperature increases.

When the preset switching value (99 °C) is exceeded, the

immersion heater is switched off.

The immersion heater cannot be restarted unless the hot

water temperature has fallen to ≤ 90 °C and the reset

button (Fig. 2) on the STB has subsequently been

pressed (may be performed by qualified personnel only!).

Fig 2: Resetting STL

2.3.3 Temperature controller for immersion heater (TC)

The temperature controller for the immersion heater controls the temperature of the water for domestic use during

the immersion heater mode of operation. The maximum temperature of this controller has been factory-set to 65 °C

(the controller is installed with the STL in a common casing). The temperature setting can be changed with the aid

of a suitable tool (see Fig. 2). Changing this setting may be performed by qualified persons only!

In the immersion heater mode, which can only be turned on manually, the domestic water is heated up to the

preset maximum temperature of the immersion heater.

2.3.4 Temperature controller of HPCDW

Temperature control in the domestic water storage tank and the control of the compressor operation is taken over

by the temperature controller. The latter senses the water temperature by means of a sensor and regulates it as a

function of the preset setpoint. The desired temperature level (setpoint) can be adjusted via the dial on the

operating panel.

85°

30°

B3

F2

STB

Partition

Panel

Reset button

Page 6

6

3. Storage and Transport

3.1 General Requirements

As a rule, the CWP is to be stored or transported in its shipping box in upright position and

without water charge

.

For a transport over short distances, and provided due care is exercised, an inclination angle of up to 45° is

permitted. Both during transport and storage, ambient temperatures of -20 to +60 °C are permissible.

3.1.1 Transport using a forklift

(or lift truck)

When transported by a fork lift, the HPCDW must remain mounted on the pallet. The lifting rate should be kept to a

minimum. Due to its top-heaviness, the HPCDW must be secured against tipping over. To prevent any damage, be

sure to place the HPCDW on a level floor.

3.1.2 Manual transport

For the manual transport, the wooden pallet can be used for the bottom part. Using ropes or carrying straps (which

can be placed around the jacket of the storage tank and secured to the water tube nipples), a second or third

handling configuration is possible. With this type of handling (applies to the transport by hand truck as well), care

must be taken that the

max. permissible inclination angle of 45°

is not exceeded (see Figure). If transport in an

inclined position cannot be avoided, the HPCDW ("heat pump" switch) should be taken into operation one hour

after it has been moved into final position at the earliest.

Caution! Do not lift the unit by its cover

(the cover is not designed to withstand the weight of the unit !)

4. Installation

4.1 Installation Site

CAUTION!

¾#

The HPCDW must be sited in a

dry and freeze-proof room

, the room air temperature and/or the air taken in

by the HPCDW must be within a temperature range of 20°C to 45 °C (required for heat pump operation).

¾#

In addition, the unit

must not

be installed in rooms where there is an explosion hazard due to gases, vapours

or dust.

¾#

The air drawn in must be not excessively contaminated or heavily laden with dust.

¾#

The floor surface must have adequate load bearing capability (the estimated HPCDW weight is 400 kg when

fully loaded!).

For trouble-free operation as well as for the performance of maintenance and repair work, provide clearance of at

least 0.6 m all around the unit, furthermore, a minimum ceiling height of approx.

2.50 m

is required

for operation

without airducts or airduct elbows

(➠"free-blowing“ installation“) (see Fig. 4). The connection to the HPCDW is

effected (optionally) by means of airducts (NW 160) which must not exceed a

total

length of 10 m.

Fig. 3: Transport of the unit

°

Page 7

7

If the ceiling is lower and no airducts are used, an air ducting elbow (90° NW 160) must be used on the

outlet air side (to ensure effective operation). When an air ducting elbow is used, care must be taken that it is

slipped onto the flange collar of the discharge side in such a way that the discharge opening of the air ducting

elbow is as far away from the intake opening of the unit as possible. Moreover, the minimum clearances shown in

Figure 4 have to be complied with. The air connection fittings, i.e. "intake pipe" and "discharge pipe", of the

HPCDW

are identified by adhesive labels.

Fig. 4: Installation requirements

4.2 Installation

¾

From the underside of the pallet, remove the three M12 bolts securing the pallet to the unit as a shipping safety

measure.

¾

Remove the pallet and mount the three levelling feet (M12 bolts – contained in the polybag, secured to the

storage tank pipe nipple).

¾

Move the HPCDW into final position and adjust the unit so that it is perfectly perpendicular by adjusting the

levelling feet! Subsequently, tighten the check nuts provided on the levelling feet.

5. Mounting

5.1 Connection of Water Piping

The nominal pipe widths of the field-installed sanitary installations must be determined on the basis of the available

water pressure and the expected pressure losses within the piping system.

The water-side

installation

has to be executed in compliance with DIN 1988 (see appendix – in the case of

excessive water pipe pressure, a pressure relief valve is to be provided, among other things !)

The water pipes may be of the rigid or flexible type. To prevent corrosion damage, make sure that the materials

used in the piping system are compatible (see section Commissioning).

Caution! When installing the pipework on the customer's site, any contamination of the piping system

must be avoided (pipes may have to be flushed prior to the connection of the HPCDW)!

* the minimum distance of

the discharge opening of

the air ducting elbow

to the wall is 1.2 m

The minimum ceiling

height for "free blowing

installation" is approx.

angesaugte Luft

ausgeblasene

Luft

1,2 * m

0,6 m

ca. 2,0 m

ca. 2,5 m

(ohne Luftschläuche und Luftführungsbogen)

discharged

drawn-in air

approx. 2.0 m

approx. 2.5 m (without airducts and air ducting elbow)

Page 8

8

5.2 Electrical Connection

The HPCDW is pre-wired, ready for connection, the power is supplied via the mains cable connected to a socket

with earthing contact (GB: "Home Office socket") (~230 V, 50 or 60 Hz). This socket must be accessible also after

the installation has been completed.

6. Commissioning

6.1 Domestic Water Circuit

➨➨➨➨

Caution!

The HPCDW may only be operated with the unit filled with water!

6.1.1 Water circuit requirements

On the consumer side, the following materials may be incorporated into the water circuit:

Â

copper  stainless steel  brass  plastic

Depending on the materials used in the hot water circuit (installation to be provided by the customer), corrosion

damage may occur due to material incompatibilities. This must be taken into account, in particular where

galvanised materials and those containing aluminium are used. A filter may have to be provided if there is a danger

of the water being contaminated during operation.

6.1.2 Commissioning of the domestic water system

•

All installations at the water and air circuits as well as all electrical installations must have been properly

executed and completed.

•

Fill

water circuit via external connection. The domestic water tank must be filled

from below

, i.e. via the

domestic water outlet tap (see Fig. 1 and hydraulic plumbing diagram in the appendix) ! (during operation, the

top-up water enters the domestic water tank from the top).

•

Bleed

the domestic water circuit (open water taps at the topmost points of use until no more air escapes, or

open air bleed cocks in the water circuit – to be provided by the customer).

•

Perform a

leak test

of the entire domestic water circuit.

•

Connect the unit to the

power supply

.

•

Turn on

the "heat pump" switch (Fig. 5).

•

The desired

domestic water temperature

is continuously adjustable (16° - 25 °C) by means of a temperature

selector dial (Fig. 5). An appropriate time period (cooling period) must be allowed for until the selected

temperature level is reached.

Page 9

9

6.2 Operation of the HPCDW

6.2.1 Operating panel

Temperature display

The sensor of the thermostat (analog remote thermometer with trend display) senses the domestic water

temperature at the middle part of the water tank. The display is located on the operating panel.

Fig. 5: Operating panel

Switch position

O

Æ

heat pump is

OFF

, in switch position

the heat pump is in operation.

"Heat pump" switch

Temperature dial for domestic water (setpoint transmitter) left stop Æ lowest cooling temperature (16°C)

right stop Æ low cooling temperature (25°C)

"Domestic water temperature" dial

Temperature display

In the I switch position, the immersion

heater is switched ON, in switch pos.

the immersion heater is switched

OFF

"Immersion heater" switch

Temperature

display

35 °C 70 °C

blue

red

20°C

Page 10

10

6.2.2 Domestic water temperature controller

(dial)

The desired domestic water temperature level can be adjusted using the selector dial (an adjustment accurate to

within one degree is not possible).

6.2.3 'Heat pump' switch

If the 'heat pump' switch is placed in position “

“ (On), the heat pump is ready for operation. When the domestic

water temperature inside the tank rises above the preset setpoint, the heat pump cooling function is activated until

the desired domestic water temperature is reached.

Note

➪➪➪➪

If the 'heat pump' switch is placed in position

“

“

(heat pump mode), it is not possible to activate the immersion

heater (selecting the 'immersion heater' switch position will have no effect).

6.2.4 'Immersion heater' switch

The integrated 1.5 kW heating element can be activated by means of the 'immersion heater' switch when there is a

demand for hot water or a preset hot water temperature level is to be reached.

When the 'immersion heater' switch is in position

" I "

, the tank content is heated up to the maximum temperature

of the immersion heater controller

(factory setting 65 °C). In switch position

‘‘ ‘‘ the immersion heater is switched off.

Note

➪➪➪➪

If the 'immersion heater' switch is in position

" I "

(heating mode), the heat pump cooling function is deactivated

until the 'heat pump' switch is placed in position “

“

“.

Note

➪➪➪➪

Immersion heater controller

The factory-set switch-off temperature of 65 °C can be changed by a qualified expert (see item 2.3)

7. Maintenance / Service

CAUTION!

Prior to opening the HPCDW, the unit must be disconnected from the power supply; be careful of fan that

may still be rotating !

General

¾¾¾¾####

The heat pump for cooling of domestic water is nearly maintenance-free. A few days following the

commissioning procedure, a visual check for possible leaks in the water system is to be performed once.

¾¾¾¾####

No maintenance activities need to be performed on the refrigeration cycle of the heat pump.

¾¾¾¾####

For cleaning the HPCDW, simply use a damp cloth and some soapy water.

Caution!

Do not allow water to

come in contact with the operating controls. Prior to commencing the cleaning procedure, withdraw the mains

plug or disconnect the unit from the power supply.

Page 11

11

7.1 Water Circuit

The inspection of the water circuit is limited to any filters that may have been field-installed, and the performance of

leak tests. Dirty water filters have to be cleaned and replaced, if necessary.

7.2 Air Circuit

The maintenance activities are limited to cleaning the fin-type heat exchanger (only) as required.

Caution!

Hazard of injury from sharp-edged fins. Fins must not be distorted or damaged !

If air filters are used, these must be regularly checked for contamination and to be cleaned or replaced, if

necessary.

7.3 Sacrificial Anode

The sacrificial anode installed in the domestic water tank for corrosion protection purposes, must be checked

electrically

on a regular basis, at least every two years

after commissioning, and be replaced, if necessary. The

electrical check is to be conducted by means of a suitable ammeter

without

draining the water in the tank.

Procedure:

n Withdraw PE wire from tab of sacrificial anode.

o Connect ammeter (0...50 mA) between PE conductor and tab.

p Evaluation of wear of sacrificial anode:

Measured value > 1 mA ➪ sacrificial anode is okay.

Measured value < 1 mA ➪ sacrificial anode must be checked or replaced.

If an unambiguous electrical check is not possible, it is recommended that a visual inspection by an expert be

performed.

(For a replacement of the sacrificial anode that may be necessary [to be performed by an expert], the water must

be drained from the tank via the drain valve (to be provided upon installation – see appendix).

Caution

: Protective anodes that are impaired in their function will reduce the life of the unit!

The sacrificial anode is screwed into the storage tank below

the immersion heater

(covered with a plastic cap)

Fig. 6:

sacrificial anode

Page 12

12

8. Malfunctions / Troubleshooting

( only for the user )

Heat pump fails to run !

Please check whether

ÖÖÖÖ

the plug is plugged in

ÖÖÖÖ

the control switch is in the OFF position

ÖÖÖÖ

voltage is present at the socket

ÖÖÖÖ

the heat pump has been switched off by the temperature controller

ÖÖÖÖ

the domestic water temperature has already reached (or is less than) 18°C

Heat pump switches off prematurely

(setpoint temperature has not been reached yet)

Please check whether

ÖÖÖÖ

airducts are kinked or their openings are closed, or

air filters that may be provided are severely contaminated (clogged)

ÖÖÖÖ

the temperature of the intake air lies above the permissible limit value (45°C)

If the malfunction cannot be corrected based on the above questions, please consult your installer or

customer service.

9. Decommissioning

Activities to be performed:

• Disconnect

HPCDW

from the power source.

• Completely shut off water circuit (supply and drain sides) and drain hot water storage tank.

10. Environmental Requirements

Environment-relevant requirements regarding the recovery, reuse and disposal of service fuels and components in

accordance with DIN EN 378 must be adhered to when repairing or decommissioning the

HPCDW

.

Caution!

Arbeiten an der Kühl-Brauchwasser Wärmepumpe dürfen nur von sachkundigen Personen ausgeführt

werden! Unfallverhütungsvorschriften sind zu beachten!

Page 13

13

11.1 Refrigeration Cycle with Legend

1 Compressor 8 Safety temperature limiter 15 Non-return valve

2 Pressostat HP 9 Temp. controller immers. heater 16 Insulation

3 Evaporator 10 Temperature display

4 Hot water tank 11 Filter drier

5 Immersion heater 12 Expansion valve

6 Corrosion protection anode 13 Condenser

7 Temperature controller HP 14 Fan

freie Tauchhülse

7

TI

-CO - L

-C I - H

3

15

8

9

10

-CO-H

-C I -L

TI

TI-CO-H

6

5

TI

4

PA-CO-H

14

2

1

11

TC

12

13

16

free immersion sleeve

Page 14

14

11.2 Hydraulic Plumbing Diagram

1 Shut-off valve 6 Draining and filling valve

2 Pressure reducing valve 7 Diaphragm safety valve

3 Test valve (

to be mounted above tank edge

)

4 Check valve 8 Drain

5 Manometer connection

Wasseranschluß nach DIN 1988

6

8

5

1

3

4

2

1

Wasserzulauf

7

8

1

Brauchwasserentnahme

Befüllung

water supply

water connection acc. to DIN 1988

domestic water outlet tap

filling

Page 15

11.3

Circuit Diagram

X3-1

1

A

K3

A1

A2

C

M1

M

grün/gelb

L

N

(bl)

14

PE

schwarz

P

F3

C1

(bn)

K2

10

M

X3-2

1

C2

X3-3

M2

L/N/PE 230VAC 50Hz

X1

1

P >F1

2

21bar

X3

L

PE

N

K3

11

14

1

Wärmepumpe

22

21

E1

B3/

F2

11

+65°C

TR

STB

+99°C

T >

(+30 - +85°C )

12

1

2

S2

Elektro - Heizstab

Betriebsthermostat WP

Regelthermostat-El.Heizung

Anlaufkondensator-Verdichter

Betriebskondensator-Ventilator

El.Heizstab

HD-Pressostat

Sicherheitsbegrenzer-Thermostat

El.Heizung

Klixon-Verdichter

Anlaufrelais-Verdichter

Sch altrelais HD-Pr e s s ostat

Verdichter

Ventilator

Schalter "EIN/AUS" Wärmepumpe

Schalter "EIN/AUS" El.Heizung

Netzstecker

Klemmleiste intern

B1

B3

C1

C2

E1

F1

F2

F3

K2

K3

M1

M2

S1

S2

X1

X3

Legende

2

S1

1

T >

B1

4

+18..+26°C

Verdichter

Ventilator

K3

31

32

2

B1 Operating thermostat, heat pump

B3 Regulating thermostat, el. heating

C1 Starting capacitor, compressor

C2 Operating capacitor, fan

E1 El. immersion heater

F1 HP pressostat

F2 Safety limiter thermostat, el. heating

F3 Klixon, compressor

K2 Starting relay, compressor

K3 All-or-nothing relay, HP pressostat

M1 Compressor

M2 Fan

S1 "ON/OFF" switch, heat pump

S2 "ON/Off" switch, el. heating

X1 Mains plug

X3 Terminal strip, internal

Fan

Compressor

Heat pump

el. Immersion heater

black

g

reen/yello

Page 16

11.4 Technical Data

Heat pump for cooling of domestic water KWP 300

Type

compact unit

Nominal tank capacity ( litres) 300

Tank material enamelled steel acc. to

DIN 4753

Nominal tank pressure ( bar ) 10

Dimensions

( height x width x depth [without tube connections] )

( cm ) 169 x 66 x 66

Weight ( kg ) approx. 110

Electrical connection ( plug-in device – cable length approx.

2.7 m )

230V ~ 50 or 60 Hz

Fusing ( A ) 16

Refrigerant R 134a, charge weight ( kg ) 1.0

Performance data

Temperature, operating range (air) ( °C) 20 to 45

Water temperature, selectable (heat pump mode) ( °C ) 16 to 25

Heat-up time from 25° C to 65 °C (electr. immersion heater) ( h ) 9.2

Power consumption, electric heating ( watt ) 1500

Average power consumption 1) at 45 °C (at 60 Hz) ( watt ) 850

Average cooling capacity 1) at 45 °C (at 60 Hz) ( watt ) 1450

Cooling-down time from 45°C to 20°C 1) ( h ) 6.5

Air flow rate: ( m3 / h ) 585

External pressure ( Pa ) 110

Maximum airduct connection length

(total)

( m ) 10

Airduct connection, diameter ( mm ) 160

Connection domestic water outlet external thread R1“

Connection domestic water supply external thread R1“

1)

The cooling process of the nominal tank content from 45°C to 20°C at an air intake temperature of 35 °C

Page 17

17

KKW Kulmbacher Klimageräte-Werk GmbH Subject to technical changes

Department Dimplex Fax (0 92 21) 709-589

Am Goldenen Feld 18 www.dimplex.de

D-95326 Kulmbach

Loading...

Loading...