Dimplex KSS 2508 AIV, KSS 4508 AIV, KSS 3508 AIV Installation And Operating Instructions Manual

Page 1

1

Installation and Operating Instructions

Split Air Conditioner for Wall Mounting

KSS 2508 AIV

KSS 3508 AIV

KSS 4508 AIV

Technical data.............................................................................................................................2

Energy efficiency.........................................................................................................................3

Checklist......................................................................................................................................4

Refrigeration plan........................................................................................................................4

Safety regulations ........................................................................................................................ 5

Device construction.....................................................................................................................6

Installation instructions................................................................................................................7

Scope of supply...........................................................................................................................7

Minimum clearances....................................................................................................................8

Assembling the indoor unit..........................................................................................................9

Assembling the outdoor unit......................................................................................................10

Refrigerant pipes.......................................................................................................................11

Connecting the refrigerant pipes on the outdoor unit.................................................................12

Electrical Connection................................................................................................................. 13

Start-up......................................................................................................................................13

Important notes on operation.....................................................................................................14

Circuit diagram...........................................................................................................................15

Operation...................................................................................................................................18

Cleaning and maintenance........................................................................................................21

Faults......................................................................................................................................... 22

Warranty, after-sales service..................................................................................................... 23

Page 2

2

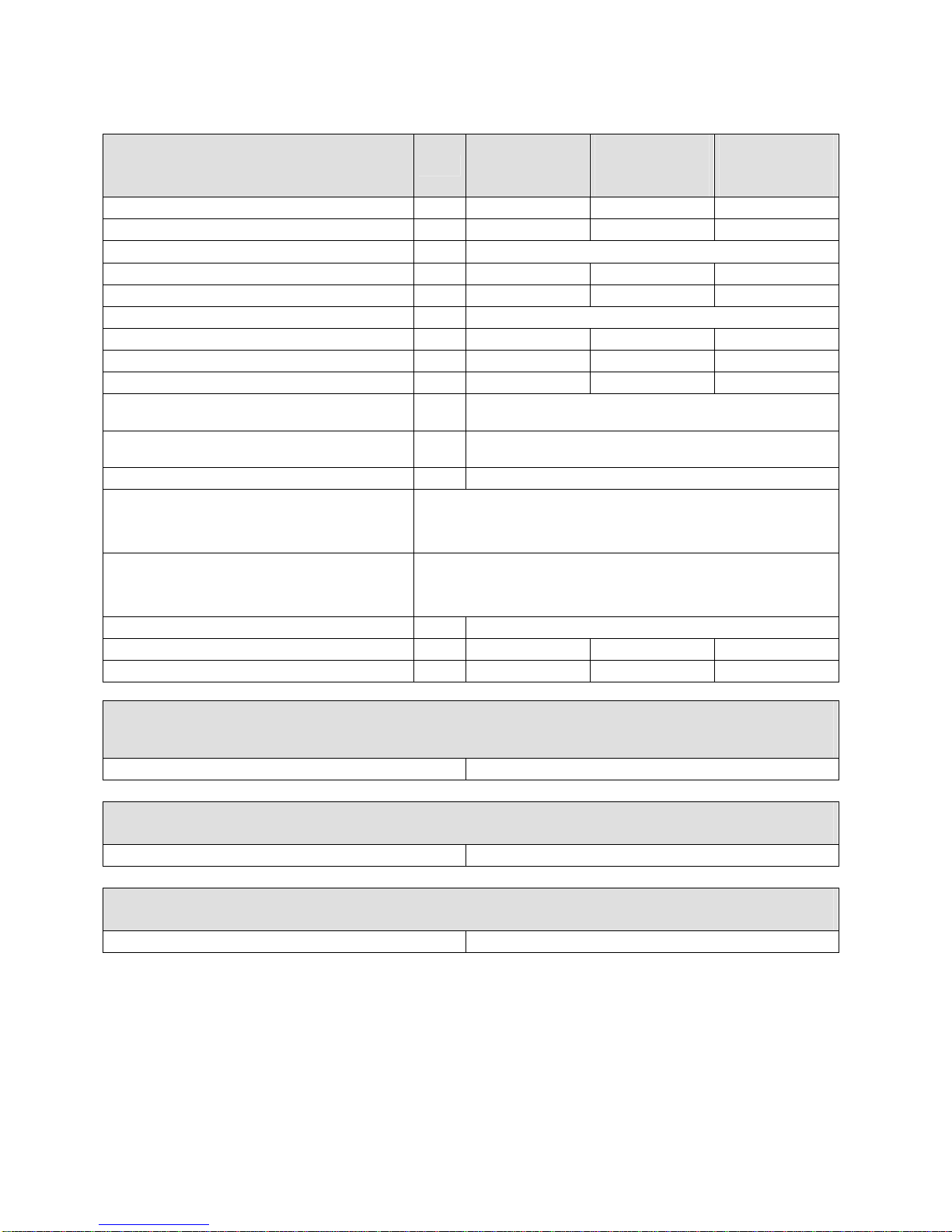

Technical data

Split room conditioners

Indoor unit

Outdoor unit

KSS 2508 AIV

KSS 2508 AIV I

KSS 2508 AIV A

KSS 3508 AIV

KSS 3508 AIV I

KSS 3508 AIV A

KSS 4508 AIV

KSS 4508 AIV I

KSS 4508 AIV A

Cooling capacity / heat output 1) kW 2.50 / 2.70 3.50 / 3.85 4.50 / 6.00

Air volumes, indoor unit m³/h 450 550 800

Connection voltage

1/N/PE ∼230 V

Nominal power consumption for cooling / heating kW 0.73 / 0.85 1.16 / 1.27 1.58 / 2.05

Sound power level, outdoor / indoor unit (approx.) db(A) 53 / 40 55 / 42 56 / 45

Refrigerant R 410A

Net weight outdoor / indoor unit kg 40 / 8.5 45 / 11 52 / 20

Dimensions, outdoor unit (W x H x D) mm 830 x 540 x 320 830 x 540 x 320 914 x 685 x 384

Dimensions, indoor unit (W x H x D) mm 770 x 250 x 180 830 x 285 x 189 1020 x 319 x 234

Condensate hose extension, indoor unit Required

inner hose diameter

mm 17

Height difference indoor unit - outdoor

unitmaximum

m 10

Length of refrigerant pipe, maximum m 20

Temperature range, cooling

Indoor unit (adjustable range) Upper operating limit +33 °C / lower operating limit +18 °C

Outdoor unit (fixed-setpoint conditions) Upper operating limit +43 °C / lower operating limit -10 °C

Temperature range, heating

Indoor unit (adjustable range) Upper operating limit +30 °C / lower operating limit +16 °C

Outdoor unit (fixed-setpoint conditions) Upper operating limit +43 °C / lower operating limit -15 °C

Length of plug cable, indoor unit m 1,5

Energy efficiency class cooling A B C

Energy efficiency value (cooling/heating) 3.42 / 2.64 3.02 / 2.73 2.93 / 2.85

Special accessories refrigerant pipe

consisting of an insulated suction and pressure pipe pre-filled with refrigerant and with coupling and electrical connecting

cable.

Pre-filled refrigerant pipes, length 2 m KMSL 1412-2 AIV

Assembly accessories

consisting of 2 brackets with dampeners for wall mounting of outdoor unit

Wall bracket WKS 357

Condensate pump accessory

consisting of float-type switch and separate pump

Condensate pump KSI 3100

Refrigerant pipes may be joined to extend them.

For refrigerant pipes longer than 8 metres, an on-site extension by the refrigeration technician is recommended.

Page 3

3

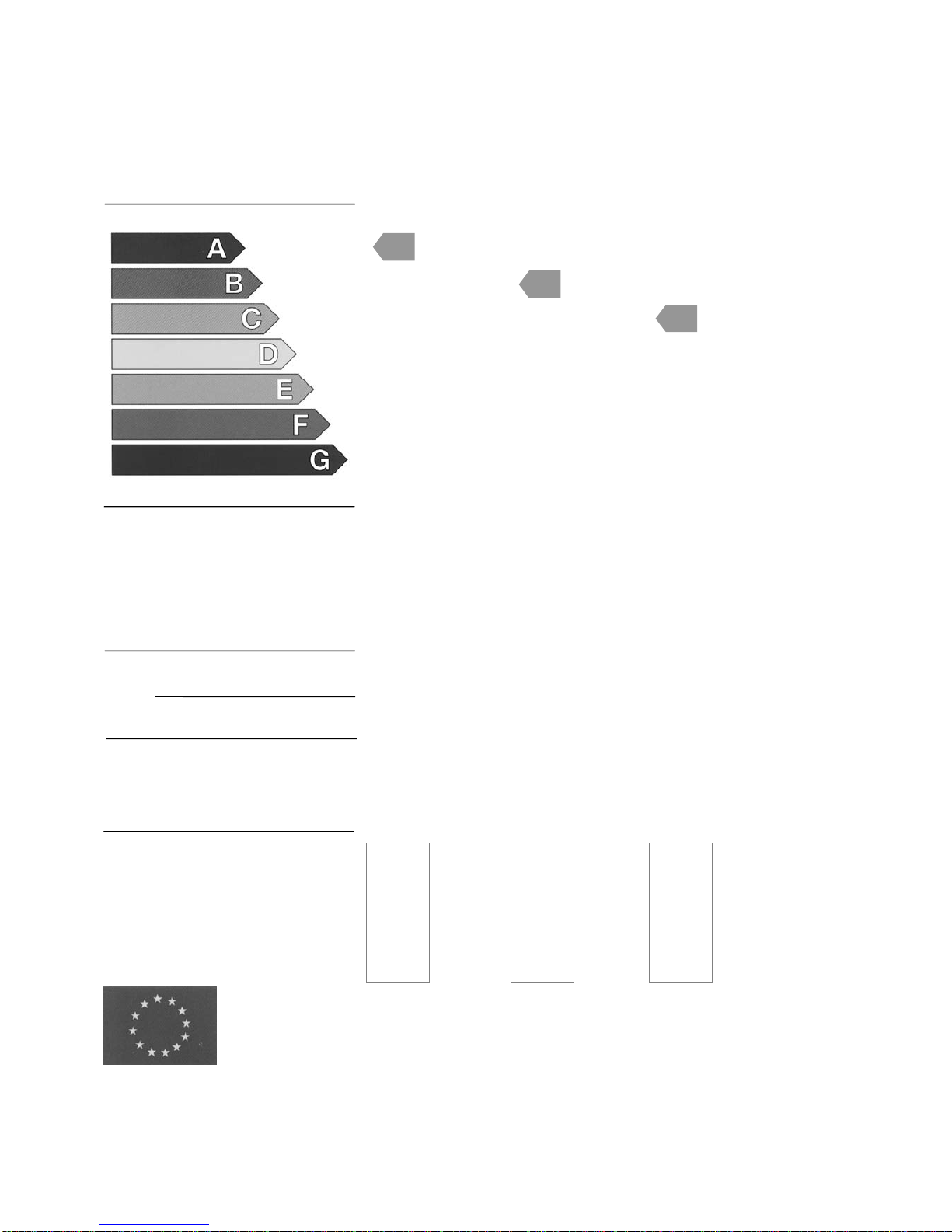

Energy efficiency

Energy Room air conditioner

Manufacturer: Dimplex Dimplex Dimplex

Outdoor unit

KSS 2508 AIV A KSS 3508 AIV A KSS 4508 AIV A

Indoor unit

KSS 2508 AIV I KSS 3508 AIV I KSS 4508 AIV I

Low energy consumption

High energy consumption

Annual energy consumption 365 579 780

kWh in cooling mode

(Actual consumption depends on

usage of the device and cooling

conditions)

Cooling capacity kW 2.50 3.50 4.50

Energy efficiency value 3.42 3.02 2.93

At full load (the higher the better)

Type Cooling function only -

Cooling function / heating function - Yes Yes Yes

Air cooling - Yes Yes Yes

Water cooling -

Heat output kW 2.70 3.85 6.00

Energy efficiency class E E D

of heating function

A: Low energy consumption

G: High energy consumption

Noise

dB(A) re 1 pW

The brochures include a data sheet

with further information on the devices

Standard EN 14511

Room air conditioner

Energy Labelling Directive 2002/31/EC

Data for

KSS 3508 AIV

Data for

KSS 4508 AIV

Data for

KSS 2508 AIV

Page 4

4

Checklist

• Has a calculation of the cooling load been made?

• Is the cooling capacity of the device sufficient for the room to be cooled?

• Are the operating limits sufficient for the purpose for which the air conditioner is intended?

• Are the walls or the foundation for the installation of the outdoor unit strong enough?

• The indoor unit should be installed in a position where it ensures uniform cooling.

• Minimum clearances must be observed.

• Planning the installation of the outdoor unit:

consider noise emission and free air circulation,

avoid direct sunlight,

ensure unimpeded access to the component,

installation at locations without access by general public.

• Is a wall bracket required for the outdoor unit?

• Plan the power cable and connection; ensure adequate fuse protection.

• Check the maximum length and feasibility of the refrigerant pipes.

• Refrigerant pipes should be as straight and short as possible.

• When routing the refrigerant pipes, it is essential to maintain a bend radius of 3.5 x pipe diameter.

• Excess piping should be wound up at a downward angle to the outdoor unit

in order to avoid displacement of refrigerant oil.

• Take the height difference between indoor and outdoor unit into account.

• If the outdoor unit is installed higher than the indoor unit: provide an oil siphon every 3 vertical meters.

• Plan condensate drainage. If the condensate hose on the indoor unit cannot be routed with a downward slope,

a condensate pump must be provided. The condensate is always formed at the “cold” side of the air conditioner;

this means for cooling in the inner component and for heating in the outdoor unit.

• Is an approval by the local utility company required?

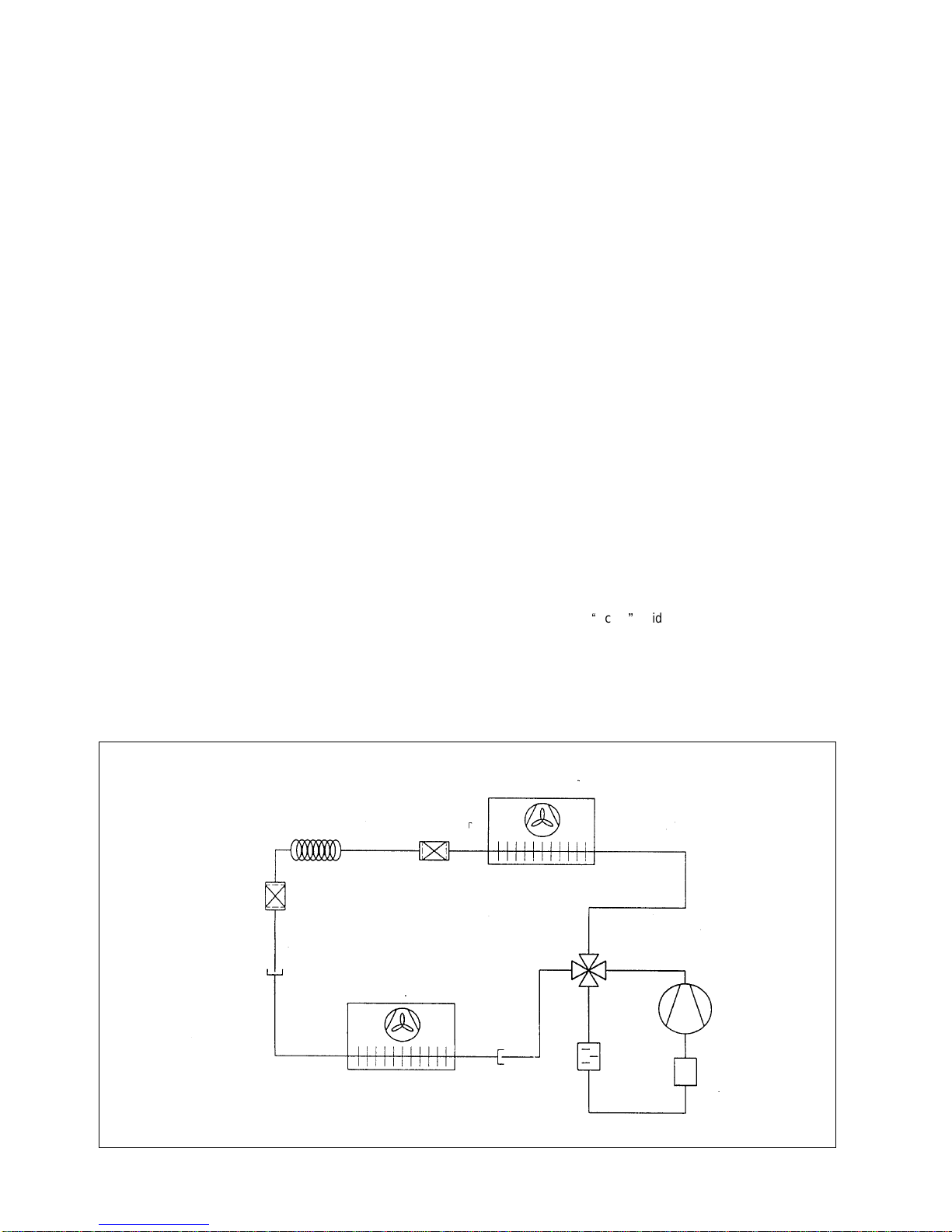

Refrigeration plan

Capillary

Collector

Damper

Compressor

4-way valve

Evaporator

Coupling

Condenser

Filter dryer

Filter dryer

Coupling

Page 5

5

Safety regulations

General

• Please read these installation and operating instructions carefully and fully before commencing installation! They contain

important information about the assembly, use and maintenance as well as safety instructions to be observed!

• After unpacking the device, inspect it for any transport damage. In case of doubt, do not put the device into use but have it

examined by a qualified technician.

• Before connecting the device, please ensure that the mains supply network corresponds to that required by the device

according to the type plate data. Observe the utility company's local connection conditions.

• The room air conditioner must not be operated in rooms where highly inflammable substances are used (e.g. solvents, etc.).

• The device must be unplugged from the mains before any cleaning or maintenance work is carried out.

• This device may be used only for the purpose for which it was manufactured, i.e. for heating, cooling, dehumidification and

air recirculation of rooms. All other purposes are not those for which it was intended and must therefore be regarded as

hazardous.

• In the case of a fault and/or functional defect, please switch the device off (disconnect from the mains). Do not try to repair

the device yourself. Necessary repairs must be carried out by the after-sales service.

• The power supply cable may only be replaced by a qualified electrician.

• The manufacturer is not liable for damage caused by improper or incorrect use or the incorrect installation of the device.

Device-specific

• The device must be installed according to the manufacturer’s specifications. Incorrect set up can cause injury to persons or

animals and damage to property.

• Where possible, the outdoor unit is to be installed in such a way that it is not exposed to direct sunlight.

• The inlet and outlet vents of the air conditioner must not be covered or blocked.

• Do not insert any objects into the device openings.

• Disconnect the air conditioner from the power supply if the device is not operated for a longer period of time.

• The air conditioner should be inspected at regular intervals (e.g. before the cooling season).

• The condensate which collects in or runs out of the air conditioner should not be drunk.

• Do not operate the room air conditioner without an air filter.

• The air filters should be cleaned at regular intervals (depending on user and room).

• Do not place any objects on top of the air conditioner.

• The indoor unit of the air conditioner may be operated in dry rooms only.

• Do not pour or spray any liquids onto or into the air conditioner.

• Do not use hairsprays, solvents or similar materials (aerosols) in the vicinity of the air conditioner.

• The air conditioner should be switched off immediately in the case of a fault (e.g. if smoke is created or an unusual smell is

noticed). Disconnect the device from the power supply (switch off the fuse or pull out the plug) and contact an authorised

after-sales service.

• Keep persons with impaired health, small children and pets away from the direct air current since this may have a

detrimental effect on their health.

• The device may be assembled and disassembled only by a qualified technician.

Page 6

6

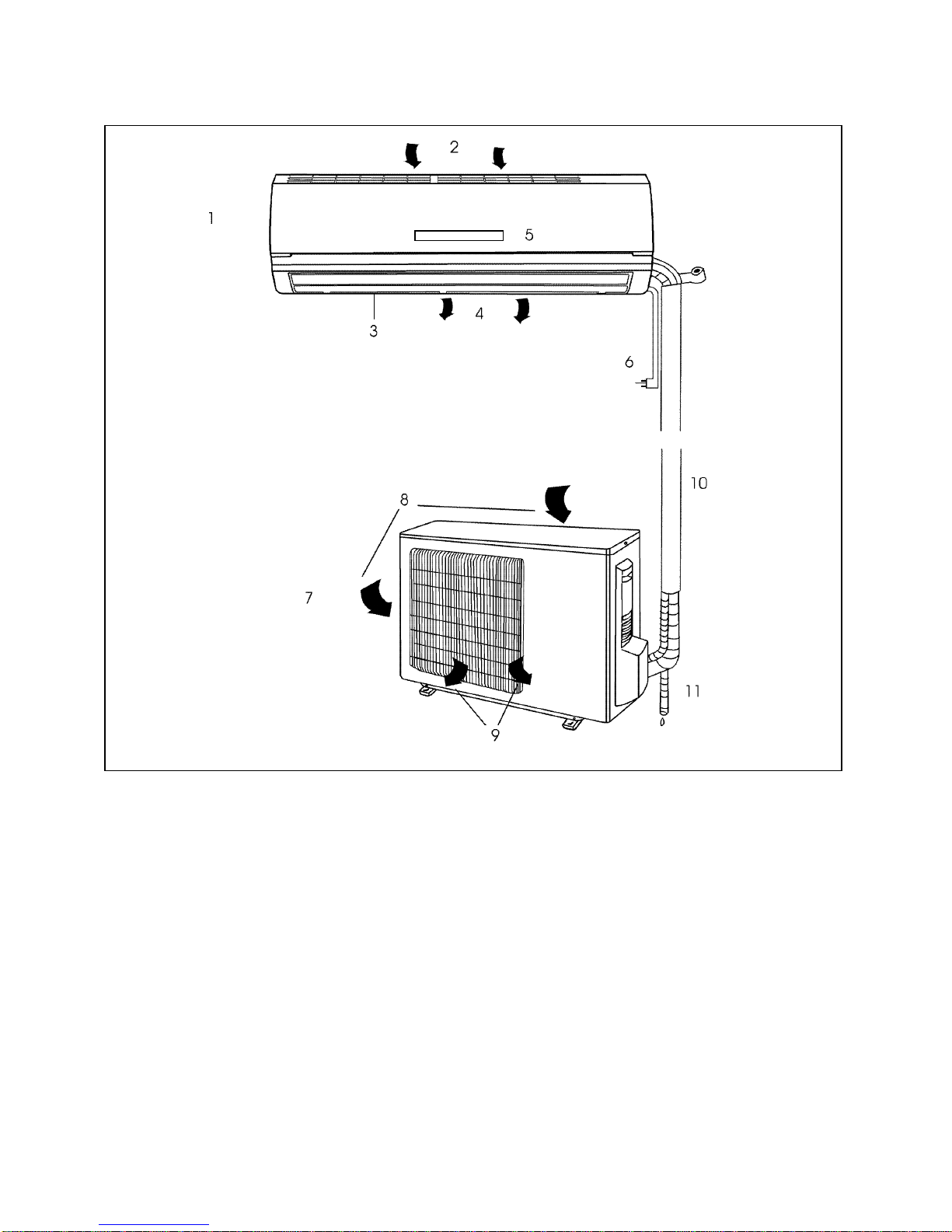

Device construction

1 Indoor unit

2 Air inlet

3 Airflow fins (for adjustable air outlet direction)

4 Air outlet

5 Signal receiver (of the remote control) with indicator lamps

6 Mains connection cable on indoor unit

7 Outdoor unit

8 Air inlet

9 Air outlet

10 Connection lines indoor unit - outdoor unit

11 Condensate outflow hose

Page 7

7

Installation instructions

Before choosing an air conditioner, we recommend carrying out a cooling load calculation according to the standard, or on the

basis of a relevant standard. Forms for cooling load calculation complete with instructions can be obtained from the

manufacturer or wholesaler or on the Internet at www.dimplex.de

Indoor or outdoor units, which are not installed according to instructions, may cause a reduction or loss of warranty in case of

repair!

Choosing the installation location

It is very important to install split devices in suitable locations as it is difficult, and thus expensive, to move them after installation.

If possible, decide on the installation location in agreement with the final customer. The installation site must be suitable for

bearing the weight and the operational vibration of the indoor or outdoor unit on a permanent basis.

Notes on the installation of the indoor unit

The circulating air should flow through the whole of the room to be cooled.

The flow of cold air should not be directed at persons or their place of work.

The condensation formed during cooling must be drained off without impairing functioning. If the condensate can only be led off

upwards or without a downward slope, then the installation of a condensate pump is necessary.

The component may not be installed in rooms subject to high humidity in which the device is in contact with moisture or water.

The device may not be installed in rooms in which oil vapour is emitted or could be emitted.

Notes on the installation of the outdoor unit

The outdoor unit should be installed in a place where it will not become soiled.

When there is a danger of condensate freezing (heating operation when outside temperatures are low), the condensate drain

stubs should be removed and additional insulation be provided for the drainage area. Freezing condensate (e.g. the formation of

ice on the heat exchanger) can impede the fan function of the outdoor unit.

The outdoor unit must be installed in compliance with the regulations regarding the assessment of operational noise in the

neighbourhood. In particular, a suitable distance from bedrooms and similar rooms should be maintained.

The device may not be installed in areas of aggressive air!

Scope of supply

Please check that the delivery is complete and that the devices are undamaged.

The scope of supply includes:

• Split air conditioner consisti ng of indoor and outd oor unit (2 packaging units in case of complete order),

• Mounting plate for wall mounting of the indoor unit, slotted into it (incl. screws)

• Remote control (incl. 2 batteries),

• Condensate drain plug for draining condensate in the outdoor unit,

• Control line with connection plug routed in the refrigerant pipe,

• Mains connection cable,

• Installation and operating instructions

Page 8

8

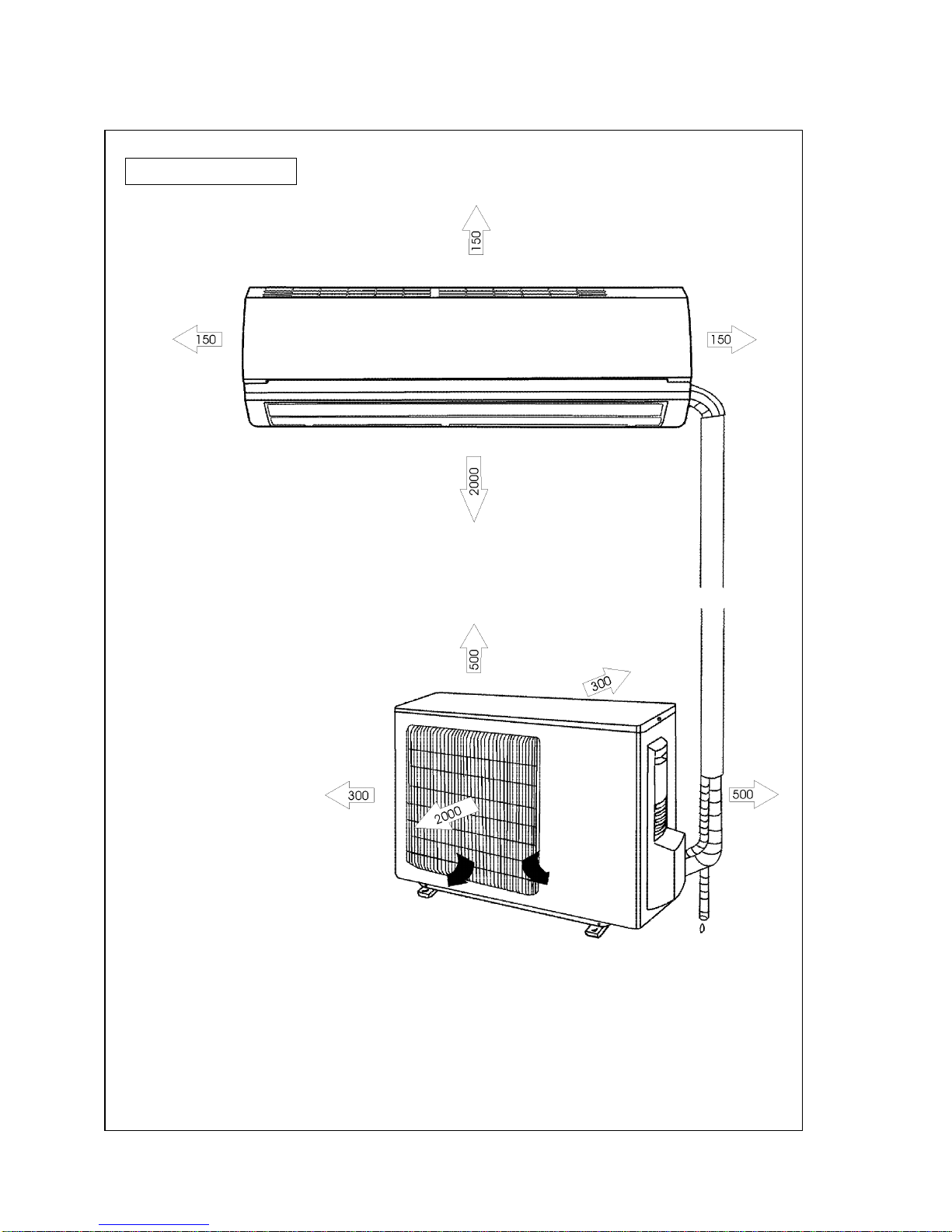

Minimum clearances

A

ll dimensions in mm

Page 9

9

Assembling the indoor unit

Installation instructions

Bends in the refrigerant pipes may not be positioned

immediately before or after refrigerant couplings!

If it does not matter whether the pipes are visible in the

room, they can be led out of the side of the indoor unit to

the left and routed through the wall at some other suitable

location.

Perforated sections are provided accordingly in the housing

area of the indoor unit.

Drilling through the wall

One opening in the wall with a minimum diameter of 80

mm is necessary for the passage of the condensation hose

as well as the refrigerant and electrical lines from the indoor

unit to the outdoor unit.

The opening must slope downward at an angle of about 5°

toward the outside wall to allow the condensate to drain.

Insert a bushing into the wall opening to prevent damage to

the lines!

The end of the condensate hose may not be stand in the

water.

The diagram below shows the recommended position for the wall opening depending on the minimum distances.

Ø=80

150 150

150

2000

80

60

Front view

A

B

KSS 2508 KSS 3508 KSS 4508

Maß A

Maß B

770

250

830

285

1020

310

Installation

- The mounting plate for the indoor unit must be aligned horizontally and mounted while observing the minimum clearances.

- Route the lines through the wall opening.

- Engage the indoor unit in the upper profiles of the mounting plate and swivel it downward

until the indoor unit engages.

Indoor unit

W

all

Downward slope

W

all mounting

min. 5°

Page 10

10

Assembling the outdoor unit

Mount the outside component on a suitable support or wall with adequate load capacity.

The wall bracket WKS 357 is available as an accessory.

• The inflow and outflow of air must be unimpeded.

• An air short circuit must be avoided.

• Minimum clearances must be observed.

• Distances to bedrooms and third-party rooms should be selected as large as possible to avoid annoying noise.

See “Technical Data” for sound power levels.

D

C

E

Distances between the drilling holes for mounting the outdoor unit. All dimensions in mm.

Type Dim. A Dim. B Dim. C Dim. D Dim. E

KSS 2508 AIV 288 320 540 760 70

KSS 3508 AIV 288 320 540 760 70

KSS 4508 AIV 342 384 550 844 70

Condensate drainage in the outdoor unit

During heating operation there is a formation of condensate which must be drained.

There is a hole (diam. 25) for condensate drainage in the base plate of the outdoor unit into which the condensate drainage plug

supplied can be inserted.

If the installation situation permits this, the condensate formed can drip down from the bottom side of the outdoor unit; otherwise

drainage must be provided by connecting a hose.

Caution!

• If possible, the drain house should not be fixed.

• If a condensate hose is is installed, it must always slope downwards.

The condensate may possibly freeze when heating below temperatures of +4 °C.

This may block the fan.

If temperatures below +4°C are to be expected at the condensate outlet during heating operation, appropriate measures, e.g.

insulation (insulation of the base of the casing and the condensate drainage area) should be taken.

Sealing the wall opening

This is not done until the outdoor unit has been installed and all necessary connections between the indoor and the outdoor unit

have been made.

The wall openings must be closed in a correct manner.

In the case of fire protection walls, the relevant regulations must be complied with.

Top view of outdoor unit

Page 11

11

Refrigerant pipes

Technical information

The refrigerant pipes, the indoor and outdoor units are pre-filled with refrigerant R410A.

The refrigerant R410A belongs to group 1 of refrigerants according to VBG 20. It is non-combustible and does not cause serious

damage to human health.

The following must be observed when installing refrigerant pipes:

• The refrigerant should not come into contact with the eyes (if necessary, protective goggles should be worn).

• Refrigerants can cause frostbite in contact with the skin (if necessary, suitable protective clothing, such as gloves, should

be worn).

• Contact with open flames or very hot surfaces can cause the refrigerant to decompose and give off poisonous gases.

• Caution! Do not smoke while disconnecting or closing refrigerant pipes!

• Do not inhale the refrigerant!

• Refrigerant is heavier than air; if it leaks it collects on the ground.

• In high concentrations it can cause a lack of oxygen. There is a danger of suffocation.

A defective refrigerant pipe must be properly disposed of by a qualified specialist company or the authorised customer service.

Installation

If possible, the refrigerant pipes should be routed in suitable conduits (e.g. conduits for electrical installations) which allow the

pipes to be replaced in case of replacement or repair.

• Subsequently wrapping the refrigerant pipes with cloth adhesive tape protects the line insulation from damages due to UV

rays and mechanical impact (rubbing against walls, bird bites). As an additional benefit, it makes the installed pipes more

rigid - thereby reducing vibration.

• The pipes may not have more than three bends in succession and not more than 12 bends over their entire length.

• The number of bends should be kept to a minimum.

• The radius of the bends must be at least 3.5 times the external diameter.

• Install the pipes with a downward slope toward the outdoor unit or wind them up to prevent residues of refrigerant oil.

If the height difference between indoor and outdoor unit is greater than 3 metres, a siphon-type bend must be created every 3

metres of height difference. For example, 2 bends at 6 metre height, 3 bends at 9 metre height, etc.

Provide a siphon every 3

vertical meters.

Oil separator

Refrigerant flow

Outdoor unit installed higher

than the indoor unit

Page 12

12

Connecting the refrigerant pipes on the outdoor unit

Important information

• Preventing dirt and moisture from entering the system is imperative; clean all connections with a dry cloth, if necessary.

• The coupling connections may be loosened or opened again after connecting them, if required. Avoid frequent opening.

• Repairs must only be carried out by an authorised after-sales service.

1 Remove dust caps/ transport protection. Pull back the locking ring.

2

Push on the refrigerant pipe coupling.

3 Push the locking ring forward again and close the fastening tab.

4 Secure the connection with a screw (A) to prevent unintentional loosening.

Insulate the refrigerant connections to prevent condensate formation.

1

4 3

2

A

Page 13

13

Electrical Connection

Electrical connection on the outdoor unit

- Remove the cover ,

- open the strain relief clamp,

- plug in the plug,

- fasten the grounding wire to the mounting plate,

- fasten the electrical cable to the strain relief clamp,

- attach the cover again.

Electrical connection on the indoor unit

The power supply of the indoor unit and the outdoor unit is

done via the pre-installed connecting cable with power plug on

the indoor unit.

• Operation only with 230 V AC!

• Observe the safety and connecting conditions!

• Provide separate fuse protection for circuit!

• Connection and repair only by a qualified specialist!

• Provide a disconnecting device in the permanently

installed wiring with at least 3 mm conctact opening at

each pole (e.g. automatic circuit breaker)

Start-up

Check the following before start-up:

• Are all refrigerant pipes and connections tight (e.g. using a leak test spray)?

• Has the electrical installation been carried out correctly?

• Have the indoor and outdoor units been installed in a secure and vibration-proof manner?

• Have the refrigerant pipes been routed correctly?

• Has the max. permitted length not been exceeded?

• Have the coupling elements on the outdoor unit been insulated?

• Have all installation residues or contamination been removed from the indoor and outdoor unit?

• Have the air filter and condensate drainage pipes been installed properly?

• Were functioning batteries correctly placed in the remote control?

Function test

• Plug in the device and turn on the circuit breaker. Operate the “ON/OFF” button of the remote control.

• Operate the “MODE” button of the remote control.

• Check all operating modes (cooling, circulation, heating, dehumidifying) if the ambient temperatures

permit this (application limits).

• Certain start-up times or pauses depend on the function when switching from one operating mode to another.

If the device cannot be switched on using the remote control:

− Open the front of the indoor unit.

− Operate the AUTO/STOP button (at the right upper corner).

Checking the function of the remote control must now be possible.

Electrical connection on the outdoor unit

Page 14

14

Important notes on operation

Use the air conditioner only for the following purposes:

• for room cooling,

• for room heating,

• for room dehumidification,

• to circulate the air in the room.

Heating operation

The device operates with heat pump switching. Heat is

extracted from the outside air, then led to the indoor unit and

released in the room.

The heat output diminishes as the temperature of the

outside air drops!

If the device does not provide sufficient heat for the room,

we recommend operating it in combination with another

heater.

Heat pump air conditioners circulate the warm air in order to

heat the entire room. It therefore takes some time until the

entire room is warm (also depends on the external

temperature and the heating requirement).

Automatic de-icing

When external temperatures are low and air humidity is high,

heating operation can cause the formation of ice on the

outdoor unit - which reduces the heat output.

In this case, the device switches automatically to the “Defrost” mode for 10 – 15 minutes, heating is interrupted and

the fans cease to operate.

Temperature too high

When, in heating operation, both room and external

temperatures are too high, the fan of the outdoor unit may

switch off periodically (protective function).

Power disruption/ power cuts

After a power cut the devices restart operation in the

operating mode last set (with the temperature setting last

stored). This occurs in cooling and dehumidify ing mo de w ith

a starting delay of approx. 3 min.

In heating operation this restart phase can last up to 17

minutes.

The alignment of the airflow fins (SWING) may need to be

reset after a power disruption.

Information on the efficient use of the device

• Keep windows and doors closed during air conditioning!

• Select the suitable setting of the airflow direction

direct the airflow downward in heating operation,

direct the airflow upward in cooling operation.

• In cooling operation, set the room temperature no more

than 5° below the outside temperature.

Permissible temperature and humidity ranges

Temperature range of outdoor unit* -10 °C to

+43 °C

Humidity range of outdoor unit

approx. 40 to 80 %

Temperature range of indoor unit* +18 °C to

+33 °C

Cooling

Humidity range of outdoor unit

approx. 40 to 80 %

If the device is exposed to high humidity over

a long period, condensate may form and drip

down.

Temperature range of outdoor unit* -10 °C to

+43 °C

Humidity range of outdoor unit

approx. 40 to 80 %

If the device is exposed to high humidity over

a long period, condensate may form and drip

down.

Temperature range of indoor unit* +18 °C to

+33 °C

Heating

Humidity range of outdoor unit

approx. 40 to 80 %

* If the device is exposed to higher temperatures, the

automatic safety mechanism may be trigg ered and

operation may be interrupted.

If the device is exposed to lower temperatures, ice

may form on the heat exchanger, which can cause water

(condensate) to run out or lead to other malfunctions.

Page 15

15

Circuit diagram

KSS 2508

Indoor unit

Outdoor unit

Page 16

16

Circuit diagram

KSS 3508

Indoor unit

Outdoor unit

Page 17

17

Circuit diagram

KSS 4508

Indoor unit

Outdoor unit

Page 18

18

Operation

Function buttons of remote control

1 Remote control

2 Display window

3 Select operating mode

Automatic / Cooling / Dehumidifying / Circulation /

Heating

4 Swing operation On/Off

5 Setting the current time

6 Setting the timer function - switch-off time

7 Setting the time - increasing the time

8 Deactivating the timer function

9 Setting the time - reducing the time

10 Timer function - setting the switch-on time

11 Sleep function On/Off

12 Fan level – Selecting the speed

13 Increasing the default room temperature

14 Decreasing the default room temperature

15 Operation On/Off

Operating display on the remote control

16 Fan speed is determined automatically

17 Fan on

18 Fan speed low / normal / high

19 Send - default is sent.

20 Dehumidifying operating mode

21 Heating operating mode

22 Sleep function set

23 Circulation operating mode

24 Swing operation ON display

25 Current time, set timer time

26 AM – time before noon

PM – time afternoon

27 ON – time timer On

OFF – time timer Off

28 Timer function activated

29 Room temperature default

30 Automatic operating mode

31 Cooling operating mode

Page 19

19

Inserting the batteries in the remote control

Remove the cover of the battery compartment.

Insert two “1.5 V MICRO AAA” batteries in the battery

compartment.

Observe the polarity (+/-) in the housing.

Replace the cover of the battery compartment.

Note:

Insert new batteries if the display of the remote control is

weak or flickers or cannot be seen at all.

Setting the time

Press the CLOCK (5) button.

The display (26) AM (before noon) or PM (afternoon)

flashes.

Set the current time with the TIME + (7) or TIME - (9)

buttons.

Briefly touching the buttons causes a change in 1-minute

increments.

Prolonged touch of the buttons causes a change in 10-

minute increments.

Press the CLOCK (5) button to store the set time.

Setting the fan speed

The fan speed can be set at three levels. The fan speed is

set with the FAN (12) button.

The fan speed cannot be changed in the dehumidifying

operating mode.

Press the ON/OFF (15) button to switch on the device.

Press the FAN (12) button once or several times until the

desired fan speed (18) is set.

Cooling

Press the ON/OFF (15) button to switch on the device.

Press the MODE (3) button once or several times until the

Cooling (31) display appears.

The desired room temperature can be set with the TEMP+

(13) and TEMP- (14) buttons.

Setting range: 16-30 °C, setting increments: 1 °C.

Dehumidification

Press the ON/OFF (15) button to switch on the device.

Press the MODE (3) button once or several times until the

Dehumidification (20) display appears.

The desired room temperature can be set with the TEMP+

(13) and TEMP- (14) buttons.

Setting range: 16-30 °C, setting increments: 1 °C.

In the Dehumidification operating mode, the fan works only

at a low speed to achieve optimal dehumidification.

Circulation mode

Press the ON/OFF (15) button to switch on the device.

Press the MODE (3) button once or several times until the

Circulation mode (23) display appears.

The desired room temperature can be set with the TEMP+

(13) and TEMP- (14) buttons.

Setting range: 16-30 °C, setting increments: 1 °C.

Heating

Press the ON/OFF (15) button to switch on the device.

Press the MODE (3) button once or several times until the

Heating (21) display appears.

The desired room temperature can be set with the TEMP+

(13) and TEMP- (14) buttons.

Setting range: 16-30 °C, setting increments: 1 °C.

Page 20

20

Automatic mode

Depending on the room temperature, the operating mode s

COOLING and HEATING are determined automatically.

The temperature cannot be set manually.

Press the ON/OFF (15) button to switch on the device.

Press the MODE (3) button once or several times until the

AUTO (30) display appears.

The operating mode COOLING is selected automatically:

at temperatures of 25 °C or higher.

The operating mode HEATING is selected automatically:

at temperatures of 25 °C or lowe r.

Timer function

The time-dependent operation of the air conditioner can be

programmed on the remote control.

Select the switch-on time

Press the T-ON (10) button – the ON (27) display flashes.

Set the current switch-on time with the TIME + (7) or TIME

- (9) buttons.

Press the T-ON (10) button once more to store the selected

switch-on time.

Select the switch-off time

Press the T-OFF (6) button – the OFF (27) display flashes.

Set the current switch-off time with the TIME + (7) or TIME

- (9) buttons.

Press the T-OFF (6) button once more to store the selected

switch-off time.

Delete timer settings

Press the CANCEL (8) button.

Sleep function

To increase your comfort while sleeping at night.

Reduces the fan speed and controls the specified room

temperature values even more precisely.

This function is only available in the operating modes

Cooling (31), Dehumidifying (20) and Heating (21).

Press the ON/OFF (15) button to switch on the device.

Press the SLEEP (11) button - the Sleep function (22)

display appears.

Swing operation

Up – down air flow

The Swing operation can be turned on and off using the

SWING (4) button.

Furthermore, the air flow can be specified for a specific air

outlet direction.

Press the ON/OFF (15) button to switch on the device.

Press the SWING (4) button.

The SWING (24) display appears.

The direction of the air flow is continuously changed from

top to bottom and vice versa.

The Swing operation is switched off again by pressing the

SWING button once more.

Left – right air flow

The horizontal air outlet direction is set manually.

NOTE:

In the operating modes Cooling and Dehumidifying,

condensate can form on the airflow fins turned to the right

or left, and may possibly drip down. Use this setting,

therefore, only for a short time.

Special c are must be taken when using the air conditioner

in rooms with infants, small children, elderly or sick persons

to prevent any danger to health.

A

djusting the airflow fins

Page 21

21

Cleaning and maintenance

The device must be disconnected from the mains and

allowed to cool down before cleaning and maintenance.

Clean the surfaces of the casings with a soft damp cloth

and then dry them. Use only lukewarm water. No scouring

agents or polishes should be used.

Cleaning the air filters

Soiled filters reduce the airflow and thus the efficiency of

the device. Soiled filters can also cause noise.

Both filters should be checked at the beginning of the

active period and cleaned as necessary.

The degree of soiling largely depends on the location and

operating conditions. More frequent cleaning may be

required.

Take hold of the front cover of the indoor unit on both sides

and flap it up until it clicks into an open position.

Push the filter slightly upward at one side until it

disengages from its locked position.

Fully remove the filter.

Repeat the procedure with the second filter.

Auxiliary filter

Remove the two auxiliary filters, if present, as well.

Clean the air filter with a vacuum cleaner.

If the filters are heavily soiled, they can also be cleaned

with a neutral cleaning solution.

The air filters must be completely dry before installing them

again.

Installation is done in the reverse order.

Page 22

22

Faults

In case of malfunction, stop the operation of the air conditioner immediately, deactivate the unit and disconnect from the mains.

Switch off the automatic circuit breaker in the manifold and pull of the mains plug, if necessary.

Contact the after-sales service.

You can detect possibly impaired function by a reduced output, smoke development, unusual odours, loud noises, increased

tripping of the fuse or unusual heat development.

However, before you contact the after-sales service, please use the list below to check whether this could be a normal

occurrence or a fault you can remedy yourself.

Type of fault Possible causes

Device does not switch on immediately If the device is switched off and then on again immediately, a safety function

prevents it operating for about 3 minutes (compressor safety function).

The same thing happens when disconnecting the air conditioner from the mains

and then switching it on again. Again the safety function prevents the operation of

the device for approx. 3 minutes.

A delay of up to 17 minutes can occur before the heating function starts or warm air

begins to circulate, e.g. when the operating mode is changed or there is a power

cut when in heating mode.

Noises Noises caused by the flow of the refrigerant through the pipes can sometimes be

heard during operation. These noises tend to occur particularly during the first two

to three minutes after switching on or off.

Temperature fluctuations cause material expansion and contraction, which can also

produce noises.

Smells The air emitted by the indoor unit may carry various smells already present in the

room, e.g. cooking smells, tobacco, new furniture, etc.). Because the airconditioned air is emitted at a higher speed, the smells can be perceived as more

intensive.

Emission of steam or vapour Slight vapour formation may be visible at the device during cooling or

dehumidification. This is due to the sudden cooling of the existing room air by the

climatised air and is normally no longer perceivable after a few minutes.

Device is not working Is it connected to the mains power supply?

Has a fuse blown?

Have the operating limits been exceeded?

Has a power cut occurred?

Are the batteries in the remote control working?

The device switches off or on

unintentionally

The timer function may possibly be activated.

The command entered on the remote

control is not executed

Depending on the operating mode selected, impractical functions cannot be

executed.

Inadequate cooling or heating Do the air filters need cleaning?

Are the device’s inlet and outlet vents covered or clogged with dirt?

Have additional sources of heat been switched on? (during cooling mode)

Are the room temperature settings appropriate?

Are the windows and doors in the room to be cooled or heated open?

Has the correct fan speed been set (air volume)?

Are larger window surfaces present during cooling operation through which direct

sunlight enters the room?

You may need to close the curtains, lower the blinds, etc.

Page 23

23

Warranty, after-sales service

The following conditions, describing the requirements and scope of our warranty service, do not affect the warranty obligations

of the sales person from the sales contract with the end customer. We offer a warranty for the devices according to the following

conditions:

Based on the following conditions, we remedy defects of the device free of charge which can be proven to be due to material

and/or manufacturing defects if they are reported to us without delay upon being detected and within 24 months after delivery to

the first end customer. This period is 12 months when the device is used commercially. If the defect appears within 6 months

after delivery and a successful start-up (heat pumps for heating purposes and central room ventilation devices) by the

authorised after-sales service for complete systems, a material or manufacturing defect can be expected.

This device is only covered by this warranty if it was purchased by a company in one of the member states of the European

Union, it is operated in Germany when the defect occurs and warranty service can also be rendered in Germany.

The defects which we have recognised as being covered by warranty are remedied in that the defective parts are repaired free

of charge at our discretion or replaced by flawless parts. Exceptional costs of defect remedy due to the type or location of the

device's use or poor accessibility of the device are not covered by us. The end customer must ensure free access to the device.

Dismantled parts which we take back become our property. The warranty time for rework and spare parts ends with the

expiration of the original warranty period for the device. The warranty does not cover easily breakable parts which affect the

value or operational use of the device only insignificantly. The original purchase receipt with purchase or delivery data must

always be presented.

The warranty becomes void if the end customer or a third party did not comply with the applicable VDE regulations, the

stipulations of the local utility company or our installation and operating instructions as well as the information and integration

diagrams included in the project planning documents or if the our accessories required for proper functioning were not used.

The liability for the consequences of modifications and work activities performed improperly by the end customer or third party

becomes void. The warranty covers the device and the parts purchased from the supplier. Parts and devices not purchased by

the supplier and system defects due to parts not purchased from the supplier are not covered by warranty.

If the defect cannot be remedied or the repair is denied by us or unreasonably delayed, the manufacturer will either deliver a

replacement free of charge or reimburse the reduced value. In case of providing a replacement delivery, we reserve the right to

apply a reasonable usage for the time of usage incurred so far. Extended or other claims, especially those for compensation of

damages incurred outside of the device, are excluded unless liability is legally mandated. In case of liability according to article

478 of the German Civil Code (BGB), the liability of the supplier is limited to the lump-sum service fees constituting the

maximum amount.

An extension of the warranty to 36 months for heater heat pumps and central room ventilation devices from the date of start-up

but no longer than 38 months after delivery ex factory is granted under the following conditions: The prerequisite for accepting

the extended warranty is the chargeable start-up by the authorised after-sales service for complete systems with a start-up log

within an operating time (compressor runtime) of less than 150 hours. Defects noted in the start-up log must be remedied

immediately. This is the basis for the warranty. The start-up log shall be submitted to the address specified below within one

month after the start-up; the extension of the warranty period will be confirmed by this same address.

The start-up costs flat charge includes the actual start-up and the travel expenses. No liability is assumed for the proper

planning, dimensioning and execution of the overall system. Remedying system defects and waiting times are extra services.

The start-up costs flat charge for all heat pumps for heating purposes is currently € 340 net and € 400 net for central

ventilation systems, for each device, and is charged to the ordering party by the authorised after-sales service for complete

systems. Price adjustments are reserved.

In case of a situation requiring service, the authorised after-sales service for complete systems on site is notified who will quickly

remedy the problem. You can find out about the after-sales service for complete systems responsible for your area by

contacting the central service hotline of Glen Dimplex Deutschland GmbH.

Glen Dimplex Deutschland GmbH

Dimplex Division

After-sales service for complete systems

Am Goldenen Feld 18 Phone No. +49 (0) 9221 709 562

95326 Kulmbach, Germany Fax No. +49 (0) 9221 709 565

E-mail address kundendienst.system@glendimplex.de kundendienst.system@dimplex.de

Internet: www.dimplex.de

To process your order, we require the production number (E-Nr.) and the device’s production date (FD).

This information can be found on the type plate in the framed field.

Page 24

24

Glen Dimplex Deutschland GmbH Telephone: +49 (0) 9221 709 562 Subject to technical changes

Am Goldenen Feld 18 Fax: +49 (0) 9221 709 565 Internet: www.dimplex.de

D-95326 Kulmbach E-mail: kundendienst.system@dimplex.de kss08-gb_ba.doc 08/08/A

Note on disposal

Do not dispose of the unit with general household waste. The device must be taken to a local waste disposal plant.

Loading...

Loading...