Dimplex KSS 2504, KSS 3204, KSS 4504, KSS 6004 Installation And Operating Instructions Manual

Page 1

KSS 2504

KSS 3204

KSS 4504

KSS 6004

Split Air Conditioner for Wall Mounting

Installation and Operating Instructions 453322.66.11 06/07/B

Contents: Page

Installation Instructions

Device-Specific Safety Regulations ................................................................................................................... 2

Check List .......................................................................................................................................................... 3

Technical Data ...................................................................................................................................................4

Device Construction ........................................................................................................................................... 6

Installation Notes for Split Air Conditioners ....................................................................................................... 7

Minimum Clearances .................................................................................................................................... 9

Assembling the Outdoor Unit ........................................................................................................................... 10

Connecting the Cooling System....................................................................................................................... 11

Pre-filled Refrigerant Pipes .............................................................................................................................. 12

Installation Notes – Laying a Split Pipe ........................................................................................................... 15

Electrical Connection .......................................................................................................................................17

Start-Up – Function Test .................................................................................................................................. 18

Refrigeration Plan ............................................................................................................................................ 19

Circuit Diagrams............................................................................................................................................... 20

Operating Instructions

Important Notes on Operation.......................................................................................................................... 23

Direction of Air Flow .................................................................................................................................... 24

Cleaning and Maintenance ......................................................................................................................... 24

Remote Control ................................................................................................................................................ 25

Battery for Remote Control .........................................................................................................................25

Functions of Remote Controls KSS 2504 / 3204 / 4504 / 6004.................................................................. 26

Cooling ........................................................................................................................................................ 27

Heating........................................................................................................................................................ 28

Dehumidification ......................................................................................................................................... 29

Auto............................................................................................................................................................. 30

Timer Function ............................................................................................................................................ 31

Sleep Function ............................................................................................................................................ 32

Faults ..........................................................................................................................................................33

Page 2

2

General Safety Requirements

Please read these installation and operating instructions carefully and fully before

commencing installation! They contain important information about assembly, use and

maintenance as well as the safety instructions to be observed!

After unpacking it, please inspect the device for any damage. In case of doubt, do not put the

device into use but have it examined by a qualified technician.

Before connecting the device, please ensure that the mains supply network corresponds to that

required by the device according to the type plate data (observe your utility company’s local

connection conditions).

The device must not be operated in rooms where highly inflammable substances are used (e.g.

solvents, etc.).

The device must be unplugged from the mains before any cleaning or maintenance work is

carried out.

This device may be used only for the purpose for which it was made, i.e. for heating, cooling,

dehumidification and air recirculation. All other purposes are not those for which it was

intended and must therefore be regarded as hazardous.

In the case of a fault and / or functional defect, please switch the device off (disconnect from

the mains). Do not try to repair the device yourself. Necessary repairs must be carried out by

the after-sales service.

The power supply cable may be replaced only by a qualified electrician.

The manufacturer is not liable for damage caused by improper or incorrect use or the

incorrect installation of the device.

Device-Specific Safety Regulations

The device must be installed according to the manufacturer’s specifications. Incorrect

installation can cause injury to persons or animals and damage to property.

Where possible, the outdoor unit is to be installed in such a way that it is not exposed to direct

sunlight.

The inlet and outlet vents of the room air conditioner must not be covered or closed.

No objects may be pushed into the air inlet and outlet vents.

Disconnect the air conditioner from the power supply if it is out of use for some time.

The air conditioner should be inspected at regular intervals (e.g. before the cooling season).

The condensation which collects in or runs out of the air conditioner should not be drunk.

Do not operate the room air conditioner without an air filter.

The air filters should be cleaned at regular intervals (depending on user and room).

Do not place any objects on the room air conditioner.

The indoor unit of the room air conditioner may be operated in dry rooms only.

Do not pour or spray any liquids into or onto the room air conditioner.

Do not use hairsprays, solvents etc (e.g. aerosols) in the vicinity of the air conditioner.

The air conditioner should be switched off immediately in the case of a fault (e.g. if smoke is

created or an unusual smell is noticed). Disconnect the device from the power supply (switch

off the fuse or pull out the plug) and contact an authorized after-sales service.

Keep persons, particularly small children, pets and plants away from the direct air flow, it could

damage their health or general condition.

The device may be assembled and disassembled by a qualified technician only.

Page 3

3

Check List

Has a calculation of the cooling load been made?

Is the cooling capacity of the device sufficient for the room to be cooled?

Are the operating limits sufficient for the purpose for which the air conditioner is intended?

Are the walls or the foundation for the installation of the outdoor unit strong enough?

The indoor unit should be installed in a position where it ensures uniform cooling.

Minimum clearances must be observed.

Planning the installation of the outdoor unit.

Consider noise emission and free air circulation, avoid direct sunlight, ensure unimpeded access to

the unit; the unit should be installed in a place to which the public does not have access.

Is a wall bracket required for the outdoor unit?

Plan the power cable and connection, ensure adequate fuses.

Check the maximum length and feasibility of the refrigerant pipes.

Refrigerant pipes should be as straight and short as possible.

When laying refrigerant pipes it is essential to maintain a bend radius of 3.5 x diameter.

Excess piping should be wound up at a downward angle to the outdoor unit in order to avoid residues of

refrigerant oil.

Take account of differences in height between the room unit and the outdoor unit; if the outdoor unit is

higher than the room unit then one or more oil siphons should be provided as necessary.

Plan condensation drainage.

If the condensation pipe cannot be laid with a downward slope, the room unit must be provided with a

condensation pump.

Condensation is always formed on the “cold” side of the air-conditioning plant, i.e. for cooling in the

room unit and for heating in the outdoor unit.

Do you require permission from the local utility company?

Page 4

4

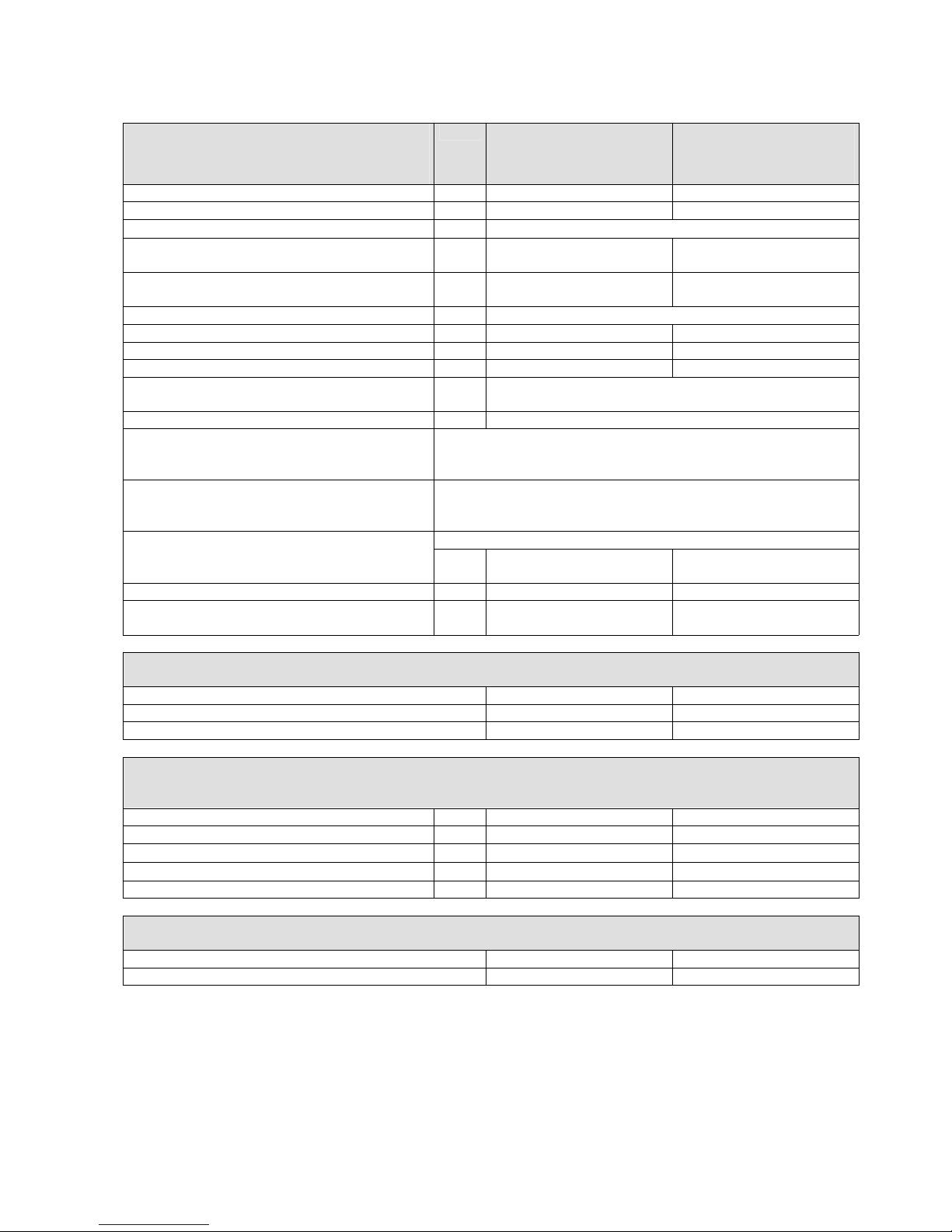

Technical Data

Split room air conditioners with rapid

refrigerant coupling

Indoor unit

Outdoor unit

KSS 2504 AB

KSS 2504 A

KSS 2504AI

KSS 2504AA

KSS 3204 AB

KSS 3204 A

KSS 3204AI

KSS 3204AA

Cooling capacity / heat output 1) kW 2.5 / 2.8 3.2 / 3.5

Air volume, indoor unit m³/h 420 460

Connection voltage

1/N/PE a230 V

Nominal power consumption for cooling /

heating

kW 0.79 / 0.97 1.09 / 1.24

Sound power level, outdoor / indoor unit

(approx.)

dB(A) 52 / 36 55 / 39

Refrigerant R 410A

Net weight outdoor / indoor unit kg 32 / 8.5 32 / 8.5

Dimensions, outdoor unit (W x H x D) mm 848 x 540 x 260 848 x 540 x 260

Dimensions, indoor unit (W x H x D) mm 770 x 250 x 180 770 x 250 x 180

Difference in height between device units,

maximum

M 10

Length of refrigerant pipe, maximum M 20

Temperature range, cooling

Indoor unit (adjustable range) Upper operating limit +30 °C / lower operating limit + 16 °C

Outdoor unit (fixed-setpoint conditions) Upper operating limit +43 °C / lower operating limit -5 °C

Temperature range, heating

Indoor unit (adjustable range) Upper operating limit +30 °C / lower operating limit +16 °C

Outdoor unit (fixed-setpoint conditions) Upper operating limit +43 °C / lower operating limit -7 °C

Electrical connection lines

Mains cable (dimension / length) mm² 3 x 1.0 / 5.2 m 3 x 1.5 / 5.2 m

Control line (dimension / length) mm² 2 x 0.75 / 6.0 m 2 x 0.75 / 6.0 m

Energy efficiency class 3) A B

Coefficients of performance (cooling /

heating)

4)

3.2 / 2.9 3.0 / 2.8

Refrigerant pipe accessories

3)

(essential)

consisting of a suction and pressure pipe, insulated and pre-filled with refrigerant

Pre-filled refrigerant pipes, length 2.5 m

KMSL 1438A-2 KMSL 1412A-2

Pre-filled refrigerant pipes, length 5.0 m

KMSL 1438A-5 KMSL 1412A-5

Split room air conditioners for wall mounting

with flanged connections, not for use with KMSL refrigerant pipes

(technical data see above)

Indoor unit KSS 2504A IB KSS 3204A IB

Outdoor unit KSS 2504A AB KSS 3204A AB

Pipe for liquid mm

© 6 x 1 © 6 x 1

Suction gas pipe mm

© 10 x 1 © 12 x 1

Split pipes max. length / max. height m 20 / 10 20 / 10

Special accessories

comprising 2 brackets for wall mounting of outdoor unit

Wall bracket

WKS 357 WKS 357

Condensation pump

KSI 3100 KSI 3100

1) Nominal data acc. to ISO 5151

2) Refrigerant pipes may be joined to extend them. The maximum permitted length of pipe must be observed.

3)

In compliance with 92/75/EC, Directive 2002/31/EC

4) Acc. to EN 14511

Page 5

5

Split room air conditioners with rapid

refrigerant coupling

Indoor unit

Outdoor unit

KSS 4504 CB

KSS 4504 C

KSS 4504CI

KSS 4504CA

KSS 6004 CB

KSS 6004 C

KSS 6004CI

KSS 6004CA

Cooling capacity / heat output 1) kW 4.5 / 5.2 6.0 / 6.5

Air volumes, indoor unit m³/h 700 720

Connection voltage

1/N/PE a230 V

Nominal power consumption for cooling /

heating

kW 1.75/ 1.75 2.30 / 2.30

Sound power level, outdoor / indoor unit

(approx.)

dB(A) 58 / 46 59 / 48

Refrigerant R 407C

Net weight outdoor / indoor unit kg 58 / 12 59 / 12

Dimensions, outdoor unit (W x H x D) mm 950 x 700 x 412 950 x 700 x 412

Dimensions, indoor unit (W x H x D) mm 907 x 290 x 195 907 x 290 x 195

Difference in height between device units,

maximum

m 10

Length of refrigerant pipe, maximum m 20

Temperature range, cooling

Indoor unit (adjustable range) Upper operating limit +30 °C / lower operating limit +16 °C

Outdoor unit (fixed-setpoint conditions) Upper operating limit +43 °C / lower operating limit 0 °C

Temperature range, heating

Indoor unit (adjustable range) Upper operating limit +30 °C / lower operating limit +16 °C

Outdoor unit (fixed-setpoint conditions) Upper operating limit +43 °C / lower operating limit -7 °C

Electrical connection lines

Mains cable (dimension / length) mm² 4 x 2.5 / 5.2 m 4 x 2.5 / 5.2 m

Control line (dimension / length) mm² 5 x 1.0 / 6.8 m 5 x 1.0 / 6.8 m

Energy efficiency class 3) D D

Coefficients of performance

(cooling/heating)

4)

2.57 / 2.97 2.6 / 2.8

Refrigerant pipe accessories

3)

(essential)

consisting of a suction and pressure pipe, insulated and pre-filled with refrigerant

Pre-filled refrigerant pipe, length 2.5 m

KMSL 3858-2 KMSL 3858-2

Pre-filled refrigerant pipe, length 5.0 m

KMSL 3858-2 KMSL 3858-2

Split room air conditioners for wall mounting

with flanged connections, not for use with KMSL refrigerant pipes

(technical data see above)

Indoor unit KSS 4504C IB KSS 6004C IB

Outdoor unit KSS 4504C AB KSS 6004C AB

Pipe for liquid mm

© 10 x 1 © 10 x 1

Suction gas pipe mm

© 16 x 1 © 16 x 1

Split pipes max. length / max. height m 20 / 10 20 / 10

Special accessories

comprising 2 brackets for wall mounting of outdoor unit

Wall bracket

WKS 357 WKS 357

Condensation pump

KSI 3100 KSI 3100

1) Nominal data acc. to ISO 5151

2) Refrigerant pipes may be joined to extend them. The maximum permitted length of pipe must be observed.

3) In compliance with 92/75/EC, Directive 2002/31/EC

4) Acc. to EN 14511

Page 6

6

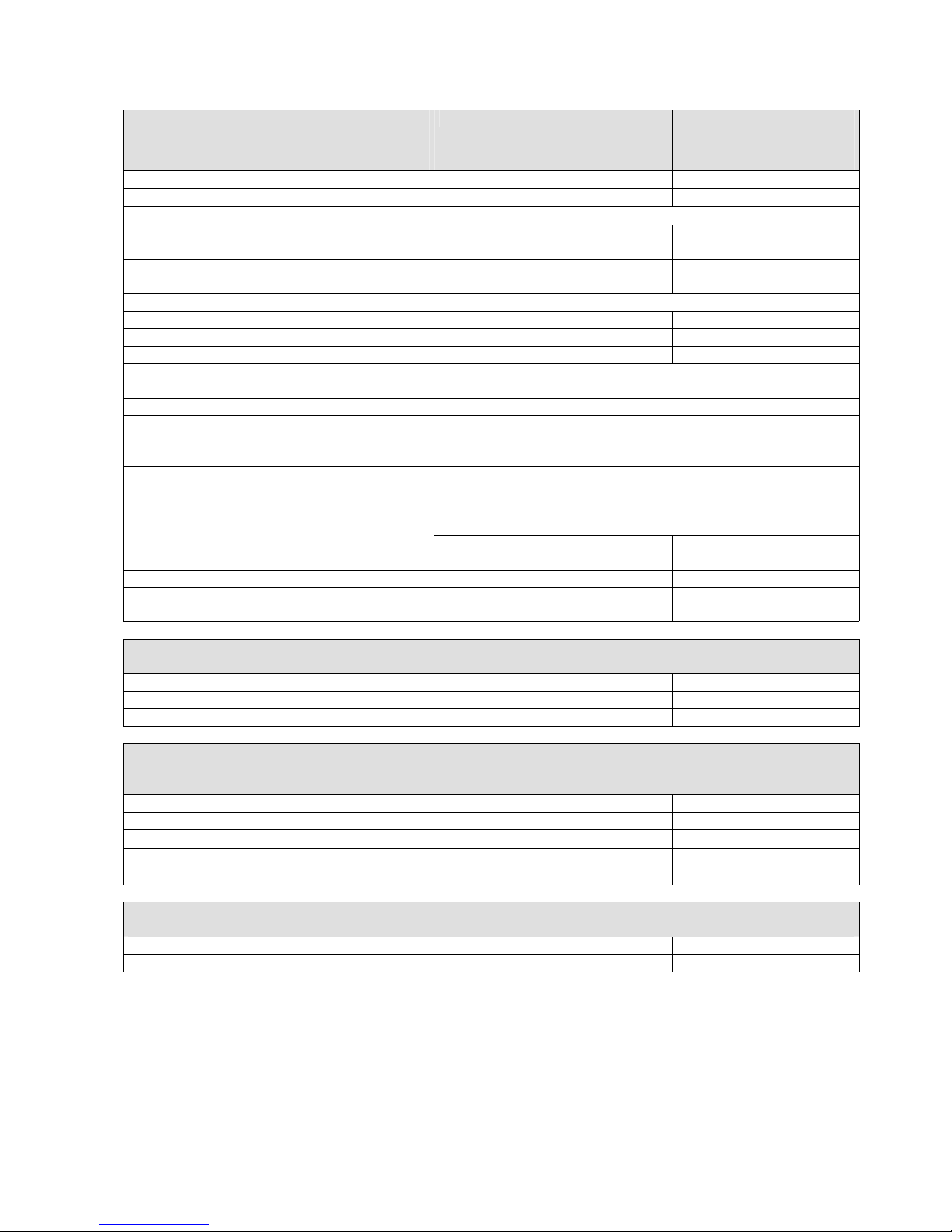

Device Construction

Outdoor

component

Room

component

(1) Casing flap

(2) Air filter

(3) Air filter Element A (option only)

(4) Air filter Element B (option only)

(5) Cover

(6) Airflow fins

(7) Connection cable

(8) Condensation drain

(9) Air outlet grid

(10) Remote control

A

ir intake

A

ir outlet

Timer

Page 7

7

Installation Notes for Split Air Conditioners

Before choosing a room air conditioner, we recommend carrying out a cooling load calculation according to

the standard, or on the basis of a relevant standard. Forms for cooling load calculation complete with

instructions can be obtained from the manufacturer or wholesaler or in the Internet at www.dimplex.de.

Note: Indoor or outdoor units which are not installed according to instructions may cause a reduction or loss

of warranty in the case of repair.

Choosing the installation location

It is very important to install split devices in suitable locations, as it is difficult, and thus expensive, to move

them after installation. If possible, decide on the installation location in agreement with the final customer.

The installation must be suitable for bearing the weight and the operational vibration of the indoor or outdoor

unit on a permanent basis.

Notes on the installation of the indoor unit

- The circulating air should flow through the whole of the room to be cooled.

- The flow of cold air should not be directed at persons or their place of work.

- The condensation formed during cooling must be drained off without impairing functioning. If

condensation can only be led off upwards or without a downward slope, then the installation of a

condensation pump is necessary.

- The unit may not be installed in rooms subject to high humidity in which the device is in contact with

moisture or water.

- The device may not be installed in rooms in which oil vapour is emitted or could be emitted.

Notes on the installation of the outdoor unit

- The outdoor unit should be installed in a place where it will not become soiled.

- When there is a danger of condensation freezing (heating operation when outside temperatures are low),

the condensate drain stubs should be removed and additional insulation be provided for the drainage

area. Freezing condensation (e.g. the formation of ice on the heat exchanger) can impede the fan

function of the outdoor unit.

- The outdoor unit must be installed in compliance with the regulations regarding the assessment of

operational noise in the neighbourhood. In particular, a suitable distance from bedrooms and similar

rooms should be maintained.

- The device may not be installed in areas of aggressive air!

Scope of supply

Please check that the delivery is complete and that the devices are undamaged.

The scope of supply includes:

1. Split air conditioner consisting of an indoor and an outdoor unit (two VPE - for a complete order)

2. Mounting plate for wall mounting of the indoor unit, slotted into it (incl. screws)

3. Remote control (incl. 2 batteries)

4. Condensation drain plug for draining condensation in the outdoor unit

5. Assembly and operating instructions

6. Length of insulating tube (approx. 250 mm x diam.

i

20 mm)

7. Control line with connection plug and a connection cable to the power supply (see Technical Data)

8. Sealant (in box – for sealing the wall around the pipes)

Page 8

8

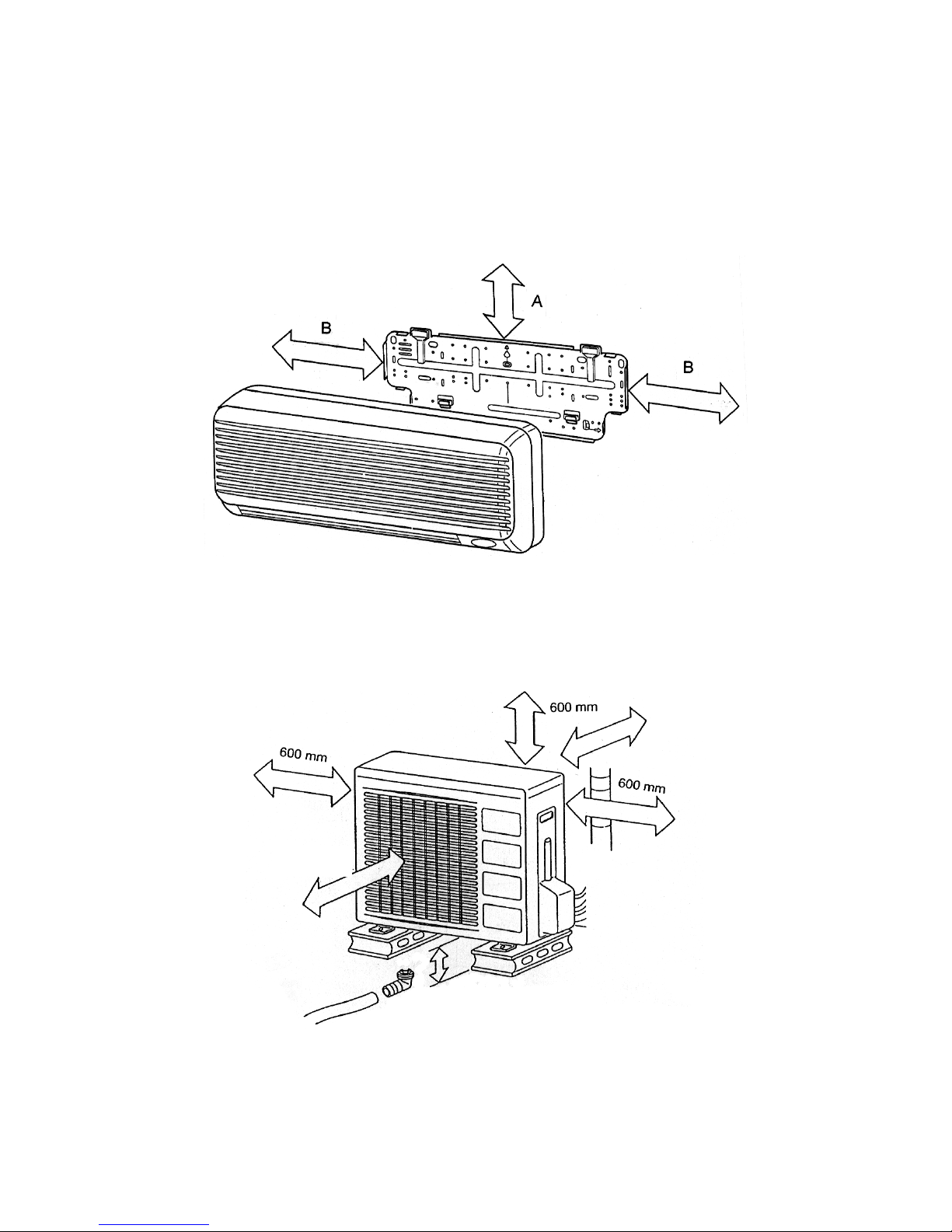

Assembling the Indoor Unit

Mounting plate:

The mounting plate for the indoor unit must be

positioned horizontally and attached firmly.

Minimum clearances must be observed. Please

use the screws provided.

Wall opening:

One opening in the wall with a minimum

diameter of 70 mm is necessary for the passage

of the condensation pipe and the refrigerant and

electrical leads from the indoor unit to the outdoor

unit (for adapted refrigerant connection pipes for

the indoor unit or for KSS split pipes) A smaller

opening, approx. diam. 55 mm, may be sufficient

for non-adapted devices [without refrigerant

couplings]. A sleeve should be placed in the wall

opening in order to prevent damage to the pipes

(in particular to the insulation of the split pipes)! It

is better to pass the refrigerant connection pipes

of the indoor unit through the wall than the split

pipes themselves as some of these have a larger

diameter and are thus difficult to lay in a small

space (at the rear of the indoor unit).

1 Insulated suction pipe

2 Pressure pipe

3 Control line

4 Condensation pipe

5 Electric connecting cables (not in diagram)

Important: The opening must slope downward at

an angle of about 5° so that the condensation

formed during de-humidification and cooling can

run away. (The end of the condensation pipe may

not be standing in water or be below the water

line!)

Position for wall opening

The diagram below shows the recommended

position for the wall opening in relation to the

mounting plate if the pipes are not to be visible in

the room after installation.

In combination with KMSL split pipes only the

position shown on the right, where dimensions are

given, is suitable for the rear!

If you use your own split leads you may be able to use

the position shown on the left (of the mounting plate) in

relation to the wall opening.

Please note that the bends in the refrigerant

pipes may not be positioned immediately in front of

or after the refrigerant couplings or the screw

fastenings for the leads!

If it does not matter whether the pipes are visible

in the room, they can all be led out of the side of

the indoor unit to the left (in the direction of the

pipe connections of the indoor unit; the perforated

areas in the casing of the indoor unit should be

cut out for this) and led through the wall in some

other suitable place.

Indoor unit:

Slot the indoor unit into the mounting plate and

close the clips provided in the lower part of the

casing.

Sealing the wall opening:

This is not done until the outdoor unit has been

installed and all necessary connections between

the indoor and the outdoor unit have been made.

The wall opening, or the remaining openings in

the wall opening sleeve, can be sealed using the

sealant provided, using mortar or a mineral fibre

plug with a silicone coating. In the case of fire

protection walls, the provisions of DIN 4102 must

be observed.

Hanging slots

ca. 50

ca. 50

∅ 70

ca. 50

ca. 60

∅ 70

KSS 4504C / 6004C

Page 9

9

Minimum Clearances

Indoor unit

The following minimum clearances (A and B) from walls are essential for the trouble-free operation of the

room air conditioner and for servicing and repairs.

The clearance between the ceiling and the lower edge of the room air conditioner must be at least 2.30 m.

For device dimensions see Technical Data.

For all devices: A ≧ 100 mm B ≧ 180 mm

Outdoor unit

Clearance from walls (see Technical Data for device dimensions)

(If mounted close to the ground: ≧ 50 mm + necessary

bend radius, if a condensation pipe is used)

≧ 300 mm (air

intake side)

2 m

Condensation outflow

Page 10

10

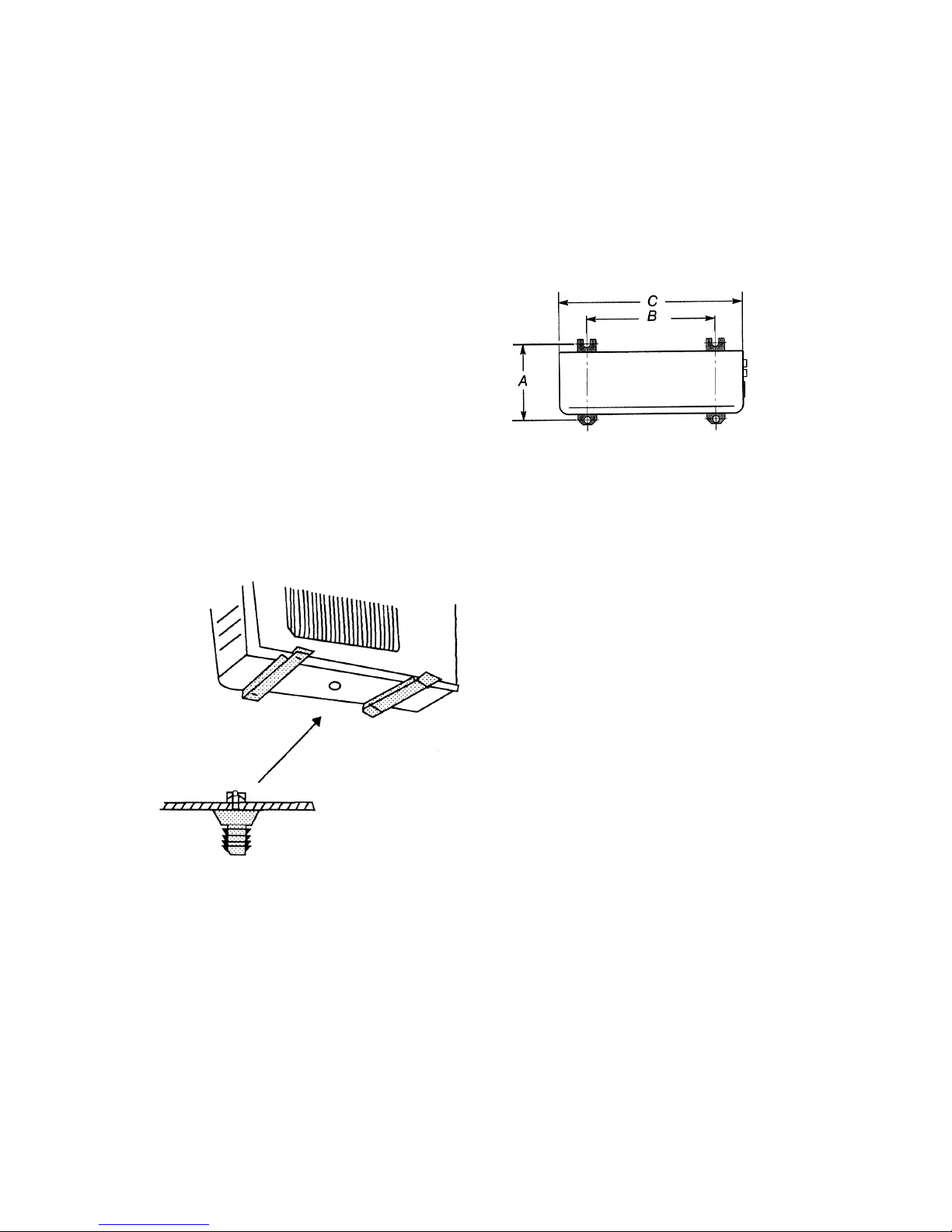

Assembling the Outdoor Unit

The outdoor unit should be attached firmly to a

suitable surface or a suitable wall of sufficient

strength (see also “Wall bracket accessory”).

It should be installed in a place where there is

unimpeded air inflow and outflow An air short

circuit must be avoided. Please observe minimum

clearances and the sound power levels given in

the technical data (distances from bedrooms or

third-party rooms etc.).

Condensation drainage in the outdoor unit

When the heat pump is in operation, condensation

is formed in the outdoor unit, which must be

drained off in a manner appropriate to the

location.

There is a hole (diam. 25) for condensation

drainage in the base plate of the outdoor unit into

which the condensation drainage plug supplied is

inserted. If the installation location allows it, the

condensation formed can simply drip away,

otherwise it must be led off through a pipe

attached to the drainage plug.

Caution:

During heating operation at temperatures below

+4 °C the condensation outlet can freeze up

under unfavourable conditions and this can block

the condensation fan. If temperatures below +4 °C

are to be expected at the condensation outlet

during heating operation, appropriate measures,

e.g. insulation (insulation of the base of the casing

and the condensation drainage area) should be

taken, or, if possible, the drainage plug should not

be installed. If a condensation pipe is used, it

must always slope downwards.

Distances between the drilling holes for

mounting the outdoor unit

Type Dim. A (mm) Dim. B (mm) Dim. C (mm)

KSS 2504A/3204A 275 540 848

KSS 4504C 375 572 950

KSS 6004C 375 572 950

Connecting the cooling system for

devices with pre-filled refrigerant

pipes KMSL… .

The refrigerant pipes of the indoor and outdoor

units are pre-filled with refrigerant R407C or

R410A.

Please observe the safety regulations for

handling CFC (HCFC) in the section “Pre-filled

refrigerant pipes KMSL…” when installing the

air conditioners and the split pipes.

(see page 12f.)

Split pipes of the KMSL series

Care must be taken to connect the refrigerant

pipes correctly. It is particularly important to

observe the torques specified (see page 14).

Incorrect connection of the split pipes, which can

be ordered as accessories, is impossible,

because each half of the coupling fits only to its

other half in the indoor or outdoor unit.

Ready-to-use refrigerant pipes in various lengths

are available (see Essential Accessories in

“Technical Data”). Excessively long pipes should

be avoided when selecting split pipes (loss of

cooling capacity). Reductions or extensions to

length may be made by the authorised after-sales

service only.

Please observe the assembly steps and the

notes in the section “Pre-filled refrigerant

pipes KMSL” on page 12ff. for installation and

the connection of the cooling system.

View from

above

Page 11

11

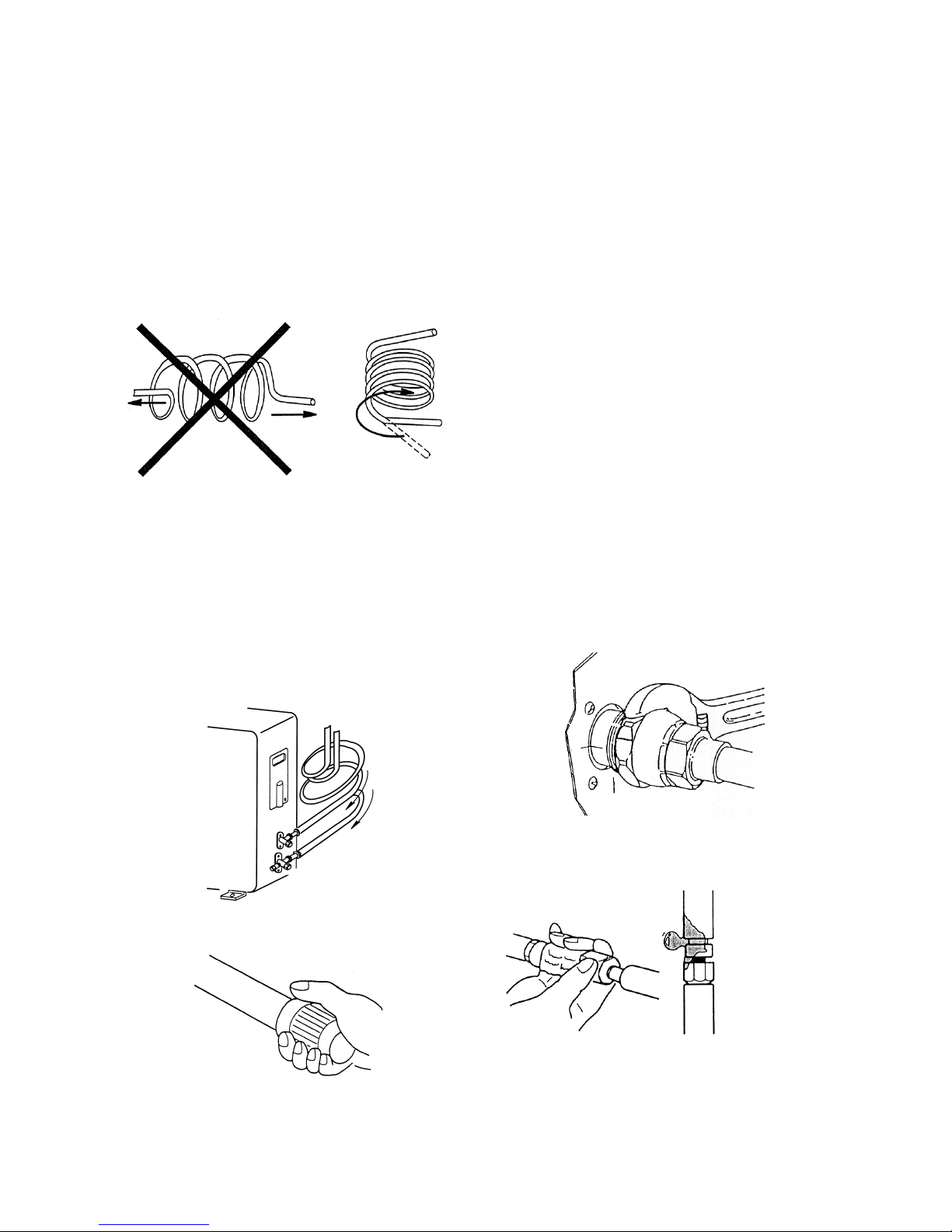

Connecting the Cooling

System

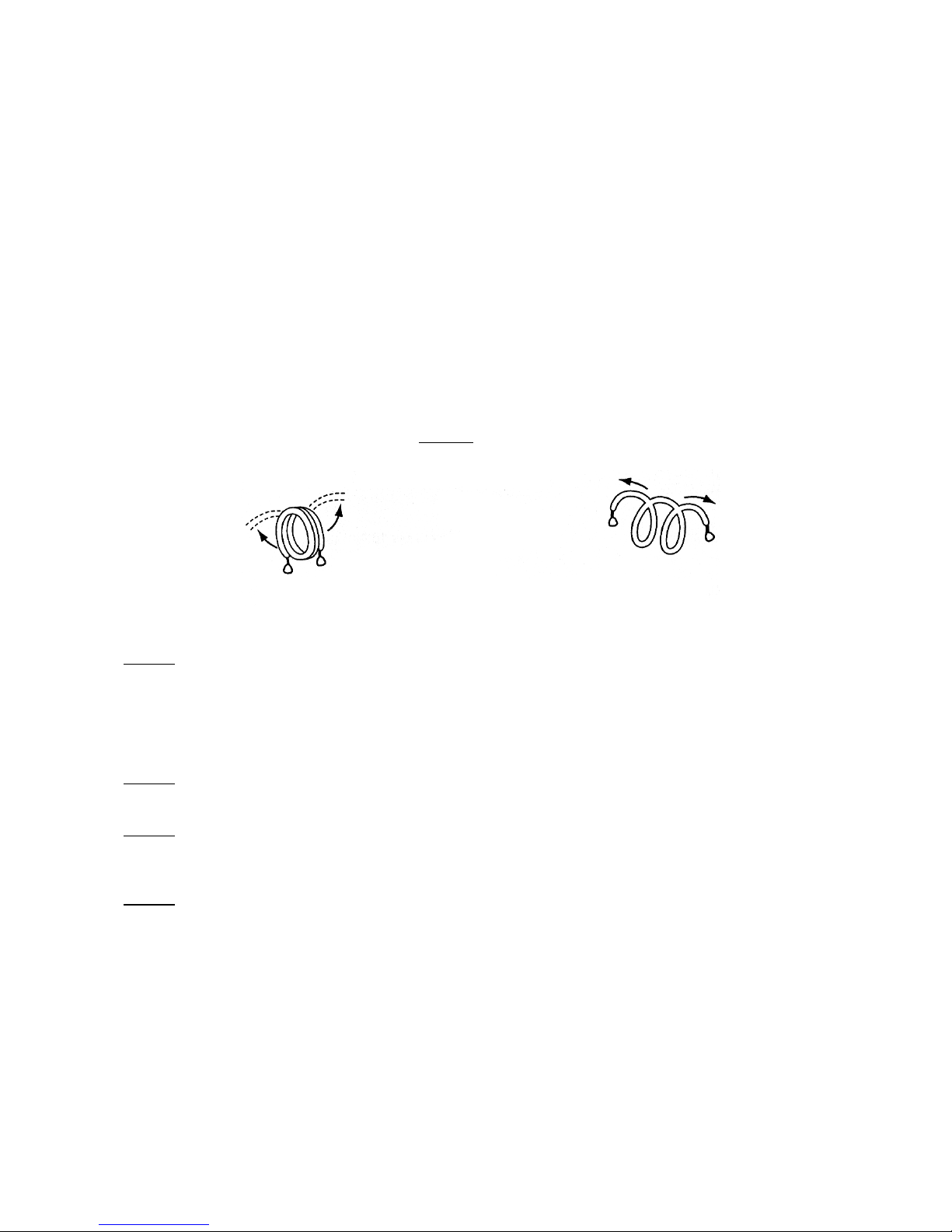

First, unwind the refrigerant pipes carefully to their

full length. The pipes may not have more than 3

bends in succession and a total of 12 bends over

their entire length.

The number of bends should be kept to a

minimum.

The radius of the bends must be at least 3.5 times

the external diameter. If necessary, a suitable

bending device should be used.

Connecting the refrigerant pipes:

See the section “Pre-filled refrigerant pipes KMSL”

for this.

Lay the suction and pressure pipes between the

indoor and outdoor unit. We recommend laying

the thicker suction pipes first, as the thinner

pressure pipes are more easily fitted in.

Excess piping should be wound up at a

downward angle to the outdoor unit in order to

avoid residues of refrigerant oil.

Remove the dust caps and dust plugs from the

two halves of the coupling.

The thread of the coupling and the seals should

be cleaned with a clean cloth to avoid trapping

dust and moisture in the system.

The membranes of the coupling and the rubber

seals of the male halves of the couplings should

be moistened with a few drops of refrigerant oil.

The matching halves of the couplings should be

screwed together by hand until the thread is well

engaged (or until the inner halves of the coupling

membrane meet – turning then becomes much

more difficult) and then tightened using a spanner

(see Torques for refrigerant pipe couplings). A

hissing noise during joining is normal.

Caution! When torque is applied, the two halves

of the coupling should always be held firm with

spanners.

Screw locks should then be applied to stop the

connection loosening unintentionally through

vibration.

After joining, the coupling connections must not

be opened (Refrigerant could escape! Repairs

must be carried out by an authorised after-sales

service only).

Torques for refrigerant pipe couplings

The necessary torques for the secure (leak-proof)

connection of the refrigerant pipe couplings are

given below:

Split pipes with refrigerant couplings with 3/8“ and

1/4" UNF threads (spanner values SW 19 und SW

21) 15 – 20 Nm.

Split pipes with refrigerant couplings with 5/8“ and

1/2" UNF threads (spanner values SW 27 und SW

34) 47 – 54 Nm.

All refrigerant pipes and connections must be

tested for leaks before first use (e.g. using a leak

search spray).

wrong

right

Page 12

12

Pre-filled Refrigerant Pipes

Order identification

KMSL 1438A-2 KMSL1438A-5 KMSL 3858-2 KMSL 3858-5

KMSL 1412A-2 KMSL1412A-5

Scope of supply

1. Pre-filled suction and pressure pipes (of different lengths depending on type) insulated with flexible foam,

provided with refrigerant couplings and pre-filled with refrigerant.

2. Pieces of flexible foam insulation of different lengths (for insulating couplings or the screw connection of

the indoor unit).

3. Refrigerant leak detection spray (400 ml can)

4. Notes on assembly

Connecting the cooling system

The refrigerant pipes (suction and pressure pipes) are pre-filled with the refrigerant R410A or R407C. Please

observe the relevant ordinances and regulations on the handling of refrigerants.

Excerpt from the “Safety regulations when handling CFC (HCFC) refrigerants”

VBG 20 classifies the refrigerants R410A and R407C as Group 1 refrigerants; they are non-combustible and

cause no serious damage to human health. The following must be observed when installing refrigerant pipes:

- The refrigerant should not come into contact with the eyes (if necessary, protective goggles should be

worn).

- Refrigerants can cause frostbite in contact with the skin (if necessary, suitable protective clothing, such as

gloves, should be worn).

- Contact with naked flames or very hot surfaces can cause the refrigerant to decompose and give off

poisonous gases.

- Caution! Do not smoke while connecting or disconnecting refrigerant pipes!

- Do not inhale the refrigerant!

- Refrigerant is heavier than air, if it leaks it collects on the ground.

- In high concentrations it can cause a lack of oxygen. There is a danger of suffocation.

If possible, split pipes should be laid in suitable conduits (e.g. conduits for electrical installations) which allow

the pipes to be replaced in the case of replacement or repair. If the split pipes or the room air conditioner are

defective and are to be disposed of, this must be done by a suitable specialist company or the authorised

after-sales service.

Page 13

13

Caution!

The connections of the room air conditioner are equipped with various self-sealing single couplings. (The

connection valve on the outdoor unit of the device has a locking device, the indoor unit does not.) Care must

be taken to ensure that the split pipes are connected using the correct connections.

Cooling system connections should be made first between the indoor unit and the split pipes and then

between the split pipes and the outdoor unit. This order must also be observed if you use your own refrigerant

pipes (without couplings)!

The split pipes (gas and liquid pipes or suction and pressure pipes) each have a “male” and a “female” half

with a Schrader valve connection.

The split pipes cannot be connected incorrectly in combination with the coupling halves already pre-installed

in the split devices (provided that the correct split pipes are used), as only one combination of two matching

coupling halves is possible. Split pipes of the same size (size of coupling) can be joined together to a

maximum length of 20 m.

After connection, these couplings may be separated or disconnected only by a qualified technician or

the authorised after-sales service (refrigerant leakage)!

Installation instructions:

The refrigerant pipes should first be unrolled carefully

against the winding direction to their full length (Do not

pull them apart in the axial direction!).

Step 1:

Lay the suction and pressure pipes between the outdoor and indoor units. The pipes may not have more than

3 bends in succession and a total of not more than 12 bends over their entire length.

The number of bends should be kept to a minimum. The radius of the bends must be at least 3.5 times the

external diameter. The pipes should not be bent more than 3 times in the same place as the material then

suffers fatigue and becomes cracked.

Step 2:

Remove the dust caps and plugs.

Step 3:

If necessary, clean the fitting surfaces of the couplings and the threads with a clean cloth to avoid particles of

dust or other foreign bodies entering the system.

Step 4:

Moisten the membranes of the male half of the coupling and the rubber seal with refrigerant oil. In order to

ensure that the threads fit together perfectly, first screw the two halves together by hand until the thread has

engaged properly or until the two halves of the coupling membrane meet and turning becomes more difficult

(the coupling membranes are penetrated at this point).

right wrong

Page 14

14

Step 5:

Now use a spanner to firmly connect the two halves of the coupling (essential to ensure the refrigerant circuit

does not leak). Screw locks should then be applied to stop the connection loosening unintentionally through

vibration.

The recommended torques for the couplings for the refrigerant pipes are shown below (It is essential to

secure the two halves of the coupling against loosening!).

Torques

Split pipes with refrigerant couplings with a 5/8“ UNF thread (spanner values SW 19 and

SW 21) 15 – 20 Nm.

Split pipes with refrigerant couplings with a 1 1/16“ UNF thread (spanner values SW 27 and

SW 34) 47 – 54 Nm.

(These torques can be transferred safely only if

the other half of the coupling is firmly fixed using a spanner!)

Step 6:

All the cooling system connections made are to be checked for leaks using the leak search spray supplied

with the split pipes!

The flexible foam insulation (see Scope of Supply) should be wrapped and fixed round each pair of couplings

at the indoor unit (use the insulating adhesive tape for this, and if necessary cable connectors as well).

Insulation is important, as temperatures fall below the dew point during operation (cooling function) and

condensation can be formed.

For longer split pipes, in particular, we recommend joining the insulated gas or pressure pipes using

insulating or fabric adhesive tape (reduces or prevents the vibration of the split pipes during operation and

protects the insulation from UV radiation).

Connection of an additional condensation pipe (if necessary).

An example of how to lay a refrigerant pipe is given below in 3 steps.

1.

2.

3.

Page 15

15

Installation Notes – Laying a Split Pipe

Siphon-shaped bending of the split pipes

Caution!

The bends are to be as tight as possible

observing the minimum permissible bend

radius (min. bend radius = 3.5 x outer

diameter of pipe)!

The split pipes can also be led out of the left side

of the indoor component (in the direction of the

pre-bent connection pipe); the thin areas in the

side of the casing must be cut out for this.

¹ Subsequent wrapping of the split pipes with fabric

adhesive tape (or aluminium adhesive tape) protects the

pipe insulation from damage by UV radiation and

mechanical damage (rubbing against masonry, bird bites)

and increases the rigidity of the pipes (if they are both

wrapped together) – we therefore recommend wrapping

the split pipes or laying them in covered conduits!

When laying split pipes, please note that if the difference in height between the indoor

and outdoor components is more than 3 m, the pipes must have a siphon-type bend and

a second siphon bend for a further 3 m difference!

Minimum height

Page 16

16

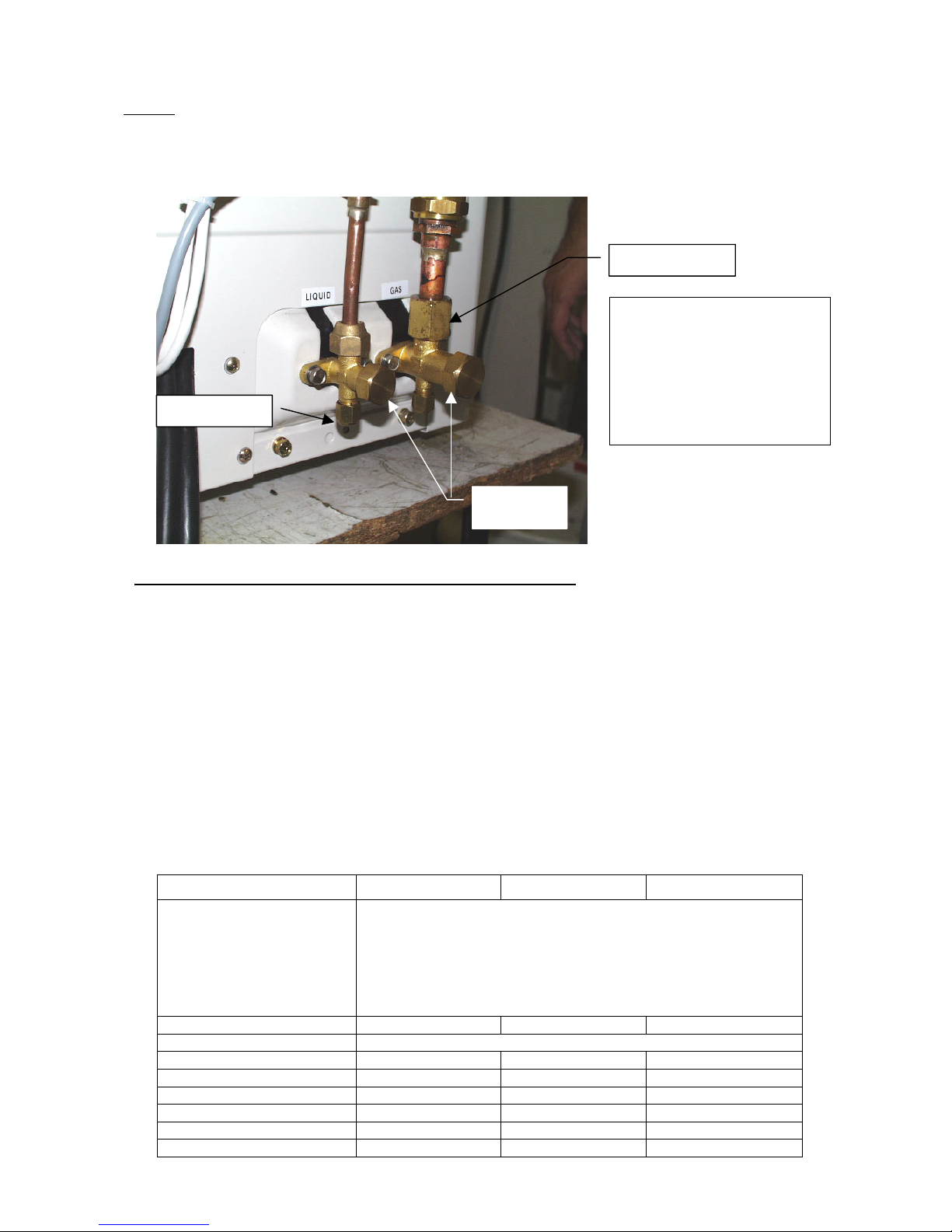

Step 7:

When the cooling system connection has been completed*, open the valves (#) for the suction and liquid

pipes at the outdoor unit. (Remove caps, open valves, screw caps back into place.)

All connections must be tested for leaks before first use!

* Note on assembly where ready-to-use split pipes are not used

If you use your own copper split pipes, you must ensure that they are the right size. The rules for the safe

handling of refrigerants apply here as well.

To make the connections (pipes for liquid and gas), remove the cap nuts on the valves of the outdoor unit and

the halves of the couplings of the indoor unit, and place them on the appropriate copper pipe (it may be

necessary to slightly enlarge the internal diameter of the nut caps). Crimp the ends of the pipes to the correct

size at the correct angle. (Note: For safety reasons, when Cu pipes of ≤ © 6 mm are used in cooling systems,

only mechanically crimped pipes are permissible.)

A filling and evacuating device (e.g. a Schrader valve) must be installed in at least one pipe in order to

evacuate the split pipes (and the interior of the device). The split pipes should then be properly insulated,

correctly laid and connected firmly in their original positions using the nut caps (see the Notes on Torque

above). Do not open the valves of the outdoor unit yet!

The split pipes and the indoor unit are then to be evacuated correctly using the filling and evacuating device

and then filled with refrigerant (depending on the device and the length of the split pipes – see table; the

longer the split pipes, the lower the effective cooling capacity – see table). The valves on the outdoor unit can

now be opened (see description above).

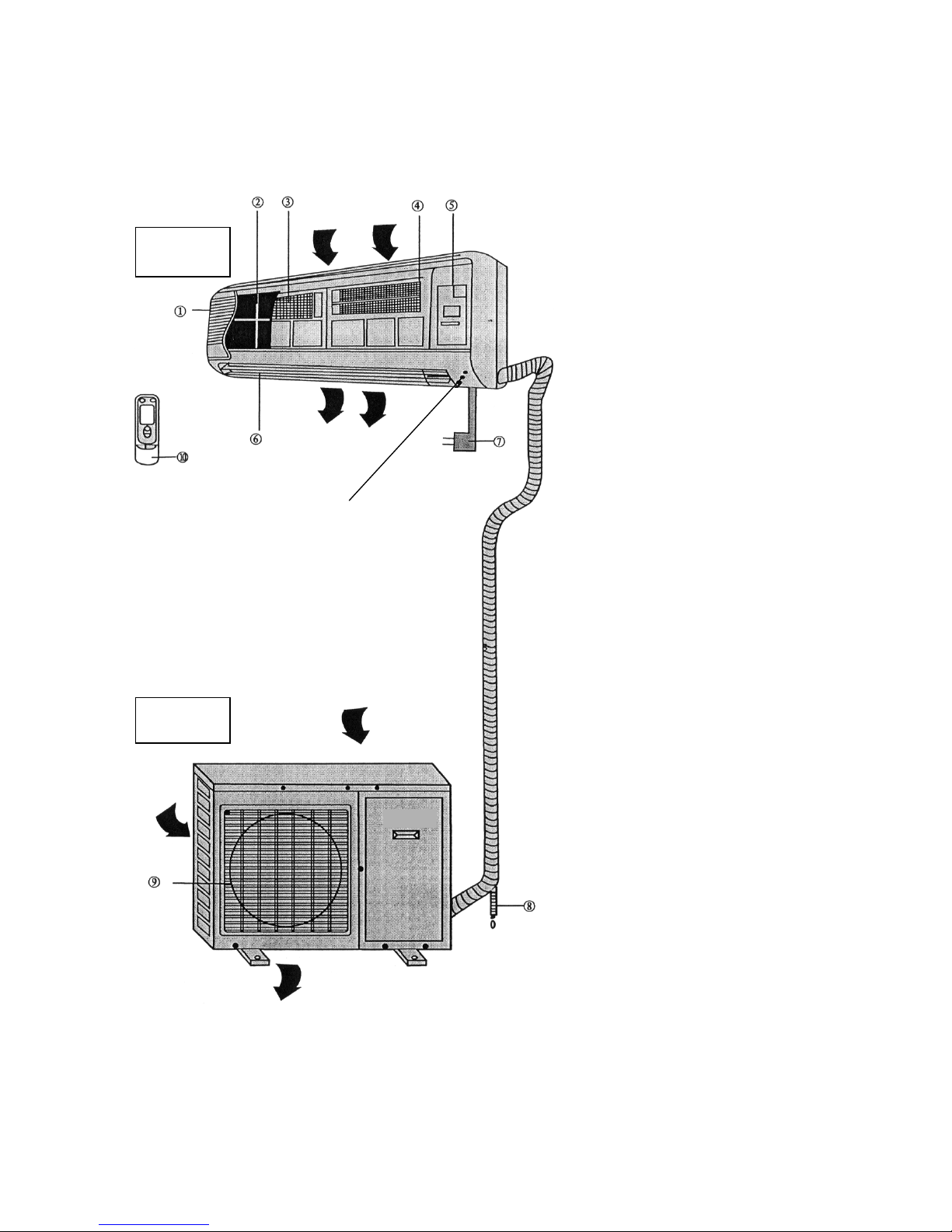

Device type KSS 2504 / 3204 KSS 4504 KSS 6004

Length of split pipe (m)

Quantity of refrigerant R410A / R407C (g per metre of split pipe)

Refrigerant to be added as of a total split pipe length of 5m

As of 5 m (length of split pipe)

20 g/m

R410A 40 g/m R410A 40 g/m R410A

Cooling capacity (in %) depending on length of split pipe

4 100 100 100

7 99 96 97

10 97 94 95

12 95 93 94

16 91 89 90

Max. length of pipe 20 87 87 87

Caps /

valves

(#

)

Cap nut

The valves (#) are opened by

turning the valve inserts with a

6-KT spanner (approx. 5 turns

up to the limit; a short, audible

hissing indicates that the valve

has been opened).

Service valve

Page 17

17

Electrical Connection

The room air conditioners are designed for

operation with 230 V AC. The electrical safety of

the device is ensured only if it is properly grounded

in compliance with current electrical safety

regulations. The local utility company’s technical

connection conditions must be observed. The

current circuit must be protected by a separate

fuse. See Technical Data for electrical protection.

The room air conditioner may only be connected or

repaired by an electrician or refrigeration technician

approved by the utility company responsible. Poorly

carried out repairs can endanger the safety of the

user.

This product complies with the valid safety

regulations for electrical devices.

Supply connection

Supply connection is to the indoor unit. The indoor

unit has a mains power connection which may have

to be extended.

Connecting the indoor and outdoor units

The indoor and outdoor units are connected by the

control line and mains cable (must be connected to

both units) provided with the device. (See also

Technical Data.)

Connecting the mains cable:

Open the plastic cover (ventilation grid) of the

indoor unit and remove the cover of the electrical

connection. Pull the mains cable from the back of

the indoor unit to the electrical connections and

connect it as shown in the circuit diagram.

At the outdoor unit, remove the side cover (KSS

2504A and 3204A) or front cover (KSS 4504C and

KSS 6004C) – the main cable is led in from the side

here too, through the rectangular opening – (using

the rectangular cable feed-through enclosed) – and

connect the mains cable according to the circuit

diagram.

Connecting the control line:

Connect the cable to the plugs in the outdoor and

indoor units.

Use the clamps provided to relieve the strain on

all cables!

KSS 2504 und KSS 3504

Outdoor component

KSS 4504

KSS 6004

Outdoor component

Cable entry

Indoor component

Cover

Mains cable to outdoor unit

Mains cable to indoor unit

Connection for Main cable indoor/

control line outdoor component

Page 18

18

Start-Up – Function Test

Start-Up

Before switching on the power supply or making a test run, check whether:

1. All electrical connections are present and have been installed properly according to the circuit diagram

(permanent screw connections and plug connections, ground, fuses).

2. The indoor and outdoor units have been installed in a secure and vibration-proof way.

3. The split pipes have been laid correctly, maximum length has not been exceeded, they are fastened with

sufficient torque, their insulation is undamaged and the couplings have been insulated.

4. The search for refrigerant leaks has been carried out with no positive results.

5. All installation residues or dirt have been removed from both parts of the device and any air vents covers

have been removed.

6. The refrigerant shutoff valves (see also Step 8 in the section “Pre-filled refrigerant pipes KMSL…”) on the

outdoor unit have been opened.

7. The air filter and the condensation drainage pipe have been properly installed.

8. Charged batteries of the size specified have been inserted correctly into the remote control.

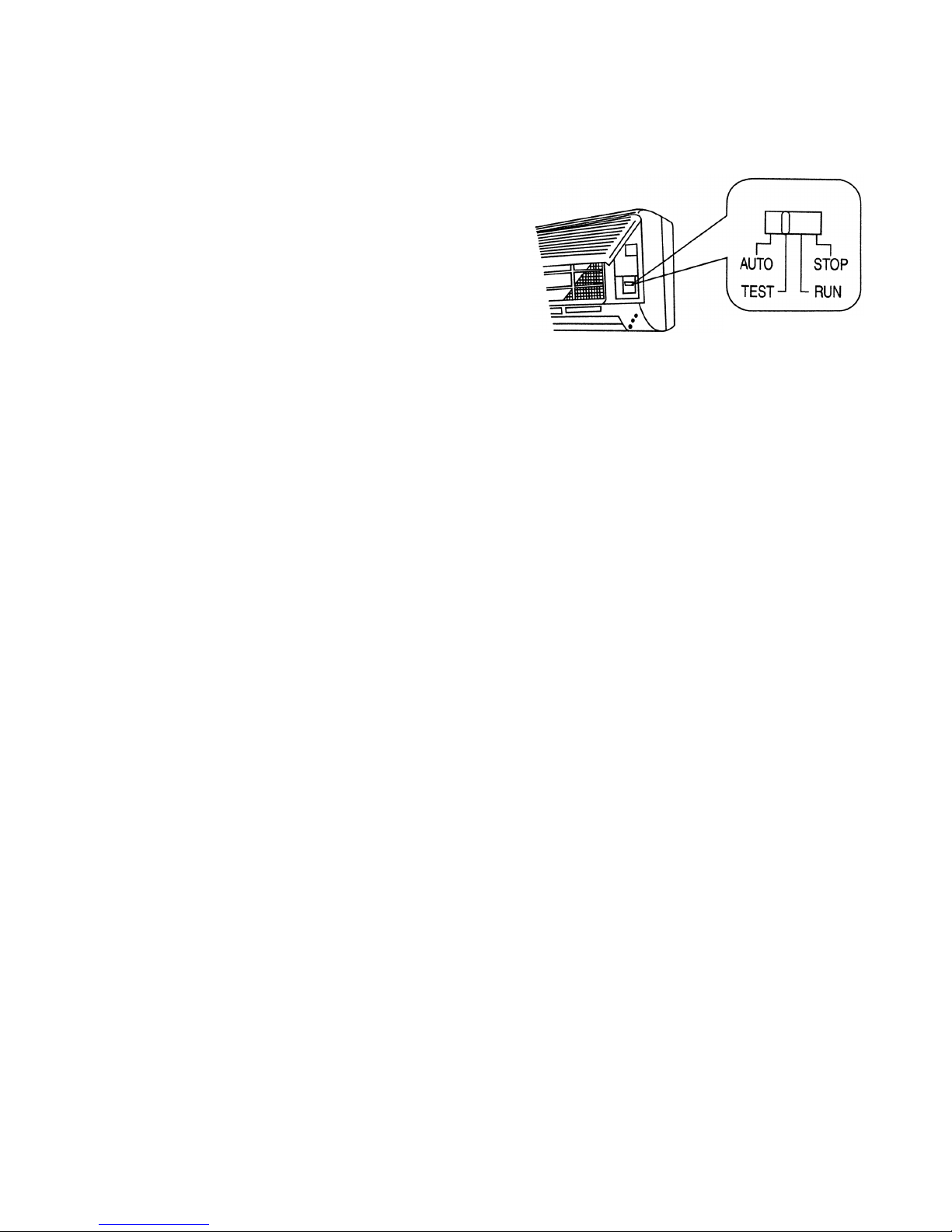

9. The manual “AUTO/STOP” switch is set to the “RUN” position.

Function test

Connect the device to the power supply and then operate the “ON/OFF” switch of the remote control

the device should now switch on (usually in “AUTO operation” or in the operation mode set previously

using the remote control).

Using the remote control, test all operating modes (cooling, air recirculation, heating, dehumidifying) as

far as ambient temperatures (remember operating limits) will allow. Please note when switching from one

mode of operation to another that certain start-up times or pauses are functionally necessary.

If the device cannot be switched on using the remote control

Switch the “AUTO/STOP“ sliding switch on the indoor unit (first open the air inlet grid) to the AUTO

setting the device should now switch to a mode of operation selected automatically (by the device)

depending on ambient temperature and it should be possible to make other settings using the remote

control. If this is not the case, please contact your after-sales service. The modes of operation can also

be tested in the “TEST” position; if used, this setting should be changed after test operation and the

sliding switch should be set to AUTO. (Permanent operation in the TEST setting leads to malfunctions!)

If the device starts up automatically when switched on and cannot be controlled using the remote

control

Set the AUTO/STOP switch on the indoor unit to “STOP”. The device switches off. Then set the sliding

switch to “AUTO” or “RUN” again. It should now be possible to set the device using the remote control; if

this is not the case, please contact your after-sales service.

“AUTO/STOP” switch

Page 19

19

Refrigeration Plan

Capillaries

Collector

Damper

Compressor

Evaporator

Coupling

4-way valve

Condenser

Filter drier

Filter drier

Coupling

Page 20

20

Circuit Diagrams

Stromlauf

p

lan KSS 3204 Circuit diagram KSS 2504

Page 21

21

Circuit diagram KSS 3204

Page 22

22

Circuit diagram KSS 4504 – outdoor unit Circuit diagram KSS 6004 – outdoor

unit

Circuit diagram KSS 4504 / 6004 – indoor unit

Indoor unit

Indoor unit

Outdoor unit

Page 23

23

Important Notes on Operation

The room air conditioner may not be used for any

purpose other than room cooling, heating or

dehumidification or air circulation (fan).

Heating operation

The device operates with heat pump switching.

Heat is extracted from the outside air, then led to

the indoor unit and given off in the room to be

heated.

Heat output reduces as the temperature of the

outside air falls.

If the device is not providing sufficient heat for the

room, we recommend operating it in combination

with another heater.

Heat pump air conditioners circulate the warm air

in order to heat the entire room. It therefore takes

some time until the entire room is warm (also

depends on the external temperature and the

heating requirement).

Automatic de-icing

When external temperatures are low and air

humidity is high, heating operation can cause the

formation of ice on the outdoor unit which reduces

the heat output. In this case, the device switches

automatically to the “De-frost” operating mode for

10 – 15 minutes, heating is interrupted and the

fans cease to operate.

An LED on the indoor unit blinks while the device

is in “De-frost” mode.

When room and external temperatures are too

high

When, in heating operation, both room and

external temperatures are too high, the fan of the

outdoor unit may switch off periodically (protective

function).

Power cuts

After a power cut the devices commence

operation again in the operating mode last set

(with the temperature setting last stored). This

occurs in cooling and dehumidifying mode with

the normal delay at start (approx. 3 min.); in

heating operation this restart phase can last up to

17 minutes. The settings of the air flow fins

(SWING) can be lost through the power cut.

Permissible temperature and humidity

ranges

In the external temperature range

device R 407 C: from approx. 0 °C to +43 °C

device R410 A: from approx. -5 °C to +43 °C

Outdoor humidity:

approx. 40 to 80 %

Room temperature range:

device R 407 C: from approx. +16 °C to

+30 °C

device R 410 A: from approx. +16 °C to

+30 °C

Cooling

Room humidity:

approx. 40 to 80 %

If the device is exposed to high humidity

over a long period, condensation may

form and drip down.

External temperature:

approx. 20 °C to 43 °C

Outdoor humidity:

approx. 40 to 80 %

Room temperature range:

approx. 20 °C to 30 °C

Dehumidification

Room humidity:

approx. 40 to 80 %

If the device is exposed to high humidity

over a long period, condensation may

form and drip down.

In the external temperature range

device R 407 C: from approx. -7 °C to +43 °C

device R410 A: from approx. -7 °C to +43 °C

Outdoor humidity:

approx. 40 to 80 %

Room temperature range:

device R 407 C: from approx. +16 °C to

+30 °C

device R 410 A: from approx. +16 °C to

+30 °C

Heating

Room humidity:

approx. 40 to 80 %

If the device is exposed to high humidity

over a long period, condensation may

form and drip down.

If the device is exposed to higher temperatures than

those specified here, the automatic safety

mechanism may be triggered and operation may be

interrupted.

If the device is exposed to lower temperatures than

those specified here, ice may form on the heat

exchanger, which can cause water (condensation) to

run out and lead to other functional defects.

General notes on efficient operation:

- Windows and doors should not be kept open during air conditioning!

- Select the air direction best suited to your purpose (down for heating, up for cooling)!

- When cooling, the room temperature selected should not be more that 5 °C below the external temperature!

Page 24

24

Direction of Air Flow

Up – down air flow

The direction of the air flow of the air conditioner

switches constantly from up to down (swing

operation).

Swing operation can be turned on and off using

the SWING switch.

The air flow can also be set to one direction.

Note:

When the device is switched off and then on

again, swing operation is selected automatically.

Left – right air flow

Horizontal airflow must be set manually.

Note:

In operating modes cooling and dehumidifying,

condensation can form on the airflow fins turned

to the right or left and may possibly drip down. In

this case, these settings should be used for a

short time only.

Special care must be taken with air conditioning

for certain groups of persons, such as babies,

toddlers, old or sick persons in order to avoid any

danger to health.

Cleaning and Maintenance

The device must be disconnected from the mains

and allowed to cool down before cleaning and

maintenance. Clean the surfaces of the casings

with a soft damp cloth and then dry them. No

scouring agents or polishes should be used.

Cleaning the air filters

Soiled filters reduce the airflow and thus the

efficiency of the device. Soiled filters can also

cause noise. The two filters should be checked at

the beginning of the heating period and cleaned or

changed as necessary. When the room air

conditioner is used regularly, the filters should be

cleaned at least once a month (the degree of

soiling is dependent to a large extent on the place

of use).

Take hold of the front cover of the indoor unit on

both sides and flap it up until it clicks into an open

position.

Press the filter up slightly, lift it up and remove it

completely.

Clean the air filter with a vacuum cleaner.

If the filters are very soiled, they can also be

cleaned with a neutral cleaning solution

(lukewarm water). The air filter must be dried

before it is reinserted.

It should then be reinserted the right way round

and the front cover should be closed (reverse

order from removal).

Optional filter elements (2 x approx. 300 x 50 mm

antibacterial filter inserts) are not enclosed with

the devices; they are available on request only.

Page 25

Remote Control

Battery for Remote Control

Remove the cover of the battery compartment.

Insert two 1.5 V batteries (type AAA), making sure that the polarity is correct! The polarity (+/-) is marked in

the compartment. If no display appears after the batteries are inserted correctly or pressing the buttons of

the remote control has no effect, please follow the instructions given in Section Start-Up / Function Test.

Note: - Use only charged batteries of the same type.

- Spent batteries must be removed, they can damage the remote control.

- Do not keep the remote control in the direct proximity of a TV set or other electrical

appliances.

- Remove the batteries if the remote control is out of use for a longer period.

Page 26

26

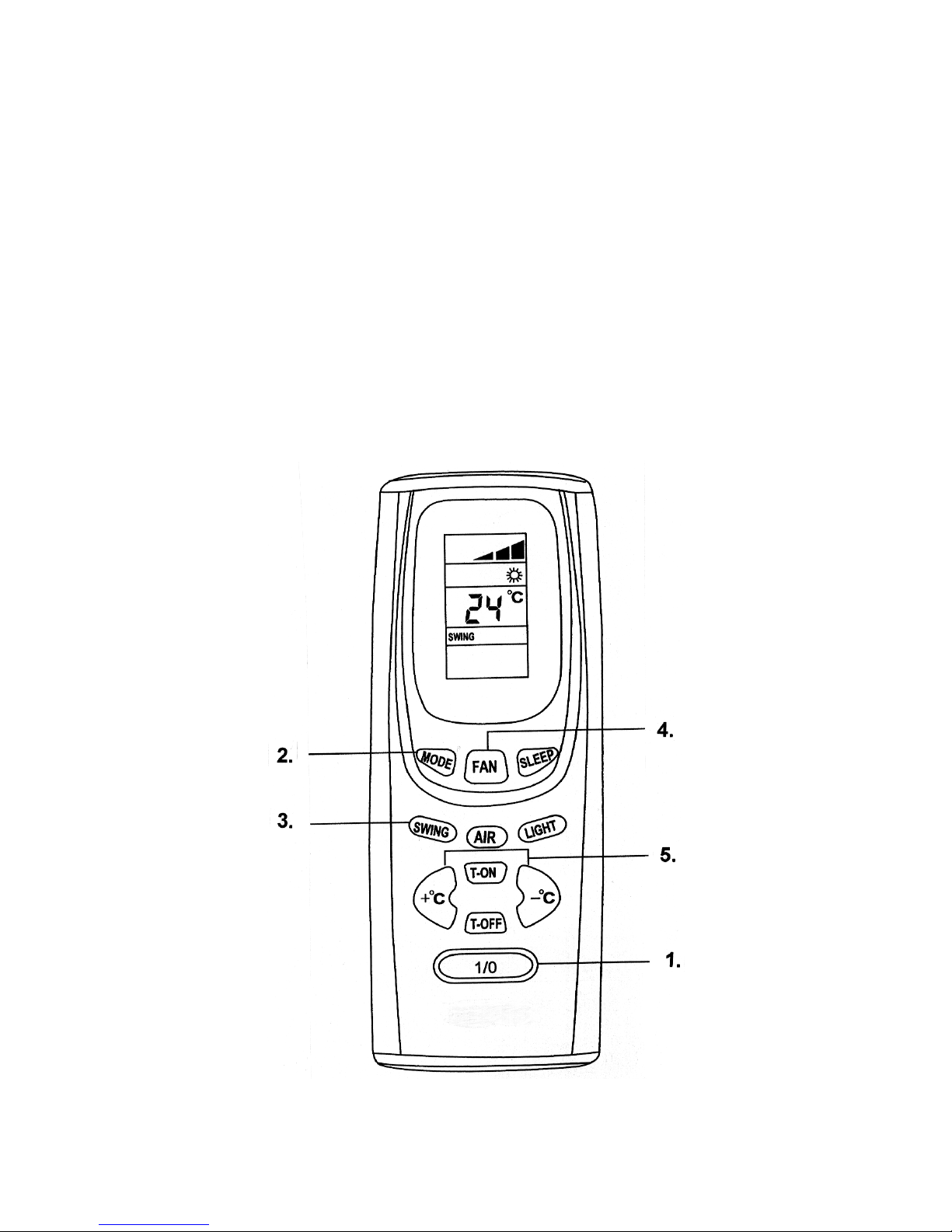

Functions of Remote Controls KSS 2504 / 3204 / 4504 / 6004

Remote control function keys

1. SWING key

Sets the desired air outflow direction,

automatic operation

2. FAN key

Sets fan speed

3. +°C / -°C key

Sets the desired room temperature

4. MODE key

Selects the operating mode of the room air

conditioner:

Automatic – Cooling – Dehumidifying –

Recirculating air – Heating

5. 1 / 0 key, also ON / OFF

Switches the device on and off

6. Operating display

Displays the various operating modes

7. SLEEP key

Sleep mode

8. TIMER ON key

Calls up timer settings (On)

9. TIMER OFF key

Calls up timer settings (Off)

Remote control displays

10. AUTO display, automatic fan control

11. Fan speed display (1-3 manual)

12. Operating mode display, heating

13. Operating mode display, recirculating air

14. Operating mode display, dehumidification

15. Display, cooling

16. Display of temperature setting

17. Display of timer setting

18. Display of automatic operation

19. Display, SLEEP function set

20. Display, SWING operation

Note: On this universal remote control the

keys for which no description is given

have no function, pressing them has

no effect on the functioning of the

device (even if a message appears in

the display). The remote control

shown here may be different from the

one supplied with your device. The

functions of the keys are the same,

however.

18

19

20

Page 27

27

Cooling

If the room temperature is higher than the temperature setting in the display, cooling is activated; if the room

temperature is lower than the value set, cooling is terminated. The fan function (without active cooling) of the

indoor unit remains in operation.

A temperature between 16 °C and 30 °C can be selected.

1. Press the 1 / 0 key.

2. Select “Cooling” with the MODE key.

3. Set the airflow fins (they determine the outflow direction of the air) by pressing the SWING key.

4. Fan speed (air volume) is set by pressing the FAN key (fan speed (air volume) is regulated

automatically in Autofan mode).

5. Set the desired temperature using the +/- (or +°C / -°C) keys.

Page 28

28

Heating

If the room temperature is lower than the temperature set in the display, heating is activated. If the room

temperature is higher than the value set, heating operation terminates; the passive air recirculation of the

room unit remains in operation for about a minute; the direction of the air outflow fins may change.

A temperature between 16 °C and 30 °C can be selected.

1. Press the 1 / 0 key.

2. Select “Heating” with the MODE key.

3. Set the airflow fins (they determine the outflow direction of the air) by pressing the SWING key.

4. Fan speed (air volume) is set by pressing the FAN key (fan speed (air volume) is regulated

automatically in Autofan mode).

5. Set the desired temperatures using the +/- (or +°C / -°C) keys.

Page 29

29

Dehumidification

If the room temperature falls to more than 2 °C below the value set, the fan in the indoor and outdoor

compartments stops. At room temperatures of ± 2 °C above or below the temperature set, the device

switches to dehumidification mode. If room temperature rises to more than 2 °C above the temperature set,

the device switches to cooling mode.

A temperature between 16 °C and 30 °C can be selected. In dehumidification mode the device operates on

AUTOFAN.

1. Press the 1 / 0 key.

2. Select “Dehumidification” with the MODE key.

3. Set the airflow fins (they determine the outflow direction of the air) by pressing the SWING key.

4. Set the desired temperatures using the +/- (or +°C / -°C) keys.

Page 30

30

Auto

In Auto mode, the air conditioner operates with pre-set, fixed temperatures for the cooling and heating

modes. At room temperatures over 25 °C, the device switches to cooling operation, and at room

temperatures below 20 °C, it switches to heating operation.

Depending on room temperature and humidity, the device may switch periodically in Auto mode to

dehumidification for more effective process control.

1. Press the 1 / 0 key.

2. Select “AUTO” with the MODE key.

3. Fan speed (air volume) is set by pressing the FAN key (fan speed (air volume) is regulated

automatically in Autofan mode).

4. Set the airflow fins (they determine the outflow direction of the air) by pressing the SWING key.

4.

Page 31

31

Timer Function

Timer On: This function should*

1

be programmed only when the device is non-operational.

Pressing the key once sets a period of 30 minutes until the device switches on (in the mode currently

programmed). Every further press of the key extends the time before the device is switched on by a further

30 min. up to a maximum of 24 h before automatic switch-on.

Timer Out: This function can

be programmed only when the device is in operation.

Pressing the key once sets an interval of 30 min. until the device switches itself off. Every

further press of the key extends the time before the device is switched off by a further 30 min.

up to a maximum of 24 h before automatic switch-off.

Note: It is not possible to change any settings during operation started by the timer; to make changes

the device must be switched off and then on again.

an

(*1 An operational device will be switched off by this command and switched on again after the programmed delay)

Timer On

Timer Off

Page 32

32

Sleep Function

Depending on the operating mode, pressing the SLEEP key changes the temperature set by 1 °C every hour for

a maximum of two hours (i.e. a maximum of 2 °C in 2 h), starting at the time the key was pressed. In cooling

and dehumidification modes, the temperature is increased, and in heating mode, the temperature is lowered.

Pressing the SLEEP key again switches this mode off.

1. Press 1 / 0 (if the device is switched off).

2. Select the function Cooling, Dehumidification or Heating.

3. Set airflow direction by pressing the SWING key.

4. Set fan speed (air volume) by pressing the FAN key.

5. Set the desired temperatures using the +/- (or +°C / -°C) keys.

6. Press the SLEEP key.

Page 33

33

Faults

If a fault occurs (e.g. inadequate performance, smoke formation, unusual smell, loud noise, frequent cut-outs,

electrical connections overheating), the air conditioner should be switched off and disconnected immediately

(switch off the circuit breaker in the distribution cabinet, or pull out the plug).

Contact the after-sales service.

Before you contact the after-sales service, however, please use the list below to check whether this could

be a normal occurrence or a fault you can remedy yourself.

Type of fault Possible causes

Device does not switch on

immediately

If the device is switched off and then on again immediately, a

safety function prevents it operating for about 3 minutes

(compressor safety function).

If the device is disconnected from the power supply and then

connected again immediately, a safety function prevents it

operating for about 3 minutes (compressor safety function).

A delay of up to 17 minutes can occur before the heating function

starts or warm air begins to circulate (e.g. when the operating

mode is changed or there is a power cut when in heating mode).

Noises Noises caused by the flow of the refrigerant through the pipes can

sometimes be heard during operation. These noises tend to occur

particularly during the first two to three minutes after switching on

or off.

Temperature fluctuations cause expansion and contraction, which

can also produce noises.

Smells The air emitted by the indoor unit may carry various smells already

present in the room (e.g. cooking smells, tobacco, new furniture,

etc.). Because the air-conditioned air is emitted at a higher speed,

the smells can be perceived as more intensive.

Emission of steam or vapour Slight vapour formation may be visible at the device during cooling

or dehumidification. This is the result of the sudden cooling of the

air in the room and soon disappears.

Device is not working Is it connected to the mains power supply?

Has a fuse blown?

Have the operating limits been exceeded?

Has there been a power cut?

Are the batteries in the remote control flat?

It is not possible to change the

settings (during operation)

The device was activated using the TIMER function, to make

changes, switch it off and then on again.

Inadequate cooling or heating Do the air filters need cleaning?

Are the device’s inlet and outlet vents covered or clogged with dirt?

Have additional sources of heat been switched on? (Cooling mode

only.)

Are the room temperature settings appropriate?

Are doors and windows open in the room to be cooled / heated?

Has the fan been set to maximum speed (air volume)?

Are there large areas of glass (windows) which are letting in direct

sunshine (draw curtains)? (Cooling mode only.)

Page 34

34

Energy Efficiency

Energy Room air conditioner

Manufacturer: Dimplex Dimplex Dimplex Dimplex

Outdoor unit

KSS 2504A A KSS 3204A A KSS 4504C A KSS 6004C A

Indoor unit

KSS 2504A I KSS 3204A I KSS 4504C I KSS 6004C I

Low energy consumption

High energy consumption

Annual energy consumption 395 545 875 1150

kWh in cooling mode

(Actual consumption depends on

usage of the device and cooling

conditions)

Cooling capacity kW 2.50 3.20 4.50 6.00

Energy efficiency value 3.20 3.00 2.57 2.60

At full load (the higher the better)

Type Cooling function only -

Cooling function /

heating function - Yes Yes Yes Yes

Air cooling - Yes Yes Yes Yes

Water cooling -

Heat output kW 2.80 3.50 5.20 6.50

Energy efficiency class D D D D

of heating function

A: low energy consumption G: high energy consumption

Noise

dB(A) re 1 pW

The brochures include a data sheet

with further information on the devices

Standard EN 14511

Room air conditioner

Energy Labelling Directive 200/31/EC

A

D

Data for

KSS 3204

Data for

KSS 4504

Data for

KSS 6004

Data for

KSS 25204

Page 35

35

Warranty

Authorised dealers can provide information on the terms and conditions of warranty. The warranty is not valid

without a sales receipt marked with the date of purchase.

Disposal notice

The product must not be disposed of with your other household waste

Page 36

36

Glen Dimplex Deutschland GmbH Phone: +49 (0) 9221 709 562 Subject to technical modifications

Am Goldenen Feld 18 Fax: +49 (0) 9221 709 565

D-95326 Kulmbach E-Mail: kundendienst.system@dimplex.de

Germany Internet: www.dimplex.de

Loading...

Loading...