Dimplex Ec-eau, Ec-eau 125, Ec-eau 150, Ec-eau 210, Ec-eau 250 Installation And User Instructions Manual

...Page 1

Important - This manual must be left with the user after Installation!

Ec

-

eau

Cylinder

Range

Installation and User Instructions

Heat Pump Cylinders

without buffer tanks

Up to 300L

Page 2

HP Installation and User Instructions R00918

-

1 03/11

Page 2

Dimplex is a licensed member of the Benchmark Scheme which aims to

improve the standards of installation and commissioning of domestic heating

and hot water systems in the UK and to encourage regular servicing to optimise

safety, efficiency and performance.

Benchmark places responsibilities on both manufacturers and installers. The

purpose is to ensure that customers are provided with the correct equipment

for their needs, that it is installed, commissioned and serviced in accordance

with the manufacturer’s instructions by competent persons and that it meets

the requirements of the appropriate Building Regulations. The Benchmark

Checklist can be used to demonstrate compliance with Building Regulations and

should be provided to the customer for future reference.

Installers are required to carry out installation, commissioning and servicing

work in accordance with the Benchmark Code of Practice which is available

from the Heating and Hot Water Industry Council who manage and promote the

Scheme. Visit www.centralheating.co.uk for more information.

Page 3

HP Installation and User Instructions R00918

-

1 03/11

Page 3

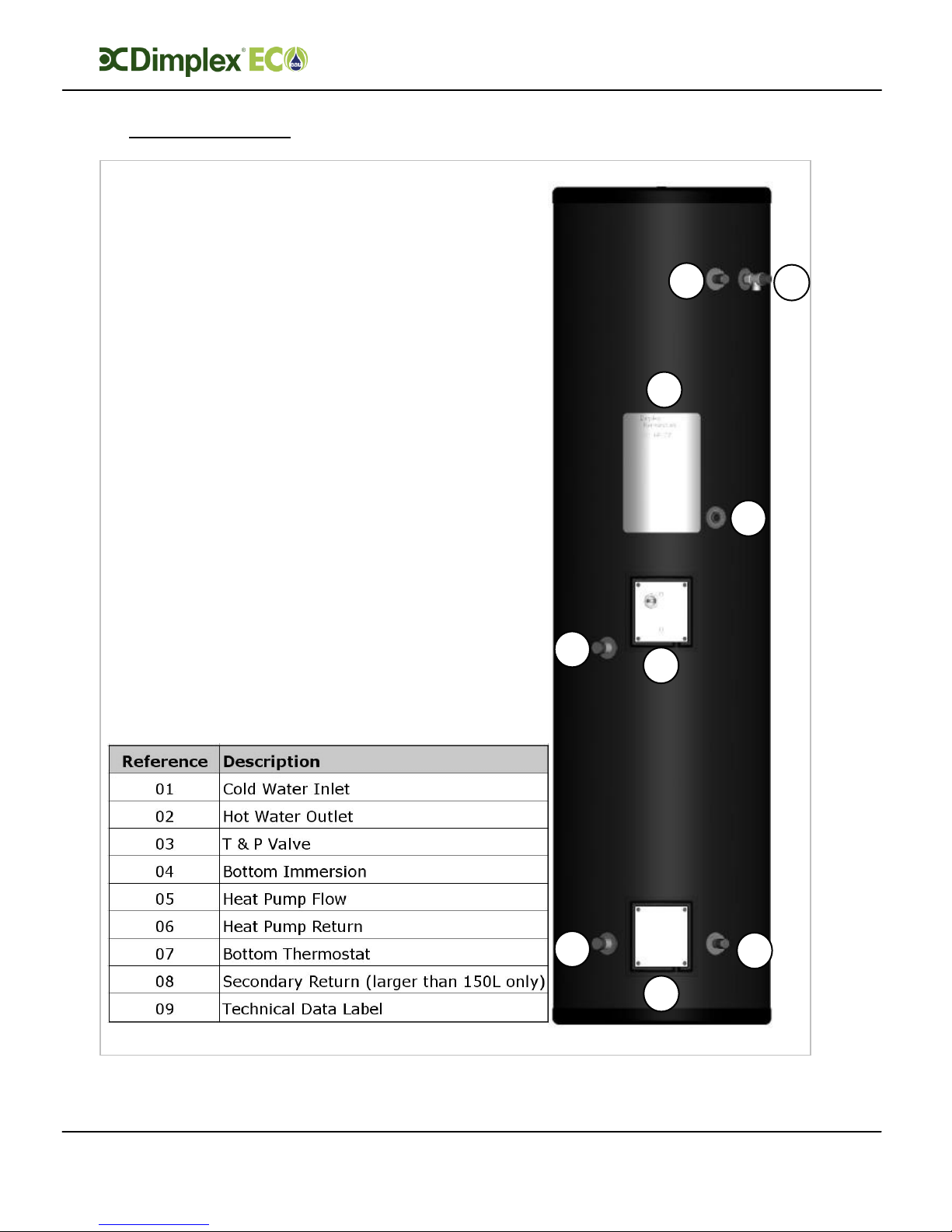

Overall View

0 Overall View

Figure 1: Overall view of Heat Pump Cylinder installation process

02 03

08

01 06

04

07

05

09

Page 4

HP Installation and User Instructions R00918

-

1 03/11

Page 4

Contents

1 Contents

0 OVERALL VIEW .......................................................................................... 3

1 CONTENTS ................................................................................................ 4

2 INTRODUCTION ......................................................................................... 6

3 SCOPE OF DELIVERY .................................................................................. 6

4 PRE-INSTALLATION ADVICE ........................................................................ 7

4.1 R

ISK ASSESSMENT

...................................................................................... 7

4.2 S

ITING CONSIDERATIONS

.............................................................................. 7

4.3 C

OLD WATER SUPPLY

................................................................................... 8

4.4 B

UILDING REGULATION G3 DISCHARGE REQUIREMENTS

.......................................... 8

4.4.1 Discharge pipe D2 ......................................................................... 9

4.4.2 Worked example ..........................................................................10

4.4.3 Termination of discharge pipe ........................................................11

4.5 L

IMITATIONS

............................................................................................11

5 INSTALLATION..........................................................................................12

5.1 C

OLD WATER INLET WITH INLET CONTROL GROUP

...............................................12

5.1.1 Correctly site the cylinder..............................................................12

5.1.2 Install the inlet group....................................................................12

5.1.3 Expansion vessel ..........................................................................12

5.1.4 Balanced cold water supply............................................................12

5.1.5 Drain valve ..................................................................................12

5.2 H

OT WATER OUTLET

..................................................................................13

5.2.1 Thermostatic mixing valve.............................................................13

5.2.2 Pipe insulation..............................................................................13

5.3 D

ISCHARGE PIPES FROM SAFETY DEVICES

..........................................................13

5.3.1 Discharge pipe D1............................................................................13

5.3.2 Discharge pipe D2 ........................................................................13

5.3.3 Tundish .......................................................................................14

5.4 I

MMERSION HEATER

....................................................................................14

5.5 C

OIL FLOW CONNECTIONS

............................................................................15

5.6 C

OIL RETURN CONNECTIONS

.........................................................................15

5.7 T

HERMOSTAT CONNECTION AND INSTALLATION OF THE HEAT PUMP

DHW

TEMPERATURE

SENSOR

..................................................................................................16

5.7.1 Connection of the sensor ...............................................................17

5.8 C

ONNECTION OF SECONDARY RETURN

..............................................................20

6 COMMISSIONING......................................................................................21

7 MAINTENANCE..........................................................................................22

8 SPARE PARTS ...........................................................................................23

9 TECHNICAL DATA......................................................................................24

9.1 C

YLINDER HEAT EXCHANGER PRESSURE DROP

.....................................................26

Page 5

HP Installation and User Instructions R00918

-

1 03/11

Page 5

Contents

10 USER INSTRUCTIONS ................................................................................28

10.1 G

ENERAL

.............................................................................................28

10.2 O

PERATION

..........................................................................................29

10.2.1 Water temperature direct electric heating........................................29

10.2.2 Water temperature auxiliary heating ...............................................30

10.3 M

AINTENANCE

.......................................................................................30

10.4 T

ROUBLESHOOTING

.................................................................................31

Page 6

HP Installation and User Instructions R00918

-

1 03/11

Page 6

Scope of Delivery

2 Introduction

Thank you for choosing a Dimplex

product. The EC-Eau heat pump

cylinders are specified with large, high

surface area heat exchangers,

specifically sized to match the

requirements of Dimplex heat pumps.

They boast 60mm of low GWP

insulation foam, together with 100%

recyclable stainless steel inner

components and a sleek black, hard

wearing outer shell manufactured

from completely recycled materials.

For more detailed information on

product features, please see the

Technical Data section in this manual.

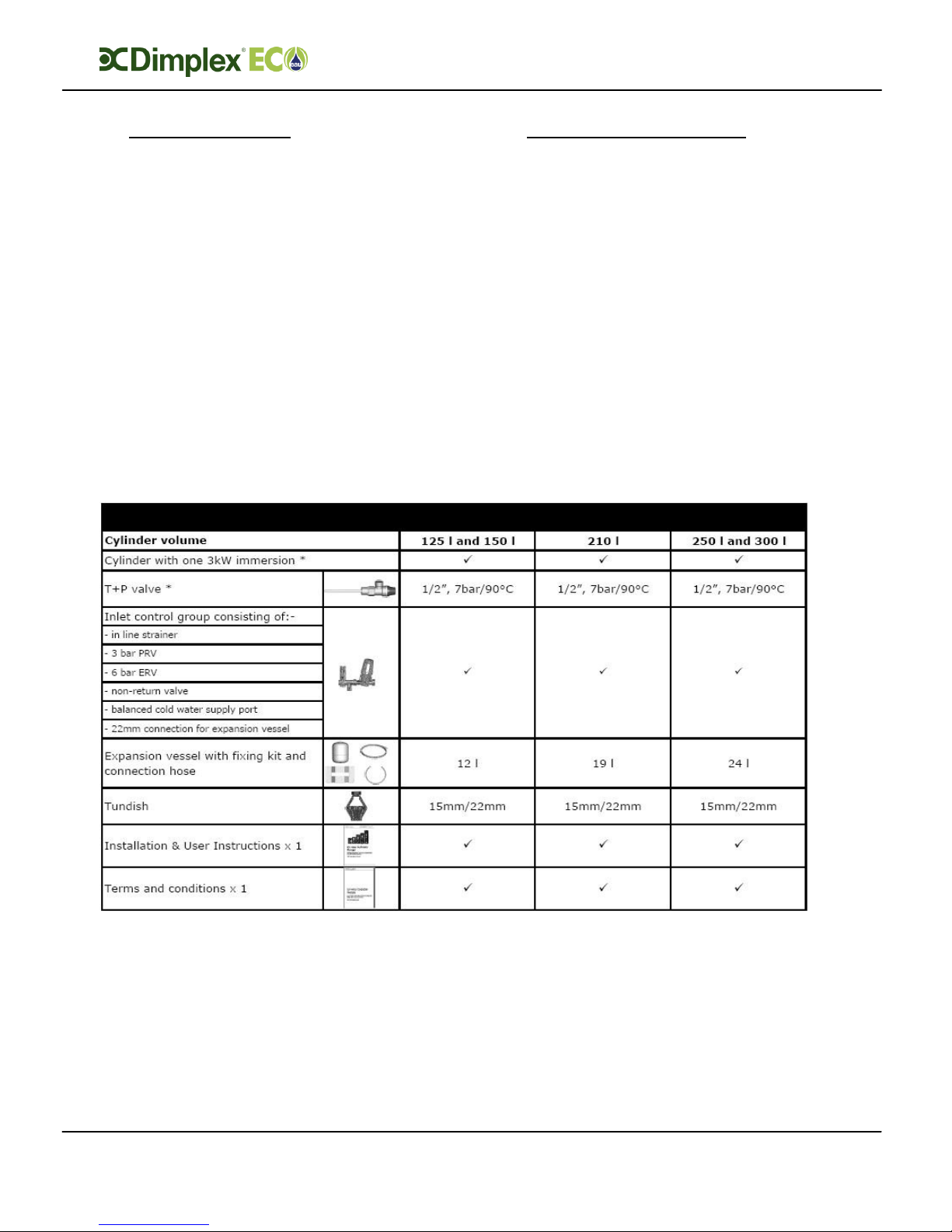

3 Scope of delivery

Please ensure you check the scope of

delivery below before signing any

delivery documentation. Claims for

missing or damaged parts after

signing for the delivery will not be

accepted.

* These items are supplied factory fitted

Table 1: Scope of Delivery

Page 7

HP Installation and User Instructions R00918

-

1 03/11

Page 7

Pre

-

Installation

4 Pre-Installation

Advice

Please read the following section

carefully before commencing

installation. If in any doubt, please

call the appropriate help desk.

Disregarding the instructions given in

this manual in its entirety and any

relevant regulations, standards and

codes of practice will void the

guarantee of this product.

Handling – depending on the size of

the unit and access to its installation

location, consideration must be given

to the handling of the unit. Please

note that handling, installation and

use of this product is subject to the

Health and Safety at Work Act.

If the unit is not installed

immediately, it should remain in its

protective packaging with all pipe

protectors/end caps applied to

prevent damage and dirt deposit

inside the cylinder and the coils.

Pipe work – the pipe runs should be

executed as short as possible, unused

pipe work should be removed and all

remaining pipe work should be lagged

in accordance with regulatory

requirements to prevent heat loss and

the formation of condensation.

Taps and fittings – all taps and

fittings incorporated in the unvented

system should have a rated operating

pressure of 0.6 MPa (6 bar) or above.

4.1 Risk assessment

The compilation of a risk assessment

is strongly recommended before

installing the product. The following

areas require particular consideration

in addition to the information required

by the Health and Safety at Work Act.

- scalding: where appropriate or

required by law a thermostatic

mixing valve is to be fitted to the

hot water outlet of the cylinder (see

also water borne organisms).

- explosion: the unit is fully equipped

with all relevant safety equipment

to comply with current regulations.

The correct design and function has

been verified by independent third

party testing. The correct

application thereof is the

responsibility of the competent

installer.

- water borne organisms (i.e.

Legionella): if applicable a risk

assessment should be carried out

following the recommendations

outlined in the Approved Code of

Practice L8.

- the user preference must be

considered when commissioning the

system, in particular when adjusting

the solar and auxiliary system

temperature and timer settings.

4.2 Siting considerations

When choosing a suitable location for

the cylinder the following aspects

should be considered:

- structural integrity

- access for installation, operation,

maintenance and replacement

- routing of discharge pipe work

- access to water mains supply, hot

and cold water distribution pipe

work

- access to suitable electricity supply

Page 8

HP Installation and User Instructions R00918

-

1 03/11

Page 8

Pre

-

Installation

- location in relation to remaining

system components such as

auxiliary and solar heating system

- frost protection

The heat pump cylinder range is

designed to be floor standing,

vertically mounted, indoors and in a

frost free environment. The cylinder

may be located on any flat and level

surface, provided it is sufficiently

robust to support the weight of the

cylinder when full of water (please see

technical data) and suitably accessible

for replacement/maintenance without

specialist tools or lifting equipment as

this will void the warranty conditions.

The position and orientation of the

cylinder should be such that easy

access is provided for servicing the

controls. A minimum distance of

400mm in front of the immersion is

recommended, to allow the

replacement of the immersion heater

should the need arise. When installing

the cylinder all labels should be clearly

visible and ensure that no pipework

hinders any work to be carried out on

the various cylinder components.

Particular care must be taken when

placing the cylinder in a garage or

outbuilding. All exposed pipe work

must be correctly insulated to avoid

frost damage.

4.3 Cold water supply

For satisfactory and safe performance

of the unvented cylinder the water

supply must meet the following

criteria:

Minimum dynamic

pressure

150 kPa

(1.5 bar)

Maximum inlet supply

pressure

1200 kPa

(12 bar)

Minimum flow rate 15 l/min

Max. chlorine content 250mg/L

Max. water hardness 200mg/L

The following instructions have to be

followed when installing the cold

water mains supply to the cylinder:

- The cold water supply to the

cylinder must come directly from

the cold water mains after the

mains stop valve to the property.

- The cold water inlet pipe work

should have at least an inside

diameter of 19mm and should meet

the requirements of the water

regulations for the supply of

wholesome water.

4.4 Building regulation G3

Discharge

requirements

As part of the requirements of

Building Regulation G3 any discharge

from an unvented system should be

conveyed to where it is visible, but

will not cause danger to persons in or

about the building. The tundish and

the discharge pipes should be fitted in

accordance with the requirements of

Building Regulation approved

document G3, (England and Wales),

Part P of Northern Ireland and

Standard 4.9 of Scotland.

Page 9

Pre

-

Installation

HP Installation and User Instructions R00918

-

1 03/11

Page 9

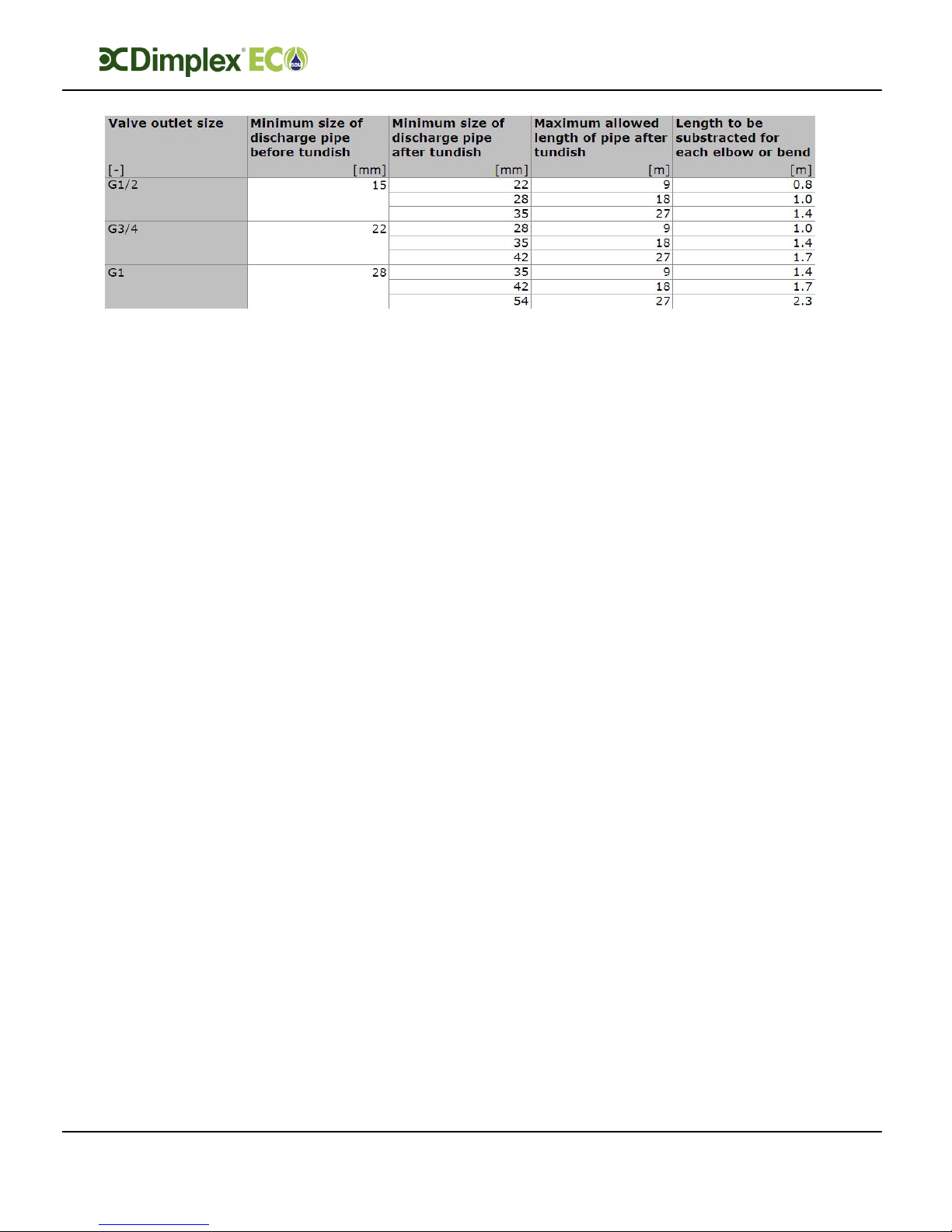

4.4.1 Discharge pipe D2

The discharge pipe (D2) from the

Tundish should:

- “have a vertical section of pipe at

least 300mm long below the

tundish before any elbows or

bends in the pipework and be

installed with a continuous fall of

at least 1 in 200 thereafter.”

The discharge pipe (D2) should be

made of:

- “metal; or other material that has

been demonstrated to be capable

of safely withstanding

temperatures of the water

discharged and is clearly and

permanently marked to identify

the product and performance

standard”

The discharge pipe D2 should be at

least one pipe size larger than the

nominal outlet size of the safety

device unless its total equivalent

hydraulic resistance exceeds that of a

straight pipe 9m long, i.e. for

discharge pipes between 9m and 18m

the equivalent resistance length

should be at least two sizes larger

than the nominal outlet size of the

safety device; between 18 and 27m at

least 3 sizes larger, and so on; bends

must be taken into account in

calculating the flow resistance. See

Figure 2, Table 2 and the worked

example.

Note: An alternative approach for

sizing discharge pipes would be to

follow Annex D, section D.2 of BS

6700:2006 + A1:2009).

Figure 2: Typical discharge pipe arrangement

Page 10

HP Installation and User Instructions R00918

-

1 03/11

Page 10

Pre

-

Installation

Table 2: Sizing of copper discharge pipe “D2” for common temperature relief valve outlet sizes

4.4.2 Worked example

This example is for a G½ temperature

relief valve with a discharge pipe (D2)

(as fitted on 125 to 300L cylinders)

having 4 No. 22mm elbows and length

of 7m from the tundish to the point of

discharge.

From Table 2, the maximum

resistance allowed for a straight

length of 22mm copper discharge pipe

(D2) from a G½ temperature relief

valve is 9.0m. Subtract the resistance

for 4 No. 22mm elbows at 0.8m each

= 3.2m.

Therefore the maximum permitted

length

equates to 5.8m, which is less than

the actual length of 7m, therefore

calculate the next largest size.

Maximum resistance allowed for a

straight length of 28mm copper

discharge pipe (D2) from a G½

temperature relief valve is: 18m

Subtract the resistance for 4 No.

28mm elbows at 1.0m each = 4m

Therefore the maximum permitted

length equates to 14m.

As the actual length is 7m, a 28mm

(D2) copper pipe will be satisfactory.

Page 11

HP Installation and User Instructions R00918

-

1 03/11

Page 11

Pre

-

Installation

- Where a single common discharge

pipe serves more than one system,

it should be at least one pipe size

larger than the largest individual

discharge pipe (D2) to be

connected.

- The discharge pipe should not be

connected to a soil discharge stack

unless the soil discharge stack is

capable of safely withstanding

temperatures of the water

discharged, in which case, it should:

- contain a mechanical seal, which

allows water into the branch pipe

without allowing foul air from the

drain to be ventilated through the

tundish.

- there should be a separate

branch pipe with no sanitary

appliances connected to it.

- if plastic pipes are used as branch

pipes carrying discharge from a

safety device, they should be

either polybutalene (PB) or crosslinked polyethylene (PE-X)

complying with national

standards.

- be continuously marked with a

warning that no sanitary

appliances should be connected

to the pipe.

4.4.3 Termination of discharge

pipe

- “The discharge pipe (D2) from the

tundish should terminate in a safe

place where there is no risk to

persons in the vicinity of the

discharge.”

- Examples of acceptable discharge

arrangements are:

- “to a trapped gully with the end of

the pipe below a fixed grating and

above the water seal;

- downward discharges at low level;

i.e. up to 100mm above external

surfaces such as car parks, hard

standings, grassed areas etc. are

acceptable providing that a wire

cage or similar guard is positioned

to prevent contact, whilst

maintaining visibility; and ,

- discharges at high level: e.g. into a

metal hopper and metal downpipe

with the end of the discharge pipe

clearly visible or onto a roof capable

of withstanding high temperature

discharges of water and 3m from

any plastic guttering system that

would collect such discharges.”

Note: As the discharge would

consist of high temperature water

and steam, asphalt, roofing felt

and non-metallic rainwater goods

may be damaged by such

discharges.

4.5 Limitations

- The heat pump must be specified

correctly, to ensure it is compatible

with the model of cylinder installed.

This is to prevent the heat pump

malfunctioning when preparing

domestic hot water.

- The heat exchangers in this range of

cylinders have been specifically

designed for heat pump

applications. Great care must be

taken if using these cylinders with

other heat sources, due to the heat

exchange capacity of the product.

Page 12

HP Installation and User Instructions R00918

-

1 03/11

Page 12

Installation

5 Installation

5.1 Cold Water Inlet with

Inlet Control Group

5.1.1 Correctly site the cylinder

Install the cylinder in an appropriate

location, ensuring all of the

recommendations have been

considered (see chapter 4.2).

5.1.2 Install the inlet group

The inlet group regulates the pressure

of the incoming mains water supply to

the cylinder and removes any debris

that might be water borne.

Note: Between the inlet group and

the cold water inlet on the

cylinder NO isolating device may

be fitted, as by doing so important

safety devices could be isolated!

5.1.3 Expansion vessel

The expansion vessel is mandatory on

all Ec-eau cylinders and can be

connected directly to the cold water

inlet group, utilising the flexible hose

supplied with the vessel. The

expansion vessel should always be

fitted in accordance with the

manufacturer’s instructions. No

isolating device should be fitted

between the water cylinder and the

cold water inlet group.

Furthermore, it is recommended to

mount the vessel higher than the

cylinder to avoid having to drain the

cylinder when maintaining and

replacing the expansion vessel.

Figure 3: Connection of the expansion

vessel to the inlet group

It is important to check the

pre-charge pressure of the

expansion vessel membrane

before filling the cylinder. The

pre-charge should be greater

than or equal to 3bar.

5.1.4 Balanced cold water supply

If balanced cold water supply is

required a connection can be taken

from the bottom of the inlet group.

5.1.5 Drain valve

It is also recommended to install a

drain valve (not supplied) in the

lowest point of the cold water feed to

the cylinder. This allows the cylinder

to be drained in a controlled manner

should this become necessary.

Page 13

HP Installation and User Instructions R00918

-

1 03/11

Page 13

Installation

5.2 Hot Water Outlet

The hot water pipe work is to be

directly connected to the hot water

outlet connection on the cylinder, see

Figure 1.

5.2.1 Thermostatic mixing valve

A thermostatic mixing valve may be

required to limit the outlet

temperature. In this case, the valve

should be installed following the

manufacturers instructions, ensuring

none of the safety equipment has

been isolated, (i.e. make sure the

connection to the thermostatic mixing

valve is taken after the safety

equipment of the inlet group).

5.2.2 Pipe insulation

It is recommended to insulate the hot

water pipe work from the cylinder to

the outlets, to reduce the energy

requirements for providing hot water.

It is also recommended to insulate all

other exposed pipework, such as the

T&P to the tundish, the coil flow and

return and the cold water inlet pipes.

5.3 Discharge pipes from

safety devices

5.3.1 Discharge pipe D1

- The temperature and pressure relief

valve must be discharged directly or

by way of a manifold via a short

length of metal pipe (D1) into a

tundish; and the discharge pipe

must be installed in a continuously

downward direction and in a frost

free environment. Water may drip

from the discharge pipe of the

pressure relief device and this pipe

must be left open to the

atmosphere.

- The diameter of discharge pipe (D1)

should not be less than the nominal

outlet size of the safety device, e.g.

temperature relief valve.

- Where a manifold is used it should

be sized to accept and discharge

the total discharge from all the D1

discharge pipes connected to it.

- The discharge pipe work from the

expansion relief valve must be

installed constantly falling to an

open point of discharge. It is

recommended to combine it with

the discharge of the temperature

and pressure relief valve.

5.3.2 Discharge pipe D2

For a detailed description of the

discharge pipework D2 see chapter

4.4.1.

Page 14

HP Installation and User Instructions R00918

-

1 03/11

Page 14

Installation

5.3.3 Tundish

- The tundish should be vertical,

located in the same space as the

unvented hot water storage system

and be fitted as close as possible to,

and lower than, the safety device,

with no more than 600mm of pipe

between the valve outlet and the

tundish (see Figure 2).

- Discharge should be visible at the

tundish, where discharges may not

be apparent, e.g. in dwellings

occupied by people with impaired

vision or mobility, consideration

should be given to the installation of

a suitable safety device to warn

when discharge takes place, e.g.

electronically operated.

Note: To comply with the Water

Supply (Water Fittings)

Regulations, the tundish should

incorporate a suitable air gap.

It is important that the

tundish is positioned away

from any electrical

components.

Figure 4: Wiring diagram for Immersion Heater

5.4 Immersion heater

The immersion heater has to be

connected in accordance with IEE

Wiring Regulations and the installer

carrying out the work has to be

suitably qualified. It must be

connected through a double pole

isolating switch or suitable controller

which must have a contact separation

of at least 3mm in all poles. The

wiring diagram can be seen in Figure

4. For further details please see

instructions provided with the

immersion heater.

The immersion heater incorporates an

independent non-self resetting over

temperature cut-out. Should the over

temperature cut-out operate, the

reset pin will be pushed upwards, and

become level or slightly proud of the

cover at the position marked “Safety”.

Use a suitable sized implement to

reset the pin by pushing it hard into

its original position.

The immersion heater typically cannot

be directly switched by the heat pump

Page 15

HP Installation and User Instructions R00918

-

1 03/11

Page 15

Installation

controller, but instead requires a

relay.

Should it be necessary to remove the

thermostat from the immersion

element, ensure that the contacts are

re-fitted correctly into the positions on

the element. Failure to do so carries

the risk of overheating the contacts

and thus damaging the appliance. The

immersion heater thermostat must

not be opened under any

circumstances.

Note: The cylinder must be filled

with water before switching on

the immersion heater. Failure to

do so will damage the element

and void any guarantee on the

product.

5.5 Coil flow connections

If the flow connection is the highest

point in the heat pump loop and if the

system was not commissioned using a

flush and fill pump, an adequate

device for de-aeration must be

installed.

5.6 Coil return connections

Equally, if the return connection is the

lowest point in the heat pump loop, a

suitable drain device should be

installed. For location of connections

see Figure 1.

It is recommended that the fittings

used to connect to the cylinder are

suitable for stainless steel, the flow

and return should use 28mm

compression fittings. Not all push fit

fittings can be used – please check

with your supplier. When using

compression fittings, ensure that the

connection is not over-tightened.

Page 16

HP Installation and User Instructions R00918

-

1 03/11

Page 16

Installation

5.7 Thermostat

connection and

installation of the

heat pump DHW

temperature sensor

The heat pump can be wired to the

cylinder in various ways as described

by the chosen supplier.

To conform to building regulations, it

is imperative that the hot water

circulating pump is installed through

the twin thermostat.

If a non Dimplex heat pump is used in

combination with this cylinder or

another heat source, a two port valve

has to be wired after the thermostat,

ensuring compliance with building

regulations.

Figure 5: Heat Pump Loop Wiring

T1

T2

T3

NOTE: T1 and T2 must be connected to the heat pump control

panel, see heat pump installation manual. T3 can replace T2 only

when a normally open configuration is required.

To HP Manager

From HP Manager

Temp

control

stat

High

temp cut

out stat

2

1

1

2

3

T4

Earth

Page 17

HP Installation and User Instructions R00918

-

1 03/11

Page 17

Installation

5.7.1 Connection of the sensor

Step 1: Access the sensor mounting plate. To do this remove the twin thermostat

box (A) by removing the screws in the 4 corners only and insulation foam (B) to

access the sensor mounting plate (C). Remove the M5 fixing screws.

Step 2: The sensor mounting plate will have two vacant slots for additional sensors

(D). Slide the heat pump sensor into place as shown (E).

D

E

A B

C

Page 18

HP Installation and User Instructions R00918

-

1 03/11

Page 18

Installation

Step 3: Fit two M5 fixing screws into the cylinder bracket (F). Slide the sensor

mounting plate behind the M5 fixing screws (G).

Step 4: Insert two remaining M5 screws (H). Tighten the screws until the thermostat

bulbs and heat pump sensor are held firmly against the wall of the inner cylinder.

Note: there should be no movement in the phials (four clips in the centre of the

sensor mounting plate) that are used to hold the bulbs and sensor. Care should be

taken not to overtighten the screws.

H

F

G

Page 19

HP Installation and User Instructions R00918

-

1 03/11

Page 19

Installation

Step 5: Replace the insulating foam over the sensor mounting plate

Step 6: Refit the twin thermostat box, taking care not to kink the capillaries that

connect the thermostat bulbs to the twin thermostat box.

Page 20

HP Installation and User Instructions R00918

-

1 03/11

Page 20

Installation

Figure 6: Secondary return loop

5.8 Connection of

Secondary Return

A secondary return port is installed on

the 210, 250 and 300L cylinders. For

cylinders that do not have a dedicated

secondary return connection, it is

possible to install a secondary return

by connecting a swept - T to the cold

water inlet of the cylinder.

The secondary return pipe should

incorporate a check valve and a WRAS

approved circulation pump; timer and

thermostat to be provided separately.

Where secondary return circuits are

used, then an additional expansion

vessel may be required.

If the secondary return is not used it

should be blanked with a ½” bung.

The secondary return loop must

avoid:

- stagnant water in long pipe runs

- long waiting times at draw off point

for hot water

- undue water wastage

To minimise the energy consumption

of the secondary return circuit and to

ensure reliable operation it is

important to consider:

- the control of the circulation pump

to be time and temperature

controlled

- the secondary return circuit pipe

work to be insulated

- the secondary return pump to be of

suitable material and specification

To Taps

From Taps

HW Outlet

Secondary

Return

Swept

-T

Page 21

HP Installation and User Instructions R00918

-

1 03/11

Page 21

Commissioning

6 Commissioning

At the time of commissioning,

complete all relevant sections of the

Benchmark Checklist located on the

inside back pages of this document.

The following commissioning

procedures only detail the required

steps to be taken for the potable

water loop and not for the heat pump

loop:

1) Before making any mains

connections to the inlet control

group, flush the mains pipework

out to ensure all debris has been

removed so as not to damage the

strainer within the combination

valve.

2) Make final mains connection on

combination valve and check all

connections and joints to ensure

they have been tightened and

secured correctly.

3) Before turning on the mains

supply to the cylinder a hot water

tap should be opened, preferably

on the same floor or the floor

below where the cylinder is

located.

4) Check the pre-charge in the

expansion vessel and ensure it is

at least 3 bar. Note actual

pressure on label on expansion

vessel.

5) Turn on the supply to the cylinder

and fill until water runs from the

open hot water tap. Continue to

flush the system until all debris

has been removed.

6) Close the hot water tap.

7) Check all joints for leaks, even

those not having been altered

especially when replacing a

vented cylinder.

8) Open temperature and pressure

relief valve to ensure proper

discharge and check after closing

that valve is not dripping.

9) Open pressure relief valve to

ensure proper discharge and

check after closing that valve is

not dripping.

10) Check all shower outlets, toilet

cisterns and other draw off points

for leaks or dripping (especially

when replacing a vented unit).

Open all water outlets to purge

air from pipe work and ensure

proper operation.

11) Adjust timer programmer and

cylinder thermostat settings in

accordance with client

requirements.

12) Instruct user in the operation of

the unit and hand over this

manual advising the owner of

annual service requirements.

13) Complete the technical data label

on the cylinder with legible and

permanent writing.

Page 22

Maintenance

HP Installation and User Instructions

R00918

-

1 03/11

Page 22

7 Maintenance

After servicing, complete the relevant

Service Record section of the

Benchmark Checklist located on the

inside back pages of this document.

To meet with warranty requirements

the cylinder must be serviced

annually.

The maintenance of this

appliance must be carried

out by a suitably qualified

person only. It is

recommended to maintain

the unit on an annual basis.

Isolate all electrical

supplies from the unit

before commencing work.

Danger of electrical shock!

1) Draw some water from cold water

tap and retain in container.

2) Isolate cold water mains supply

from cylinder.

3) Briefly open temperature and

pressure relief valve, assure safe

discharge and check that valve is

not dripping when closed.

4) Briefly open pressure-relief valve,

assure safe discharge and check

that valve is not dripping when

closed. The pressure-relief valve

should be operated regularly to

remove lime deposits and to

verify that it is not blocked.

5) Open hot water tap and release

remaining pressure from unit.

6) If the system is drained

completely for an internal

inspection, ensure the hot water

tap remains open, connect a hose

to the drain valve and ensure a

safe discharge.

7) Note the set pressure of the

pressure reducing valve. Remove

cartridge and clean strainer in

water provided in container. Reassemble pressure reducing valve

ensuring the correct pressure is

set.

8) Periodically the immersion

heaters should be removed

cleaned and the unit flushed out.

Check the O-ring seal for damage

and replace if necessary.

9) Check electrical wiring

connections and the condition of

the cable of the immersion heater

and the thermostat.

10) The immersion heater boss can

also be used for access to view

the internal components of the

cylinder.

11) Re-commission unit (see chapter

6).

If the cylinder is not in use for

excess of 1 month, it must be

drained down by a competent

person and recommissioned

before use. Note: The immersion

must be switched off at the mains

before draining the cylinder.

If replacement parts are required,

please see Figure 7 for part

descriptions and part numbers.

Page 23

Spare Parts

HP Installation and User Instructions R00918

-

1 03/11

Page 23

8 Spare Parts

Figure 7: Replacement part numbers for Heat Pump range of cylinders

Page 24

HP Installation and User Instructions

R00918

-

1 03/11

Page 24

Technical Data

9 Technical data

Figure 8: Heat Pump Cylinder and Cross-section (for reference only)

Heat Pump Cylinder Range

Reference 125 150 210 250 300

Weight (full) [kg]

152 182 251 302 350

Reheat time [mins]* 7 7 12 17 20

Average draw off temperature [°C]*

61 60 62 63 62

97 120 180 238 267

Hot water draw off capacity (l)* /

draw off flow rate (l/s)

0.25 0.25 0.25 0.25 0.50

HX performance [kW]* 45 51 47 47 43

Heat loss [kWh]

- - - - -

Height [mm]

960 1130 1505 1780 2080

Outer Diameter [mm]

580 580 580 580 580

HW Outlet [mm] 730 900 1275 1550 1850

T&P Valve [mm] 730 900 1275 1550 1850

Secondary Return [mm]

- -

967 1105 1255

CW Inlet [mm] 190 190 190 190 190

Bottom Immersion [mm] 208 208 208 208 208

HP Return [mm]

190 190 190 190 190

HP Flow [mm] 710 845 895 895 930

Bottom Thermostat [mm] 460

545

732

870

1020

Table 3: Heat Pump Cylinder Dimensions

Note: All measurements are taken from the base of the cylinder to the mid point on the item.

* Determined in accordance with EN12897 at 80°C flow temperature and 0.42l/s flow rate.

Page 25

HP Installation and User Instructions

R00918

-

1 03/11

Page 25

Technical Data

Heat Pump Cylinder Range

Reference 125 150 210 250 300

Actual capacity [L] 120 145 210 250 300

Materials

- inner cylinder Duplex stainless steel LDX2101

- outer cylinder HIPS

- inlet/outlet Stainless steel

- coils Stainless steel

- insulation 60mm PU foam (GWP=1, ODP=0)

Maximum operating conditions

- potable water temperature

70°C

- heating water temperature

95°C

- operating pressure 3 bar

Cold water supply

- minimum dynamic pressure 1.5 bar

- maximum pressure 12 bar

- minimum flow rate 15 l/min

Connections

- cold water inlet 22mm stainless steel

- hot water outlet 22mm stainless steel

- coil flow and return 28mm stainless steel

Coil specification

- surface area [m²]

2.2 2.8

3.0

3.2

- rating [kW] 45 51

47

43

Immersion heater

1 ¾ F BSP 3kW @ 240 V

Thermostatic control

- direct input integral immersion heater thermostat and cut out

- indirect input

integral twin thermostat (10 to 70°C) and cut out

(~85°C)

Safety components

- pressure reducing valve and strainer

3 bar

- expansion relief valve

6 bar

- temperature and pressure relief valve

½” 7 bar/90°C

- factory pressure test

12 bar

Other features Over 60% in volume from recycled materials

Surface mounted sensor devices for compatibility

and ease of maintenance

Approvals

KIWA

approval number:

-

1012717

Guarantee

- inner cylinder

25 yrs

- immersion heaters

2 yrs - excluding the effects of lime scale or other

water borne contaminants

- other components 2 yrs - excluding expansion vessel membrane

pressure

Table 4: Heat Pump Product features

Page 26

HP Installation and User Instructions

R00918

-

1 03/11

Page 26

Technical Data

9.1 Cylinder heat exchanger pressure drop

Figure 9: Heat exchanger pressure drops for 2.2m² and 2.8² coils

2.2m2 Coil Pressure Drop

0

5000

10000

15000

20000

25000

30000

35000

40000

45000

0.0 0.5 1.0 1.5 2.0 2.5

Flow Rate (m3/h)

Pressure Drop (Pa)

2.8m2 Coil Pressure Drop

0

10000

20000

30000

40000

50000

60000

0.0 0.5 1.0 1.5 2.0 2.5

Flow Rate (m3/h)

Pressure Drop (Pa)

Page 27

HP Installation and User Instructions

R00918

-

1 03/11

Page 27

Technical Data

Figure 10: Heat exchanger pressure drop for 3.0m² and 3.2m² coils

3.0m2 Coil Pressure Drop

0

10000

20000

30000

40000

50000

60000

70000

0.0 0.5 1.0 1.5 2.0 2.5

Flow Rate (m3/h)

Pressure Drop (Pa)

3.2m2 Coil Pressure Drop

0

10000

20000

30000

40000

50000

60000

70000

80000

0.0 0.5 1.0 1.5 2.0 2.5

Flow Rate (m3/h)

Pressure Drop (Pa)

Page 28

HP Installation and User Instructions

R00918

-

1 03/11

Page 28

User Instructions

10 User Instructions

10.1 General

“This appliance is not intended for use

by persons (including children) with

reduced physical, sensory or mental

capabilities, or lack of experience and

knowledge, unless they have been

given supervision or instruction

concerning the use of the appliance by

person responsible for their safety.”

“Children should be supervised to

ensure they do not play with this

appliance.”

Please read the following

statements carefully as it affects

your warranty:

Please ensure that the installer has

fully completed the Benchmark

Checklist on the inside back pages of

this document and that you have

signed it to say that you have

received a full and clear explanation of

its operation. The installer is legally

required to complete a commissioning

checklist as a means of complying

with the appropriate Building

Regulations Part G3 (England and

Wales), Part P of Northern Ireland and

Section 6 of Scotland.

All installations must be notified to

Local Area Building Control either

directly or through a Competent

Persons Scheme. A Building

Regulations Compliance Certificate will

then be issued to the customer who

should, on receipt, write the

Notification Number on the

Benchmark Checklist.

This product should be serviced

annually to optimise its safety,

efficiency and performance. The

service engineer should complete the

relevant Service Record on the

Benchmark Checklist after each

service.

The Benchmark Checklist will be

required in the event of any warranty

work.

Page 29

HP Installation and User Instructions

R00918

-

1 03/11

Page 29

Operation

10.2 Operation

Once the system has been fully

commissioned, no user intervention

should be required to fully enjoy the

comfort and benefits of the unvented

hot water cylinder.

The hot water temperature can be set

to various requirements. For operation

with a heat pump it is recommended

to set the hot water temperature to

between 45°C and 55°C (this is

between 2 and 3 on the dial, please

refer to Figure 12 for approximate

settings). Higher temperatures can

cause tripping of the high limit

thermostat, introduce more heat loss

from the unit and increase the risk of

scalding significantly.

When turning on a hot tap for the first

time after a heat up period there

might be a short surge of water. This

is normal in unvented systems and

does not constitute a fault. Sometimes

the water may appear milky – this is

due to very fine air bubbles in the

water which will clear quickly.

10.2.1 Water temperature direct

electric heating

Before removing the cover

from the immersion heater

isolate appliance using

isolating switch! Danger of

electrical shock! Only use

suitable electrically insulated

equipment when working

inside immersion housing.

The hot water temperature achieved

by the direct electric heating element

can be adjusted by removing the

cover from the immersion heater and

adjusting the dial up or down as

indicated below.

Figure 11: Adjustment water temperature direct electric heating element

Dial to adjust water

temperature

Page 30

HP Installation and User Instructions

R00918

-

1 03/11

Page 30

Operation

10.2.2 Water temperature auxiliary

heating

The water temperature achieved by

the auxiliary heating system depends

on the setting of the thermostat on:

- the cylinder AND

- the auxiliary heating source

The adjustment at the cylinder is

carried out on the twin thermostat

fitted to the cylinder as shown in

Figure 12. In the event that the high

temperature cut-out engages, it will

be necessary to manually reset the

thermostat. Use a suitable electrically

insulated tool to push the manual

reset button and inform the installer.

Figure 12: Adjustment water temperature auxiliary source

10.3 Maintenance

The maintenance of this

appliance must be carried

out by a suitably qualified

person only. It is

recommended to maintain

the unit on an annual basis.

Isolate all electrical

supplies from the unit

before commencing work.

Danger of electrical shock!

Dial to adjust water

temperature

Manual re

-

set

Page 31

HP Installation and User Instructions

R00918

-

1 03/11

Page 31

Troubleshooting

10.4 Troubleshooting

Fault Cause Solution

A No water

from hot

water taps

A.1 Stop valve closed

A.2 Strainer blocked

A.3 Pressure reducing valve

fitted against flow

A.1 Open stop valve

A.2 Turn water supply off,

clean strainer and recommission

A.3 Re-fit with arrow showing

in direction of flow

B No hot water B.1 Timer/Programmer not set

correctly

B.2 Auxiliary heating

malfunction

B.3 Direct heating mal function

B.4 Auxiliary/direct heating high

limit thermostat has tripped

B.1 Set timer/programmer

correctly

B.2 Consult auxiliary heating

system instructions

B.3 Call for qualified person

to check immersion

heater

B.4 Reset limit thermostat(s)

and inform installer

C Intermittent

water

discharge

through

tundish on

warm-up

C.1 Expansion vessel lost

charge

C.1 Check expansion vessel

(see

commissioning/maintena

nce), top up or replace

D Continuous

discharge

D.1 Pressure reducing valve not

working

D.2 Pressure relief or T&P valve

not seating correctly

D.3 Malfunction of high limit

thermostat or appliance

D.1 Check pressure after

valve and replace if

faulty

D.2 Manually lift valve once

or twice to clear debris,

otherwise replace

D.3 Check function of

thermostats and

appliances

E Leakage from

casing

E.1 Compression/threaded

joints not formed correctly

E.1 Re-seal joints with care

F Hot water

from cold tap

F.1 Hot pipe work being routed

adjacent to cold pipe work

F.2 Leaking seal in mixer tap

F.1 Insulate hot pipe work or

re-route

F.2 Replace seals in mixer

tap

G Metallic noise

from system

G.1 Pipe work not sufficiently

supported

G.1 Add extra pipe work

fixings

H Humming

noise from

system during

re-heat

H.1 Air in system

H.2 Flow rate well in excess of

specification

H.1 Bleed system thoroughly

and re-pressurize

H.2 Reduce pump speed

Page 32

Page 33

Page 34

Page 35

Page 36

Notes

HP Installation and User Instructions R00918

-

1 03/11

Page 36

Dimplex a division of GDC Group Ltd

Millbrook House Grange Drive, Hedge End, Southampton SO30 2DF

Tel.: 0845 600 5111

e-mail:

aftersales@dimplex.co.uk

www.dimplex.co.uk

Loading...

Loading...