Page 1

Service Manual

Model Number:

DWOP20R

UL Part Number

6909030100

IMPORTANT SAFETY INFORMATION: Always read this manual rst before attempting to service this replace. For your

safety, always comply with all warnings and safety instructions contained in this manual to prevent personal injury or property damage.

Dimplex North America Limited

1367 Industrial Road Cambridge ON Canada N1R 7G8

1-888-346-7539 www.dimplex.com

In keeping with our policy of continuous product development, we reserve the right to make changes without notice.

© 2013 Dimplex North America Limited

REV PCN DATE

00 - 1-NOV-13

7400760100R00

Page 2

TABLE OF CONTENTS

OPERATION .........................................................3

MAINTENANCE ......................................................4

EXPLODED PARTS DIAGRAM ..........................................5

REPLACEMENT PARTS ...............................................5

WIRING DIAGRAM ...................................................6

HEATER ASSEMBLY REPLACEMENT ....................................7

COMPONENT ACCESS ................................................7

ON/OFF SWITCH REPLACEMENT .......................................7

3 POSITION SWITCH REPLACEMENT ....................................8

THERMOSTAT REPLACEMENT .........................................8

POTENTIOMETER REPLACEMENT ......................................8

REMOTE RECEIVER REPLACEMENT ....................................8

POWER BOARD REPLACEMENT .......................................9

TRANSFORMER REPLACEMENT .......................................9

IR SENSOR REPLACEMENT ...........................................9

POWER CORD REPLACEMENT .........................................9

FAN ASSEMBLY REPLACEMENT - MOTOR AND HOUSING .................10

LIGHT ASSEMBLY REPLACEMENT .....................................10

TROUBLESHOOTING GUIDE ..........................................11

Always use a qualied technician or service agency to repair this replace.

!

NOTE: Procedures and techniques that are considered important enough to emphasize.

CAUTION: Procedures and techniques which, if not carefully followed, will result in damage to the equipment.

WARNING: Procedures and techniques which, if not carefully followed, will expose the user to the risk of re, serious

injury, or death.

2 www.dimplex.com

Page 3

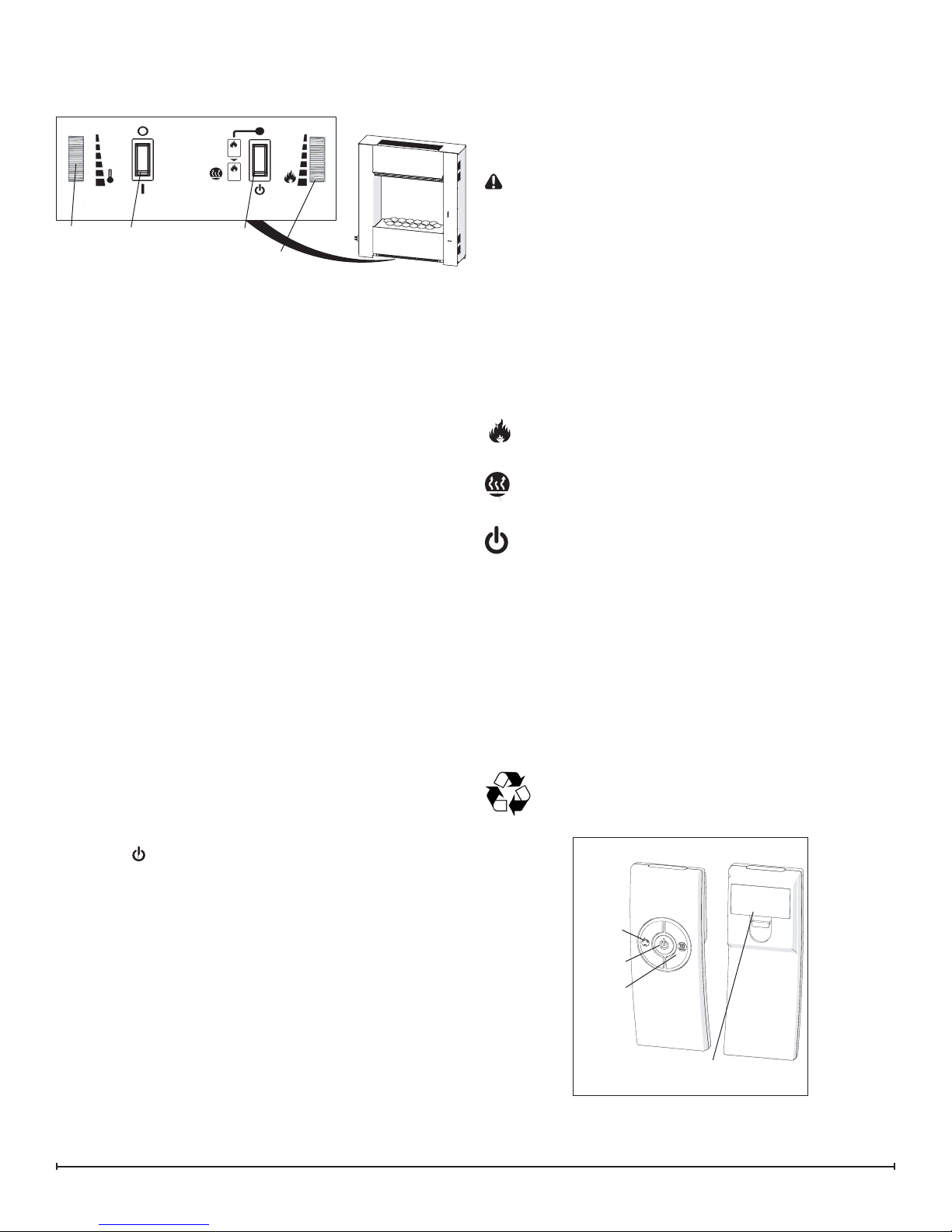

OPERATION

Figure 1

2kw

B

!

where background noise is very low, it may be possible to

hear a sound which is related to the operation of the ame

effect. This is normal and should not be a cause for concern.

!

wall in a level position.

The manual controls for the wall mount engine are located

on the bottom of the unit. (Figure 1)

A. On/Off Switch

Supplies power to the engine.

B. Thermostat Control

To adjust the temperature to your individual requirements,

turn the thermostat control backwards all the way to turn on

the heater. When the room reaches the desired temperature, turn the thermostat knob forward until you hear a click.

Leave thermostat in this position to maintain the room tem-

perature at this setting. For additional heat, turn clockwise

until you hear the click again and the heater will turn on.

C. Mode Selector Switch

Press once to turn on the ame effect. This will be indicated

by an audible “beep”. Although the lights turn on immedi-

ately it will take 30 seconds before the ame effect starts.

• Press again to give ame effect and full heat. This will

• Press again to return to ame effect only. This will be

• Press to put re in to standby mode. This will be

D. Flame Intensity Control

Adjusts the intensity of the ame and smoke effect when the

heater has been activated.

Turning the control knob towards you decreases the inten-

sity of the ame and smoke effect. Turning the control knob

away from you will increase the ame and smoke effect.

!

changes you may make on the ame control knob.

!

off after 30 seconds. See instructions under Maintenance

Section for relling tank. When this procedure is complete,

the main lamps will illuminate but it will take 30 seconds

before the ames return.

A

C

D

NOTE: When the engine is used in an environment

NOTE: Always ensure that the appliance is xed to the

be indicated by two “beeps”.

indicated by one “beep”.

indicated by one “beep”.

NOTE: Give the ame generator some time to react to

NOTE: When the water tank is empty the unit will turn

Resetting the Temperature Cutoff Switch

Should the heater overheat, an automatic cut out will turn

the replace off and it will not come back on without being

reset. It can be reset by switching the On/ Off Switch to Off

and waiting ten (10) minutes before switching the unit back

on.

CAUTION: If you need to continuously reset the heater,

unplug the unit and call Dimplex North America Limited at

1-888-346-7539 for technical support. Please have your

model and serial number ready when calling.

Remote Control

The On/Off Switch must be in the ‘ON’ ( I ) position in order

for the remote control to operate. There are 3 buttons on

the remote control. (Figure 2)

!

NOTE: To operate correctly the remote control must be

pointed towards the heater outlet.

The remote control functions are as follows:

Press once to turn on Flame effect only. This will be

indicated by one beep.

Press once to turn on Full heat and Flame effect. This

will be indicated by two beeps.

Standby - This will be indicated by one beep.

!

NOTE: Once the mist has been activated, the unit will

have to be turned Off, using either the momentary button,

on the unit, or the Off button on the remote control, then

back on to return to Level 1 - Logs and Light only operation.

Battery Replacement

To replace the battery:

1. Slide battery cover open on the remote control (Figure

10).

2. Install two 1.5 Volt (AAA) battery in the battery holder.

3. Close the battery cover.

Battery must be recycled or disposed of properly.

Check with your Local Authority or Retailer for recycling advice in your area.

Figure 2

Flame

Button

Standby

Button

Heat

Button

Battery Cover

3

Page 4

MAINTENANCE

WARNING: Disconnect power before attempting any

maintenance or cleaning to reduce the risk of re, electric shock or damage to persons.

Filling the water tank

When the water tank is empty, the ame effect shuts off

and you will hear 2 audible beeps, follow these steps.

CAUTION: Allow at least ve minutes for components to

cool before disassembling the unit to rell.

1. Turn the On/Off switch to the off position (0) (Figure 1)

2. Gently remove the rock media and the media tray and

place them carefully on the ground.

3. Remove the rell container by lifting upwards and

outwards.

4. Rell the container with tap water.

!

NOTE: Normal tap water can be used in the Optimyst®

as long as the tap water is not considered to be hard water.

In the event your tap water is hard, you may use softened

water or distilled water with 1/8 tsp of salt (0.5 mL) added to

the water reservoir. (The addition of additional salt should

only be when you notice that the unit is not producing mist

as expected.)

5. Screw the cap back on, do not overtighten.

6. Return the rell container to the sump, with the tank

cap facing down and the at side of the tank facing

outward.

7. Gently place the media tray and rock media back into

position.

8. Turn the On/Off switch to the off position (I). (Figure 1)

If you do not intend on using the unit for longer than 2

weeks, empty and drain the unit of water, and dry all of the

water containing components.

media.

Cleaning

It is recommended that all of the components that contain

water are cleaned with soap and water on a biweekly basis. A small brush has been included to assist in cleaning

difcult items/areas, i.e. the transducer.

CAUTION: Do not put plastic components in the dish-

washer.

Filter Cleaning

The air lter can be removed and gently rinsed with water

to clean and dried on a towel before reinstalling.

!

NOTE: Replace the lter so that the course black lter is

facing the front of the engine.

Surface Cleaning

Use a warm damp cloth only to clean surfaces of the engine. Do not use abrasive cleaners.

!

NOTE: If you need to move the unit ensure that all of

the components that contain water have been emptied before relocating.

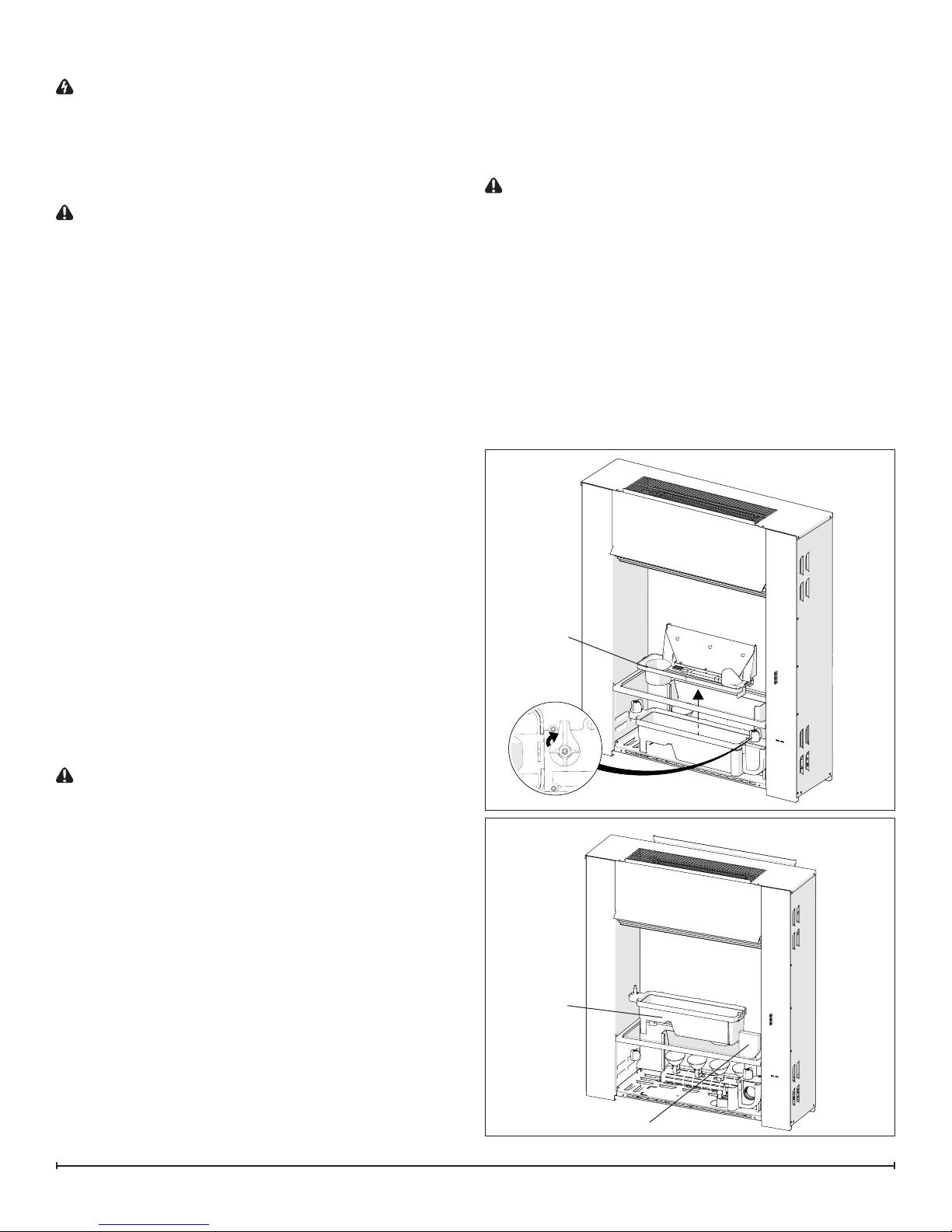

Figure 3

Top

Cover

Replacing the Light bulbs

If a large amount of the smoke appears grey or colourless it

may be that one or more of the light bulbs have burnt out.

CAUTION: Allow at least twenty minutes for light bulbs

to cool before touching bulbs to avoid accidental burning of

skin.

1. Leaving the ame effect on, remove the rock media,

tray and water tank and lift out the top cover (Figure 3).

2. View the lamps from a distance in front of the re and

observe which lamp needs to be changed.

3. Turn the unit off, and unplug the engine.

4. Leave the appliance for 20 minutes to allow the lamps

to cool down before removing them.

5. Remove the water tank and sump (Figure 4) by lifting

upwards and placing to the side.

6. Remove the defective bulb, by gently lifting vertically

and disengaging the pins from the lamp holder.

!

NOTE: Replacement light bulbs can be obtained by

contacting Dimplex Customer Service at 1-888-346-7539.

7. Carefully insert the two pins of the new bulb into the

two holes in the lamp holder. Push lamp rmly in place.

8. Replace the top cover, rell container, media tray and

Figure 4

Sump

Filter

4 www.dimplex.com

Page 5

EXPLODED PARTS DIAGRAM

1

18

5

25

24

3

9

22

4

7

REPLACEMENT PARTS

1. Remote Control ...................9600385600RP

2. Remote Control Receiver ...........9600580300RP

3. Rock Media . . . . . . . . . . . . . . . . . . . . . .9600650100RP

4. Media Tray ......................9600660100RP

5. Heating Assembly (with cutout) .......9600680100RP

6. Light Holder Assembly .............9600610100RP

7. Removable Rell Container with Cap 0441440100RP

8. Cap for Rell Container. . . . . . . . . . . . .0441440300RP

9. Top Cover Assembly ...............9600670100RP

10. Water Reservoir (Sump) ...........0441380100RP

11. Fan Assembly . . . . . . . . . . . . . . . . . . . .5300300100RP

12. Fan Housing Assembly . . . . . . . . . . . . .9600540100RP

13. Fan Filter . . . . . . . . . . . . . . . . . . . . . . . .8600300100RP

11

6

14

10

15

21

16

17

14. Transducer ......................3800040100RP

15. Power Cord

Mod 0-A ........................9600385500RP

Mod B . . . . . . . . . . . . . . . . . . . . . . . . . .9600740100RP

16. On/Off Switch ....................9600383500RP

17. 3-Position Switch .................9600383600RP

18. Transformers. . . . . . . . . . . . . . . . . . . . .9600690100RP

19. Mounting Hardware Kit . . . . . . . . . . . . .9600700100RP

20. Potentiometer ....................9600640100RP

21. Thermostat Assembly . . . . . . . . . . . . . .9600620100RP

22. Control Knob . . . . . . . . . . . . . . . . . . . . .9600630100RP

23. Power Board . . . . . . . . . . . . . . . . . . . . .9600590100RP

24. IR Receiver with Lens . . . . . . . . . . . . . .9600600100RP

25. Light Bulbs ............................ RB400

12

13

20

23

2

5

Page 6

WIRING DIAGRAM

6 www.dimplex.com

Page 7

HEATER ASSEMBLY REPLACEMENT

Tools Required: Philips head screwdriver

Flat head screwdriver

WARNING: If the replace was operating prior to ser-

vicing, allow at least 10 minutes for light bulbs and heating

elements to cool off to avoid accidental burning of skin.

WARNING: Disconnect power before attempting any

maintenance to reduce the risk of electric shock or damage

to persons.

1. Carefully remove the rocks from the front tray.

2. Remove the replace assembly from the wall by care-

fully lifting it upward, releasing it from the anges of the

wall-mounting bracket.

3. Carefully set the unit upright on a at working surface.

!

NOTE: If necessary, lay a protective barrier between

the unit and your work surface, (i.e. cloth, cardboard, thick

plastic) to avoid scratching your work surface.

4. Remove the three screws along the back edge of the

top of the unit and the two screws along the top of the

side edge. (Figure 5)

5. Gently remove the top panel, laying it on the work sur-

face so that all of the components can easily be seen.

6. Remove the 4 screws that secure the heater assembly

to the back panel. (Figure 6)

7. Disconnect the wiring connections noting their original

locations.

!

NOTE: A at head screwdriver can be used to gently

pry between the end of the connector and the switch to

release the wires.

8. Transfer the mounting brackets from the old heater as-

sembly to the new heater assembly.

9. Properly orient and install the new assembly and con-

nect all of the wiring.

10. Reassemble in the reverse order as above.

Figure 5

Top Panel

Figure 6

COMPONENT ACCESS

Tools Required: Phillips Head Screwdriver

WARNING: If the replace was operating prior to ser-

vicing, allow at least 10 minutes for light bulbs and heating

elements to cool off to avoid accidental burning of skin.

WARNING: Disconnect power before attempting any

maintenance to reduce the risk of electric shock or damage

to persons.

1. Carefully remove the rocks from the front tray.

2. Remove the replace assembly from the wall by care-

fully lifting it upward, releasing it from the anges of the

wall-mounting bracket.

3. Carefully set the unit upright on a at working surface.

!

NOTE: If necessary, lay a protective barrier between

the unit and your work surface, (i.e. cloth, cardboard, thick

plastic) to avoid scratching your work surface.

4. Remove the three screws along the back edge of the

top of the unit and the two screws along the top of the

side edge.

5. Remove the remaining 4 along the front side edge of

the unit on both sides and the three along either side of

the middle back of the unit. (Figure 7)

6. Lay the unit carefully down on the back surface.

7. From this point the entire front (sides and top) can be

lifted off of the back exposing all of the inner components.

ON/OFF SWITCH REPLACEMENT

Tools Required: Philips head screwdriver

Flat head screwdriver

WARNING: If the replace was operating prior to ser-

vicing, allow at least 10 minutes for light bulbs and heating

elements to cool off to avoid accidental burning of skin.

WARNING: Disconnect power before attempting any

maintenance to reduce the risk of electric shock or damage

to persons.

7

Page 8

Figure 7

1. Follow “Component Access” instructions before proceeding.

2. Locate the On/Off switch and disconnect the wiring

connections noting their original locations. (Figure 8)

!

NOTE: A at head screwdriver can be used to gently

pry between the end of the connector and the switch to

release the wires.

3. Depress the retainer clips on the rear of the switch and

push the switch out through the opening.

4. Properly orient and insert the new switch and connect

all of the wiring.

5. Reassemble in the reverse order as above.

3 POSITION SWITCH REPLACEMENT

Tools Required: Philips head screwdriver

Flat head screwdriver

WARNING: If the replace was operating prior to ser-

vicing, allow at least 10 minutes for light bulbs and heating

elements to cool off to avoid accidental burning of skin.

WARNING: Disconnect power before attempting any

maintenance to reduce the risk of electric shock or damage

to persons.

1. Follow “Component Access” instructions before pro-

ceeding.

2. Locate the 3 Position switch and disconnect the wiring

connections noting their original locations. (Figure 8)

!

NOTE: A at head screwdriver can be used to gently

pry between the end of the connector and the switch to

release the wires.

3. Depress the retainer clips on the rear of the switch and

push the switch out through the opening.

4. Properly orient and insert the new switch and connect

all of the wiring.

5. Reassemble in the reverse order as above.

THERMOSTAT REPLACEMENT

Tools Required: Philips head screwdriver

Flat head screwdriver

WARNING: If the replace was operating prior to ser-

vicing, allow at least 10 minutes for light bulbs and heating

elements to cool off to avoid accidental burning of skin.

WARNING: Disconnect power before attempting any

maintenance to reduce the risk of electric shock or damage

to persons.

1. Follow “Component Access” instructions before pro-

ceeding.

2. Locate the thermostat and disconnect the wiring con-

nections noting their original locations. (Figure 8)

!

NOTE: A at head screwdriver can be used to gently

pry between the end of the connector and the board to

release the wires.

3. Remove the screws securing the thermostat to the

chassis and gently lift the thermostat off.

4. Properly orient and install the new thermostat and con-

nect all of the wiring.

5. Reassemble in the reverse order as above.

POTENTIOMETER REPLACEMENT

Tools Required: Philips head screwdriver

Flat head screwdriver

WARNING: If the replace was operating prior to ser-

vicing, allow at least 10 minutes for light bulbs and heating

elements to cool off to avoid accidental burning of skin.

WARNING: Disconnect power before attempting any

maintenance to reduce the risk of electric shock or damage

to persons.

1. Follow “Component Access” instructions before pro-

ceeding.

2. Locate the potentiometer and disconnect the wiring

connections noting their original locations. (Figure 8)

!

NOTE: A at head screwdriver can be used to gently

pry between the end of the connector and the board to

release the wires.

3. Remove the screws securing the potentiometer to the

chassis and gently lift the potentiometer off.

4. Replace the control knob, if required.

5. Properly orient and install the new potentiometer and

connect all of the wiring.

6. Reassemble in the reverse order as above.

REMOTE RECEIVER REPLACEMENT

Tools Required: Philips head screwdriver

Flat head screwdriver

WARNING: If the replace was operating prior to ser-

vicing, allow at least 10 minutes for light bulbs and heating

8 www.dimplex.com

Page 9

Figure 8

Transformer

Thermostat

On/Off

Switch

3 Position Switch

Heater Assembly

IR

Sensor

Remote

Receiver

Power

Board

Potentiometer

elements to cool off to avoid accidental burning of skin.

WARNING: Disconnect power before attempting any

maintenance to reduce the risk of electric shock or damage

to persons.

1. Follow “Component Access” instructions before pro-

ceeding.

2. Locate the remote control receiver and disconnect

the wiring connections noting their original locations.

(Figure 8)

!

NOTE: A at head screwdriver can be used to gently

pry between the end of the connector and the board to

release the wires.

3. Remove the screws securing the remote receiver to the

chassis and gently lift the receiver off.

4. Properly orient and install the new remote control re-

ceiver and connect all of the wiring.

5. Reassemble in the reverse order as above.

POWER BOARD REPLACEMENT

Tools Required: Philips head screwdriver

Flat head screwdriver

WARNING: If the replace was operating prior to ser-

vicing, allow at least 10 minutes for light bulbs and heating

elements to cool off to avoid accidental burning of skin.

WARNING: Disconnect power before attempting any

maintenance to reduce the risk of electric shock or damage

to persons.

1. Follow “Component Access” instructions before pro-

ceeding.

2. Locate the power board and disconnect the wiring con-

nections noting their original locations. (Figure 8)

!

NOTE: A at head screwdriver can be used to gently

pry between the end of the connector and the board to

release the wires.

3. Remove the screws securing the power board to the

chassis and gently lift the board off.

4. Properly orient and install the new power board and

connect all of the wiring.

5. Reassemble in the reverse order as above.

TRANSFORMER REPLACEMENT

Tools Required: Philips head screwdriver

Flat head screwdriver

WARNING: If the replace was operating prior to ser-

vicing, allow at least 10 minutes for light bulbs and heating

elements to cool off to avoid accidental burning of skin.

WARNING: Disconnect power before attempting any

maintenance to reduce the risk of electric shock or damage

to persons.

1. Follow “Component Access” instructions before pro-

ceeding.

2. Locate the transformer and disconnect the wiring con-

nections noting their original locations. (Figure 8)

!

NOTE: A at head screwdriver can be used to gently

pry between the end of the connector and the board to

release the wires.

3. Remove the screws securing the transformer to the

chassis and gently lift the board off.

4. Properly orient and install the new transformer and

connect all of the wiring.

5. Reassemble in the reverse order as above.

IR SENSOR REPLACEMENT

Tools Required: Philips head screwdriver

Flat head screwdriver

WARNING: If the replace was operating prior to ser-

vicing, allow at least 10 minutes for light bulbs and heating

elements to cool off to avoid accidental burning of skin.

WARNING: Disconnect power before attempting any

maintenance to reduce the risk of electric shock or damage

to persons.

1. Follow “Component Access” instructions before pro-

ceeding.

2. Locate the IR sensor and disconnect the wiring con-

nection noting their original locations. (Figure 8)

3. Properly orient and install the new IR sensor and con-

nect the wiring.

4. Reassemble in the reverse order as above.

POWER CORD REPLACEMENT

Tools Required: Philips head screwdriver

Flat head screwdriver

Needle nose pliers

WARNING: If the replace was operating prior to ser-

vicing, allow at least 10 minutes for light bulbs and heating

elements to cool off to avoid accidental burning of skin.

WARNING: Disconnect power before attempting any

maintenance to reduce the risk of electric shock or damage

9

Page 10

Figure 9

to persons.

1. Follow “Component Access” instructions before proceeding.

2. Locate the power cord and disconnect the wiring connections noting their original locations.

!

NOTE: A at head screwdriver can be used to gently

pry between the end of the connector and the switch to

release the wires.

3. With needle nose pliers, grasp the power cord strain

relief grommet from inside the back of the bottom panel

and push while twisting to remove.

4. Install the new power cord.

5. Reassemble in the reverse order as above.

FAN ASSEMBLY REPLACEMENT MOTOR AND HOUSING

Tools Required: Philips head screwdriver

Flat Head Screwdriver

WARNING: Disconnect power before attempting any

maintenance to reduce the risk of electric shock or damage

to persons.

!

NOTE: Ensure that all of the components that

contain water have been emptied before performing any

maintenance.

1. Carefully remove the rocks from the front tray.

2. Remove the replace assembly from the wall by care-

fully lifting it upward, releasing it from the anges of the

wall-mounting bracket.

3. Carefully set the unit upright on a at working surface.

!

NOTE: If necessary, lay a protective barrier between

the unit and your work surface, (i.e. cloth, cardboard, thick

plastic) to avoid scratching your work surface.

4. Disassemble the sump components. (Figure 9)

5. Remove the 3 screws that hold the cover onto the fan

housing.

6. Remove the fan motor out of the housing and disconnect the wiring connection located near the bottom of

the housing.

7. If replacing only the motor, attach new motor and reassemble the remainder of the cassette in reverse order

from the instructions above.

• If replacing the housing, remove the 3 screws attaching

the base to the cassette. (Figure 6)

8. Attach new fan housing base to the cassette.

9. Transfer the lter from the old housing to the new housing.

10. Reinstall the fan motor and reconnect the wire.

11. Re-assemble the remainder of the cassette in reverse

order from the instructions above.

LIGHT ASSEMBLY REPLACEMENT

Tools Required: Phillips Head Screwdriver

WARNING: If the replace was operating prior to ser-

vicing, allow at least 10 minutes for light bulbs and heating

elements to cool off to avoid accidental burning of skin.

WARNING: Disconnect power before attempting any

maintenance to reduce the risk of electric shock or damage

to persons.

1. Carefully remove the rocks from the front tray.

2. Remove the replace assembly from the wall by care-

fully lifting it upward, releasing it from the anges of the

wall-mounting bracket.

3. Carefully set the unit upright on a at working surface.

!

NOTE: If necessary, lay a protective barrier between

the unit and your work surface, (i.e. cloth, cardboard, thick

plastic) to avoid scratching your work surface.

4. Disassemble the sump components. (Figure 9)

5. Lay the unit carefully down on the back surface.

6. Remove the light bulbs and place in a safe location.

7. Remove the two screws securing the light assembly

and housing bracket to the bottom panel.

8. Lift the assembly out and disconnect the wiring connec-

tions noting their original locations.

9. Remove the light assembly from the housing bracket.

10. Properly orient and install the new light assembly and

connect all of the wiring.

11. Reassemble in the reverse order as above.

10 www.dimplex.com

Page 11

TROUBLESHOOTING GUIDE

PROBLEM CAUSE SOLUTION

General

Circuit breaker trips or fuse

blows when unit is turned on

Lights dim in room while the unit

is on

Power cord gets warm Normal Operation The power cord may get slightly warm to the touch

Unpleasant smell when unit is

used.

Appearance

Fireplace does not turn on

Manually

Fireplace does not turn on with

the Remote Control

The ame effect will not start Switch A is in the ‘ON’ (I) position, but

The ame effect is too low. Flame effect control knob is set too low.

The ame effect has too much

smoke.

Mist is not coming out and the

red light by the transducer is

not on

Mist is coming out fast Filter is missing off of Fan Housing Replace Fan Filter

Mist does not appear to be coming out evenly

Short in unit wiring. Trace wiring in unit.

Improper circuit current rating Additional appliances may exceed the current rating

of the circuit breaker or fuse. Plug unit into another

outlet or install unit on a dedicated 15 amp circuit.

Unit is drawing close to circuit current

rating

Defective power cord Replace power cord if cord gets hot to the touch.

Dirty or stale water. Clean the unit as described under maintenance.

Improper operation Refer to Operation Section

No incoming voltage from the electrical

wall socket

Defective 3 Position Switch Replace 3 Position switch

Improper operation Refer to Operation Section

The batteries in the remote control are

dead.

Defective remote control Replace Remote Control

Defective remote control receiver Replace remote control receive

Defective IR sensor Replace IR sensor

mode Switch B has not been pressed.

(Figure 2)

Low water level. Check the water tank is full and there is water in the

Water in unit is too cold Allow water to warm to room temperature.

If using distilled or reverse osmosis water,

unit will not produce a consistent mist

Check that the fan is operating correctly Replace fan assembly

Cord is located over emitter on transducer Relocate cord so that mist is free to rise off of trans-

Defective Transducer Replace Transducer

(Figure 2)

Flame effect setting is too high. Turn the ame effect Control knob “C” to the right until

The cord from the power board is not

working

Unit is not level Level unit

Media is blocking air ow Rearrange media

A light bulb is burnt out Replace light bulb

Move the unit to another outlet or install unit on a dedicated 15 amp circuit

when the heater is on

Check Fuse/Breaker Panel

Install new battery into the remote control

Press Switch B once for ame effect. (Figure 2)

sump.

Add 1/8 tsp of table salt to water reservoir to introduce electrolytes, only repeat when mist is not being

produced correctly

Ensure that the air lter is clean and dry

ducer.

Increase level of ame by turning Control knob C to

the left slowly. (Figure 2)

it is at minimum and slowly turn to the left, about ¼ a

turn, at a time. Give the ame generator some time to

adjust before increasing. (Figure 2)

Ensure that the cord is not pinched.

Ensure that the cord is fully inserted into the connection on the power board.

11

Page 12

PROBLEM CAUSE SOLUTION

Heater

Heater is not turning off Improper operation Refer to Operation Section

Defective 3 position switch Replace 3 position switch

Defective thermostat Replace thermostat

Heater is not turning on Improper operation Refer to Operation Section

Loose wiring Trace Wiring

Defective heater assembly Replace heater assembly

Defective 3 position switch Replace 3 position switch

Heater is turning off after a

couple of minutes of operation

Heater emits an odor Normal Operation Normal operation is when the heater emits an odor

Heater fan turns on but heater

lacks heat

Heating element is glowing red Normal Operation Small glowing sections of the element are considered

Heater fan runs continuously Loose wiring Trace wiring in unit

Noise

Excessive noise with the heater onDirty heater assembly Ensure that exterior intake louvers and rebox cavity

Build up of dirt/dust in heater assembly Ensure that exterior intake louvers and rebox cavity

are free of dirt/dust.

Defective Heater Assembly Replace Heater Assembly

for a brief period after the heater is initially turned on.

The heater is burning off any dust accumulated during

manufacturing or operation.

Defective heater assembly Replace heater assembly

Improper operation Refer to Operation Section

Loose wiring Trace wiring in unit

Defective heater assembly Replace heater assembly

normal.

Defective heater assembly If larger glowing sections are causing the heater to trip

the thermal cutout, unplug unit, discontinue use and

replace heater assembly.

Defective momentary switch Replace momentary switch

Defective heater assembly Replace heater assembly

are free of dirt/dust.

Defective heater assembly Replace heater assembly

12 www.dimplex.com

Loading...

Loading...