Page 1

ContactDetails

Pleasenotethatsomeofthecontactdetailson

thisPDFdocumentmaynotbecurrent.

Pleaseusethefollowingdetailsifyouneedto

contactus:

Telephone:08448793588

Email:customer.services@gdcgroup.co.uk

Thecustomersupportsectionofourwebsitealsofeaturesawide

rangeofinformationwhichmaybeofusetoyouandisavailable

24hoursaday.Itincludes:

• Operatingandinstallationinstructions

• Easy‘Howtouse’guidesforstorageheaters

• Serviceandrepairs

• Where

tobuyourproducts

• Literaturedownloads

• Heatingrequirementcalculator

Visit‐www.dimplex.co.uk/support

A division of GDC Group Ltd

Millbrook House Grange Drive Hedge End Southampton SO30 2DF

www.dimplex.co.uk

Registered No: 1313016 England

VAT GB 287 1315 50004

EEE Producer Registration Number –

WEE/GE0057TS

Paper from sustainable sources

Page 2

INSTALLATION AND USER MANUAL

WOOD BURNING CASSETTE

Page 3

INSTALLATION AND USE MANUAL

Data

Label

page

2

Technical service – Dimplex - all rights reserved - Reproduction prohibited

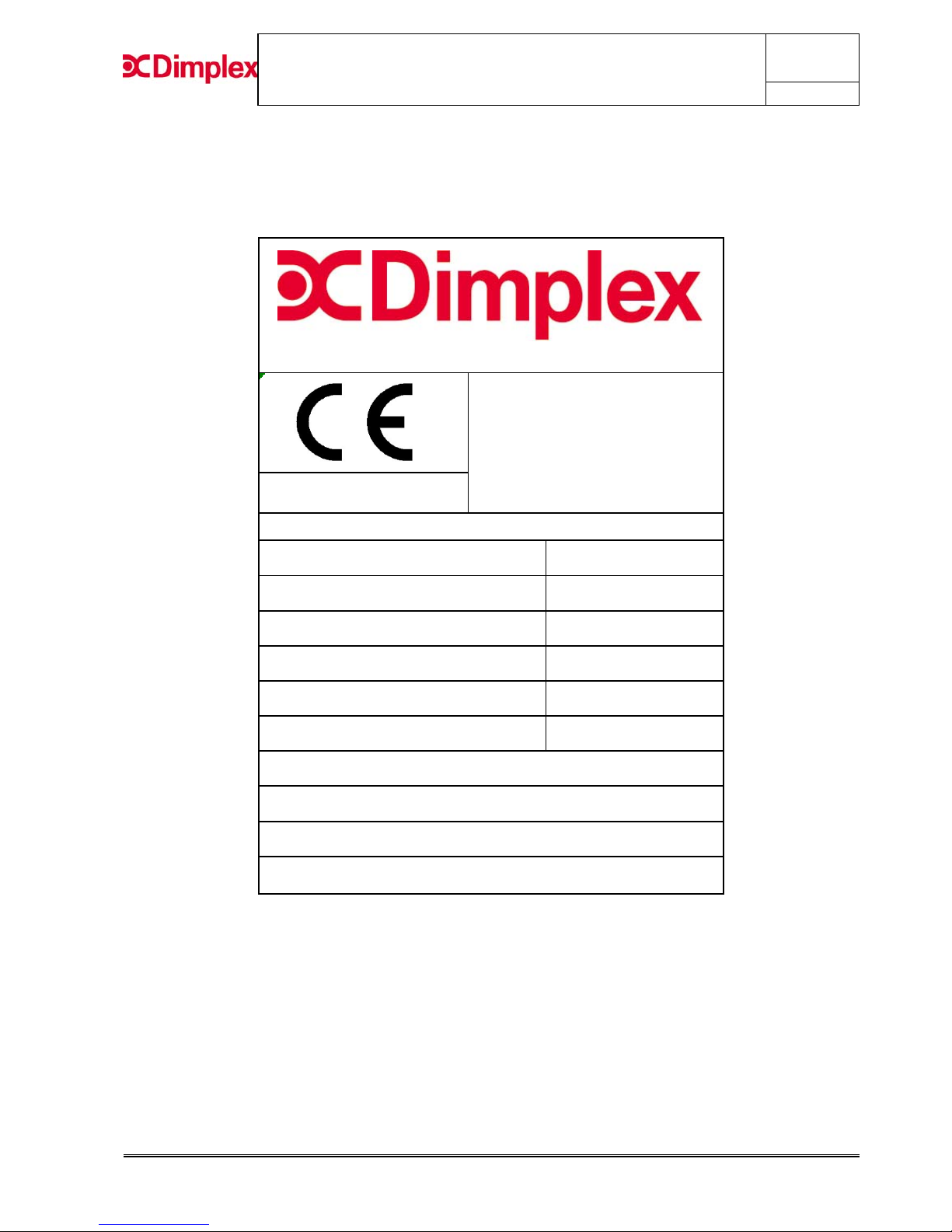

EN 13229:2001, A1:2003,

A2:2004, AC:2006, A2/AC:2006

Nominal Heat Output:

CO Emission (at 13% O2)

Efficiency:

Flu e Gas Temperature:

Safe Clearence d i st an ce

to combustib l es (back):

Safe Clearence d i st an ce

to combustib l es (side):

GDC GROUP Ltd - Millbrook House Grange Drive Hedge End

Southampton Hampshire SO30 2DF - England

10

VKF AEAI

Art. 15a B-VG

Rege nsburger - Münchener BStV

BImSchV

8 kW

0.11%

83.7%

240 °C

100 mm

Read and follow the user instructions

COD: 8901005900

100 mm

Intermi ttent ope ra ting uni t

Wood burning use only

DC700 Wood Burni ng Casse t t e

Do not insta ll on a shared flue

Page 4

INSTALLATION AND USE MANUAL

Contents

page

3

Technical service – Dimplex - all rights reserved - Reproduction prohibited

INTRODUCTION .................................................................................................................................... 5

1. WARNINGS AND WARRANTY CONDITIONS ..................................................................................... 6

1.1. SAFETY WARNINGS ........................................................................................................................ 6

1.2. OPERATING WARNINGS .................................................................................................................. 6

1.3. WARRANTY CONDITIONS ................................................................................................................ 7

1.3.1. Restrictions .............................................................................................................................. 7

1.3.2. Exclusions ................................................................................................................................ 7

1.3.3. After Sales Service.................................................................................................................... 7

2. INSTALLATION GUIDELINES ............................................................................................................. 8

2.1. OPERATING AREA ........................................................................................................................... 8

2.2. PRECAUTIONS ................................................................................................................................ 8

2.3. CONNECTION TO THE EXTERNAL AIR INTAKE .................................................................................. 9

2.4. CHIMNEY FLUE PREPARATION ....................................................................................................... 10

2.5. CHIMNEY FLUE PIPE ..................................................................................................................... 10

2.5.1. Examples of chimney flue pipes ............................................................................................... 10

2.6. COWL .......................................................................................................................................... 12

3. DIMENSIONS AND TECHNICAL SPECIFICATIONS .......................................................................... 14

4. INSTALLATION AND ASSEMBLY ...................................................................................................... 15

4.1. PREPARATION AND UNPACKING .................................................................................................... 15

4.2. ELECTRICAL CONNECTION ............................................................................................................ 15

4.3. SELECTION OF OPERATING MODE ................................................................................................. 16

4.3.1. Natural convection ................................................................................................................. 16

4.3.2. Forced convection (ventilation kit) ........................................................................................... 16

4.4. GENERAL ASSEMBLY RULES .......................................................................................................... 17

4.4.1. FITTING OF REFRACTORY WALLS (ALUTEC

®

) .......................................................................... 18

4.4.2. INSERT ASSEMBLY ................................................................................................................. 18

4.4.2.1. Removal of the Flue Collar ................................................................................................ 18

4.4.2.2. Removal of the firebox ..................................................................................................... 18

4.5. CONNECTION TO THE FLUE PIPE ................................................................................................... 19

4.5.1. DIRECT CONNECTION TO FLUE PIPE ....................................................................................... 19

4.5.2. FLUE DAMPER (NOT SUPPLIED) .............................................................................................. 20

4.6. INSTALLATION OF CLADDING FRAME AROUND THE STOVE ............................................................ 20

4.7. INSTALLATION OF FINISHING FRAME (OPTIONAL) ......................................................................... 20

4.8. INSULATING A WOODEN BEAM ..................................................................................................... 21

4.9. SUMMARY DIAGRAM FOR OPTIMUM CONNECTION OF THE INSERT STOVE ...................................... 21

5. OPERATION ..................................................................................................................................... 22

5.1. PRE-LIGHTING WARNINGS ............................................................................................................ 22

5.2. CHOICE OF FUEL .......................................................................................................................... 23

5.3. FIRST LIGHTING .......................................................................................................................... 23

5.4. LOADING THE FUEL ...................................................................................................................... 24

5.5. CONTROL OF COMBUSTION .......................................................................................................... 25

5.6. EMERGENCY SITUATIONS ............................................................................................................. 25

Page 5

INSTALLATION AND USE MANUAL

Contents

page

4

Technical service – Dimplex - all rights reserved - Reproduction prohibited

6. MAINTENANCE AND CLEANING ...................................................................................................... 26

6.1. CLEANING TO BE PERFORMED BY THE USER .................................................................................. 26

6.1.1. Cleaning the glass .................................................................................................................. 26

6.1.2. Cleaning out the ashes ........................................................................................................... 26

6.1.3. Cleaning the refractory material walls (ALUTEC

®

) ..................................................................... 26

6.1.4. Cleaning the upper deflector (Calorite) ..................................................................................... 27

6.1.5. Cleaning of painted parts ........................................................................................................ 27

6.2. CLEANING TO BE DEALT WITH BY SPECIALIZED TECHNICIAN ......................................................... 27

6.2.1. Cleaning flue pipe ................................................................................................................... 27

Page 6

INSTALLATION AND USE MANUAL

Chapter 1

page

5

Technical service – Dimplex - all rights reserved - Reproduction prohibited

INTRODUCTION

Dear customer,

Thank you for choosing this wood burning cassette

stove. We are sure that, with use, you will appreciate

the quality of an attentively designed and tested

product. Our goal is to combine technology with easy

use and, above all, safety.

For best stove operations and to fully enjoy the

heat and sense of well-being it will spread

throughout your home, we suggest you

carefully read this booklet before use. Please

contact your dealer for full assistance in

resolving any doubts or problems.

Congratulations on your choice and remember, the

stove MUST NEVER be used by children who should

always be kept at a safe distance!

Revisions to the publication

In order to improve the product, the Manufacturer

reserves the right to modify and update this

publication without prior notice.

Reproduction, even partial, of this manual without the

Manufacturer's authorisation is prohibited.

Manual preservation

• Please take care of this manual and keep it in a

place that can be quickly and easily reached.

• If this manual should be lost or destroyed, or if it

is in poor condition, ask for a copy from your

retailer or directly from the manufacturer,

providing product identification data.

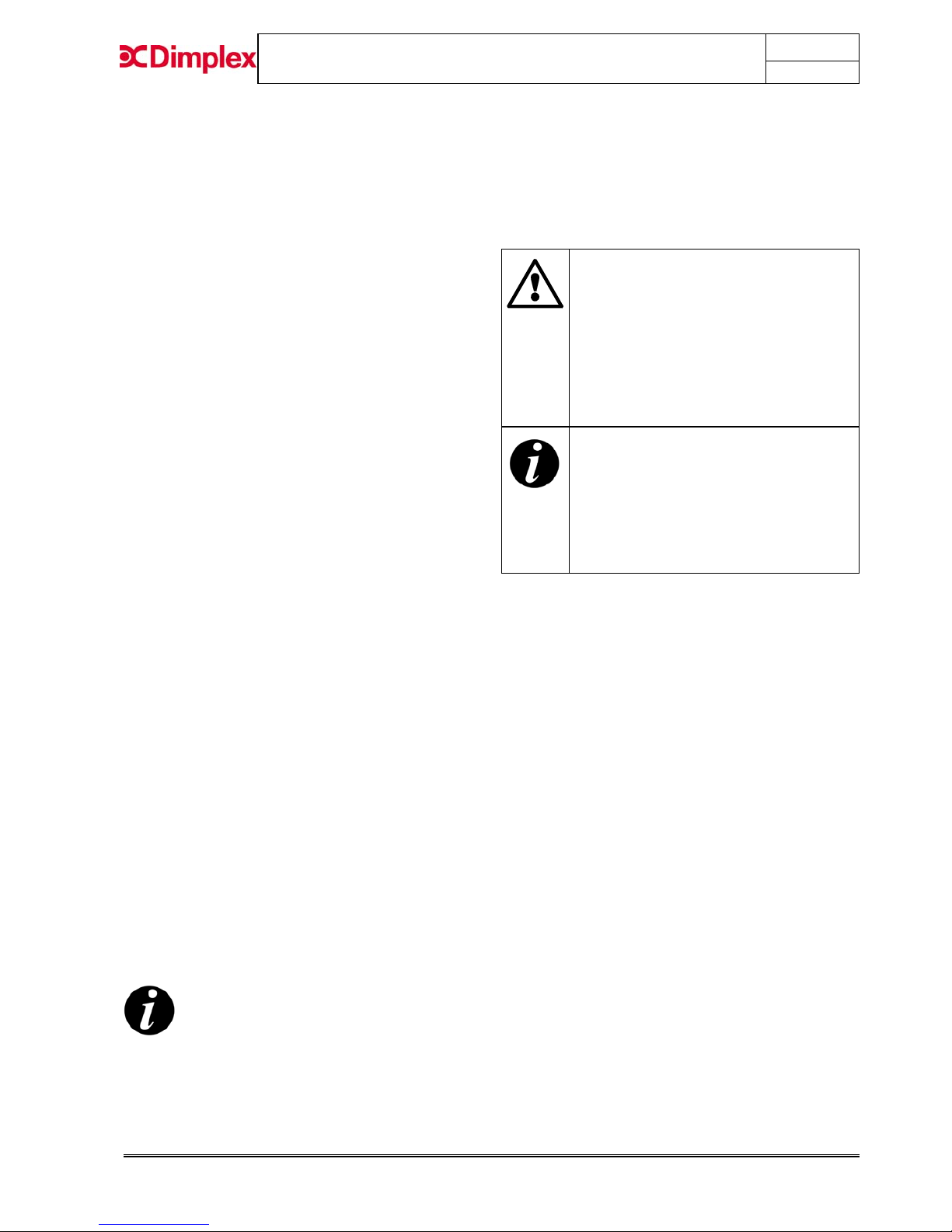

How to read the manual

• An essential item or one that requires specific

attention is published in “bold”.

•

“Italics"

are used for any additional clarification.

• NOTE: the “NOTE” provides the reader with

additional information on the subject.

This appliance is suitable for wood

burning only. Only use fully seasoned

timber that has been allowed to dry for a

period of at least 12 months. Do not use

other types of fuel and do not use as an

incinerator.

(Refer to section 5.2 for further details).

These symbols signal specific messages

in this booklet

WARNING:

This warning symbol found in various

points in this manual indicates that the

user should carefully read and understand

the message to which it refers since

neglect to follow these instructions

could cause serious fireplace stove

damage or injury to the user.

INFORMATION:

This symbol intends to emphasise

important information for good fireplace

stove operations. Failure to observe these

instructions could jeopardise product use

and operations may be unsatisfactory

Page 7

INSTALLATION AND USE MANUAL

Chapter 1

page

6

Technical service – Dimplex - all rights reserved - Reproduction prohibited

1. WARNINGS AND WARRANTY

CONDITIONS

1.1. SAFETY WARNINGS

• Please read these instructions carefully before

installing or using this appliance. Failure to do so

may result in damage to persons and property.

• Installation of this appliance must be carried out

by a suitably qualified competent person in

accordance with all Building Regulations,

including those referring to Local Authority ByeLaws, National and European Standards and

Codes of Practice.

• Dimplex is not civilly or criminally liable for

damages to persons and property arising from

incorrect installation or poor maintenance (not

compliant with the provisions of this manual).

• This apparatus should not be used by people

(including children) with limited physical,

sensorial or mental abilities or with little

experience and know-how unless they have been

instructed on the use of the apparatus by the

person responsible for its safety.

• For correct use of the fireplace stove and

accessories, and to prevent accidents, always

follow the instructions in this booklet.

• The fireplace stove must be used only for its

intended purpose. Any other use is considered

improper and therefore hazardous.

• The user is fully liable for improper product use,

releasing Dimplex from any liability.

• Any tampering with the fireplace stove, or use of

non-original spare parts, may be hazardous to

the user and releases Dimplex from any liability.

• This appliance operates at very high

temperatures and surfaces become hot during

use and for a period after use. Avoid direct

contact with the stove unless wearing suitable

protective clothing (e.g. glove provided). All

persons including children and the infirm should

be warned of this and not allowed to touch any

surfaces while in use. Please use a suitable

fireguard to prevent contact when in use.

1.2. OPERATING WARNINGS

• Do not use this appliance in the event of faults or

poor stove operation. If the stove is over-firing or

if there are problems with chimney draught, turn

off the air supply to this stove and consult a

suitably qualified technician (HETAS Engineer or

Chimney Sweep).

• Once installed, never place flammable materials

closer than 150 cm to the fireplace stove.

• Avoid installation in rooms with B type gas

devices, hoods with or without exhaust, heat

pumps or collective ventilation conduits.

• Do not fit an extractor fan in the same room as

this appliance.

• Do not install this appliance on a shared flue.

• Do not install several flue pipes in one room, and

avoid having a stairwell in the vicinity. Check that

in adjacent connected room there are not any

units whose simultaneous use would create

negative pressure in one of the two rooms.

• Install the stove in a location which is suitable for

fire lighting, and equipped with all services such

as air supply, smoke discharge and electricity

supply (if forced ventilation kit is used).

• Ensure that there is adequate ventilation in the

room in accordance with Building Standards. Do

not obstruct any of the air inlets or outlets on the

appliance.

• The stove should sit on a non-combustible

surface that conforms to Building Regulations.

Allow a hearth of 300mm to the front at floor

level in case of spills when re-fuelling or deashing.

• This appliance is suitable for wood burning

only. Do not burn petroleum coke or other solid

fuels (including coal, ancit, briquettes, etc),

household waste or plastic in this appliance.

• Do not use flammable liquids in this product.

• Burn only wood with low moisture content -

burning softwood, wet or unseasoned timber will

only result in a build-up of tar in the stove and

the chimney and will cause staining of the glass.

INFORMATION:

• For any problem, please contact your dealer or

qualified and authorised personnel and always

request original spare parts for repairs.

• Check and clean the flue prior to installation and

have flue cleaned yearly thereafter.

• If there is a fire in the flue pipe, keep the door of

the fireplace stove and the combustion air

register closed at all times. Request assistance

from the emergency services.

• Carefully conserve the instruction booklet. It

must remain with the fireplace stove for its entire

life cycle. If the stove is sold or transferred to

another user, make sure the manual

accompanies the product.

• If lost, please request a copy of this instruction

from your dealer.

Page 8

INSTALLATION AND USE MANUAL

Chapter 1

page

7

Technical service – Dimplex - all rights reserved - Reproduction prohibited

1.3. WARRANTY CONDITIONS

Your stove is guaranteed against defects arising from

faulty manufacture, except for the elements

subject to normal wear listed below, for 2 years

from the date of purchase proven by a document that

indicates the dealer's name and date of sale and only

if the product was installed and inspected by a

specialised installation technician (HETAS Engineer or

equivalent), according to the detailed instructions

indicated in this instruction manual supplied with the

product. Upon installation a certificate of compliance

must be presented by your installer.

The warranty includes the free replacement or repair

of parts recognised as factory defective.

1.3.1. Restrictions

The above guarantee does not cover components

relating to electrical parts (where fitted), on which the

guarantee period is 1 year from the purchase of the

product, documented as specified above. The

warranty does not cover parts subject to normal wear

such as: gaskets, glass, and all removable fire

box parts (including Alutec

®

and Firebrick).

Replaced parts will be guaranteed for the remaining

warranty period from the date of product purchase.

Only genuine spare parts must be used for all

replacements.

1.3.2. Exclusions

The warranty does not cover any part that may

be defective due to negligence or careless use,

incorrect maintenance, installation that is not

compliant with that specified (see relevant

chapters in this manual).

Dimplex refuses to accept any responsibility for any

damage which may be caused, directly or indirectly,

by persons, animals or property as a result of the

failure to observe all the provisions set forth in the

instruction booklet, especially those concerning

warnings on the subject of installation, use and

maintenance of the appliance.

In the event of product inefficiency, please contact

your dealer and/or area importer.

Damages caused by transport and handling are not

covered by the warranty.

Exclusively refer to the supplied manual for product

installation and use.

The warranty is null and void in the event of damage

due to tampering, weather, natural calamities,

lightening, fire, defective electrical and hydraulic

systems and the lack or incorrect maintenance as per

the manufacturer's instructions.

1.3.3. After Sales Service

Should you require after sales service or should you

need to purchase any spares, please contact the

retailer from whom the appliance was purchased.

Please do not return a faulty product to us in the first

instance as this may result in loss or damage and

delay in providing you with a satisfactory service.

Please retain your receipt as proof of purchase.

For further information about this product, please

contact Dimplex in the UK (Tel: 0845 600 5111) or

Dimpco in ROI (Tel 01 842 4833).

Dimplex is not liable in the event the

product and any other accessory is

improperly used or modified without

authorisation.

Page 9

INSTALLATION AND USE MANUAL

Chapter 2

page

8

Technical service – Dimplex - all rights reserved - Reproduction prohibited

2. INSTALLATION GUIDELINES

These instructions give a guide for the installation of the stove but in

no way absolves the installer from responsibilities to conform to all

relevant standards relating to the installation of solid fuel appliances.

We recommend that for UK installations a HETAS registered installer

should be used, who will be able to give a Certificate of Compliance to

prove that installation complies with Building Regulations. In Ireland a

registered installer from the Irish National Fireplace Organization should

be used.

2.1. OPERATING AREA

For good operation and good heat distribution, your stove should be

installed in a room that is large enough for heat to circulate.

To allow

sufficient area for heat dissipation and prevent room overheating, the

room volume must not be less than 60 m

3

.

Please note:

• Fireplace stoves may not be installed in

bedrooms, bathrooms or where another heating

device is installed without autonomous air flow

(fireplace, stove, etc.).

• Placing the fireplace stove in explosive

environments is prohibited.

• In all instances the stove should be positioned on

a non-combustible hearth. The construction of the

hearth must conform to Building Regulations,

must be firm, non-combustible and capable of

supporting the stove.

• A protective hearth must provide an apron of

300mm to the front of the stove at floor level in

case of spills when refuelling or de-ashing.

• The walls surrounding the stove should be made

from non combustible materials where possible

and at all times minimum safe distances to

combustibles (100mm to sides and rear) must be

observed.

• A minimum air gap of at least 5mm should be

observed from any masonry, brick or other non

flammable type walls surrounding the stove.

2.2. PRECAUTIONS

The fireplace stove must be installed in a suitable location that permits

routine opening and maintenance operations. The room must be:

• suitable for stove operating conditions

• equipped with an adequate smoke exhaust system

• equipped with outdoor ventilation

Page 10

INSTALLATION AND USE MANUAL

Chapter 2

page

9

Technical service – Dimplex - all rights reserved - Reproduction prohibited

IMPORTANT!

• The fireplace stove must be installed and

assembled by qualified personnel.

• The fireplace stove must be connected to a flue

pipe or other vertical smoke stack that can

discharge smoke at the highest point of the

house.

• The fireplace stove must be connected to a flue

pipe or an internal or external vertical duct

conforming to Building Regulations.

• Smoke is generated from burning wood and,

therefore, may dirty adjacent or nearby walls.

• Before positioning the fireplace stove, you must

make a hole for the intake of external air.

2.3. CONNECTION TO THE EXTERNAL AIR INTAKE

The room where the stove is installed must have a constant supply of

combustion air in compliance with local Building Regulations.

Combustion air must be provided (in addition to normal room

ventilation) through open vents in the walls near the fireplace stove.

These vents must not be obstructed in any way.

For this purpose, we recommend the stove is be provided with a

permanently open vent of minimum open section 100cm² for the

supply of combustion air, protected by an indoor and outdoor grille. A

larger vent may be used if it is also required to supply room ventilation

in addition to combustion air (refer to local Building Regulations).

It is extremely important to comply fully with

providing vents for combustion air, otherwise the lack

of oxygen during stove use may compromise the

safety of the installation.

The air intake must:

• directly communicate with the installation area

• be protected by a grille, made of metallic anti-insect mesh or a

suitable protection as long as it does not reduce the minimum

section.

• be installed so as to avoid obstruction

• increase in duct size by 5% for duct lengths between 0.5m to

3.5m. For duct lengths over 3.5m the duct size should be

increased by 15%.

Remember that the ventilation grills always have a cm

2

useful section on one side. When selecting the grill and hole

dimension, make sure the useful grill section is greater than

or equal to the section required for product operations.

Page 11

INSTALLATION AND USE MANUAL

Chapter 2

page

10

Technical service – Dimplex - all rights reserved - Reproduction prohibited

IMPORTANT!

Air flow may also be obtained from a room adjacent

to the installation room as long as this flow is free

through permanent apertures that directly

communicate with the outdoors; avoid air outlets

connecting with heating units, garages, kitchens or

bathrooms.

2.4. CHIMNEY FLUE PREPARATION

The connection to the chimney flue is a very important element. Before

installing, check the chimney flue is in good condition; dry and free

from cracks and obstructions. The diameter of the chimney flue should

not be less than 180mm and not more than 220mm in diameter. If any

of these requirements are not met, the chimney should be lined by a

suitable method by a qualified person.

The chimney height and the position of the chimney terminal should

conform to Building Regulations. If you have any doubts about the

suitability if your chimney, consult your local dealer or stockist.

The chimney must be swept before connection to the stove and should

be swept yearly thereafter.

Do not install this appliance on a shared flue.

2.5. CHIMNEY FLUE PIPE

The chimney flue pipe is a fundamental element in discharging

smoke and therefore must have the following requisites:

• It must be waterproof and thermally insulated.

• It must be made with heat resistant materials, resistant to

combustion products and any condensation.

• It must have a vertical slope where possible with axis

deviations not over 45° and without narrowing.

• It must meet the requisites indicated in the technical table for

the internal chimney section and height.

• It must preferably have a circular interior section.

• It must be cleaned before installation and at least once yearly

thereafter.

The flue pipe is of primary importance for the correct

functioning and safety of your fireplace stove.

2.5.1. Examples of chimney flue pipes

Page 12

INSTALLATION AND USE MANUAL

Chapter 2

page

11

Technical service – Dimplex - all rights reserved - Reproduction prohibited

Square or rectangular section flue pipes must have rounded internal

corners with radius not less than 20mm. For the rectangular section,

the ratio between internal dimensions must be ≤1.5.

The recommended section for a flue pipe according to its length is

listed in the table below:

Height (m) Useful section (cm²)

Up to 5 m

600 (20x30 cm o ∅ 22 cm)

Between 5 and 7 m.

400 (20x20 cm o ∅ 20 cm)

Over 7 m

324 (18x18 cm o ∅ 18 cm)

N.B. Too small or too large a section reduces draught and insulation.

Where the chimney flue is not vertical or access for cleaning is

restricted, the chimney flue should be equipped with a solid material

collection chamber at the flue base to be easily opened with an airtight

door.

IMPORTANT!

In the event of doubt on your chimney flue operations or

that its dimensions are different from those recommended,

we highly suggest an authorised technician inspect and

measure chimney flue performance.

The company shall not be held liable for poor operation of

the fireplace stove that is due to a flue pipe of improper size

or installation that does not comply with this instruction

booklet and Building Regulations.

AISI 316 stainless steel flue

pipe with dual chamber

insulated with ceramic wool

or equivalent resistant to

400°C.

EXCELLENT

Flue pipe in refractory brick

with insulated double wall and

external coat of cement mix

lightened with honeycomb

material such as clay.

GOOD

Traditional square section

clay flue pipe with insulating

hollow inserts.

GOOD

Avoid flue pipes with internal

rectangular sections whose

larger side is double the smaller

such as 20x40 or 15x30.

AVERAGE

Page 13

INSTALLATION AND USE MANUAL

Chapter 2

page

12

Technical service – Dimplex - all rights reserved - Reproduction prohibited

2.6. COWL

If incorrectly specified, the type of cowl used can be a severe

impediment to correct "chimney system" operations. Flue pipe

draught also depends on its cowl.

If your cowl is hand-made, the exhaust area must correspond to more

than twice the internal section of the flue pipe.

Having to exceed the peak of the roof, the cowl will be

exposed to wind. The most suitable type of cowl will depend

on your location, therefore seek assistance from your installer.

The cowl must meet the following requisites:

• It must comply with Building Regulations.

• It must have an internal section equal to that of the chimney.

• It must have a useful output section not less than double that

of the internal section of the flue pipe.

• It must be built to prevent rain, snow and any foreign objects

from getting into the flue pipe.

• They must be installed to guarantee adequate smoke

dispersion and out of the reflux area where negative pressure

forms.

For paired flue pipes, the cowl for solid combustion

and the one for the upper floor must be at least 50cm

higher than the other to avoid pressure transfers

between paired flues.

The cowl must not have obstacles within 10 m such as

walls, roof slopes and trees. Otherwise, raise it at least

1 m over the obstacle and, in the event of other

nearby cowls, keep them at least 2 m away. In any

case, the cowl must exceed the peak of the roof by at

least 1m.

1

m

t

0

,

5

m

t

An industrial cowl,

with prefabricated

sections fitting

together, allows

optimal disposal of

the flue gases.

A traditional

handmade cowl.

The right exhaust

section must be at

least twice the

internal section of

the flue pipe, 2.5

times is ideal.

Steel cowl for flue pipe

with internal smoke

deflector cone.

Page 14

INSTALLATION AND USE MANUAL

Chapter 2

page

13

Technical service – Dimplex - all rights reserved - Reproduction prohibited

Page 15

INSTALLATION AND USE MANUAL

Chapter 3

page

14

Technical service – Dimplex - all rights reserved - Reproduction prohibited

3. DIMENSIONS AND TECHNICAL SPECIFICATIONS

DC700 Technical specifications

4

5

0

2

5

0

Ø180

695

5

1

5

5

0

8

.

5

Fuel type Wood

Hourly consumption 2,1kg/h

(load 1,7 in 50 min)

Nominal thermal power kW 8 Kcal 6880

Efficiency 83.7%

Recommended draught 12 Pa / 0,12 mbar

Smoke temperature 240°C

Smoke outlet Ø 18 cm

Fire box dimensions 45x18 H17 cm

Net weight 100 kg

External combustion air outlet cm² 150

CO emission in smoke

(13 %O

2

)

0.11%

Flue Gas Mass Flow 6.7 g/s

Flue pipe

Up to 5 m 20x30 cm Ø22

Between 5 and 7 m. 20x20 cm Ø20

Over 7 m 18x18 cm Ø18

Note

Intermittent Burning Appliance.

Do not install this appliance on a shared flue.

Page 16

INSTALLATION AND USE MANUAL

Chapter 4

page

15

Technical service – Dimplex - all rights reserved - Reproduction prohibited

4. INSTALLATION AND ASSEMBLY

IMPORTANT!

The fireplace stove must be installed and connected

to the chimney flue only by a specialized technician,

so that all local and national regulations are complied

with.

Installation must in any case be carried out in

compliance with Building Regulations.

When the fireplace is unpacked, check for perfect operation of all

its parts or any damage which may have occurred during

shipping. The retailer or the carrier must be immediately

informed of any damage.

If the fireplace stove is installed in a place that is difficult to reach, its

weight can be reduced by removing the internal parts that make up the

fire box. However, be sure to put all of the parts back in place.

This operation is to be carried out only by specialized

personnel.

The company shall not be held liable if the preceding warning

is not complied with.

4.1. PREPARATION AND UNPACKING

Open the packaging, remove the stove unit from the pallet and position

it in the chosen location, taking care that its position complies with the

above instructions.

The fireplace stove must always be kept in a

VERTICAL position during handling, using the

appropriate handles located on the sides.

Be especially careful that the door and its glass are protected from

mechanical collisions that could jeopardise their integrity.

Moving the product must be done with care. If possible, unpack the

fireplace stove in the area where it is to be installed.

The materials which make up the packaging are not toxic or harmful,

so no special procedures for disposal are required.

The final user must store, dispose or recycle packaging material in

accordance with local regulations.

4.2. ELECTRICAL CONNECTION

If the optional forced ventilation kit has been specified, before

positioning the stove insert, a 230V - 50 Hz electrical power outlet must

be prepared near the insert in order to connect the electrical cable that

powers the forced ventilation fans.

The socket must be fitted with earth and must be accessible at all times

to cut off power when servicing equipment. The socket must be

protected from heat given through stove operation – observe safe

distances to combustibles at all times.

Example of fireplace stove packing

Page 17

INSTALLATION AND USE MANUAL

Chapter 4

page

16

Technical service – Dimplex - all rights reserved - Reproduction prohibited

IMPORTANT!

Connection of electrical cables should only be carried

out by a suitably qualified engineer or electrician. The

ventilation kit must be connected to a bipolar switch

complete with fuses.

When preparing the connection of the electric cable

provided with the Forced Ventilation kit, be very

careful not to crush the cable while inserting the

product. This could cause short circuits that can

damage the entire electrical system.

Make sure that the cables do not come into contact

with the hot metal parts of the structure, as they

could melt and short circuit the electrical system.

The motor and the thermostatic switch must be

accessible when installed in the stove for

maintenance or repair.

4.3. SELECTION OF OPERATING MODE

IMPORTANT!

With either NATURAL CONVECTION or with FORCED

V

ENTILATION it is necessary to provide connection to

an external air intake. Do not for any reason obstruct

the air intakes if the fireplace stove or ventilation kit is

in operation.

Your DC700 is designed to use convection currents within the doubleskinned casing of the product to draw cold air in at the base of the

stove which emerges as heated air from the vents above the door. This

effect circulates the heat from the product more effectively than relying

on radiant heat only.

Where installation permits, the DC700 can be built into an opening that

incorporates additional convection space around the outer casing to

enhance Natural Convection. Alternatively the convection effect can

also be enhanced through use of a Forced Ventilation Kit.

4.3.1. Natural convection

If this system is chosen, an air intake must be prepared (A) below the

stove, that has a free passage surface of at least 150 cm

2

to allow the

natural fresh air flow into the installation cavity and around the stove

body. The air for the natural convection ventilation (B) will exit from

the front part in the opening between the firebox and the outer

cladding and will be uniformly dispersed throughout the room (fig.1).

4.3.2. Forced convection (ventilation kit)

A Forced Ventilation kit can be installed to supplement the natural

convection of the room and circulate the heat where room convection is

low. For this system an air intake must be prepared (fig 1. A) below

the stove, at east 150cm

2

free area same as for natural ventilation.

Once installed, a built in temperature sensor turns the fan unit on when

the motor ambient reaches 50/60°C. This in turn circulates air around

the stove and into the room to help the convection process.

A

B

B

B

Figure 1 – Natural convection

Figure 2 - FV kit assembly

A

B

C

D

E

Page 18

INSTALLATION AND USE MANUAL

Chapter 4

page

17

Technical service – Dimplex - all rights reserved - Reproduction prohibited

5

0

5

0

5

0

50

50

AIR

INSULATION

WALL

WALL

AIR

INSULATION

5

0

5

0

50

50

The motor and thermostatic switch should be checked when

they are installed and wired up to ensure correct operation

of the motor. To check the operation use a hairdryer (or

similar heat device) to direct hot air at the temperature

sensor. The motor should switch on when the temperature

sensor reaches a temperature 50/60°C. Do not use naked

flames (matches, lighter, etc) to check the sensor

operation as these can damage irreparably the

motor, wires or sensor.

The time taken for the motor to switch on will vary for each burn cycle

depending on type and amount of fuel used (see paragraph “5.2 choice

of fuel”). If the motor fails to switch on during normal burning it may

be indicative of some other problem with the combustion process (e.g.

poor flue draught or air convection or insufficient combustion air, etc).

KIT ASSEMBLY:

Open the door and unscrew the fixing screws C to remove the

protective motor cover B (fig. 2). Carefully place the motor ventilation

kit inside the stove chassis taking care that the motor or temperature

sensor contacts to not get damaged or come into contact with stove

body. Use fixing screws provided to secure the kit to the chassis at

fixing points D. Feed the motor cable through the rubber grommet on

the side of the stove until it meets the stop on the cable (fig. 3).

Reasssemble the motor cover using fixing screws C.

4.4. GENERAL ASSEMBLY RULES

The stove insert can be installed either in an existing suitable firebox

cavity (of solid wall construction) or installed within a purpose-made

structure.

If the fireplace stove is positioned in an existing firebox cavity, check

that the dimensions of the firebox are compatible for insertion.

Always leave a minimum 10 mm airspace between the stove

and any adjoining walls of solid wall construction (i.e. made of

solid block, masonry, brick or concrete). This is required to allow

the stove body to expand/contract during use.

For purpose built structures, please comply with the following

minimum safe distances from combustible materials (as shown

in Fig 4).

• 50 mm air + 50 mm insulation from the side, the back

and the top.

• Non Combustible surface on the bottom.

If the stove is positioned over a floor or close to

walls made of flammable materials, it is advisable to

use sufficient insulation.

The stove can be installed at a desired height above the ground

provided there is suitable support structure in place. In all instances the

stove should be positioned on a non-combustible surface that conforms

to Building Regulations. Allow a hearth of 300mm to the front at floor

level in case of spills when re-fuelling or de-ashing.

Figure 3 - FV kit assembly detail

Figure 4 – Minimum Clearance to

Combustibles (Purpose Built Structure)

Page 19

INSTALLATION AND USE MANUAL

Chapter 4

page

18

Technical service – Dimplex - all rights reserved - Reproduction prohibited

The walls surrounding the stove should be made from non combustible

materials (e.g. block, brick, concrete, fire-rated plasterboard

construction, etc) and at all times minimum safe distances to

combustibles must be observed.

We recommend installing the outer body of the stove first in the

required cavity (see section 4.4.2 to remove firebox).

4.4.1. FITTING OF REFRACTORY WALLS (ALUTEC®)

To protect against damage during shipping, the rear refractory firebrick

(inner ceramic wall) is not in place and must be installed before the

stove is used.

To install the rear brick first open the door and remove the upper

deflector in Calorite B. Hold the rear brick in place with the smooth side

facing out and slide the holding brackets down either side of the brick

to secure in position against the side bricks.

To facilitate stove installation all of the refractory firebricks may be

lifted out of the stove to make it lighter for handling. Please handle

the refractory firebricks very carefully as they are brittle and

may crack or chip if handled roughly.

Sequence for Removing Refractory Walls:

First remove the upper deflector B and then the rear brick. Lift out the

left hand side brick followed by the 3 base bricks. Remove the right

hand side brick last. Refit in reverse sequence.

4.4.2. INSERT ASSEMBLY

To facilitate insertion of the insert, the firebox can be removed from the

outer cladding or and the flue collar can be removed to facilitate the

connection to the flue pipe.

4.4.2.1.

Removal of the Flue Collar

Open the stove door, remove the upper deflector in calorite B and

unscrew the screws that tighten the flue union D (fig.5); after creating

the connection to the flue pipe and inserting the fireplace stove,

reinstall the union D being careful to connect it correctly with the flue

pipe tube, tighten the screws properly and reposition the deflector in

calorite B.

4.4.2.2.

Removal of the firebox

After removing the flue collar, continue by removing the protective

panel A by unscrewing the locking screws and then remove the fixing

screws (C) that hold the firebox to the outer cladding; at this point the

firebox can be separated from the outer cladding by sliding it forwards

to facilitate the assembly.

A

B

C

D

Figure 5 – Insert removal

Page 20

INSTALLATION AND USE MANUAL

Chapter 4

page

19

Technical service – Dimplex - all rights reserved - Reproduction prohibited

4.5. CONNECTION TO THE FLUE PIPE

The connection must be made with a great deal of care; in the event of

poor construction or assembly, it is extremely difficult to remedy

without damaging the installation. In addition, the connection is made

in a part of the stove where temperatures are very high, and for this

reason it is important to use materials that are capable of resisting heat

and also the acidity of the fumes produced by combustion.

Before beginning work, please note the following:

• The chimney flue should be vertical wherever possible to offer

least resistance for passage of flue gasses. Where a bend is

necessary, it must have a slope no greater than 45 degrees to

the vertical. This is to minimise the build up of soot and

condensates in the flue. It also keeps the release of smoke

from being slowed down.

• Connection of the stove to the main chimney shaft

should be made using clay flue pipe, Cast Iron, 316

grade stainless steel or vitreous enamelled steel,

nominal thickness 1.2mm.

• If metal connecting pipes are used, they must be

insulated with suitable material such as ceramic fibre

matting, to avoid deterioration of any nearby masonry

or plasterwork.

• It is prohibited to use flexible stainless steel or

aluminium hoses as they compromise the safety of the

connection and are subject to tears and gaps, causing

leakage of smoke.

• The components making up the connecting pipe must be

perfectly sealed using fire cement or other high temperature

sealant.

• The joint to the flue pipe must not be too long (to avoid

obstructions), nor too short (to avoid smoke leakage).

• Note that all flue sockets must face upward.

IMPORTANT!

Any increase in the section of the connecting pipe

must start immediately above the hood of the

fireplace and not along the flue pipe section

When installation is complete, the smoke connection

must be insulated with ceramic fibre matting or

material that is resistant up to at least 600°C.

Carry out any infilling necessary in order to prevent

soot or ashes from the chimney flue from settling

above the insert (fig. 7).

Do not install this appliance on a shared flue.

4.5.1. DIRECT CONNECTION TO FLUE PIPE

Engage the elements in the chimney flue, being careful not to exceed

the 45° inclination and to correctly carry out any infilling necessary in

order to prevent soot or ashes from the chimney flue from settling

above the insert (fig. 7). Make sure flue sections maintain safe distance

or are suitably insulated against contact with combustible materials.

Figure 7 – Direct connection to the flue pipe

Figure 6 - Example of fireplace stove

connection with a chamber and sealed door

for solid combustion product collection and

discharge at the foot of the external

ascending segment.

Flue connection

Ceramic fibre

insulation

Flue pipe

Hood grille

45° max

Page 21

INSTALLATION AND USE MANUAL

Chapter 4

page

20

Technical service – Dimplex - all rights reserved - Reproduction prohibited

4.5.2. FLUE DAMPER (NOT SUPPLIED)

In case of excessive draught in the flue chimney, combustion may

become unbalanced and consequently less efficient. In this case, in

order to improve combustion efficiency, it is advisable to install a flue

damper directly above the output of the fireplace stove (fig.8).

When the damper is set in the open position the chimney draws at full

draught. Shutting the damper restricts the flow, slowing the rate of

burning.

4.6. INSTALLATION OF CLADDING FRAME AROUND

THE STOVE

The stove support structure and the parts of the cladding must be

attached to one another WITHOUT COMING INTO CONTACT WITH

THE STEEL OUTER CASING to prevent transmission of the heat to

any decorative surfaces (e.g. Marble).

Use care with wood finishes such as beams or shelves, these must be

suitably insulated. In particular, shelves must be placed at a distance of

not less than 30 cm from the upper part of the unit.

We recommend making the stove cavity liner in fire-resistant

plasterboard of 15/20 mm thickness, with a self-supporting frame in

galvanised profile, so as not put weight on components of the cladding

(such as wooden beams and marble architraves) which do not have a

load-bearing structure and to make it easy to work in the event of

future anomalies and/or maintenance.

Dry install the fire bed of the cladding, leaving an aperture of

10mm between the fireplace stove and the fire bed to provide

insulation (fig.9).

4.7. INSTALLATION OF (OPTIONAL)

FINISHING FRAME

An optional finishing frame can be assembled on DC700, which covers

either three or four sides of the product-depending on installation. This

optional frame (available from your DC700 retailer) is assembled at the

end of installation and after the cladding has been completed and is

anchored directly to the insert structure. This frame is designed to

finish and cover the crack that is formed between the metal structure

of the fireplace stove and the wall.

For frame assembly proceed as follows (fig.10):

• Remove door A by unscrewing the two screws B on the upper

part of the fireplace stove

• Insert the frame C until it comes into contact with the cladding

and fasten it with the four screws D

• Reinstall the door A inserting it in the pin of the lower hinge

and fasten it with the screws B

THERMAL PROTECTION OF CROSSBEAM

1. Insulation applied or to be applied.

2. Wood beam

3. Marble or other material

1

1

2

3

10 mm

Figure 9 – Insulating a wooden beam

Figure 8 – Flue Damper Position

Figure 10– Frame assembly

A

B

C

D

Page 22

INSTALLATION AND USE MANUAL

Chapter 4

page

21

Technical service – Dimplex - all rights reserved - Reproduction prohibited

4.8. INSULATING A WOODEN BEAM

If there is a shelf or beam made of wood or other combustible material

above the hot air outlet opening, it is absolutely necessary to

protect it with panels made of suitable insulating material (e.g.:

calorite). To attach the protection, fix the protective panels to the

underside of the beam using appropriate wood screws (fig.11).

4.9. SUMMARY DIAGRAM FOR OPTIMUM

CONNECTION OF THE INSERT STOVE

The installation described below (fig.12) is the optimum set up for

inserts assembled on old or new fireplaces. The insert must never be

walled up completely but positioned 10mm away from any masonry

surface since it needs to be able to expand when it is hot; furthermore,

if it is walled up there is a significant drop in air circulation around the

stove and the effective output is reduced.

The structure must be insulated thoroughly if there

are parts of the construction in wood or other

flammable material. Observe safe distances to

combustible materials at all times.

CONVECTION AIR INLET

CHIMNEY FLUE

CONNECTION

COMPENSATION

NETWORK

CALORITE

INSULATION

FLUE PIPE

R

E

A

R

I

N

S

U

L

A

T

I

O

N

UPPER

INSULATION

BEAM

BEAM

INSULATION

CONVECTION AIR

OUTLET

VENTILATION

AIR OUTLET

VENTILATION AIR

INLET

CONVECTION

AIR INLET

MINIMUM DISTANCE 3-5 CM

SUPPORT IN

MASONRY

C

O

N

V

E

C

T

I

O

N

A

I

R

D

U

C

T

(

U

S

E

F

U

L

F

O

R

T

H

E

E

X

C

H

A

N

G

E

)

P

I

P

E

÷

1

5

0

Figure 11 – Beam protection kit assembly

Figure 12 – Optimum stove set up.

Page 23

INSTALLATION AND USE MANUAL

Chapter 6

page

22

Technical service – Dimplex - all rights reserved - Reproduction prohibited

5. OPERATION

5.1. PRE-LIGHTING WARNINGS

Make sure you have read and completely understood the contents of

this instruction booklet.

Remove all accessories and parts that could burn from the firebox and

from the door.

Remove the stickers from the ceramic glass or the high

temperature could melt them and irreparably damage the

glass. In this case, the company warranty does not cover the

glass.

Avoid touching the stove paintwork when it is lit for the first

time. During the initial firing of the stove the paint cures

and hardens. If the paint is touched during this period, you

may expose the steel surface.

Provide plenty of ventilation in the room during the initial

firing, as the stove may give off a small amount of smoke

or fumes during the curing process

If necessary, touch up the paint with the aerosol spray in

the original colour (see “Fireplace stove accessories and

inserts")

Do not stay near the fireplace stove, and as previously mentioned,

ventilate the room. The smoke and the smell of paint will vanish after

about one hour of operation. There are no health risks involved.

During start-up and cooling, the fireplace stove is subject to expansion

and contraction; therefore, you may hear slight creaking noises.

This phenomenon is absolutely normal, the structure being made of

sheet steel, and must not be considered a fault.

It is very important not to bring the stove up to full

heat immediately. Bring it up to temperature

gradually.

This avoids damages to welds and the steel

structure.

Do not demand full heating

performance straight away!

Page 24

INSTALLATION AND USE MANUAL

Chapter 6

page

23

Technical service – Dimplex - all rights reserved - Reproduction prohibited

5.2. CHOICE OF FUEL

To obtain the maximum performance from your Dimplex stove, it is of

primary importance to use wood with suitable characteristics.

It is advisable to use wood for heating such as beech, birch, oak

or ash with good calorific energy, or logs of pressed wood that do not

have resin. These have a high calorific power and must be used

with caution to avoid overheating which could damage the

stove.

It is less advisable to use fuels such as poplar, pine, lime tree, or

chestnut which have low calorific power, since they are soft wood and

also they do not burn for a long time.

Avoid using fuels such as pine or fir as they contain a high degree of

resin and their combustion may substantially soil the fire mouth and the

ceramic glass; also, they do not have a high calorific value.

Even when using the recommended wood types the calorific

energy they contain will be affected by their moisture content.

Only use fully seasoned timber that has been allowed to dry for

a period of at least 12 months.

Do not use treated fuels (such as painted or

varnished wood, or particle board) or unsuitable

materials (such as plastics and derivatives), which

could release toxic or polluting substances. Do not

burn rubbish.

The gases produced by combustion due the use of

unsuitable fuels cause damage to the fireplace stove

and the chimney, they cause pollution and can

compromise your health.

A high percentage of moisture in the wood produces

condensation in the smoke duct and causes an alteration in

the draught. The smoke generated from damp wood can

cause a significant deposit of soot on the glass of the door

and in the flue pipe with a possible risk of a chimney fire

later on.

5.3. FIRST LIGHTING

It is advisable to approach the first lighting with caution, using

good-quality, well-seasoned wood.

The primary air inlet must be fully open. Do not use alcohol,

petrol, or other volatile flammable substances. On first lighting,

fumes and unpleasant smells may be given off, caused by curing of the

paint; this is not hazardous to the health, and it is sufficient to ventilate

the room adequately. Once combustion has started, pieces of wood of

normal size may be added.

The flame must have as far as possible a smooth and laminar flow. On

the various occasions when the stove needs reloading, the

door should be opened slowly, to avoid blowbacks of smoke

into the room.

Wood drying

time (e.g. beech)

%

moisture

Heat

power

Kcal/h

Freshly cut 50 /

3 months 40 2410

6 months 35 2700

9 months 30 2900

12 months 25 3150

15 months 20 3400

18 months 15 3710

21 months 10 3980

Figure 13 – Calorific energy (e.g. beech) in

relation to moisture contained.

Figure 14 – Air register

Page 25

INSTALLATION AND USE MANUAL

Chapter 6

page

24

Technical service – Dimplex - all rights reserved - Reproduction prohibited

Proceed as follows:

• Place a small amount of balled paper in the stove.

• Cover the paper with a small quantity of twigs and a few pieces of

wood.

• Open the primary air register completely (fig.15 A)

• Light the paper, and if necessary leave the door open; when the

twigs are burning, the door can be closed.

• Only once the flame is burning well (presence of a bed of ash and

full combustion) should the air register be moved to the desired

setting (see fig.15, section 5.5).

As the fire burns, add wood. Never overload the fireplace stove

with wood (see technical specifications in the table, Section 3).

As soon as the flames have died down and a bed of ash has formed,

load the stove normally. Small loads of wood are preferable to large

ones for combustion.

Attention

• Do not use volatile, flammable substances

(petrol, alcohol etc.) for lighting the fire.

• Do not use fuels which could release toxic

substances or pollutants.

• Do not put the fire out by throwing water on it.

• Check the external and internal air intakes, and

the flue pipe, at least once a year, arranging for

them to be cleaned.

• During use, the metal parts and the glass reach

high temperatures. For all jobs of loading the

stove, adjustment or cleaning the ash drawer,

use the insulating glove provided.

• Never leave children unattended near the

fireplace stove when it is in use.

• The risk of burns from contact with hot surfaces

is very high.

5.4. LOADING THE FUEL

For normal fuel loading, open the fire door by turning the handle and

pulling the door towards you.

During use, the metallic structure, the handles and the glass

become very hot. Use the thermal glove provided when

handling these parts.

During normal use, always keep the fire door completely

closed, since intermediate positions cause abnormal combustions

(forge effect), rapid consumption of wood and a drastic reduction in the

heating efficiency of the unit.

Open the door only to add fuel, and only for brief periods of

time.

The fireplace stove works best and provides the greatest heat output

when the door is closed, because the sealed combustion chamber and

the calibrated inlet of oxygen allow increased performance.

Page 26

INSTALLATION AND USE MANUAL

Chapter 6

page

25

Technical service – Dimplex - all rights reserved - Reproduction prohibited

5.5. CONTROL OF COMBUSTION

The stove has an inflow on the front of the firebox that permits the

entry of the primary and secondary air required for combustion. The

settings for the air input are displayed in Fig 15.

PRIMARY AIR

The Primary air is controlled between the air register setting fully open

(A) to centre (B) position. At position (A) the primary air is at

maximum input. The primary air is reduced by pushing the air register

in until position (B) where the primary air is closed.

Between positions (A) and (B) the Secondary air is at maximum input

and cannot be reduced.

The air register should be moved to position (A) for lighting the stove.

Once the flame in the fireplace stove is burning well, push the register

until the knob reaches the centre position (B).

SECONDARY AIR

The secondary air input is only controlled between the air register

settings centre (B) and fully closed (C). At setting (B) the secondary air

input is at maximum. To reduce the secondary air push the register in

until it reaches position (C) where it is closed.

The Primary air input is closed between positions (B) and (C).

In normal conditions of use, dirt deposits on the glass at

lighting, but disappears as soon as the combustion chamber

is hot enough.

The use of damp or treated wood emits a higher quantity of

smoke than normal that can dirty glass faster. Also the low

performance of the flue pipe can jeopardise glass cleanliness

since smoke remains in the combustion chamber longer than

normal.

5.6. EMERGENCY SITUATIONS

If for any reason the stove fire needs to be suddenly and quickly put

out or a fire in the flue pipe needs to be put out, proceed as follows:

• The equipment door must be kept closed.

• Disconnect the power supply and do not use water (shock

hazard).

• Contact the emergency services.

Figure 15– Air Register Control

MAX

MIN

A

C

B

Page 27

INSTALLATION AND USE MANUAL

Chapter 7

page

26

Technical service – Dimplex - all rights reserved - Reproduction prohibited

6. MAINTENANCE AND CLEANING

ATTENTION!

All cleaning operations of all parts should be

conducted with the fireplace stove cold.

6.1. CLEANING TO BE PERFORMED BY THE USER

6.1.1. Cleaning the glass

The stove glass may become dirty during start up lighting period or if

damp wood is used. The glass should burn clear again when the stove

chamber reaches its optimum operating temperature.

If there are any un-burnt residues left on the glass after burning these

may be cleaned off when the stove has cooled. To clean the glass, use

a soft cloth dampened with water and glass cleaner. Do not use

abrasive substances as these may damage the glass.

ATTENTION!

Do not spray cleaning products on the painted parts

or on the gaskets of the door (ceramic fibre cord)

6.1.2. Cleaning out the ashes

This must be done when the fireplace stove is off and cold.

It is advisable to adequately clean the fire bed for proper combustion.

To remove the ashes from the fire bed, use a metal scoop and brush.

Place the ashes in a non-flammable container for transport.

Ashes that are still hot should be kept outdoors with great

care, and not placed in a waste container. Leave them to cool

down in the open air in a metal container.

6.1.3. Cleaning the refractory material walls (ALUTEC®)

These do not require any cleaning, since the feature of this material

(ALUTEC

®

) is that it does not absorb soot but rather repels it when the

fire box is hot.

During the lighting period the stove chamber may tend to blacken,

particularly if the wood is not fully dried. However when the chamber

reaches optimum internal temperature (~ 400° C) the refractory wall

materials will gradually turn white again as the soot is burnt off.

If this does not happen, it may be due to the following:

• Humid or resinous wood that does not release enough heat or

that dirties the combustion chamber

(see chapter 5.2)

• Flue pipe with poor performance resulting in smoke remaining

too long in combustion chamber, dirtying the fire box.

• Flue pipe with poor performance which does not allow fireplace

stove to reach high yield that result in adequate temperature of

the refractory material.

Page 28

INSTALLATION AND USE MANUAL

Chapter 7

page

27

Technical service – Dimplex - all rights reserved - Reproduction prohibited

Never clean the refractory material with a damp cloth

or anything else, as it may be stained.

Use a dry paintbrush if necessary to remove heavy

soot build-up.

If the Alutec does not whiten, it is not to be

considered as a defect in light of the warnings and

instructions above.

6.1.4. Cleaning the upper deflector (Calorite)

This does not require particular care. With prolonged use, however, the

effective but porous material of which the deflector inside the firebox is

made can wear out or become damaged. It should be replaced if it

becomes damaged or if it cracks.

6.1.5. Cleaning of painted parts

Do not clean the painted parts with wet rags when the unit is in

operation or hot in order to prevent thermal shock to the paint which

may cause it to detach. Do not use abrasive or aggressive products or

materials. Clean with damp cotton or paper towels.

The silicone paints used to paint products have top quality

technical properties that make them resistant to very high

temperatures.

There is however a physical limit (380°-400°) beyond which

the paint begins to fade or (over 450°) to vitrify; it may then

flake and detach from the steel surface. If these effects are

noticed, this means temperatures have been reached that

are well above those at which the product should properly

operate. Therefore, you should use the amount of fuel

specified in the technical tables.

6.2. CLEANING TO BE DEALT WITH BY SPECIALIZED

TECHNICIAN

6.2.1. Cleaning flue pipe

Mechanical cleaning of the flue pipe is recommended at least once a

year. Excessive deposits of un-burnt solid material can cause problems

with the evacuation of smoke, and gives rise to a risk of chimney fires.

To access the appliance's flue pipe for cleaning, remove the smoke

deflectors.

WARNING!

The frequency with which the product is cleaned

should be determined based on the amount of use of

the product, the quality of the fuel and the type of

installation.

You should have your chimney flue cleaned and

repaired at least once yearly (typical) by a fully

qualified chimney sweep. Any required maintenance

to product installation or flue should be carried out

during flue cleaning.

Page 29

Page 30

DIMPLEX

MILLBROOK HOUSE

GRANGE DRIVE

HEDGE END

SOUTHAMPTON

SO30 2DF

UK

TEL: 0845 600 5111

FAX: 01489 773050

WEBSITE: www.dimplex.co.uk

DIMPCO

AIRPORT ROAD

CLOGHRAN

CO DUBLIN

IRELAND

TEL: 01 842 4833

FAX: 01 842 4839

WEBSITE: www.dimpco.ie

DIMPLEX [c] is a Division of GDC Group Ltd.

All rights reserved. Material contained in this publication may not be reproduced in whole or in part, without prior permission

in writing of GDC Group Ltd.

8901006100 Rev. 5 05/2010

Loading...

Loading...