Page 1

ContactDetails

Pleasenotethatsomeofthecontactdetailson

thisPDFdocumentmaynotbecurrent.

Pleaseusethefollowingdetailsifyouneedto

contactus:

Telephone:08448793588

Email:customer.services@gdcgroup.co.uk

Thecustomersupportsectionofourwebsitealsofeaturesawide

rangeofinformationwhichmaybeofusetoyouandisavailable

24hoursaday.Itincludes:

• Operatingandinstallationinstructions

• Easy‘Howtouse’guidesforstorageheaters

• Serviceandrepairs

• Where

tobuyourproducts

• Literaturedownloads

• Heatingrequirementcalculator

Visit‐www.dimplex.co.uk/support

A division of GDC Group Ltd

Millbrook House Grange Drive Hedge End Southampton SO30 2DF

www.dimplex.co.uk

Registered No: 1313016 England

VAT GB 287 1315 50004

EEE Producer Registration Number –

WEE/GE0057TS

Paper from sustainable sources

Page 2

CABR

CAB10AR, CAB10ER, CAB10WR,

CAB15AR, CAB15ER & CAB15WR

08/50590/0 (UK) Issue 2

The product complies with the European Safety Standards EN60335-2-30 and the European Standard Electromagnetic Compatibility (EMC)

EN55014, EN60555-2 and EN60555-3. These cover the essential requirements of EEC Directives 2006/95/EC and 2004/108/EC

Page 3

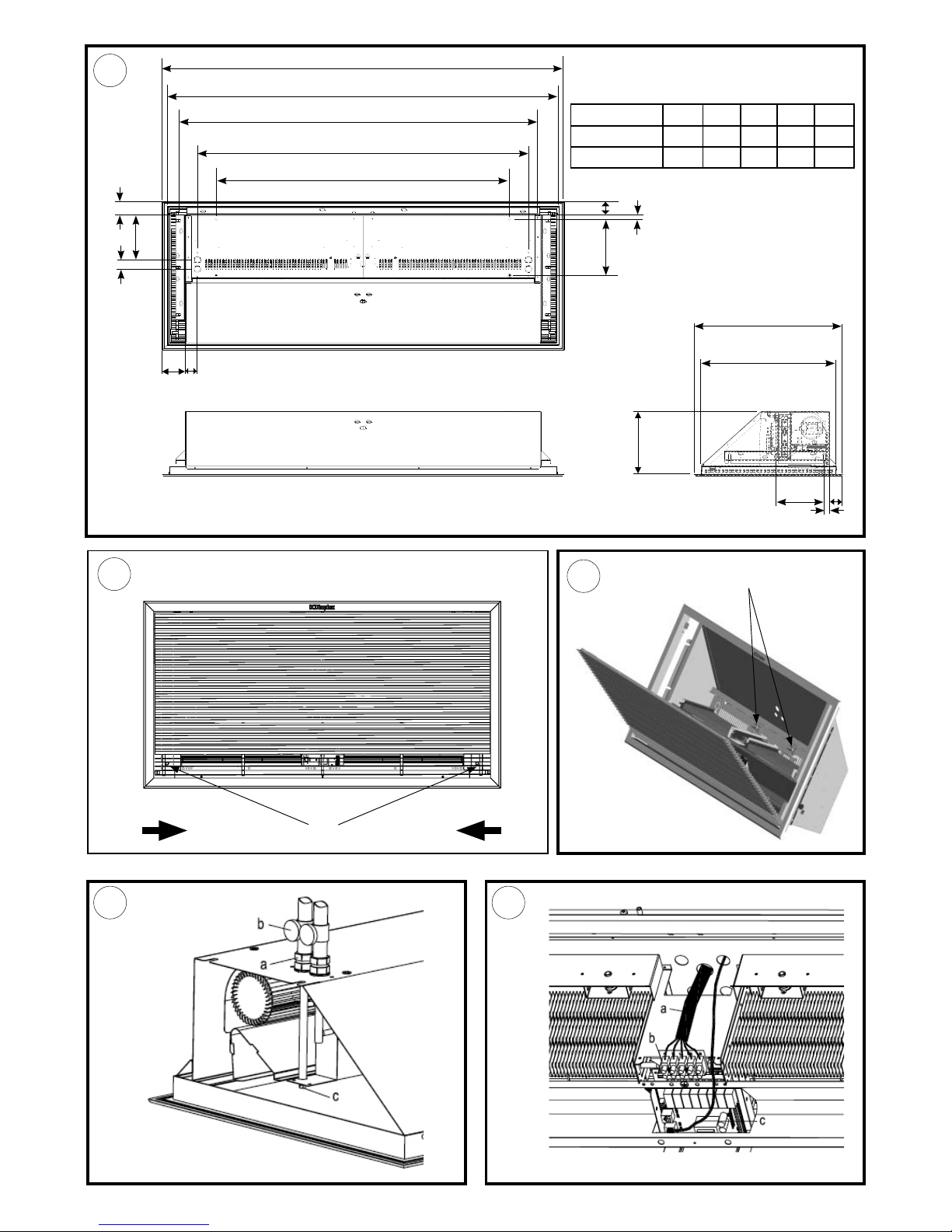

269

639

580

405

58

23

99 53

192

40

59

240

59

20

E

D

C

B

A

ABCDE

CAB10 E/W/A R 1224 1160 1065 920 840

CAB15 E/W/A R 1724 1660 1570 1420 1260

1

2B

2A

3 4A

CAB E

X

y

Page 4

4B

CAB W/A

5

7A

7B

Page 5

8

9

Page 6

Dimplex Compact Air Curtains

Models : CAB10ER, CAB10WR, CAB10AR

CAB15ER, CAB15WR & CAB15AR

IMPORT ANT: THESE INSTRUCTIONS SHOULD BE READ CAREFULLY AND RETAINED FOR FUTURE REFERENCE

IMPORTANT SAFETY ADVICE

DO NOT COVER OR OBSTRUCT the air inlet or outlet

grille.

ENSURE THE APPLIANCE IS EARTHED.

Do not use this heater in areas where excessive dust

exists.

This heater must not be located immediately above or

below a fi xed socket outlet or connection box.

Always disconnect supply before working on the

product.

This appliance should only be connected to the fi xed

wiring of the premises by means of conduit.

This product should only be mounted safely to solid

ceiling surfaces.

This product must not be subjected to water spray or

immersion.

Ensure the supply cables are of adequate current

carrying capacity and are protected by a suitable fuse.

If the appliance is mounted in a toilet or washroom, the

appliance should be mounted such that no part of it can

be touched by a person using a fi xed bath or shower.

If the appliance is mounted in a toilet or washroom

an isolating switch must be provided outside the

washroom adjacent to the entrance door.

This appliance is not intended for use by persons

(including children) with reduced physical, sensory

or mental capabilities, or lack of experience and

knowledge, unless they have been given supervision or

instruction concerning use of the appliance by a person

responsible for their safety.

WARNING: Isolate electrical supply to ALL modular

linked units when carrying out maintenance.

Model Heat Output kWElectrical Supply Electrical

Load

(per phase)

Weight KGMax

Installed

height

M

AMBIENT / COLD STORE

CAB10AR n/a 220-240V ~1PN 0.3 20.5 3.0

CAB15AR n/a 220-240V ~1PN 0.5 29.5 3.0

ELECTRICALLY HEATED

CAB10ER 4.5 / 9.0 380-415V ~3PN 14 26 3.0

CAB15ER 6.75 / 13.5 380-415V ~3PN 20 35 3.0

WATER HEATED (at 82/71 °C - LPHW)**

CAB10WR 9.0 220-240V ~1PN 0.3 23 3.0

CAB15WR 13.5 220-240V ~1PN 0.5 32.5 3.0

Models

This range of air curtains are specifi cally designed to be

recessed into ceiling spaces and above suspended ceilings.

Electrical

The installation of this appliance should be carried out by a

competent electrician and be in accordance with the current IEE

wiring regulations.

Fixing Positions

This appliance must be mounted to a suitable ceiling - see Fig.

1 for fi xing dimensions and Fig. 5, 6, or 7 for mounting positions

and ‘Mounting’ sections below for fi xing details. This appliance

should not be mounted less than 1.8m from the fl oor.

Mounting into a Standard Ceiling Void

1. Side Fixings - Using a suitable ceiling surface, mark off and

drill for M8 drops rods. Dimensions can be found on Fig.1. Cut

the M8 drop rods to the desired length, taking note of the fi nal

position of the appliance relative to the distance to the mounting

surface. Mount the drop rods to the ceiling surface. Remove the

ceiling tiles on the appliance. (see Fig. 2) Using suitable lifting

equipment raise up the appliance to the drop rods as shown in

Fig. 5. Connect the appliance to the drop rods using standard M8

lock nuts and washers.

2. Top Mounted Inserts - If a suitable (unistrut) structure is

available, mark off and drill for M8 threaded bolts. Insert the bolts

down through the structure. Dimensions can be found on Fig.

1. Using suitable lifting equipment raise up the appliance to the

bolts. Screw the bolts into the threaded inserts on the top of the

appliance, and tighten securely.

Electrical connection

All products are fi tted with a microprocessor control. Electrical

power and control connections are made as shown in Fig. 4. A

suitable local isolating switch must be provided in the electrical

supply circuit with at least 3mm clearance on each pole. In order

to access the electrical connections, remove the outlet grilles (‘x’

in Fig. 2) by undoing the four fasteners in each tile. For the Water

heated and Ambient models only, the pressure plate must also be

removed.

All Electric Models - Having removed a ‘knock out’ in the

top panel, feed an appropriate supply cable (see ‘a’ in Fig. 4A)

through a suitable cable gland (not supplied) fi tted in the top

panel and attach to the terminal block (see ‘b’ in Fig. 4A).

All Water heated and Ambient Models - Having

removed a ‘knock out’ in the top panel, feed an appropriate

supply cable (see ‘a’ in Fig.4B) through a suitable cable gland

(not supplied) fi tted in the top panel and attach to the PCB (see

‘b’ in Fig. 4B).

Page 7

All Models - A suitable cable (CAT5 or equivalent) for a switch

panel (kit ref. - CABC5 for electrically heated models or CABC6

for water heated/ambient models) can be similarly introduced

through the top panel and plugged into the circuit board as

shown in Fig. 4A & 4B. If the unit is to be operated in conjunction

with a door switch, a normally open switch should be wired as

per ‘D’ in Fig. 8 & 9 as appropriate.

Note: If using a door switch, an additional 2 core (low voltage)

cable is required between the door switch and the air curtains.

If the unit is to be connected to a Building Energy Management

System, connections are made as per ‘S0, S1, & S2’ in Fig. 8 &

9 as appropriate.

Water connection

Models designed for use in conjunction with a low pressure

hot water supply should be individually connected (in a parallel

circuit) to the fl ow and return pipe-work. Connections (see ‘a’ in

Fig. 3) are: ½” BSPT (CAB series) and isolation valves (see ‘b’

in Fig. 3) should be fi tted as close to the air curtain connection

points as possible. For commissioning, air bleed valves (see ‘c’

in Fig. 3) are fi tted to the coil, which can be accessed by removal

of the ceiling tile - see Fig. 2.

Maximum water supply conditions are 125ºC and 8 bar

(0.8MPa).

To aid installation, the water coil connections may be moved to

either side of the appliance. By removing the water coil and

appropriate knockouts the water coil can then be re-inserted into

the required orientation. This procedure should be carried out

before mounting the appliance.

Switch Panel Installation

The backing box (standard double gang) should be surface

mounted onto a suitable wall, alternatively a recessed box

can be used (not supplied). Suitable conduit should be used

where applicable to carry the cable between the heater and the

switch. A CAT5 computer network cable with straight through

connections should be used to connect the switch panel to the

appliance PCB.

Warning: Ensure cable is secure and the cable path does not

come into contact with heater element or other moving parts.

Note: If using a door switch, an additional 2 core (low voltage)

cable is required between the door switch and the air curtains.

Test all switch settings once installation is complete.

Electrically heated variants

Operation using switch box - CABC5

Switch on electrical supply to the air curtain. Rotate the switch to

the desired heat setting. Settings available are;

OFF

Low Fan

Low Fan with Low Heat

High Fan

High Fan with Low Heat

High Fan with Full Heat

The rocker (auto / manual) switch allows for manual over-ride of

a door switch if fi tted. Manual allows the appliance to run at the

desired setting, while Auto provides an energy saving feature by

shutting down the appliance while the door is closed.

The unit should always be switched OFF using the switch

box control, and not by mains power supply interruption.

When the unit is switched off (via the switch box) the fan will run

on for 1 minute without heat to discharge any residual energy

from the heating elements.

When fi rst turned on the control will run through a system check.

The selected settings will be reached and maintained after a 30

second period.

Thermostatic control

A capillary type thermostat is factory fi tted within the unit, as per

‘C’ in Fig. 8, giving a selection scale of 0-40ºC. When the thermostat operates, the power output will reduce depending on the

switch setting.

- Fan only - No effect

- Half Heat - Heater will reduce to Fan only

- Full Heat - Heater will reduce to Half Heat

To override the thermostat, fi rst Isolate the supply to the heater.

Remove the connection on terminal ‘1’ of the thermostat and

reconnect it onto the piggy back connection on terminal ‘C’.

Door switch control (Electric models)

By including a door switch in the circuit (as per ‘D’ in Fig. 8) the

air curtain will respond to door openings as follows:

(1) Door opening will energise the air curtain at the set condi-

tions (switch box settings).

(2) On door closure operation will continue at the set condi-

tions for a further 1 minute.

(3) Between 1 minute and 2 minutes from door closure, set

back operation, ½ heat (if heat selected) and ½ fan will

activate.

(4) Between 2 minutes and 3 minutes, the fan only (½ speed)

shut down cycle will be engaged.

(5) After 3 minutes, the air curtain will return to a dormant

state until the door is re-opened.

If the door re-opens during this 3 minute run on cycle, the

process will restart at (1).

Thermal Safety cut outs

The power supply to the heating elements will be interrupted if

one or a combination of the following abnormal events occur:

1. Air inlet or outlet grilles are obstructed.

2. Internal ventilation is impaired due to build up of dust and

fl uff.

3. Blower unit stalls.

Before resetting the thermal safety cut-outs you must turn

the power OFF. Unlock the grille by moving the two sliders

into the open position ‘x’ as shown in Fig. 2A, using a small

screw driveror other suitable tool. With the grille partially open

disconnect the safety cord to allow the grille to fully open. Then

access the reset buttons as shown in ‘y’ in Fig. 2B. Before

re-setting the reason for activation must be determined and

corrective action taken.

Low Pressure Hot Water (LPHW) heated

Ambient (fan only) variants

Operation using switch box - CABC6

Switch on electrical supply to the air curtain. Rotate the switch to

the desired heat setting. Settings available are;

OFF

Low Fan

High Fan

The rocker (auto / manual) switch allows for manual over-ride of

a door switch if fi tted. Manual allows the appliance to run at the

desired setting, while Auto provides an energy saving feature by

shutting down the appliance while the door is closed.

The unit should always be switched OFF using the switch box

control, and not by mains power supply interruption. When

fi rst turned on the control will run through a system check. The

selected settings will be reached and maintained after a 30

second period.

Page 8

Thermostatic control (optional)

1) A thermostatic regulation valve with a remote sensing bulb

(not supplied) can be positioned in the supply water pipe-work to

regulate the heat output.

2) An electrical 3-Port Solenoid Valve can also be connected into

the system. Please contact your sales or service agent using the

contact details provided.

Door switch control (Water heated & Ambient

models)

By including a door switch in the circuit (as per ‘D’ in Fig. 9 the

air curtain will respond to door openings as follows:

(1) Door opening will energise the air curtain at the set conditions

(switch box settings).

(2) On door closure operation will continue at the set conditions

for a further 1 minute.

(3) Between 1 minute and 2 minutes from door closure ½ fan set

back operation will activate.

(4) After 2 minutes, the air curtain will return to a dormant state

until the door is re-opened. If the door re-opens during this 2

minute run on cycle, the process will re-start at (1).

Wiring Diagrams

CAB & DAB ‘E’ - Electric models - see Fig. 8

CAB & DAB ‘W’ / ‘A’ - Water heated & Ambient models - see

Fig. 9

C - Thermostat

D - Door Switch (Optional)

E - Thermal Safety Cut-out Circuit

F - Elements

- BMS Switches (Optional)(S0,S1,S2)

M - Motor

Remote (BMS / BEMS) Operation

Connection to Building Energy Management Control Systems

(BEMS) is possible so that remote control of the air curtain can

be carried out in conjunction with other equipment. Please refer

to the table in Fig. 8 & 9 to make the appropriate connections to

the PCB.

Modular Connection

Refer to instructions provided with the modular linking kit.

De-rating the unit to operate at ½ heat setting

Please contact your sales or service agent using the contact

details provided.

Operation on a Single Phase Supply

Please contact your sales or service agent using the contact

details provided.

Page 9

Recycling

For electrical products sold within the European

Community.

At the end of the electrical products useful life it

should not be disposed of with household waste.

Please recycle where facilities exist. Check

with your Local Authority or retailer for recycling

advice in your country.

Cleaning

WARNING: DISCONNECT SUPPLY before carrying out

maintenance.

External appearance can be maintained by wiping occasionally

with a damp cloth ; for stain removal, a weak soap solution can

be applied with a cloth and the surface wiped dry. Care must be

taken to avoid any moisture ingress into the product.

After Sales Service

Your product is guaranteed for three years from the date of

purchase.

Within this period, we undertake to repair or exchange this product free of charge provided it has been installed and operated in

accordance with these instructions.

Your rights under this guarantee are additional to your statutory

rights, which in turn are not affected by this guarantee.

Should you require after sales information or assistance with this

product please go to www.dimplex.co.uk wher you will fi nd our

self help guide by clicking on “After Sales” or ring our helpdesk

on 0845 600 5111 (UK) or 01 842 4833 (R.O.I.) .

Spare parts are also available on the website

www.dimplex.co.uk

Please retain your receipt as proof of purchase.

The product complies with the European Safety Standards EN60335-2-30 and the European Standard Electromagnetic Compatibility (EMC)

EN55014, EN60555-2 and EN60555-3. These cover the essential requirements of EEC Directives 2006/95/EC and 2004/108/EC

Dimplex UK Ltd.

Millbrook House

Grange Drive

Hedge End

Southampton

Hampshire. SO30 2DF

www.dimplex.co.uk

Republic of Ireland Tel. 01 8424833

© Dimplex UK Limited

All rights reserved. Material contained in this publication may not be reproduced in whole or in part, without prior permission in writing of Dimplex UK Limited.

Loading...

Loading...