Page 1

A-Class Heat Pumps

A8M, A12M & A16M Installation Manual

dimplex.co.uk

8/60472/0

Issue 1.07

Page 2

Page 3

Contents

1. Introduction 5

1.1 Manual Information 5

1.2 Important Safety Information 6

1.3 Intended Use 8

1.4 Legal 8

1.5 Heat Pump Labels and Pipe Connections 9

1.6 Heat Pump Dimensions 9

1.7 Scope of Delivery 10

1.7.1 Installation pack 1 - Space heating and Dimplex A-Class cylinder 11

1.7.2 Installation pack 2 - Space heating and Dimplex standard cylinder 12

1.7.3 Installation pack 3 - Space heating only 13

2. Important pre-installation information 14

2.1 Connection to the Grid - Notifying the DNO 14

2.1.1 Heat Pump Sizing 14

2.2 Heat Pump Location 14

3. Installation instructions 16

3.1 16

3.1.1 Temperature Control Devices 18

3.1.2 Space Heating Zones 19

3.1.3 Location of Wiring Centre 19

4. Installation 20

4.1 Important - Plumbing Information 20

4.1.1 Pipe Sizing Information 22

4.1.2 Buffer tank 23

4.1.3 Adjusting the spring loaded by-pass valve (if fitted) 23

4.1.4 Metering for the Domestic Renewable Heat Incentive - UK 24

4.2 Electrical Information 25

4.2.5 Access to Electrical Connections - Opening the heat pump 25

4.2.6 Electrical Connections - power and Modbus cable heat pump connections 26

4.2.7 Modbus Cable Information 28

4.2.8 Opening and Installing the User Interface 28

4.3 Heat Pump Controller / Commissioning 30

4.3.1 Important pre-startup information 30

4.4 Commissioning 31

4.4.1 Starting the heat pump in cold weather 31

4.4.2 General / Schematic 31

4.4.3 Waterside Check 33

Page 4

4.4.4 Temperature Check 34

4.4.5 Electrical connections 34

4.4.6 Water Flow Check 34

4.4.7 DHW set-up 36

4.4.8 Electrical connections (DHW) 36

4.4.9 DHW Test 36

4.4.10 Disinfection (thermal) 38

4.4.11 Weather compensation 39

4.4.12 Heating curves 39

4.4.13 Comfort level 40

4.4.14 Setup complete 40

4.5 Additional Installer Menu Options 40

4.5.1 Service menu 40

4.5.2 Message log 40

4.5.3 Output Tests 41

4.5.4 Defrost 41

4.5.5 Operating data 41

4.5.6 History 41

5. System Health Check / Maintenance 42

5.1 Heat pump: 42

5.2 Electrical: 42

5.3 Hydraulics: 42

5.4 Indoor settings: 42

6. Appendices 43

6.1 44

6.2 Refrigeration cycle 45

6.3 Schematics - Example 1 46

6.4 Schematics - Example 2 47

6.5 Schematics 1, 2, 3 & 4 : Space Heating Only 48

6.6 Schematics 5, 6, 7, 8 : Zone space heating + DHW 49

6.7 Schematics 9, 10, 11, 12 : Bivalent space heating 50

6.8 Schematics 13, 14, 15, 16 - Bivalent zone space heating + DHW 51

6.9 52

6.10 53

6.11 54

6.12 Controller cable connections 55

6.13 56

6.14 Installer hand-over form 57

6.15 58

Page 5

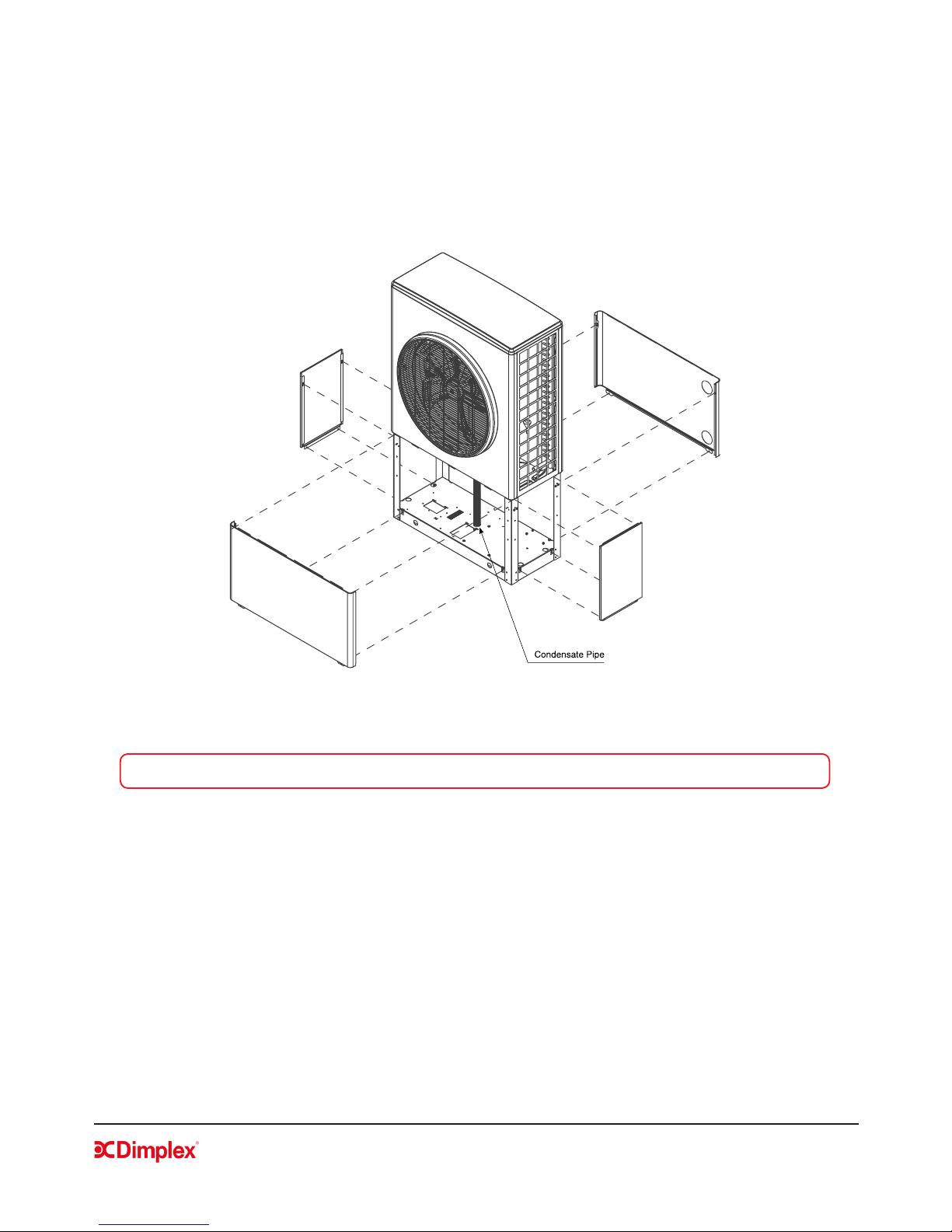

Millbrook House, Grange Drive, Hedge End, Southampton, SO30 2DF

0844 879 3587

dimplex.co.uk | gdcgroup.co.uk

5

1. Introduction

1.1 Manual Information

NOTE: This manual is intended for electricians and qualied installers only!

This manual is intended for installers and electricians installing Dimplex A-Class air-source heat pumps.

All installers must have prior knowledge regarding the installation of Dimplex A-Class air-source heat pump

systems, and must be competent to install the system safely and successfully.

Installers must have knowledge of any local or national standards, codes or regulations that may apply, as

well as safe methods of practice. Dimplex accept no responsibility for compliance with these codes and

regulations on the part of the installer.

All electrical installations must be carried out in accordance with local and national standards and

regulations, including BS 7671.

NOTE: Repair should not be attempted by unqualied persons.

NOTE: Retain this manual for information

The instructions included in this manual are important for the correct installation and use of Dimplex

A-Class air-source heat pumps. Please ensure that you retain this manual for reference.

The specications and information supplied in this manual may be subject to change without notice at the

discretion of Dimplex. All attempts have been made to ensure that this document is complete and that the

information supplied is correct at the time of publication, however Dimplex will assume no responsibility

for damages (including consequential and indirect / accidental damages) resulting from reliance on the

information presented in this document.

NOTE: Check that you have the latest issue of this manual before installation.

NOTE: Go to http://www.dimplex.co.uk/customer_support/downloads and enter your A-Class heat

pump model number for the latest PDF download of this manual.

These original instructions must be left with the user after installation, including the hand-over form at the

back, where the installer should record key information during commissioning.

Unauthorised reproduction of this document is prohibited.

Page 6

Millbrook House, Grange Drive, Hedge End, Southampton, SO30 2DF

0844 879 3587

dimplex.co.uk | gdcgroup.co.uk

6

1.2 Important Safety Information

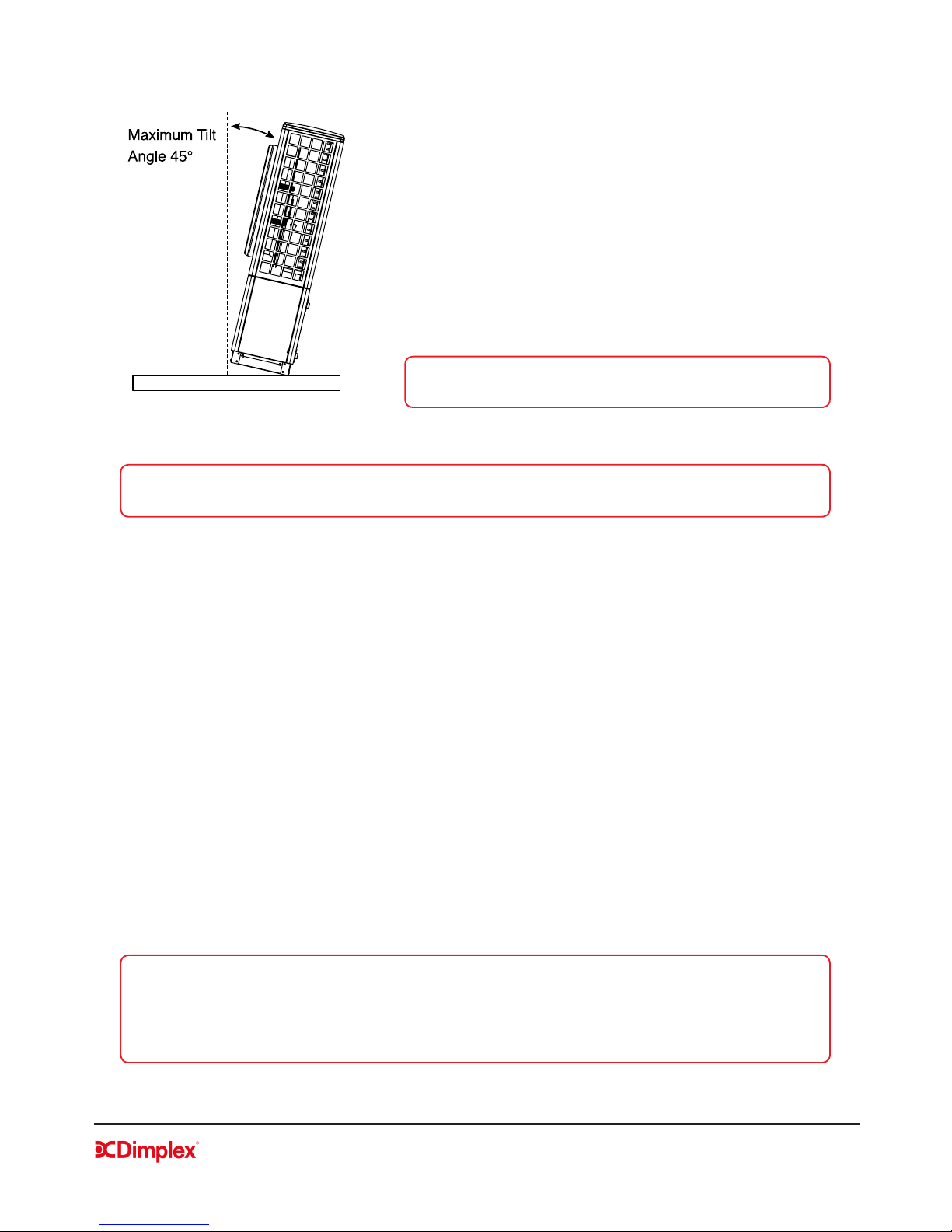

• Do not tilt the heat pump by more than 45° in any

direction.

• Do not lift without using correct lifting devices.

• Ensure that all clearance dimensions are observed - this

is important for correct heat pump operation and air ow.

• Use a suitable lifting device in accordance with any

relevant health and safety regulations.

• Do not move or transport the heat pump at.

WARNING: When using lifting rods to lift the heat pump,

straps must also be used to prevent toppling.

Figure 1: Maximum tilt angle

NOTE: Leaving a clear pathway for delivery will allow the heat pump to be delivered as close to the

installation site as possible to minimize moving / lifting.

• Never use cleaning agents containing sand, soda, acid or chloride as these can damage surfaces

/ components.

• Do not use muddy or dirty water to ll the heating system. This can cause components to

malfunction and poses a corrosion risk to the system.

• If the heat pump may be disconnected from the power supply for long periods of time, or where

power supplies are susceptible to failure, antifreeze must be added to the system.

Example: Mono ethylene glycol at 25% volume to protect down to -14°C in a holiday home.

• Use a suitable ltration protection system and a corrosive additive to prevent the formation of

oxides or solids in the heat pump condenser.

• This appliance can be used by children aged from 8 years and above and persons with reduced

physical, sensory or mental capabilities or lack of experience and knowledge if they have been

given supervision or instruction concerning use of the appliance in a safe way and understand

the hazards involved.

• Children shall not play with the appliance.

• Cleaning and user maintenance shall not be made by children without supervision.

NOTE: The heat pump contains refrigerant at high pressure.

Safety measures are in place to avoid system pressure build up;

Stage 1: Pressure transducer stops compressor.

Stage 2: Pressure switch switches heat pump off. All safety devices reset automatically.

Page 7

Millbrook House, Grange Drive, Hedge End, Southampton, SO30 2DF

0844 879 3587

dimplex.co.uk | gdcgroup.co.uk

7

WARNING: Before removing the cover of the heat pump, cylinder or wiring centre, ensure that all

electrical circuits are isolated.

NOTE: The heat pump has a multi-layered, software generated alarm management system, which

prevents it from running outside its operating limits.

NOTE: If an alarm / message occurs, the heat pump will attempt to take remedial action before causing

the system to stop completely if the problem persists. However, the overriding safety feature is the high

pressure switch, which de-energises the main contactor supplying power, in accordance with EN378.

NOTE: This device is suitable for mains connection only (230V, 1P&N, 50Hz) and is not suitable for

operation with an electrical generator or power modulator, due to possible effects on the quality of the

electrical supply. Any attempt to do so will void warranty.

• Means for disconnection from the supply mains must be incorporated into the xed wiring in

accordance with the national wiring regulations.

• This device must be installed in accordance with national wiring regulations.

• The local wiring regulations should always be followed paying particular attention to the mixing of

low voltage and extra low voltage cabling.

• Ensure the incoming power supply and the distribution board are suitably rated.

• Ensure that the regulations specied by the local electricity supplier have been adhered to.

• All fuse rating and protective overload device information is provided in the wiring label located

on the inside of the front bottom panel of the heat pump. For instruction on how to remove this

panel please see section 3.1.

• The installation of a heat pump designated residual current device (type B RCD) having a rated

residual operating current not exceeding 30mA is recommended, in accordance with local

regulations (BS7671 for UK installations).

• The correct earthing (grounding) of the heat pump is of the utmost importance.

CAUTION: The heat pump has a high leakage current and must be properly grounded for safety in

accordance with local and national regulations regarding equipment with a leakage current exceeding

3.5ma.

CAUTION: Two separate, designated RCD devices should be tted - one for the heat pump and one for

the cylinder. The heat pump system must not share an already existing domestic RCD device.

Page 8

Millbrook House, Grange Drive, Hedge End, Southampton, SO30 2DF

0844 879 3587

dimplex.co.uk | gdcgroup.co.uk

8

1.3 Intended Use

This product is designed to extract heat from outside air to provide energy for a water-based heating

system, and is intended for domestic and light commercial use. Any other use beyond that intended by

the manufacturer is prohibited. This requires the user to abide by the manufacturer’s product information.

Please refrain from tampering with or altering the device.

NOTE: Additional heating may be required if the heat pump is intended to dry out a new or renovated

building, as the initial heat load may be higher than the design load.

1.4 Legal

The construction and design of the heat pump complies with all relevant EU directives (see CE declaration

of conformity in Appendices section).

When connecting the heat pump to the power supply, the relevant EN and IEC standards must be adhered

to. Any further connection requirements stipulated by the network operation must also be observed.

When connecting to the heating system all applicable regulations must also be adhered to.

NOTE: Products not installed with the Dimplex hydraulics packs will not be supported by Dimplex. This

includes but is not limited to thermal stores.

NOTE: Installation and any service work on the heat pump may only be performed by an authorised and

qualied installer and after-sales service technicians.

Page 9

Millbrook House, Grange Drive, Hedge End, Southampton, SO30 2DF

0844 879 3587

dimplex.co.uk | gdcgroup.co.uk

9

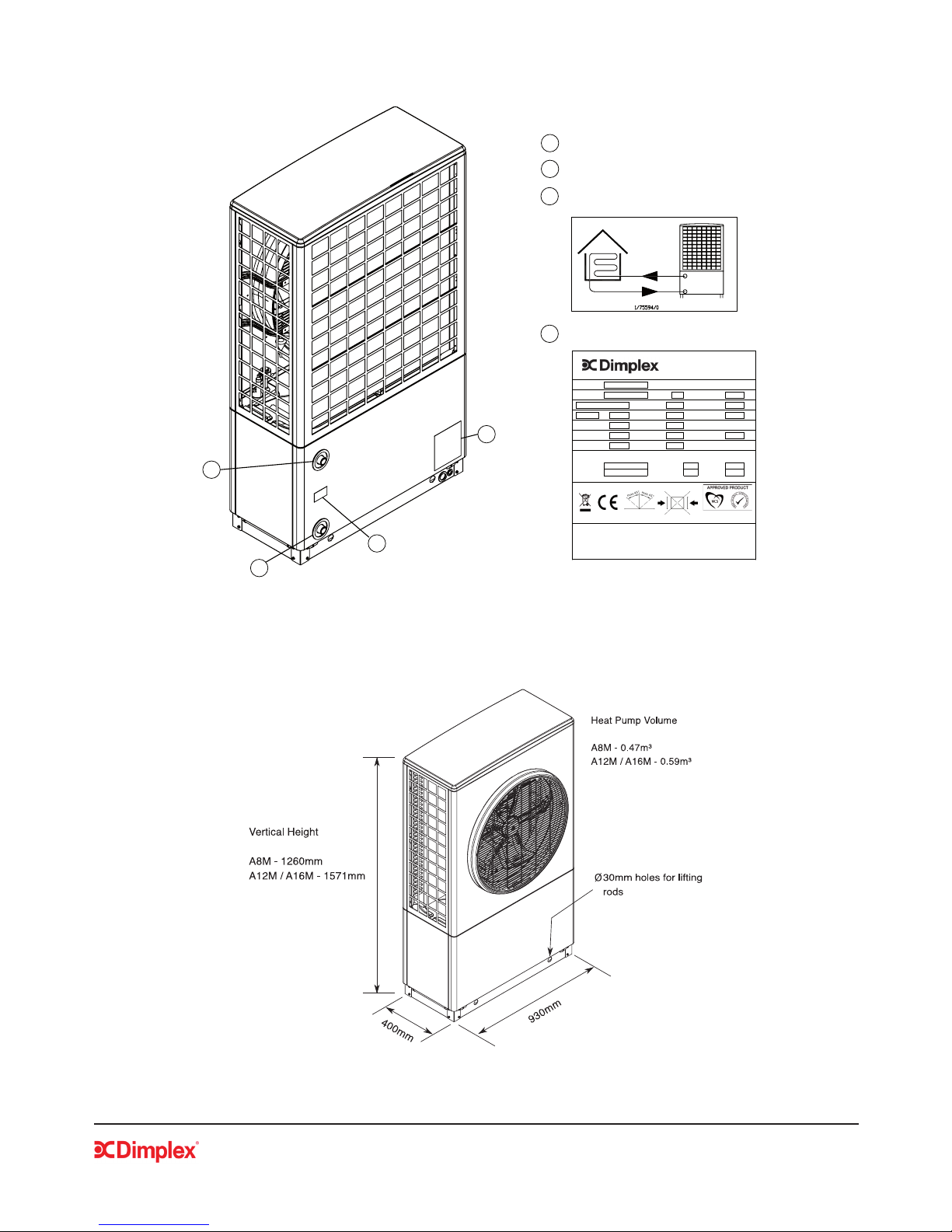

1.5 Heat Pump Labels and Pipe Connections

Figure 2:Heat pump connections and labels

1.6 Heat Pump Dimensions

Figure 3:Heat pump dimensions

1

3

2

4

1

2

Water outlet connection

Water inlet connection

Water connection label

3

Rating label

4

Model:

Serial No. 001

8.0

R410A 2.0 kg

bar

C20 A

C°h/³m0073riA

aPk1.4C°h/³m1.2

Protection: IP 24 kg

12.30 kW COP 4.72

12.90 kW COP 2.20

1/75733/0

The refrigeration cycle is hermetically sealed.

Contains Kyoto-Protocol defined fluorinated greenhouse gases.

All work to be carried out on this unit is to be carried out by a

competent person.

Power Factor

A-2W55

P

Heating

Air to Water Variable Speed Heat Pump

Max Op.

Pressure

Revision:

Single Phase 230V/50Hz

45

kW

Δp

Electrical Power (Max)

P

Heating

A7W35

Heating Water:

EN14511-2 Conditions

A16T

Fabrication Date:

0.99

Fuse Protection

Min.

Flow

T

y

pical

Flow

-20 / +35

+25/+65

Min / Max

Op. Temp.

Min / Max

Op. Temp.

Weight 130

GDC Group

Greenbank Industrial Estate,

Rampart Road,

Newry

Northern Ireland

BT34 2QU

Tilt angle

Do not clamp

on sides

MCS HP0017

HEAT PUMPS

Page 10

Millbrook House, Grange Drive, Hedge End, Southampton, SO30 2DF

0844 879 3587

dimplex.co.uk | gdcgroup.co.uk

10

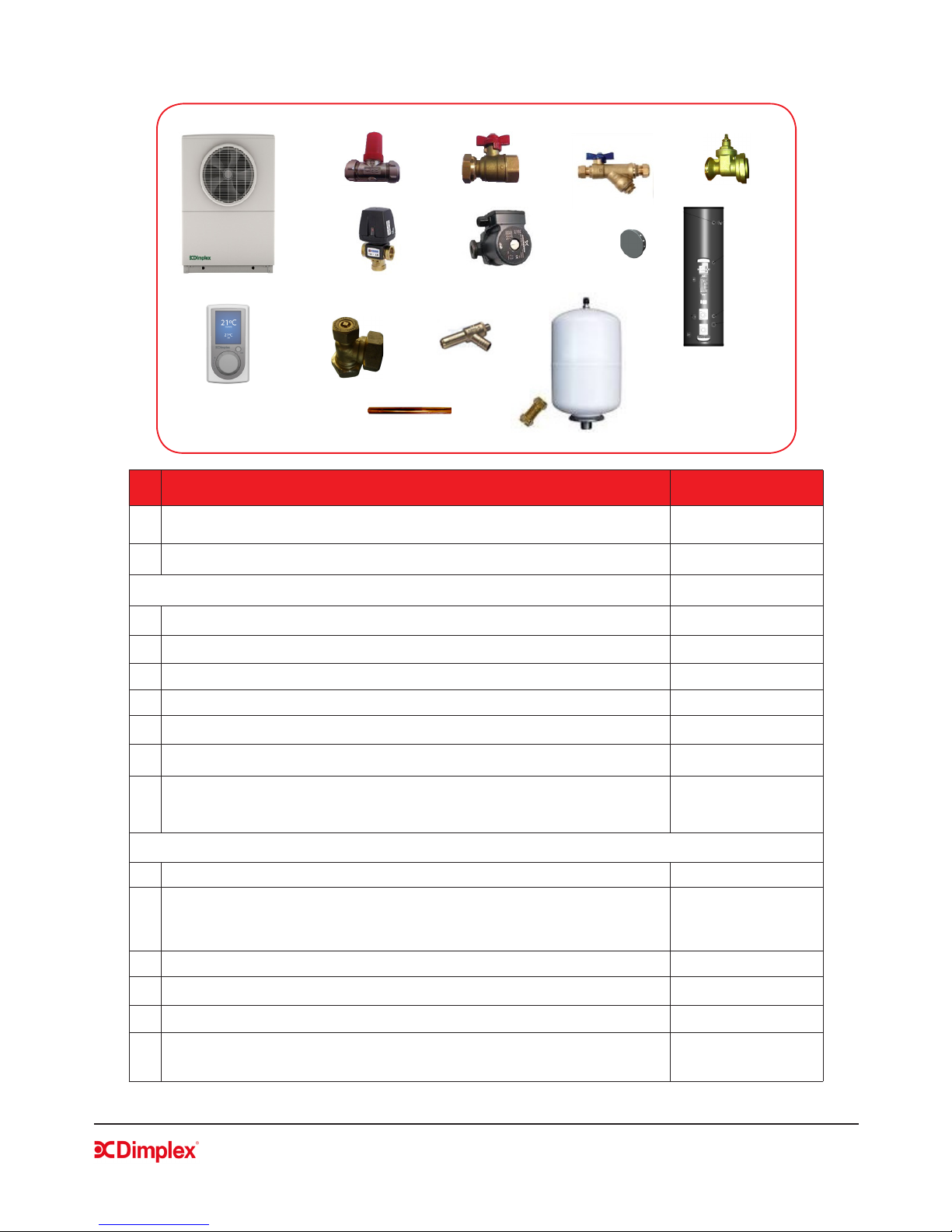

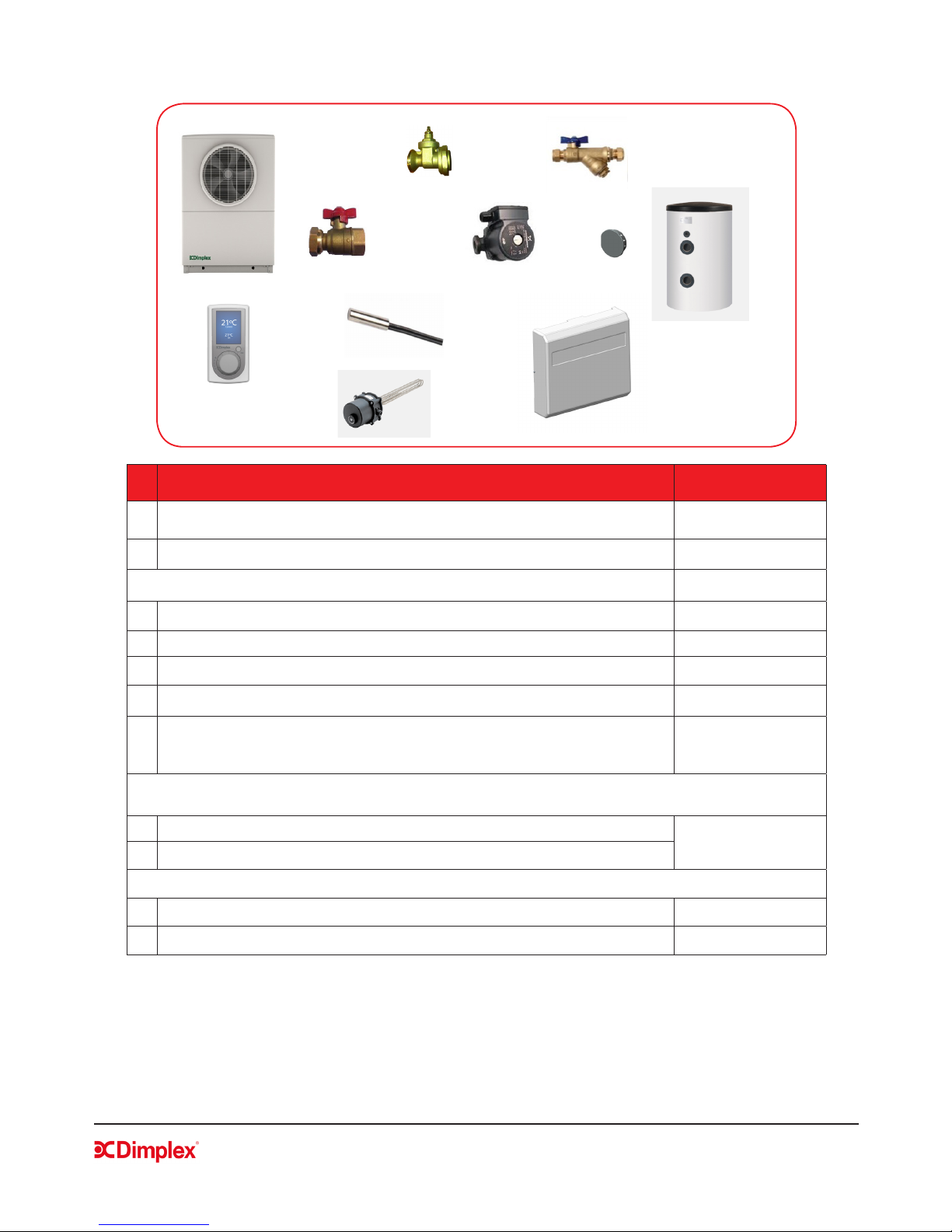

1.7 Scope of Delivery

Please ensure you check the scope of delivery before signing any delivery documentation.

Below is a guideline checklist for what should be contained in each pack.

Claims for missing or damaged parts after signing for the delivery will not be accepted.

There are 3 options to select from when installing a Dimplex Heat Pump:

Pack 1 - Space heating and Dimplex A-Class Cylinder

This pack should contain four boxes;

• Heat Pump

• ACCHYPK Hydraulics Kit A (contains all of the necessary hydraulic components)

• Cylinder

• Cylinder Accessories

A separate wiring centre is not required as the wiring centre is built into the cylinder.

Pack 2 - Space heating and Dimplex Standard Heat Pump Cylinder

This pack should contain ve boxes;

• Heat Pump

• ACCHYPK Hydraulics Kit A (contains all of the necessary hydraulic components)

• Cylinder

• Cylinder Accessories

• Wiring Centre

A separate wiring centre is required as the wiring centre is not built into the standard cylinder.

Pack 3 – Space heating only

This pack should contain three boxes;

• Heat Pump

• ACSHYPK Hydraulics Kit B (contains all of the necessary hydraulic components)

• Wiring Centre

• Accessories

A separate wiring centre is required to wire the circulation pumps and controls.

NOTE: Details for each installation pack are shown on pages 11-13.

All hydraulic kits listed in the following tables include the following documents;

• ASHP Installation manual, part number 8/60472/0 A8M, A12M, A16M

• ASHP User manual, part number 8/60476/0 A8M, A12M, A16M

Please ensure that these manuals are left with the end user. Manuals must be stored safely for

future reference.

Page 11

Millbrook House, Grange Drive, Hedge End, Southampton, SO30 2DF

0844 879 3587

dimplex.co.uk | gdcgroup.co.uk

11

1.7.1 Installation pack 1 - Space heating and Dimplex A-Class cylinder

No.

Description Part No.

1 A-Class heat pump A8M / A12M / A16M

10 Blanking plugs (x4, stored inside heat pump) 4592624105

Hydraulics Kit A ACCHYPK

2 User interface (UI) 1754600

3 ERES spring loaded by-pass valve (22mm comp. tting) 1755780

4 3-port diverting valve (28mm comp. ttings) 1755750

5 Pump - UPM GEO 25-85 180 (1500mm cable) 1755740

6 Isolation valves (1” swivel BSP to 28mm comp.) - Flow 1755760

7 Isolation valves (1” swivel BSP to 28mm comp.) - Return with strainer 1755770

13

2 x Circulation Pump Gate Valve 11/2” swivel to 28mm comp

2 x Washer 30.1x21x2mm

1756090

Dimplex A-Class cylinder kit, which includes;

8 A-Class cylinder with integrated buffer

9

Safety group DHW side; expansion vessel, hose and bracket, inlet group,

tundish

11 Drain

12 3x copper pipes - Pump to buffer / cylinder

14 Air vent

Pipe connections to coil, pipe, drain and vent.

Pipe connections to pump.

q

w

e

r t

y u

i

o

a

s

d

f

g

Page 12

Millbrook House, Grange Drive, Hedge End, Southampton, SO30 2DF

0844 879 3587

dimplex.co.uk | gdcgroup.co.uk

12

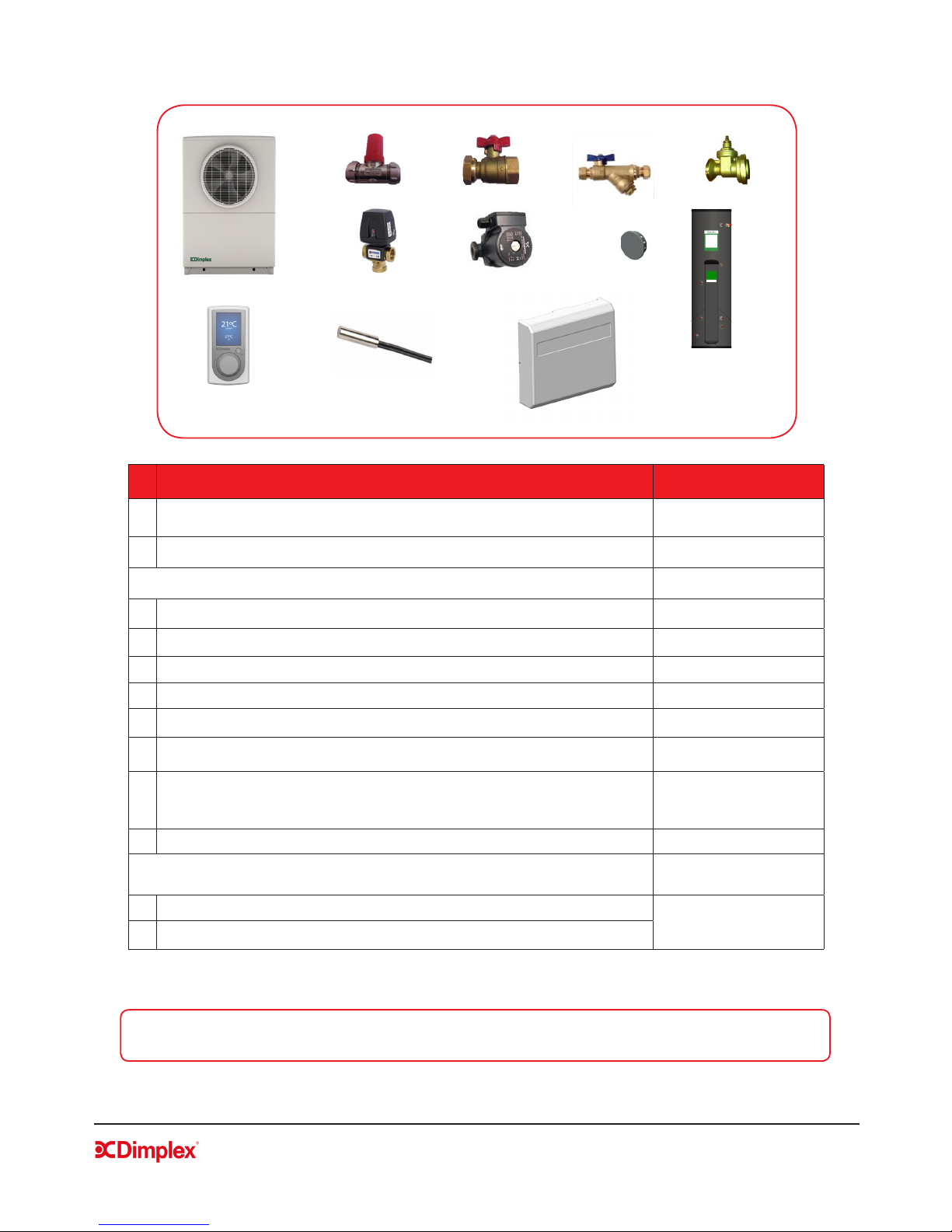

1.7.2 Installation pack 2 - Space heating and Dimplex standard cylinder

NOTE: Cylinder required for pack 2 installation; please see Dimplex EC-EAU cylinder manual for range of

non A-Class cylinders.

No. Description Part No.

1 A-Class heat pump A8M / A12M / A16M

10 Blanking plugs (x4, stored inside heat pump) 4592624105

Hydraulics Kit A ACCHYPK

2 User interface (UI) 1754600

3 ERES spring loaded by-pass valve (22mm comp. tting) 1755780

4 3-port diverting valve (28mm comp. ttings) 1755750

5 Pump - UPM GEO 25-85 180 (1500mm cable) 1755740

6 Isolation valves (1” swivel BSP to 28mm comp.) - Flow 1755760

7 Isolation valves (1” swivel BSP to 28mm comp.) - Return with strainer 1755770

12

2 x Circulation Pump Gate Valve 11/2” swivel to 28mm comp

2 x Washer 30.1x21x2mm

1756090

8 Dimplex standard cylinder

Wiring centre module, which includes;

9 Wiring centre module

049162

11 1 x Temperature probe (NTC10) for DHW

q

w

e

r t

y u

i

o

a

d

s

Page 13

Millbrook House, Grange Drive, Hedge End, Southampton, SO30 2DF

0844 879 3587

dimplex.co.uk | gdcgroup.co.uk

13

1.7.3 Installation pack 3 - Space heating only

q

w

r

t

y

u

o

a

s

i

No. Description Part No.

1 A-Class heat pump A8M / A12M / A16M

10 Blanking plugs (x4, stored inside heat pump) 4592624105

Hydraulics Kit B ACCHYPK

2 User interface (UI) 1754600

5 Pump - UPM GEO 25-85 180 (1500mm cable) 1755740

6 Isolation valves (1” swivel BSP to 28mm comp.) - Flow 1755760

7 Isolation valves (1” swivel BSP to 28mm comp.) - Return with strainer 1755770

4

2 x Circulation Pump Gate Valve 11/2” swivel to 28mm comp

2 x Washer 30.1x21x2mm

1756090

Wiring centre module, which includes;

9 Wiring centre module

049162

11 1 x Temperature probe (NTC10) for DHW

Accessories

8 100L / 200L / 300L buffer tank (depending on installation) 025586

3 2kW buffer immersion element 363610

e

Page 14

Millbrook House, Grange Drive, Hedge End, Southampton, SO30 2DF

0844 879 3587

dimplex.co.uk | gdcgroup.co.uk

14

2. Important pre-installation information

CAUTION: You must read and understand all of the information in this section before attempting an

installation!

2.1 Connection to the Grid - Notifying the DNO

Before you connect a heat pump to the grid, the necessary permissions must be granted by the

distribution network operator. Not obtaining the necessary permissions may result in an unexpected

network upgrade charge, and may compromise the integrity of the local supply if a ‘disturbing load’ is

connected to the network.

The required forms are supplied by Dimplex and must be lled in by the heat pump installer alongside the

client. We recommend notifying the DNO as early as possible in the planning stage to discuss the project

and any additional information. Further information can be found on the Energy Networks website

(www.energynetworks.org) or from your local DNO.

2.1.1 Heat Pump Sizing

NOTE: Ensure that the correct size heat pump has been selected in accordance with the latest version of

MIS3005 (for UK installations).

If a non A-Class heat pump cylinder is being used, ensure that it has been accurately sized with the

appropriate coil surface area of the cylinder to match the heat pump’s output and ow rate requirements,

and that all necessary hydraulic connections have been considered in connecting it to the heat pump

system.

Ensure that suitable heat emitters have been sized in accordance with the BRE publication Design of low-

temperature domestic heating systems: A guide for system designers and installers. To maximise

system efciency it is important to design the system with the lowest ow temperature possible.

For more information on sizing heat emitters or to order BRE publications, please visit the BRE bookshop

website: www.brebookshop.com

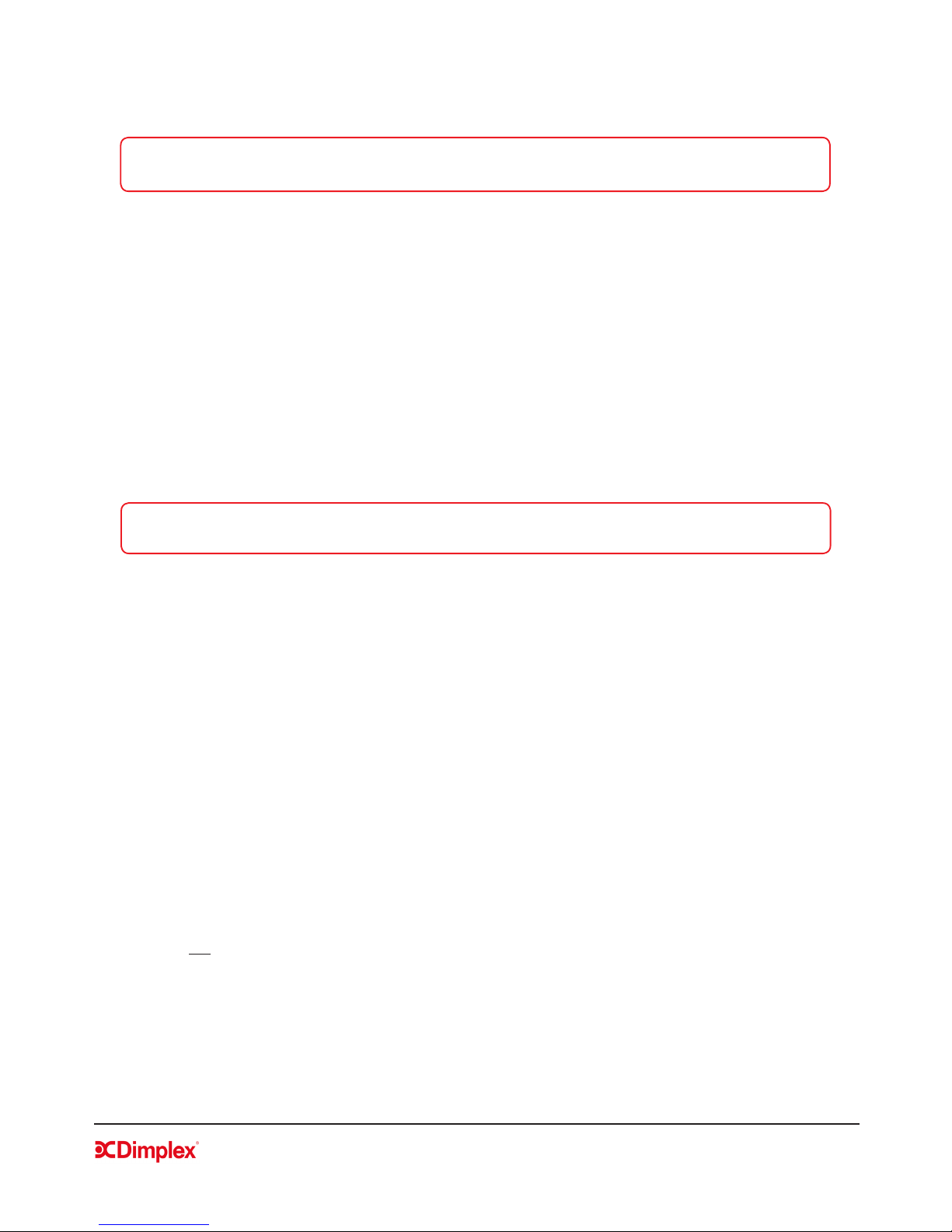

2.2 Heat Pump Location

• The heat pump must be installed outdoors.

• The fan should not face prevailing winds to ensure correct air ow through the evaporator.

• The minimum clearance distances provided in this manual must be followed.

• NO obstructions in front of the heat pump fan for at least 1m.

• Clearance is important for good air ow and service access to the heat pump.

• Do not position the heat pump close to bedroom windows, as the fan and compressor may be

operational at night.

Page 15

Millbrook House, Grange Drive, Hedge End, Southampton, SO30 2DF

0844 879 3587

dimplex.co.uk | gdcgroup.co.uk

15

Figure 4: Poor air ow

CAUTION: Ensure that there are no obstructions in front of the heat pump fan for at least 1m - however,

2m is recommended. ANY type of obstruction in front of the heat pump, even small shrubs, can block the

air ow and cause cold air recirculation.

Figure 5: Good air ow with recommended clearances

Page 16

Millbrook House, Grange Drive, Hedge End, Southampton, SO30 2DF

0844 879 3587

dimplex.co.uk | gdcgroup.co.uk

16

3. Installation instructions

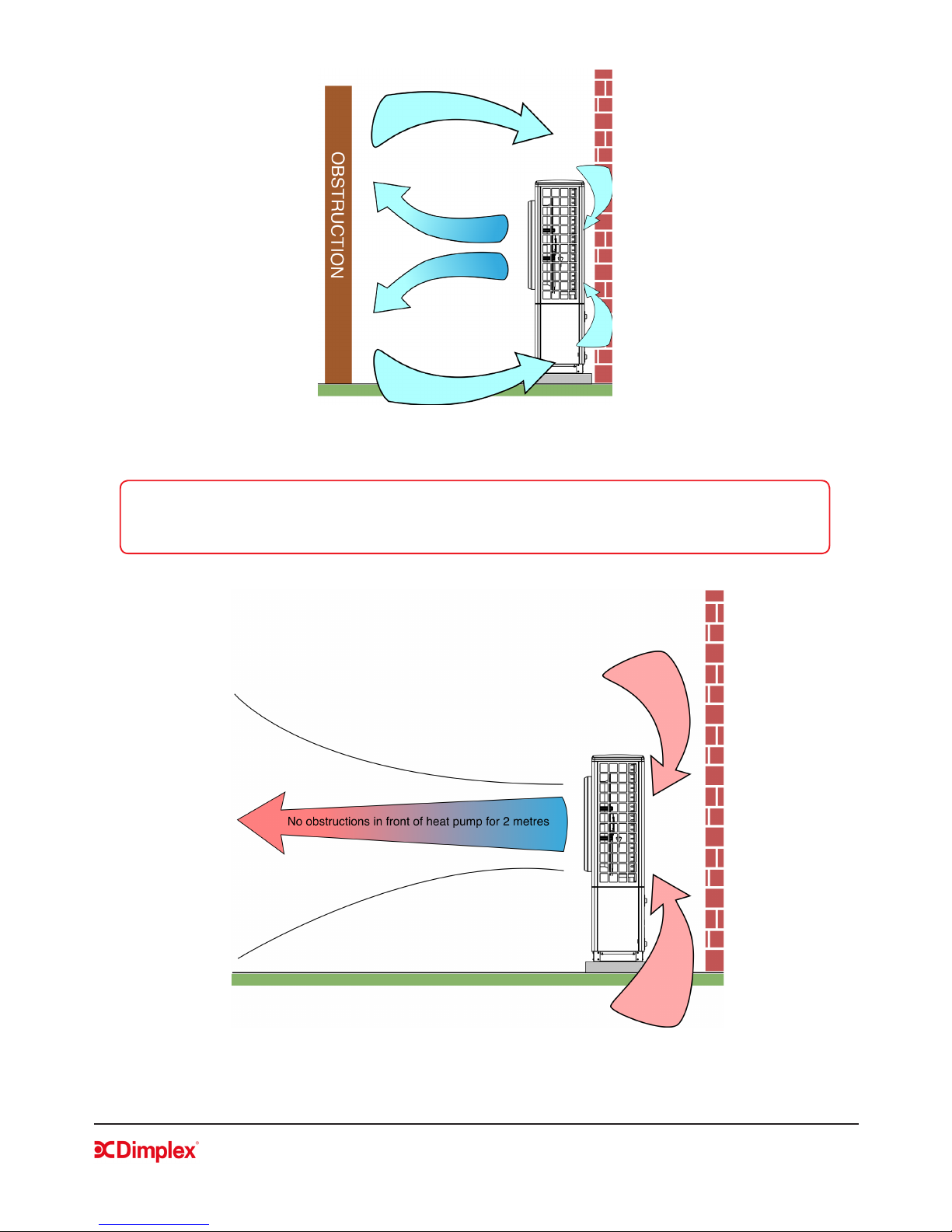

3.1 Positioning and xing the heat pump

• The heat pump must be xed onto a level, stable concrete plinth of minimum dimensions approx.

1000mm x 500mm.

• The concrete plinth must be able to withstand the unit’s weight of 110-140kg (depending on

model).

• A minimum distance of 50mm between the heat pump and the edge of the plinth is required on

all sides.

CAUTION: The minimum clearance distances around the heat pump are shown in gure 3; 300mm

at the rear for air ow, 500mm each side for service and at least 1000mm in front of the fan to avoid air

recirculation.

Figure 6: Required service and air ow clearance dimensions

Page 17

Millbrook House, Grange Drive, Hedge End, Southampton, SO30 2DF

0844 879 3587

dimplex.co.uk | gdcgroup.co.uk

17

1) Check that plinth dimensions are within the required clearances, as per figure 6.

Positioning the heat pump in a conned space, frost hollow or well will result in reduced heat pump

efciency.

The cold air which is expelled by the fan cannot disperse and may be drawn back into the system.

This means that the heat pump may be operating using a lower inlet temperature than what is actually

available from the ambient air.

Figure 7: Removing the panels to t xing bolts and condensate pipe

CAUTION: Ensure that the condensate pipe is uncoiled and is running to a drain

2) Remove the heat pump panels to mark drilling holes on plinth.

The heat pump panels must be removed so that the base panel is visible. To do this, remove the screws

and slide the panels downwards and out.

Once the panels are removed, mark the holes for the xing bolts (gure 6), then lift or slide the heat pump

out of the way to drill the holes. Leave the panels off until all xing and positioning of the heat pump, bolts

and condensate pipe have been carried out (steps 3 -4).

3) Run the condensate pipe to an appropriate drain

The condensate drain pipe is coiled up inside the heat pump for protection during transportation. In order

to access this for installation, the panels will need to be removed (see gure 7). The condensate pipe must

be uncoiled and run through the condensate pipe hole in the base panel to the drain.

Page 18

Millbrook House, Grange Drive, Hedge End, Southampton, SO30 2DF

0844 879 3587

dimplex.co.uk | gdcgroup.co.uk

18

• The pipe should be prevented from exposure to the elements, as this may contribute to freezing

issues. The condensate pipe must run through the base panel and underground to the drain. Freezing

of this pipe due to incorrect installation can result in irreparable damage and void warranty.

• Approximately 2 litres of condensate water are drained from the system every time a defrost cycle

occurs (approximately once every hour in cold and humid weather). Therefore, it is essential that the

condensate pipe is fed into a rain water drain or soak away to allow for safe disposal of the excess

water, away from footpaths or patios.

• The removal of condensate must be secured and the condensate pipe must be kept free from debris

and frost.

• The condensate pipe should not run into sewer pipe as fumes may travel into the heat pump and

cause corrosion to the evaporator coil.

4) Inserting the fixing bolts

Once the holes for the xing bolts are drilled, place the heat pump back onto the plinth and x in place

using the M10 bolts supplied in the installation pack.

5) Positioning and Fixing Indoor Components

The controller and thermostats should be installed on internal walls in living area to reect the correct

room temperature, and away from direct sunlight, drafts (windows and doors) and heat emitters.

3.1.1 Temperature Control Devices

• The controller/user interface that is supplied with the Dimplex A-Class heat pump is used as a

heat pump controller as well as a space heating and domestic hot water (DHW) controller.

The preferred option is to use the user interface as a room temperature control device.

• The user interface and room thermostats should be installed indoors in a location that is out of

reach of children, but where the LCD display can be easily seen (usually 1.2m – 1.7m from the

oor).

While only one user interface is currently available per system, there are additional options

of either temperature probes or mechanical thermostats, which can be used to control the

temperature in up to four zones.

• Mechanical thermostats provide less control over the heating system, while the temperature

probe option allows the heat pump to sense changes in demand and adjust accordingly. The

temperature probe option is generally recommended over the mechanical thermostat option.

Page 19

Millbrook House, Grange Drive, Hedge End, Southampton, SO30 2DF

0844 879 3587

dimplex.co.uk | gdcgroup.co.uk

19

3.1.2 Space Heating Zones

A zone is dened as the physical area of the home in which temperatures are controlled by each individual

device. For example, there might be a user interface installed in the living area, in which case this may be

referred to as zone 1. There may also be a temperature probe installed upstairs in the sleeping/bedroom

area, which would then be designated as zone 2, and so on.

Extra zones are an additional, optional feature of the heating system. The standard package comes with

one user interface and the possibility of four separate zones. Each heating zone can be assigned a heat

curve specic to the type of heat emitters.

3.1.3 Location of Wiring Centre

If a Dimplex A-Class cylinder is used, the wiring centre is built in to the A-class cylinder and pre-wired.

If a non A-Class cylinder is used, the wiring centre module must be installed.

The wiring centre module is designed to be wall mounted, and it is recommended that it is installed in

close proximity to the cylinder to allow for installation of components which require a control cable

(modbus) connection, i.e. pump, DHW probe, 3-port valve and heat pump connections.

Page 20

Millbrook House, Grange Drive, Hedge End, Southampton, SO30 2DF

0844 879 3587

dimplex.co.uk | gdcgroup.co.uk

20

4. Installation

4.1 Important - Plumbing Information

NOTE: To simplify underoor heating initial screed heating, it is essential to have a thermostatic mixing

valve on the underood heating (UFH) manifold.

This allows the heat pump to run at higher temperature and capacity when the screed is cold.

• If multiple heat emitter circuits are installed, operating at different ow and return temperatures (such

as under oor heating and standard radiators), a mixing valve must be used on low temperature

circuits to prevent high temperature water from entering the under oor heating manifold.

• Isolation valves (non-return valve and ball valve with strainer), supplied in the Dimplex heat pump

hydraulics pack, allow the strainer to be removed and cleaned without having to drain the system.

• Existing hot water systems should be ushed prior to connection to the heat pump to remove all

contaminants and impurities, in accordance with the latest version of MIS3005.

• Flow and return isolation valves and piping must be tted to each of the heat pump water connections

on the back of the heat pump, as shown in gure 1.

• The isolation valve on the return is also tted with a non-return valve and a strainer (included in the

Dimplex heat pump hydraulics pack). This means that in order to clean the strainer, the system does

not have to be drained. Instead, it is possible just to close the isolation valves on the return and

remove the strainer. This way, the only water that will be lost from the system is that between the non-

return valve and strainer.

• The strainer must be tted in order to prevent contamination of the condenser heat exchanger. If an

alternative strainer is used, it must be at least 7 microns in size.

• System should be pressurised and the system pressure must be checked once valves are re-opened.

• Direct condensate drain pipe to soak away or drain.

• All piping must be properly insulated and external length kept to a minimum.

• The return isolation valve provided in the hydraulics pack has a built in strainer to help prevent debris

entering the condenser and must be tted.

• The system must be lled and ushed with clean fresh water to ensure the removal of all the air from

the installation.

CAUTION: When lling the system, always ensure that clean, fresh water is used. Using dirty or

untreated water may cause severe damage to components and may affect the efciency of the system

when operating.

• Air bleed points must be installed at the highest point in the system; in particular, the installer must

remember to install an air bleed on the heat pump pipe if it is a local high point since there is no air

bleed point on the heat pump itself. Dimplex recommend the use of a power ush and purge cart to

facilitate this process.

Page 21

Millbrook House, Grange Drive, Hedge End, Southampton, SO30 2DF

0844 879 3587

dimplex.co.uk | gdcgroup.co.uk

21

• Flow and return isolation valves and piping must be tted to each of the heat pump water connections

on the back of the heat pump, as shown in gure 8.

• The isolation valve on the return is also tted with a non-return valve and a strainer (included in the

Dimplex heat pump hydraulics pack). This means that in order to clean the strainer, the system does

not have to be drained. Instead, it is possible just to close the isolation valves on the return and

remove the strainer. This way, the only water that will be lost from the system is that between the non-

return valve and strainer.

• The strainer must be tted in order to prevent contamination of the condenser heat exchanger. If an

alternative strainer is used, it must be at least 7 microns in size.

• System should be pressurised and the system pressure must be checked once valves are re-opened.

• Direct condensate drain pipe to soak away or drain.

• All piping must be properly insulated and external length kept to a minimum.

• The return isolation valve provided in the hydraulics pack has a built in strainer to help prevent debris

entering the condenser and must be tted.

Figure 8: Details of ow and return isolation valves

CAUTION: The quality of the water used to ll the heating system is of vital importance. Muddy or dirty

water, for example, from a freshly drilled well, is not suitable, as this can lead to the incorrect functioning of

some components and poses a corrosion risk to the system.

Page 22

Millbrook House, Grange Drive, Hedge End, Southampton, SO30 2DF

0844 879 3587

dimplex.co.uk | gdcgroup.co.uk

22

4.1.1 Pipe Sizing Information

When selecting piping to install w ith the heat p ump please ensure that:

•

• The safety group and expansion vessel (space heating side) are accurately sized by the installer

based on the system volume (these are not supplied by Dimplex).

• External pipework and valves should be adequately insulated with vapour resistant insulation and

protected against damage to prevent excessive heat losses. All joints should be suitably sealed

and exposed pipework must be avoided.

• Ensure the water out and water in pipes are positioned correctly for connection to the heat pump

NOTE: The hydraulic installation information provided in this manual applies only to the components

provided in the Glen Dimplex hydraulics pack (see Scope of Delivery for information).

A8M A12M / A16M

Space heating only

DHW with

A-Class cylinder

Water ow rate

@ 1100 l/h

(nominal)

@ 2100 l/h

(nominal)

@ 1800 l/h

(nominal)

Associated head available 60kPa 14kPa 18kPa

Pipe diameter

(mm)

Internal diameter

(mm)

Maximum equivalent pipe length

90 N/A N/A

300 23 38

22

28

32

19.8

25.6

29.6

0.31 l/m

0.51 l/m

0.69 l/m 600 46 77

Table 1: Maximum equivalent length for copper pipe - water only

CAUTION: Table 1 above is provided as a guideline when using water only. Any percentage of anti-freeze

added will affect the pressure drop of the system greatly and will render this table invalid.

Not all types of pipe will have the same internal diameter, e.g. multi-layered/plastic pipes will have

a thicker wall so the guidelines set out in table 1 will not apply. Microbore (8mm) and 15mm pipe is

not suitable.

As a rule of thumb, the equivalent straight length (L [mm]) of each elbow is found by multiplying

the outer diameter of the pipe (D [mm]) by 30, e.g. 4 elbows of diameter 22mm pipe is equivalent to

2.5m of 22mm pipe.

Volume of

water per

metre of pipe

Page 23

Millbrook House, Grange Drive, Hedge End, Southampton, SO30 2DF

0844 879 3587

dimplex.co.uk | gdcgroup.co.uk

23

4.1.2 Buffer tank

The heat pump uses a reverse cycle defrost in order to defrost the evaporator by taking heat from the

heating system. It is therefore necessary to connect a buffer tank in series with the heat pump, as shown

in the hydraulic schematic diagrams (Appendices). The Dimplex A-Class cylinder range come with an

integrated buffer tank, which;

• Provides some energy storage for the unit to carry out successful defrost.

• Increases compressor life due to reduction in the number of starts.

It is recommended that a buffer with a heating element/immersion is used as it may be required if initial

start-up and commissioning are carried out in very cold weather.

Buffer Tank Sizing

The minimum total system water volume (including water in heat emitters) should be no less than 100l.

Water volume in pipework, heat emitters and the built-in 40l buffer tank included in the A-Class cylinder

must all be taken into account. This is particularly important when using Smartrads, as their water content

is low compared to standard radiators (0.6l for SRX180 model).

4.1.3 Adjusting the spring loaded by-pass valve (if tted)

CAUTION: If an externally controlled zone pump is connected when using any schematic, the spring

loaded bypass must not be used and instead must be replaced by an open bypass tted with a gate valve.

This is to ensure that the zone pump(s) is/are not running against a dead head when the heat pump is idle

or in DHW mode

The bypass valve is used to maintain a minimum ow rate and prevents faulty operation of the heat pump,

as well as allowing it to run efciently. The bypass valve must be adjusted correctly after commissioning

the heat pump.

Please ensure that the following steps are taken when adjusting the bypass valve;

1. Ensure that the bypass valve is open fully and begin running the heat pump.

2. Close all of the heating circuits that may be closed during the operation of the heating system so

that the least favourable ow rate can be achieved. This should cause all of the ow to go through the

bypass valve. To check that all of the water ow is going through the bypass valve, feel the pipe after the

valve to check its temperature (it should be getting heat from the heat pump).

3. Slowly close the valve until the water is no longer owing through it, then turn the valve back

slightly (approx. 0.5 to 1 turn) to allow some ow and prevent the heat pump from tripping.

4. Open the zone valves while the heat pump is still running, and again check the ow through the

bypass valve by feeling the pipe after the valve and checking its temperature (it should not be as hot as

ow temperature). The bypass setting should allow hot water to ow through the bypass valve when some

of the heating circuits are closed.

Page 24

Millbrook House, Grange Drive, Hedge End, Southampton, SO30 2DF

0844 879 3587

dimplex.co.uk | gdcgroup.co.uk

24

4.1.4 Metering for the Domestic Renewable Heat Incentive - UK

Please take note of the following requirements if the installation is to be fitted with a meter;

• Leave sufcient space for appropriate meters to be tted in dened locations.

• For Dimplex installations using 22mm pipe, please leave 440mm of straight pipework on the

meter inlet pipe and 175mm of straight pipework on the outlet pipe;

• For installations using 28mm pipe, please leave 560mm of straight pipework on the meter inlet

pipe and 175mm of straight pipework on the outlet pipe.

• Install low pressure-drop isolation valves to avoid the need to drain systems when tting heat

meters. See the schematics (Appendices) for more information on valve locations.

• Leave sufcient pipework accessible, i.e. not boxed in or under oor boards, to enable meters to

be tted.

• Guidelines for tting an MCS approved meter can be found in the Domestic Renewable Heat

Incentive essential guide to metering, available on the Ofgem website: www.ofgem.gov.uk

Page 25

Millbrook House, Grange Drive, Hedge End, Southampton, SO30 2DF

0844 879 3587

dimplex.co.uk | gdcgroup.co.uk

25

4.2 Electrical Information

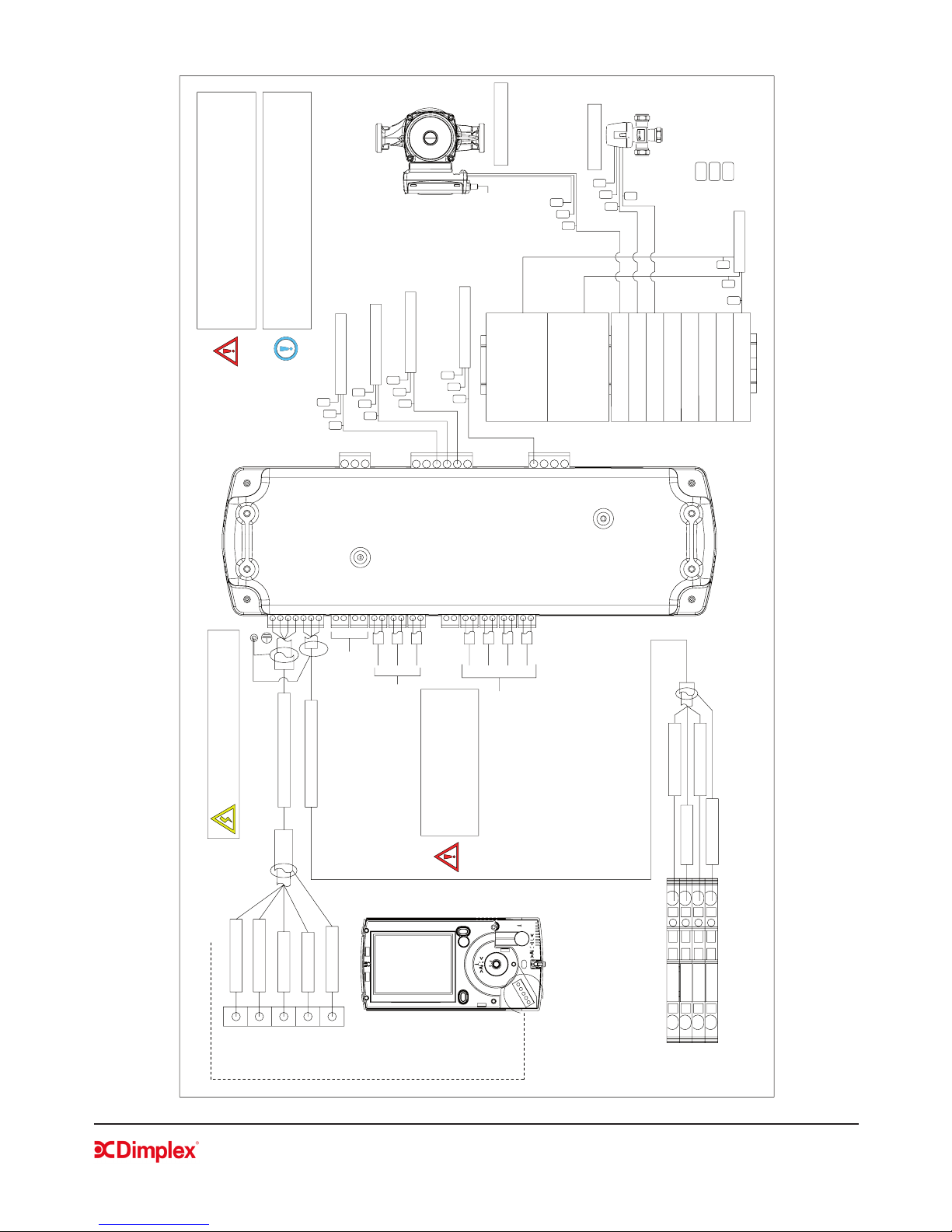

The heat pump system consists of the heat pump, wiring centre and user interface. If a Dimplex A-Class

cylinder is also used, the wiring centre is built into the cylinder.

The user interface acts as a thermostat and is sufcient if one heating zone is present. Optional, additional

temperature probes or room thermostats are required for additional heating zones.

The wiring diagrams in the Appendices section show the different possible wiring congurations for

systems with and without a Dimplex A-Class cylinder.

WARNING: Before opening the heat pump, ensure all circuits are isolated.

WARNING: Ensure that the components in the electrical box do not get wet when the electrical box is

opened.

WARNING: The main 230V power cable must be supplied via a suitable sized exterior isolator, lockable

in the OFF position.

4.2.5 Access to Electrical Connections - Opening the heat pump

Figure 9: Access to the electrical box

Page 26

Millbrook House, Grange Drive, Hedge End, Southampton, SO30 2DF

0844 879 3587

dimplex.co.uk | gdcgroup.co.uk

26

To open the heat pump, follow the procedure shown in gure 9;

1) Unscrew 2 screws (1) holding front bottom panel (2) using a PZ2 screwdriver

2) Pull the front bottom panel (2) down then out to remove

3) Unscrew 5 screws (3) holding the front cover (4) of the electrical box to open and then pull down

4) Remove 2 PZ2 screws (6) holding the door ap in place to access cable connections.

5) Cable access cover (7) only used on some models.

For model cable connection congurations for your heat pump model, please see gure(s) 11/12.

6) The cable access covers (5 and 7) can be opened by removing a screw to allow access to cables.

CAUTION: Ensure that cable access covers are closed correctly when not in use.

CAUTION: Follow steps in reverse order to close the heat pump. When closing the heat pump front

panel, ensure that the top and bottom panels are interlocked.

4.2.6 Electrical Connections - power and Modbus cable heat pump connections

The electrical connections to the heat pump may have one of two congurations, depending on the model.

Please see diagrams 11/12 for your conguration.

Figure 10: Heat pump electrical connections

NOTE: ‘S’ as shown in gure 10 above is the earth shield and must be connected during installation.

Controller Cable (RS485 MODBUS)

to be connected to S, OV, B, A

Mains power supply cable to

be connected to PE, L, N

Connections on this side are pre-wired

EARTH SHIELD

WHITE / Orange

BLUE / White

WHITE / Blue

Page 27

Millbrook House, Grange Drive, Hedge End, Southampton, SO30 2DF

0844 879 3587

dimplex.co.uk | gdcgroup.co.uk

27

• For conguration 1, the cables are fed through the holes at the back of the heat pump and directly

inside the electrical box through the base of the heat pump (see gure 11).

Figure 11: Electrical cabling conguration 1

• For conguration 2, the cables are fed through the holes at the back of the heat pump, up through the

holes in the base of the heat pump and then from outside the electrical box through the cable glands

(see gure 12).

Figure 12: Electrical cabling conguration 2

M16X1.5 Cable

Gland

RS485 Modbus Cable

M16 Lock Nut

M25x1.5 Cable

Gland

Armoured Power

Cable

M25 Lock Nut

Page 28

Millbrook House, Grange Drive, Hedge End, Southampton, SO30 2DF

0844 879 3587

dimplex.co.uk | gdcgroup.co.uk

28

Allow sufcient cable length to ensure the connections are not strained when the cover is opened.

Once cables have been routed through the cable glands, close the access cover.

Connect power cable and controller cable as shown in gure 10. Do not strip the cables before pulling

them through the glands in the access panel. Where stranded cable is being used, a ferrule must be tted

before inserting into the push connections.

The controller (Modbus) cable is then connected from the heat pump to the wiring centre (see wiring

diagrams in Appendices).

4.2.7 Modbus Cable Information

Table 2: Recommended cable specications/electrical characteristics for Modbus cable

4.2.8 Opening and Installing the User Interface

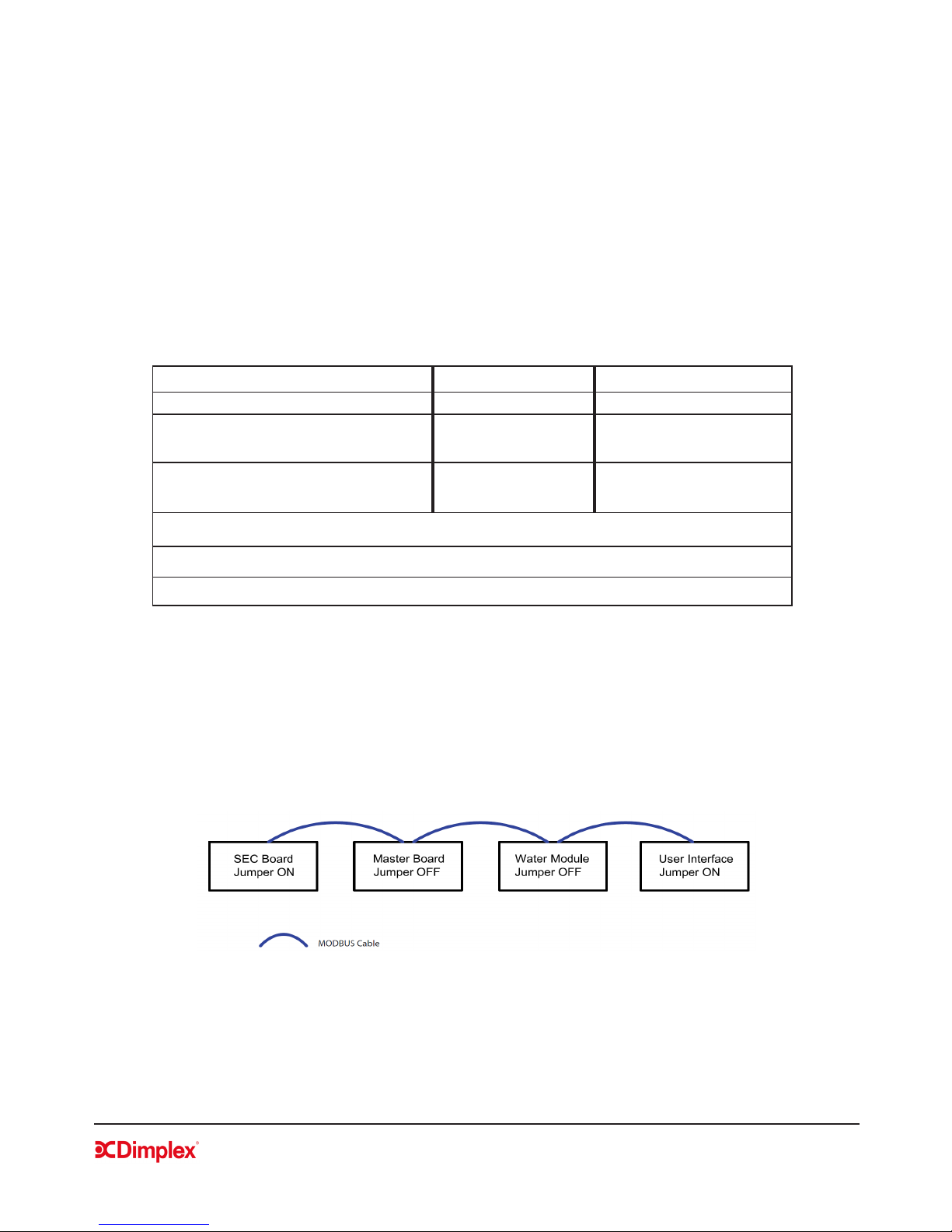

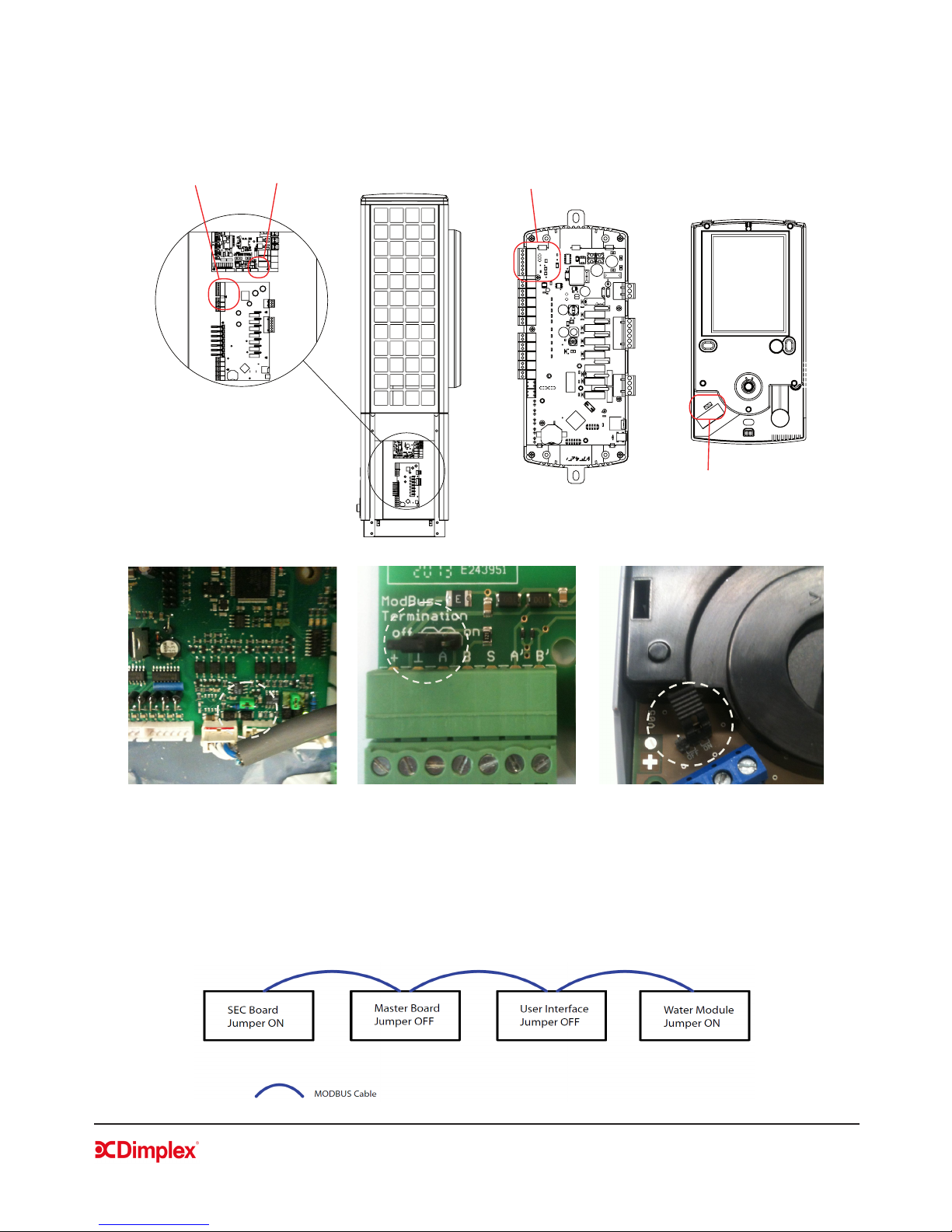

It is recommended to connect the Modbus cable in daisy-chain series (as shown in gure 13) from the

heat pump on to the wiring centre and then on to the UI. The jumpers will be in the correct factory setting

for this wiring conguration by default. If using the recommended conguration, the jumper position does

not need to be changed.

Figure 13: Recommended MODBUS cable conguration

If it is deemed necessary to install the Modbus cable in a different order, please see Appendices.

The cover of the UI must be removed in order to move the jumper. To remove the cover, unscrew the

screw at the bottom of the UI and lift the cover and rotary dial.

Belden Cable 9842 Typical Equivalent Cable

Nominal Characteristic Impedance 120Ω 120Ω

Nominal Conductor DC Resistance

24.0Ω/1000ft

78.7401 Ω/km*

78.80 Ω/km*

Nominal Capacitance Core to Core

12.8pF/ft

41.99pF/m

42pF/m

*Conversion factor for ft to m = 3.28 ft = 1m

1km of Belden cable would have a resistance of 78.74 Ω/km

1km of Equivalent cable has a resistance of 78.8 Ω/km

Start

End

Page 29

Millbrook House, Grange Drive, Hedge End, Southampton, SO30 2DF

0844 879 3587

dimplex.co.uk | gdcgroup.co.uk

29

To replace the cover, position the rotary dial over the holding pin on the board, ensuring the two are lined

up correctly. Replace the cover and bottom screw. Ensure that rotary dial is tested and working once cover

has been replaced.

Page 30

Millbrook House, Grange Drive, Hedge End, Southampton, SO30 2DF

0844 879 3587

dimplex.co.uk | gdcgroup.co.uk

30

4.3 Heat Pump Controller / Commissioning

4.3.1 Important pre-startup information

When starting up the heat pump, you must rst ensure that;

• All covers are replaced.

• The heat pump isolator switch is switched on.

• The heat pump is connected to the mains power supply via a separate suitable circuit breaker and

RCD protection.

• The wiring centre or DHW cylinder is connected to the mains power supply.

The Modbus network is complete and the UI and the heat pump are connected to the wiring centre or

DHW cylinder.

Once the connections have been made and the power supplies have been switched on, the system may

take a couple of minutes to start up.

When switching on the heat pump for the rst time, and after the start up sequence, you will be greeted by

the main menu or screensaver if the heat pump is idle (use the Esc button to return to the main menu).

To access the Installer Menu, you must select the

information menu, represented by the ‘i’ icon on the

main menu (shown in gure 14).

Use the rotary dial to select the ‘Login’ option and to

scroll through numbers from 0 - 999.

Input the code to access the installer settings (22),

then the code to bring up the installer menu (55).

NOTE: You will not be able to access any other

options on the main menu, except the information

menu, until the heat pump has been fully

commissioned.

Figure 14: Starting up the user interface

NOTE: Some of the commissioning checks are functional and will require physically starting pumps,

valves. etc. rather than inputting information on the UI only.

NOTE: The model no. displayed on the information screen will be 8, 12 or 16 depending on your heat

pump model. The serial number displayed will be specic to your heat pump.

CAUTION: Access to functions by unatuhorised personnel negates warranty and may cause damage to

the system.

Page 31

Millbrook House, Grange Drive, Hedge End, Southampton, SO30 2DF

0844 879 3587

dimplex.co.uk | gdcgroup.co.uk

31

When you enter the installer menu, select the Language Selection option, which will bring you to the Start

Guide screen. Selecting UK will bring you back to the installer menu, which will now display

Commissioning as an option.

Figure 15: Installer and commissioning menu options (when complete)

4.4 Commissioning

Select Commissioning to begin and follow the instructions on the system controller.

The commissioning routine will take you through a number of checks and tests to complete the

installation.

When you nish using each submenu in the commissioning process, selecting Next will take you back to

the main commissioning menu, where a new submenu will be available.

4.4.1 Starting the heat pump in cold weather

When carrying out a commissioning and setting a heat pump to work in conditions where defrosting is

required (≤12°C) and/or the space heating return temperature is ≤18°C, start by heating the buffer tank.

There is not currently a software function to close down the heating circuits, so to do this the rest of the

heating circuit must be closed down manually to allow the buffer tank to heat up (well above 25°C).

Once this temperature has been achieved, individual heating circuits (i.e. zones) can be opened gradually.

During this procedure, DO NOT:

• Allow excess volumes of cold water to return from the heating circuit

• Allow the heat pump return temperature to drop below 18°C

• Bivalent Mode (Alternative back-up heat sources)

• If the heat pump cannot meet the heating load (if it is undersized for extreme conditions), the system

must call on an alternative, back-up heat source. This bivalence feature is automatically triggered by

the controller and allows a backup heater to help the heat pump in reaching its set point.

4.4.2 General / Schematic

Accessing General/Schematic menu allows you to set the date and time, and the level of access allowed.

It is recommended that the Standard user access level is selected for most installations.

Page 32

Millbrook House, Grange Drive, Hedge End, Southampton, SO30 2DF

0844 879 3587

dimplex.co.uk | gdcgroup.co.uk

32

Selecting Next will bring you to the Schematic menu, as shown in gure 16.

The schematic number refers to one of the plumbing schematics described in

the Appendices section.

Please ensure that your plumbing reects the diagram set up to ensure correct

operation. The schematic coding is explained below.

Numbers that are shaded grey do not change. These are determined by the type

of device being installed.

Numbers not shaded are determined by the type of installation being used.

Figure 16: Schematics

Table 3: Explanation of digits of schematic codes

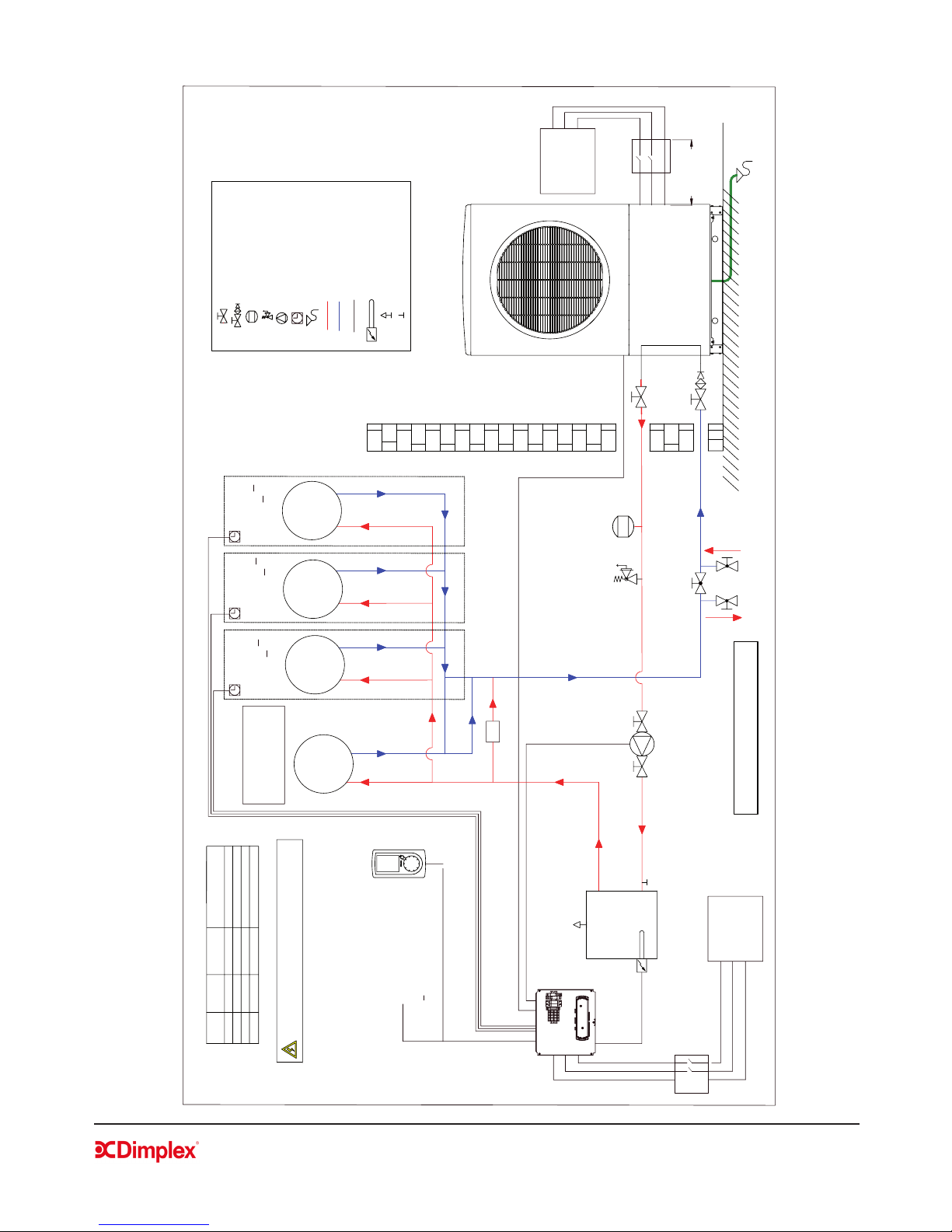

The example schematics 1 and 2 (appendix) would

therefore both use the schematic code 10220290, as

they are both;

• mono-energy systems

• using an immersion heater

• two zones

• space heating and DHW functions

The difference between examples 1 and 2 is that

example 1 shows an example of a system requiring an

open by-pass while example 2 requires the installation

of a spring by-pass.

Table 4: Schematic codes information

1 0 0 0

3rd Digit

2: mono-energy (heat pump + electric back-up)

3: bivalent (heat pump with boiler as back-up)

4th Digit

0: no DHW function

2: using immersion heater (for top-ups above the

maximum achievable temperature of the heat

pump)

6th Digit

number of zones (up to 4 zones with UI and

temperature probe instead of thermostat)

7th Digit

1: space heating only

9: space heating + DHW

No. on UI Code Appendix No.

1 10200110 6.5

2 10200210 6.5

3 10200310 6.5

4 10200410 6.5

5 10220190 6.6

6 10220290 6.6

7 10220390 6.6

8 10220490 6.6

9 10300110 6.7

10 10300210 6.7

11 10300310 6.7

12 10300410 6.7

13 10310190 6.8

14 10310290 6.8

15 10310390 6.8

16 10310490 6.8

Page 33

Millbrook House, Grange Drive, Hedge End, Southampton, SO30 2DF

0844 879 3587

dimplex.co.uk | gdcgroup.co.uk

33

4.4.3 Waterside Check

The ‘Waterside Check’ menu allows you to select whether temperature control is based on the ow or

return temperature. This will apply to heating curves, as discussed in section 4.4.12.

It is generally always recommended to set the temperature control based on the return temperature

(the default selection on the UI), unless it is absolutely necessary to use ow temperature instead for a

particular set up.

CAUTION: Flow control may lead to unnecessary stopping and starting of the heat pump.

Selecting Next will bring you to the waterside checks menu (gure 17).

A number of waterside checks must be carried out as part of commissioning, and must be ticked as

completed. In the Waterside check menu:

• The system must be ushed.

• The strainer must be tted to the return pipe and checked to ensure that it is

clean.

• The system must be pressurized (you must enter the system pressure).

• The system must be fully bled.

• The expansion vessel must be tted

• Membrane pressure of the expansion vessel must be checked and adjusted

Figure 17: Waterside Check

When checks are completed and ‘Next’ is selected, the type of temperature measurement devices to be

used in each heating zone must also be selected by scrolling across and pressing conrm. The following

options are available;

• User Interface (usually in zone 1 – heating system controller)

• Temperature probe (option for temperature probe 1 to 3, for additional

zones).

• Mechanical thermostat (option for mechanical stat 1 to 3, for additional

zones).

• Using a mechanical stat limits the level of heating control on the zone from

the UI. Heating in zones using temperature probes can be fully controlled using

the UI. Selecting ‘Next’ will bring you to the ‘Temperature check’ menu.

Figure 18: Temperature device

selection

NOTE: If any changes must be made to the commissioning conguration (e.g. selecting a different

probe), it is strongly advised that a factory reset is performed and that the heat pump is recommissioned

entirely. Changing individual settings during the commissioning process may cause commands to be

ignored or cause the heat pump to stop working correctly.

Page 34

Millbrook House, Grange Drive, Hedge End, Southampton, SO30 2DF

0844 879 3587

dimplex.co.uk | gdcgroup.co.uk

34

NOTE: If you leave the commissioning menu before you successfully complete commissioning, all

previous information entered will be saved and completed menus will be highlighted in green. You can

then return at a later stage to complete the process.

4.4.4 Temperature Check

This screen displays the temperatures currently being read by all temperature

probes. It is the duty of the installer to ensure that all sensors are installed and

working correctly.

CAUTION: The boxes on this menu should not be ticked unless all displayed

temperatures have been conrmed to be within an acceptable and expected

range.

Figure 19: Temperature check

4.4.5 Electrical connections

This menu provides a list of electrical connections that should be made prior

to commissioning for space heating. The list is based on the schematic zone

diagram selected and also the type of temperature devices that will be used in

each zone.

Once you have conrmed all checks and select Next, you will return to the

commissioning menu where you can now access the ‘Water ow check’ menu.

Figure 20: Electrical connections

4.4.6 Water Flow Check

Select ‘Run Test’ to start the circulation pump. Ensure that all valves are

open to allow ow. The circulation pump will be tested rst by running for 30

seconds. When the timer reaches zero, the pump will continue to run until

ow is conrmed, which allows time for the installer to check that the pump is

working.

Figure 21: Pump check

Once you are condent that the pump is on and that there is water ow, select Continue to conrm that

the pump is working correctly. Do not conrm that the pump is working in this menu unless you have

physically checked it, as the UI requires your input and does not detect this automatically.

Page 35

Millbrook House, Grange Drive, Hedge End, Southampton, SO30 2DF

0844 879 3587

dimplex.co.uk | gdcgroup.co.uk

35

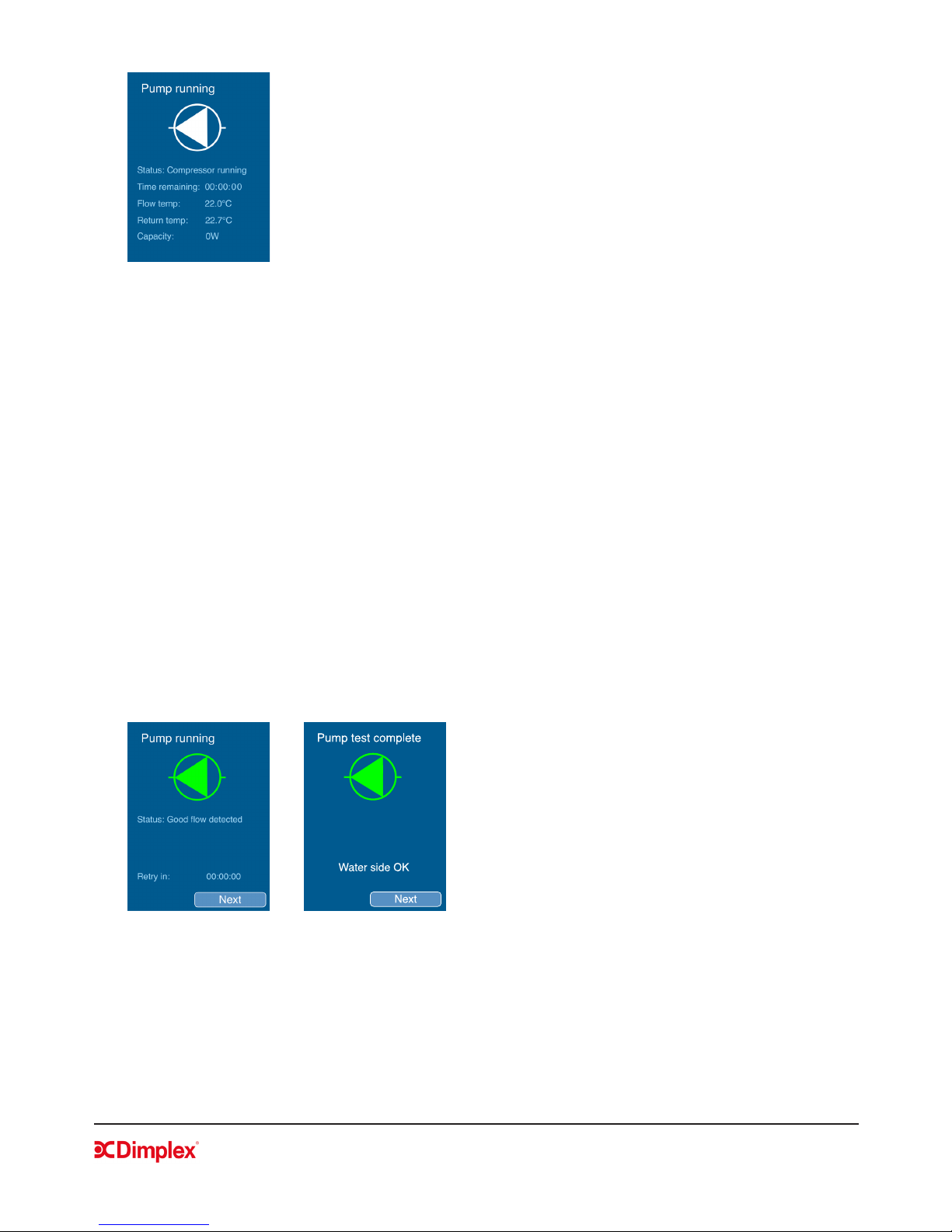

Once this is successful, the compressor will run for 5 minutes. As the test runs,

the screen will give you information on the status of the heat pump and the time

remaining on the test.

If you do not have ow or if there is a problem, you can stop the test. If you

stop the test, there is a 5 minute delay before you can attempt to run the test

again. It is not possible to bypass the test, as good water ow is critical to the

operation of the heat pump.

Figure 22: Compressor test

If there is no ow at all, a high pressure fault will appear on the UI screen and the commissioning will be

aborted. Once the test is completed, you will see one of three messages:

1. No ow detected

2. Flow too low

3. Flow detected

If you see message 1 or 2, this might be an indication of an air-lock, dirty strainer, ow restriction or pump

too small for the required pipework. Please check for these issues and if present, rectify to ensure that

there is sufcient ow then repeat the test. There will be a time delay before you can restart the test.

When you seea screen with the pump highlighted in green, ow has been detected and the compressor

‘ow check’ test is complete. You will receive the status ‘Waterside is OK’ when the waterside checks are

completed. Selecting Next brings you to the Electrical Connections menu.

Figure 23: Good ow detected and water side OK conrmation screens

If carrying out start up in cold weather, commission the heat pump heating only the buffer. Once it reaches

the required temperature open each zone slowly and in series, especially for under oor heating. If you

have selected Schematic 1 or 3 (Space heating only or Bivalent space heating), move now to section

4.4.12 Heating Curves to complete the commissioning process.

Page 36

Millbrook House, Grange Drive, Hedge End, Southampton, SO30 2DF

0844 879 3587

dimplex.co.uk | gdcgroup.co.uk

36

CAUTION: For safety reasons, if the heat pump pressure exceeds 38 bar/temperature exceeds 60°C,

the commissioning will be aborted. Under these conditions, measures should be taken to allow the

temperature to drop below 60°C, i.e. a zone should be opened.

4.4.7 DHW set-up

Before commissioning the DHW, a number of checks must be carried out, as

shown in gure 24. When you have ticked each box to conrm each DHW

check, Next will bring you back to the installer menu, where you can now select

Electrical Connections (DHW).

Figure 24: DHW set-up

NOTE: It is possible to use space heating without completing the DHW setup. This can be done by

selecting ‘N’ on the DHW setup screen where it asks if the cylinder is connected (see gure 24).

This may be necessary where the DHW is not yet connected or where the cylinder has not yet been lled.

When the cylinder is ready, it will be necessary to return to this step of the commissioning and select ‘Y’

instead for “Cylinder Connected?” to set up domestic hot water.

4.4.8 Electrical connections (DHW)

This menu provides a list of electrical connections that should be made prior to

commissioning the domestic hot water cylinder. You must check and conrm all

connections in order to make the DHW Test available in the installer menu.

The numbers listed on the LHS of the screen refer to the connections which are

labelled in the wiring diagrams included in this manual.

Figure 25: DHW electrical

connections

4.4.9 DHW Test

Before you run the DHW test, which consists of heating up the cylinder to maximum temperature from

the heat pump, you will be asked to check that the valve (gure 27) is in the DHW position (A position), as

shown on the screen in gure 26. Check that the red actuator marker changes to the correct position (the

default position is B).

NOTE: If the 3-port valve head is removed and the valve moved by hand, the valve must be power

cycled (switched off and on again) in order to ensure normal operation.

Page 37

Millbrook House, Grange Drive, Hedge End, Southampton, SO30 2DF

0844 879 3587

dimplex.co.uk | gdcgroup.co.uk

37

Figure 26: Valve check

Figure 27: Valve positions

When you have completed the valve check and select Next, you will see the

DHW test screen, which informs that the test can take up to 90 minutes (based

on a 300L cylinder). Selecting ‘Run test’ begins the DHW cycle and shows you

the time remaining (see gure 28).

The DHW test is important for non A-class cylinders to ensure that the cylinder

is compatible with the heat pump. If the coil in the cylinder is too small, the

maximum achievable temperature might be too low for comfort (e.g. < 40°C)

Figure 28: DHW Test

For system with A-class cylinders, the “Finish” button (gure 29) can be used before 60°C temperature has

been reached, as the compatibility doesn’t have to be proven.

Once the DWH cylinder is showing signs of being heated up then the Finish function allows to shorten the

DHW test without having to wait until temperature achieves 60°C.

This Finish function should be used in cold humid conditions to avoid defrost issues (defrost is currently

not enabled during DHW test).

It is recommended to pre-heated the cylinder rst by using normal function and then do a DHW test to

top-up the cylinder. Please refer to technical bulletin for detailed procedure.

NOTE: During the DHW test, the defrost function will be disabled. If the coil starts frosting due to

external conditions, it is possible to postpone the test by selecting Finish while the test is still running.

Even if this test is postponed, the DHW function may be used.

Page 38

Millbrook House, Grange Drive, Hedge End, Southampton, SO30 2DF

0844 879 3587

dimplex.co.uk | gdcgroup.co.uk

38

NOTE: Selecting ‘Stop test’ will cancel the test completely. If the DHW test

has been cancelled rather than postponed, the information regarding the

immersion displayed on the set temperature menu for DHW will not be correct

(the immersion will not be used until the maximum temperature achievable by

the heat pump has been reached).

Figure 29: DHW test

nish function

Figure 30: DHW test fail and DHW test completed

If the test fails, you will see the screen shown on the left in gure 30, which provides information on why

the test failed, and advice on checks to carry out.

If the test is complete and has been successful, you will see the screen shown on the right in gure 30,

which shows the maximum temperature that the cylinder can achieve.

4.4.10 Disinfection (thermal)

Thermal disinfection is a function which keeps the level of legionella bacteria

in the cylinder under acceptable levels. This is carried out by heating the hot

water in the cylinder to a high temperature for a minimum set time.

The temperature and frequency of the disinfection cycle can be adjusted in this

menu.

Figure 31: Disinfection setup

If the temperature is set to above what the heat pump can achieve, text on the screen will appear which

noties that the immersion heater will be used at the end of the cycle to top up to the required disinfection

temperature.

39

39

Page 39

Millbrook House, Grange Drive, Hedge End, Southampton, SO30 2DF

0844 879 3587

dimplex.co.uk | gdcgroup.co.uk

39

4.4.11 Weather compensation

The biggest factor in dening the heat demand required for a building is typically the weather. Which

affects the required heat load for a building. Weather compensation works by adjusting the set point

temperature of the heating system to reect changes in the outside (external) temperature, allowing the

heat pump to operate more efciently.

Weather compensation is determined by the heat curve settings for the system. The pre-dened heating

curves should only be modied by an installer to best match the heat emitters used.

4.4.12 Heating curves

Each zone is associated to a pre-set heat curve. Selecting the zone and pressing Next will allow you to

assign a pre-set curve for typical heat emitters.

The four pre-set heating curves are shown the table below.

Each curve can be reviewed and modied to meet the requirements of the heating system by selecting

Edit.

This will bring you to a default heating curve for the selected emitter. Selecting Next will select the default.

The pre-dened curves have recommended temperature ranges for each heat emitter;

Table 5: Heating Curve Parameters

The values that generate the heating curve graph can be changed, by scrolling through the temperature

value to adjust and setting it.

This is validated using the Set button when complete (see gure 32).

• The green line on the right indicates the maximum outdoor temperature at

which space heating stops running (DHW is still adjusted independently).

• The yellow line on the left indicates the minimum outdoor temperature at

which the bivalent heating system starts working and may need to be adjusted

depending on the location/property.

• The red line indicates the temperature that the water will be heated to, based

on the outdoor temperatures.

• The Def option will reset the pre-dened values. Nxt will save entered values.

Figure 32: SmartRad

Heating Curve

Heat Emitter Type Max. Water Temp. At Low External Temp. Min. Water at High External Temp.

SmartRad 48°C -10°C 35°C 10°C

Underoor Heating 30°C -10°C 25°C 12°C

Standard Radiator 55°C -10°C 40°C 15°C

Custom (at line) 55°C -15°C 55°C 15°C

Page 40

Millbrook House, Grange Drive, Hedge End, Southampton, SO30 2DF

0844 879 3587

dimplex.co.uk | gdcgroup.co.uk

40

NOTE: If the heat pump is in heating “ON” mode and the maximum outside temperature is reached,

the heat pump will revert to and maintain the set back temperature until the heating is turned off and

on again. To prevent this, it is recommended to set your summer temperature (see heat curves section

4.4.12), at a higher value (the default outside ambient setting is 18°C).

4.4.13 Comfort level

For end-users, the preferred method of modifying the heating system comfort level is by using the comfort

level function rather than modifying the heat curve. Here, it is possible to raise or lower the water input

temperature within a range of 9K (-3 to +6) by accessing the comfort level.

For more information please see the A-Class User Manual

4.4.14 Setup complete

NOTE: To complete commissioning and allow the heat pump to operate, you

must select the ‘Setup complete’ submenu in the installer menu, as shown in

gure 33. if you do not see this screen, commissioning has not been successful

and the heat pump will not operate correctly.

Once all of these steps have been carried out successfully, you will see the

screen shown in gure 33.

Figure 33: Setup complete

Selecting Auto will activate all settings, where as selecting Off will enable the heat pump only to carry out

frost protection (i.e. no heating is required but the heat pump is protected from freezing conditions).

The default setting for the heat pump is Off. To turn on the heat pump, you must return to the home screen

to access the user menu.

For further information on end user controller instructions please see A-Class Air Source Heat Pump User

Guide supplied in the hydraulics pack.

4.5 Additional Installer Menu Options

Once the commissioning process has been completed, additional menus will be available to the installer,

as outlined in this section. These options must be accessed through the service menu.

4.5.1 Service menu

The service menu can be accessed, in a similar manner to the installation menu, by inputting the installer

menu code (22) and then using the ’Login’ access code 998. Access to this menu may be required for fault

nding or servicing.

4.5.2 Message log

The message log menu provides a list of all errors that have taken place, including the date and time when

they occurred. Selecting an individual error code will provide more information on the type of error that

occurred if an SD card is present. Active error messages will show a ticked box.

Page 41

Millbrook House, Grange Drive, Hedge End, Southampton, SO30 2DF

0844 879 3587

dimplex.co.uk | gdcgroup.co.uk

41

Figure 34 shows an example of the messages shown in the message list menu.

When a new error occurs, it will appear at the top of the list.

Up to 20 errors can be shown on the list at once, then, if another error occurs, the

oldest error will be pushed off the list to make room for the new error. If the same

error message is being displayed more than once, it may be necessary to check

back through some of the older error messages in order to nd the cause of the

problem.

Figure 34: Message log

NOTE: If a major fault occurs many times, the compressor will go into lock-out mode to prevent any

further damage to the heat pump. In order to resolve this, the power to the compressor will have to be

turned off for at least 2 minutes and turned on again.

4.5.3 Output Tests

The output tests menu allows you to turn ON/OFF tests on individual

components of the system, as shown in gure 35, and can be accessed once

Electrical Connections (Space Heating) are conrmed.

The relays which control the immersion and backup heater/buffer use

an electric interlocking system, and therefore R7 and R8 must be used

together in order for the backup heater to function. Testing these relays

individually will not reflect this.

Figure 35: Output tests

4.5.4 Defrost

Before running a manual defrost cycle you must ensure the buffer has been isolated from the heating, as

stated by the message on the UI. Selecting ‘Start Defrost’ begins the defrost cycle. The defrost screen will

state the time remaining in the defrost cycle.

A heating water return temperature of 18°C is required for proper defrosting of the evaporator.

4.5.5 Operating data

The operating data menu provides a list of all the system parameters, such as all temperatures, including

each zone set and actual temperatures, ow rate, and heat pump status. If an SD card is present, this data

will be recorded to every message listed.

4.5.6 History

The History menu shows the temporary and permanent run time history of the system. These values

can be reset in order to record run times over a certain time period. Selecting ‘Next’ brings you to the

permanent run time history which cannot be reset unless a software update is installed.

Page 42

Millbrook House, Grange Drive, Hedge End, Southampton, SO30 2DF

0844 879 3587

dimplex.co.uk | gdcgroup.co.uk

42

5. System Health Check / Maintenance

NOTE: These are checks that should be carried out regularly to ensure that your Dimplex product

performs at its best.

5.1 Heat pump:

• Is the fan grille clear from debris? - Visual check

• Is the tray clear from debris and water owing freely? - Visual check

• Is the condensate drain clear from debris?

• Is the evaporator coil clean and free from damage? E.g. attened ns

• Are all of the outer panels secure?

5.2 Electrical:

• Is the power cable rmly xed?

• Is the earth wire connection secure?

• Is the supply voltage correct?

5.3 Hydraulics:

• Is the system correctly pressurized?

• Are there any water leaks in the system? Is the required pressure holding?

• Is the strainer on the return pipe clear of debris?

See section 4.1.3 for details on isolating and cleaning the strainer.

5.4 Indoor settings:

• Are the set temperatures and heating times suitable for the occupants?

• Is the building warm enough for the occupants or does the heating curve need to be adjusted?

NOTE: It is recommended that the strainer is checked and cleaned 24 hours after commissioning, and

each time the system is modied or has service work carried out thereafter.

Page 43

Millbrook House, Grange Drive, Hedge End, Southampton, SO30 2DF

0844 879 3587

dimplex.co.uk | gdcgroup.co.uk

43

6. Appendices

6.1 Technical Specications

6.2 Refrigeration Cycle diagram

6.3 Schematics - Example 1

6.4 Schematics - Example 2

6.5 Schematics 1, 2, 3 & 4 : Space Heating Only

6.6 Schematics 5, 6, 7 & 8 : Zone Space Heating & Domestic Hot Water

6.7 Schematics 9, 10, 11 & 12 : Bivalent Space Heating

6.8 Schematics 13, 14, 15 & 16 : Bivalent Zone Space Heating & Domestic Hot Water

6.9 Wiring Centre Electrical Connections - with A-Class Cylinder

6.10 Jumper Information for Alternative Wiring Conguration

6.11 Controller Cable Connections

6.12 Installer Menu Flow Chart

6.13 Installer Hand-Over Form

6.14 Certicate of Conformity

Page 44

Millbrook House, Grange Drive, Hedge End, Southampton, SO30 2DF

0844 879 3587

dimplex.co.uk | gdcgroup.co.uk

44

6.1 Technical Specications

1

According to EN 12102.

2

Fan is variable speed, rated input relates to nominal input power.

T

ECHNICAL SPECIFICATIONS

1 T

YPEAND ORDER CODE U NITS A8M A12M A16M

2 DESIGN

2.1 Degree of protection according to EN 60529 for compact

unit or heating element

IP 24

2.2 Installation Location Outside

3 PERFORMANCE DATA

3.1 Heating Water Operating Temperature Range (min 56/52 C° )xam /

Outside Air Operating Temperature Range (min / max) 03/02- C°

3.2 Heat Output / COP

Heating Water Temperature Difference

@ Standard Rating Condition

These figures characterise the size and performance of

the system according to EN 14511. Abbreviations have

the following meaning, e.g. A7 W35: Outside temperature

7°C and heating water supply temperature 35°C .

@ A7W35 kW/--- 6.30 / 4.42

12.30 / 4.72 12.30 / 4.72

@ A7W55 kW/--- 6.2 / 3.1 12.5 / 3.2 12.5 / 3.2

@ A7W65 kW/--- 6.3 / 2.7 12.4 / 2.6 12.4 / 2.6

@A-2W35 kW/--- 6.7 / 2.9 12 / 3.3 15.5 / 3.2

@A-2W55 kW/--- 7.1 / 2.1 12.0 / 2.5 15.6 / 2.4

@ A-7W35 kW/--- 7.0 / 2.9 12.0 / 3.0 13.2 / 3.0

@ A-7W55 kW/--- 7.1 / 2.1 12.0 / 2.2 15.3 / 2.2

3.3 Sound Power Level

1

dB(A) 63 63.5 63.5

3.4 Sound Pressure Level @ 10m (Heat Pump positioned

against wall)

dB(A) 41.5 38.5 38.5

3.5 Heating Water Flow Rate @ A7W35, nominal / minimum m³/h 1.15 / 0.85 2.1 / 1.2 2.1 / 1.2

3.6 Condenser Pressure Drop @ nominal flow rate (A7W35) kPa 3 4 4

3.7 Air Flow @ A7W35 m³/h 2600 3700 3700

3.8 Refrigerant; total filling weight Type/kg R410A / 1.75 R410A / 2.0 R410A /

2.0

3.9 Water Capacity of Stainless Steel Heat Exchanger litre 0.85 1 1

3.10 Polyol Ester Oil in Compressor 81.1 ertil

4 DIMENSIONS, CONNECTIONS & WEIGHT

4.1 Device Dimensions Without Connections H x W x L (mm) 1260 x 932 x 401 1571 X 932 X 401

4.2 Physical Volume 95.0 5.0 ³m

xe ”1 hcni metsyS gnitaeH ot snoitcennoC eciveD 3.4 t. thread

4.4 Weight of the Transportable Unit (Excluding Pac 031 011 gk )gnigak

5 ELECTRICAL CONNECTIONS (HEAT PUMP)

1 / V032 - ycneuqerF / esahP / egatloV lanimoN 1.5 ph / 50 Hz 230V / 1ph / 50 Hz

5.3 Nominal Power Consumption / Nominal Current @

A7W35

kW/A 1.4 / 6.3 2.6 / 11

5.4 Maximum Power Consumption / Maximum Current

@ A-2W55

kW/A 4 / 16 6.9 / 30 8.1 / 35

5.5 Maximum Starting Current - Inverter Ramp Up

A5.2 tnerruC gnitratS laudarG A

5.6 Power Factor A7W35 / (cos )

-

0.94 0.95 0.95

5.7 Power Input of Integral Fan @ A7W35

2

06 06 05 W

6 OTHER DESIGN CHARACTERISTICS

6.1 Defrosting Mode / Type Automatic / Reverse Cycle

6.3 Device Freeze Protection Yes : Heating Water in Device Protected Against Freezing by Software

5.2 Fuse Protection 04 C 02 C

Page 45

Millbrook House, Grange Drive, Hedge End, Southampton, SO30 2DF

0844 879 3587

dimplex.co.uk | gdcgroup.co.uk

45

6.2 Refrigeration cycle

PTH

PTL

FLOW

RETURN

essor

eceiver

e

essure transducer

essure switch

essure transducer

essure transducer

1. Coil temp

2. External air temp

3. Flow temp

4. Retur

n temp

5. Compressor suction temp

6. V

apor injection temp

7. Liquid line temp

1

2

3

4

5

678

9

10

12

14