Page 1

Thank you for purchasing the Dill TPMS Trailer Kit. Properly inflated tires

increase fuel economy, reduce tire wear, and increase handling. A warning

system to notify you of an underinflated tire will help give you time to respond

prior to potentially damaging your tire or trailer.

For more information visit our website at http://www.trailertpms.com

Key Features:

Visual and audible warnings

Set desired PSI levels

Adjustable windshield mount

included

Alerts when tire

pressure is too

low or too high

Alerts when tire

temperature is

too high

Easy Plug-In DC power source

Adjustable Angle Valve Stems fit

a variety of wheels

Page 2

2

Table of Content Page

1. System Overview: 3

1.1 System Components 3

1.2 How the System Works 3

1.3 Display indicators and Controls 4

1.4 Transmitter Components 4

1.5 Position of Transmitter and ID Module 5

2. Transmitter Installation & Position 6-7

3. Using TPMS Unit: 7

3.1 Getting Started 7-8

3.2 Transmitter Activation 8

3.3 Cold Inflation Pressure Setting 9

3.4 Restore Default Setting 9

3.5 Normal Monitoring 9

3.6 Warnings 9-11

3.7 Antenna Installation & RF Interference 11-12

3.8 Tire Rotation 13

3.9 Replace Transmitter and ID Module 13

4. Specifications: 14

4.1 Transmitter 14

4.2 Display Unit 14

4.3 Component Part Numbers 14

4.4 Available Valve Configurations 15

3.10 Restart System 13

Page 3

3

1. System Overview

As a vehicle safety device, the TPMS trailer kit monitors tire pressure and

temperature. It will provide warnings about abnormal conditions such as low

pressure, high pressure, and high temperature.

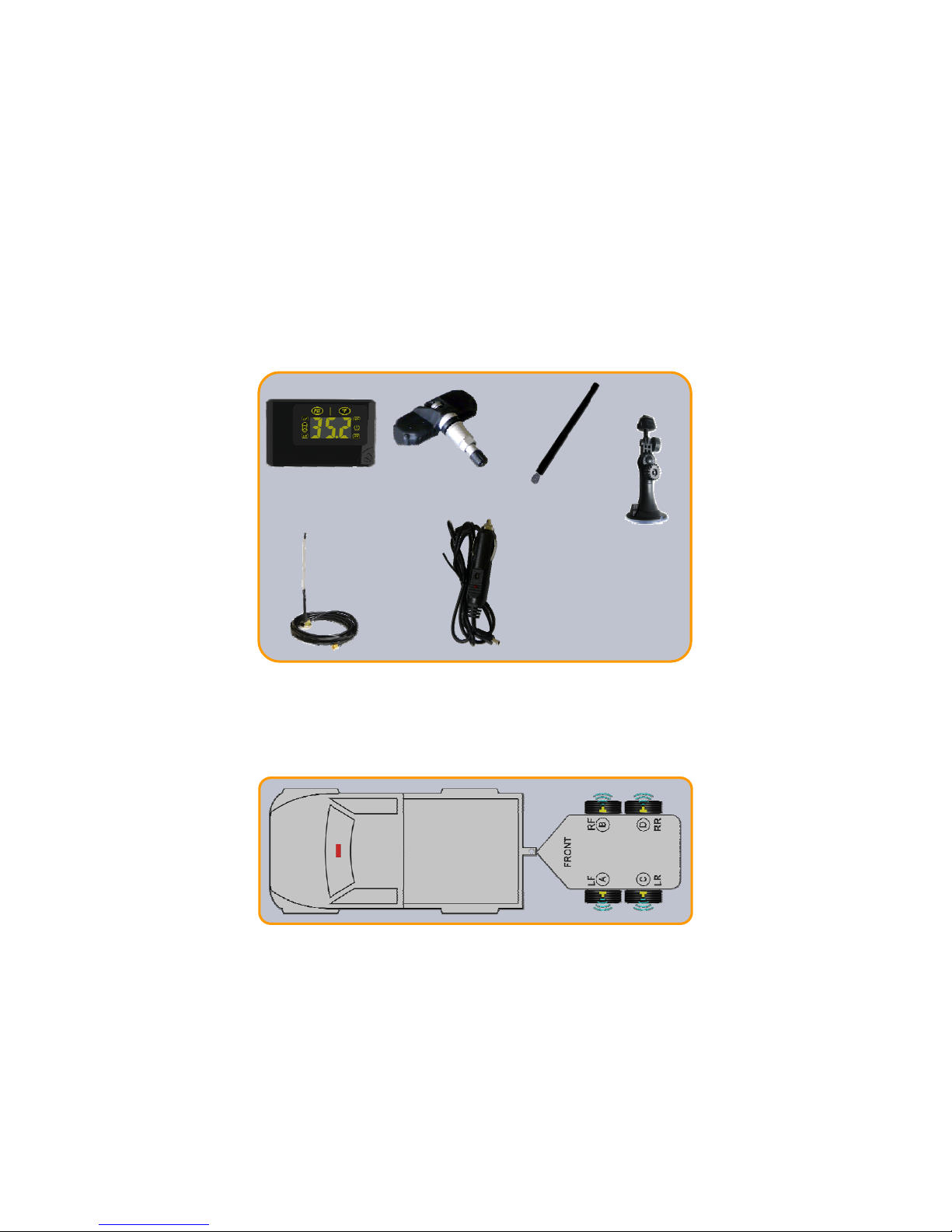

1.1 System Components

1.2 How the System Works

A transmitter is installed in each wheel with an aluminum valve stem and

monitors the pressure and temperature conditions inside each wheel of the

vehicle. This data is wirelessly sent to the receiver that is installed on the

vehicle. The receiver displays the pressure and temperature for each tire

position. When an abnormal condition is detected, the display will alert the

driver.

DISPLAY

DISPLAY

MOUNT

TRANSMITTERS

EXTERNAL

ANTENNA

(IF NEEDED)

DISPLAY

UNIT

ANTENNA

12V DC POWER

CORD & HARDWIRE

CONNECTION

Page 4

4

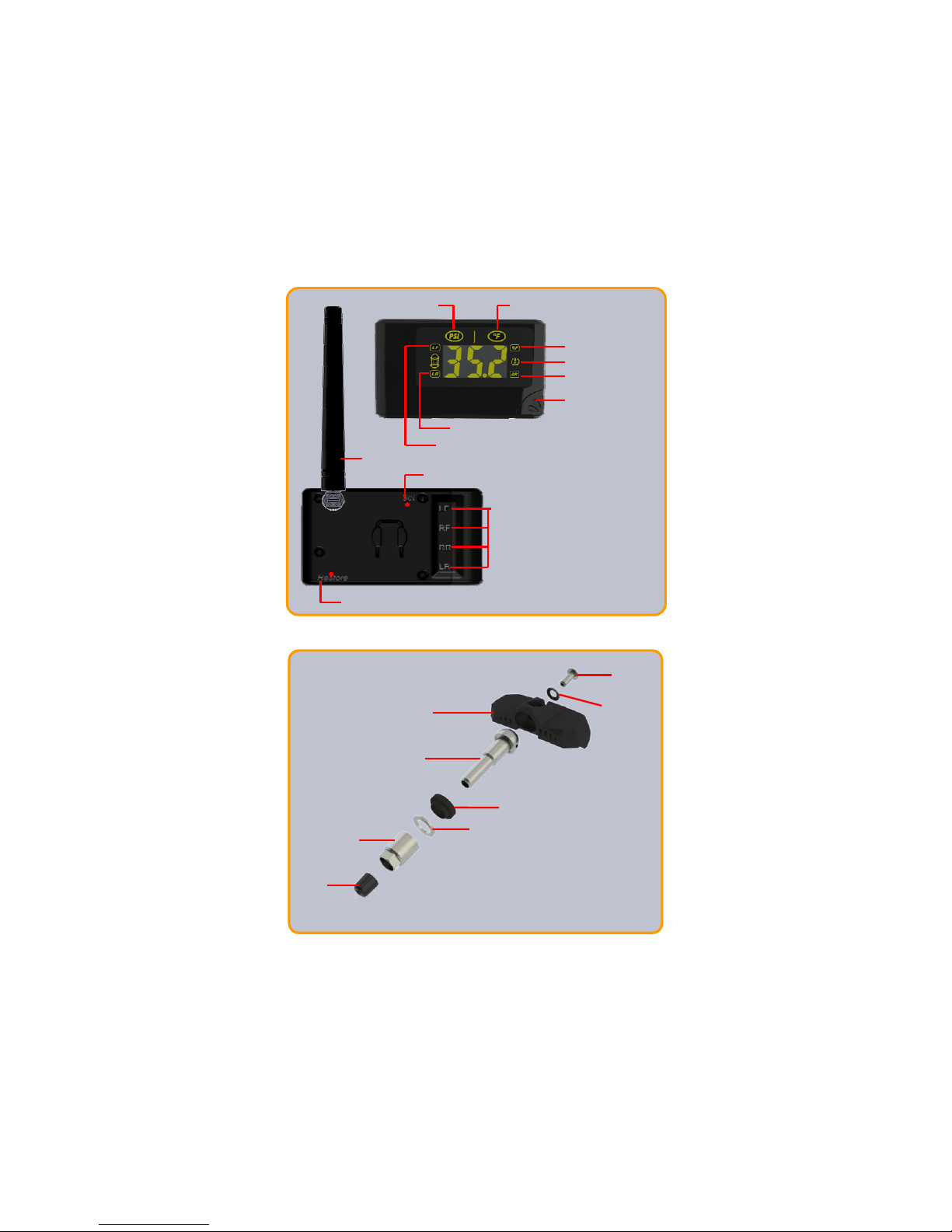

1.3 Display Indicators and Controls

PRESSURE

UNIT

RIGHT FRONT TIRE

RIGHT REAR TIRE

TEMPERATURE

UNIT

ABNORMAL ICON

CYCLE BUTTON

LEFT REAR TIRE

LEFT FRONT TIRE

CHIP IDENTIFIER

LOCATION FOR

TRANSMITTERS

ANTENNA

SET KEY

RESTORE KEY

1.4 Transmitter Components

NOTE:

Only plastic (non-chrome) caps

and nickel plated valve cores can

be used as replacement.

HEX NUT

RUBBER GROMMET

METAL WASHER

VALVE STEM

VALVE

CAP

ELECTRONIC

TRANSMITTER

SCREW

LOCK

WASHER

Page 5

5

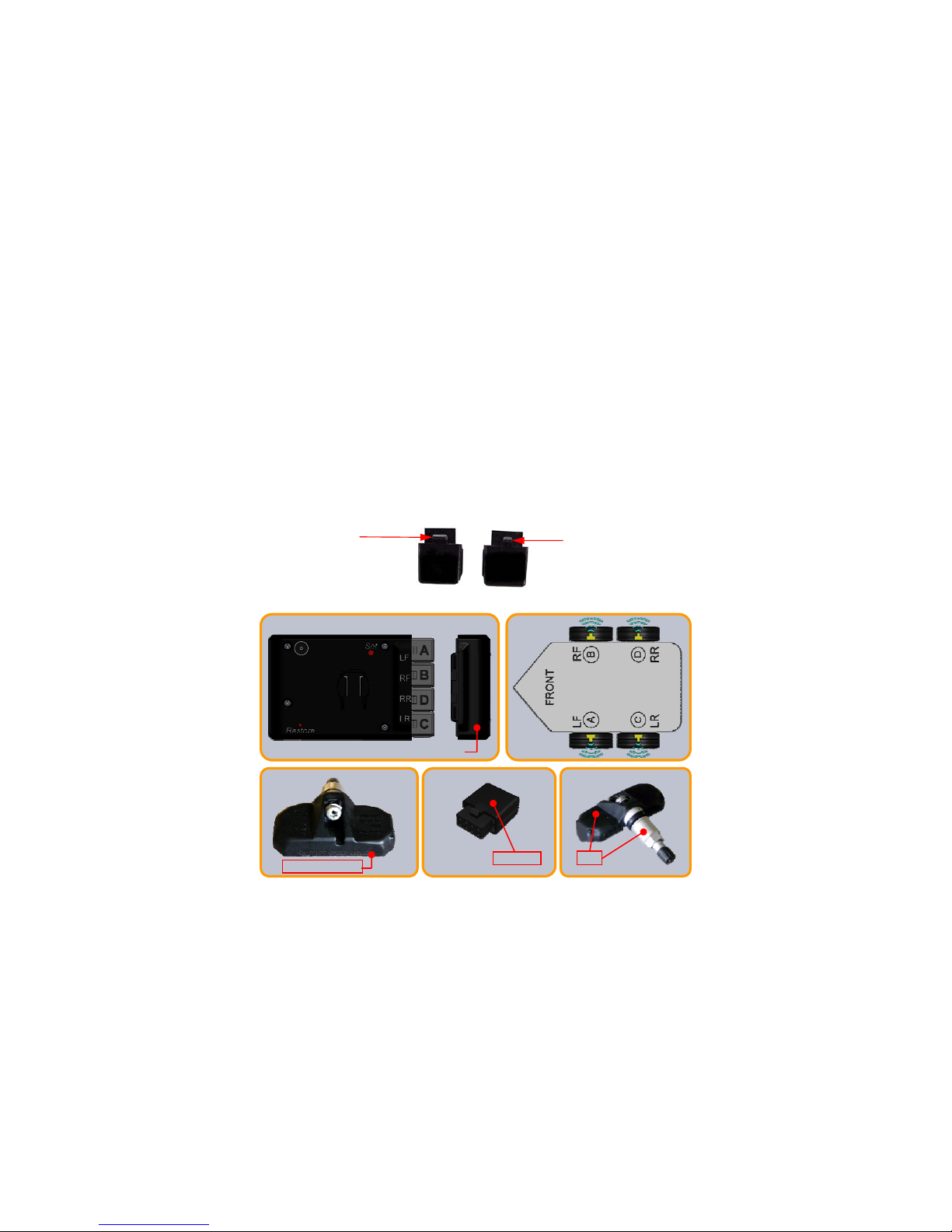

1.5 Position of Transmitter and ID module

Note the default installation position of the transmitter and ID modules as

illustrated. A letter identifier marked on the transmitter, ID module, and hex nut

is shown on each component.

The letters “LF/RF/LR/RR” on the back of the display unit correspond to the

tires’ respective positions. Each pair of transmitter and ID module need to be

installed in the same position.

To access the ID modules, pull the ID module cover away from the display unit.

For example, if you install transmitter “A” in the left front tire, then you should

plug the ID module “A” in “LF” position on the receiver .

NOTE:

When installing the ID chips into the display unit verify the ID letters are facing

towards the back of the display and is in the correct orientation. Small clip must

face the back, regardless if the letter identifier is facing the

wrong orientation.

Transmitter I.D.

ID MODULE COVER

I.D. Module

1101143

080908-1101134

Hex Nut I.D.

C

Small clip must

face towards the

back of the display.

Large clip

faces towards

front of display.

Page 6

6

2.2 Place the valve stem onto the transmitter and use the lock washer & screw

to hold valve stem against the transmitter body.

Note: DO NOT TIGHTEN THE SCREW.

2.3 Insert the valve stem through the rim hole and verify that the rubber

grommet is seated against the rim hole surface.

2.4 Adjust the angle of the transmitter body and verify the transmitter is resting

flat against the wheel rim surface.

2.5 Tighten the screw at 35 inch pounds into valve stem at the same time verify

3 conditions:

2.5.1 At least one of the transmitter’s feet always contacts the rim surface.

2.5.2 The grommet is fully seated against the valve hole.

2.5.3 From the outside of the wheel, the valve stem is perpendicular to the

rim’s valve hole.

2.6 Place the metal washer and hex nut on the valve stem and turn the hex nut

clockwise until the rubber grommet is pressed against the wheel rim

surface.

2.7 Tighten the hex nut 35 to 40 inch pounds of torque to secure the valve stem

to the rim. Verify at least one of the transmitter’s feet has direct contact on

the wheel rim surface. If not, uninstall the transmitter and redo it from 2.5.

2.8 Lock the wheel rim on the tire changer. Apply lubricant on both tire beads

and rim. Mount the lower tire bead on the rim. Ensure that the tire bead

does not touch the electronic module during mounting.

2.9 Mount the upper tire bead the same way and inflate the tire to standard cold

inflation pressure. Avoid damaging the antenna.

Wheel Mount

Head

Transmitter

Transmitter

Wheel Mount

Head

2.0 Transmitter Installation

Before installation into the rim hole, you must assemble the transmitter and

valve stem together.

2.1 Unscrew the hex nut and remove the metal washer from the valve stem.

Page 7

7

3. Using TPMS Unit

3.1 Getting Started

3.1.1 Install the supplied antenna to your display unit located at the back of the

unit.

3.1.2 Use the display mount to affix the display unit on the windshield or

dashboard. Do not block the driver’s view. Adjust the viewing angle of

the display, if necessary.

2.10 Apply suds on the valve tip, grommet / rim seal. If no leakage is found,

install the valve cap. Otherwise, re-inspect and resolve leak issue.

2.11 Dynamically balance the wheel before it is put back on the vehicle.

2.12 Visually inspect the wheel rim, valve stem, and electronic module to

ensure no damage has occurred. Pressurized the tires to your desired

cold inflation setting.

Page 8

8

An immediate audible “Beep” sound will indicate the display unit is on. In 2 to 3

minutes, the display unit will show the tire pressures in yellow, along with four

blue tire position lights.

3.2 Transmitter Activation

Note: reference section 2 for transmitter installation.

The transmitters are shipped in “sleep” mode for battery conservation and will

be activated when the transmitter detects pressure in the tires or when the

vehicle speed exceeds 20mph.

The default cold inflation pressure setting of the display unit is 35PSI. The

display unit is programmed to provide a low pressure warning when the

pressure is 20% lower (28PSI) and 30% higher (46PSI).

PSI LEVEL 20% LOWER 30% HIGHER

35 28 46

50 40 52

80 64 104

Cold inflation pressure can be set to your desired pressure and a warning will

alarm at 20% below and 30% above this pressure. For example, the driver will

be alerted at the following low and high pressures base on various set pressure:

3.1.2 Plug the power cord into the display unit and plug the adapter into

auxiliary power supply.

Page 9

9

3.5 Normal Monitoring

3.5.1 Stationary State:

The transmitter will detect tire pressures and temperatures at 8second intervals and transmit the data to the display at 2-minute

intervals as long as they are normal. As the data is received, the

display will refresh.

3.5.2 Moving State:

The inertia switch of transmitter is on when the speed exceeds

16mph.

The transmitter will detect tire pressures and temperatures at

4-second intervals and transmit the data to the display at 30-second

intervals as long as they are normal. As the data is received, the

display will refresh.

3.5.3 Normal Data Display:

The display will automatically circulate among the tire positions in the

following order LF/RF/RR/LR.

Press and release the “Cycle Button” to view the tire temperatures.

3.6 Warnings

3.6.1 Low Pressure Warning

If the current pressure in a tire is 28PSI or lower in default mode or

20% lower than the cold inflation pressure setting, then the following

will occur:

3.3 Cold Inflation Pressure Setting

Cold inflation pressure setting is pre-set at the to 35PSI, when installation and

replacement of each transmitter and ID modules.

To change cold inflation pressure setting, perform the following:

3.3.1 Inflate the tire pressures to the recommended cold inflation pressure.

3.3.2 Press the “SET” key on the back of display and hold for 8 seconds to

enter new cold inflation pressure setting. A ‘beep’ will sound and all

indicator lights will turn off and the screen display will show “ddd”.

Allow 3 to 5 minutes for the receiver to accept new cold inflation

pressure setting.

3.3.3 To check a tire’s cold inflation pressure setting, press and release the

“Cycle Button” twice. Repeating this step will cycle through each

tire’s pressure setting.

3.4 Restore Default Setting

To switch to default setting, press and hold the “RESTORE” key for 3 seconds.

The display unit will switch back to default operations within 30 seconds.

Page 10

10

1. The display will show the pressure of the abnormal tire and the

digits will flash.

2. An audible alert warning sound will be heard.

3. The abnormal icon will become red.

4. The indicator for the abnormal tire will become red.

The system will not return to normal monitoring until the

problem(s) is corrected.

3.6.2 High Pressure Warning

When current pressure in a tire is 46PSI or higher in default mode or

30% higher than the cold inflation pressure setting, then the following

will occur:

1. The display will show the pressure of the abnormal tire and the

digits will flash.

2. An audible alert warning sound will be heard.

3. The abnormal icon will become red.

4. The indicator for the abnormal tire will become red.

The system will not return to normal monitoring until the

problem(s) is corrected.

3.6.3 High Temperature Warning

When the current temperature in a tire exceeds 176°F, the following

will occur:

1. The display will show the temperature of the abnormal tire and the

digits will flash.

2. An audible alert warning sound will be heard.

3. The abnormal icon will become red.

4. The indicator for the abnormal tire will become red.

The system will not return to normal monitoring until the

problem(s) is corrected.

3.6.4 System Malfunction

If the display is not receiving the signals from a transmitter(s), in the

tires, the display screen will appear as dashed lines “---” .

If you are not receiving a signal from the transmitter(s), verify the

following conditions .

1. Verify that the unit is plugged into the DC power supply. Power

off the display unit and restart the system. The system will return

to normal monitoring after properly receiving signals from the

transmitter(s).

2. Verify that the ID module chip(s) are installed properly in the cor-

rect locations of the display unit.

Page 11

11

1. Check your antenna connection.

2. Drive your vehicle over 20mph for 3 to 5 minutes. This will

“wake” the transmitter and begin to transmit a signal to your

display unit.

If the display unit is working properly and it still does not receive a signal from

the transmitter(s), then the transmitter(s) and ID module(s) must be replaced

simultaneously.

A replacement transmitter and ID module can be purchased from a Dill

distributor or retailer, list available at www.trailertpms.com.

3.7 Antenna Installation (Optional) and RF Interference*

If the display unit is receiving a signal on an intermittent basis, i.e. when the

distance is greater than what is recommended or there is interference

preventing a continuous signal reaching the display from the wheel, you will

need to install an exterior antenna. The added benefit of an exterior antenna is

to assure a better reception from your transmitters to the display/receiver.

The antenna is assembled with an industrial strength magnet, 19 feet of coaxial

wire, and a coaxial connector to install into the back of your display/receiver.

19’ COAXIAL

WIRE

DISPLAY/RECEIVER

CONNECTOR

ANTENNA

MAGNET NOTE: MAGNETIC

STRENGTH WILL ADHERE

QUICKLY TO ANY METALLIC

OBJECTS. KEEP FINGERS

AWAY FROM THE BOTTOM

OF THE MAGNET.

Page 12

12

Remove the original antenna from the back of the display unit and replace it

with the coaxial wire antenna via display connector.

Installing the external antenna involves a small degree of experimentation for

maximum signal reception. Temporarily connect the antenna cable to the

display, passing the cable through the vehicle’s door or window. This temporary

connection allows you to test the antenna’s location. If the location you have

selected for the antenna has difficulty in picking up signals from all tire locations, change the antenna’s location slightly and continue to test. Install the

magnet/antenna at the rear of the vehicle, which will give it the nearest proximity to the transmitters. Thus, increasing signal reception between the display/

receiver and transmitters. When signals from all tire locations report, install the

antenna permanently in the vehicle.

Do not install the magnet/antenna directly on the trailer.

Caution: Stay away from transmission, oil and exhaust lines avoiding the

inherent heat from those locations which can melt the coaxial cable.

It is the installer/end user’s discretion how to install the antenna and coaxial

wire from the exterior through the interior of the vehicle cabin.

If proper reception is not achieved with the external antenna, a signal boost will

be required.

A signal booster is an optional part for RV’s, fifth wheels and tow-vehicles and

trailers. It enhances the signal from the transmitters. A signal booster is

recommended to effectively receive the signals from each transmitter, when

there may be interference from electronics, RV construction, length, etc.

*The system has been tested to work 40 feet, along line-of-sight pathways.

However, tire construction, vehicle construction, electronic interference and low

temperatures all reduce this distance. RF signals are subject to interference

from many types of signals and products, which can cause errors in the

operation of the product. As with cell phones and other types of electronics using RF signals, signal interruption can occur and cause lost signal transmission.

Page 13

13

LR

LF

3.8 Tire Rotation

3.8.1 Reference your tire manufacturer for proper tire rotation on your

trailer.

3.8.2 Note the current installation positions of the transmitter and ID

modules.

For example, if you need to rotate the Left Front Wheel (LF)

transmitter A and Right Rear Wheel (RR) transmitter C, then

interchange ID chip module A and ID chip module C.

Reactivate the system (reference section 3.2) to accept new

transmitter positions and to indicate the proper location of the

transmitter on the display unit.

3.9 Replacement of Transmitter and ID Module

Verify a “System Malfunction (reference section 3.6.4)” before replacing the

transmitter or ID module.

3.9.1 Replace the inoperable transmitter and ID module with a new one.

3.9.2 Transmitter Activation (reference section 3.2).

3.9.3 Reset the cold inflation pressure setting (reference section 3.3).

3.10 Restart the system

The system has to be restarted to re-identify the ID module in the following

situations:

3.10.1 Tire rotation.

3.10.2 Replacement of a transmitter and ID module.

3.10.3 To restart the system, disconnect the power cord for 1 minute and

plug in again.

Page 14

14

4. Specifications

4.1 Transmitter

Weight: 1.25 oz. (35g)

Dimensions: 0.59” x 2.50” x 1.11” (1.5 x 2.8 x 6.4 cm)

Operating Temperature Range: -40°F to 257°F (-40°C to 125°C)

Pressure Accuracy: ±2PSI (±.14Bar)

Temperature Accuracy: ±5.4°F (±3°C)

Battery life: 5 to 7 years

Maximum Sensing Pressure: 188PSI (12.96Bar / 1296Kpa)

Maximum Cold Inflation Pressure: 144PSI (9.93Bar / 993Kpa)

Frequency: 433.92MHz

4.2 Display

Power Consumption: 130mW (regular) / 230mW(Max)

Power Supply: DC12 Volt

Weight: 1.06oz. (30g)

Dimensions: 3.3” x 1.97” x 0.58” (8.5 x 5 x 2 cm)

Pressure resolution: 0.1PSI (.01Bar / 1Kpa)

Temperature resolution: 2°F (1°C)

4.3 Component Part Numbers

PART NUMBER DESCRIPTION

1700 DISPLAY, MOUNT, 12V CORD, & MANUAL

9300 TPMS TRANSMITTER & CHIP

1905 SIGNAL BOOSTER

Page 15

15

4.4 Available Valve Configurations

WHEEL RIM HOLE SIZE: .453”

WHEEL RIM HOLE SIZE: .625”

WHEEL RIM HOLE SIZE: .390”

P/N: TP 416

P/N: TP 501

P/N: TP 572

P/N: TP 555

Page 16

16

1500 Williamsboro Street Oxford, North Carolina 27565

~ Quality Automotive Products Since 1909 ~

Customer Service:

800-815-3455

www.dillvalves.com

Dill Air Controls Products

Trailer Kits—Tire Pressure Monitoring Systems

Loading...

Loading...