Page 1

FCD II & FCD 3

O p e r a t i n g m a n u a l

Table of contents

Safety rules .............................................................................. 3

1 Introduction............................................................................ 4

2 V ersions................................................................................4

2.1 Contents of packing (standard version) ...................................................5

3 Installation ............................................................................. 5

3.1 Electrical connection..............................................................................7

3.1.1 Flowmeter...................................................................... 7

3.1.2 Power supply ................................................................ 8

4 Preparation........................................................................... 8

4.1 Front panel.............................................................................................8

4.2 Keyboard................................................................................................9

4.3 Operation (FCD-II only) .........................................................................10

4.4 Working mode (FCD-II only) .................................................................10

4.5 Indicator of empty keg (FCD-II only)...................................................... 11

4.6 Master key (FCD-II only) ...................................................................... 11

4.7 Host mode (FCD-II only) ....................................................................... 11

4.7.1 Programming litre calibration (FCD-II only) .............. 12

4.7.2 Programming the portion size (FCD-II only) ............. 12

4.8 Setting to zero (FCD-II only) ................................................................. 13

4.9 Re-calibration (FCD-II only)...................................................................13

4.10 Cleaner key (FCD-II only).................................................................... 14

Digmesa AG, Keltenstrasse 31, CH-2563 Ipsach / Switzerland

Phone +41 (32) 332 77 77, Fax +41 (32) 332 77 88

Bedienungsanleitung FCD 3 823-1001_GB / Mai 2005

www.digmesa.com

Page 1

Page 2

4.1 1 Clock setting (FCD-II only) ..................................................................14

4.12 Date setting (FCD-II only) ...................................................................14

5 T roubleshooting................................................................... 15

6 S pecifications*.................................................................... 16

7 Appendix............................................................................. 17

7.1 Assembling an extra module ...............................................................17

7.2 How to change a module ......................................................................1 8

7.3 Location of the fuse ..............................................................................18

Software addition FCD-III ............................................................................19

1 General Operation ................................................................................... 19

2 Cleaning (CLEAN-Dallskey)..................................................................... 20

3 HOST - Mode (Master-Dallskey).............................................................. 20

4 Counters / resetting counters ..................................................................20

5 Calibration...............................................................................................21

6 Parameter settings..................................................................................22

7 Date settings...........................................................................................22

8 Data inquiry via interface .........................................................................22

The user is not entitled to indemnities for possible technical imprecisions or

misprints present in this manual.

This manual may be modified without forewarn.

Page 2

Page 3

Safety rules

1. Read throught the instructions before you put the FCD-II into

operation. Follow all the operations according exactly to the directions

for use.

2. Keep to the directions for use and to the indications that may appear

on the FCD-II.

3. Cut off power supply before opening the connection cover or

unscrewing the front panel.

4. The FCD-II is protected according to the safety rules IP65, i.e. it is

protected against sprays of water , but only if the transparent cover is

closed.

5. The voltage must agree with the values written on the label on the

back.

6. The FCD-II is provided with a terminal for the earthwire. The

grounding must be absolutely connected.

7. The FCD-II should not be put into operation without the connection

cover (danger of wounding if the electronics is touched).

8. Cut off power supply and call a technician if one of the following

cases occurs:

- if water or other fluids have entered the FCD-II.

- the FCD-II doesn’t work correctly even though you have followed all

the instructions given. Do not try to change anything on your own;

do not press any key trying to get some reaction.

- if the FCD-II falls down and the box is damaged.

Page 3

Page 4

1 Introduction

The FCD-II is a precise control system with the most modern

microprocessors.

The quantity of fluids, that passes throught the installation is constantly

measured. Bar keepers don’t have to change their habits: the FCD-II corrects

the intertias present inside the flowmeter automatically .

The FCD-II has several counters that can be questioned at any time. Each

pipe can be calibrated precisely according to its use (i.e. according to the

drinks that have to be measured: beer , mineral water, pre-mix, etc...).

The access to special functions on the flow computer FCD-II is possible only

by using intelligent keys.

The FCD-II signals whenever a keg is empty by using a flowmeter provided

with foam detection. Also in the standard version a relay is avalaible with

which further alarm systems can be connected.

2 Versions

The FCD-II is avalaible in the following versions:

- control of four pipes, art. no 923-9104 (standard version)

- control of eight pipes, art. no 923-9108

- control of twelve pipes, art. no 923-91 12

- control of sixteen pipes, art. no 923-91 16

The FCD-II can be equipped with additional modules. Four additional pipes

per modules can be added. The FCD-II can contain no more than four

modules (i.e. 16 pipes).

Page 4

Page 5

2.1 Contents of packing (standard version)

- 1 FCD-II

- 2 cable inlets PG1 1 (art. no 699-0003)

- one for the power supply cable 230V ( 3 wires with min. section of

2

0.75mm

- one for four flowmeter cables (external diameter max. 4mm).

- 1 cable inlet PG9 (art. no 699-0002) used for the cable of the serial

interface RS-485.

- 1 intelligent key with the black ring (master key) art. no 990-0002

- 1 intelligent key with the silver ring (cleaner key) art. no. 990-0000

- 1 manual art. no 823-1001

and external diameter 6.80mm)

3 Installation

Choose a suitable place for the FCD-II and keep to the following instructions:

- the unit has to be easily reached.

- the unit has to be put at a comfortable height.

- the place has to be well illuminated (the display has no rear light)

Choose whether to install the cable inlets on the rear side or on the bottom

side of the FCD-II box.

Bottom side

Page 5

Page 6

rear side

Cut out as many holes as you need on the side chosen by using a

screwdriver and a hammer . T ake one of the cable inlet s PG-1 1 in order to

connect the first group of the four flowmeters. Unscrew the nut and put the

screw into the corresponding hole and fix it. Then install the second cable

inlet PG-1 1 for the 230 V cable. If you need an interface, install the cable inlet

PG-9 as well.

Place the FCD-II as follows:

Fix a screw into the wall and hang the FCD-II on it. Open the connection

cover . For additional safety of the unit, two more screws can be fixed on its

corners.

Page 6

Page 7

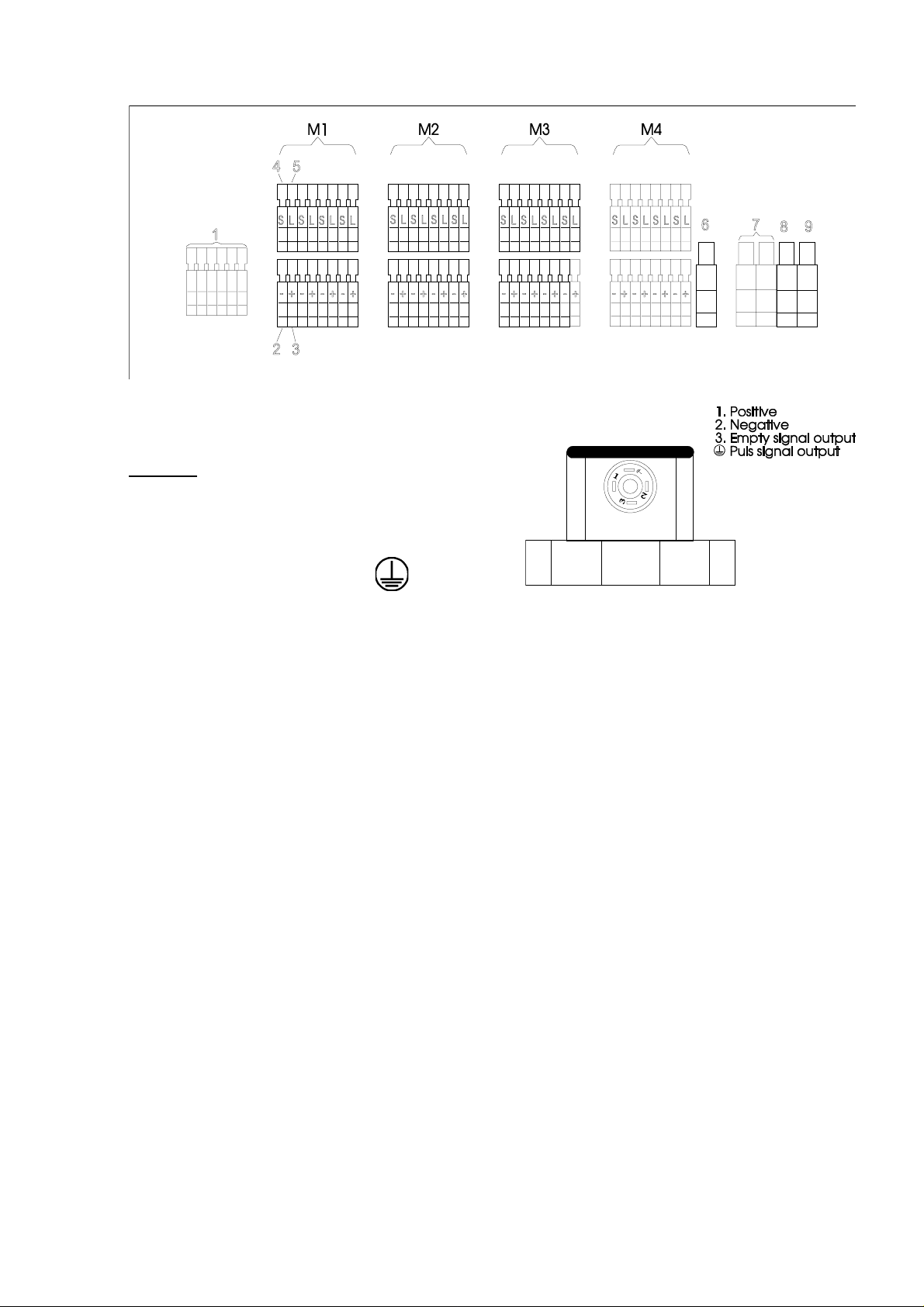

3.1 Electrical connection

diagram connection

Legend

1 = serial interface RS-485

2 = negative pole "-" on Flowmeter 2

3 = positive pole "+" on Flowmeter 1

4 = signal on Flowmeter

5 = empty keg indicator on Flowmeter 3

6 = connection for a flowmeter group

7 = earthing

8 = additional relay connection for empty keg indicator

9 = power supply neutral

10 = power supply phase

3.1.1 Flowmeter

Number progressively each cable of the flowmeters which will be connected

to the FCD-II. Insert the cable of the first flowmeter into the corresponding

cable inlet. Take off the cable insulation for about 5 cm and strip each wire

(about 5mm).

Put each wire of the first flowmeter into the terminal as follows:

Press the white lever by using a small screwdriver (no 0 or no 1). At the same

time, insert the wire into the terminal. Release the lever.

Connect the flowmeter wires as follows:

Page 7

Page 8

- green wire = terminal „-“ on Flowmeter 2

- brown wire = terminal „+“ on Flowmeter 1

- white wire = terminal „S“ (signal)

- yellow wire* = terminal „L“ (empty keg indicator) on Flowmeter 3

*Not all flowmeter models dispose of a foam indicator .

Repeat this operation for each flowmeter .

Note: the wire colours listed above are a DIGMESA-code and can be

changed.

3.1.2 Power supply

Insert the 230V cable ( a 3-pole cable with a section of 1,5mm2 is

recommended) into the cable inlet. Take off the cable insulation for about 5

cm and strip each wire (about 5mm).

Connect each wire as follows:

Phase = orange terminal

Neutral = blue terminal

earthing = green terminal

Close the connection cover , connect the flowmeters and turn power on.

4 Preparation

Before operating the FCD-II, note that:

- Text written in italics represents a message on the display.

- Text written in bold refers to the keyboard.

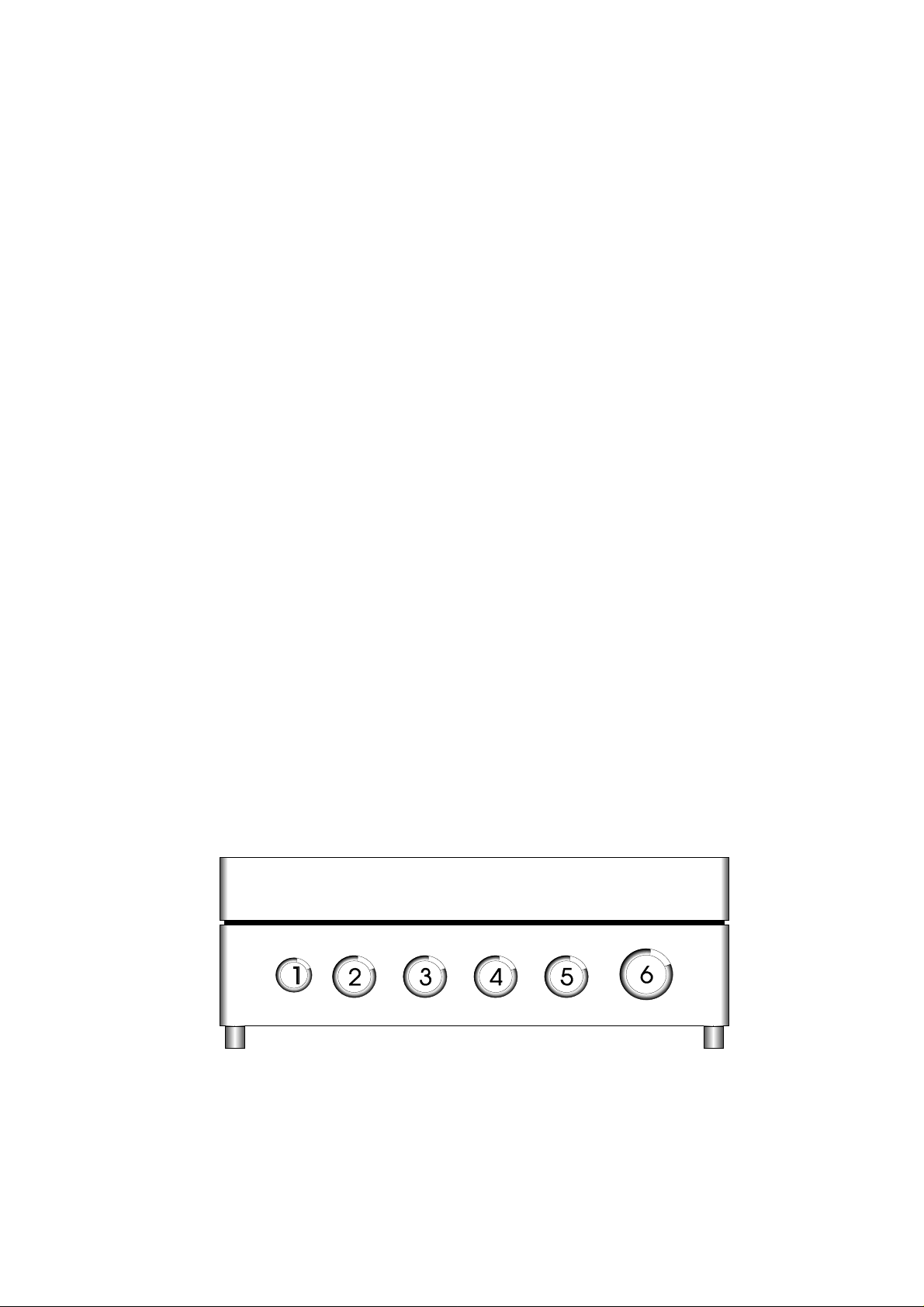

4.1 Front panel

1. LED indicator (empty keg indicator).

2. LCD display

3. Keyboard

4. intelligent key socket

5. Connection cover

Page 8

Page 9

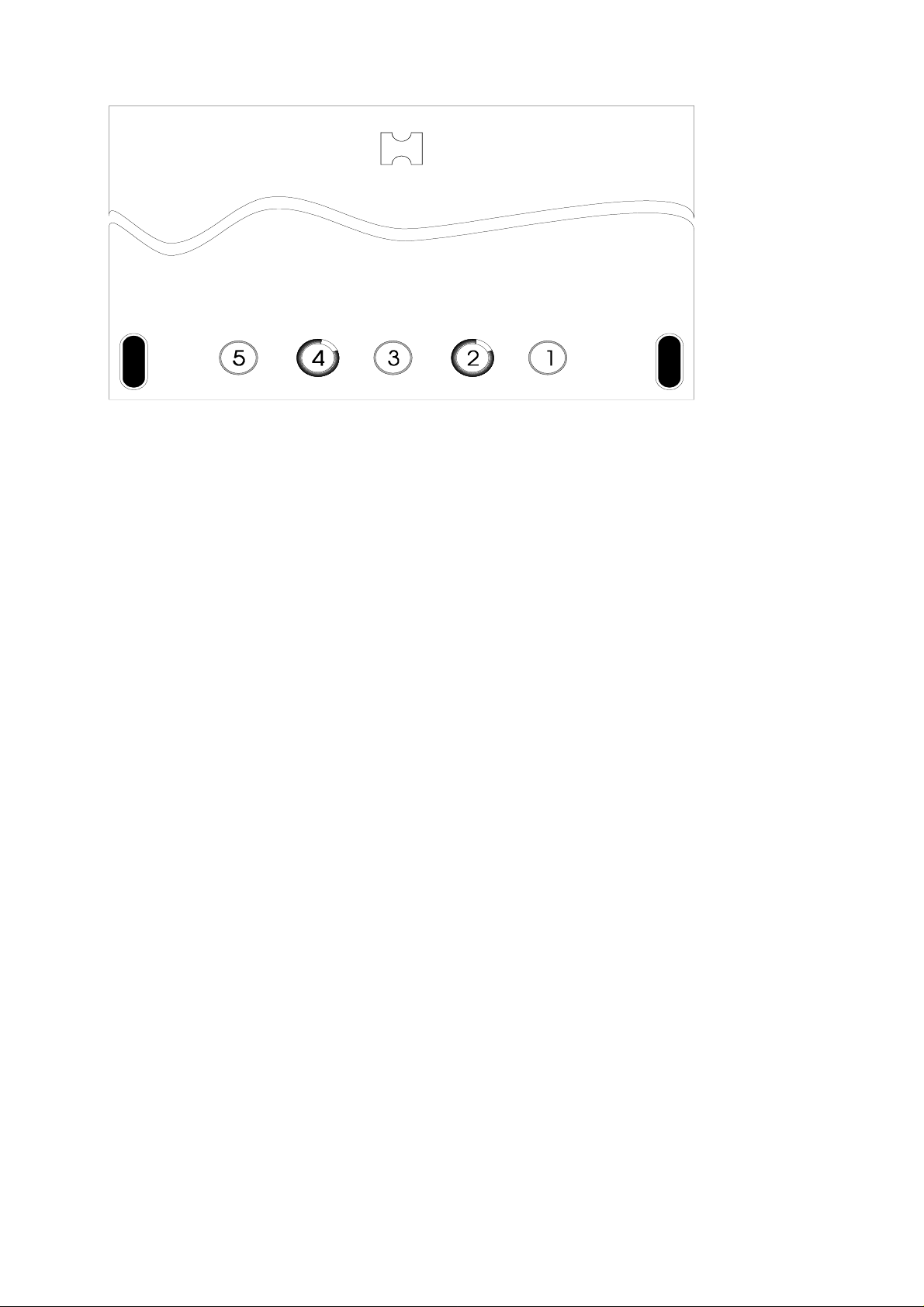

4.2 Keyboard

to the previous line

to the next line

confirm entry

entering the values in programming mode

program/examine the portion size

program/examine litre calibration

setting to zero

go to programming mode

Page 9

Page 10

4.3 Operation

NOTE FOR FCD-III USERS : the following chapters (4.3 to 4.12) are only

valid for FCD-II. Please go to page 19 'Software addition for FCD-III' !

As soon as the tension is connected, FCD-2 will appear on the display . If no

button is pressed for about one minute, the clock will appear on display .

4.4 Working mode

Any lines can be reached by pressing <- or ->. The display will show

automatically the first line just after the selection of the last one. The number

of lines connected to the unit can be controlled as well.

As soon as the requested line is displayed, press the Enter button. The unit

will show either nodEF (not defined) if the line is not programmed yet, or it

will show the quantity in litres or in portions.

At the very bottom of the display it will be indicated whether the quantity is

expressed in litres or in portions. There are two different litre counters:

Litre flag flashes = shows the quantity poured out of the connected keg.

This counter can be set to zero by pressing the RESET

button at any time without the master key (intermediate

counter).

Litre flag normal = shows the quantity poured out of the line. This counter

can be set to zero only by pressing the RESET button

using the master key . (global counter)

Portion flag = shows the number of portions poured out. This counter

can be set to zero only by pressing the RESET button

using the master key.

By pressing the ENTER button, you can go to the next counter . The FCD-II

displays per line only what is programmed. Examples:

- If nothing is programmed in the correspondent line, nodEF will appear on

the display.

- If it is programmed only in portions, only the portion counter will appear .

- If only the liter calibration is programmed, only the two-litre counters will

appear .

- if both values are programmed, the counters will appear in this order:

intermediate counter , portion counter, global counter .

Page 10

Page 11

4.5 Indicator of empty keg

As soon as the signal „no more fluid in the line“ comes from the connected

flowmeter (which must have four pins), the red LED (1) lights up on the FCDII. When the unit is in standby mode (it displays the clock), the

correspondent line number will be displayed as AL-XX where XX represents

the line number.

If you are working on the FCD-II and the LED lights up, it means that one or

more kegs are empty . You can finish up normally . Now reach one line after

another by pressing the arrow buttons. The lines which are empty will appear

and begin to flash.

Y ou can also use the additional relay connection to drive an external alarm

(for ex.: a lamp, a horn, etc... ).

4.6 Master key

When the master key is put on its socket for the first time, you will hear

three beeps and the message HOSt will appear on the display. From now on,

you will hear only one beep when you put the master key .

Only one master key per FCD-II is valable. If the master key of the FCD-II

gets lost, another one can be bought. As soon as the new key is put on the

socket, only this one will be right for this unit.

As long as the master key remains on the socket, you have access to all

features of the unit:

- setting all the counters to zero.

- programmation of the litre and the portion calibration.

- continuous flow monitoring.

All lines have to be programmed before FCD-II is ready to work. Otherwise,

some errors in the data can occur .

4.7 Host mode

Put the master key on the socket to enter the host mode. The FCD-II has

two calibration values per lines: one for litres and one for portions.

Page 11

Page 12

4.7.1 Programming litre calibration

Choose one line by using the arrow button. Then press the PROG button.

Now the number of pulses per litre is displayed (max 32,766 pulses/litre)

depending on the flowmeter mounted in the pipe (for ex.: FFB-50 = about 240

pulses/litre; FFC-40 = about 335 pulses/litre). Y ou can programm this value

in two ways:

1st possibility

Modify directly the value. Press the RESET button, in ordre to set this value

to 00000. By using the arrow buttons, you can choose the digit that you want

to change (the chosen digit flashes). The digit can be changed by pressing

the + button. Number 0 appears after number 9. If the + button is pressed

continuously , the digit will change its value automatically. Release the button

as soon as the requested number is reached. Press the ENTER button to

confirm. The display will show the line number which has been programmed.

2nd possibility

The FCD-II can be programmed even when the number of pulses is not

known. When the number of pulses is displayed, press LITER and then

PROG. A little horizontal dash appears on the display. Any quantity of liquid

(at least 0.5 l. ) can now be poured out of the tap. Meanwhile the little dash

moves. When the requested quantity is poured out, press ENTER. By

pressing the + button and the arrow keys set the poured quantity in litres (for

ex.: 00.760). Press ENTER to confirm otherwise press the PROG button to

start again. Press the LITER button to check up the litre calibration. The

pulse/litre measured appears on the display for two seconds.

4.7.2 Programming the portion size

To program the portion size, it is important to consider that:

If the litre calibration is set to zero, the portion size can not be given in litre

but only in pulses.

1st possibility (litre cal. = 00000)

Choose one line. Press PROG and then PORTION. By pressing the arrows

and the + button set the number of pulses which correspond to the requested

portion. Press ENTER to confirm.

2nd possibility (litre cal. is set)

Page 12

Page 13

Choose one line. Press PROG and then PORTION. By pressing the arrows

and the + button set the portion size in litres (for ex.: 00.300 = 3dl = 300ml).

Press ENTER to confirm.

3rd possibility (litre cal. = 00000)

Choose one line. Press PROG and then PORTION and then PROG again. A

little horizontal dash will appear on the display . Now pour the requested

portion out of the tap. Meanwile the little dash moves. As soon as the portion

is poured out, press ENTER to confirm. The measured number of pulses

appears on the display . If everything is all right, press ENTER to confirm,

otherwise press PROG and start again.

4th possibility (litre cal. is set)

Choose one line. Press PROG, then PORTION and then PROG again. A little

horizontal dash will appear on the display . Now pour the requested portion

out of the tap. Meanwile the little dash moves. As soon as the portion is

poured out, press ENTER to confirm. The measured portion in litres appears

on the display . If everything is all right, press ENTER to confirm. If the

requested quantity is not exact, it can be corrected by using the keyboard

(for ex.: poured quantity = 00.276 real portion size=00.300).

Note: the reference of the FCD-II is pulses. When the portion size is given in

litre, the FCD-II will approximate this value according to the litre calibration.

Example: Litre calibration = 24 4

Portion size = 00.300 litre

Portion pulses = 244 x 0.3 = 73.2

reference number = 73

rounded portion size = 73 : 244 = 00.299

Once the programmation of every line is completed, take out the key .

4.8 Setting to zero

Put the master key on the socket and choose a line using the arrows. Once

reached the requested line, press the ENTER button. Go to the requested

counter by pressing the ENTER button. By pressing RESET, the value will be

cleared to zero. After setting all the requested lines to zero, t ake out the key.

4.9 Re-calibration

Page 13

Page 14

If, for example, a 50-litre keg is emptied but the value on the display does not

correspond (for ex.: 47 litres), this value can be corrected as follows:

- choose the requested line by using the arrow buttons.

- press the PROG button and then the LITER button: the display will show

the global counter (litre counter).

- correct this value to the actual one by using the + button and the arrows

- press ENTER to confirm.

4.10 Cleaner key

The FCD-II has a special function to clean the pipes. Put the cleaner key on

the socket, you will hear two consecutive beeps and CLEAN will appear on

the display . The key has to be kept on the socket during the entire cleaning

and will be taken away at the end of it. The counters do not change during

the cleaning.

4.1 1 Clock setting

Clock setting is possible only if the FCD-II is in standby mode. Press the

PROG button first, the minute indicator flashes. Keep pressing the + button

as long as you reach the right number . By pressing the arrow button, you can

reach the hour indicator . Set the hour by pressing the + button. Press

ENTER to confirm.

4.12 Date setting

Put the master key on the socket and wait until the FCD-II go into the

standby mode (about 1 minute). Press the PROG button first, the minute

indicator flashes. Press the ENTER button if you want to bypass the clock

setting. The year will be shown. You can modify it by pressing the arrow and

the + buttons. Press the ENTER button to confirm. Mt (= month) and Dt

(=date) will appear consecutively on the display . You can modify these values

by pressing the + button. Press ENTER to confirm each one. Then the clock

will appear on the display . Take out the master key .

Page 14

Page 15

5 Troubleshooting

The indicator is empty

a) check the power supply

b) check the connection between the main and the front print

c) check the fuse (see schema 7.3.)

d) call a technician

A flowmeter group does not work

a) check the cables of each flowmeter (reversed polarity)

The empty keg indicator flashes without reason

a) exchange the wire of the signal indicator with that of the empty keg

indicator

The display shows incomprehensible values

a) cut off power supply for 10 seconds

b) call a technician

Page 15

Page 16

6 Specifications*

Power requirement : 230V~ / +/- 10% 50-60Hz

(1 15 V~ 50-60Hz at request)

Power consumption: max 5 Watt charged with 16 flowmeters

T emperature tolerance

operating: -10°C to +70°C

storage: -20°C to +70°C

Measure functions: 3 pulse counters per line (32 bits)

Display functions

intermediate counter: 0.01 to 99,999 litres with automatic range

selection

global counter: 0.1 to 99,999 litres with automatic range

selection

portion counter: 1 to 99,999 portions

Display: 5 digits LCD display

Keyboard: 10-key keyboard

Memory: Battery backed-up memory (10 years)

Flowmeters: All the DIGMESA flowmeters. The Sm

flowmeters (4 pins) are specially suitable to

work with the FCD-II. It permits to monitor

the empty kegs.

Inputs : 16 flowmeter inputs divided into four

modules.

Outputs: one relay contact max. 6Amps / 230V~

Interface: 1 RS-485 interface.

*technical modification rights reserved.

Page 16

Page 17

7 Appendix

7.1 Assembling an extra module

When you order an extra module to monitor four extra flowmeter lines, the

package will contain:

- 1 cable inlet PG 1 1, for 4 flowmeter cables ( 4mm diameter).

- 1 module

Follow the procedure below to mount the module on the FCD-II.

- cut off power supply .

- unscrew the connection cover .

- assemble the cable inlet as described in § 3.

- connect the cables with the FCD-II (§ 3.1.1.)

- unscrew the front panel.

- take out carefully the plug from the front print.

- put the module on the next free 30-pole socket which corresponds to the

flowmeter group. Press the module down and turn until it remains fixed

vertically .

Page 17

Page 18

- connect the plug with the front print again.

- fasten the front panel.

- fasten the connection cover .

- turn power on.

- go throught every line by using the arrow keys. Check if the new module is

recognized. If everything is all right, the new 4 lines will appear on the

display.

7.2 How to change a module

Open gently both lockings which are located at the extremities of the

connector , turn the module down and take it away .

7.3 Location of the fuse

legend

a = module 1 (flowmeter 1 to 4)

b = module 2 (flowmeter 5 to 8)

c = module 3 (flowmeter 9 to 12)

d = module 4 (flowmeter 13 to 16)

s = fuse holder

Page 18

Page 19

SOFTWARE FCD-III

Addition of the operating instructions FCD-II

In the context of the technical progress our FCD-II received a more modern microprocessor

as well as a completely new designed system software. Since in terms of hardware for the user

did not change anything, the past manual of FCD II keeps its validity.

What has changed, is the operation of the equipment. This is described in detail in this

appendix to the FCD-II manual. Furthermore, the data exchange protocol has also changed.

You experience more information in addition in chapter 8 of this auxiliary documentation.

1 General operation

After switching on the power, the device announces itself with display and sound check; and thereafter it will

display the installed

you can

restart

The display shows alternating the selected line number and the corresponding counter reading. If is

displayed in place of a value, then this value is greater than and cannot be displayed. Big values can only

be accessed via the serial interface. Internally, the range is limited to 4294967295 impulses, that means,

a flowmeter with a calibration value of 240 Imp/Lt. will count up to 17,9 mill. litres and then will continue at zero.

version number

for a certain time. To get the version number from already running device,

the device by pressing simultaneously the keys

+

Enter

+

Reset

LED

As function control, the

blinks periodically briefly . If a data communication takes place, then this flickers

during the time of the data communication; simultaneous a gnashy noise is to be heard. This serves for the

simplified error tracing in case of difficulties during the data communication .

If you use

measuring instruments with integrated empty detection

, thus the LED goes into steady light as soon

as one of the attached measuring instruments is empty . At the same time, the display changes on the

corresponding line to alternating: > > (example : Line 3 Alert). If at least one of the

lines is empty, then also the relay is switching with a defined debounce time (

With the keys you

Liter

With you alternate the display between

With the key the

Portion

portioncounter

selected counter announcement. The

You can

adjust the time

(not however the date) without masterkey : change on time indication and press

select the line

is indicated. The key alternates between

date

(the minutes blinks now), then adjust the value with and change between minutes and hours

with or . Terminate with .

If the parameter settings allows, you can

which will be indicated.

totalcounter

LITER

( ) and

Enter

is periodically represented during time indication as scrolling text.

+

Enter

reset the splitcounters

without masterkey :

change to the desired line and make sure that the splitcounter is displayed ( flashing).

If it's allowed, the display will show ' ' by pressing the key . After 4 seconds of continuous

Reset

Conn. AUX

splitcounter

LITER

- closing contact).

LITER

( flashing).

time indication

and the

Prog

actuation, the splitcounter of the selected line will be set to zero with acoustic acknowledgement.

For this, you receive more information in chapters 4 and 6.

Page 19

Page 20

2 Cleaning (CLEAN-Dallaskey)

At an FCD, as many as desired

However,

additional

cleaning keys with

cleaning keys

individual key numbers

can be used ; one is delivered in each case.

can be ordered at any time.

Simply apply the cleankey to the support plate and the display announces ' ' blinking. After some seconds,

the unit beep's twice and the flashing announcement change to statically. Starting from this time, the cleaning

is activated and registered in the internal

portion counters are suppressed. Each line is documented with its own

cleaning diary

. For the duration of the cleaning process, litres- and

cleaning counter

, how many litres

actually flowed through with the respective cleaning. If the cleaning key is removed, the announcement changes

again to blinking; after a few seconds, a threefold beep appears and the display change into the normal mode;

the cleaning is terminated. The ten last cleanings are stored internally constantly and are, if necessary,

accessible via the serial interface

(starting time, stop time, keynumber, quantities).

3 HOST - Mode (MASTER-Dallaskey)

For all further functions than the already described you must change first into the

Set for this the provided

can

be used only at it's associated device

MASTER Dallaskey

on the support plate. This keys are

. Thus pay attention if you operate several FCD's in your installation.

Newly delivered keys are not assigned yet. By putting the key the first time on, the device recognizes a

automatically and assigns it themselves irrevocable .

Master keys possibly

assigned in former times

are defined thereby as

to be invalidly

Once assigned to a certain FCD, the master key cannot be made valid for another FCD, except it will be

sent back to DIGMESA for reinitialization.

If you put a

beep

moment : ' '. If the key is

new key

. If the key is

on the first time, then the FCD will acknowledge this after a few seconds with a

already assigned to this FCD

already assigned to another FCD

, then a

unique beep

, then nothing happens (invalid key).

appears. The display shows for one

host mode

individual

from now on.

.

, i.e. a master key

new key

threefold

4 Counters / resetting counters

The FCD's have by default

- 1 : Totalcounter (editable) - 2 : Splitcounter (editable)

- 3 : Portioncounter (editable) - 4 : Cleningcounter (not editable)

Counters 1, 2 and 4 contains a common

his own factor possess. You can use it as freely calibratable portion counter like also for indicating

consumption in another unit (gallones(US/GB)Quart etc.) or for example a price, so that the computational

amount can be read out directly without converting, as portion counter : E.G. 1 litre product corresponds

to 224 impulses per litre - 1 litre costs 3,45$ = (224: 3,45) 65 impulses per $.

Counters 1 and 3 can be resetted only in the host mode, while for counter 2 (splitcounter) it can be

intended whether he may be resetted without masterkey or not. (see chapter 1 and 6)

Counter 4 serves for the documentation in the cleaning diary and is not influenceable.

Resetting counters in the HOST-Mode :

Put on the Masterkey, then select first the desired line with

Splitcounter : hold for 4 seconds

Totalcounter : hold and for 4 seconds

Portioncounter : hold and for 4 seconds

The procedure is acoustically acknowledged.

four counters each line

calibration factor

Reset

Reset

Reset

Liter

Portion

; three are directly editable:

(pulses per unit) during counter 3 (portions)

Page 20

Page 21

5 Calibration (HOST Mode only)

Flowmeters delivers differently amounts of

impulses per litre

; dependent mainly on the

nozzle size

and the

of the measured medium . Therefore it is necessary to calibrate all lines before the operation.

Different methods are to you at the disposal. If you already know the number of delivered impulses per litre,

then you can use the

Press the keys or at the same time, depending whether you would like to calibrate

a litre or a portion.

manual calibration

Prog Liter

+

Ex factory preset

: put on the masterkey and select the desired line with and .

Prog

Portion

+

, the display shows now or the last adjusted value.

With the keys you select the decimal place which can be edited (this blinks) and with the key

you adjust their value. Terminate and assume the value with .

Breaking off

NOTICE :

a begun calibration is at any time possible

A change of the calibration affects immediately the counter reading, since

Enter

by removing the masterkey

.

the actual impulses

and not

the calibrated quantities are cumulated internally!

Automatic Calibration :

and press 4 seconds . The display indicates : . ('A' blinking)

NOTICE :

An automatic calibration procedure sets previous the respective total counter to zero, not however the

begin as with manual calibration until the display shows the actual calibration value

Reset

other counters. The taken quantity per procedure is credited thereafter to all counters of this line.

viscosity

+

There are

two measuring possibilities

The display shows the number of measured impulses. Terminate and assume the adjustment with .

In addition, you can do

2:

extract

a measuring beaker. In place of ENTER you press . The display will show now ; with and

available; 1: You ext ra c t

any quantity

into a tared container and this thereafter

Prog

exactly 1 litre

product into a measuring beaker.

Enter

weigh

or filling partly

+

you have to change the value in accordance with the level of the measuring beaker or the weight in kilograms.

The

1:1 input of kilograms

For products with strikingly

in accordance with their

works satisfactorily with

different density

specific weight

than water (oils, etc..)

.

most usual beverages

converting

.

into litres is however recommended

NOTICE

that,

as larger as the calibrated quantity is

In order to obtain a

NOTICE

that a recalibration always is oriented at the counter reading of the total counter. As example for a

very exact calibration value

, as

more exact the long-term measurement

, you have the possibility of a

recalibration

will be.

.

successful recalibration we make use of a keg beer with 30 litres contents : attach the absolutely new keg

and set the total counter to zero. If the keg becomes empty, re-elect and thereafter

press 4 seconds

value ( ) with and .Terminate and assume the value with . You can use

Prog

.

The display shows now the value measured so far, e.g. . Adjust now the correct

+

Prog Liter

+

Enter

this feature also from the beginning of initial operation, since with the automatic calibration, the total counter

will be set to zero and the extracted quantity from calibration is already credited to the total counter. You must

start thus only with a new container .

Page 21

Page 22

6 Parameter settings (HOST Mode only)

The FCD-III software contains 3 operating parameters since version 1.00, which are described in the following.

Possibly newly added parameters on higher OS-Versions will be separately documented.

The fundamental editing steps itself will remain the same however : change into HOST-Mode (Masterkey) and

Prog

press for 4 seconds. With the keys you can choose the desired parameter, with the key

you can change it's value and with the key you quit the parameter-editing mode. Note, that in this mode

Enter

+

an abort is not possible by removing the master key; changes are directly valid.

The parameters and their effects are :

date & timemode : european / american

automatic summertime : yes / no

reset of splitcounter allowed without masterkey : yes / no

7 Date setting (HOST Mode only)

The FCD-III software contains an extensive time and date system. It is appropriate for the use in Europe

as well as for the American continent. The display changes as follows :

European : 24 hours, TT/MM/JJJJ American : 12 housr AM:PM, MM/DD/YYYY

The leap year compensation happens automatically. Further it can be adjusted whether an automatic

summer- wintertime compensation is to take place or not. This happens depending upon time zone

NOTE

adjustment (EU/US) at the respective fixed dates.

during spanning date adjustment, the time will automatically adjusts without further inquiry.

Thus during setting up, first adjust of the date and afterwards of the correct time.

(Parametersettings see chapter 6; time settings chapter 1)

that with activated summer time compensation

+

Enter

Enter

Enter

Enter

Date setting : put on the masterkey and press , the display shows now the year.

Edit the year with the keys , or ; terminate with . The display shows : (month)

Edit the month the same way like the year and terminate with . The display shows : (date).

Edit the date the same way and terminate with . The date setting is now completed.

8 Data inquiry via interface

The FCD's have alternatively a RS-232 or a RS-485 interface (has to be indicated at the order)

with the objective to exchange datas with an superordinate device. If only one FCD shall to be

connected to another device (PC, countersystem etc.), RS-232 is the best solution, since no peripheral

interface adapter is needed. However, if several FCD's have to communicate at a single connection,

then RS-485 is obligatory. In this case, each FCD must be configured with an unique device number,

which is adjustable via jumpers. Details for this see in the main manual to FCD-II.

The protocol of FCD-III

is no longer compatible

can be made compatible without larger expenditures. Detailed documents and support to this you will

receive upon request by our development department.

Upon demand, there is also a Windows PC software available, with which the FCD III's can be read out

and get configured easily. This contains also an export function to transfer datas into free configurable

cell's in an EXCEL table.

to the protocol of FCD-II. However, existing software

Page 22

Page 23

Page 23

Page 24

Digmesa AG, Keltenstrasse 31, CH-2563 Ipsach / Switzerland

Phone +41 (32) 332 77 77, Fax +41 (32) 332 77 88

www.digmesa.com

Page 24

Bedienungsanleitung FCD 3 823-1001_GB / Mai 2005

Loading...

Loading...