DIGIWAY PTY LTD

SW50 V2.X Dual Swing Gate Motor

INSTRUCTION MANUAL

- 1 -

IMPORTANT SAFETY WARNING

Electricity and power motors associated accessories could be fatal or at

least cause seriously injury. Digiway suggested some safety device to be

used so as to prevent personnel from being injured by motorized device

being controlled. All main voltage wiring must be installed by a licensed

electrician.

Recommended install PE beams or loop detectors for additional

safety.

Do not operate gate unless gate is in full view and free from objects.

Remote control must be keep away from children.

- 2 -

MAIN FEATURES

1. General Descriptions and features

1.1 General descriptions

It is recommended reading and understanding this manual before start to install the control board.

Some features and idea are new. So take some time to read through the manual to get better

understanding of the board. That will save your time during installation and get the best benefit

from the control board.

1.2 General features

SW50 is designed for most of domestic swing gate. It can be mounted on brick wall/pier or steel

post. The arm supplied can be met most of application situations. If special need, customer can

modified arm or ask supplier/dealer to contact manufacturer for different arm.

Before installation must check:

A) Gate moves freely by hand without any difficulty in either open and closing directions.

B) The post or pier must be strong enough.

C) Gate must have open and closed stopper

D) 240V 10A power point must be available within one metre of the post/pier

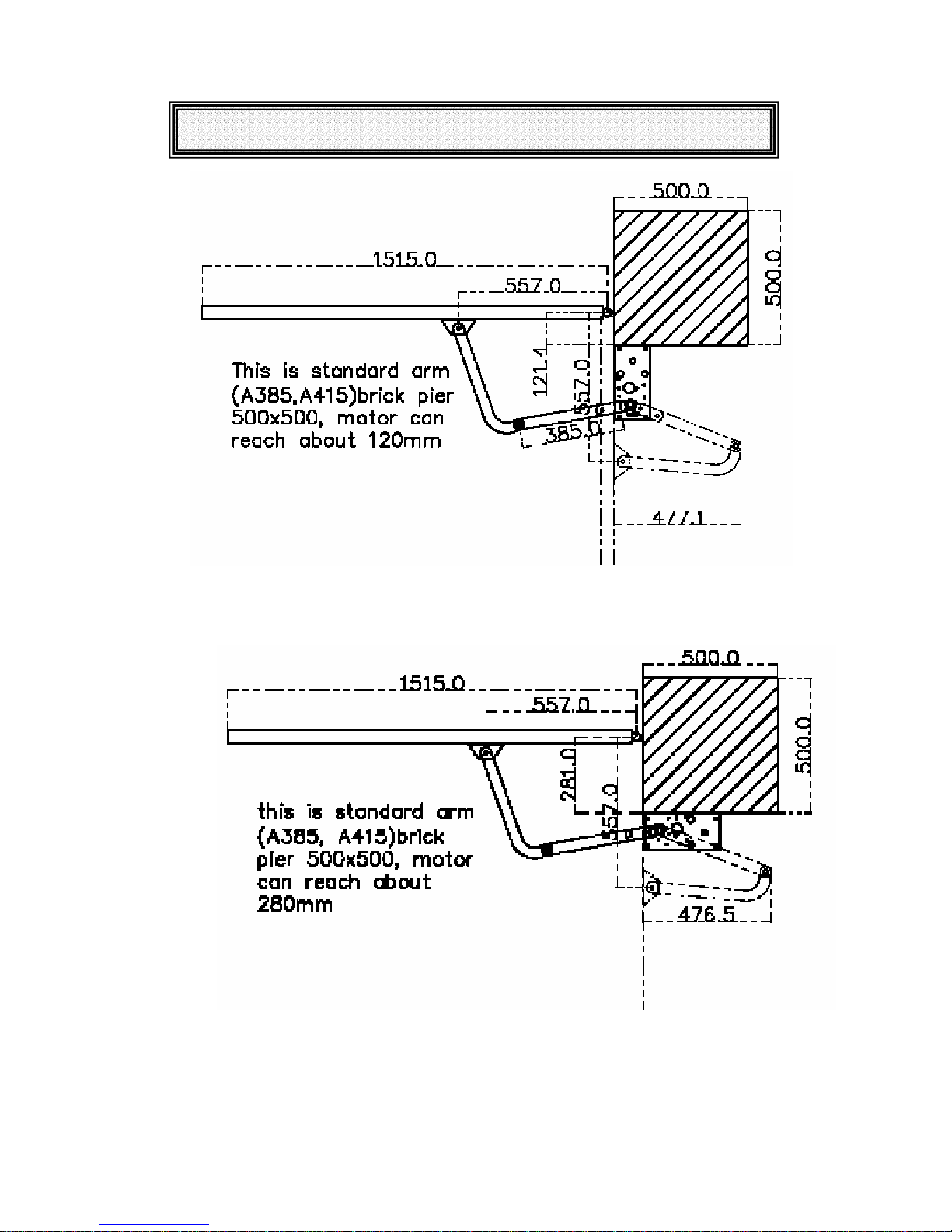

E) If there is not enough side room, minimum side room requirement see following drawing.

2. Motor installation

Here are the arms. Different combination (some need minimum modify, drilling holes) and

different motor mounting positions can drive different gate.

Fig. 1 SW50 different arms

- 3 -

GATE MOTOR MOUNTING

Fig. 2 A385, A415 arms swing in vertical mounting

Fig. 3 A385, A415 arms swing in parallel mounting

- 4 -

GATE MOTOR MOUNTING

Fig. 4 A385, A585 arms swing out vertical mounting

Fig. 5 A385, A585 C800 arms swing in vertical mounting small side room

- 5 -

GATE MOTOR MOUNTING

Fig. 6 A585, A585 arms swing in vertical mounting

Fig. 7 SW50 motor side view

- 6 -

GATE MOTOR MOUNTING

Fig. 8 SW50 clutch/manual release

Manual operation: Disengage motor by undo manual release bolt several turns, so that motor

basis can move on chassis, hold motor move away from output shaft. To re-engage motor by move

motor towards to output shaft and then tight manual release bolt.

- 7 -

GATE MOTOR CONTROLLER

3. Control board

The SW50 swing gate motor controlled by DC2 control board, which has following features:

• Control one or two 12 or 24V DC motors. For Swing gates, Sliding Gates, Roller shutter

doors etc.

• Limit switch inputs, N/C or N/O

• Lock or lights relay output.

• Adjustable timers: auto close time and PE trig auto close time.

• Pedestrian cycle

• Safety control inputs.

• Self-learn soft start and soft stop.

View of Control board

1 243

5

8

9 12 13

10 11

1. OPN open push button

2. CLS close push button

3. PED pedestrian open push button

4. OSC stop push button

5. Gate status display, open green, close red

6. Mode selection DIP switch

7. Close motor force (reverse power)

8. Control inputs terminals.

9. Limit switch input

10. Lock output relay

11. M1 output

12. M2 output

13. Accessary power supply12V/24V

14. Battery terminals

15. Power supply 12 V or 24V AC.

6

Fig. 9 DC2 PCB

7

14 15

- 8 -

GATE MOTOR CONTROLLER

3.1 Control inputs

Fig.10. DC2 PCB dimensions and mounting holes

Control Terminals

OPN ----- N/O open input.

PED ------ N/O pedestrian open push button, only open motor-1

CLS-------N/O Close Gate

OSC------ N/O pedestrian open push button, only open motor-1

STP-------N/C Stop motor

PEB ------ N/C photo electrical beams

OL1 ------ Motor 1 open limit switch, N/C or N/O selected by DIP4

CL1 ------ Motor 1 close limit switch, N/C or N/O selected by DIP4

OL2 ------ Motor 2 open limit switch, N/C or N/O selected by DIP4

CL2 ------ Motor 2 close limit switch, N/C or N/O selected by DIP4

Plug in receiver or on board receiver

Buttons

OPN button ---- full (M1&M2) open gate and used for settings

PED button ----- Ped (M1) open gate and used for settings

CLS button ----- CLS gate and used for settings

OSC button ----- Stop motor

3.2 DIP Switch Settings

DIP1---- SET ON—set, OFF – Run

DIP2---- SYNC ON—SYNC mode, OFF – No Sync mode

DIP3---- LKPS ON—Lock Pulse Output, OFF – Lock Presence Output

DIP4---- NOLS ON—N/C limit switch, OFF – N/O limit switch

DIP5---- PECL ON—PE trig Auto Close, OFF – No PE trig Auto close

DIP6---- AUCL ON—Auto Close Mode, OFF – No Auto close

- 9 -

CONTROLLER SETTINGS

3.3 Motor Force

In N/C limit switch mode, if any motor current over current setting, both motors will stop in

opening cycle or reopen in closing.

In N/O limit switch mode (this model also called no limit switch, current detect mode), if M1 over

current settings, only stop M1, while M2 current over current setting, only stop M2.

3.4 Power input

12 or 24V AC power input. 12VAC for 12VDC motor, 24VAC for 24V DC motor

3.5 Battery Backup

12V battery --- 12VDC motor, 12VAC input.

24V battery --- 24VDC motor, 24VAC input.

Solar regulator output can be direct connected to this terminal if in case of solar application.

3.6 Motor output

M1: Motor 1 output. M2: Motor 2 output

3.7 Power output

Power out for accessaries. About 14V----- 12VAC supply, about 26V------24VAC supply

3.8 Timers setting

Push Buttons functions

Button SET ON---Setting SET OFF---Running

OPN Sync Delay Time Open gate

PED Lock Pulse Time Partial open gate

CLS PE Trig Close Time Close gate

OSC Auto Close Time Stop gate

Note

Set time settings

Turn SET on, red and green LED flashes a little fast alternatively.

Push and hold on OPN for Sync Delay Time

Push and hold on PED for Lock Pulse Time

Push and hold on CLS for PE Trig Close Time

Push and hold on STP for Auto Close Time

Factory setting

Timer F/Setting Step Setting Method Range

Sync Delay Time 2 sec. 0.1 sec. SET on + OPN Button 0-25 sec.

Lock Pulse Time 2 sec. 0.1 sec. SET on +PED Button 0-25 sec.

PE Auto close Time 2 sec. 0.1 sec SEC on + CLS Button 0-25 sec

Auto Close Time 30 sec. 0.1 sec. SET on + PRO Button 0-6553 sec

To restore factory setting, turn power off and set DIP1 (SET) on, push and hold

CLS button, then power on. While hold CLS button, set SET1 off and then release

the CLS button. Now controller restored factory setting from memory.

Get into special setting model:

Turn power off, set DIP1 o, push and hold CLS button, power up. Then release CLS button. Now

controller gets into special setting model

.

- 10 -

4 Motor Connections

4.1 Two wires motor

MOTOR CONNECTION

To controller

Fig.11. Two wires system with limit switch

- 11 -

MOTOR CONNECTION

4.2. Five Wires motors (SW50 config to 2 wires system)

Five wires motor drawing as the drawing.

.

Fig.12. Five wires system with limit switch

4.3. Two wires motors without limit switch

DC2 controller can also control linear drive motor without limit switch. Set pot/motor force

according to the motor. Controller detects motor current to stop motor.

4.4 Step by step set up motor.

a) Mounting and connect motor

b) Disengage cutch and push two gates in middle position, then engage clutch. Power up,

push OPN button, gate should open, if any gate goes close direction, switch motor two

wires.

c) Adjust limit switch (make sure DIP4 limit switch selection is matched to limit switch).

(1) If 5 wires system, turn power off and disengage clutch and setting limits switch.

Move gate to closed potion and adjust closed limit stop to touch the limit switch

and this limit should connect to closed limit switch in put on control board. Open

gate to opened position do the same things for opened limit switch.

(2) If 2 wires system with limit switch with diode, need keep power on, push remote,

while gate is running(either open or close), using screw driver touch limit switch,

so can find out which limit is for open or close. Turn power off, then disengage

clutch, push gate and set up limit switch.

(3) If two wires system without limit switch, in this case, opened and closed

mechanical stopper must be installed. Adjust motor force pot to suit actual gate

power requirement.

d) Power up, use remote or push button to operate gate. Controller will automatically learn

soft stop positions. After two fully close and open cycles, auto-learn procedure finish.

- 12 -

TROUBLE SHOOTING GUIDE

5 Trouble shooting guide

5.1 General checking

Normally if installation is done properly, there would be trouble free. If in case of malfunction,

please checking as following steps.

1) Check the DIP setting limit switch selection is right.

2) Gate status LED green (open) and red (close), one or both should be flashing depending on the

gate position. If not flashing, please check the power supply and 12V DC output circuits if there is

a short circuits.

5.2 Gate not open

1) Check the limits switch type selection if it is right.

2) Push button on the control board, if gate status green LED flashing and red LED off, please

check motor fuse and motor.

5.3 Gate not close

1) Check the limits switch type selection if it is right

2) Check the DIP switches auto close mode selection if it is right.

3) Check control input. If one or more of OPN, PED, PEB input LED are on, which means access

control system hold gate open.

- 13 -

Loading...

Loading...