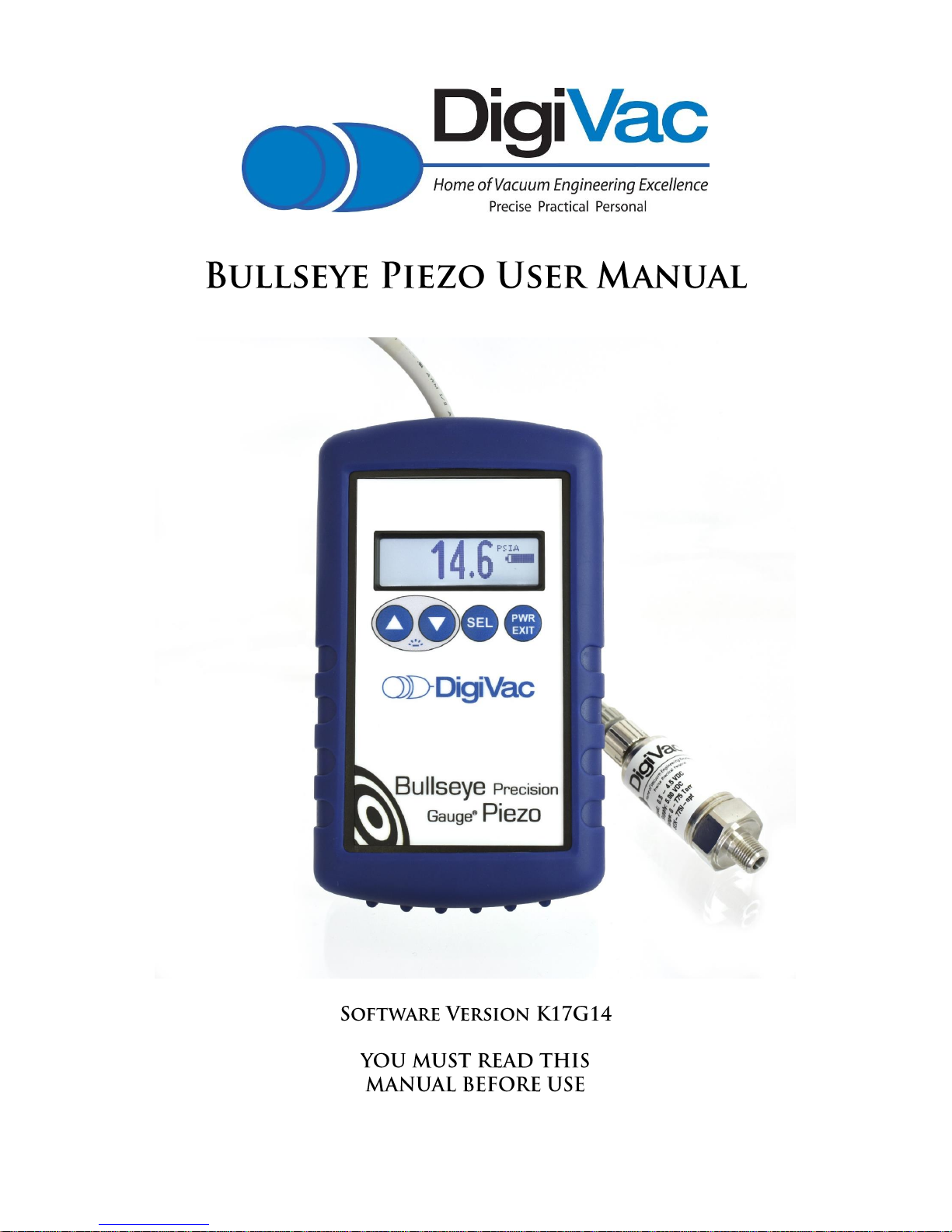

DigiVac Bullseye Precision Gauge Piezo User Manual

3

The Bullseye Precision Gauge Piezo was developed to make vacuum measurement easy, useful

and intuitive. The Bullseye Piezo is a rugged portable vacuum instrument that is sensitive and

highly accurate. It was designed to suit the demands of field use. It’s amazing. Its main

features include a graphical LCD display with a white backlight for showing large numerical

fonts and digital graphics to show line graphs and time horizons of data from 1 minute to 1

hour. This graphical display of vacuum pressure makes understanding system trends easy by

showing points of inflection and small changes in pressure with sub second resolution.

• Rugged design for field or laboratory use

• Dimensions: 6.2” x 3.7” x 1.3”

• Only requires 4 AA alkaline or Micro-B USB

• Range of 1 to 775 Torr, -29.92 to 0.59 inches Hg, and mbar

• +/- 2 Torr, +/- 0.08 inches Hg Accuracy

• Numerical graphing display

• Resolution of +/- 0.1 Torr, +/- 0.01 inches Hg

• 12 Units: microns, millitorr, Torr, mbar, Bar, kPa, pascals, PSIA, mmHg, inHg, mmH2O,

inH2O

• Isolated sensor – Low risk of sensor contamination

• Battery life of 2800mah/25ma, or 127 hours ~ 5 days

• Vacuum Interface of ⅛” NPT male or PTFE hose barb, KF16, KF25

• CE & RoHS compliant

• Simple, easy-to-use design

• On/Off soft switch

• LCD graphical, white backlight, sunlight readable

• Large numerical font

• Digital graphics to display line graphs and time horizons of 1 minute and 1 hour

• 7-foot sensor cable length

• Sensor electrical interface: M12

• Magnet

4

While this vacuum instrument has many features, it is very simple to use. Start by unpacking

the unit to verify you've received everything you've ordered.

• Vacuum instrument with white backlight and purple rubber boot

• Attached: 7' sensor cable with keyed connector designed to thread directly into the

sensor

• Piezo vacuum sensor and PTFE hose adapter

• Quick Start guide or (this) user manual

• Remove protective boot

• Remove the battery cover and install 4 AA batteries or attach a Micro-B USB

• Plumb Piezo vacuum sensor into the system to be measured, taking care to

differentiate between the threaded end and the end connecting the sensor to the cable

• Thread sensor cable into sensor (cable connector is keyed)

• Power on the device by pressing the PWR/EXIT button. It will take about 5 seconds to

fully power up and for the reading to settle.

• If need be, turn on the backlight. The backlight does not affect gauge reading or

accuracy.

• Read vacuum!

5

6

The Bullseye Precision Gauge Piezo incorporates an isolated Piezo resistive sensor. A piezo

resistive sensor is effectively a silicon strain gauge. When the pressure is placed upon the

silicon, the resistance of a MEMS measurement resistor changes which can be measured by

the sensor electronics. The sensor itself incorporates a wheatstone bridge that is very

sensitive to absolute pressure levels from 1 Torr = 1 mbar to 775 Torr = 1033 mbar. Piezo

resistive sensors are often referred by their full scale or maximum pressure that they measure.

For example, our 775i sensor has a maximum pressure sensitivity of 775 Torr or 15PSIA. There

are other piezo-resistive types of sensors that are sensitive in other pressure levels. Other

pressure levels that are common with piezo resistive sensors are 30 PSI, 100 PSI, 200 PSI and

1000 PSI.

Piezoresistive sensors have exceptional durability combined with low cost and better than 1%

full scale accuracy. They are chosen when a combination of durability, cost and accuracy are

all important.

The accuracy of a piezo resistive sensors are typically given in % of full scale. For example, a

100 PSI piezo sensor that is 1% accurate would have an accuracy of ± 0.01 * 100 PSI or ± 1

PSI. Note this makes the % of reading accuracy very good near its full range of 100 PSI, but

not so good near its base pressure (lowest detectable pressure) of 1 PSI. The 775i sensor has

an accuracy of ± 2 Torr, or 0.25% of full scale. This would make it’s accuracy at 10 Torr ± 2/10

or ± 20% of reading at an actual pressure of 10 Torr; and at 200 Torr, ± 2/200 or 1% of

reading.

The most important thing about accuracy is knowing what you need for your process. Do you

really care about the difference between 100 Torr and 102 Torr? All sensors have trade offs of

cost and convenience. There is a tendency of us science types to demand the best most

accurate instruments. However, if our process doesn’t require the best accuracy available, it

may be more efficient to do work with a gauge that is slightly less accurate but more robust.

For example, a more accurate alternative to the Bullseye Piezo is a 1000 Torr capacitance

manometer. Some can be had at 0.15% of reading, and are also isolated. However, they tend

to be expensive, don’t travel well (easily damaged), and require frequent maintenance to

maintain that accuracy, especially around 10 Torr. The Bullseye Precision Gauge Piezo was

built from the ground up to be rugged and thrive with field use.

The isolated part of the sensor is important. Isolated means that the sensing electronics are

separated and protected from the process gas pressure being measured. Who cares? When

measuring clean dry gasses, isolated doesn’t matter. Non-isolated sensors where the silicon

die of the piezo resistive would come in contact with clean dry gasses like air and nitrogen

work just fine. These electronics can survive a lifetime exposed to clean dry air and even low

humidity and an occasional splash of water (when not energized). Corrosive gasses on the

other hand will corrode the silicon die and wires that make up a sensor just like the ocean

Loading...

Loading...