Digitronic CamCon DC50, CamCon DC51 User Manual

Digital Cam Switch Unit

CamCon DC50/51

Digitronic Automationsanlagen GmbH

Steinbeisstraße 3 • D - 72636 Frickenhausen • Tel. (+49)7022/40590-0 • Fax -10

Auf der Langwies 1 • D - 65510 Hünstetten-Wallbach • Tel.(+49)6126/9453-0 • Fax -42

Internet: http://www.digitronic.com • E-Mail: mail@digitronic.com

2 rue René Laennec 51500 Taissy France

Fax: 03 26 85 19 08, Tel : 03 26 82 49 29

E-mail:hvssystem@hvssystem.com

Site web : www.hvssystem.com

Digitronic Digital Cam Switch Unit

Automationsanlagen GmbH CamCon DC50/51

For your attention

This instruction manual relates to the CamCon DC50/51 from 10/2003. The company Digitronic

Automationsanlagen GmbH reserves the right to make changes which present an improvement of the

quality or functionality of the device without prior notice. The instruction manual was created with great

care, although it may not be error-proof. We would be grateful for any communication relating to any

errors you may have found.

UP-date

You can also obtain this instruction manual on the Internet at http://www.digitronic.com in the latest

version as PDF file.

Qualified personnel

This device may only be started and operated by qualified staff. By qualified we mean personnel who

are entitled to handle, to earth and to lable devices, systems and power circuits in accordance with the

technology safety standards.

Liability

(1) The supplier is liable for damages caused by himself or by the owner of the rights up to the sum of

the sales price. He is not liable for loss of profits, forfeited savings, intermediate and successive

damages.

(2) The above mentioned limits to liability do not apply to insurance of named characteristics and

damages which were caused deliberately or through negligence.

Protection

The CamCon DC50/51 and this instruction manual are protected by copyright. All rights are reserved.

Neither the CamCon DC50/51, nor this document may be copied as a whole or partially, photocopied,

reproduced, translated or transferred to electronic media of any kind or into machine readable format

without prior written permission by the company Digitronic Automationsanlagen GmbH.

Note: We have examined the devices of the CamCon series for year 2000 compatibility and

have not found any adverse effects on any functions.

Note: CamCon is a registered trademark of the company Firma Digitronic

Automationsanlagen GmbH.

Note: The devices of the CamCon series comply with the standards for electromagnetic

compatibility: EN 55011, EN 55022, EN 55024 Part 2, EN 50082 Part 2, ENV 50140,

VDE 0843 Part 2, VDE 0843 Part 4, VDE 0871, VDE 0875 Part 3 ("N"),

VDE 0875 Part 11, VDE 0877 Part 2, IEC 801 Part 3, IEC 801 Part 2, IEC 801 Part 4,

IEC 801 Part 5.

(c) Copyright 1992 - 2004 / File: DC50E.DOC

Digitronic Automationsanlagen GmbH

Auf der Langwies 1

D-65510 Hünstetten - Wallbach

Tel. (+49)6126/9453-0 Fax. (+49)6126/9453-42

Internet: http://www.digitronic.com

E-Mail: mail@digitronic.com

,Version from: Aug. 04 Page: 2

2 rue René Laennec 51500 Taissy France

Fax: 03 26 85 19 08, Tel : 03 26 82 49 29

E-mail:hvssystem@hvssystem.com

Site web : www.hvssystem.com

Digitronic Digital Cam Switch Unit

Automationsanlagen GmbH CamCon DC50/51

TABLE OF CONTENTS

1. Introduction..........................................................................................................................................8

2. Operating Pinciples..............................................................................................................................9

2.1. Speed Compensation .....................................................................................................................10

2.1.1. Measuring delay time for Speed Compensation..........................................................................12

2.1.1.1. Measuring delay time through actual differences.....................................................................12

2.1.1.2. Measuring delay time by means of different measuring points.................................................12

2.1.2. Speed Compensation using off-centre pressure, e.g. brake functions........................................13

2.1.3. Separate delay time for Speed Compensation of switch-ON and switch-OFF points.................14

2.2. Time - Cam.....................................................................................................................................14

3. Installation..........................................................................................................................................15

3.1. Dimensions.....................................................................................................................................15

4. Electrical connections........................................................................................................................16

4.1. Pin allocation of the CamCon .........................................................................................................16

4.1.1. Pin allocation of the analog output...............................................................................................16

4.1.2. Pin allocation of the SSI measuring system.................................................................................16

4.1.3. Pin allocation of the incremental measuring system....................................................................17

4.1.4. Pin allocation of the inputs...........................................................................................................17

4.1.5. Pin allocation of the outputs.........................................................................................................17

4.1.6. Pin allocation of the voltage supply..............................................................................................18

4.1.7. Pin allocation of the serial interface.............................................................................................18

4.1.7.1. Pin allocation of the serial RS232 interface..............................................................................18

4.1.7.2. Pin allocation of the serial RS485 interface..............................................................................19

4.1.8. Pin allocation of the external interface.........................................................................................20

4.2. The measuring system....................................................................................................................21

4.2.1. SSI Measuring system input........................................................................................................21

4.2.2. Parallel measuring system input..................................................................................................21

4.2.3. Incremental measuring system input...........................................................................................22

4.2.3.1. Incremental measuring system input with 5V RS422 level.......................................................22

4.2.3.2. Incremental measuring system input with 24V PNP level.........................................................22

4.2.3.3. Incremental Hiperface measuring system input with SINCOS level.........................................23

4.2.4. Analog measuring system input...................................................................................................23

4.2.5. PLL measuring system input........................................................................................................24

4.2.6. Timer as a measuring system......................................................................................................24

4.2.7. RS232 as a measuring system....................................................................................................24

4.3. The outputs.....................................................................................................................................25

4.3.1. The 40mA outputs (only CamCon device with aluminium back wall)..........................................25

4.3.2. The 500mA outputs......................................................................................................................25

4.4. The inputs.......................................................................................................................................25

4.5. Precautionary measures for welding work......................................................................................25

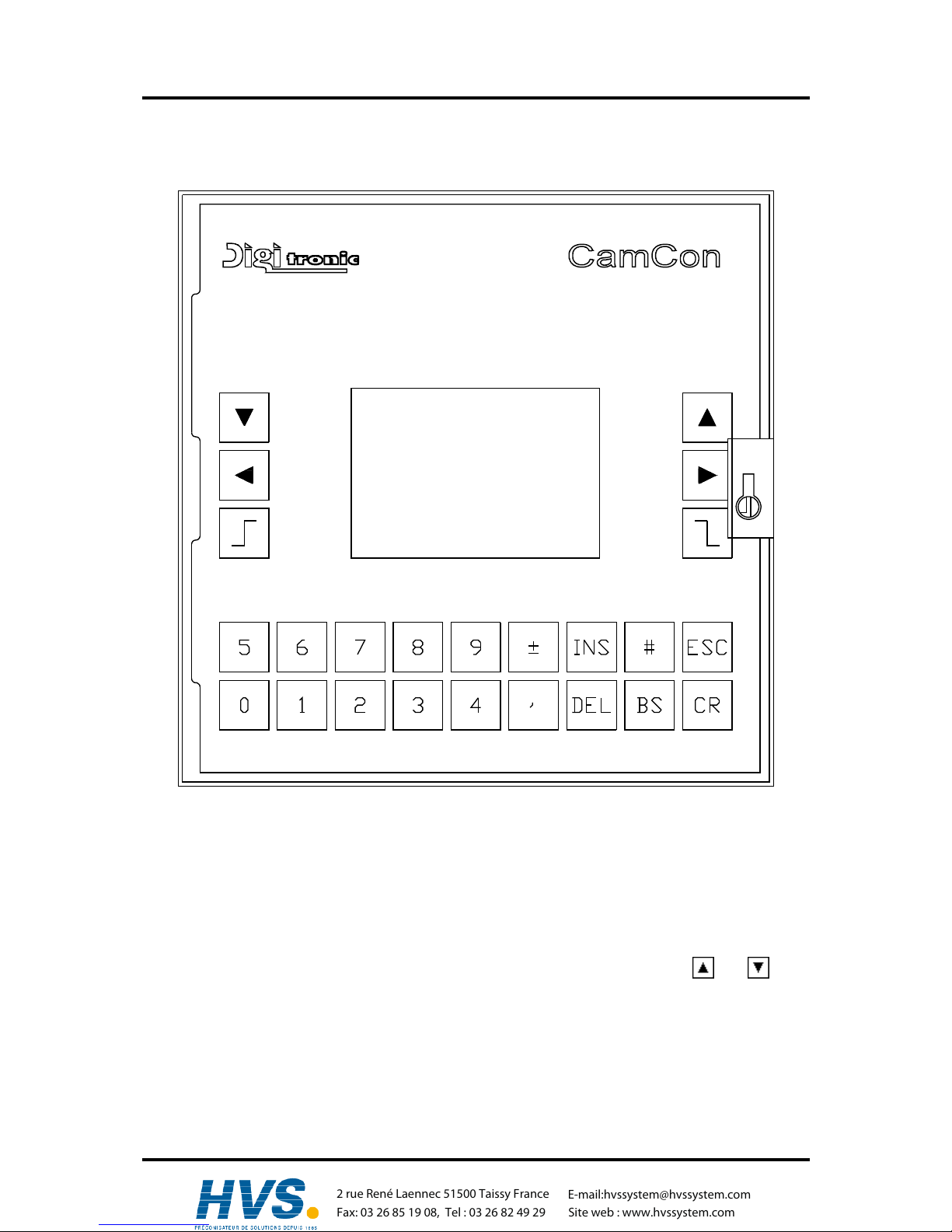

5. Outline of the operator terminal.........................................................................................................26

5.1. Frontview CamCon.........................................................................................................................26

5.2. The liquid crystal display (LCD) ......................................................................................................26

5.3. Contrast setting...............................................................................................................................26

5.4. The keyboard..................................................................................................................................26

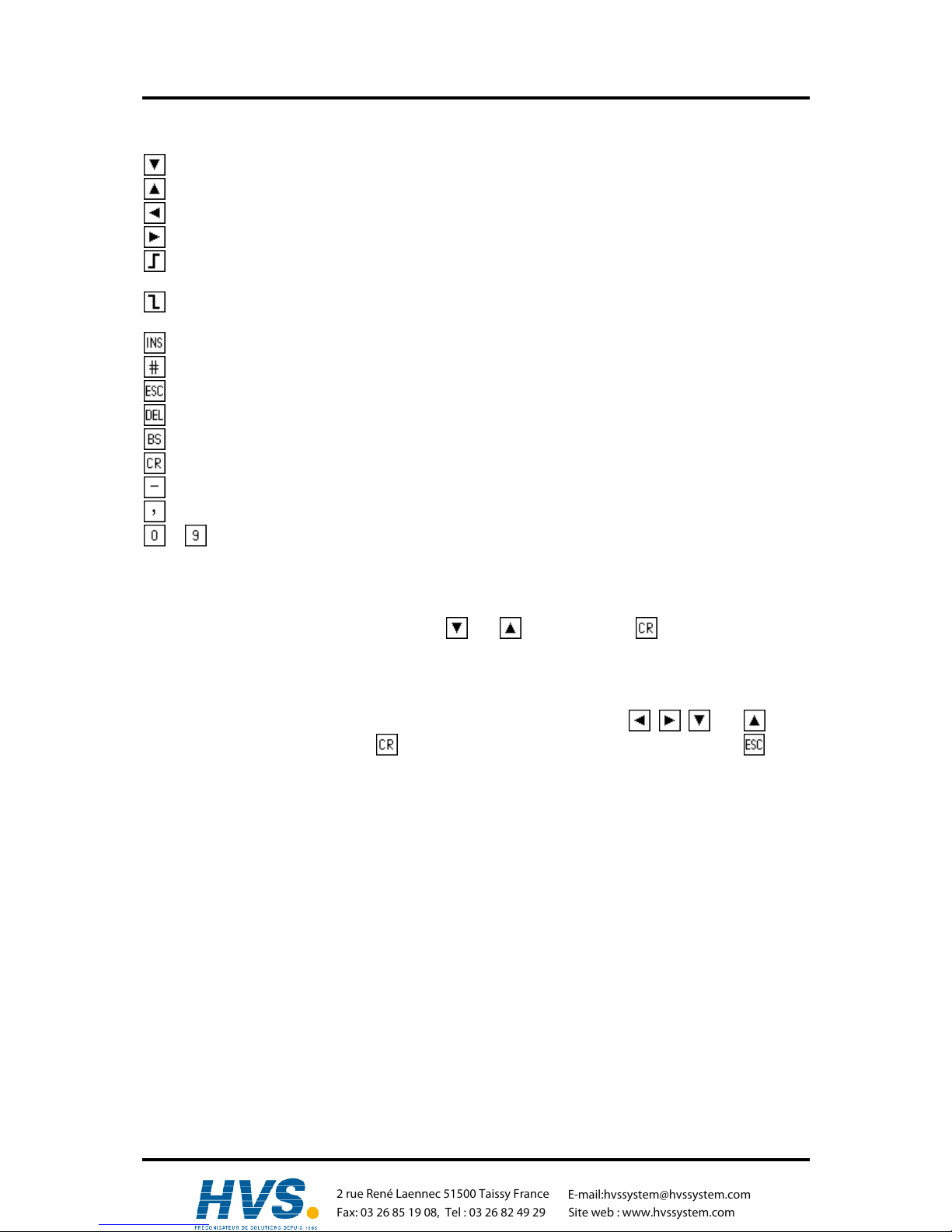

5.5. Outline of key functions...................................................................................................................27

5.6. Menu selection................................................................................................................................27

5.7. Selection of a menu point ...............................................................................................................27

5.8. Text input........................................................................................................................................28

6. Commissioning ..................................................................................................................................29

7. Operation of the CamCon..................................................................................................................31

7.1. The main menu...............................................................................................................................31

7.2. The standard display.......................................................................................................................31

,Version from: Aug. 04 Page: 3

2 rue René Laennec 51500 Taissy France

Fax: 03 26 85 19 08, Tel : 03 26 82 49 29

E-mail:hvssystem@hvssystem.com

Site web : www.hvssystem.com

Digitronic Digital Cam Switch Unit

Automationsanlagen GmbH CamCon DC50/51

7.2.1. Changing the display....................................................................................................................31

7.2.2. Program change ..........................................................................................................................32

7.2.3. Program name.............................................................................................................................32

7.3. Cam programming..........................................................................................................................33

7.3.1. Output selection for programming ...............................................................................................33

7.3.2. Program selection for programming............................................................................................34

7.3.3. Programming the delay time/speed compensation......................................................................34

7.3.4. Programing Time-Cams...............................................................................................................35

7.3.5. Programming the output name....................................................................................................36

7.3.6. Cam Input ....................................................................................................................................36

7.3.7. Adding cams................................................................................................................................37

7.3.8. Cam Teach - In............................................................................................................................37

7.3.9. Cam Search.................................................................................................................................37

7.3.10. Cam deletion..............................................................................................................................38

7.3.11. Output (cam track) deletion .......................................................................................................38

7.3.12. Copying programmed outputs (cam tracks)...............................................................................39

7.3.13. Shifting cam tracks ....................................................................................................................39

7.3.14. Deleting programs......................................................................................................................40

7.3.15. Copying programs......................................................................................................................40

7.3.16. Examples for cam programming................................................................................................41

7.3.16.1. First cam programming...........................................................................................................41

7.3.16.2. Programming additional cams on an output...........................................................................42

7.3.16.3. Deletion of a particular cam....................................................................................................43

7.3.17. Programming analog cams........................................................................................................44

7.3.17.1. Creating the first analog cam..................................................................................................45

7.3.17.2. Adding an analog cam............................................................................................................45

7.3.17.3. Changing the analog cam.......................................................................................................45

7.4. Unit configuration (system setting)..................................................................................................46

7.4.1. Measuring system........................................................................................................................46

7.4.1.1. The standard measuring systems.............................................................................................46

7.4.1.2. The actual position hysteresis...................................................................................................46

7.4.1.3. Controlling the measuring system.............................................................................................47

7.4.1.4. The electronic gear...................................................................................................................48

7.4.1.4.1. Electronically changing the rotation direction.........................................................................48

7.4.1.5. The display format of the actual position..................................................................................48

7.4.1.6. Configuration of a special measuring system...........................................................................49

7.4.1.6.1. SSI - measuring system.........................................................................................................49

7.4.1.6.2. Parallel - Gray measuring system..........................................................................................50

7.4.1.6.3. Incremental - measuring system............................................................................................50

7.4.1.6.4. Multiturn measuring system with electronic gear...................................................................51

7.4.1.6.5. PLL measuring system ..........................................................................................................52

7.4.1.6.6. Timer way simulation (time emitter).......................................................................................52

7.4.1.6.7. RS232 measuring system......................................................................................................53

7.4.1.6.8. AG615 - Single - Multiturn - Measuring system.....................................................................53

7.4.1.6.9. SIM - measuring system simulator ........................................................................................54

7.4.1.6.10. HIPER i.e. incremental - measuring system with Roll - Over - funktion..............................54

7.4.1.7. Deleting the special measuring system ....................................................................................55

7.4.2. The measuring offset...................................................................................................................56

7.4.2.1. Zero offset with rotatory movements.........................................................................................56

7.4.2.2. Measuring offset with a linear moved system...........................................................................56

7.4.2.3. Zero offset with linear movements............................................................................................56

7.4.2.4. Actual position preset................................................................................................................57

7.4.3. The speed adjustment.................................................................................................................58

7.4.3.1. The speed factor.......................................................................................................................58

7.4.3.2. The display format of the speed display...................................................................................58

7.4.3.3. Range adjustment of the speed display....................................................................................58

7.4.3.4. Accuracy of the speed display..................................................................................................59

7.4.3.5. Display, Type ............................................................................................................................59

,Version from: Aug. 04 Page: 4

2 rue René Laennec 51500 Taissy France

Fax: 03 26 85 19 08, Tel : 03 26 82 49 29

E-mail:hvssystem@hvssystem.com

Site web : www.hvssystem.com

Digitronic Digital Cam Switch Unit

Automationsanlagen GmbH CamCon DC50/51

7.4.4. Cable length / Cycle time.............................................................................................................60

7.4.4.1. The cable length .......................................................................................................................60

7.4.4.2. The cycle time of the CamCon..................................................................................................60

7.4.5. The special outputs......................................................................................................................60

7.4.5.1. The security output....................................................................................................................60

7.4.5.2. The output of the actual position...............................................................................................61

7.4.5.3. Direction output.........................................................................................................................61

7.4.5.4. The standstill output..................................................................................................................61

7.4.5.5. The hysteresis...........................................................................................................................61

7.4.5.6. The analog speed output..........................................................................................................62

7.4.5.7. Configuration of the analog cams.............................................................................................62

7.4.5.8. The analog position output........................................................................................................64

7.4.6. System upgrading........................................................................................................................64

7.4.6.1. Setting the inputs......................................................................................................................64

7.4.6.2. Setting the outputs....................................................................................................................64

7.4.6.3. Setting the outputs with speed compensation..........................................................................64

7.4.6.4. Setting the keyboard lock..........................................................................................................64

7.4.6.5. Error - aknowledging Input (EQ)...............................................................................................64

7.4.6.6. Input for enableling Outputs......................................................................................................64

7.4.6.7. Setting the external program selection.....................................................................................65

7.4.6.8. Setting the program selection mode.........................................................................................65

7.4.7. Masterprogram.............................................................................................................................66

7.5. Unit configuration............................................................................................................................67

7.5.1. User key allocation.......................................................................................................................67

7.5.1.1. Creating a new user key...........................................................................................................67

7.5.1.2. Deletion of a user key...............................................................................................................68

7.5.1.3. Checking the key configuration.................................................................................................68

7.5.2. Complete deletion........................................................................................................................69

7.5.3. Unit configuration.........................................................................................................................70

7.5.3.1. Setting the serial interface ........................................................................................................70

7.5.3.1.1. The "Cam-BUS" communication mode..................................................................................70

7.5.3.1.2. The "Standard" communication mode...................................................................................70

7.5.3.1.3. The "Multiuser" communication mode...................................................................................70

7.5.3.1.4. The "S5 - L1" communication mode......................................................................................70

7.5.3.1.5. The "3964(R)" communication mode.....................................................................................70

7.5.3.1.6. Input of the unit number.........................................................................................................71

7.5.3.1.7. Programming via remote .......................................................................................................71

7.5.3.2. Additional device options..........................................................................................................71

7.5.3.2.1. PLC Logic Module..................................................................................................................71

7.5.3.2.1.1. Examples for using the PLC logic module..........................................................................71

7.5.3.2.2. PLC Logic Module with text display.......................................................................................72

7.5.3.3. Analog outputs..........................................................................................................................73

7.5.3.3.1. Clearing the integrated analog outputs..................................................................................73

7.5.3.3.2. Adjusting the integrated analog outputs.................................................................................73

7.5.3.3.3. External analog outputs.........................................................................................................73

7.5.3.4. Locking EEProm memory.........................................................................................................74

7.5.4. Language.....................................................................................................................................75

7.5.5. Configure user .............................................................................................................................75

7.5.5.1. User text....................................................................................................................................75

7.5.5.2. User-Menu/OP-functions..........................................................................................................76

7.5.6. Configure Hardware.....................................................................................................................76

7.5.6.1. CP16 Module............................................................................................................................76

8. Device info.........................................................................................................................................77

8.1. Stack Info........................................................................................................................................79

9. Error messages and removal of errors (FAQ)...................................................................................80

9.1. Problem: Display shows "No contact to unit: XX"...........................................................................80

9.2. Problem: "Pos - Err:1".....................................................................................................................80

9.3. Problem: "Pos - Err:2".....................................................................................................................80

9.4. Problem: "Pos - Err:3".....................................................................................................................81

,Version from: Aug. 04 Page: 5

2 rue René Laennec 51500 Taissy France

Fax: 03 26 85 19 08, Tel : 03 26 82 49 29

E-mail:hvssystem@hvssystem.com

Site web : www.hvssystem.com

Digitronic Digital Cam Switch Unit

Automationsanlagen GmbH CamCon DC50/51

9.5. Problem: "Pos - Err:5".....................................................................................................................81

9.6. Problem: An "Pos-Error:" occurs during operation..........................................................................81

9.7. Problem: "RAM-Full" = RAM memoryis full.....................................................................................81

9.8. Problem: The EEProm memory is full.............................................................................................82

9.9. Problem: Outputs will not activate...................................................................................................82

9.10. Problem: "Out - Error"...................................................................................................................82

9.11. Problem: Error in the EEPROM....................................................................................................82

9.12. Problem: "Error ???".....................................................................................................................82

9.13. Problem: "Clear...."........................................................................................................................83

10. Menu outline.....................................................................................................................................84

11. Calculation EEPROM cam storage..................................................................................................85

12. Calculation the RAM storage-requirement for CamCon..................................................................86

13. Technical data of the CamCon........................................................................................................87

14. Key word table .................................................................................................................................88

,Version from: Aug. 04 Page: 6

2 rue René Laennec 51500 Taissy France

Fax: 03 26 85 19 08, Tel : 03 26 82 49 29

E-mail:hvssystem@hvssystem.com

Site web : www.hvssystem.com

Digitronic Digital Cam Switch Unit

Automationsanlagen GmbH CamCon DC50/51

1. Introduction

Electronic Cam Switch Units have been successfully used in industry for a long time. Experiences

collected in close liaison with users over the years have been included in the development of the

CamCon series. The result is a compact digital cam switch unit which is user friendly and reliable to a

high degree. The following characteristics testify the excellence of the CamCon:

* Tested and reliable hardware

* Short-circuit-proof outputs

* Graphic liquid crystal display with 128x64 pixels in the CamCon DC50,51.

* Large and clearly visible 7-Segment display for program, position and speed on

CamCon DC30,33 and 40.

* Any number of cams per output can be programmed.

* Up to 32000 Programs for product administration

* Master, for example: machine cams

* Optimising switch points when machine is in operation

* Compensation of mechanical delay time of switch components for switch-ON and switch-OFF

points can be set in steps of 100µs separately (DTC = delay time or Speed Compensation).

* Position - Triggert - Time - Cams

* Power supply 24V DC +/- 20%

* Mounting of suspension rails to EN 50022 on CamCon DC16 and 90

* Switchboard panel standard casing 144 x 144 x 63mm to DIN 43700 on CamCon DC33,40 and 51

* S5 Components group for S5 115U, 135U and 155U on CamCon DC115

* S7 Components group for S7 300 on CamCon DC300

* AB Components group for ControlLogix 1756 on CamCon 1756-DICAM

* S5 Switch-ON via PG interface with L1 - Bus on CamCon DC16,40,50,51 and 90

* PLC Logic Module (optional)

* Shift register (optional)

* OP - Functions

* Analog outputs (optional)

Cam switch units are used wherever switching operations are periodically repeated. Digital cam switch

units are an optimum replacement of mechanical units and offer in addition many other advantages,

such as:

* Simplification of mounting and adjustment operations

* Repeatable adjustment facility

* Standardised for almost all areas of application

* Reliability

* High switch speed

* Speed Compensation

* Product administration for quick format change

,Version from: Aug. 04 Page: 7

2 rue René Laennec 51500 Taissy France

Fax: 03 26 85 19 08, Tel : 03 26 82 49 29

E-mail:hvssystem@hvssystem.com

Site web : www.hvssystem.com

Digitronic Digital Cam Switch Unit

Automationsanlagen GmbH CamCon DC50/51

2. Operating Pinciples

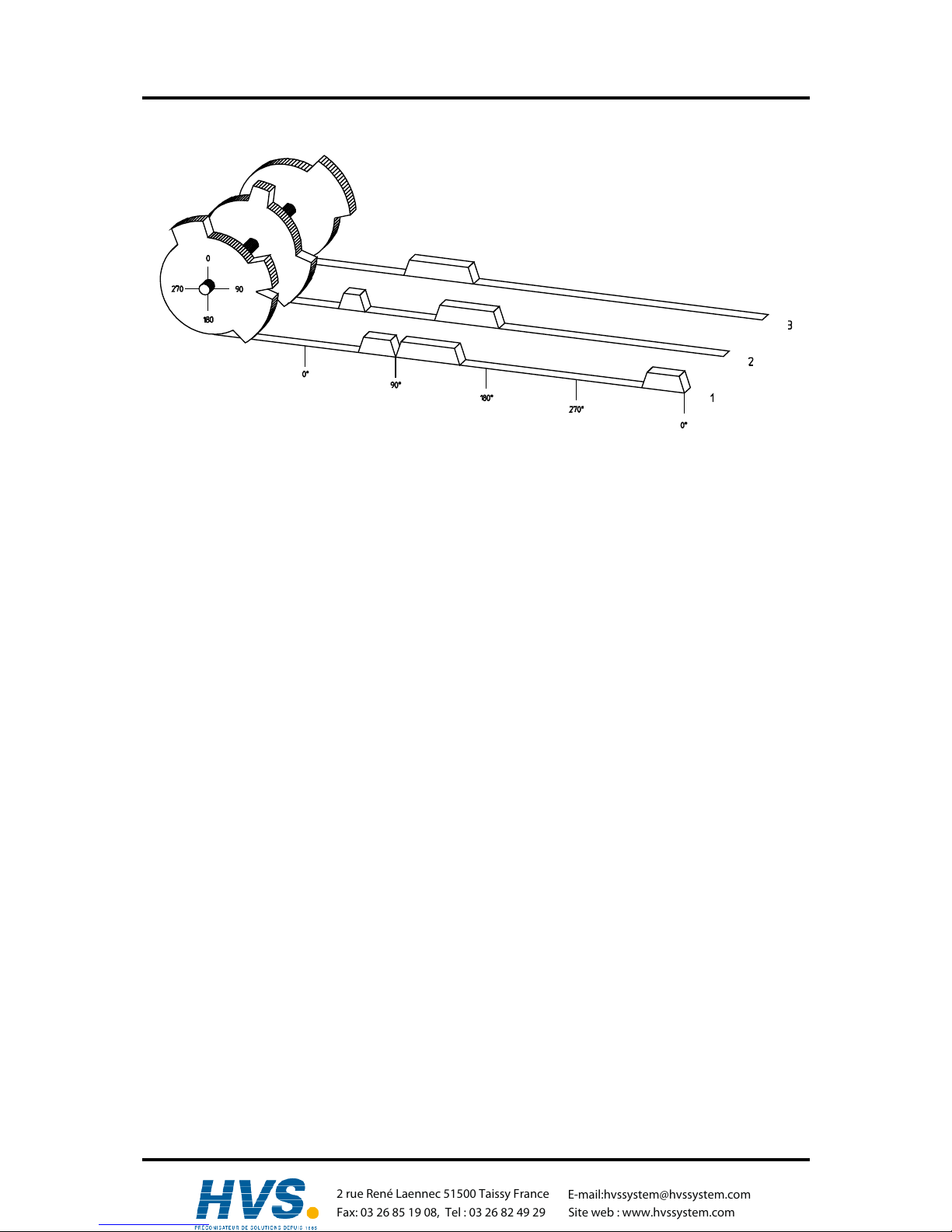

Diagram: Principles of a Cam Switch Unit

A principle for better comprehension of the function of a Cam Switch Unit is here presented. It has 3

outputs with the following cams:

Output 1: Cam 1: Switch-ON position60° Switch-OFF position 85°

Cam 2: Switch-ON position95° Switch-OFF position 145°

Cam 3: Switch-ON position325° Switch-OFF position 355°

Output 2: Cam 1: Switch-ON position5° Switch-OFF position 20°

Cam 2: Switch-ON position95° Switch-OFF position 145°

Output 3: Cam 1: Switch-ON position30° Switch-OFF position 85°

The positions of the output signals, here presented as three tracks, occur when the three cam disks

turn anti-clockwise past a sensor, which scans the cams on the 0°-axis.

In a mechanical cam switch unit, the switch interval, i.e. the range between switch-ON and switch-OFF

position are determined by the length of the cam. The length and the position of the cam can only be

varied marginally and this is mechanically highly demanding and time consuming. With CamCon such

adjustments can be realised in a fraction of time; in addition, there can be any number of tracks. A

measuring system which is fitted to the device reports the position to the CamCon. The CamCon

compares it with the programmed switch-ON and Switch-OFF positions of all outputs. If the position

lies in the range of a programmed switch-ON / switch-OFF position (cam), then the respective outputs

are active.

,Version from: Aug. 04 Page: 8

2 rue René Laennec 51500 Taissy France

Fax: 03 26 85 19 08, Tel : 03 26 82 49 29

E-mail:hvssystem@hvssystem.com

Site web : www.hvssystem.com

Digitronic Digital Cam Switch Unit

Automationsanlagen GmbH CamCon DC50/51

2.1. Speed Compensation

Each mechanical switch component (e.g. shield, magnetic valve) has a delay time, i.e. the time

between the start signal and the actual switching of the contacts. In processes where positioning is

executed on a moving system, this can cause problems. If such a process is driven with different

speeds, different positions are caused. To avoid this happening, new timings for the switch signals of

each speed would have to be calculated.

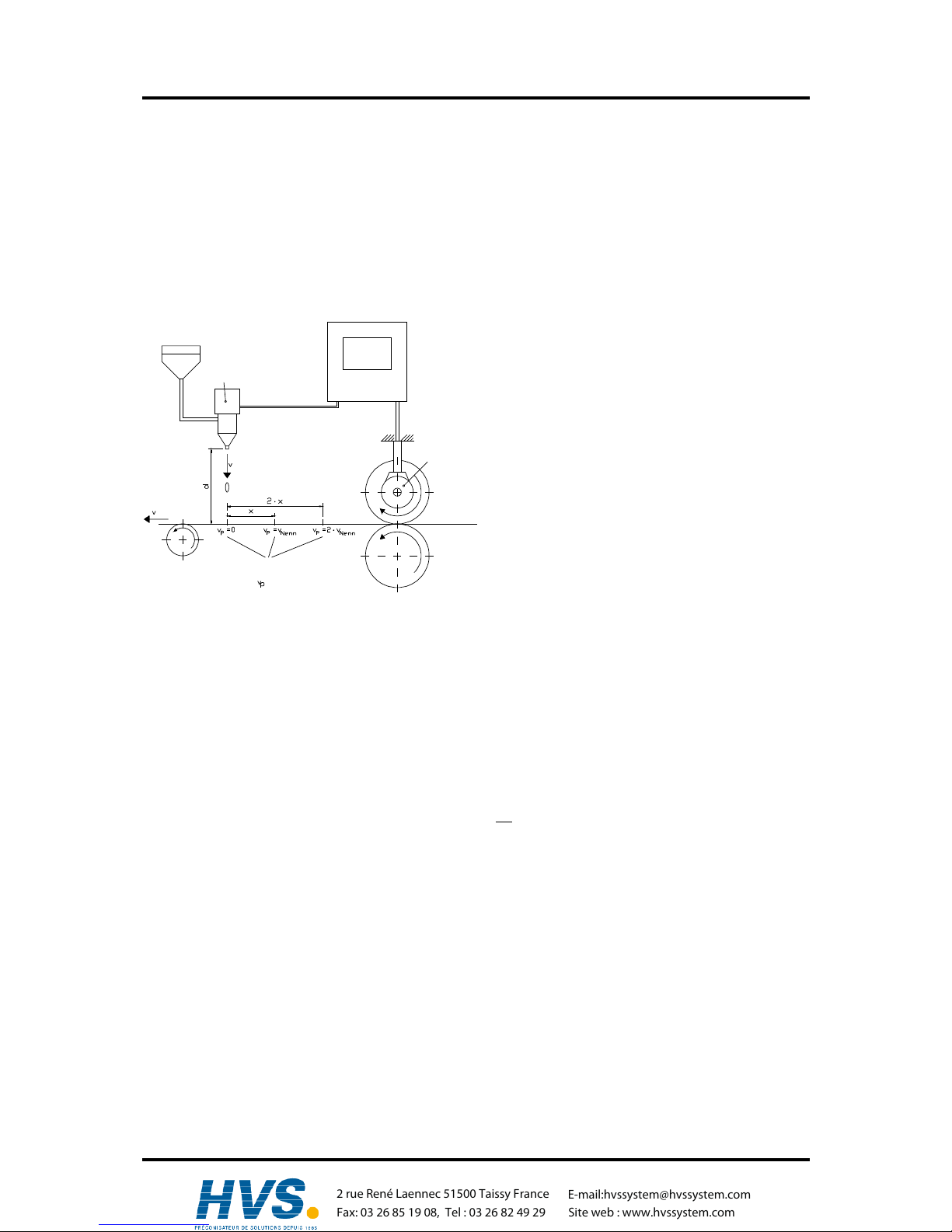

In order to ilustrate the complicated issues surrounding delay time or speed compensation, this will be

shown on the example of a packaging machine. In the process shown in the diagram, a glue point has

to be placed in an exactly defined spot on a moving paper track.

magnetic valve

glue nozzle

drop

paper

Points where the glue

hits the paper at the

different speeds .

paper track

encoder

CamCon

The system has the following parameters:

v

p

- Speed of the paper track

v

T

- Falling speed of the drop of glue

d - Distance between the glue nozzle and

the paper track

T

MV

- Delay time of the magnetic valve

Without speed compensation the following would happen:

As soon as the measuring system has reached a certain position, the CamCon sends a signal to the

magnetic valve. The glue nozzle opens for a short time during which a drop of glue ejects. Between the

start of the impulse and the exit of the drop time passes, which is mainly caused by the delay time of

the magnetic valve T

MV.

. A further delay is caused by the time which the droplet needs to pass the

distance between the glue nozzle and the surface of the paper.

This flight time is calculated as follows:

t

Flight

=

d

v

T

In total there the delay time is tFlight+T

MV.

During this time the paper track moves on by a specific

distance x.

It would now be possible to move the position, where the magnetic valve is switched on, forward by a

specific amount, so that the glue droplet hits the same spot again as during standstill. In this way a

speed compensation is created which works only at a specific speed of the paper. As soon as the

speed of the device and consequently that of the paper track is, for example, doubled, the hit point of

the glue droplet is shifted by the distance x, so that, without any speed compensation, it would move

backward by double the distance (2 ⋅ x) in total.

The automatic speed compensation of the CamCon makes it now possible to drive processes with

variable speed; CamCon registers the speed of the device continuously and adjusts the cams which

determine the switch time points "On Line" depending on the speed. This has the effect that the

outputs for the switch components are switched ON or OFF earlier. The direction of the movement is

of no significance in this instance.

,Version from: Aug. 04 Page: 9

2 rue René Laennec 51500 Taissy France

Fax: 03 26 85 19 08, Tel : 03 26 82 49 29

E-mail:hvssystem@hvssystem.com

Site web : www.hvssystem.com

Digitronic Digital Cam Switch Unit

Automationsanlagen GmbH CamCon DC50/51

A small example in figures was designed to eludicate:

Supposing the drive cylinder with the measuring system has a circumference of 360mm, so that one

millimeter of the circumference corresponds to exactly one angle degree of the measuring system.

The device has the following parameters:

v

droplet

= 20m/s

d = 20cm

T

MV

= 20ms

This results in the following flight time of the droplet:

tFlight=

d

v

T

=

0,2m

20m/s

= 10ms

The total delay time is then Tdead

, altogether

= TMV + tFlight = 20ms + 10ms = 30ms

During this time the paper track moves on by the distance x = v

paper

⋅ T

total delay.

= 1m/s ⋅ 30ms =

30mm. In order to compensate the delay time, the switch point for the magnetic valve must be moved

forward by 30°.

If the speed of the device and consequently that of the paper is doubled v

paper

, then the distance x is

also doubled by the speed of the paper track. In this case the switch point must be moved by 60°.

Note: Please take into account in these explanations that delay time is of a fixed size, which is

determined by the mechanical constants of the set and switch components and by the

dimensions of the construction and therefore does not change!

If the total delay time of 30ms was programmed into the respective output of CamCon, then the glue

droplet would always hit the right spot, regardless of the speed.

,Version from: Aug. 04 Page: 10

2 rue René Laennec 51500 Taissy France

Fax: 03 26 85 19 08, Tel : 03 26 82 49 29

E-mail:hvssystem@hvssystem.com

Site web : www.hvssystem.com

Digitronic Digital Cam Switch Unit

Automationsanlagen GmbH CamCon DC50/51

2.1.1. Measuring delay time for Speed Compensation

Several ways of measuring delay time of a relay or valve are available.

2.1.1.1. Measuring delay time through actual differences

First the switch-ON point of a valve or relay is programmed. We assume that the programmed switch

point lies at 200 degrees in this case. If the machine is driven with a speed of for example 40 rpm, a

shift occurs due to delay time. This shift is then measured and, in this example, will amount to 40

degrees.

Warning: For the calculation of the shift the programmed delay time in the cam switch unit must be

set to zero!

The delay time of the switch component is now calculated as follows:

Delay time ( in sec. ) =

∆ way (in °) * 60 (sec./min.)

speed (in rpm) * 360 (°/turn)

Delay time ( in sec. ) =

40 * 60

40 * 360

= 0.1667 sec.

The resultant delay time is then entered into the cam switch unit.

See Chapter "7.3.3. Programming the delay time" an page 33.

2.1.1.2. Measuring delay time by means of different measuring points

First the switch point is calculated at a speed of, for example, 50 rpm. We assume that the

programmed switch point lies at 200° in this case. The second measurement is taken at a speed of 80

rpm The necessary switch point must be set to 160°, if the exact switch point is to be also achieved at

80 rpm.

Warning: For the calculation of the two switch points the programmed delay time in the cam switch

unit must be set to zero!

The delay time of the switch component is then calculated with the following formula:

Delay time ( in sec. ) =

∆ way (in °) * 60 (sec./min.)

∆ speed (in rpm) * 360 (°/turn)

Delay time ( in sec. ) =

40 * 60

30 * 360

= 0.222 sec.

The resultant delay time is then entered into the cam switch unit.

See Chapter "7.3.3. Programming the delay time" an page 33.

Since the entered delay time shifts the switch point, the previously programmed cam must be changed.

For the calculation of the exact switch-ON position, the difference to the speed O rpm (here using 50

rpm) must be added to the first measured switch-ON point (here 200°). The difference is calculated

with the following formula:

∆ way (in degrees) =

dead time ( in sec. ) * ∆ time (in min-1) * 360 (degrees/rotations)

60 (sec./min.)

∆ way (in degrees) =

0.222 * 50 * 360

60

= 66.6 degrees

The switch-ON point of the cam is now shifted from 200° by approx. 67° to 267°.

,Version from: Aug. 04 Page: 11

2 rue René Laennec 51500 Taissy France

Fax: 03 26 85 19 08, Tel : 03 26 82 49 29

E-mail:hvssystem@hvssystem.com

Site web : www.hvssystem.com

Digitronic Digital Cam Switch Unit

Automationsanlagen GmbH CamCon DC50/51

2.1.2. Speed Compensation using off-centre pressure, e.g. brake functions

The Speed Compensation of the CamCon Cam switch unit works using a linear function. If, for

example, the speed doubles, then the shift of the compensated cam changes and also moves forward

by twice the amount. If the ram on an eccentric press should be brought to a standstill at the exact

upper stop point, the brake action of the press under different speeds results in a quadratic function.

The Speed Compensation can therefore only find an approximation of the exact switch point for the

stopping of the press by adjusting the line of the cam lines to the brake curves in the working range of

the press.

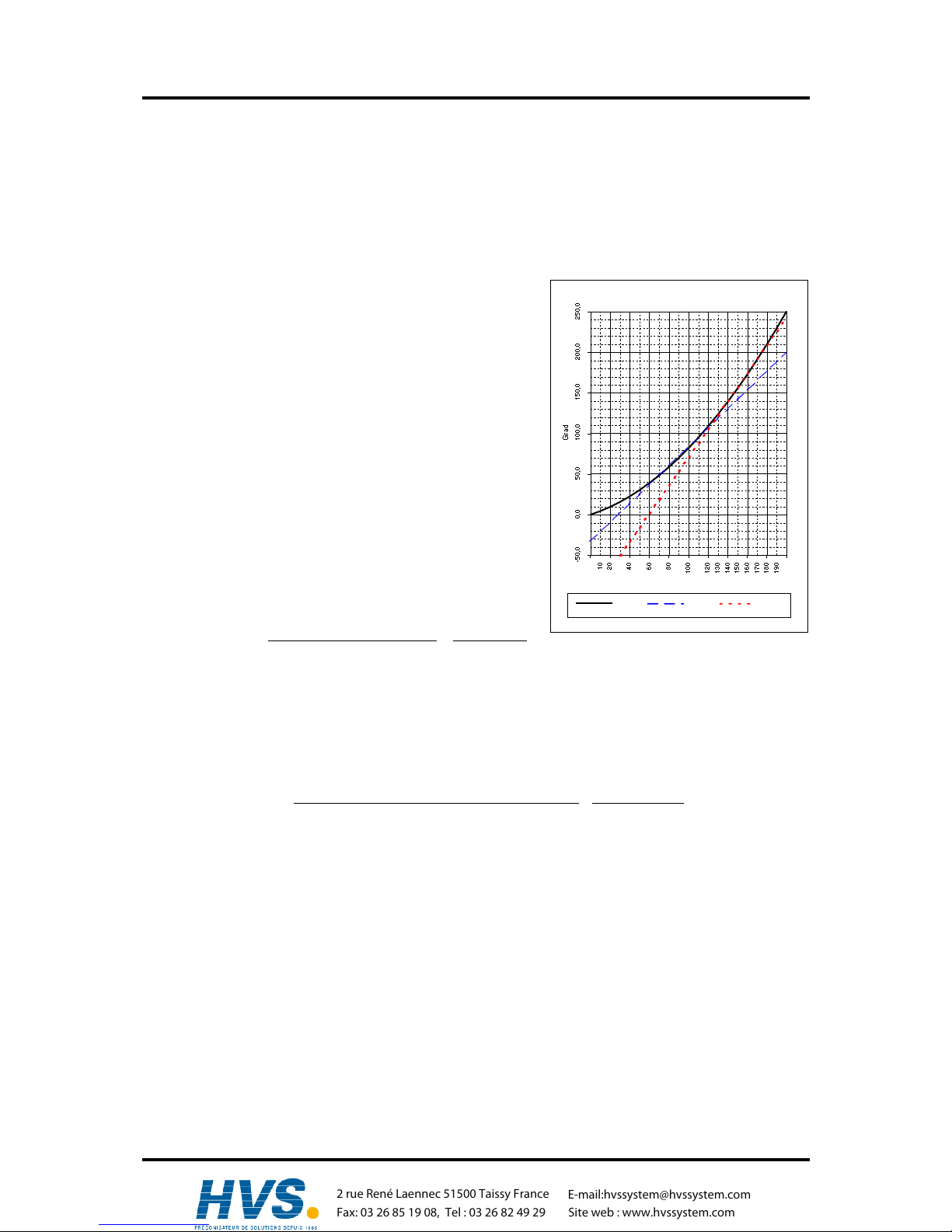

In the graphic on the right the curved line represents the

brake point of the ram in relation to the speed.

U/min

Verlauf Nocke 1 Nocke 2

For the calculation of the parameters to be programmed

please proceed as follows:

- Define the working range (e.g. 20-50 rpm) and determine

two measuring points which have to be specified in the

working process (e.g. 30 and 40 rpm).

- Now let the machine run at 30 rpm and program or

optimise a cam without Speed Compensation so that, at

switch-OFF, the ram comes to a halt in top stop. Note the

switch-ON point of the cam (e.g. 340°).

- Now let the maching work with 40 rpm and program or

optimise one cam without Speed Compensation so that,

at switch-OFF, the ram comes to a halt in top stop. Once

again, note the switch-On point of the cam. (e.g. 332°).

- Now calculate the delay time, taking into account the

distance and speed difference, using this formula:

Delay time ( in sec. ) =

∆ way (in °) * 60 (sec./min.)

∆ Speed (in rpm.) * 360 (°/turn)

=

340-332 * 60

40-30 * 360

=

0.133 sec.

- The calculated delay time is now entered into the cam switch unit.

- Since the switch-OFF point has shifted through the entered Speed Compensation, the previously

programmed cam must be changed first. For the calculation of the exact switch-ON position, the

difference to the speed 0 rpm (here 30 rpm) must be added to the first measured switch-ON point

(first measuring point here 340°) The difference is calculated with the following formula:

∆ way (in °) =

delay time ( in sec. ) * ∆ Speed (in rpm.) * 360 (°/turn)

60 (sec./min.)

=

0.133 * 30 * 360

60

= 23.94°

- The switch-ON point of the cam has now shifted from 340° by approx. 24° to 364°.

As a result a cam with a switch-ON point of 4° and a speed compensation of 0.133 sec has been

calculated. This is entered in the cam switch unit as switch-OFF cam of the press.

Note: If the degree of accuracy is no longer sufficient when switch-OFF is done with one cam, two

or several outputs can be switched in parallel and the cam of those is then adjusted to the

required working range. For the calculation of two switch-OFF cams divide the working

range in 5 parts with 4 measuring points and then calculate the delay time value and the

cam value with the same formula as described above. For the calculation of the first cam,

use the measuring points 1 + 2 and for the calculation of the second cam use the

measuring point 3 + 4.

Through this association of the linear cam functions to the brake functions it is now possible to switch

OFF the cam via the entire working range of the press in the top stop.

,Version from: Aug. 04 Page: 12

2 rue René Laennec 51500 Taissy France

Fax: 03 26 85 19 08, Tel : 03 26 82 49 29

E-mail:hvssystem@hvssystem.com

Site web : www.hvssystem.com

Digitronic Digital Cam Switch Unit

Automationsanlagen GmbH CamCon DC50/51

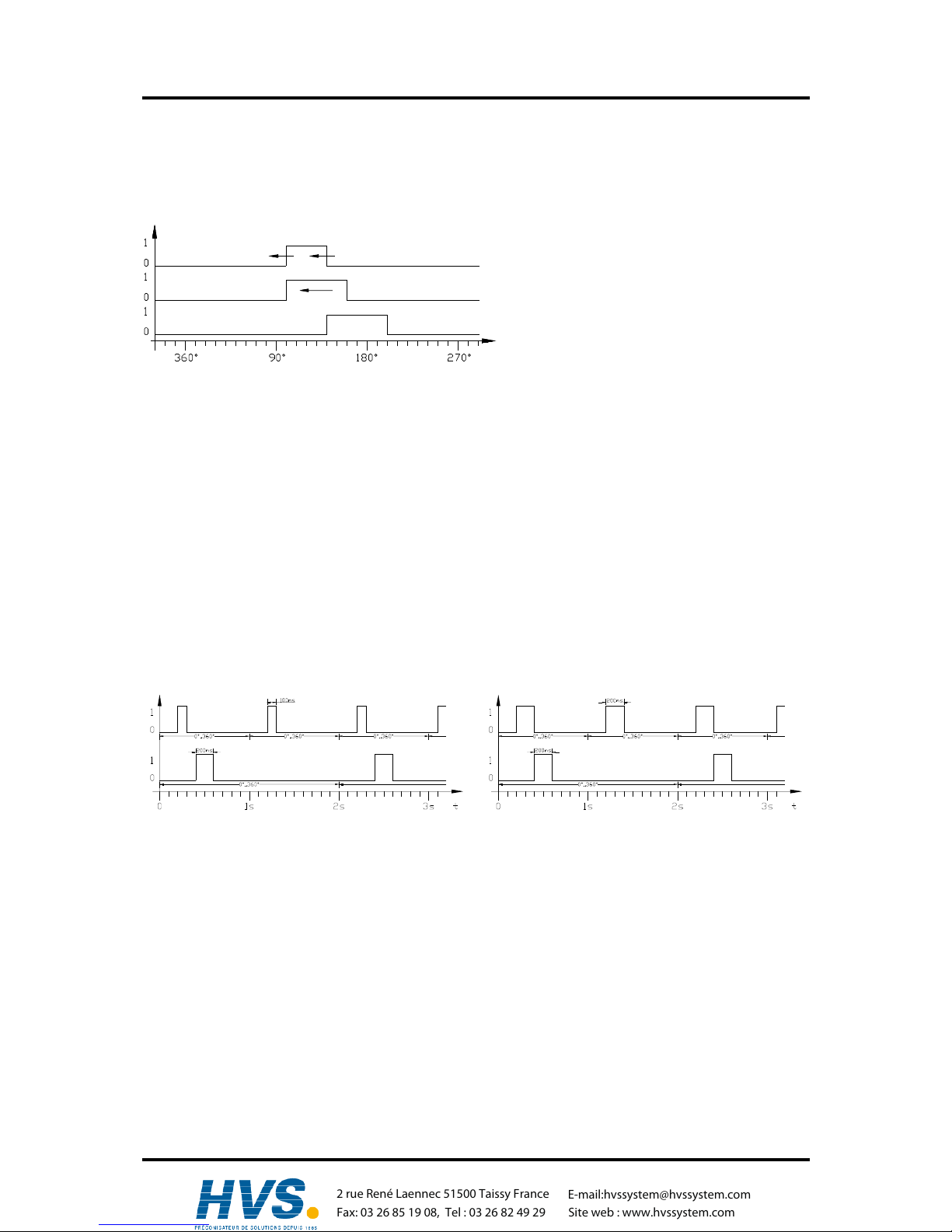

2.1.3. Separate delay time for Speed Compensation of switch-ON and switch-OFF points

For CamCon devices of Software from 3/2002 Speed Compensation is now available for separate

switch-ON and switch-OFF points. This is necessary since some valves need longer to switch OFF

than to switch ON.

Switching attitude of a cam programs from 140° to 200° with 60 min-1.

Cam with 111ms Speed compensation for switch on point and 166ms

compensation for switch off point.

Cam with 111ms Speed compensation.

Cam without Speed compensation.

For the calculation of both delay times the same formuli are used as for a normal compensation. See

Chapter "2.1.1. Measuring delay time for Speed Compensation" on page 11 for entering delay time see

Chapter "7.3.3. Programming the delay time" on page 33.

Attention: If the switch-off-point of a Cam overtakes the switch on point at rising speed, the result will

be an non-defined signal.

2.2. Time - Cam

With nomale cam becomes with increasing plant speed switch-on time ever more briefly. If controlling

a glueing-station, the result would be an insufficent ammount of spreaded glue.

A Time - cam however has with each plant speed a firm temporal length, so that excactly the same

ammount of glue could be spread at changing speeds. The switch-on point of the Cam on a normal as

well as on a Time-Cam is appointed by a position-dependent Position value and a delay-time/speed

compensation.

Normal - cam Time - cam

60min-1

30min-1

60min-1

30min-1

For CamCon devices of software releases after 3/2002 Time Cam is also available for devices without

PLC - Logic - Module.

For entering a Time - Cam see Chapter "7.3.4. Programing Time-Cams" on page 34.

,Version from: Aug. 04 Page: 13

2 rue René Laennec 51500 Taissy France

Fax: 03 26 85 19 08, Tel : 03 26 82 49 29

E-mail:hvssystem@hvssystem.com

Site web : www.hvssystem.com

Digitronic Digital Cam Switch Unit

Automationsanlagen GmbH CamCon DC50/51

3. Installation

The unit is inserted into a cutout for front plate installation (see chapter "3.1. Dimensions" on page 14).

Connect the groundig pins on the back of the encasement as well as the cable cover to a grounding

point of the switchboard door in the shortest possible way. All cable connections must be done in a

cold state! The connection cables, e.g. for the measuring system or the serial interface, must be wired

with covers, and the covers have to grounded on both ends. Analog signals must also be wired with

covers, and the covers have to be grounded on one end.

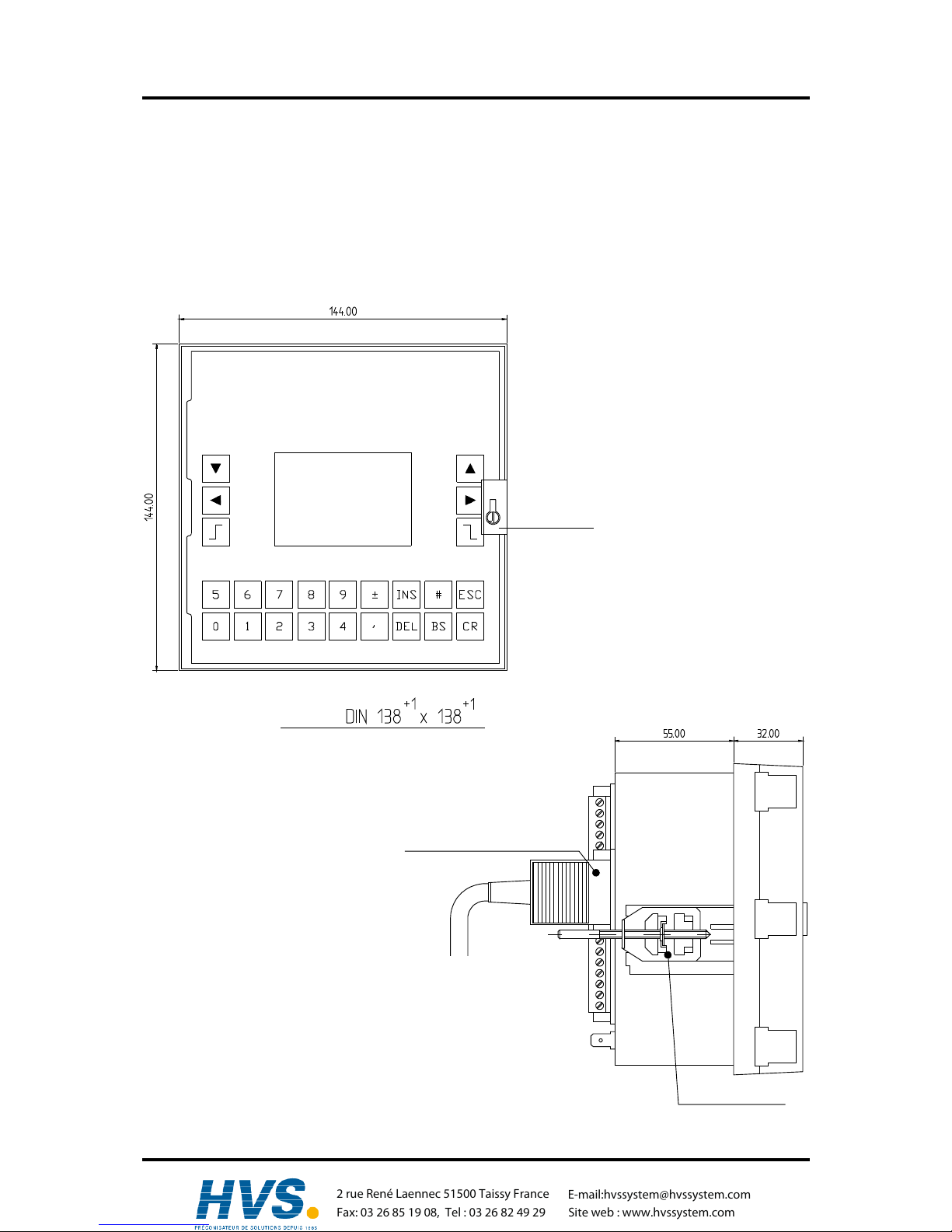

3.1. Dimensions

DIGITRONIC

cutout as per

front door

can be locked

CamCon

plug input for encoder

attachment clip

Fig.: Drawing to aid the installation of CamCon

,Version from: Aug. 04 Page: 14

2 rue René Laennec 51500 Taissy France

Fax: 03 26 85 19 08, Tel : 03 26 82 49 29

E-mail:hvssystem@hvssystem.com

Site web : www.hvssystem.com

Digitronic Digital Cam Switch Unit

Automationsanlagen GmbH CamCon DC50/51

4. Electrical connections

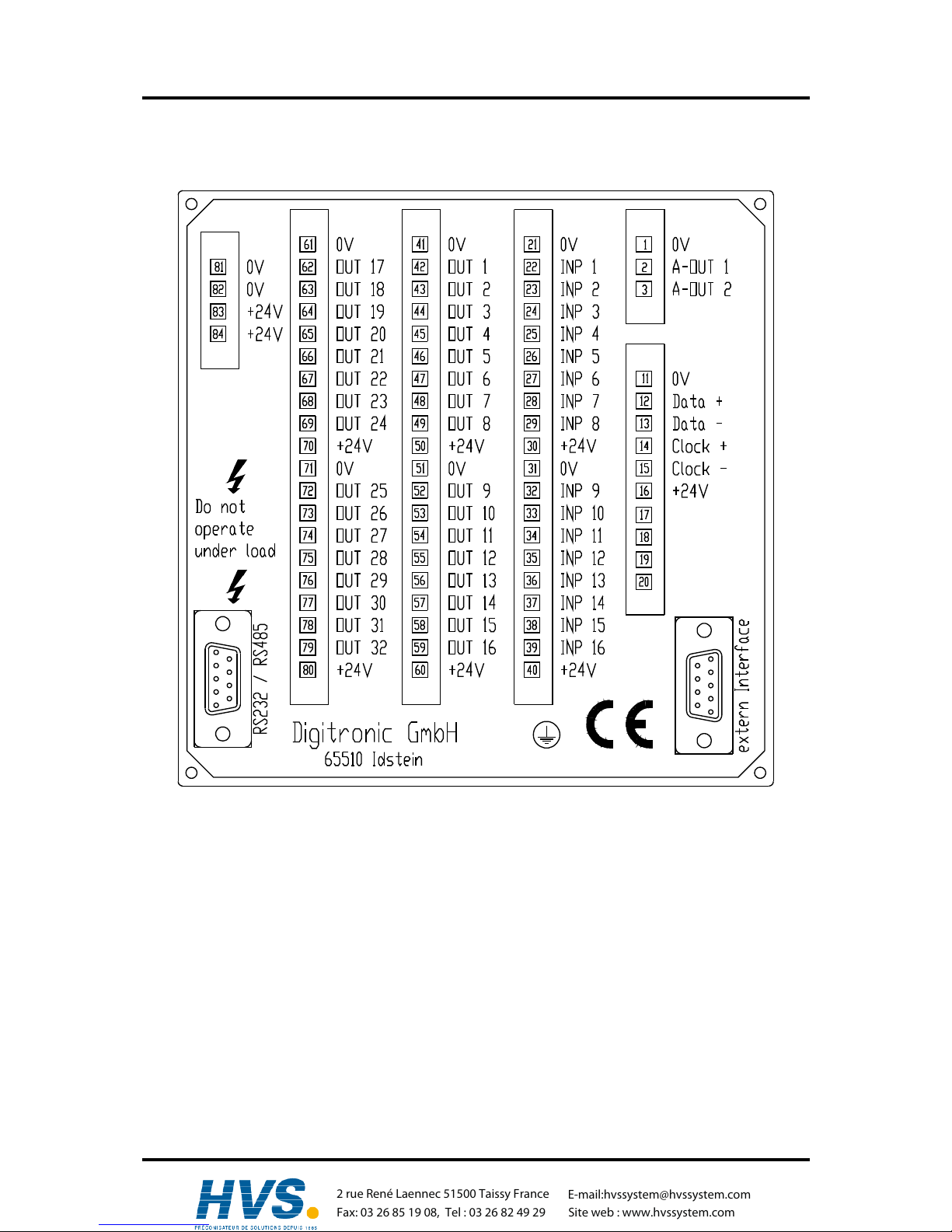

4.1. Pin allocation of the CamCon

CamCon

Fig.: Backview of the CamCon with pin allocation

4.1.1. Pin allocation of the analog output

Pin 1: 0V signal mass for the analog output

Pin 2: Analog output 1

Pin 3: Analog output 2

4.1.2. Pin allocation of the SSI measuring system

Pin 11: 0V voltage supply for the SSI measuring system (encoder)

Pin 12: Data A or +

Pin 13: Data B or Pin 14: Clock A or +

Pin 15: Clock B or Pin 16: +24V DC voltage supply for the SSI measuring system (encoder)

,Version from: Aug. 04 Page: 15

2 rue René Laennec 51500 Taissy France

Fax: 03 26 85 19 08, Tel : 03 26 82 49 29

E-mail:hvssystem@hvssystem.com

Site web : www.hvssystem.com

Digitronic Digital Cam Switch Unit

Automationsanlagen GmbH CamCon DC50/51

4.1.3. Pin allocation of the incremental measuring system

Pin 11: 0V voltage supply for theincremental measuring system (encoder)

Pin 12: A Imp. (+)

Pin 13: A Imp. (-)

Pin 14: B Imp. (+)

Pin 15: B Imp. (-)

Pin 16: +24V DC voltage supply for the incremental measuring system (encoder)

Pin 17: C1 Imp. (+)

Pin 18: C1 Imp. (-)

Pin 19: C2 Imp. (+)

Pin 20: C2 Imp. (-)

4.1.4. Pin allocation of the inputs

Pin 21: 0V signal mass for inputs

Pin 22: Input 1

Pin 23: Input 2

Pin 24: Input 3

Pin 25: Input 4

Pin 26: Input 5

Pin 27: Input 6

Pin 28: Input 7

Pin 29: Input 8

Pin 30: +24V DC voltage supply for the outputs 1 to 16

Pin 31: 0V signal mass for inputs

Pin 32: Input 9

Pin 33: Input 10

Pin 34: Input 11

Pin 35: Input 12

Pin 36: Input 13

Pin 37: Input 14

Pin 38: Input 15

Pin 39: Input 16

Pin 40: +24V DC voltage supply for the outputs 1 to 16

4.1.5. Pin allocation of the outputs

Pin 41: 0V voltage supply for the outputs 1 to 16

Pin 42: Output 1

Pin 43: Output 2

Pin 44: Output 3

Pin 45: Output 4

Pin 46: Output 5

Pin 47: Output 6

Pin 48: Output 7

Pin 49: Output 8

Pin 50: +24V DC voltage supply for the outputs 1 to 16

Pin 51: 0V voltage supply for the outputs 1 to 16

Pin 52: Output 9

Pin 53: Output 10

Pin 54: Output 11

Pin 55: Output 12

Pin 56: Output 13

Pin 57: Output 14

Pin 58: Output 15

Pin 59: Output 16

Pin 60: +24V DC voltage supply for outputs 1 to 16

,Version from: Aug. 04 Page: 16

2 rue René Laennec 51500 Taissy France

Fax: 03 26 85 19 08, Tel : 03 26 82 49 29

E-mail:hvssystem@hvssystem.com

Site web : www.hvssystem.com

Digitronic Digital Cam Switch Unit

Automationsanlagen GmbH CamCon DC50/51

Pin 61: 0V voltage supply for the outputs 17 to 32

Pin 62: Output 17

Pin 63: Output 18

Pin 64: Output 19

Pin 65: Output 20

Pin 66: Output 21

Pin 67: Output 22

Pin 68: Output 23

Pin 69: Output 24

Pin 70: +24V DC voltage supply for the outputs 17 to 32

Pin 71: 0V voltage supply for the outputs 17 to 32

Pin 72: Output 25

Pin 73: Output 26

Pin 74: Output 27

Pin 75: Output 28

Pin 76: Output 29

Pin 77: Output 30

Pin 78: Output 31

Pin 79: Output 32

Pin 80: +24V DC voltage supply for the outputs 17 to 32

4.1.6. Pin allocation of the voltage supply

Pin 81: 0V voltage supply for the CPU

Pin 82: 0V voltage supply for the CPU

Pin 83: +24V DC voltage supply for the CPU

Pin 84: +24V DC voltage supply for the CPU

Attention : Pins 30, 40, 50 and 60 are connected to each other.

Pins 1, 11, 21, 31, 41, 51, 61, 71, 81 and 82 are connected to each other.

4.1.7. Pin allocation of the serial interface

When you order the CamCon you can choose the type of the serial interfaec between RS232 or

RS485. Wiring and connector allocation are different for each type of the serial interface.

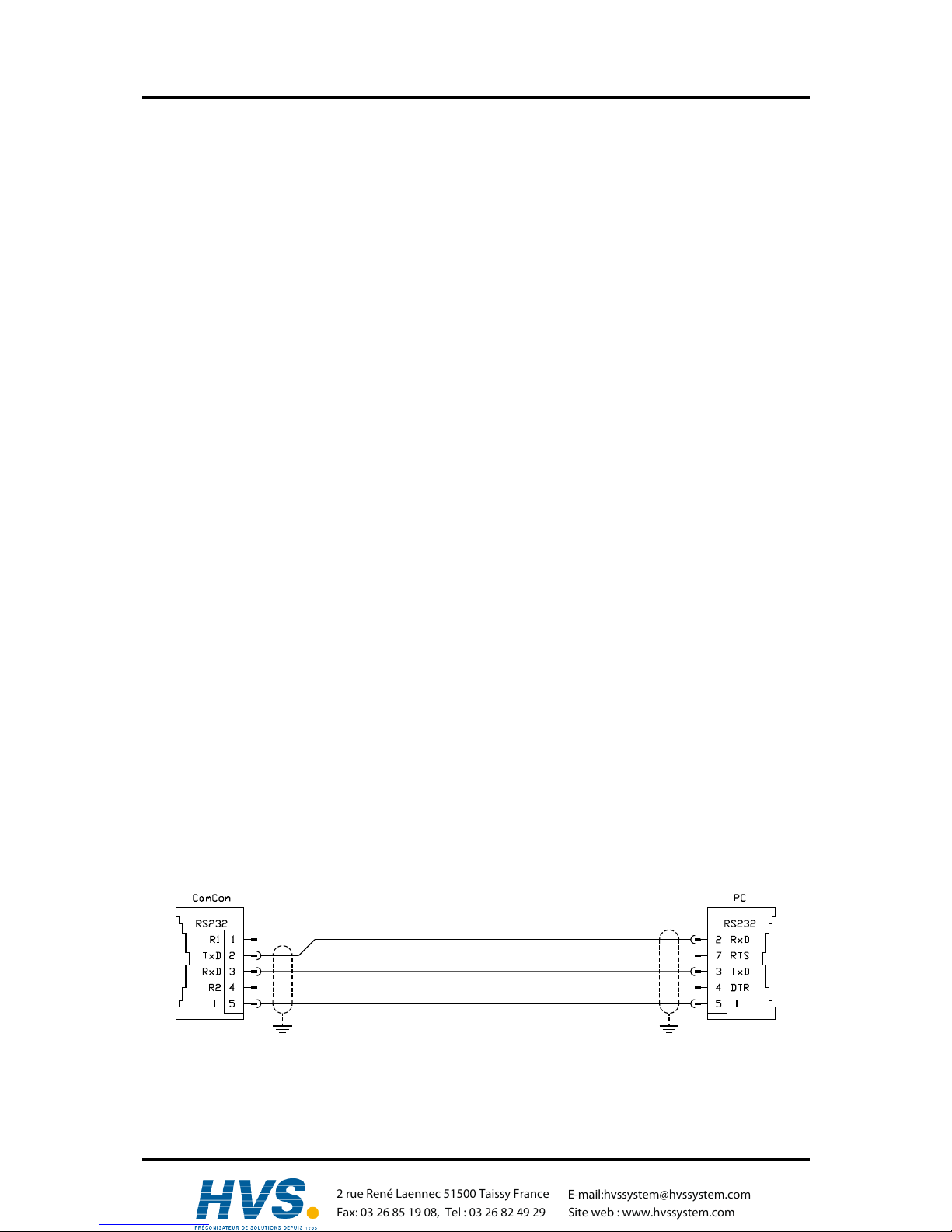

4.1.7.1. Pin allocation of the serial RS232 interface

DSUB 9 pinboard: RS232 Interface for PC attachment (max. 15m cable length)

Pin 1,4 Do not connect !

Pin 2 TXD

Pin 3 RXD

Pin 5 Mass

Pin 6-9 N.C.

,Version from: Aug. 04 Page: 17

2 rue René Laennec 51500 Taissy France

Fax: 03 26 85 19 08, Tel : 03 26 82 49 29

E-mail:hvssystem@hvssystem.com

Site web : www.hvssystem.com

Digitronic Digital Cam Switch Unit

Automationsanlagen GmbH CamCon DC50/51

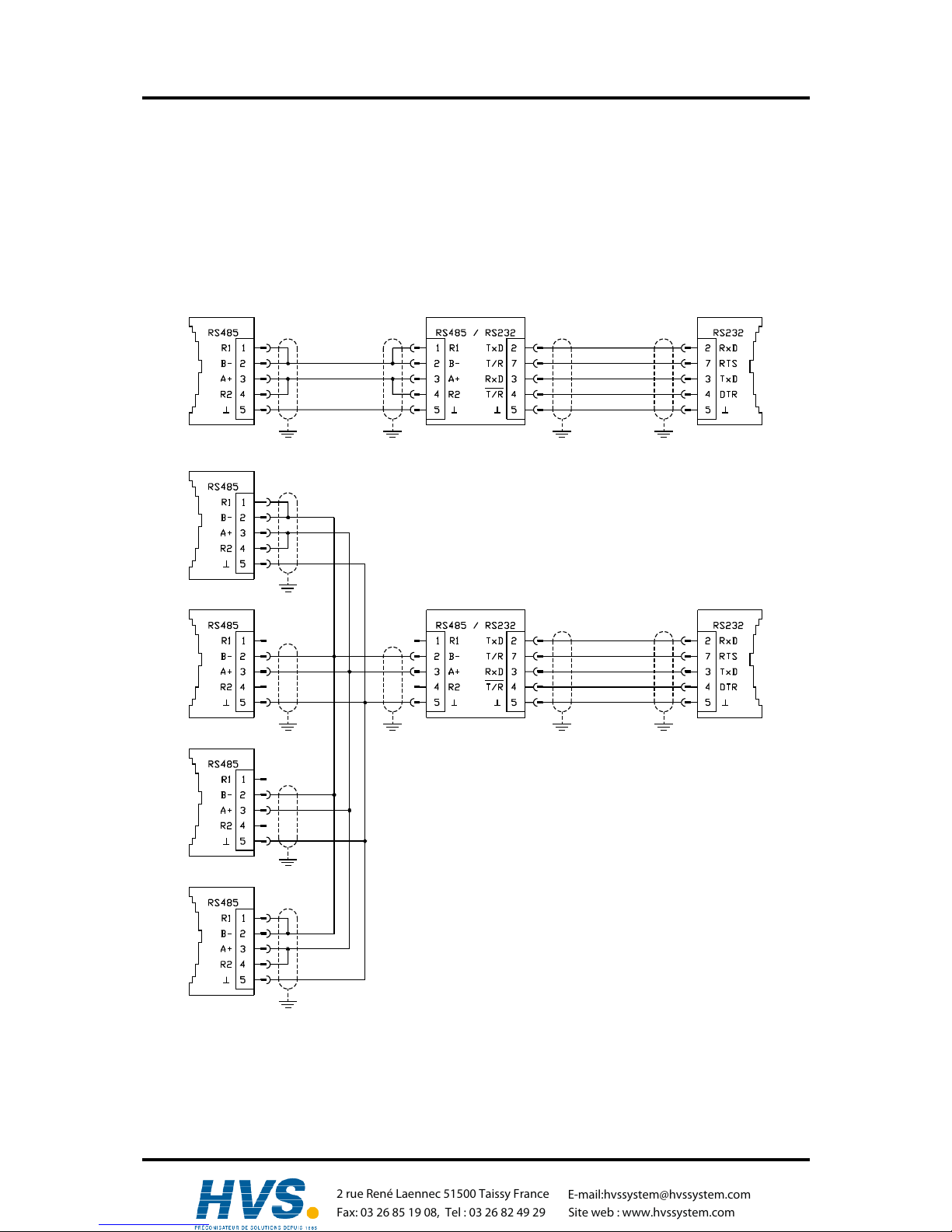

4.1.7.2. Pin allocation of the serial RS485 interface

DSUB 9 pinboard: RS485 Interface for PC attachment or for the networking of many devices

(max. 1000m cable length).

Pin 1,4 Closedown resistors for RS485

Pin 2 B (-)

Pin 3 A (+)

Pin 5 GND

Pin 6-9 N.C.

Interface converterCamCon

CamCon

CamCon

CamCon

CamCon

Interface converter PC

PC

Note: The pins 1 and 2, as well as the pins 3 and 4 have to be bridged in the

attachment plug of the first and last device in a networked chain at the RS485

Interface, to close the data and reception line perfectly. Corresponding

closedown resistors are attached to the system at pin 1 and 4.

,Version from: Aug. 04 Page: 18

2 rue René Laennec 51500 Taissy France

Fax: 03 26 85 19 08, Tel : 03 26 82 49 29

E-mail:hvssystem@hvssystem.com

Site web : www.hvssystem.com

Digitronic Digital Cam Switch Unit

Automationsanlagen GmbH CamCon DC50/51

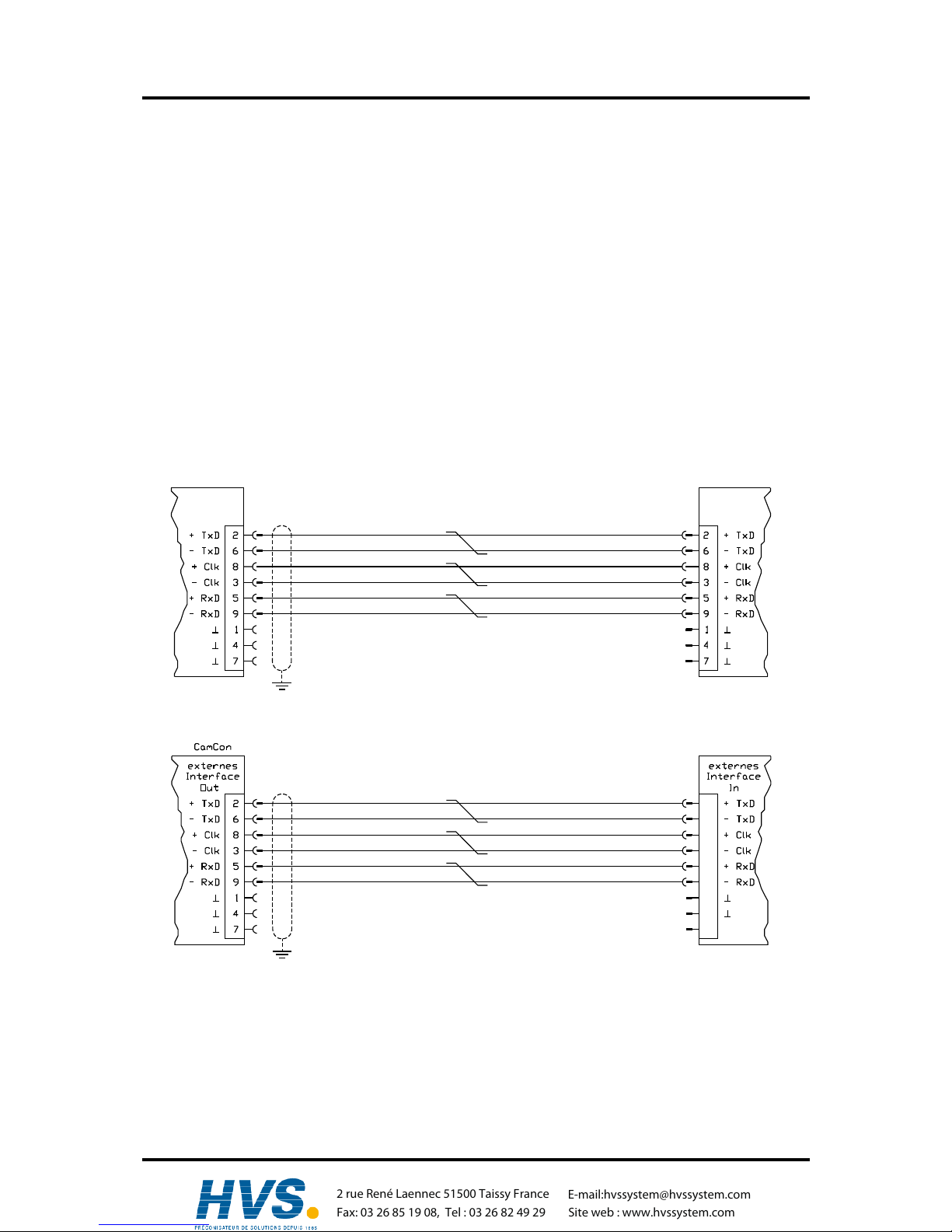

4.1.8. Pin allocation of the external interface

If you ordered the external interface along with the CamCon, you have the possibility to extend your

CamCon by a CamCon DC91/IO, DC92/I or DC16/IO. The extensions are clipped on to a rail in the

clipboard. They are connected with a cable with 6 poles, type "KK91/IO-XX" with the 9pole D-Sub male

plug "external Inter in" at the CamCon module (maximum cable length is 300m). The data transfer is

done through optical couplers, so that the connection remains potential free.

For the CamCon DC16/IO a DSUB cable with flatwire adapter can be ordered, order No. "KK50-16/IOXX" (Note: XX refers to the cables length in meters).

DSUB 9 socket: link of external in - and output modules e.g. DC91

Pin 1,4,7 GND

Pin 2 TxD +

Pin 6 TxD Pin 8 CLK +

Pin 3 CLK Pin 5 RxD +

Pin 9 RxD -

Connection cable CamCon DC91/IO

external

interface

OUT

CamCon CamCon DC 91

IN

external

interface

Connection cable CamCon DC91/IO

CamCon DC16/IO

2

3

5

6

8

9

4

7

1,10

Stift

,Version from: Aug. 04 Page: 19

2 rue René Laennec 51500 Taissy France

Fax: 03 26 85 19 08, Tel : 03 26 82 49 29

E-mail:hvssystem@hvssystem.com

Site web : www.hvssystem.com

Digitronic Digital Cam Switch Unit

Automationsanlagen GmbH CamCon DC50/51

4.2. The measuring system

The measuring system is designed to record the necessary actual values (positions) for the Cam

Switch Unit. Many different measuring system can be linked with the CamCon.

See chapter "4.1. Pin allocation" on page 15 and for adjustment of the measuring system to the

software of the CamCons please also consult Chapter "7.4.1. Measuring system" on page 45.

Note: Please also consult the instruction manual for your measuring system.

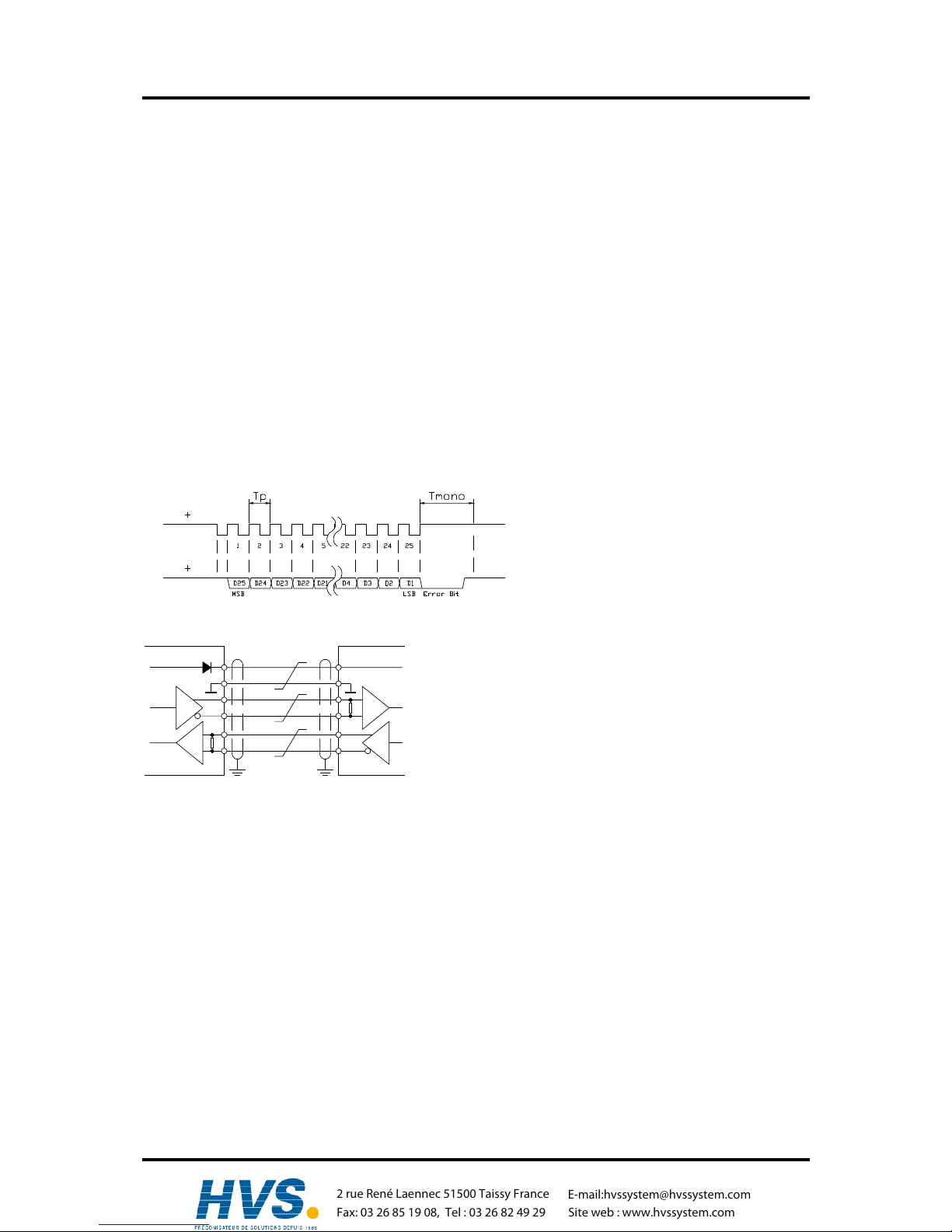

4.2.1. SSI Measuring system input

Systems with a synchronous series interface = SSI. The SSI interface is widely used in industry for

absolute single and multi-turn angle encoder. At this interface the CamCon supplies the measuring

system with 24Volt. For the purpose of data reading the CamCon sends a stroke signal (clock) with

RS422 level to the measuring system. This answers synchronously with the data output of the position

in the grey code. The frequency of the pulse signal depends on the length of the cable to the

measuring system and can be set in the CamCon.

Note: The data record corresponds to the Stegmann SSI Standard!

Clock

Data

Tp = clock impulse

max. 1MHz to min. 66kHz.

(adjustable through the cable

length)

Tmono = Mono flop time 25µs

CamCon

Encoder

+24V DC

0V

Clock +

Clock Data +

Data -

Please note:

Use a screened dual strand connection cable. Do not place

the cable parallel to a high voltage cable. If possible, lay the

screening down on both sides.

4.2.2. Parallel measuring system input

Systems with parallel 24V data leads, e.g. single turn - angle encoder or via a transformer with parallel

data output.

In this instance a gray or binary encoded value is attached to the free inputs of the CamCon and this

will be read as actual value. Since the connection cable are quite expensive and the EMV compatibility is limited, this interface type is rarely used in industry nowadays.

Note: Since the outputs are partly switched parallel to the inputs in CamCon DC16, DC115,

DC300 and CamCon 1756-DICAM, these must not be programmed under any

circumstances and this reduces the number of available outputs.

Warning: Reading a binary encoded value into the CamCon is only permitted after consultation with

the Service department of the company Digitronic.

,Version from: Aug. 04 Page: 20

2 rue René Laennec 51500 Taissy France

Fax: 03 26 85 19 08, Tel : 03 26 82 49 29

E-mail:hvssystem@hvssystem.com

Site web : www.hvssystem.com

Digitronic Digital Cam Switch Unit

Automationsanlagen GmbH CamCon DC50/51

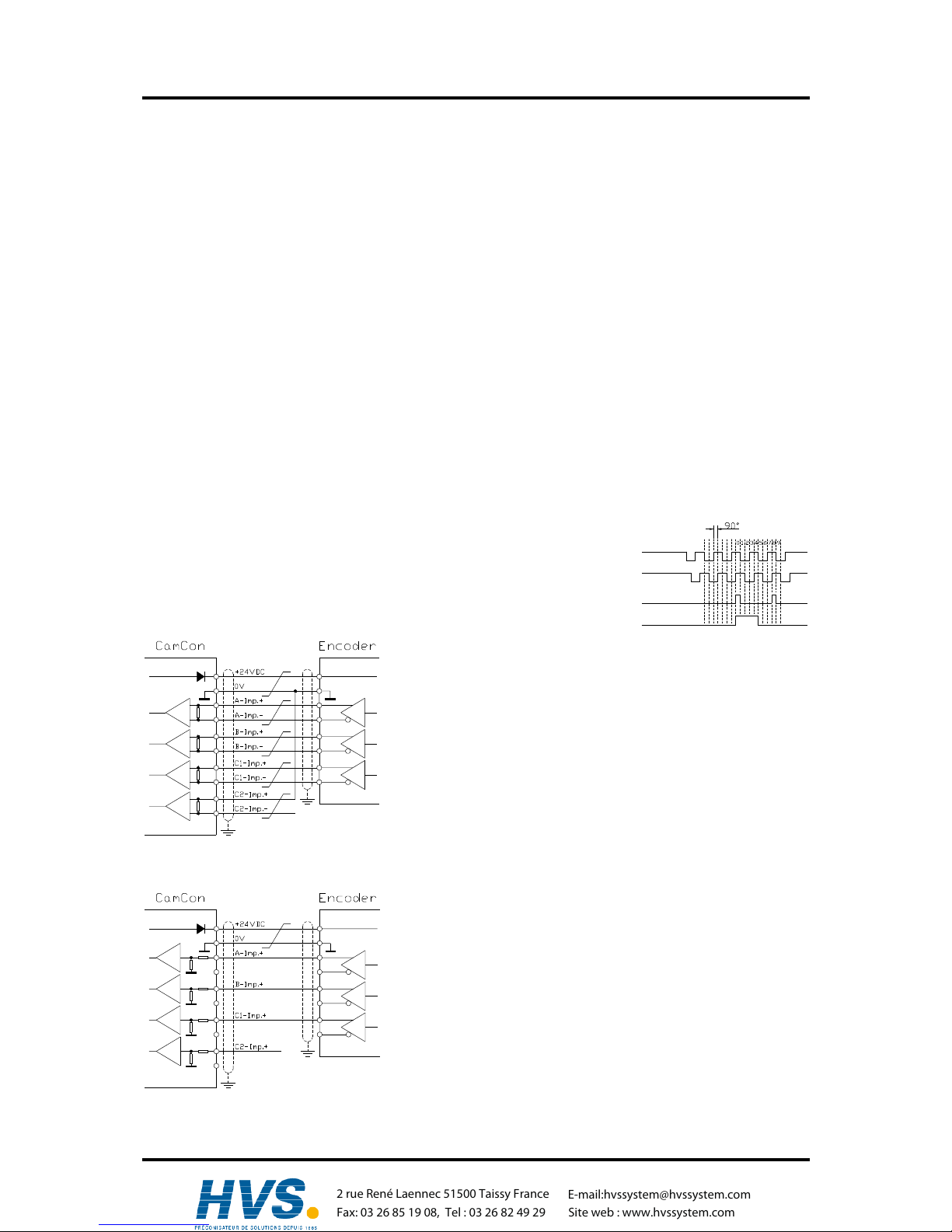

4.2.3. Incremental measuring system input

Systems with 90° phase shift signals such as turning angle encoders, glass measuring rods or flow

measuring devices.

At the present time incremental measuring inputs for the CamCon DC16/50/51/115/300 and DC1756

are available as an option. We differentiate between three signal levels:

- 24V PNP Signal inputs (Order number Option: J)

- 5V RS422 Signal inputs (Order number Option: I)

- Hiperface Signal inputs (Order number Option: H)

Note: For the CamCon DC16 and DC300 only the version with 24V PNP signal is available. For

the CamCon 1756-DICAM the version with 24V PNP signal and Hiperface Signal is

available. If a different signal level is necessary, this can be converted externally with the

INCDRV converter.

In all cases the CamCon supplies the measuring system with 24Volt/DC or in CamCon DC115

optionally with 5 or 24Volt/DC. As a counting signal the measuring system gives out two impulses at a

time shifted by 90° (A + B). These are counted in the CamCon and are evaluated as position values. In

addition, for each rotation another zero impulse (Clear 1) is given out for synchronisation purposes. In

order to stop synchronisation (zero setting) of the counter, a further clear signal (Clear 2) is available

on the CamCon.

The signals Clear 1 and Clear 2 are to standard AND linked and can be

changed in their function with the software. See Chapter "7.4.1.6.3.

Incremental - measuring system" on page 49

Clear 1

Clear 2

B Imp.

A Imp.

4.2.3.1. Incremental measuring system input with 5V RS422 level

If the 5V RS422 system is used, all signals of the measuring

system input must be active, otherwise the input conditions are

undefined. If no signal is available for one of the two Clear

inputs, then this input must be switched to mass on the (+)

signal in order to switch the input to low. The inputs of the

measuring system can be activated with a maximum voltage of

5V. Please pay attention to the power supply of the angle

encoder which can be 5Volt as well as 24Volt. Only the CamCon

DC115 can at present provide a voltage of 5Volt for the supply of

the angle encoder.

4.2.3.2. Incremental measuring system input with 24V PNP level

If a 24V PNP signal is used for data input, then only the (+)

signals of the inputs may be connected. The (-) signals must

stay inactive in this case. The connection of such a measuring

system requires a change of the interal switch system and must

therefore be stated on the order form.

Note: At the incremental input of the CamCon DC16,

DC300 and DC1756 no (-) signals are available.

,Version from: Aug. 04 Page: 21

2 rue René Laennec 51500 Taissy France

Fax: 03 26 85 19 08, Tel : 03 26 82 49 29

E-mail:hvssystem@hvssystem.com

Site web : www.hvssystem.com

Digitronic Digital Cam Switch Unit

Automationsanlagen GmbH CamCon DC50/51

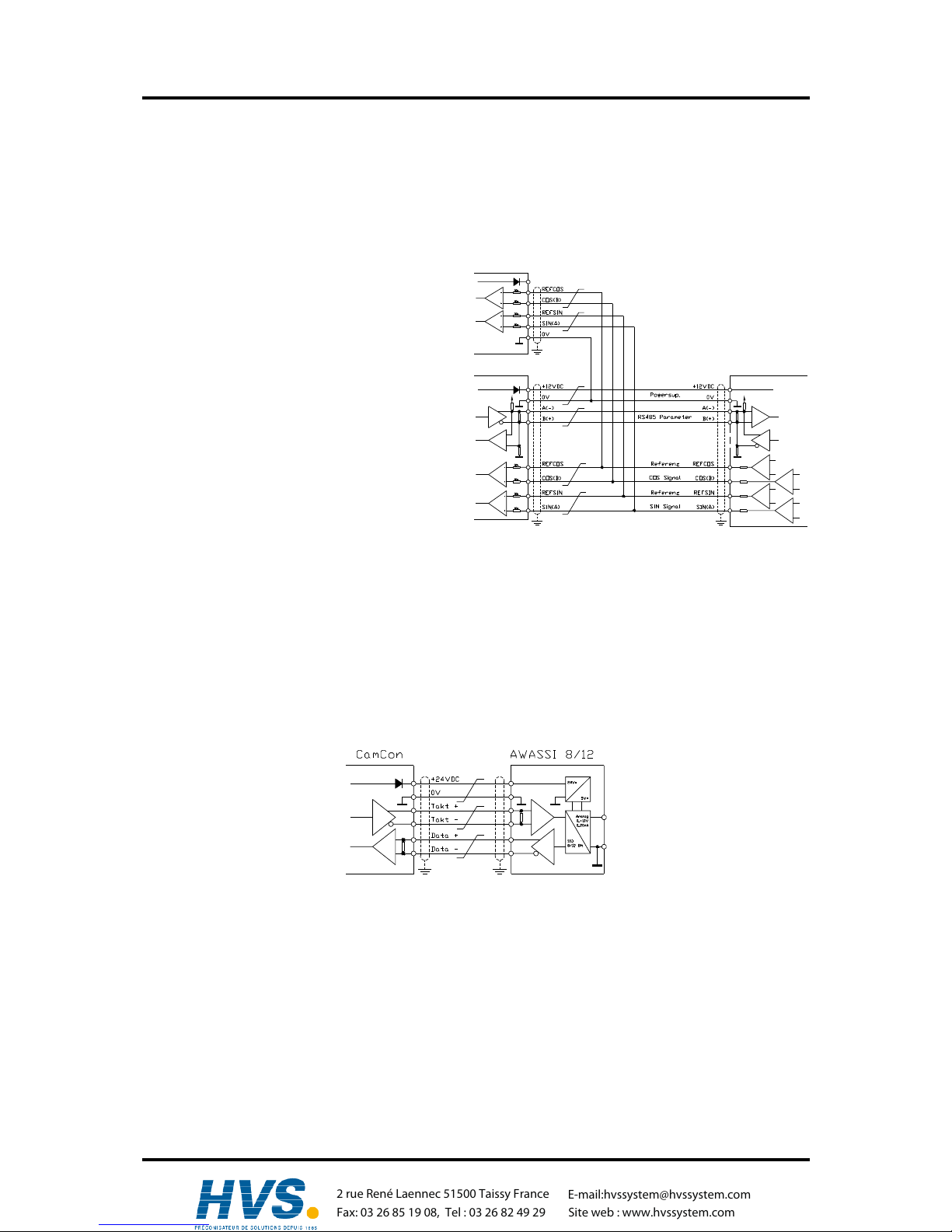

4.2.3.3. Incremental Hiperface measuring system input with SINCOS level

The Hiperface measuring system is a feedback system for servo-motors of the company Stegmann.

It is a mixed system and consists of an absolute measuring system and an incremental measuring

system. The absolute measuring system sends its values via RS485 interface to the counter. The

incremental measuring system works with analog sine - and cosine interface with a resolution of 512 or

1024 impulses per revolution.

The CamCon with the Hiperface signal input

(option: H) reads only the incremental sine - and

cosine signal. The signals are converted and

counted in the CamCon into normal incremental

measuring system signals.

controller SINCOS

CamCon

Since the absolute measuring system of the

Hiperface interface is not used and no clear signals are available, the CamCon must be

initialized after each restart.

This must be done by the preset input of the

CamCon. See for this to chapter 7.4.2.4. Actual

position preset on page 56.

Note: The maximum number of

revolutions per minute is 3000 min

-1

with 512 Impulse per revolution.

The maximum number of revolutions per minute is 1500 min

-1

with 1024 Impulse per

revolution.

4.2.4. Analog measuring system input

These are systems which receive their actual value through conversion of current or voltage signal,

such as temperature or pressure sensors.

For the recording of analog signals the analog to SSI conversion module AWA/SSI in 8 and 12 bit

resolution is available for the CamCon. This module is connected to the SSI of the CamCon and is

switched ON through the selection of the analog measuring system in the menu ”Measuring system”.

,Version from: Aug. 04 Page: 22

2 rue René Laennec 51500 Taissy France

Fax: 03 26 85 19 08, Tel : 03 26 82 49 29

E-mail:hvssystem@hvssystem.com

Site web : www.hvssystem.com

Digitronic Digital Cam Switch Unit

Automationsanlagen GmbH CamCon DC50/51

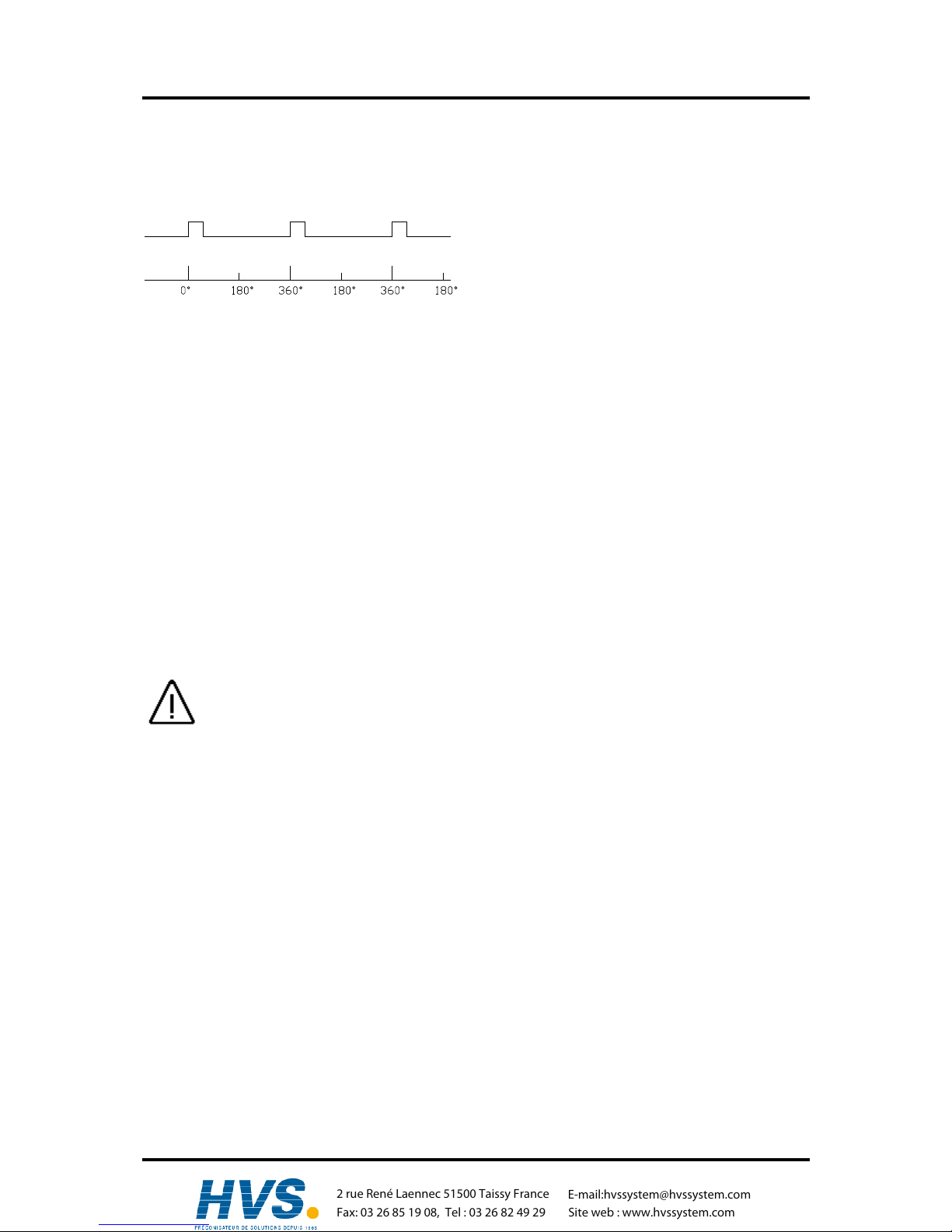

4.2.5. PLL measuring system input

Systems with Phase - Lock - Loop data recording. In these systems the actual value is found through

interpolation of initiator impulses. This measuring system is applied to machines with constant speed

and with a cyclic pulse.

= Initiator impulse

= Found actual value

The Initiator can be connected to any free input of the CamCon.

Note: For CamCon DC115 a special input is available on the 25pol. SUB-D plug.

See also chapter "7.4.1.6.5. PLL measuring system" on page 51.

4.2.6. Timer as a measuring system

Systems which are controlled by elapsed time. In this case the CamCon makes a time available with a

time basis of minimum 1 ms as actual value. Through laying on of input signals it is possible to

influence the elapsed time. This measuring system is applied to machines with a fixed time scanner as

a control feature, e.g. washing machines.

See also chapter "7.4.1.6.6. Timer way simulation" on page 51.

4.2.7. RS232 as a measuring system

Systems, receiving their actual position through the RS232 interface, e.g. for a junction of a Stegmann

POMUX linear scale to a RS232 data output.

Warning The activation of this measuring system blocks the RS232 interface for

programming. This measuring system is only reasonable with a CamCon

DC50/51.

,Version from: Aug. 04 Page: 23

2 rue René Laennec 51500 Taissy France

Fax: 03 26 85 19 08, Tel : 03 26 82 49 29

E-mail:hvssystem@hvssystem.com

Site web : www.hvssystem.com

Digitronic Digital Cam Switch Unit

Automationsanlagen GmbH CamCon DC50/51

4.3. The outputs

The CamCon has, concerning each upgrading level, up to 32 outputs and with extreme extension (e.g.

CamCon DC16/IO, DAC16 or DC91/IO) up to 200 short circuit-proof outputs. They deliver 24Volt high

active signals and are not potentially free towards the CPU. The outputs 1 to 16, as well as 17 to 32 of

the unit have to be supplied with 24Volt , because the power supply of the outputs has been separated

in order to achieve a better power distribution.

4.3.1. The 40mA outputs (only CamCon device with aluminium back wall)

If all outputs are activated, not more than 40 mA permanent current in the complete temperature range

should be extracted per output, else the unit will deactivate with an error message. If a higher starting

performance is required, one has to know that the outputs are combined in 4 groups, each group

consisting of 8 outputs. Within each group, 480 mA permanent current at a surrounding temperature of

50°C, and at a surrounding temperature of 25°C even 700mA permanent current is available. This

permanent current can be dirtributed freely within a group, as long as the single output current of 300

mA is not overshot (see chapter "7.4.6.2. Setting the outputs" on page 63).

4.3.2. The 500mA outputs

At a surrounding temperature of 25°C even 500mA permanent current is available for each output. If

your outputs are overloaded or short-circuited the unit will deactivate with an "out-err" message

(see chapter "7.4.6.2. Setting the outputs" on page 63).

Attention: For inductive loads the inductances have to be tripped with a freewheeling

diode.

4.4. The inputs

The CamCon has, concerning each upgrading level, up to 16 inputs and with extreme extension up to

200 inputs. These inputs work with high externally active 24Volt signals and are not potentially free

towards the CPU.

The input wiring:

The input resistance

is about 5.7 KOhm.

The inputs of the CamCon have not been covered with functions by the factory. The user would have

to do this himself in the process of setting system data of the CamCon depending on his requirements.

See chapter "7.4.6. System upgrading" on page 63, chapter "7.4.1. Measuring system" on page 45,

chapter "7.4.6.7. Setting the external program selection" on page 64 and chapter "7.4.6.4. Setting the

keyboard lock" on page 63.

4.5. Precautionary measures for welding work

Attention: For the duration of welding operations carried out at the machine, the

connecting wires concerning the data exchange from the measuring system to

the CamCon and the power supply as well as the grounding connections and

inputs and outputs have to be separated from the CamCon.

,Version from: Aug. 04 Page: 24

2 rue René Laennec 51500 Taissy France

Fax: 03 26 85 19 08, Tel : 03 26 82 49 29

E-mail:hvssystem@hvssystem.com

Site web : www.hvssystem.com

Digitronic Digital Cam Switch Unit

Automationsanlagen GmbH CamCon DC50/51

5. Outline of the operator terminal

5.1. Frontview CamCon

5.2. The liquid crystal display (LCD)

The display unit of the CamCon 50 contains a graphical LCD with 128x64 picture elements. For the

visual user prompting, all menus concerning the programming of the unit, state and error messages of

the outputs, as well as the current position and speed, are represented here. The contrast can be

adjusted to the current surrounding temperature with the keyboard.

5.3. Contrast setting

You can increase or decrease the contrast of the LCD in this display mode with the and keys.

Keeping these keys pressed continues the change of contrast.

5.4. The keyboard

The plastic foil keyboard of the CamCon is non-sensitive towards dirt and is solvent resisting. The keys

have a noticable action point for the tactile feedback, as well as an acoustic input acknowledgement

(see chapter 7.4.6.4.7.4.6.4. Setting the keyboard lock on page 63).

,Version from: Aug. 04 Page: 25

2 rue René Laennec 51500 Taissy France

Fax: 03 26 85 19 08, Tel : 03 26 82 49 29

E-mail:hvssystem@hvssystem.com

Site web : www.hvssystem.com

Digitronic Digital Cam Switch Unit

Automationsanlagen GmbH CamCon DC50/51

5.5. Outline of key functions

cursor down

cursor up

cursor to the left, shifting cams

cursor to the right, shifting cams

choose cam activation point, character selection during text input,

(or PC 'PageUp' key)

choose cam deactivation point, character selection during text input

(or PC 'PageDown' key)

input of cams, special measuring systems, character during text input

place holder for display formats, reset during error messages, special functions

Escape: leaving the current menu, returning to the next higher menu

deletion of cams, outputs, programs and single characters during text input

deletion of single characters during text input

confirm input and save data

changes the algebraic sign during data input

comma

... numeric keys for data input

5.6. Menu selection

You can select a desired menu by pressing the corresponding numeric key or by moving the cursor

(the black beam) on the menu name with keys and and pressing the key.

5.7. Selection of a menu point

The input in the single menus issubdevided into menu points. These are active (or selected), if the

display is inverted. The selection of these menu points is made with keys , , and and a

confirmation of your choice with the key. You can always cancel an input by pressing the key. If

you pressed a wrong key, the unit shows a hint of the keys you can use in this menu and their

functions.

,Version from: Aug. 04 Page: 26

2 rue René Laennec 51500 Taissy France

Fax: 03 26 85 19 08, Tel : 03 26 82 49 29

E-mail:hvssystem@hvssystem.com

Site web : www.hvssystem.com

Digitronic Digital Cam Switch Unit

Automationsanlagen GmbH CamCon DC50/51

5.8. Text input

With menu points, in which texts have to be implemented, the and keys function together with

the and keys like a coordinate control. You select the desired position for the first character,

using the and keys. Then you can choose the character with the and keys, by going up

and down through the alphabet or the ASCII characters. If you move the cursor to the right with the

key, character entered prior to this will appear in the new position of the cursor, simplifying making

repeated inputs of the same character.

If you have made an error you can go back to the wrong character to correct it, using the key or the

key. This will cause the other characters to become erased. To abandon the input press the

key.

Attention: The software for the text input at the CamCon has changed since EPROMS of 1/97. The

selection of desired characters is now realized with keys and . With keys and

you can now position the cursor anywhere in the previously entered text. You can

overwrite characters, insert characters by pressing the key or delete characters with

keys or .

Note: The text input is also possible directly via PC.

,Version from: Aug. 04 Page: 27

2 rue René Laennec 51500 Taissy France

Fax: 03 26 85 19 08, Tel : 03 26 82 49 29

E-mail:hvssystem@hvssystem.com

Site web : www.hvssystem.com

Loading...

Loading...