Digitrex 3-3000-00a-F User Manual

Mark III Directional Drilling

Locating System

Operator’s Manual

DCI Headquarters

nd

19625 62

Kent, Washington 98032 USA

Tel 425 251 0559

Fax 253 395 2800

E-mail DCI@digital-control.com

www.digitrak.com

Ave. S., Suite B-103

/ 800 288 3610

DCI Europe

Kurmainzer Strasse 56

D-97836 Bischbrunn

Germany

Tel +49(0) 9394 990 990

Fax +49(0) 9394 990 999

DCI.Europe@digital-control.com

DIGITAL

ONTROL

C

I

NCORPORATED

DCI India

SCO # 259, Sector 44-C

Chandigarh (UT) 160 047

Punjab, India

Tel +91(0) 172 464 0444

Fax +91(0) 172 464 0999

DCI.India@digital-control.com

DCI China

USA Excalibre

2803 Bldg C, 70 Cao Bao Rd

Shanghai P.R.C. 200233

Tel +86(0) 21 6432 5186

Fax +86(0) 21 6432 5187

DCI.China@digital-control.com

DCI Australia

2/9 Frinton Street

Southport, Queensland 4215

Australia

Tel +61(0) 7 5531 4283

Fax +61(0) 7 5531 2617

DCI.Australia@digital-control.com

DIGITAL CONTROL INCORPORATED

3-3000-00-F

© 1999-2006 by Digital Control Incorporated. All rights reserved. July 2006 Edition.

Trademarks

®

The DCI logo, CableLink®, DataLog®, DigiTrak®, Eclipse®, iGPS®, Intuitive®, look-ahead®, SST®, target-in-

the-box

LT™, TeleLock™, and TensiTrak™ are trademarks of Digital Control Incorporated.

®

, and Target Steering® are U.S. registered trademarks and DucTrak™, FasTrak™, SuperCell™,

Patents

The DigiTrak® Locating System is covered by one or more of the following U.S. Patents: 5,155,442;

5,337,002; 5,444,382; 5,633,589; 5,698,981; 5,726,359; 5,764,062; 5,767,678; 5,878,824; 5,926,025;

5,933,008; 5,990,682; 6,002,258; 6,008,651; 6,014,026; 6,035,951; 6,057,687; 6,066,955; 6,160,401;

6,232,780; 6,396,275; 6,400,159; 6,525,538; 6,559,646; 6,593,745; 6,677,768; 6,693,429; 6,756,783;

6,756,784; 6,838,882; 6,924,645; 6,954,073; 7,015,697; 7,049,820; 7,061,244. Sale of a DigiTrak

Receiver does not convey a license under any patents covering the DigiTrak

drill housing. Other patents pending.

®

Transmitter or underground

®

Important Notice

All statements, technical information, and recommendations related to the products of Digital Control

Incorporated (DCI) are based on information believed to be reliable, but the accuracy or completeness

thereof is not warranted. Before utilizing any DCI product, the user should determine the suitability of the

product for its intended use. All statements herein refer to DCI products as delivered by DCI and do not

apply to any user customizations not authorized by DCI nor to any third-party products. Nothing herein

shall constitute any warranty by DCI nor will anything herein be deemed to modify the terms of DCI’s

existing limited warranty applicable to all DCI products.

FCC Compliance Statement

This equipment has been tested and found to comply with the limits for a Class B digital device, pursuant

to Part 15 of the Rules of the Federal Communications Commission. These limits are designed to provide

reasonable protection against harmful interference in a residential installation. This equipment generates,

uses, and can radiate radio frequency energy and, if not installed and used in accordance with the

instructions, may cause harmful interference to radio communications. However, there is no guarantee

that interference will not occur in a particular installation. If this equipment does cause harmful interference to radio or television reception, which can be determined by turning the equipment off and on, the

user is encouraged to try to correct the interference by one or more of the following measures:

¾ Reorient or relocate the DigiTrak Receiver.

¾ Increase the separation between the problematic equipment and the DigiTrak Receiver.

¾ Connect the equipment into an outlet on a different circuit.

¾ Consult the dealer for help.

Changes or modifications to the DCI equipment not expressly approved and carried out by DCI will void

the user’s limited warranty and the FCC’s authorization to operate the equipment.

ii DigiTrak® Mark III Operator’s Manual

®

DIGITAL CONTROL INCORPORATED

Table of Contents

SAFETY PRECAUTIONS AND WARNINGS..................................................................................vi

INTRODUCTION..............................................................................................................................1

Basic DigiTrak Equipment...................................................................................................1

Basic DigiTrak Operation.....................................................................................................2

Technical Support................................................................................................................3

RECEIVER .......................................................................................................................................5

Display Window Icons .........................................................................................................6

On/Off..................................................................................................................................7

Receiving the Transmitter’s Signals....................................................................................8

Clicking vs. Holding the Trigger ..........................................................................................8

Changing the Receiver’s Channel Setting...........................................................................9

Changing the Depth Measurement Units (English vs. Metric) ..........................................10

Battery Status Display for Receiver and Transmitter ........................................................10

Warning Tones for Transmitter Overheat..........................................................................11

Ultrasonic Function............................................................................................................11

Setting the Ultrasonic Distance or Height-Above-Ground Measurement....................12

Zeroing the Ultrasonics................................................................................................12

Calibrating the Receiver....................................................................................................13

1-Point Calibration Procedure .....................................................................................13

2-Point Calibration Procedure.....................................................................................14

Calibrating with Transmitter Underground at Shallow Depth (<10 ft).........................16

Using Depth Antenna Plumb Line to Mark Locate Points ................................................16

Finding Firmware Version..................................................................................................17

5.0 Series Firmware Functions..........................................................................................17

Predicted Depth Key Points........................................................................................17

Procedure for Observing the Predicted Depth............................................................18

Viewing the Transmitter’s Temperature and the Receiver’s Battery Status ..............18

Viewing the Receiver’s Battery Voltage......................................................................18

Off Feature..................................................................................................................18

Accessing the Receiver’s Running Time Meter..........................................................18

TRANSMITTER..............................................................................................................................19

How a Transmitter Works..................................................................................................19

Batteries.............................................................................................................................20

Temperature Display.........................................................................................................20

Battery Status Display.......................................................................................................20

Temperature Overheat......................................................................................................20

Sleep Mode (Automatic Shutoff)........................................................................................21

Verifying Proper Fit of Transmitter in Housing ..................................................................21

Locating the Transmitter....................................................................................................23

Sensitive-Pitch Transmitters..............................................................................................23

Transmitter as an Inclinometer..........................................................................................23

Serial Numbers..................................................................................................................24

Specifications.....................................................................................................................24

DigiTrak® Mark III Operator’s Manual iii

IGITAL CONTROL INCORPORATED

D

Table of Contents (Cont.)

REMOTE DISPLAY SYSTEM........................................................................................................25

On/Off and Setting the Channel........................................................................................26

Transmitter Temperature and Battery Status....................................................................26

Remote Steering................................................................................................................27

Finding Firmware Version..................................................................................................28

DataLog Capability............................................................................................................28

BATTERY CHARGER....................................................................................................................29

Charging a Battery.............................................................................................................30

Conditioning a Battery in the Charger...............................................................................31

Conditioning a Battery Manually........................................................................................31

Indicator Lights and Meanings...........................................................................................31

SYSTEM OPERATING INSTRUCTIONS ......................................................................................33

Start-up Procedure............................................................................................................33

Shutdown Procedure.........................................................................................................33

Moisture and Temperature Avoidance..............................................................................33

Optimal Operating Temperatures......................................................................................34

General Maintenance........................................................................................................34

SIGNAL INTERFERENCE .............................................................................................................35

Electrical Interference/Background Noise Check..............................................................35

Suggestions for Dealing with Interference.........................................................................36

OPERATIONAL TESTS .................................................................................................................37

Self-Test for Mark III Receivers.........................................................................................37

Receiver Balance Check...................................................................................................37

Receiver Gain Test............................................................................................................38

Transmitter Tests...............................................................................................................38

Transmitter Salt Water Range Test...................................................................................40

Transmitter Battery Tests..................................................................................................41

LOCATING .....................................................................................................................................43

Locate Points (FNLP & RNLP) and Locate Line (PLL) .....................................................43

Handling the Receiver.......................................................................................................44

Distance Between FNLP and RNLP Due to Depth, Pitch, and Topography.....................44

Using Plus/Minus Indicators for Locating..........................................................................45

Locating the Transmitter from the Drill..............................................................................45

Finding the Rear Negative Locate Point (RNLP)........................................................45

Finding the Positive Locate Line (PLL).......................................................................46

Finding the Front Negative Locate Point (FNLP)........................................................47

Finding the Transmitter and Its Depth.........................................................................48

Locating the Transmitter from the Front............................................................................49

Method for Confirming Position.........................................................................................49

Locating on the Fly............................................................................................................50

Off-Track Locating.............................................................................................................50

Splitting the Front and Rear Negative Locate Points ........................................................51

Four Turn Technique.........................................................................................................51

®

iv DigiTrak® Mark III Operator’s Manual

®

DIGITAL CONTROL INCORPORATED

Table of Contents (Cont.)

LOCATING (Cont.)

Calculating Depth Based on Distance Between FNLP & RNLP .......................................52

Running Off Pitch or Calculating Depth from Pitch ...........................................................53

Transmitter’s Signal Shape ...............................................................................................54

Antennae Configuration.....................................................................................................54

Signal Reception ...............................................................................................................54

Front and Rear Negative Locate Points............................................................................55

Positive Locate Line Above Transmitter............................................................................55

CABLE TRANSMITTER SYSTEM .................................................................................................57

Power Supply.....................................................................................................................59

Cable Transmitter..............................................................................................................60

Remote Display with Cable Transmitter Capability...........................................................61

Viewing the Cable System Battery Status ........................................................................62

Operation...........................................................................................................................62

TROUBLESHOOTING ...................................................................................................................63

GLOSSARY....................................................................................................................................69

APPENDIX......................................................................................................................................73

Depth Increase in Inches per 10-foot Rod.........................................................................74

Percent of Grade to Degree Conversions (1% Pitch Transmitters) ..................................75

Percent of Grade to Degree Conversions

(0.1% Pitch Transmitters or Sensitive Pitch)...............................................................76

Degree to Percent of Grade Conversions (1% Pitch Transmitters) ..................................77

Degree to Percent of Grade Conversions (0.1% Pitch Transmitters) ...............................78

Calculating Depth Based on Distance Between FNLP and RNLP....................................79

REMOTE TELEMETRY LICENSE

LIMITED WARRANTY

DigiTrak® Mark III Operator’s Manual v

IGITAL CONTROL INCORPORATED

D

Safety Precautions

and Warnings

Important Note: All operators must read and understand the following Safety

Precautions and Warnings before using the DigiTrak Locating System.

1 Serious injury and death can result if underground drilling equipment makes contact

with an underground utility such as a high-voltage electrical cable or a natural gas

line.

) Substantial property damage and liability can result if underground drilling equipment

makes contact with an underground utility such as a telephone, fiber-optic, water, or

sewer line.

®

) Work slowdown and cost overruns can occur if drilling operators do not use the

drilling or locating equipment correctly to obtain proper performance.

¾ Directional drilling operators MUST at all times:

•

Understand the safe and proper operation of drilling and locating equipment, including the

use of ground mats and proper grounding procedures.

•

Ensure that all underground utilities have been located, exposed, and marked accurately

prior to drilling.

•

Wear protective safety clothing such as dielectric boots, gloves, hard-hats, high-visibility

vests and safety glasses.

•

Locate and track the drill head accurately and correctly during drilling.

Comply with state and local governmental regulations (e.g., OSHA).

•

Follow all other safety procedures.

•

¾ The DigiTrak System cannot be used to locate utilities.

¾ Continued exposure to heat, due to frictional heating of the drill head from drilling in sand, gravel,

or rock without sufficient fluid flow around the Transmitter, can cause inaccurate depth to be

displayed and may permanently damage the Transmitter. For more information see “Temperature Overheat” in the Transmitter Section.

) The DigiTrak equipment is not explosion-proof and should never be used near

flammable or explosive substances.

vi DigiTrak® Mark III Operator’s Manual

®

DIGITAL CONTROL INCORPORATED

Safety Precautions

and Warnings (Continued)

¾ Prior to the start of each drilling run, test the DigiTrak System to confirm that it is operating

properly and check that it is providing accurate drill head location and heading information (see

Receiver Section) and accurate drill head depth, pitch, and roll information with the Transmitter

inside the drill head.

¾ During drilling, the depth will not be accurate unless:

•

The Receiver has been properly calibrated and the calibration has been checked for

accuracy so that the Receiver shows the correct depth.

•

The drill head has been located correctly and accurately and the Receiver is directly above

and parallel to the Transmitter in the tool underground or above the front negative locate

point (FNLP).

•

The Receiver height-above-ground or ultrasonic distance has been set correctly.

•

The Receiver is kept level.

¾ Interference can cause inaccuracies in the measurement of depth and loss of pitch, roll, or the

Transmitter’s location or heading. The locating operator should perform an electrical interference check prior to drilling (see “Electrical Interference/Background Noise Check” in the Signal

Interference Section).

•

Sources of interference include traffic signal loops, invisible dog fences, cable TV, power

lines, fiber-trace lines, metal structures, cathodic protection, transmission towers, and radio

frequencies.

•

Interference with the operation of the Remote Display may also occur from other sources

operating nearby on the same frequency, such as car rental agencies using their remote

check-in modules, other directional drilling locating equipment, etc.

¾ Carefully review this Operator’s Manual and the Di giTrak training video and be sure you always

operate the DigiTrak System properly to obtain accurate depth, pitch, roll, and locate points. If

you have any questions about the operation of the DigiTrak System, please call DCI’s Customer

Service Department at 425-251-0559 or 800-288-3610 betw een the hours of 6:00 a.m. and 6:00

p.m. Pacific Time, Monday through Friday, and we will assist you in any way possible.

REMEMBER

If you are having difficulty on the job, call DCI (425-251-0559 or

800-288-3610) and we’ll attempt to help you solve the problem.

DigiTrak® Mark III Operator’s Manual vii

IGITAL CONTROL INCORPORATED

D

Dear Customer:

We would like to thank you for choosing the DigiTrak Locating System. We are proud of

the equipment that we have been designing and building in Washington State since

1990. We believe strongly in providing a unique, high-quality product and standing

behind it with superior customer service and training.

We ask that you take the time to read this entire manual—especially the section on

safety. Also, please fill in the warranty registration and mail it in or fax it to us at 253395-2800. We will put you on the Digital Control mailing list and send you product

upgrade information and our monthly newsletter FasTrak™.

®

We also ask that you feel free to contact us at 425-251-0559 or 800-288-3610 if you are

experiencing any problems with the equipment or have any questions regarding its use.

Our Customer Service Department is available to provide assistance.

The DigiTrak equipment has evolved considerably since the first Mark I system in 1990.

Many of the improvements to the equipment have been made in response to our

customer’s needs and suggestions. This manual is written for all versions of the

equipment—from our first units to the most recent Mark III.

As this industry grows, we try to keep an eye on the future to develop equipment that

will make your job faster and easier. We encourage you to stay current by visiting our

web site on the Internet at

www.digitrak.com or calling us at 425-251-0559 or 800-288-

3610.

We welcome questions, comments, and ideas.

Digital Control Incorporated

Kent, Washington

July 2006

3-3000-00a-F

viii DigiTrak® Mark III Operator’s Manual

®

DIGITAL CONTROL INCORPORATED

Introduction

Receiver

Remote Display

Batt ery Cha rg e r

DigiTrak

The DigiTrak Locating System is used during horizontal directional drilling operations for locating and

tracking the transmitter within the tool. This manual provides detailed information about the DigiTrak

System and how to use it. The main system components are the Receiver, the Transmitter, the Remote

Display, and the Battery Charger, which are described below. The optional DataLog

used with the DigiTrak equipment to record and map your drilling data. These systems can be upgraded

for use with the Cable Transmitter System, providing locating capability up to 140 ft (42.7 m) from the

transmitter.

DataLog

Module

Cable

Transmitter

®

Directional Drilling Locating System

Transmitters

®

System can be

Basic DigiTrak Equipment

Receiver – The DigiTrak Receiver receives signals from the transmitter, processes the signal information,

and displays the transmitter’s status (roll, pitch, depth/distance, predicted depth, battery, and temperature). It may also be equipped to send this information to the remote display at the drill. The most

current model of DigiTrak Receivers is the Mark III. Older versions are the Mark II or Mark I. Only on the

Mark III Receiver is the version identified; older versions are not specified on the receiver. If you need to

know what version you have, you can contact DCI.

Transmitter – Also referred to as a sonde, beacon, or probe, the DigiTrak Transmitter is placed in the drill

tool/housing to send information to the receiver. The receiver displays depth/distance, signal strength,

pitch, roll, battery, and temperature status. Power is supplied using C-cell alkaline batteries, except for

DigiTrak® Mark III Operator’s Manual 1

®

Introduction

the optional cable transmitter, which requires a 12V to 28V DC system. For gravity sewer installations,

DCI manufactures a sensitive-pitch transmitter that measures pitch in 0.1% increments.

Remote Display – The DigiTrak Remote Display unit enables the drill operator to view the transmitter’s

pitch, roll, depth, predicted depth, and temperature, and can also be used for remote steering when walkover tracking is not possible.

Battery Charger – The DigiTrak Battery Charger is used to charge and condition the DigiTrak NiCad

battery packs. May be used with AC or DC sources and is easily adapted for worldwide usage.

DataLog System – The DigiTrak DataLog System is an optional “as-built” mapping system used for recording and plotting the borepath location.

Cable Transmitter System – The DigiTrak Cable Transmitter System is an optional add-on deep locating

system used for borepaths that are deeper than 50 ft (15 m), have lengths that require several days to

drill, do not allow walkover locating, and/or are in high-interference areas.

Basic DigiTrak Operation

Safety Precautions and Warnings – All DigiTrak operators must review the safety precautions and

warnings provided at the front of this manual before using the DigiTrak System.

Trigger Click / Hold – The trigger under the receiver’s handle can be either clicked (pushed in and im-

mediately released in less than ½ second) or held in. These two actions provide different results and are

used in different operating procedures. (see “Clicking vs. Holding the Trigger” in the Receiver Section)

Calibration – The DigiTrak System requires calibration prior to first time use and when any of the

following equipment is introduced: transmitter, receiver, or transmitter housing. Calibration is not required every day; however, DCI recommends you verify the calibration by checking the distance readings

(bottom window) with a tape measure prior to the beginning of each drilling run. (see “Calibrating the

Receiver” in the Receiver Section)

Ultrasonic Distance / Height-Above-Ground Measurement – The ultrasonic distance or height-aboveground measurement is the distance between the DigiTrak Receiver and the ground. This distance is

measured by the two ultrasonic transducers on the bottom of the receiver. (see “Ultrasonic Function” in

the Receiver Section)

Depth vs. Distance – When the trigger is not held in, the bottom window of the receiver displays the

distance from the receiver to the transmitter, unless the receiver is out of range of the transmitter. Once

the receiver is on and calibrated, it is not necessary to wait for depth readings because the receiver

continuously measures this distance. When the receiver is directly above the transmitter, the information

in the bottom window is referred to as the depth. When the receiver is not directly above the transmitter,

the number in the bottom window is referred to as the “slant” distance. (see “Clicking vs. Holding the

Trigger” in the Receiver Section)

Predicted Depth – If the trigger is held in, the bottom window will display the predicted depth, which will

only be accurate if the receiver is at the front negative locate point (FNLP). The predicted depth is

displayed in the bottom window as a flashing number with a solid squiggle. (see “Clicking vs. Holding the

Trigger” and “5.0 Series Firmware Functions” in the Receiver Section)

2 DigiTrak® Mark III Operator’s Manual

®

Introduction

Operational Tests – Before drilling and during operation it is necessary to check the following: proper

calibration, correct ultrasonic measurement, status of battery power, transmitter temperature, and signal

interference problems. (see Operational Tests Section)

Locating – The DigiTrak System is used to locate the transmitter underground; the trigger under the

receiver’s handle is held in during locating to show signal strength in the upper left window. The operator

systematically follows the signals received from the transmitter to establish the FNLP and the rear

negative locate point (RNLP), which then guide the operator to the transmitter’s location. (see Locating

Section)

Tracking – The DigiTrak Receiver automatically “tracks” and displays the transmitter’s orientation (pitch/

roll) and distance. It is not necessary to push the trigger or take any other steps to see this information.

Troubleshooting – The DigiTrak System is a sensitive instrument whose operation can be affected by

many different factors. We have listed many of the common problems and solutions in the Troubleshooting Section in this manual. If you cannot find the answers you need there, then please call DCI for

assistance. (see “Technical Support” below)

Technical Support

If you are having difficulties with your DigiTrak System and cannot find solutions by reviewing this manual

or the DigiTrak Training Video, then call DCI’s Customer Service Department at 425-251-0559 or 800288-3610. When you call, you should be prepared to provide the following information:

¾ Serial numbers on the DigiTrak Receiver, Transmitter, Remote Display, etc.

¾ Description of problem.

¾ How you have tried to solve the problem.

¾ Availability of other equipment to troubleshoot with.

You may also want to visit our web site (

DCI@digital-control.com.

www.digitrak.com) for more information, or e-mail us at

DigiTrak® Mark III Operator’s Manual 3

Introduction

Notes

®

3-3000-00b-F

4 DigiTrak® Mark III Operator’s Manual

®

DIGITAL CONTROL INCORPORATED

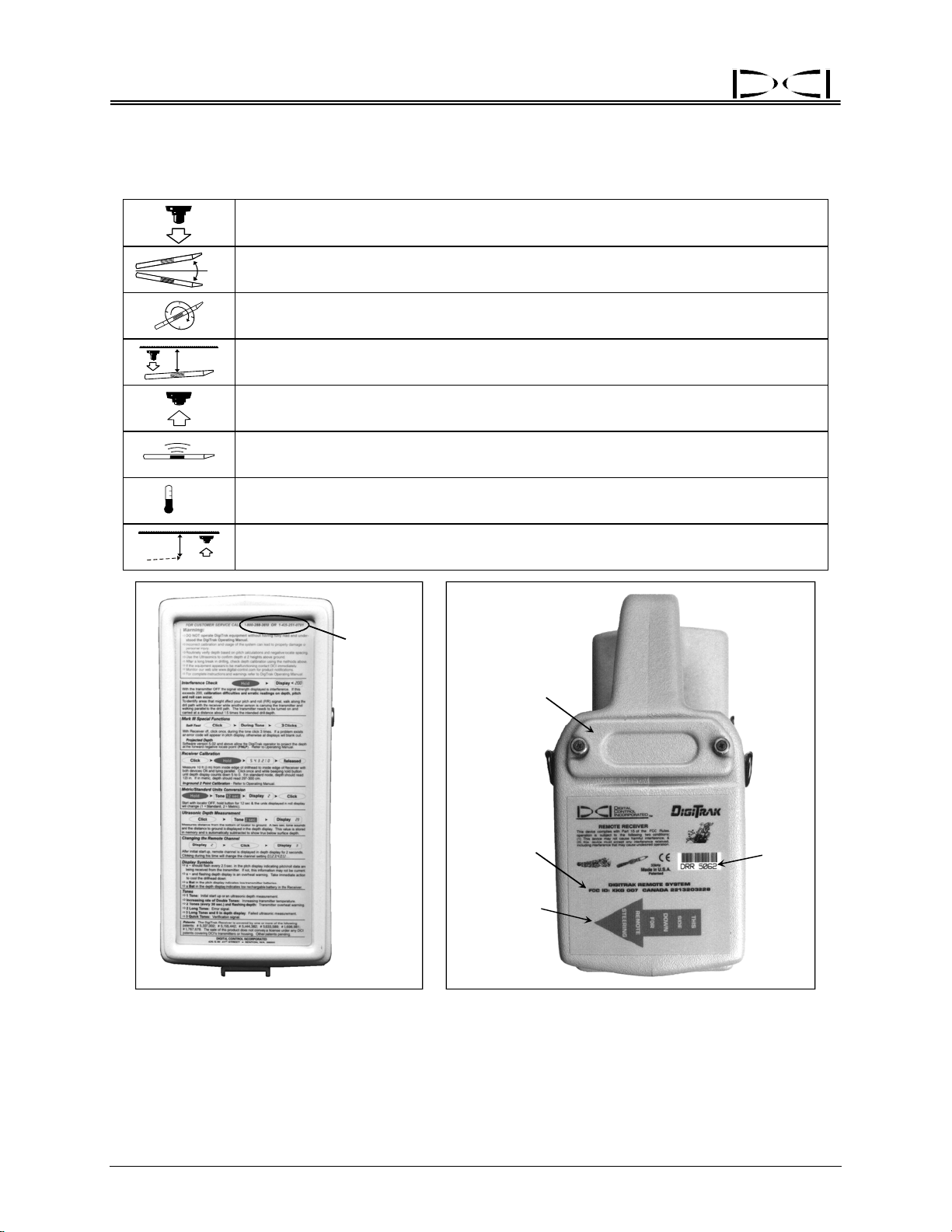

Receiver

Trigger

Temperature

& Distance

Conversion

Chart

Battery

Compartment

Back Panel

Pitch/Roll

Antenna Screws

Handle

Speaker

DigiTrak Receiver – Side View

The DigiTrak Receiver is a hand-held unit used for locating and tracking the transmitter. It receives and converts

signals from the transmitter and displays the following

information: pitch, roll, depth/distance, predicted depth,

temperature, and battery status. The display windows

are located on the top of the receiver.

Next to each DigiTrak display window are symbols or

icons to help you identify the functions of each window

(see table on next page). The icons below each window

represent the pitch, roll, and depth/distance of the

transmitter, which are displayed when the trigger is

released, as shown by the trigger down icon. When the

trigger is held in (trigger up), the top left window will

display the signal strength and the top right window will

display the temperature. Note the predicted depth icon

below the bottom window. When the trigger is held in

and the receiver is positioned at the front negative locate

point (FNLP), the predicted depth of the transmitter at

the FNLP is displayed in the bottom window. This

predicted depth number will flash quickly and the bottom

window will also show a solidly illuminated squiggle (“~”)

to further set it apart from the depth display.

NOTE: Should the trigger be held in at any location

other than the FNLP, the predicted depth shown will not

be valid.

Display

Windows

Depth/Locating

Antenna Screws

Front Panel

Trigger Up

Signal

Strength

Pitch

Depth

DigiTrak Receiver

~

I 5

I

I

Temperature

8

8

– Top View

Showing Display Window Icons

Trigger

Down

Roll

Predicted

Depth

DigiTrak® Mark III Operator’s Manual 5

Receiver

+%

- %

12

9

3

6

x

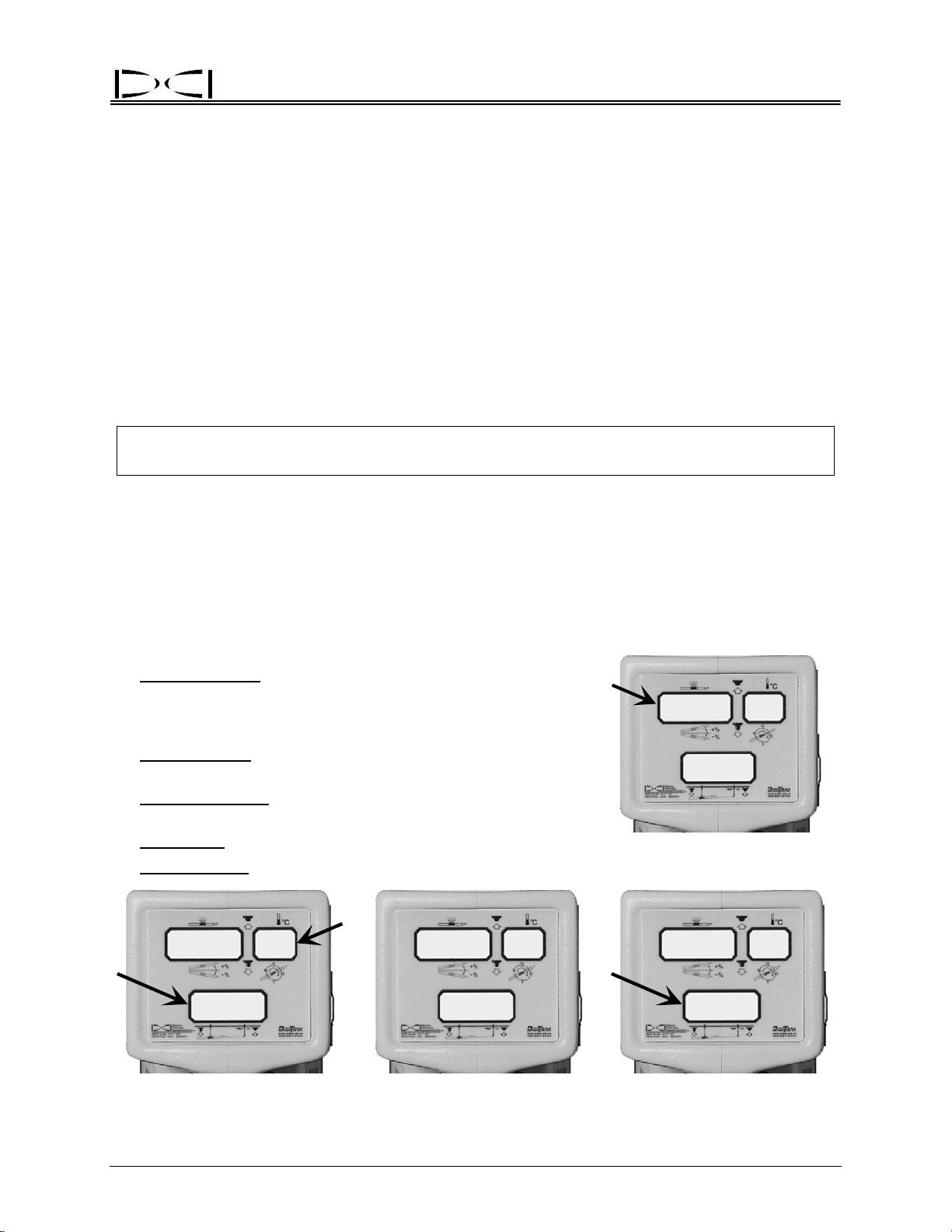

Display Window Icons

Trigger down – Trigger is released; display windows show pitch, roll, and

distance/depth of the transmitter.

Pitch – Numbers from 0% to ±100% show the inclination of the transmitter with

respect to horizontal; 100% represents a 45° angle (top left window, trigger down).

Roll – Numbers from 1 to 12 show the roll position (1 o’clock to 12 o’clock) of the

transmitter (top right window, trigger down).

Depth – The bottom window displays the depth or slant distance of the transmitter

with respect to the surface of the ground when the trigger is down.

Trigger up – Trigger is held in; display windows show signal strength, transmitter

temperature, and predicted depth when operator is at FNLP.

Signal strength – Numbers from 0 to 999 are displayed to show the strength of the

signal from the transmitter (top left window, trigger up).

®

o

C

x

FNLP

–

+/

Transmitter temperature – Temperature of the transmitter in degrees Celsius (top

right window, trigger up).

Predicted depth – The bottom window displays the predicted depth of the

transmitter at the FNLP when the trigger is up and the receiver is at the FNLP.

Customer

Service

Phone

Numbers:

800-288-3610

and

425-251-0559

Orange Arrow

Battery

Compartment

Telemetry

Information

Indicates

Remote

Capability

Serial

Number

DigiTrak Receiver – Front Panel DigiTrak Receiver – Back Side

Showing Condensed Instructions Showing Identification Information

The front panel of the receiver has condensed instructions for quick field reference and DCI’s phone

numbers for troubleshooting assistance. There is also a sticker under the handle for temperature and distance conversions. The serial number is located on the back panel of the unit below the battery compartment; it is preceded by the letters DR or DRR (for DigiTrak Receiver and DigiTrak Remote Receiver,

6 DigiTrak® Mark III Operator’s Manual

®

Receiver

respectively). If there is an orange arrow below the serial number, then it is a remote receiver, and it is

capable of sending a signal to a remote display unit at the drill. All receivers can be upgraded to remote

capability. The Mark III Receivers (serial numbers greater than 4676) are also equipped with a backlit

display for dim viewing conditions. All receivers can be upgraded to have a backlit display.

DigiTrak equipment is like a computer in that it requires firmware. The firmware determines how a unit

will convey information. Over time, the firmware is changed and upgraded to accommodate new features

and functions in the system. New versions of the firmware are available for upgrading older systems, but

the firmware must be upgraded by DCI. To determine the firmware version installed in your equipment,

see “Finding Firmware Version” in the Receiver and Remote Display Sections.

All Mark III Receivers have the capability of performing a self-test to determine if the unit appears to be

operating properly. DCI recommends that you complete the self-test every day before locating (see “SelfTest for Mark III Receivers” in the Operational Tests Section).

IMPORTANT: The receiver is designed to be held comfortably in such a manner that it levels itself.

Keeping the receiver level is critical for the most accurate locating.

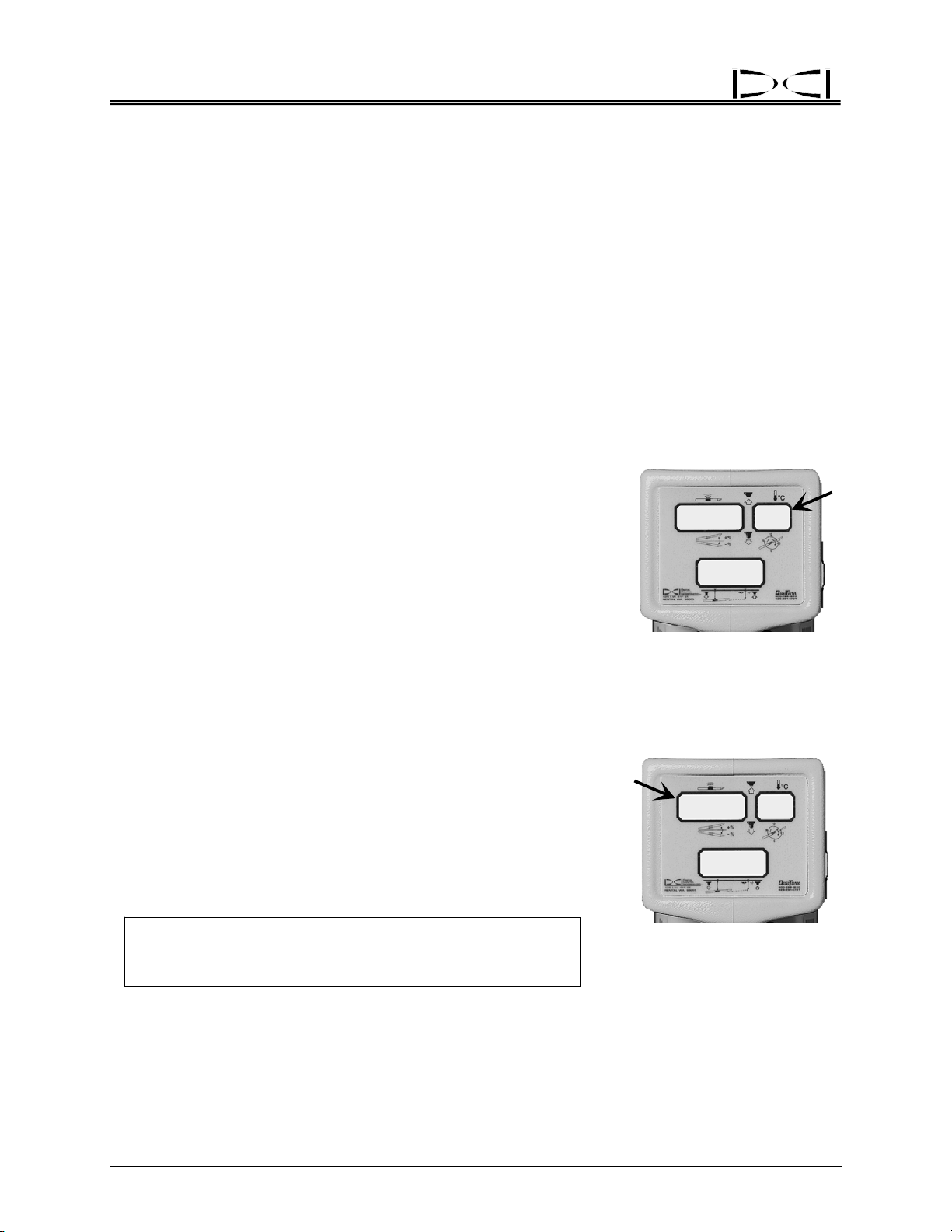

On/Off

To turn the receiver on:

1. Place a fully charged battery pack into the battery compartment, terminal end in first.

2. Click the trigger one time. The unit will sound a tone from the speaker adjacent to the trigger.

3. During the start-up sequence, the three display windows will quickly flash the following information, in

the order given here:

¾

Top Left Window: Firmware version in the receiver (version is

shown with no decimal point—e.g., 507 is version 5.07); older

units will display the firmware version only if the trigger is held in

at start-up.

¾

Bottom Window: Receiver’s battery voltage in tenths of a volt

(155 is 15.5V DC); older units will not display this information.

¾ Top Right Window: English or metric depth measurement units

(1 = inches, 2 = centimeters).

¾

All Windows: LCD test (888’s and all symbols will display).

¾

Bottom Window: Remote channel setting (0 = off, 1,2,3,4 = on).

~

507

I

BAT

+

888

88

507

Firmware Version

~

55

I

Depth Measurement Units

and Receiver Battery Voltage LCD Test Remote Channel Setting

DigiTrak® Mark III Operator’s Manual 7

BAT

–

888

I

2

®

Receiver

The depth measurement units (centimeters or inches) and remote channel setting can be changed only

during start-up (see “Changing Depth Measurement Units” and “Changing the Channel Setting” below).

After the start-up process, the windows will display pitch, roll, and distance if there is an active transmitter

within range (see Tracking Mode display below). If an active transmitter is not within range, 1999 will

appear in the bottom window and the top windows will be blank. If the bottom window is not displaying

1999 and there is no active transmitter within range, an unknown signal is present.

To turn the receiver off:

The receiver will automatically shut itself off if no signal is received for 15 minutes.

To turn off a receiver when a signal is present, click the trigger once and, during the tone, quickly click 4

times. All windows will blank out, signifying that the unit is off.

To turn off a receiver with pre-5.0 series firmware when a signal is present, the battery must be removed

manually.

(For more information on the 5.0 series firmware and operating/display differences, see “Clicking vs.

Holding the Trigger” and “5.0 Series Firmware Functions” in this section.)

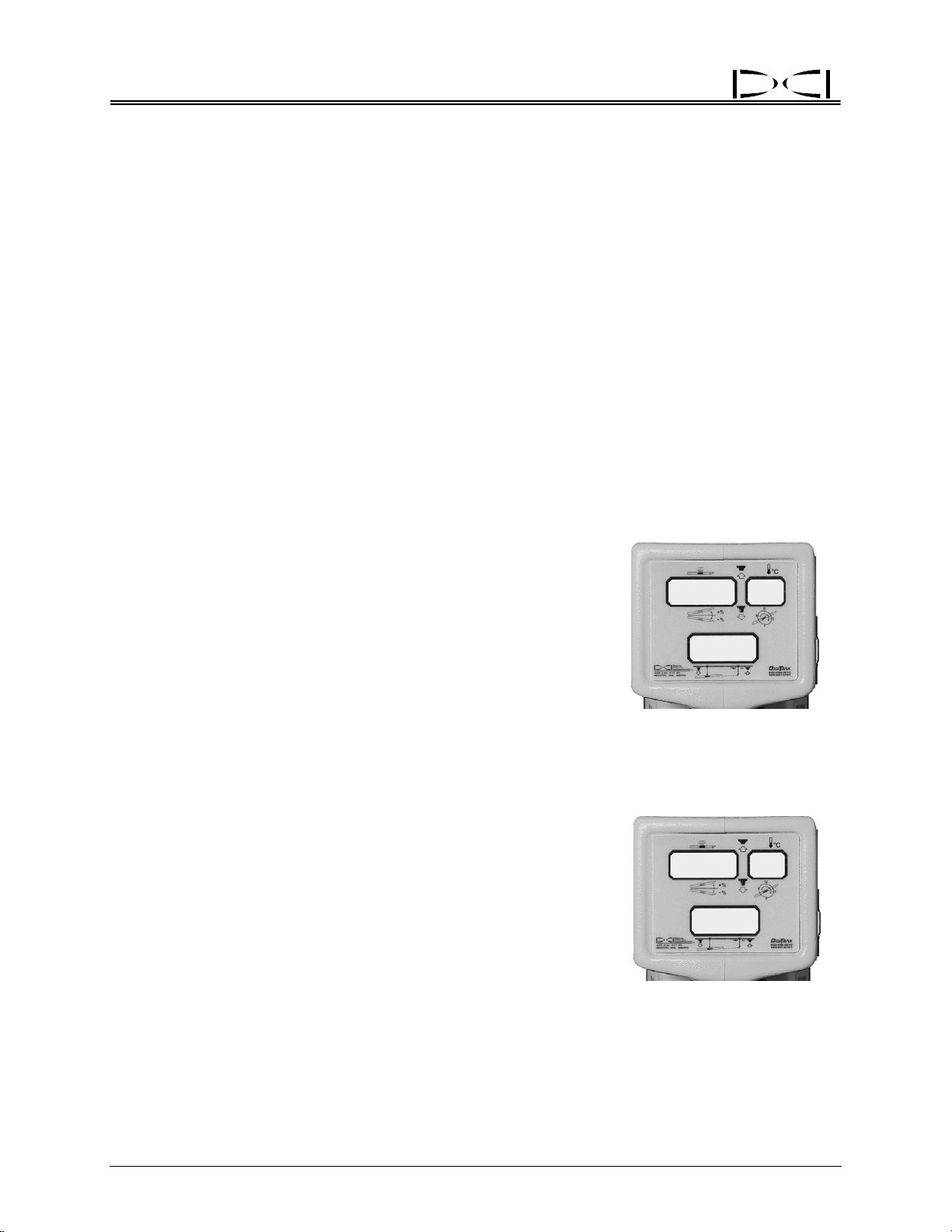

Receiving the Transmitter’s Signals

After charged batteries are loaded into the transmitter (positive end

first), the receiver enters “tracking” mode and will display pitch in the

top left window, roll (12 positions) in the top right window, and depth

(or distance) in the bottom window. With the DigiTrak System it is not

necessary to push any buttons to receive pitch, roll, or depth/distance;

this information is updated and displayed automatically. The flashing

squiggle (“~”) in the top left window indicates that pitch and roll

updates are being received from the transmitter. For the best results,

wait for two squiggles with the same pitch/roll information before

giving a steering command to confirm the accuracy of the data.

Clicking vs. Holding the Trigger

Clicking the trigger versus holding the trigger will initiate different

modes with your receiver. When the trigger is held in (trigger up) the

receiver is in the “locating” mode, and the top left window will display

signal strength. Also displayed in the top left window, along with the

signal strength, are the plus (“+”) and minus (“–”) symbols. These

symbols are the key to locating the transmitter (see Locating Section).

The bottom window will display the predicted depth, along with a

flashing squiggle. The top right window will flash the transmitter’s

temperature in degrees Celsius.

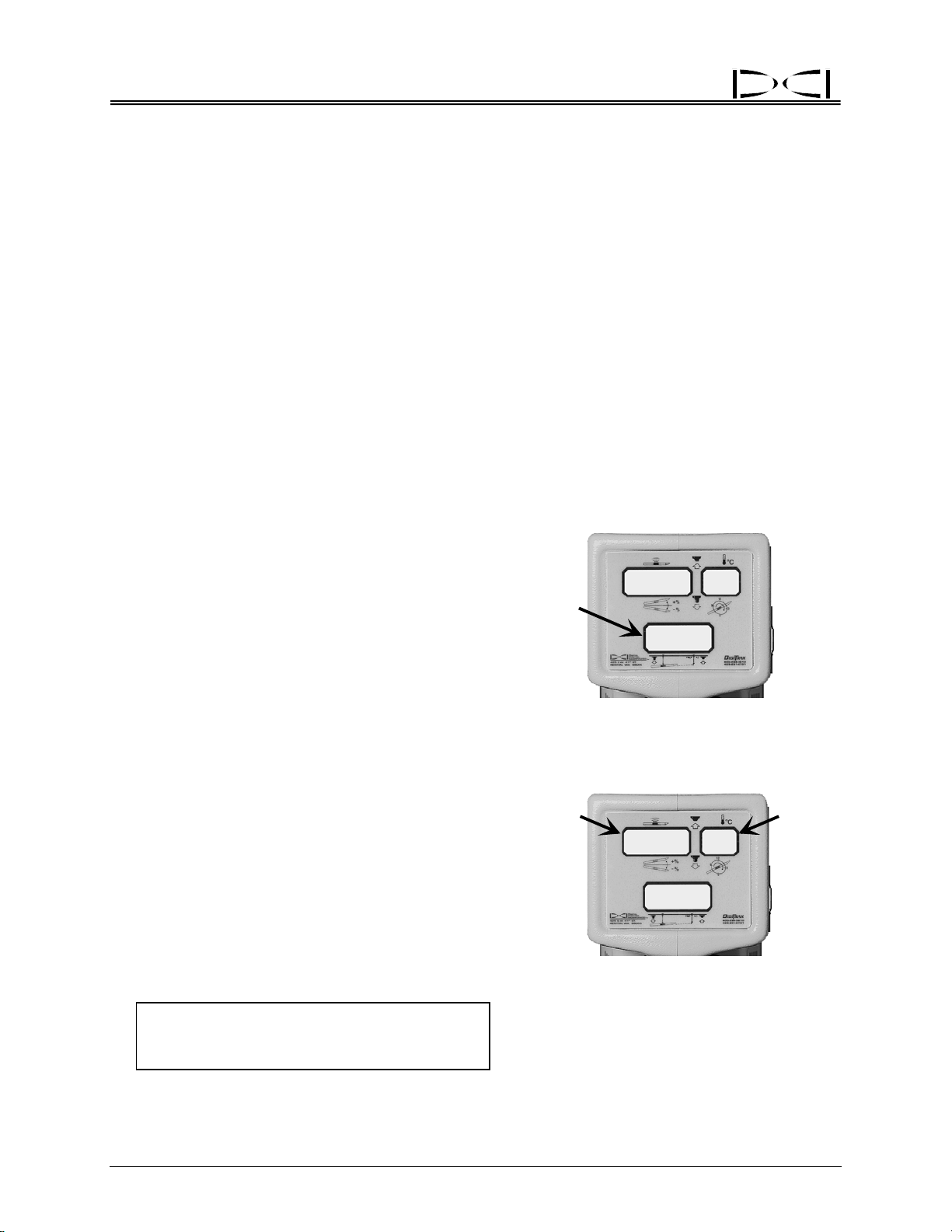

~

I 5

Tracking Mode Showing

Pitch, Roll, Depth/Distance,

and Update Symbol

+

653

~

I

I

I

27

8

8

22

Locating Mode Showing

Signal Strength,

Transmitter Temperature,

and Predicted Depth

8 DigiTrak® Mark III Operator’s Manual

®

Receiver

For receivers that have pre-5.0 series firmware, the bottom window will continue to display the receiver’s

distance from the transmitter in the bottom window, not the predicted depth. (For more information, see

“5.0 Series Firmware Functions” in this section or see the Locating Section.)

Any time the trigger is clicked (pushed in and released in less than ½ second), the receiver will initiate an

ultrasonic measurement, which is also referred to as the height-above-ground measurement. This

measurement is the distance between the receiver and the ground, which is measured by the ultrasonic

transducers on the bottom of the receiver. An ultrasonic measurement can be taken an unlimited number

of times (reset) without affecting the receiver’s calibration. The ultrasonic function is independent of the

transmitter and measures the receiver’s elevation above the ground. The ultrasonic distance is

automatically subtracted from the distance to the transmitter to provide the operator with a display of the

transmitter’s depth/distance below the ground’s surface. The ultrasonics were designed to reduce the

effects of interference by increasing the separation between the interference source in the ground (e.g.,

rebar) and the receiver. (For more information, see “Ultrasonic Function” later in this section.)

Changing the Receiver’s Channel Setting

If using a remote display unit, the receiver and remote display unit must each be set to the same channel.

Changing the receiver’s channel selection can only be done at start-up.

To change the channel:

At the end of the start-up sequence, the bottom window will display the current remote channel setting (0,

1, 2, 3, or 4) for 2 seconds. During this time, the trigger can be clicked to change the channel to the

desired setting. This setting will remain until you change it. Replacing the batteries in any piece of

equipment will not affect the current channel setting, the ultrasonic setting, or the receiver’s calibration.

NOTE: A zero (0) remote channel setting indicates that the receiver’s telemetry signal is shut off and no

signal is being sent to the remote display unit. “Dashes” will appear across the three display windows on

the remote display to indicate no signal is being received. Setting the receiver to channel 0 can be done

to conserve the receiver’s battery (see Remote Display Section).

The DigiTrak System uses ultrahigh-frequency telemetry to communicate between the receiver and the

remote display. Both the receiver and the remote display must have the same type of telemetry to

communicate properly.

DigiTrak® Mark III Operator’s Manual 9

®

Receiver

Changing the Depth Measurement Units (English vs. Metric)

The DigiTrak Receiver is capable of displaying depth in either inches (English) or centimeters (metric).

The depth measurement units can only be changed during the start-up process.

To change the measurement units:

Instead of clicking the trigger to initiate start-up, simply squeeze and hold in the trigger for 12-14 seconds

(the unit may or may not make a tone during this time depending upon the firmware version). The top

right window will display a 1 or a 2 (1 = inches, 2 = centimeters). With the trigger still held in, the unit will

beep 3 times and then change to the other setting. When the desired setting is displayed, release the

trigger. This mode will remain the same until changed and is not affected by battery replacement.

Older receivers that have not been upgraded require a different method for changing the depth measurement units. Contact DCI Customer Service (425-251-0559 or 800-288-3610) for assistance.

Battery Status Display for Receiver and Transmitter

The receiver will prompt the operator when the rechargeable NiCad battery is low (approximately 1 hour of usage

left) by displaying BAT in the bottom window.

The receiver’s battery voltage is displayed in the bottom

window during start-up. It is the first information to be displayed in the bottom window. The voltage is shown in

tenths of a volt, for example, 155 is 15.5V DC. (For more

information about the NiCad’s associated voltages, see

the Battery Charger Section.)

The percentage of remaining battery life in the receiver

will display in the top right window after releasing a held-in

trigger (locating mode). It will display only as 99, 90, 75,

50, 25, 10, 5, or 0.

If you observe the BAT symbol in the top left window, then

the transmitter batteries are low, and the transmitter battery status should be checked. To view the percentage of

battery life remaining in the transmitter’s battery, hold and

then release the trigger. The status is displayed in the top

left window for 2 seconds, after which the pitch display will

resume. This information will display only as 100, 90, 75,

50, 25, 10, 5, or 0. The receiver’s NiCad battery percent

remaining also displays during this 2-second period in the

top right window.

NOTE: Mark III Receivers do not display

the transmitter battery and temperature

information until 4 minutes after start-up.

507

55

I

Receiver Battery Status,

Voltage Remaining

90

BAT

I

Transmitter (left) and Receiver (right)

Battery Life Remaining

in Percentages

I

75

9

I

10 DigiTrak® Mark III Operator’s Manual

®

Receiver

Warning Tones for Transmitter Overheat

Beginning with firmware version 3.76, the DigiTrak Receiver will emit a series of increasing warning tones

to signal transmitter overheating as follows:

Temperature Range Warning Signal

14°C and below

15°C to 35°C One double tone with every 4°C increase in temperature.

36°C to 45°C Two double tones with every 4°C increase in temperature.

45°C to 60°C Three double tones with every 4°C increase in temperature.

60°C and above

No audio or visual warnings.

Audible error tones (two long tones) and the bottom window will flash;

1999 may appear when the transmitter shuts down at about 80°C.

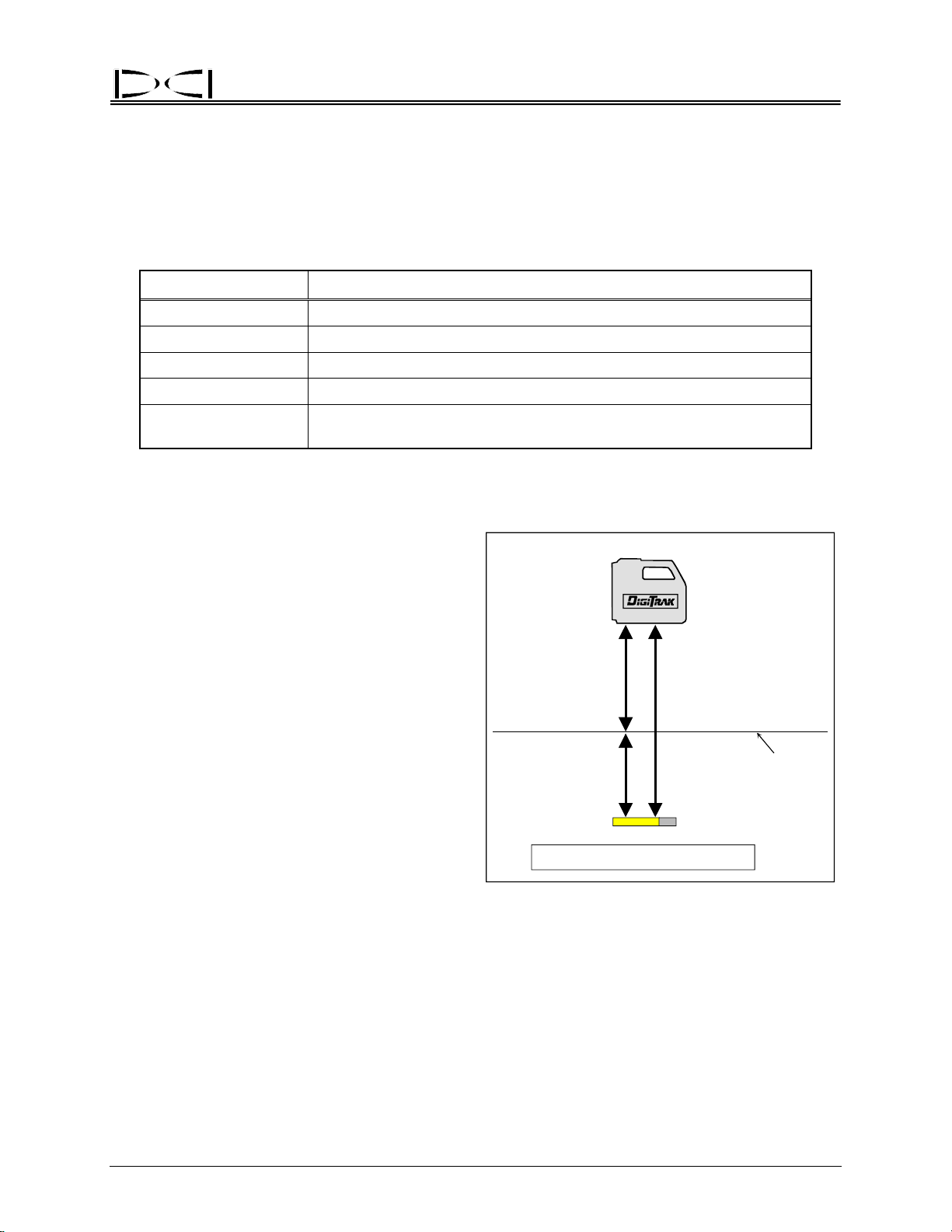

Ultrasonic Function

The ultrasonic function measures the receiver’s

elevation above the ground and subtracts that

distance from the total magnetic distance to

calculate the depth of the transmitter below the

ground’s surface. The ultrasonic function is designed to help the operator observe the depth

reading while maintaining separation between

the receiver’s antennas and potential sources of

interference. An ultrasonic measurement can

only be taken after start-up is completed.

The ultrasonic function is particularly useful when:

¾ Locating over obstacles.

¾ Obtaining adequate separation from utilities

in the ground or rebar interference.

Ultrasonic

Measurement

Depth

Magnetic

Distance

Surface of

Ground

¾ Locating above water.

¾ Verifying calibration when the transmitter is

underground.

¾ Recalibrating in the ground (see

Calibration” below).

The ultrasonic measurement is made by emitting and receiving signals from the two small round holes/

where transducers are mounted on the bottom of the receiver. When the trigger is clicked, one

transducer emits a high-frequency sound wave that travels to the nearest surface and bounces back to be

received by the other transducer. The time required for the signal to return is used to calculate the

distance to the ground. The operating range of the ultrasonic measurement is between 12 inches (30 cm)

and 90 inches (230 cm). The ultrasonic measurement is displayed in the bottom window for 2 seconds

after the trigger is clicked one time.

DigiTrak® Mark III Operator’s Manual 11

“2-Point

Depth = Magnetic – Ultrasonic

Use of Ultrasonic Measurement

To Determine Actual Depth

®

Receiver

Following are some general points regarding the ultrasonic function:

¾ The ultrasonic function in the receiver is independent of the transmitter receiving functions.

¾ A single click to activate the ultrasonic function can be used an unlimited number of times without

affecting the receiver’s calibration.

¾ The ultrasonic measurement is held in memory until the trigger is clicked again for a new ultrasonic

measurement or until t h e r ec e i v er t ur n s o ff .

¾ The

¾ The ultrasonic setting will require resetting after a 2-point calibration.

ultrasonic measurement will be reset to zero after completing a 1-point calibration.

Setting the Ultrasonic Distance or Height-Above-Ground Measurement

1. Hold the receiver comfortably and level in your hand as you would during locating/tracking.

2. Click the trigger (the receiver must already be powered up). This will initiate the ultrasonic measurement.

3. A single tone is emitted during which the ultrasonic distance is displayed for 2 seconds in the bottom

window before the depth/distance display resumes. The bottom window will now display the

transmitter’s depth below the ground instead of the total magnetic distance.

Zeroing the Ultrasonics

1. Set the receiver on the ground or agains t some other flat surface.

2. Click the trigger (the receiver must already be powered up). This will initiate the ultrasonic

measurement.

3. The receiver will beep 3 times and display a “0” in the bottom window for 2 seconds before the depth

display resumes.

IMPORTANT: If another crew member takes over the locating and does not reset the ultrasonics, the

depth display may be inaccurate. For instance, if one person holds the DigiTrak Receiver comfortably 20

inches (50 cm) above the surface of the ground, and another person begins to locate the tool by setting

the DigiTrak on the ground (without zeroing the ultrasonics), the tool will appear to be 20 inches shallower

because the DigiTrak is still subtracting the 20-inch ultrasonic distance.

NOTE: If by chance the trigger is clicked twice within a 1 or 2 second period, the receiver will

enter into a 2-point calibration mode. Wait until all the tones stop before touching the

trigger again. Otherwise the calibration could be changed.

12 DigiTrak® Mark III Operator’s Manual

®

v

r

r

Receiver

Calibrating the Receiver

There are two different calibration methods: 1-point and 2-point. The 1-point calibration is performed

with the transmitter in the housing parallel to and 10 ft 5 in. (3.18 m) from the receiver, as described

below. A 2-point calibration is generally performed when the transmitter is below ground and it is not

possible to perform a 1-point calibration.

Calibration is necessary prior to first time use and when any of the following occur:

¾ The transmitter is changed.

¾ The receiver is changed.

¾ The housing/drill tool is changed.

Do not calibrate if:

¾ You are within 10 ft (3 m) of metal structures, such as steel pipe, chain link fence, metal siding, con-

struction equipment, or automobiles.

¾ The receiver is over rebar or underground utilities.

¾ The receiver is in the vicinity of excessive electrical interference (see “Electrical Interference/

Background Noise Check” in the Signal Interference Section).

¾ The transmitter is not installed into the housing.

¾ The transmitter is not turned on.

NOTE: Calibration should be checked at 10 ft 5 in. (3.18 m) daily and before every use. Calibra-

tion only affects the depth/distance reading, not pitch or roll.

1-Point Calibration Procedure

1. Confirm the lack of interference (see Electrical Interference/Background Noise” Check in the Signal

Interference Section). Make sure there are no other active transmitters within range of the receiver.

2. Place an operating transmitter inside the housing on level ground.

3. After the receiver has completed the start-up sequence, place it exactly 10 ft 5 in. (3.18 m) from the

housing as shown in the sketch (a tape measure must be used for accuracy; measure from centerline

of transmitter to inside edge of receiver). Hold in the trigger to confirm a stable signal, then release

the trigger; note signal strength

reading. The signal strength must

be at least

calibration. If your reading is less

than 250, the transmitter may be

malfunctioning, and you should call

DCI.

250 points for proper

10 ft 5 in. (3.18 m)

e

Recei

Determining 1-Point Calibration Signal

Transmitter

Centerline

Transmitte

(Inside

Housing)

DigiTrak® Mark III Operator’s Manual 13

®

Receiver

4. Click the trigger one time.

5. The receiver will beep. During the beep, pull in the trigger and hold it.

6. Continue to hold the trigger and watch the countdown (from 5 to 0) displayed in the bottom window.

This countdown is accompanied by a chirping sound.

7. When the countdown reaches zero, let go of the trigger.

8. A good calibration will be confirmed by 3 short beeps. Two long tones indicate a failed calibration,

which may be due to an inadequate signal from the transmitter or interference.

9. The bottom window should display 120 inches (±2 inches) or 297 cm (±5 cm).

10. Using a tape measure for precise positioning, as in step 3, move the receiver to at least two other

locations (e.g., 60 inches [152 cm] and 240 inches [610 cm]) and confirm proper depth/distance

readings. Verify that your target drilling depth displays accurately.

11. Note the signal strength for possible later use.

Confirming Proper Calibration

Check the calibration using a tape measure with the transmitter above ground in the housing. Place the

receiver parallel to the housing at a series of accurately measured distances, and verify that the distance

displayed in the bottom window corresponds to the distance on the tape measure. If there is a considerable discrepancy between the measured distance and that displayed on the receiver (greater than ±5%),

then recalibrate.

2-Point Calibration Procedure

A 2-point calibration is used when the transmitter is below ground. It is recommended that more than one

2-point calibration procedure be conducted to verify a good calibration. Two procedures are given

below—one for newer receivers and one for older receivers (manufactured before 1995 and never

upgraded).

To calibrate (newer receivers):

1. Confirm the lack of background interference by first waiting for the transmitter to fall asleep (10–15

minutes). An acceptable background interference should show a signal strength of less than 150

points (in the top left window with the trigger held in). Make sure that there are no other active

transmitters within range of the receiver. (See “Electrical Interference/Background Noise Check” in

the Signal Interference Section.)

2. Turn on the transmitter if it is still asleep by rotating the drill string. Position the receiver parallel to

and directly over the transmitter; the transmitter’s pitch must be less than 20%. The ground surface

under the receiver must be relatively solid, flat, and level. The receiver should be displaying pitch,

roll, and distance.

3. Hold the receiver level, directly above the transmitter, and at least 12 inches (30 cm) above ground.

4. Click the trigger; you will hear a tone.

14 DigiTrak® Mark III Operator’s Manual

®

Receiver

5. During the tone, click the trigger again and continue to hold the receiver level and steady. You will

then hear 2 beeps followed by a long 6-second tone, indicating that the first calibration point is found.

6. During the 6-second tone, raise the receiver straight up, keeping it level and in the same plane above

the transmitter, as high as you comfortably can. Before the 6-second tone ends you must steady the

receiver and click the trigger.

7. Continue to hold the receiver in this position until you hear 3 beeps indicating that the second

calibration point was found and the calibration procedure is com plete.

8. Reset the ultrasonic measurement to zero and check the depth reading while the receiver is sitting on

the ground directly above the transmitter. To verify a good calibration, check the depth at two

different elevations above ground using the ultrasonics, as described below under “Confirming Proper

Calibration.”

NOTE: If you hear 2 long beeps, there has been a calibration error, which can be caused by

an unstable or weak signal or a failed ultrasonic reading.

To calibrate (older receivers manufactured prior to 1995 that haven’t been updated):

1. Place the transmitter into the drill head housing and place on the ground.

2. Cover the transmitter with a flat surface (e.g., a clipboard, piece of cardboard, plywood, etc.) to provide an ultrasonic response surface.

3. With the trigger held in, position the receiver over the tool using the plus/minus (“+/–”) flip to verify that

the receiver is directly over the transmitter’s antenna. Be sure that the signal strength is less than

200 (top left window). If it is more than 200, raise the receiver slightly.

NOTE: Mark I Receivers without upgrades do not show 0-999 signal strength. You should

see a 7 in the top right window (gain stage 7) and a value of 200 or less in the top left

window when performing the 2-point calibration.

4. Follow the instructions given above for calibrating newer receivers beginning with step 4.

Confirming Proper Calibration

The ultrasonic function can be used to confirm proper calibration when the transmitter is below ground.

Check the depth measurement with the receiver held at one position (above the transmitter), then raise

the receiver to a new elevation, click the trigger to set the ultrasonics, and note the depth reading. If the

depth readings are the same (within 2 inches [5 cm]), then the calibration is good. If the depth readings

are not within 2 inches, then the depth/distance readings cannot be relied on and recalibration should be

performed.

DigiTrak® Mark III Operator’s Manual 15

®

Receiver

Calibrating with Transmitter Underground at Shallow Depth (< 10 feet)

Should recalibration be necessary when the transmitter is below ground at depths less than 10 ft (3 m), it

is possible to conduct a modified 1-point calibration procedure. This requires knowing the signal strength

of the transmitter in the housing at 10 ft. (You should always note the value of the signal strength when

you first perform a 1-point calibration.)

With the transmitter below ground (shallower than 10 ft), place the receiver parallel to the transmitter at a

distance to cause the same signal strength as noted during the most recent 1-point calibration. To do

this, simply hold in the trigger and move the receiver away from or closer to the transmitter until you see a

signal strength reading (top left window) that equals the 1-point calibration signal. Set the receiver on the

ground, and complete the 1-point calibration procedure. However, if the transmitter is deeper than 10 ft, it

will be necessary to perform a 2-point calibration.

For example, if you noted that the signal strength during the most recent 1-point calibration was 560, then

move the receiver parallel to the transmitter to a distance that will result in a reading of 560 and complete

the procedure for a 1-point calibration. Remember, this procedure will not work if you are drilling deeper

than 10 ft. If this is the case, you will have to perform a 2-point calibration, or, if a spare transmitter is

available, you can calibrate to it at a distance equivalent to 560 points of signal (or whatever the signal

strength was during the most recent 1-point calibration) and then resume drilling with the same transmitter that is below ground.

When using this modified procedure, you are assuming that the in-ground transmitter is still performing at

the same signal strength it was when the most recent 1-point calibration was performed. If the transmitter

has been damaged or has overheated, this modified procedure should not be relied upon.

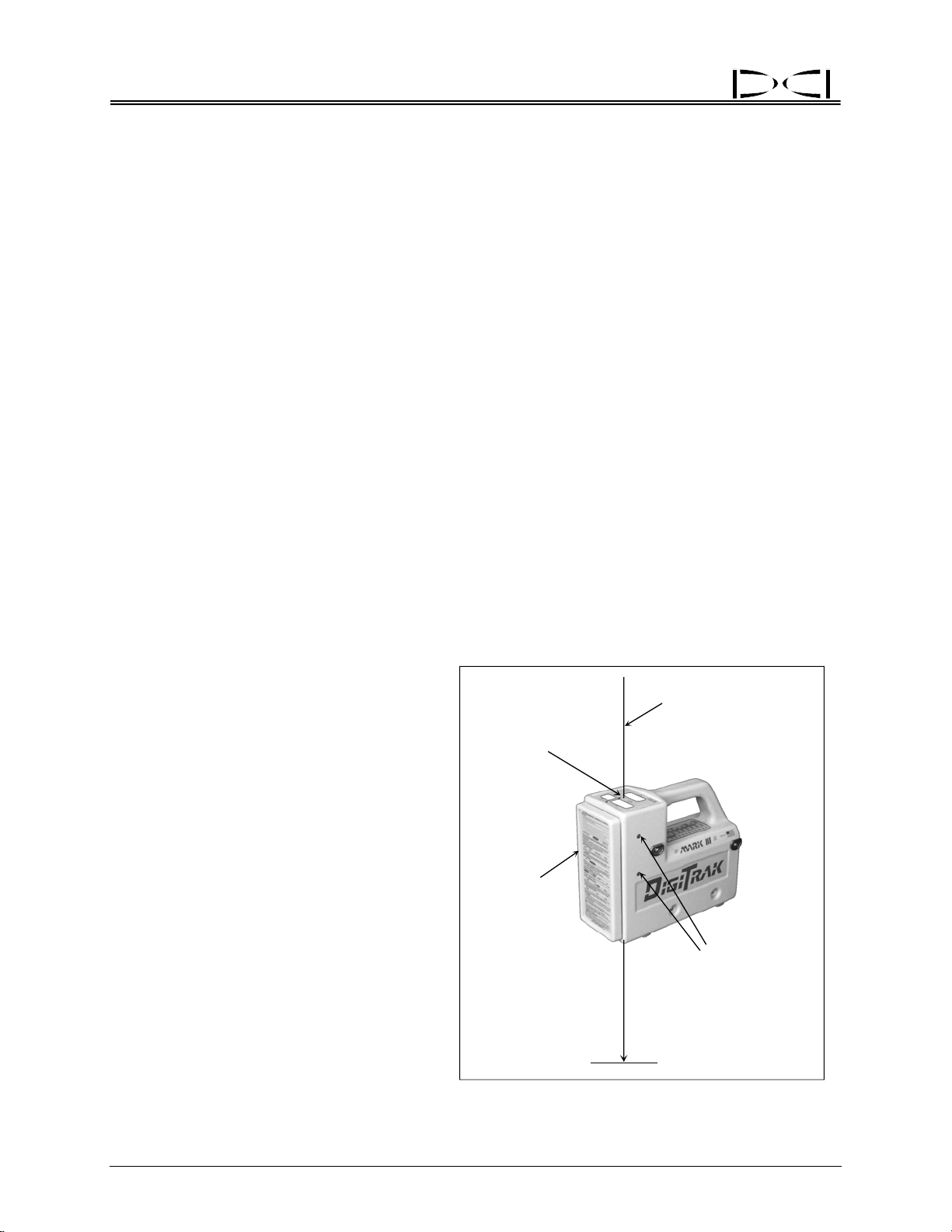

Using Depth Antenna

Plumb Line to Mark

Plumb Line

Locate Points

Center of

To mark the important locating positions

(the front negative locate point or FNLP;

the rear negative locate point or RNLP;

and the positive locate line or PLL) accu-

you must use the vertical axis (plumb

rately,

line) that runs through the center of the

display windows and bisects the depth/

locating antennas (see sketch at right).

Where this axis intersects the ground is the

location that you should mark. This plumb

line also serves as the axis around which

you can rotate the receiver for confirming

the FNLP and RNLP. (For more information, see “Method for Confirming Position”

in the Locating Section.)

Display

Windows

Front of

Receiver

Depth/Locating

Antenna Screws

Place Marker

Straight Down

on Ground

Depth Antenna Plumb Line

16 DigiTrak® Mark III Operator’s Manual

®

Receiver

Finding Firmware Version

It is possible to determine the firmware version in the receiver. This information is necessary to complete

troubleshooting diagnostics with DCI Customer Service by telephone. At start-up the firmware version is

displayed briefly in the top left window. If you do not see the firmware version, it is likely that you have an

older receiver. If this is the case, to see the firmware version, you must remove and replace the battery in

the receiver and then simply hold in the trigger during start-up instead of clicking it, as you would normally

do to turn on the receiver. The firmware version will display in the top left window as long as you have

the trigger held in. Do not hold in the trigger for more than 12 seconds, however, or you will change the

receiver depth measurement units (see “Changing the Depth Measurement Units” earlier in this section).

Note that the firmware version will not display the decimal point; therefore, a display of 507 corresponds

to firmware version 5.07.

NOTE: Receivers with firmware version 3.77 and above are DataLog capable.

5.0 Series Firmware Functions

Receivers that have 5.0 series or later firmware will display information differently than pre-5.0 series

receivers when the trigger is held in. This firmware is designed to:

¾ Predict the depth of the transmitter while the receiver is positioned at the FNLP.

¾ Display the receiver’s rechargeable battery status in percent and voltage remaining (see “On/Off” in-

structions earlier in this section).

¾ Turn off the receiver by clicking the trigger in a prescribed sequence instead of removing the battery

(see “On/Off” instructions earlier in this section).

¾ Provide the operator with 3 confirmation beeps after successfully completing the Mark III self-test. If

an error is detected 2 long tones will emit and the error code will display in the top left window. (For

more information, see “Self-Test for Mark III Receivers” in the Operational Tests Section.)

¾ Provide a running time meter on the operating hours of the receiver.

Predicted Depth Key Points

¾ The 5.0 series firmware provides a predicted depth for the transmitter when it reaches the FNLP.

¾ The predicted depth is only valid when the operator is standing at the FNLP.

¾ The predicted depth is never taken at the rear negative locate point (RNLP).

¾ The predicted depth assumes no substantial change in pitch between the time of the prediction and

the time that the transmitter reaches the FNLP.

¾ The predicted depth number will flash quickly (bottom window) to distinguish it from the depth, which

appears as a solid (not flashing) number.

¾ A solidly illuminated squiggle (“~”) will appear in the bottom window to further distinguish the pre-

dicted depth.

¾ The original slant distance or depth can still be viewed simply by releasing the trigger.

¾ Pitch updates must occur in order for the predicted depth to be accurate.

¾ If there is no current pitch, the depth display will not show the predicted depth but instead will show a

squiggle when the trigger is held in.

DigiTrak® Mark III Operator’s Manual 17

®

Receiver

Procedure for Observing the Predicted Depth

When the receiver (with 5.0 firmware) is at the FNLP and held level with the trigger in, the bottom window

will rapidly flash the predicted depth number accompanied by a solidly lit squiggle (“~”); the predicted

depth information is also displayed in the bottom window on the remote display. Should the trigger be

held in at any other location than the FNLP, the predicted depth in the bottom window will be invalid and

should be disregarded. The depth prediction feature requires pitch; should the pitch information become

unavailable, the predicted depth display (with trigger held in) will show only the squiggle in the bottom

window, and there will be no number for the predicted depth. This feature also requires that the ultrasonic distance be set prior to measuring the predicted depth.

Viewing the Transmitter’s Temperature and the Receiver’s Battery Status in Percent of Remaining Life

While the trigger is held in, the top left window will display the signal strength (as with pre-5.0 firmware

versions) and the top right window will display the transmitter’s temperature in degrees Celsius as a

flashing number. When the trigger is released, the top right window will display for 2 seconds the

percentage of battery life remaining in the receiver’s rechargeable NiCad battery as 100, 90, 75, 50, 25,

10, 5, or 0, and the top left window will display the transmitter’s battery percentage remaining as 99, 90,

75, 50, 25, 10, 5, or 0. The pitch and roll information will resume 2 seconds after releasing the trigger.

Viewing the Receiver’s Battery Voltage

The receiver’s NiCad battery voltage is displayed only during the start-up process. The receiver battery

voltage is displayed for 2 seconds during initial start-up in the bottom window and is in tenths of a volt,

i.e., 155 is 15.5V DC. A fully charged, properly operating NiCad battery is approximately 16.5V to 17.1V

DC. At 14.0V DC, the battery is considered discharged.

Off Feature

To shut the receiver off, click the trigger as if you are taking an ultrasonic measurement. As soon as the

unit begins to beep click the trigger 4 or more times (observe 4 or greater in the bottom window). The

receiver’s windows will all blank out, indicating the receiver is off. The battery need not be removed to

shut off the receiver.

Accessing the Receiver’s Running Time Meter

The running time meter tracks the operating hours for receivers

having 5.0 series and later firmware. To view accumulated running time hours, the receiver must be started with an “on by 4”

clicking sequence, as follows:

Place a battery in the receiver. Click the trigger once followed

by 4 rapid clicks. The hours will be displayed in the top left window (up to 999), minutes in the top right window, and thousands

of hours in the bottom window.

Hours Minutes

0 I I

8

Thousands

0

of Hours

To exit the running time meter display, click the trigger once and

the unit will shut off. To restart, click the trigger.

3-3000-00c-F

18 DigiTrak® Mark III Operator’s Manual

Running Time Meter

Display

®

DIGITAL CONTROL INCORPORATED

Transmitter

Batteries Antenna

Index Slot

Back

DigiTrak Transmitter

A transmitter (also referred to as a sonde, beacon, or probe) is a device that emits electromagnetic

signals at radio frequencies and fits inside the tool housing. It transmits information regarding its location,

position, and heading. The transmitter emits signals that the receiver “hears” and converts into the

information shown in the three display windows. The range of a transmitter depends upon its type. For

more information, see the DigiTrak Transmitter Specifications table at the end of this section.

NOTE: The range of any transmitter with any DCI receiver is dependent upon the amount of inter-

ference at a job site. The range decreases as interference increases.

Front

How a Transmitter Works

The transmitter emits two types of signals, both at approximately 33 kHz. The first signal is the depth or

signal strength. The second signal sends pitch, roll, and battery and temperature status information. The

pitch/roll signal has a wider bandwidth than the depth signal and occasionally may be more susceptible to

interference. For more information about interference and transmitter signal interruption, see the Signal

Interference Section, the Troubleshooting Section, and “Electrical Interference/Background Noise Check”

in the Signal Interference Section.

With the trigger released, verify that the transmitter is sending adequate pitch and roll information to the

receiver—the top left window of the receiver will flash a squiggle (“~”) every 2.5 seconds. It is important

to wait for two consecutive squiggles with the same pitch and roll information before relying on the information to give any steering commands. Waiting assures confirmation of an accurate reading. As the

transmitter reaches its maximum range, the squiggles will become less frequent than every 2.5 seconds.

For further information on pitch/roll and the squiggle, see the Operational Tests Section (particularly

“Transmitter Tests”).

Transmitter pitch is displayed in percent slope as 1% increments or 0.1% increments (if using a sensitivepitch transmitter) in the top left window of the receiver with the trigger released. For more information see

“Sensitive-Pitch Transmitters” later in this section.

DigiTrak® Mark III Operator’s Manual 19

®

Transmitter

Transmitter roll positions are displayed digitally as a whole number from 1 through 12 in the top right

window with the receiver’s trigger released. The numbers correspond to the hour hand of a clock. At the

12 o’clock position, the transmitter is oriented with the index slot at the top. The tapered or flattened surface of the drill head should be indexed to this position.

Batteries

All DCI transmitters (except the cable transmitter) are powered by C-cell alkaline batteries (see Transmitter Specifications at the end of this section). The long-range transmitters, including the sensitive-pitch

transmitters, have a 4 C-cell option for longer bores. The status of the batteries in the transmitter can be

viewed (in percent life remaining) using the receiver’s display (see “Battery Status Display” below). The

cable transmitter requires an above-ground power supply (see Transmitter Section).

Temperature Display

Transmitter temperature is displayed in degrees Celsius. Every 4°C

increase in the transmitter’s temperature will flash for 2 seconds in the

top right window of the receiver and the remote display. The receiver

will also sound audible tones that increase in intensity as the

transmitter’s temperature increases. When the remote display has a

DataLog module attached, the transmitter’s temperature increase

tones will be heard at the drill. To manually view the temperature of

the transmitter, simply hold in the receiver’s trigger; the temperature

will flash in the top right window. Receivers with pre-5.0 series

firmware will display the temperature in the top right window while the

trigger is held in, but it will not flash. To view the transmitter temperature at the drill, see the Remote Display Section.

+

6 I 9

~

Transmitter Temperature

Display (Flashing)

I

26

22

Battery Status Display

The percent of battery life remaining in the transmitter is displayed in

the top left window for 2 seconds upon releasing a held-in trigger. The

transmitter’s battery status in percent remaining life is displayed as

100, 90, 75, 50, 25, 10, 5, or 0. (The receiver’s battery status in

percent remaining life is also displayed during this 2-second interval in

the top right window as 99, 90, 75, 50, 25, 10, 5, or 0.) If the word

BAT occurs in the top left window when not viewing the transmitter’s

battery status, the transmitter batteries must be replaced.

NOTE: Neither the temperature nor the battery status will

be available until 4 minutes after initial start-up for

receivers with 5.0 series or later firmware.

Transmitter Battery Status

in Percent Remaining Life

905690

BAT

Temperature Overheat

All transmitters have a temperature overheat indicator (temp dot) that has an outer yellow ring with a 1/8inch (3-mm) white dot in the center. This temp dot is located on the stainless-steel front end cap. On

older transmitters, the temp dot is located inside the battery compartment next to the battery terminal.

20 DigiTrak® Mark III Operator’s Manual

Loading...

Loading...