Page 1

Directional Drilling Guidance System

Operator’s Manual

dci@digital-control.com

www.DigiTrak.com

Page 2

DIGITALCONTRO LINCORP ORATED

403-2400-21-B metric,Russia, printed on 5/30/2017

© 2017 DigitalControl Incorporated. Allrights r eserved.

Параметры электромагнитной совместимости соответствуют Техническому регламенту Таможенного союза

«Электромагнитная совместимость технических средств» ( ТС ТР 020/2011).

“ООО РадиоСерт”

ул. Раменки, д. 31, кв. 135, г. Москва, 119607

7.495.669.11.64

mail@radiocert.com

Trademarks

The DCI®logo, F5®, and DigiTrak®are U.S. registered trademarks.

Patents

U.S. and foreign patents applyto the product covered by this manual. For details,please visit www.DigiTrak.com/patents.

Limited Warranty

Allproducts manufactured and sold by Digital Control Incorpor ated (DCI) are subject to the terms of a Limited Warranty. A copy of the

Limited Warranty isincluded at the end of this manual; it can also be obtained at www.DigiTrak.com.

Important No tice

Allstatements, technical information, and recommendations related to DCI products are based on information believed to be reliable.

However, DCI does not warrant or guar antee the accuracy or completeness of such information. Before using any DCI product, the

user should determine the suitability of the product for its intended use. All statements herein r efer to DCI products as delivered by DCI

for use with horizontaldirectional drilling in the or dinary course, and do not apply to any user customizations, third-party products, or

any usage of the DCI product outside of the ordinary course. Nothing herein shall constitute a warranty by DCI nor willanything herein

be deemed to modify the terms of DCI’s existing Limited Warranty applicableto allDCI products. DCI may update or correct the

information in this manual from time to time. You may find the most recent version of this manual on DCI's website, www.DigiTrak.com.

Under Service & Suppo rt, click Documentation and select from the Manu als drop-down menu.

Compliance Statement

This equipment complies with Part 15 of the Rules of the FCC and with Industry Canada license-exempt RSS standards and with

Australia Class License 2000 for LIPD ( low interference potential devices). Operation is subject to the following two conditions: ( 1) this

equipment may not cause harmful interference, and (2) thisequipment must accept any interfer ence r eceived, including interference

that may cause undesired operation. DCI is responsible for FCC compliance in the United States: Digital Control Incorporated, 19625

62nd Ave S, Suite B103, Kent WA 98032; phone 425.251.0559 or 800.288.3610 (US/CA).

Changes or modificationsto any DCI equipment not expressly approved and carried out by DCI willvoid the user’s Limited Warranty

and the FCC’s authorization to operate the equipment.

CE Requ irements

DigiTrak receivers are classified as Class 2 radio equipment per the R&TTE Directive and may not be legal to oper ate or

require a user license to operate in some countries. T he list of restrictionsand the required declarations of conformity

are availableon DCI’s website at www.DigiTrak.com. Under Service & Support, clickDocumentat ion and select from the CE

Docu ments drop-down menu.

ii DigiTrak Falcon F 5®Operator's Manual

Page 3

Contact Us

DIGITALCONTRO LINCORP ORATED

United States

DCI Headquarters

Australia

China

Europe

19625 62nd Ave S, Suite B103

Kent, Washington 98032, USA

1.425.251.0559 / 1.800.288.3610

1.425.251.0702 fax

dci@digital-control.com

2/9 Frinton Street

Southport QLD 4215

61.7.5531.4283

61.7.5531.2617 fax

dci.australia@digital-control.com

368 Xingle Road

Huacao Town

Minhang District

Shanghai 201107, P.R.C.

86.21.6432.5186

86.21.6432.5187 传 真)

dci.china@digital-control.com

Brueckenstraße 2

97828 Marktheidenfeld

Deutschland

49.9391.810.6100

49.9391.810.6109 Fax

dci.europe@digital-control.com

India

Russia

DTJ 203, DLF Tower B

Jasola District Center

New Delhi 110025

91.11.4507.0444

91.11.4507.0440 fax

dci.india@digital-control.com

Молодогвардейская ул., д.4

стр. 1, офис 5

Москва, Российская Федерация 121467

7.499.281.8177

7.499.281.8166 факс

dci.russia@digital-control.com

DigiTrak Falcon F 5®Operator's Manual iii

Page 4

DIGITALCONTRO LINCORP ORATED

Dear Customer,

Thank you for choosing a DigiTrak guidance system. We are proud of the equipment we have been designing

and building in Washington State since 1990. We believe in providing a unique, high-quality product and

standing behind it with world-class customer service and training.

Please take the time to read this entire manual, especially the section on safety. Please also register your

equipment online at access.DigiTrak.com. Or, fill in the product registration card provided with this

equipment and either fax it to us at 253-395-2800 or mail it to DCI headquarters.

Product registration entitles you to free telephone support (in the USA and Canada), notification of product

updates, and helps us provide you with future product upgrade information.

Our Customer Service department is available 24 hours a day, 7 days a week in the U.S. to help with

problems or questions. International contact information is available in this document and on our website.

As the horizontal directional drilling industry grows, we’re keeping our eye on the future to develop equipment

that makes your job faster, easier, and safer. Visit us online any time to see what we’re up to.

We welcome your questions, comments, and ideas.

Digital Control Incorporated

Kent, Washington

2017

Watch our DigiTrak Training Videos at www.youtube.com/dcikent

For system component name and model information, refer to Appendix A on page 65.

iv DigiTrak Falcon F 5®Operator's Manual

Page 5

DIGITALCONTRO LINCORP ORATED

Table of Contents

Important Safety Instructions 1

General 1

Pre-Drilling Testing 2

Interference 2

Potential Interference Received 2

Potential Interference Generated 2

Battery Pack Storage 3

Equipment Maintenance 3

General Transmitter Care Instructions 3

Getting Started 5

Introduction 5

Using This Manual 6

Powering On 6

Receiver 7

Transmitter 7

Remote Display (Aurora) 7

Setup Summary 7

Select Frequency Optimizer 7

Assign Frequency Bands 8

Interference Check 8

Calibrate 8

Above Ground Range Check 8

Drill 8

Receiver 9

Overview 9

Toggle and Trigger Switches 9

Audible Tones 10

Startup Screen 10

Using the Keypad 11

Your Remote Display 11

Receiver Menus 12

Locate Mode 13

Power Off 13

Calibration and AGR 13

1-Point Calibration 14

In-Ground Calibration 16

View Calibration 17

Above Ground Range (AGR) 17

15 m Calibration (Optional) 18

Height-Above-Ground (HAG) 18

Settings 20

Depth Units Menu 20

Pitch Units Menu 20

Set Time and Calendar Menu 21

DigiTrak Falcon F 5®Operator's Manual v

Page 6

DIGITALCONTRO LINCORP ORATED

Telemetry Channel Menu 21

Roll Offset Menu 22

Pressure Units Menu 23

Temperature Units Menu 23

Language Selection Menu 23

Transmitter Selection and Frequency Optimization 23

Frequency Optimization 24

So I Just Paired, Now What? 27

Transmitter Selection 27

View Frequency Optimization 28

Transmitter Information and Runtime 28

DataLog 29

Left/Right Offset 30

Deviation 30

Flags and Pins 30

Diagnostics 31

Perform Level Check 32

Perform System Self-Test 33

Perform Signal Self-Test 33

System Information 34

Locating Basics 35

Locating Screens 36

Locate Screen 36

Locate Screen Shortcuts 37

Depth Screen 37

Predicted Depth Screen 38

Depth Screen, Invalid Location 39

Interference 39

What is Interference? 40

Checking for Interference 40

Roll/Pitch Check 41

Suggestions for Dealing with Interference 42

Locate Points (FLP & RLP) and Locate Line (LL) 43

Effects of Depth, Pitch, and Topography on Distance Between FLP and RLP 44

Marking Locate Points 45

Locating the Transmitter 45

Finding the Front Locate Point (FLP) 46

Finding the Locate Line (LL) 47

Finding the RLP to Confirm Transmitter Heading and Position 49

Advanced Locating 51

Tracking “On-the-Fly” 51

Off-Track Locating 52

Target Steering 54

Feasible Target Steering Area 55

Turning Target Steering On 55

Positioning the Receiver as the Target 56

Steering to the Target with the Remote Display 57

Target Steering in Interference Areas 57

Turn Target Steering Off 57

vi DigiTrak Falcon F 5®Operator's Manual

Page 7

DIGITALCONTRO LINCORP ORATED

Transmitter 58

Batteries and Power On/Off 59

19-inch Transmitters 59

15-inch Transmitters 59

Installing Batteries / Power On (19- and 15-inch) 59

Transmitter Battery Strength 60

Sleep Mode 60

Transmitter Drill Head Requirements 61

Temperature Status and Overheat Indicator 61

Transmitter Temperature Warning Tones 62

Transmitter Overheat Indicator (Temp Dot) 62

Transmitter Warranty Timer 62

Changing Frequency Bands 62

Above Ground (Pre-Bore) Tilt Method 63

Below Ground (Mid-Bore) Roll Methods 63

AppendixA: System Specifications 65

Power Requirements 65

Environmental Requirements 65

Storage and Shipping Requirements 65

Temperature 65

Packaging 65

Equipment and Battery Disposal 65

Transmitter Pitch Resolution 65

AppendixB: Receiver Screen Symbols 67

AppendixC: Projected Depth Versus Actual Depth and the Fore/Aft Offset 69

AppendixD: Calculating Depth Based on Distance Between FLP and RLP 73

AppendixE: Reference Tables 74

Depth Increase in cm per 3-m Rod 74

Depth Increase in cm per 4.6-m Rod 75

WARRANTY

DigiTrak Falcon F 5®Operator's Manual vii

Page 8

DIGITALCONTRO LINCORP ORATED

viii DigiTrak Falcon F 5®Operator's Manual

Page 9

DIGITALCONTRO LINCORP ORATED

Important Safety Instructions

General

The following warnings relate generally to the operation of DigiTrak®guidance systems. This is not

an exhaustive list. Always operate your DigiTrak guidance system in accordance with the manual

and be aware of interference that may affect efforts to retrieve accurate data with this guidance

system. Failure to do so can be hazardous. If you have any questions about the operation of the

system, please contact DCI Customer Service for assistance.

To prevent potentially dangerous conditions, all operators must read and understand the safety

precautions, warnings, and instructions before using a DigiTrak guidance system.

DigiTrak guidance systems cannot be used to locate utilities.

Failure to use the front and rear locate points technique described in this manual for locating the

transmitter can lead to inaccurate locates.

Serious injury and death as well as substantial property damage can result if underground drilling

equipment makes contact with an underground utility, including natural gas lines, high-voltage

electrical cable, or other utilities.

DCI equipment is not explosion-proof and should never be used near flammable or explosive

substances.

Work slowdowns and cost overruns can occur if drilling operators do not use the drilling or

guidance equipment correctly to obtain proper performance.

Directional drilling operators MUST at all times:

l Understand the safe and proper operation of drilling and guidance equipment, including proper grounding

procedures and techniques for identifying and mitigating interference.

l Ensure all underground utilities and all potential sources of interference have been located, exposed, and

accurately marked prior to drilling.

l Wear protective safety clothing such as dielectric boots, gloves, hard hats, high-visibility vests, and

safety glasses.

l Locate and track the transmitter in the drill head accurately and correctly during drilling.

l Maintain a minimum distance of 20 cm from the front of the receiver to the user’s torso to ensure

compliance with RF exposure requirements.

l Comply with federal, state, and local governmental regulations (such as OSHA).

l Follow all other safety procedures.

Remove the batteries from all system components during shipping and prolonged storage. Failure to do so

may result in battery leakage, which may lead to risk of explosion, health risks, and/or damage.

Store and transport batteries using a suitable protective case that will keep batteries safely isolated from one

another. Failure to do so may result in short circuits, which may lead to hazardous conditions including fire.

See Appendix A for important restrictions on shipping lithium-ion batteries.

Use of this equipment is restricted to internal use at a construction site.

DigiTrak Falcon F 5®Operator's Manual 1

Page 10

DIGITALCONTRO LINCORP ORATED

Pre-Drilling Testing

Before each drilling run, test your DigiTrak guidance system with the transmitter inside the drill head to

confirm it is operating properly and providing accurate drill head location and heading information.

During drilling, the depth will not be accurate unless:

l The receiver has been properly calibrated and the calibration has been checked for accuracy so the

receiver shows the correct depth.

l The transmitter has been located correctly and accurately and the receiver is directly above the

transmitter in the drill head underground or at the front locate point.

l The receiver is placed on the ground or held at the correct height-above-ground distance, which has been

set correctly.

Always test calibration after you have stopped drilling for any length of time.

Interference

The Falcon frequency optimizer selects frequencies based on measured active interference at a given point

in time and space. Active interference levels can change with time and location, passive interference (which

the system does not detect) may be present, and performance may vary as a result. Selections by the

frequency optimizer are not a substitute for prudent operator judgment. If performance drops while drilling,

consider switching to the other selected band or using Max Mode.

Potential Interference Received

Interference can cause inaccuracies in the measurement of depth and loss of the transmitter’s pitch, roll, or

heading. Always perform a background noise check using your receiver (locator), as well as a visual

inspection for possible sources of interference, prior to drilling.

A background noise check will not identify all sources of interference, as it can only pick up sources that are

active, not passive. Interference, as well as a partial list of sources of interference, are discussed in the

section Interference on page39.

Never rely on data that does not display quickly and/or remain stable.

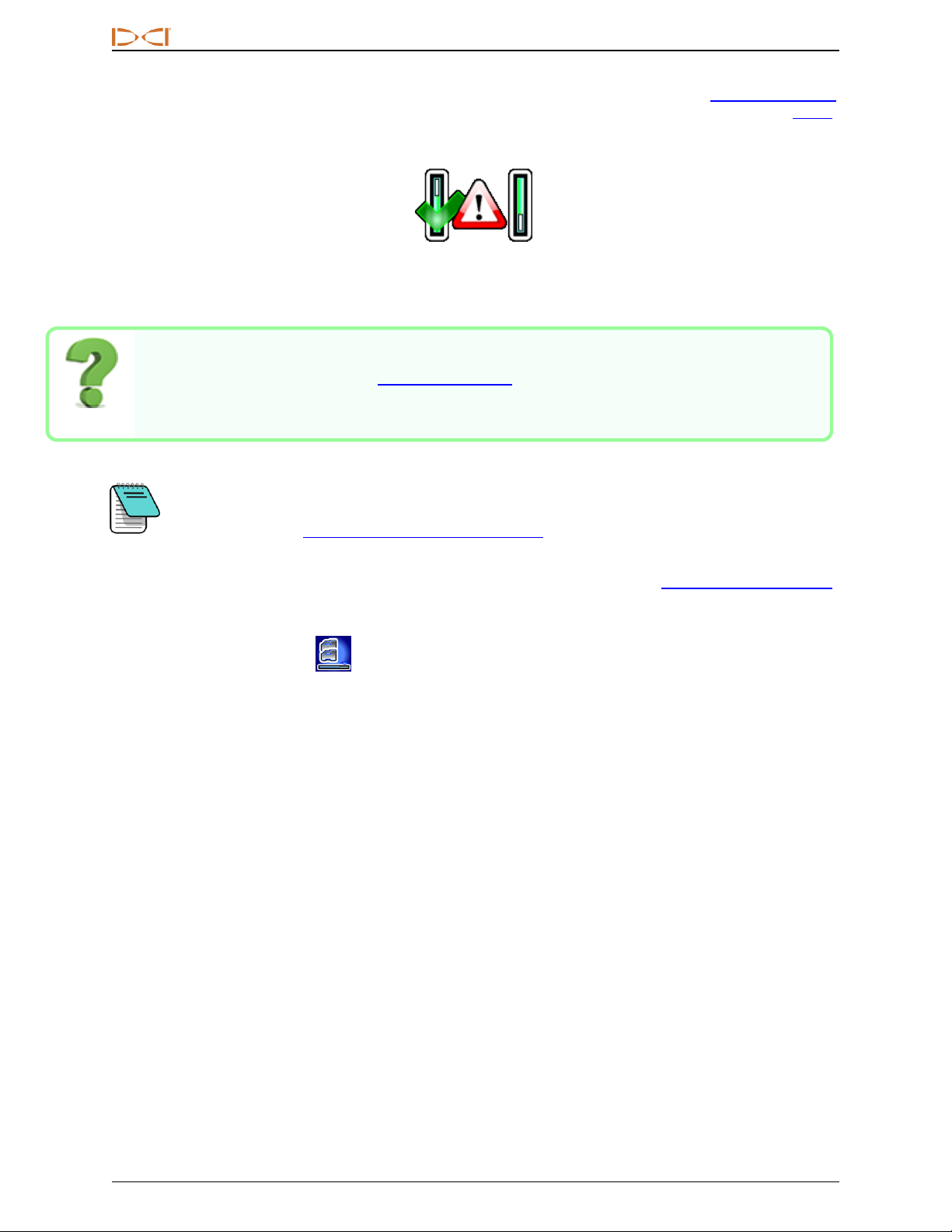

If an A displays at the top right of the roll indicator or frequency optimizer at distances greater than 3.0 m from

the transmitter, attenuation is in effect, indicating the presence of excessive noise that can lead to inaccurate

depth readings. A flashing signal strength and A icon indicate the presence of extreme interference; depth

and locate points will not be accurate.

Potential Interference Generated

Because this equipment may generate, use, and radiate radio frequency energy, there is no guarantee that

interference will not occur at a particular location. If this equipment does interfere with radio or television

reception, which can be determined by powering the equipment off and on, try to correct the interference

using one or more of the following measures:

l Reorient or relocate the receiving antenna.

l Increase the separation between the receiver and affected equipment.

l Consult the dealer, DCI, or an experienced radio/TV technician for help.

l Connect the equipment to an outlet on a different circuit.

2 DigiTrak Falcon F5®Operator's Manual

Page 11

DIGITALCONTRO LINCORP ORATED

Battery Pack Storage

If you plan to store the battery packs for any period of time, please follow these guidelines:

l Do not store the battery pack at temperatures greater than 45° C.

l Do not store the battery pack in a fully discharged state.

l Do not store the battery pack in the battery charger.

l Do not store multiple batteries together where their terminals or other loose conductive materials may

contact one another and cause a short circuit.

If a lithium-ion battery pack will be stored for an extended period of time, pre-charge the battery to a charge

level of 30% to 50% (two or three LEDs illuminated on the meter). Do not store the battery pack for more than

one year unless it is periodically recharged to the 30% to 50% level.

Equipment Maintenance

Turn off all equipment when not in use.

Store the equipment in cases, away from extremes of heat, cold, and moisture. Test to confirm proper

operation prior to use.

Clean the glass screens on the receiver and remote display only with a cleaner specifically formulated to not

harm the protective coatings on the glass. If in doubt, use only warm water and a microfiber cloth. Do not use

household or commercial window cleaning products that include chemicals such as ammonia, alcohol, or

any acidic liquid; these cleaners can contain microscopic abrasive granules that will damage the antireflective coating and may cause the display to spot.

Clean equipment cases and housings using only a soft moist cloth and mild detergent.

Do not steam clean or pressure wash.

Inspect the equipment daily and contact DCI if you see any damage or problems. Do not disassemble or

attempt to repair the equipment.

Do not store or ship this equipment with batteries inside. Always remove the batteries from the equipment

before shipping or periods of non-use.

The battery charger provided with your DigiTrak guidance system is designed with adequate safeguards to

protect you from shock and other hazards when used as specified within this document. If you use the

battery charger in a manner not specified by this document, the protection provided may be impaired. Do not

attempt to disassemble the battery charger, it contains no user-serviceable parts. The battery charger shall

not be installed into caravans, recreational vehicles, or similar vehicles.

General Transmitter Care Instructions

Periodically clean the spring and threads inside the battery compartment as well as the spring and threads of

the battery end cap to ensure a proper power connection with the batteries. Use an emery cloth or wire brush

to remove any oxidation that has built up. Be careful not to damage the battery cap O-ring; remove it while

cleaning if necessary. After cleaning, use a conductive lubricant on the battery cap threads to keep it from

binding in the battery compartment.

For better battery performance, all DCI battery-powered transmitters ship with both

a special battery contact spring and a nickel-based anti-seize lubricant on the

battery end cap to aid in electrical contact.

DigiTrak Falcon F 5®Operator's Manual 3

Page 12

DIGITALCONTRO LINCORP ORATED

Before use, inspect the battery cap O-ring for damage that may allow water to enter the battery compartment.

Replace the O-ring if the one installed becomes damaged.

Do not use chemicals to clean the transmitter.

Placing tape around the fiberglass tube of the transmitter, if space allows, will keep the fiberglass protected

from most corrosive and abrasive environmental wear. Do not tape over the IR port as this will interfere with

IR communication.

Falcon 19- and 15-inch transmitters have a threaded hole (1/4”-20 thread) in the battery cap to allow the use

of an insertion/extraction tool for installing and removing the transmitters in end-load housings. Ensure this

hole remains clear of debris.

Send in the Product Registration Card or register online at access.DigiTrak.com within 90 days of purchase

to enable the warranty on your equipment, including a 3-year/500-hour warranty on your transmitter. Ask your

dealer about our extended 5-year/750-hour transmitter warranty.

4 DigiTrak Falcon F5®Operator's Manual

Page 13

Getting Started

Introduction

DIGITALCONTRO LINCORP ORATED

1. Aurora touchscreen

remote disp lay

2. Receiver

3. Transmitter

4. Li-ion/NiMH battery

charger

DigiTrak Falcon F5®Guidance System with Aurora®Remote

Display

Congratulations on your purchase of the DigiTrak Falcon F5®, the flagship system of the DigiTrak Falcon line

of guidance systems. Falcon technology represents a significant advancement in helping crews overcome

one of the biggest obstacles to completing their underground drilling projects: active interference. Falcon F5

provides crews with Falcon technology alongside all the advanced features of the classic F5 system, like

DataLog, fluid pressure monitoring, and Target Steering.

In today’s competitive underground drilling landscape of deeper bores and more challenging jobsites,

interference has emerged as one of the primary obstacles to completing HDD installations on time.

Interference varies from jobsite to jobsite, at different points within the same jobsite, and even with time of

day. After extensive research and testing in some of the most challenging interference environments in the

world, DCI concluded that selecting a transmitter frequency that sidesteps interference is far more effective

at overcoming this obstacle than simply increasing power.

The Falcon approach involves dividing a wide range of frequencies into bands, then selecting the frequencies

that are least susceptible to the interference in each band. Falcon F5 has eight bands that each use the bestperforming of hundreds of frequencies between 9.0 and 45 khz. Optimize one band for best performance on

the majority of the bore and the other for a high-interference segment. The system is easy to learn and simple

to use every day. By following a few easy steps at the beginning of each pilot bore, you will be ready to drill

within minutes.

Competing systems define success in terms of depth and data range. Falcon technology also provides

tremendous range, but that isn’t what makes Falcon great. DCI defines success as enabling crews to

complete the largest number of jobs possible in the shortest periods of time. Falcon technology is designed

around that principle.

DigiTrak Falcon F 5®Operator's Manual 5

Page 14

DIGITALCONTRO LINCORP ORATED

What if I have a question about this topic?

As you read this manual, you may have questions. We've already answered some of them right at

the source in boxes like this. If the topic isn't for you, skip it and read on.

You might need this.

Sometimes it's handy to have some extra information at your fingertips. While it may be

discussed in detail elsewhere in the manual, we've extracted and placed some important data

right where you need it, with a page link if you want to read more.

Go watch some TV.

Subjects with training videos available online will be marked with this icon.

Toggle, trigger, go.Page9

At the Locate screen, toggle down to open the Main menu. Toggle in any direction to reach the

icon you want. Click the trigger to make a selection. In some cases, hold the trigger for

additional information, such as a depth reading at the Locate screen.

The Falcon system comes standard with a receiver, transmitter, batteries, and battery charger. The separate

operator's manuals for these devices are located on the flash drive that accompanied your guidance system

and also at www.DigiTrak.com.

Using This Manual

This manual is an important tool for you as the operator of a Falcon guidance system. You can find it on the

flash drive that accompanied your system or at www.DigiTrak.com. We encourage you to load it onto your

mobile device and keep it handy so the information you need is always close at hand.

When something is worth a little extra attention, we'll mark it with this handy Notebook icon.

To help find those distant details, the manual includes hyperlinks that will take you right there, like this

example:

Prior to use, the receiver must be paired to and calibrated with the

transmitter.

Calibration and AGR

Page13

Powering On

The regional designation number in the globes on the receiver startup screen and transmitter body

must match. If they don’t, contact your DigiTrak dealer.

6 DigiTrak Falcon F5®Operator's Manual

Page 15

DIGITALCONTRO LINCORP ORATED

Receiver

1. Install a fully charged battery pack.

2. Power on the receiver by holding the trigger briefly.

3. Click to accept the “Read the manual before using” statement. The

subsequent information screen provides useful information such as

software version and compatible transmitters. Click to advance.

4.

First time use: from the Main > Settings menu , set the depth units,

pitch units, date/time, and telemetry channel.

5.

On the Main menu, set the optional Height-Above-Ground .

Transmitter

Do not power on the transmitter until after running the frequency optimizer on

the receiver (see next section). After that, or after resuming work (such as

after lunch) using the same frequency bands, simply install batteries with the

positive end first and completely fasten the battery cap.

Settings

Page20

Height-Above-Ground

(HAG)

Page18

Batteries and Power On/Off

Page59

Remote Display (Aurora)

The Aurora®remote display powers on automatically with the drill rig.

1. Connect the telemetry antenna and connect the Aurora to 10–28 VDC power on the drill rig. It

displays the Home screen.

2.

Tap Main Menu in the taskbar, then Receiver to set your type of receiver, telemetry

channel to match that of the receiver, and region.

3.

Tap to return to the Main Menu, then in the Settings tab, tap Device to set the date, time,

and depth and pitch units. Use the same settings as on the receiver. It is also good practice to use

the same system of units (English or metric) on both devices.

4.

Tap Home to return to the Home screen. If the receiver is receiving data from a transmitter,

that data will now display on the Aurora.

If you are using an existing DigiTrak remote display, select F5 to receive data from the locator, and refer to

the separate operator's manual located on the flash drive that accompanied your guidance system and also

at www.DigiTrak.com.

Setup Summary

Getting started with a Falcon F5 receiver is easy: run the frequency optimizer, walk and scan the bore path,

pair the receiver with the transmitter, calibrate, check Above Ground Range, and check for active

interference. It's all summarized in the following several paragraphs, with links to the details later in this

manual. If you're hungry for the details now, skip to Receiver on page9.

Select Frequency Optimizer

1. With the transmitter off (batteries not installed), take the receiver to the point along the intended

bore that might create the biggest locating challenge, like the deepest point of the bore or where

there is obvious active interference such as a railway crossing, transformer, traffic lights, or power

lines.

DigiTrak Falcon F 5®Operator's Manual 7

Page 16

DIGITALCONTRO LINCORP ORATED

2. Power on the receiver and from the Main menu

> Frequency Optimizer

select Transmitter Selection, then Frequency

Optimizer (FO).

3. With the FO results active, walk the entire intended bore path with the receiver and note areas of

high background noise (active interference). The higher a frequency band's bar is on the graph, the

greater the interference. Note which band remains consistently low, since the band with the lowest

level of interference will likely be the one you want to use.

Assign Frequency Bands

1. On the receiver, use the toggle to move the selector on the bottom of the frequency optimizer graph

to the band you want to use and hold the trigger briefly to select.

2. Assign as the Up or Down band.

3. Optional: select and assign a second frequency band.

4.

Select Pair .

5. Insert batteries in the transmitter, positive end first, install the battery cap, and allow several

seconds for the transmitter to fully power on and begin sending data to the receiver.

6.

Align the receiver and transmitter IR ports within four cm of each other. Select to open the

pairing menu, then again to pair.

Page23

Interference Check

Now that your transmitter is paired with your receiver, walk the bore with

both the receiver and transmitter powered on to check for active

interference on both frequency bands.

Changing Frequency Bands

Interference

Page39

Page62

Calibrate

Perform a separate 1-point (1PT) calibration for each newly optimized frequency

band in a low-noise area with the transmitter in a housing. Always calibrate after

assigning a new frequency band.

If you paired two bands and want to be able to switch between them later, calibrate both bands.

Calibration

Page13

Above Ground Range Check

Perform an Above Ground Range check on the new optimized frequency band (or

bands) before drilling. The AGR screen displays automatically after calibration.

If the above-ground AGR distance at 15 m is not accurate, conduct a 15M

15M Calibration

calibration (which also uses only one point) to improve the accuracy of the aboveground distance measurement. A 15 m calibration is not necessary for drilling.

The AGR check shows the distance between the receiver and transmitter without having to constantly hold

the trigger, as when taking a depth reading at the locate line.

AGR

Page17

Page18

Drill

What are you waiting for? Start drilling. Or read on for more details and cool acronyms to know about the best

locator on the planet.

8 DigiTrak Falcon F5®Operator's Manual

Page 17

Receiver

I know what a trigger switch is; can I skip this?Page12

This section is like shaking hands with your Falcon for the first time. If you and your receiver

already have a solid relationship, you can probably jump ahead to Receiver Menus.

DIGITALCONTRO LINCORP ORATED

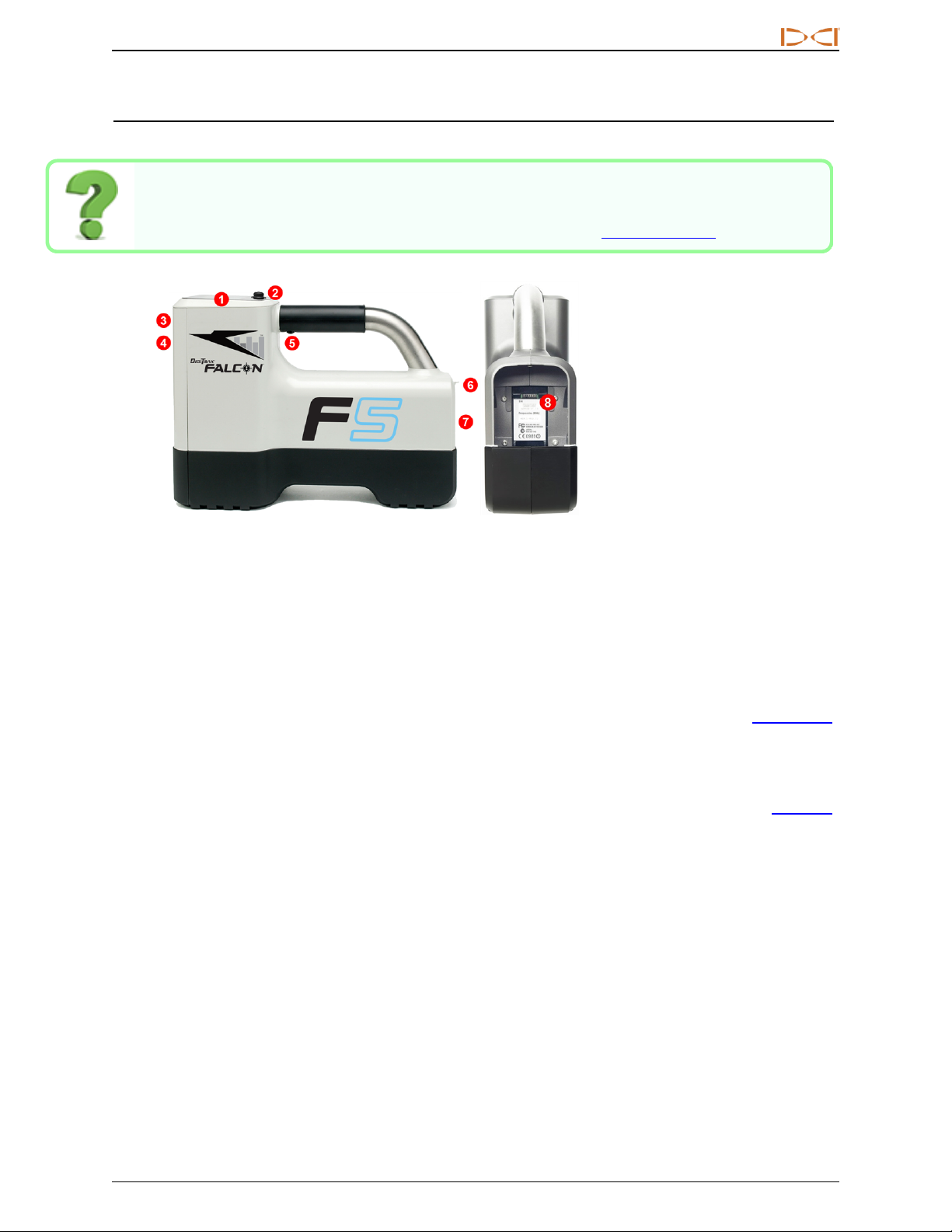

1. Screen

2. Toggle Switch

3. Front

4. Infrared port

5. Trigger switch

6. Battery tab

7. Battery compartment

8. Serial n umber

Falcon F5 Receiver – Side and Back Views

Overview

The DigiTrak Falcon F5®receiver (locator) is a handheld unit used for locating and tracking a Falcon

wideband transmitter. It converts signals from the transmitter to display depth, pitch, roll, temperature, and

battery level, plus sends this information to the remote display on the drill rig.

The receiver and transmitter must meet specific operational requirements for

different global regions. A regional designation number is located on the

Startup Screen

Page10

receiver’s startup screen. This number must match the one stamped on the

transmitter for proper communication.

Prior to use, the receiver must be paired to and calibrated with the transmitter.

Calibration

Page13

Toggle and Trigger Switches

The Falcon F5 receiver has two switches for operating the system: a toggle switch located on the top of the

unit and a trigger located under the handle.

l Use the Toggle Switch to access and navigate menus.

l Use the Trigger Switch to turn on the receiver, select (click on) menu options, and change the screen

view for depth readings. Pull and release (click) once, hold briefly and release, or use in combination with

the toggle switch, depending on the desired action.

DigiTrak Falcon F 5®Operator's Manual 9

Page 18

DIGITALCONTRO LINCORP ORATED

Can I change the screen brightness?

No. The display is pre-tuned for optimal contrast and visibility in all conditions.

Audible Tones

The Falcon F5 receiver beeps to signal power on/off, confirm menu

changes, and acknowledge the pass/fail status of actions. The receiver

also beeps with transmitter temperature increases.

Transmitter Temperature Warning

Tones

Page62

Two long beeps indicate a problem with the menu option selected and a failure screen will appear until you

click the trigger or remove the battery (in the case of a critical failure). Verify your setup and try the operation

again or contact DCI Customer Service for assistance.

Startup Screen

Insert a charged battery pack. To power on the receiver, click the trigger. After you have read the warning

screen, click again to acknowledge you have read and understand this manual. The receiver displays the

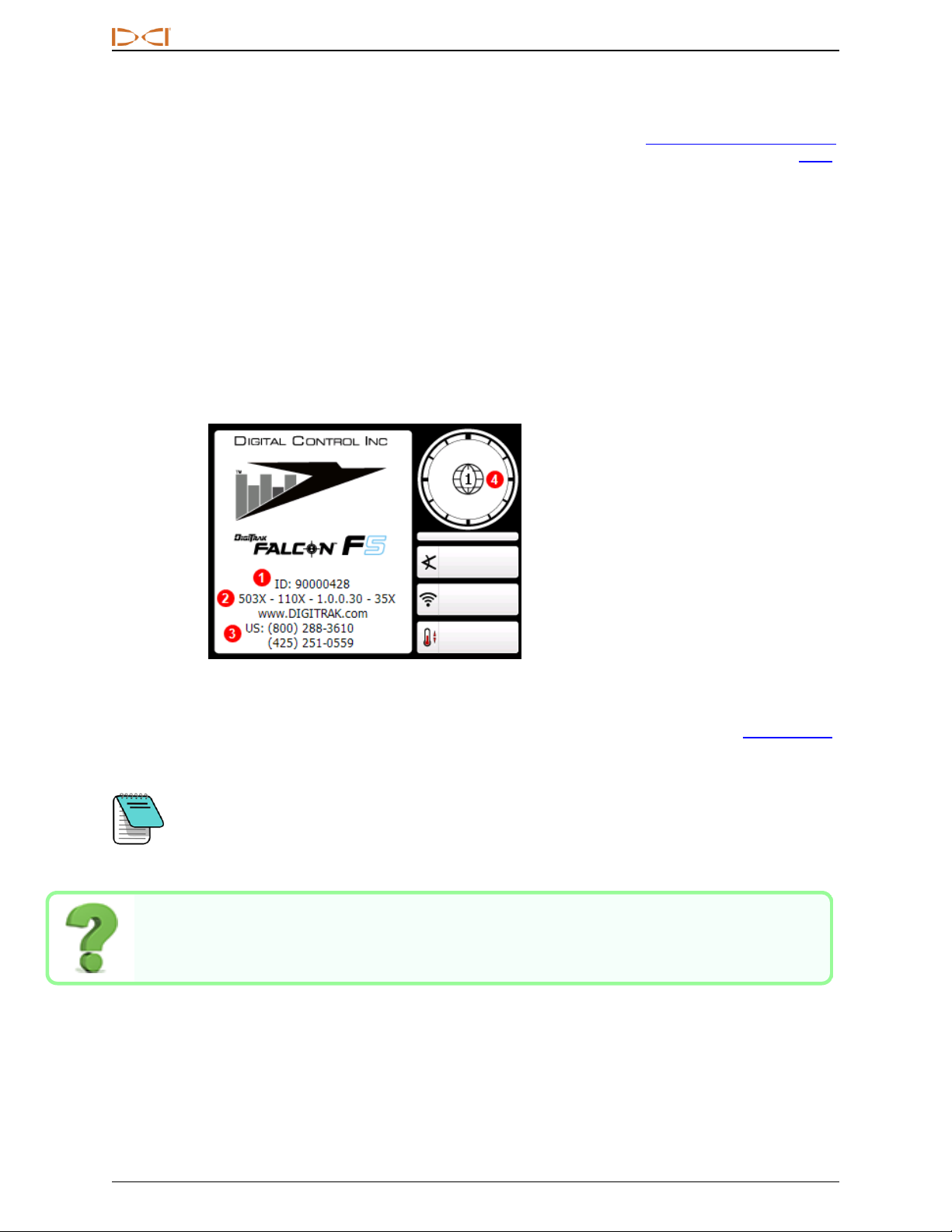

startup screen:

1. Receiver ID number

2. Software version

3. Customer service phone

numbers

4. Regional designation number

must match that o f

transmitter

Receiver Startup Screen

Click to exit the startup screen and open the Main menu.

If an item of the self-test fails, a warning displays and a failure message appears in place of the

system name. An exclamation mark(!) may also appear in the roll indicator on the Locate

screen. Please contact DCI Customer Service.

Receiver Menus

Page12

10 DigiTrak Falcon F5®Operator's Manual

Page 19

DIGITALCONTRO LINCORP ORATED

Using the Keypad

Use the keypad for setting the height-above-ground (HAG) value, a target depth for Target Steering, date and

time, and for programming rod lengths and survey points in the DataLog function.

1. Display window

2. Backspace

3. Enter

Standard Keypad

To input a value, toggle to and select the desired digits from left to right. When a decimal value is required

(such as for feet only or meters), then the last two digits entered will be to the right of the decimal point. To

enter a whole value, enter two zeros at the end of the value. Use backspace to delete the last digit entered.

Once the desired number is in the display window, select Enter to lock in the value and turn on the function.

Your Remote Display

The Falcon F5 receiver is compatible with the following remote displays:

Remote Display Minimum Software Version Select on Remote Display

Falcon Compact Display - FCD 4.0 Falcon F5

Multi-Function Display - MFD 3.0, F5 compatible F5

F Series Display - FSD all F5

Aurora - AP8 , AF8, AF10 all Falcon F5, F5

A remote display that accompanied your Falcon F5 receiver will already be set to communicate with your

receiver.

If you purchased your Falcon receiver by itself, your existing remote display may not include the required

option. If so, contact your regional DCI office or Customer Service for a software upgrade.

The operator's manuals for these remote displays are located on the flash drive that accompanied your

Falcon system and also at www.DigiTrak.com. For an MFD, use the FSD manual.

DigiTrak Falcon F 5®Operator's Manual 11

Page 20

DIGITALCONTRO LINCORP ORATED

I am already familiar with DigiTrak receiver menus; can I skip this?Page35

If you have used a DigiTrak F5 receiver, you are well on your way to mastering a Falcon. Read

the section on the Frequency Optimizer, then skip ahead to Locating Basics. Come back and visit

later as needed for reference. If this is your first DigiTrak, keep reading.

Is there a faster way to get to the menu item I want?

Yes, it's called screen wrapping. If you're at the top of a menu page, toggle up to jump to the

bottom, or if you're at the left side, toggle left to jump to the right, and so on. To get from the topleft icon to the bottom right on the next page, you could toggle right-right-down-down, or just leftup. Yeah. Pretty cool.

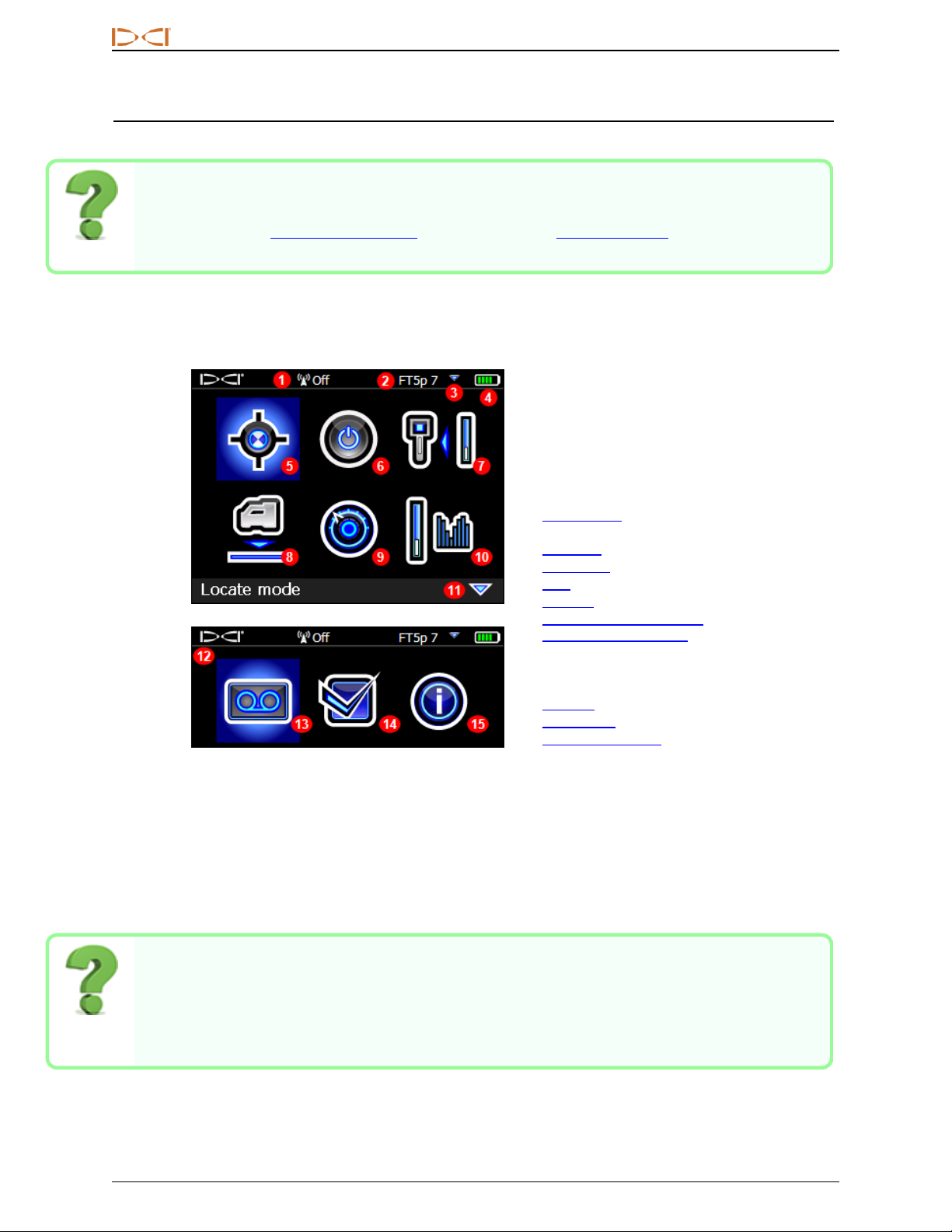

Receiver Menus

To access the Main menu from the Locate screen, toggle down. The Locate Mode icon is shown selected

below; clicking the trigger would take you to the Locate screen.

1. Telemetry channel

2. Transmitter type an d freq uency

band

3. Band Up or Do wn

4. Receiver battery strength

5. Locate Mode (blue backgrou nd =

selected )

6. Power Off

7. Calibration

8. HAG

9. Settings

10. Transmitter Selectio n and

Frequency Optimization

11. Down arrow ind icates seco nd page

below (toggle do wn to view)

12. Second page

13. DataLog

14. Diagnostics

15. System Information

Receiver Main Menus

The top of the Main menu displays the telemetry channel, transmitter, transmitter frequency band, and

receiver battery strength.

The following sections describe the Main menu items in order. Use the links above to jump straight to a

section.

12 DigiTrak Falcon F5®Operator's Manual

Page 21

Locate Mode

Is it okay to power off by pulling the battery out?

Yes, your Falcon can handle it.

Calibrate each band separately

If you select an optimized band that has not been calibrated yet, appears in the roll indicator.

Calibrate and verify Above Ground Range separately for each optimized frequency band prior to

each job. Calibration affects depth readings, but not roll/pitch.

DIGITALCONTRO LINCORP ORATED

When the receiver is detecting a signal from a transmitter, the Locate screen

provides real-time data about the transmitter’s location, temperature, pitch, roll, fluid

pressure (when a fluid pressure transmitter is used), and signal strength.

Locating Screens

Page36

Power Off

Select Power Off from the Main menu to turn the receiver off. The receiver automatically shuts down after 15

minutes of inactivity, or after 30 minutes when in Target Steering mode.

Calibration and AGR

Use the Calibration menu to calibrate the receiver to a transmitter and to verify the Above Ground Range

(AGR). Calibration is required prior to first-time use and before using a different transmitter, receiver, drill

head, or optimized transmitter band. Calibration is not necessary, however, when switching between bands

on a transmitter that are already paired and calibrated.

DigiTrak Falcon F 5®Operator's Manual 13

Page 22

DIGITALCONTRO LINCORP ORATED

Do not calibrate if:

l You are within 3 m of metal structures, such as steel pipe, chain-link fence,

metal siding, construction equipment, automobiles, etc.

l The receiver is over rebar or underground utilities.

l An A is displayed at the top right of the roll indicator on the locating screen, as

Attenuated Signal

this indicates signal Attenuation is in effect, likely due to excessive

interference. If possible, relocate to a quieter location before calibrating.

l The receiver is in the vicinity of extreme interference, as shown by high

Frequency Optimizer

background noise readings on the frequency optimizer graph or a flashing

signal strength value on the locate screen along with the A icon (calibration is

prohibited when the signal strength is flashing).

l The receiver is not displaying transmitter data.

l The signal strength from the transmitter is less than 300 points (too low) or

Installing Batteries /

greater than 950 points (too high). Outside this range, a calibration failure

screen will indicate low or high signal strength.

The transmitter must be installed in a drill head during calibration.

During calibration, Height-Above-Ground (HAG) is automatically turned

Height-Above-Ground (HAG)

off. After calibration, HAG must be turned back on manually.

1-Point Calibration

Calibrating depth readings is accomplished above ground, prior to drilling.

1. Place the receiver and the transmitter (in a drill head) parallel to each other on level ground, with

both devices powered on.

Page67

Page23

Power On

Page59

Page18

2. With the receiver at the Locate screen, verify that roll and pitch values are being displayed and that

a steady signal is being received from the transmitter. The transmitter’s signal strength at

calibration is available under View calibration. A change in signal strength at 3 m later can indicate

you are currently in an interference environment or there is a problem with your equipment.

3. Move the locator within 0.5 m of the transmitter to enable signal attenuation, indicated by an A at

the top right of the roll indicator. Move the locator back to 3 m away and verify attenuation turns off.

If it does not, excessive noise may be present. Due to its higher signal strength, a 19 in. transmitter

must be moved more than 3 m away from the receiver before attenuation will turn off.

14 DigiTrak Falcon F5®Operator's Manual

Page 23

DIGITALCONTRO LINCORP ORATED

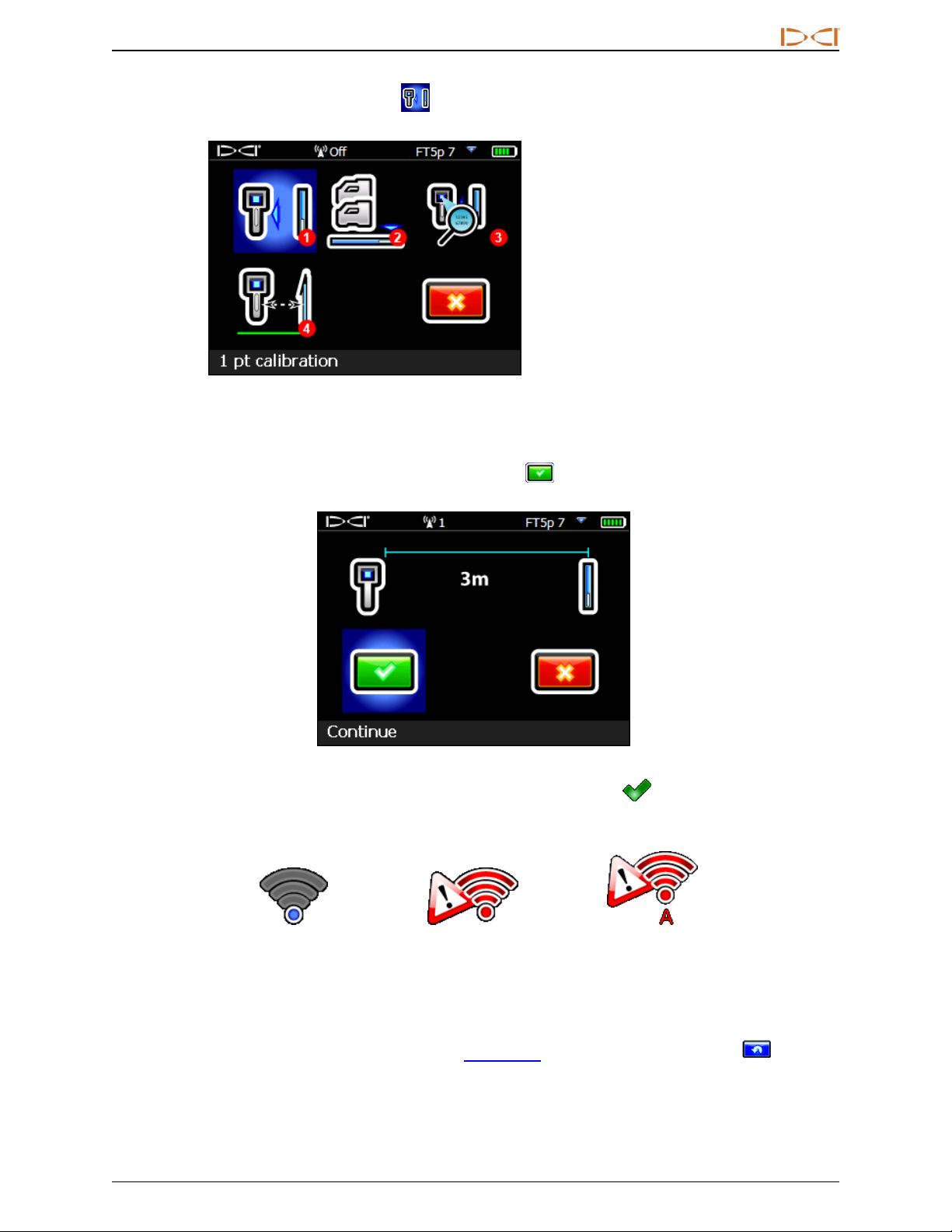

4.

At the Main menu, select Calibration and then 1 pt calibration.

1. 1 p t calibration

2. In-Ground Calibration

3. View Calibration

4. Above Ground Range (AGR)

Calibration Menu

5. Use a tape measure to ensure the distance from the center of the transmitter to the inside edge of

the receiver is 3 m as shown below, then click Continue to begin the calibration.

6.

Do not move the receiver. A successful calibration yields a check mark and four beeps.

Calibration can fail for one of three reasons:

Transmitter signal is

too low (below 300

points)

Transmitter signal is

too high (above 950

points)

Extreme signal

attenuation is in effect

If calibration fails, review the items mentioned in the question titled Why do I keep getting calibration

errors? below, read more about signal attenuation in Appendix B (if it applies), then click Retry to try

calibrating again.

DigiTrak Falcon F 5®Operator's Manual 15

Page 24

DIGITALCONTRO LINCORP ORATED

Why do I keep getting calibration errors?

Carefully review the items under Do not calibrate if at the beginning of this section. Try

calibrating in a different location. Make sure the transmitter is on and paired (data showing on

the Locate screen). If you're still having trouble, give us a call, we'll get you going.

After a successful calibration of one band, before proceeding to the AGR screen

to verify above-ground distances for this calibration, the receiver briefly displays

this icon:

Above Ground Range

(AGR)

Page17

This simply means the Down band (on the left) has been calibrated, but the up band has not. After checking

AGR for the current band, remember to calibrate and check the AGR of the other band.

If depth data does not display, hold the trigger while over the transmitter to display the locate

line. For additional information on obtaining this reference lock (“R”), see step 4 in the

discussion under Finding the Front Locate Point (FLP) beginning on page46.

If you just completed AGR after calibration, don't forget to turn

Height-Above-Ground (HAG) back on, if necessary.

Height-Above-Ground (HAG)

Page18

In-Ground Calibration

This calibration procedure is rarely needed. If you find it necessary to calibrate with the transmitter in the

ground, contact DCI customer service for information on this option, and perform this procedure with caution.

16 DigiTrak Falcon F5®Operator's Manual

Page 25

DIGITALCONTRO LINCORP ORATED

AGR: It's Just What You Do

Performing an AGR test on both frequency bands at every jobsite is just good practice.

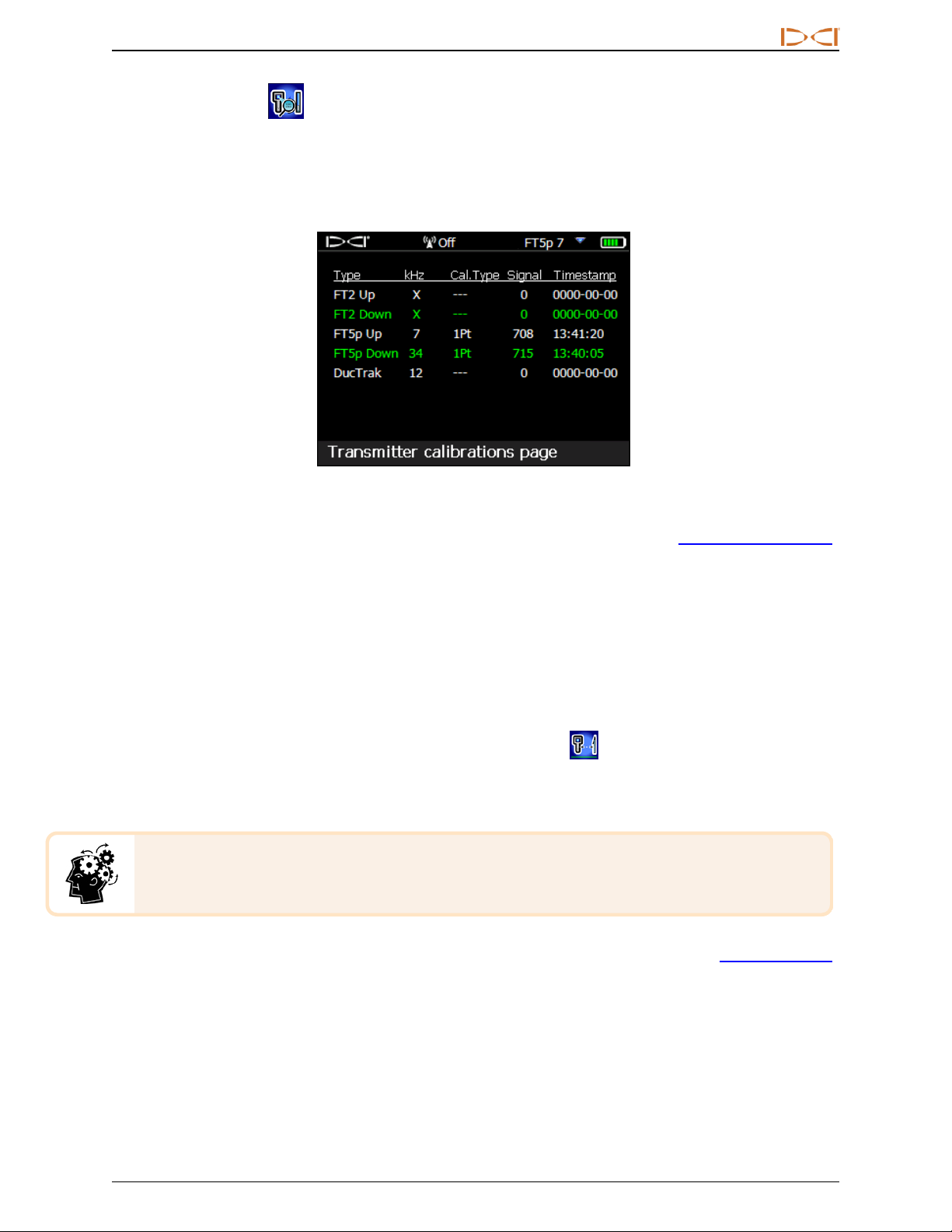

View Calibration

Use this feature to check the most recent calibrations for your transmitter(s). The data will include the model

of transmitter, type of calibration (1-point or in-ground/2Pt), signal strength, and a timestamp. Though this

window lists all transmitters compatible with your receiver, only transmitter bands calibrated to your receiver

will display data in the Signal and Timestamp columns.

View Calibration Window

After calibrating a fluid pressure transmitter, turning the fluid pressure

feature on or off does not require a new calibration. However, a

separate calibration is required for each frequency band if you want

the option of switching between them mid-bore.

Click to return to the Calibration menu.

Changing Frequency Bands

Page62

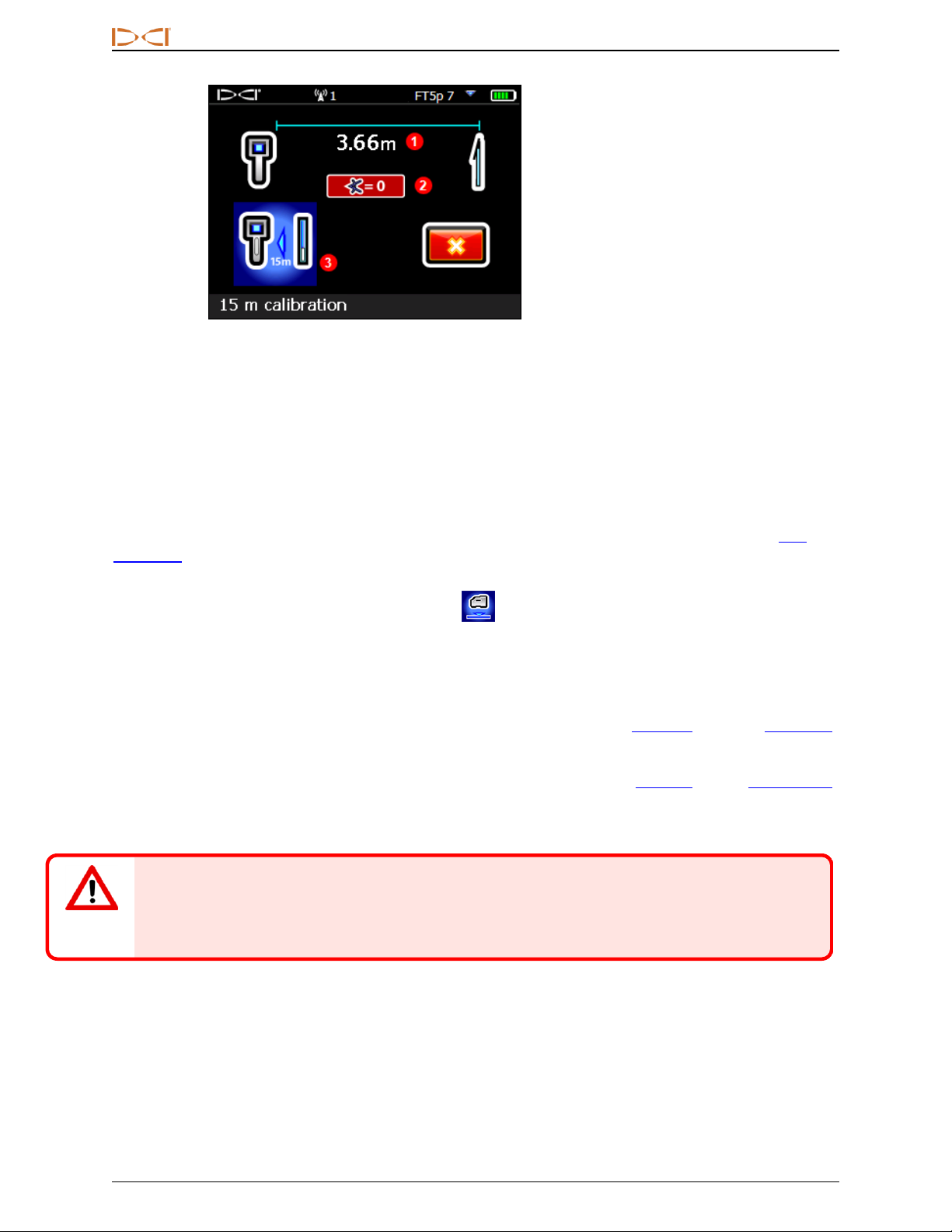

Above Ground Range (AGR)

After successfully completing a 1-point calibration, the receiver displays the Above Ground Range screen,

which is an active measurement between the transmitter and receiver. You can also access this tool directly

from the Main menu > Calibration > Above Ground Range (AGR) . Use this screen along with a tape

measure to verify calibration of the transmitter at different depths/distances. With the transmitter level, the

depth readings should be within ±5% of the measured distance.

Note that because AGR intentionally does not consider pitch when

calculating range, it displays a symbol indicating "Warning, pitch is

unknown, assume zero". It also ignores any HAG setting.

Note that the 15 m calibration button does not appear when the AGR screen appears immediately after

calibration.

Pitch Assumed Zero

Page37

DigiTrak Falcon F 5®Operator's Manual 17

Page 26

DIGITALCONTRO LINCORP ORATED

Prior to enabling HAG, verify accurate range/depth readings at a minimum of two points using

AGR (see link above) or a regular depth reading (hold the trigger). If the transmitter is not

properly calibrated, inaccurate depth readings will be made worse by an inaccurate HAG

distance.

1. AGR

2. Pitch assumed zero

3. 15 m calibration

Above Ground Range (AGR)

If you just completed AGR after calibration, don't forget to turn Height-Above-Ground (HAG) back on, if

necessary.

15 m Calibration (Optional)

This feature is primarily used for demonstrations of the guidance system above ground and is not necessary

for drilling. Above ground range (AGR) measurements beyond 12.2 m often read shallower (shorter) than they

actually are due to variations in ground conditions, and this feature calibrates these measurements to

account for these variations. Using this feature is substantially similar to the procedure described for 1 pt

calibration; if you require further information, please contact DCI customer service.

Height-Above-Ground (HAG)

Use Height-Above-Ground (HAG) to set a height measurement on the receiver so you don’t have to set it

on the ground for a depth reading. Raising the receiver above the ground also provides separation from

underground interference that might otherwise reduce the transmitter’s range or cause variable readings.

To prevent incorrect readings, Falcon F5 always powers on with

the HAG function off (disabled). HAG also automatically shuts

Calibration

Page14

off during calibration and is ignored during Target Steering and

AGR tests. Until you enable HAG, the receiver must be placed

on the ground for accurate depth readings.

AGR Test

Page17

1. To determine your desired HAG distance, hold the receiver comfortably at your side, maintaining 20

cm of separation from the front of the receiver to your torso as specified in the Safety section on

page1. Measure the distance from the bottom of the receiver to the ground.

2. From the Main menu, select HAG. The HAG menu displays with Enable HAG highlighted and the

current or 0.51 m default HAG setting shown in the description line at the bottom of the screen. If

the HAG had been enabled, Disable HAG would be highlighted.

Depth Units

Page20

Target Steering

Page 54

18 DigiTrak Falcon F5®Operator's Manual

Page 27

DIGITALCONTRO LINCORP ORATED

I use HAG all the time; can I set it to turn on automatically?

No. In the name of safety, HAG must be turned on manually for each use. However, the feature

does remember the last height value used.

1. Disable HAG

2. Enable HAG

3. Set HAG

HAGMenu

3. If the HAG value shown at the bottom of the screen is acceptable, select Enable HAG. The

receiver beeps four times as it enables HAG and returns to the Main menu. Skip the next step.

4. To change the HAG value shown at the bottom of the screen, select Set

HAG and enter a new value. After you select Enter on that screen, the

Using the Keypad

Page11

receiver beeps four times as it enables HAG and returns to the Main

menu.

Depth readings (holding the trigger) must now be taken with the receiver held at this height.

As noted above, to prevent incorrect readings, HAG must be turned on manually each time after the receiver

is powered on or calibrated.

DigiTrak Falcon F 5®Operator's Manual 19

Page 28

DIGITALCONTRO LINCORP ORATED

Settings

Use this menu to set the following options:

1. Depth Un its

2. Pitch Units

3. Date/Time

4. Telemetry Ch annel

5. Roll Offset

6. Pressure Units

7. Second pag e

8. Temperature Units

9. Language

Settings Menus

DCI recommends that you program the receiver and the remote display Depth and Pitch settings to use the

same units of measure.

Depth Units Menu

Choose between xx" inches, x'xx" feet and inches, x.xx' decimal feet, and x.xx m metric units (meters and

centimeters).

Pitch Units Menu

Choose between degrees (x°) and percent (x%). Typical HDD bores use percent pitch instead of degrees.

20 DigiTrak Falcon F5®Operator's Manual

Page 29

DIGITALCONTRO LINCORP ORATED

Set Time and Calendar Menu

Set the time and date on your receiver. This is necessary when you are using the DataLog function.

1. Time value (date displays

here when calendar is the

active function)

2. Time (shown active)

3. Calendar

4. Enter

Time and Calendar Keypad

Setting the Time

The time function runs on a 24-hour clock. To set the time:

1.

Select the time icon so it is the active function .

2. Enter the time one digit at a time from left to right. For example, to set the clock to 13:39 (1:39 pm),

select 1, then 3, 3, and 9.

3. Select the blue Enter arrow.

Setting the Calendar

The calendar function displays the date by month/day/year. To set the date:

1.

Select the calendar icon so it is the active function . The display window on the keypad

changes to show a date format.

2. Enter the date one digit at a time from left to right. The date format is MM/DD/YYYY. For example,

to set the date to January 2, 2016 (01/02/2016), select 0, then 1, 0, 2, 2, 0, 1, and 6.

3. Select the blue Enter arrow.

Telemetry Channel Menu

This menu has five telemetry channel settings (1, 2, 3, 4, and 0). For communication to occur between the

receiver and remote display, both devices must be set to the same telemetry channel. The current telemetry

setting is highlighted when this menu opens.

Select the desired telemetry channel on the receiver. To turn telemetry off and conserve receiver battery life,

select “0”. Channel 0 is also used when there are more than four receivers operating in the same area; using

more than one receiver per channel within telemetry range of each other will cause conflicting signals to be

sent to the remote display on the drill rig.

DigiTrak Falcon F 5®Operator's Manual 21

Page 30

DIGITALCONTRO LINCORP ORATED

Roll Offset Menu

Enable Roll Offset

1. Select Set and enable the roll offset.

Roll Offset Menu

1. Set and enable the roll offset

2. Disable roll offset

2. Ensure the drill head is at its 12:00 position and that the transmitter is on.

1. Transmitter’s true roll position with

housing at 12:00

2. Set th e roll o ffset

Set Roll Offset Menu

3. Select Set the roll offset.

If you need to know the original roll value later (perhaps to change a transmitter frequency in-bore as

discussed on page62), simply toggle to the Roll Offset option in the Settings menu, and if Roll Offset is

enabled, the original roll value displays at the bottom of the screen after "Roll offset enabled".

When the roll offset function is enabled, the roll indicator will change to a circle and RO appears at the bottom

left of the roll indicator. RO will also appear on the remote display.

Roll Offset Enabled

22 DigiTrak Falcon F5®Operator's Manual

Page 31

DIGITALCONTRO LINCORP ORATED

Disable Roll Offset

Select Disable the roll offset from the Roll Offset menu. The receiver beeps four times as the screen

returns to the Settings menu. The value that displays for roll on the Locate screen will now be that of the

transmitter, not necessarily the drill head.

Pressure Units Menu

Choose between pounds per square inch (psi) and kilopascals (kPa).

Temperature Units Menu

Choose between Fahrenheit (F) and Celsius (C).

Language Selection Menu

This menu has multiple language options. Selecting a new language will cause the receiver to restart.

Transmitter Selection and Frequency Optimization

Transmitter Selection Menu

1. Frequency Optimization

2. Transmitter Selection

3. View Frequen cy Optimization

4. Transmitter Information and

Run time

DigiTrak Falcon F 5®Operator's Manual 23

Page 32

DIGITALCONTRO LINCORP ORATED

Do I have to optimize every time I power the receiver on?Page59

No, the receiver remembers both optimized bands until you pair it to a new band. Power the

transmitter on horizontally to use the last active band. But don't forget to optimize at your next

bore.

If my optimized band worked great at my last jobsite, can I keep using it at my next one?

Because sources of interference differ at every jobsite, DCI recommends optimizing at every

jobsite to obtain the best selection of frequencies for the current conditions.

Some of my bands are missing on the optimizer. Is my Falcon F2 broken?

No. A maximum of nine bands are available, but some country regulations limit the number of

frequencies and bands available.

Frequency Optimization

This section addresses Falcon technology's ground-breaking frequency optimizer (FO) feature, which finds

the lowest-noise (optimal) group of frequencies available in each of eight bands. When the results display in

graph form showing the levels of active interference in each band, choose the one or two bands you want to

use, pair, and you're ready to calibrate and start drilling.

You can switch the transmitter between the two optimized bands at any time, either pre-bore or mid-bore.

Start in the optimized band that works best for the normal-interference portion of the bore and switch to the

other band that works better for the portion that has higher interference. Or use one optimized band for the

whole bore, or start drilling in one optimized band and switch only if you need to. The choice is yours.

To optimize and select a frequency band:

1. Ensure all transmitters are powered off or are more than 30 m away from the receiver.

2. Take your receiver to the point along the proposed bore that you expect to have the greatest amount

of noise (active interference).

3.

With thereceiver parallel to theborepath, open theMain menu, select Transmitter Selection ,

then Frequency Optimization (FO) .

When frequency optimization is complete, the receiver shows active noise readings in each of the eight

frequency bands using an optimized selection of the lowest-noise frequencies within each band. The

shorter the bar on the graph, the less interference present in that band.

-90 to -72 dB Low interference levels

-72 to -54 dB Moderate interference

-54 to -18 dB Interference will become an issue as depth increases

24 DigiTrak Falcon F5®Operator's Manual

Page 33

DIGITALCONTRO LINCORP ORATED

Optimize as often as you want. You can't wear it out.

If noise levels rise substantially at any point along the bore, consider selecting and pairing one

band (see next step) that performed well up to this point. Then select Exit and restart FO at this

point to perform a new scan and select and pair a second band for use in this higher-interference

area. Optimize as often as you want and wherever you want before assigning a band.

Are high frequency bands better than low frequency bands?

Interference varies with time and location, and no band works perfectly in all conditions.

Different bands are better for different kinds of interference. Lower frequency bands tend to

perform well despite passive interference. Middle bands can perform better in deeper bores and

may have longer Target Steering capability. High bands have slightly less signal strength but tend

to offer better performance around active interference such as power lines.

1. Maximum noise reading

2. Current Up b and

3. Current Down b and

4. Current optimized noise

readings

5. Att enuation enab led

6. Band number

7. Band selecto r

8. Pair

9. Exit

Frequency Optimizer Results

4. To measure noise readings from the entire intended bore, simply walk the bore with the frequency

optimizer results displayed, keeping the receiver parallel to the bore path. As the receiver continues

sampling background noise, it marks the maximum noise reading of each band at the top of each

bar.

5. Toggle to the band you want to use and click to select. Typically this will be a band with a low

interference level that did not experience high maximum noise readings along the bore path. The

band number represents the approximate middle kHz frequency of each band.

Band Number 11 16 20 25 29 34 38 43

Range in kHz 9.0 – 13.5 13.5 – 18 18 – 22.5 22.5 – 27 27 – 31.5 3 1.5 – 36 36 – 40.5 40.5 – 4 5

6. Select whether to assign this as the Up or Down band (the band the Tx powers on with when facing

Up or Down).

DigiTrak Falcon F 5®Operator's Manual 25

Up Down

Page 34

DIGITALCONTRO LINCORP ORATED

Can I exit the pairing screen and go back to the optimizer results without running it again?

Yes. Toggle left and select Return to frequency graph . Maximum readings will be reset

and you can continue observing the noise readings of the last optimized frequency bands. Exiting

from the frequency graph will erase optimization results.

If the band number you want to use is already displayed at the right edge of the screen and

marked in red on the bottom of the graph, select it anyway. The band you select now will be

optimized with different frequencies than the last time that band was used.

7. Optional: click to select a second band, then assign as the opposite (Upor Down) band; changing

both bands is not required.

8. The receiver displays the transmitter pairing screen. Insert batteries in the

Transmitter

transmitter, install the battery cap, and wait 15 seconds for the transmitter

to fully power on. The increase in frequency optimizer noise readings

show the transmitter is on.

9.

Select Pair , then Transmitter Pairing Request . If you assigned two new bands, both will

pair at the same time.

10. Position the infrared (IR) port of the transmitter within 5cm of and facing the IR port on the front of

the receiver.

1. Transmitter IR port

11.

Select again (we really like this icon) to pair the transmitter frequency band(s) to the receiver.

Hold the transmitter in place for up to ten seconds for pairing. A blue circling icon indicates the

receiver and transmitter are not yet connected; check alignment and proximity of the IR ports.

Moving the transmitter during pairing may cause an error code to display on the screen; if this happens,

simply restart the pairing process. Earlier generation transmitters may take as long as 20 seconds to

pair.

Page58

When the pairing is successful, the receiver/transmitter icon briefly shows a happy green check mark

and the receiver beeps. Both the receiver and transmitter are now using the new optimized band(s) you

selected. If you assigned two new bands, the system defaults to using the Down band first.

l

If the pairing is unsuccessful, the receiver/transmitter icon shows an unhappy red . Select Repeat

and try pairing a second time. If still unsuccessful, ensure you have the correct transmitter selected

(Page27), remove and reinstall the transmitter batteries (positive end first) and battery cap, realign the

two IR ports, and try again. To verify the receiver can communicate with the transmitter, see Transmitter

Information and Runtime on page 28. If still unsuccessful, give us a call and we'll get you going.

l If the pairing doesn't complete, no new optimized frequency is stored in the receiver. Upon exiting the

Frequency Optimizer screen, the receiver remains paired to the transmitter at the last optimized bands

used. The last frequency optimization is saved and viewable under View Frequency Optimization .

26 DigiTrak Falcon F5®Operator's Manual

Page 35

DIGITALCONTRO LINCORP ORATED

l As mentioned at the end of step 4, the second band can be paired to a completely different optimization. If

you just paired one band but want to re-optimize at a different location for the other band, simply run the

frequency optimizer at the new location (step1), select a band, and assign as the opposite (Up or Down)

band.

So I Just Paired, Now What?

After pairing, the receiver proceeds to the calibration screen as a

reminder that with the selection of a new frequency band, the transmitter

and receiver need to be calibrated. Install the transmitter in the drill head

and calibrate.

Prior to calibration, "Calibration required" is indicated on the Locate screen by an error symbol in

the roll indicator in place of the roll value. To change between bands mid-bore, both bands must be

separately selected and calibrated prior to drilling.

Calibration

Page13

Before or during drilling, switch between bands any time if interference is

compromising the current band.

After pairing optimized frequency bands, for typical operations your next

steps before drilling would be:

l calibrate

l check Above Ground Range (AGR)

l check for background interference

Changing Frequency Bands

Page62

Above Ground Range

Page17

Interference

Page39

Complete each of these checks on both optimized frequency bands.

Transmitter Selection

Use this option to select between a Falcon F5, Falcon F2, or DucTrak transmitter, as well as select the other

band on your current transmitter.

Transmitter Selection Menu

After you select a different transmitter than is currently in use, the display returns to the previous screen.

DigiTrak Falcon F 5®Operator's Manual 27

Page 36

DIGITALCONTRO LINCORP ORATED

If you select the same transmitter that is currently in use, the display continues to the Band Selection menu,

where you can switch between the Up and Down bands, as well as enable or disable fluid pressure

monitoring on an FT5p transmitter.

1. Up band

2. Fluid pressu re

3. Down band

4. Current 1-p oint calibration

signal st rength

5. Return to Locate screen

Band Selection Menu

To reach this menu directly from the Locate screen, hold the toggle right for one second.

View Frequency Optimization

Want to see what the active interference is right now on your optimized band? Sure you do.

Select either the Up or Down band icon. Falcon displays the current interference levels for the current

optimized frequencies in that band. You may optionally select and pair a different optimized band from this

screen. If so, remember to calibrate again prior to drilling.

Transmitter Information and Runtime

Select this option to view information about your transmitter, including serial number, maximum temperature,

and active runtime hours . It's also a handy to way to double-check that the receiver is able to

communicate (pair) with the transmitter.

Position the recessed infrared (IR) port of the transmitter within 5 cm of and facing the IR port on the front of

the receiver, then select Transmitter information request .

Transmitter Information

28 DigiTrak Falcon F5®Operator's Manual

Page 37

DIGITALCONTRO LINCORP ORATED

Click to return to the Main menu.

DataLog

The DataLog®feature on your receiver lets you capture and store the rod-by-rod data of your pilot bore. When

used with our mobile phone app LWD Mobile, using DataLog while drilling lets you view a real-time plot of

your bore in progress right on your phone, as well as geo-tag the entry and exit. If you use the DigiTrak Aurora

remote display, its LWD Live app also lets you view the drill profile in real-time as each rod is completed,

whether DataLog is enabled on the receiver or not.

In addition to the rod data DataLog has always captured, with Falcon F5 we’ve added features like left/right

offset and deviation, which let you record with even greater detail precisely where your pilot bore is in relation

to surrounding landmarks. Increasingly, this data is also required by the client to ensure drilling parameters

were met. When you import your DataLog job into our Log-While-Drilling (LWD) 3.0 software for your PC, you

can edit, annotate, and create the precise report you or your client requires.

Use this menu to record pilot hole drill data, set up new drill jobs, view and delete drill jobs from the receiver,

and upload drill jobs via Bluetooth to a computer for analysis with DCI's Log-While-Drilling (LWD) software.

Falcon F5 is not compatible with LWD v2.12.

1. Set up job

2. Upload

3. Delete

4. Enable/disable

5. Survey po int

6. View jobs

7. Second pag e

8. Left/righ t offset

9. Deviation

10. Exit

Drill DataLog Menus

The LWD software has a variety of options for analyzing, editing, and displaying DataLog drill data.

Complete instructions for using the advanced DataLog feature and the supporting LWD software are

provided in the separate operator's manual and quick start guides available for DataLog/LWD at

www.DigiTrak.com.

DigiTrak Falcon F 5®Operator's Manual 29

Page 38

DIGITALCONTRO LINCORP ORATED

If you are already familiar with the DataLog feature, Falcon F5 includes four new functions requested by

users like you: Left/Right Offset, Deviation, Flags, and Pins.

1. Sidewalk

2. Right offset

3. Right deviation

4. Fire hydrant

5. Pin distance to the rig ht

6. Set pin marking fire hydrant

7. Intended bore path

8. Actual bore path

9. Set flag marking gas lin e

crossing

10. Marked gas line

Left/Right Offset, Deviation, Flags, and Pins

Left/Right Offset

On the DataLog menu, L/R Offset lets you specify a given horizontal distance you intend to maintain from a

feature beside the bore path, such as a curb, guardrail, or surveyed path. Think of this as a "running

waypoint" that is recorded as long as the offset is in effect.

In the image above, the offset is a "right" offset, meaning the intended bore path is to the right of the sidewalk

feature.

Deviation

Also on the DataLog menu, Deviation lets you mark how far the drill head is deviating from the intended bore

path. If an offset is in effect, it is how far the drill head is deviating from the offset.

Each time you log a rod at the Locate screen (hold trigger, toggle right), this feature lets you also record your

current deviation from the bore path. For example, if you know you are supposed to be a certain distance

from a guardrail but locate the drill head at a slightly farther distance, or are following a surveyed path and

locate the drill head slightly to one side of the path, enter the difference as a left or right deviation.

Flags and Pins

While recording a DataLog, at the Locate screen, toggle right to set a Flag or Pin. Match flags and pins later

with entries in your drilling log book to add important detail to your Log-While-Drilling report.

30 DigiTrak Falcon F5®Operator's Manual

Page 39

DIGITALCONTRO LINCORP ORATED

Flags

Select a Flag when crossing any item of interest along the bore path, like a sidewalk, marked utility line, or

river bank. The receiver assigns a sequential flag number starting at 1. Enter the approximate distance along

the current rod (if halfway along a 3 m rod, enter 1.5 m). The receiver will calculate the total horizontal

distance of the flag based on the total number of rods already logged.

Pins

Select a Pin to mark the location of a nearby land feature point (station mark, survey flag, fire hydrant, light

post) that can help locate the bore path later. Setting a pin requires three pieces of data:

1. An identifying number. Use any number, like a survey station mark.

2. The approximate distance along the current rod (if halfway along a 3 m rod, enter 1.5 m).

3. The distance of the drill head to the right or left of the feature (perpendicular). In the preceding

image, because the drill head is to the right of the fire hydrant "feature", the pin is recorded as to the

right.

Diagnostics

This menu lets you check the performance of your Falcon F5 receiver.

Diagnostics Menus

1. Level check

2. System self-test

3. Signal self -test

4. Exit

DigiTrak Falcon F 5®Operator's Manual 31

Page 40

DIGITALCONTRO LINCORP ORATED

Perform Level Check

This check confirms that the internal sensors that measure the inclination of the receiver are working

correctly. An inaccurate sensor would cause erroneous depth and location readings.

Place the receiver on generally level ground and click Continue . The ground does not have to be

perfectly level.

Level Check Screen 1

Rotate the receiver 180 degrees so it faces the opposite direction, as illustrated by the icon on the screen,

and click Continue again.

Level Check Screen 2

The receiver beeps four times, flashes a confirmation message, and returns to the Main menu.

If the level check fails, the receiver beeps twice and displays an error screen. Click Retry and repeat the

test as described above. If the check fails again, contact DCI Customer Service.

32 DigiTrak Falcon F5®Operator's Manual

Page 41

DIGITALCONTRO LINCORP ORATED

Perform System Self-Test

This self-test performs a system check on internal components. Ensure no transmitters are powered on

during this test. The receiver beeps four times after a successful test and displays the receiver Startup

Screen (shown on page10). Click to return to the Diagnostics menu.

If the receiver returns any other results, contact DCI Customer Service.

Perform Signal Self-Test

This self-test tests antenna gain calibration for all transmitter frequencies.

Ensure no transmitters are powered on during this test. Perform this test only

in a low-noise environment with minimal interference. The transmitter signal

strength as displayed on the Locate Screen must be less than55 counts.

Locate Screen

Page36

The receiver beeps four times after a successful test and displays the startup

screen. Click to return to the Diagnostics menu.

Startup Screen

Page10

If the receiver returns any other results, contact DCI Customer Service.

Potential test failures

Background noise

If the test begins in an area with too much background noise, the test stops and the receiver displays a

warning similar to Background signal is too high. Find a lower-noise area and try the test again.

Test Loop

If there is a problem with the depth antenna in the receiver, the receiver displays the error message Fault:

Depth Antenna Failure on the Locate screen and locks the receiver. Contact DCI Customer Service.

DSP channel failure

In the event of a Digital Signal Processor (DSP) channel failure, the receiver displays the error message

Critical: DSP channels on the Locate screen and locks the receiver. Contact DCI Customer Service.

DigiTrak Falcon F 5®Operator's Manual 33

Page 42

DIGITALCONTRO LINCORP ORATED

System Information

This menu displays technical system information such as ID, region, and numerous firmware versions. The

numbers for BT (Bluetooth®) and ID (serial number) are necessary to move DataLog files to a PC. Click to

return to the Main menu.

System Information Screens

1. Serial n umber

2. Region

3. Primary software

4. Bluetoo th address

5. Second pag e

34 DigiTrak Falcon F5®Operator's Manual

Page 43

Locating Basics

Are you ready?Page39

If you're new to locating and first want to know everything about the locating screens, you've

come to the right place. If you already know locators and want to jump right in and start locating

with your Falcon F5 system, skip to Interference.

Refer to the DigiTrak YouTube site at www.youtube.com/dcikent for helpful videos on these and

many other locating topics.

DIGITALCONTRO LINCORP ORATED

Locating in a High-Interference Area

This section covers locating basics:

l Locating screens

l Checking for interference and suggestions for dealing with it

l Performing a roll/pitch check

l Finding and marking front and rear locate points (FLP and RLP) and the locate line (LL) to pinpoint the

transmitter

l The geometry of the FLP, RLP, and LL with respect to the transmitter

l Methods to verify depth readings

DigiTrak Falcon F 5®Operator's Manual 35

Page 44

DIGITALCONTRO LINCORP ORATED

Do I have to know all this?Page45

Get this down first, then you'll be ready to locate like a professional. If you skip to Locating the

Transmitter and feel like you're missing a little background information, come back here for a

refresher.

How do I check which frequency bands are assigned?

The current band in use is listed at the top of the Main menu (page12). Hold toggle right at the

Locate screen to see and switch between bands.

Locating Screens

The Locate, Depth, and Predicted Depth screens are the primary screens you will use for locating. The type

of depth screen that displays depends on the position of the receiver relative to the transmitter at the time of

the depth reading.

For a description of the icons on the Locate screens, see AppendixB on page67.

Locate Screen

When the receiver is detecting a signal from a transmitter, the Locate screen provides real-time data about

the transmitter’s location, temperature, pitch, roll, and signal strength.

1. Locating ball (FLP or RL P)

2. Yaw indicator

3. Receiver

4. Roll indicator

5. Roll value

6. Roll/pitch update meter

7. Transmitter pitch

8. Transmitter signal strength

9. Transmitter fluid pressu re

10. Transmitter temperature

Locate Screen with Transmitter in Range

If the transmitter is on and there is no roll or pitch data, hold the trigger for five seconds to engage Max Mode

and the data should appear. If it doesn't: