Page 1

Power On Receiver

1.

Install battery and cli ck trigger to

power on the receiver.

2.

Ensure the region number in the

globe icons on the startup screen and

transmitter match.

3.

Click the trigger to reach the Locate

screen.

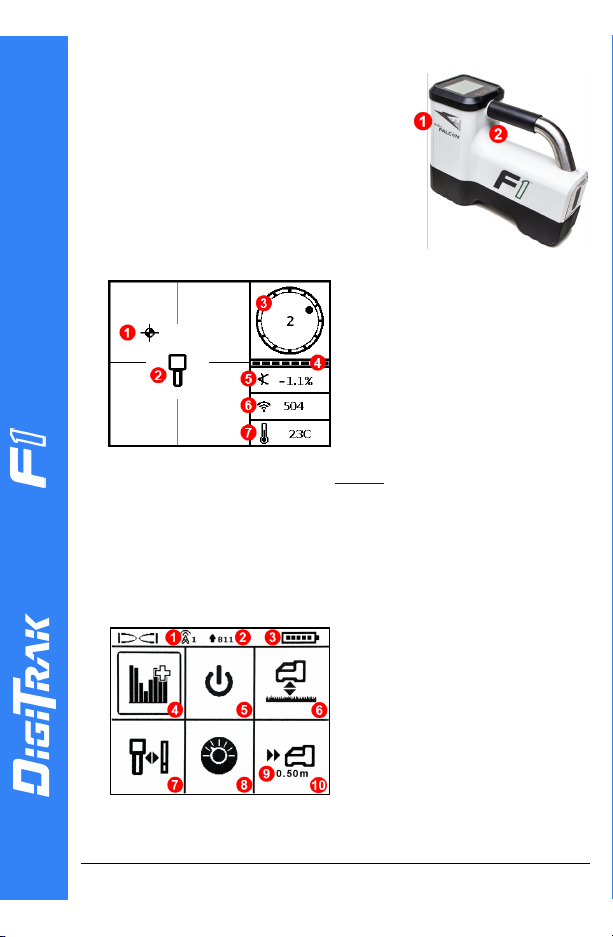

Receiver Locate Screen

1. Locate point (ball)

2. Receiver

3. Rollindicator

4. Roll/pitch update me ter

5. Transmitter (Tx) pitch

6. Txs ignal stren gth

7. Tx temperature

Transmitter and receiver must be Paired before data will display

(page 3). For DigiTrak remote displays, see separate manual or

Quick Start Guide.

1. IRport2. Trigger

Receiver Main Menu

Click to open the Main menu. Click between menu options, hold

briefly and release to select.

Falcon Quick Start Guide

1. Teleme try channe l

2. Frequency band

3. Batte ry strength

4. Fre quency Optimizer

5. Power off

6. HAG

7. Calibration

8. Settings

9. Target depth

10. Target Steering

- 1 -

© 2018 DigitalControlIncorporated, Oct

All rights reserved. 402-1028-21-B metric

www.digital-control.com

Page 2

Steps Required Before Drilling

It is important to run FO for each new project. FO s elects differe nt

frequencies for Band 11 based on the noise at each jobsite.

Your receiver can only detect active interference, not passive

interference. Falcon F1 use s Band 11 in part because frequencies in this

band tend to perform well despite passive inte rference.

1.

Optimi ze and measure active i nterference.

2.

Select frequency Band 11 .

3.

Pair the rec eiver with the transmitter.

4.

Check for background noise.

5.

Calibrate.

6.

Check Above Ground Range.

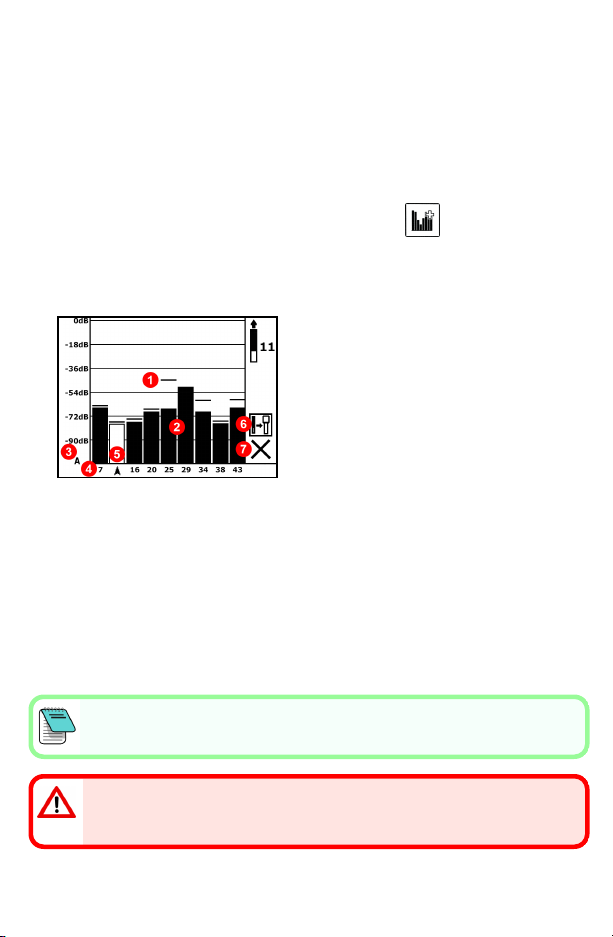

Optimize and Measure Active Interference

1. With the transmitter off, select Frequency Optimizer (FO) from the

Main menu. The FO will show active interference (noise) readings for

Band 11 (and other bands not available on Falcon F 1).

1. Maximum noise reading

2. Noise

3. Attenuation in e ffect

4. Band number

5. Selector

6. Pair

7. Exit

Frequency Optimization Results

2.

With the FO results displayed, walk the receiver along the bore path

while observing the noise readings and mark those points where

significant changes occur. If noise levels rise substantially at any point

along the b ore, consider re-optimizing at this higher-interference

point.

Select Frequency Band 11

3.

Click to move the selector to Band 11, hold briefly to select, then assig n

as the Up band.

- 2 -

Page 3

Pair the Receiver with the Transmitt er (Tx)

This error symbol will display in the roll indicator (Locate scre en) if the

frequency band is not calibrated.

4.

Install transmitter batteries and endcap; the increase in FO noise

readings show the Tx is on.

5. Select Pair (flashing).

6.

Position the transmitter's infrared (IR) port wi thin five cm of the

receiver's IRport.

1. IR port

7.

Select the check mark to complete pairing.

Check for Background Noise

8.

Exit to the Locate screen. Have a coworker hold the transmitter beside

you at the approximate d istance of the maximum intended depth of

the bore. Walk the bore together i n parallel, with the receiver over the

bore. Wherever the data or sig nal strength becomes unstable or

disappears, consider re-optimizing i n that area (see step1).

Calibrate

Calibration in an interference-free envi ronment

is required after each optimizati on.

9.

Place the Tx in a housing on level ground 3m

from receiver as shown.

10. From the Mai n menu, select Calibration,

1PTCAL, and click to calibrate.

- 3 -

Check Above Ground Range (AGR)

11.

Always check AGR with a tape measure to

verify depth readings for Band 11 at various

distances up to the maximum expected bore

depth. Distance readings should be within

±5%.

Page 4

To access the AGR screen later, select Calibration, 1PTCAL, and

- 4 -

wait 15 seconds for the AGR screen.

Settings Menu

Use the Settings menu to set the depth units, p itch units, roll offset, and

telemetry channel. Set the remote di splay to match receiver depth and

pitch settings.

Height-Above-Ground (HAG) Menu

HAG is the distance from the ground to the base of the receiver while it is

held. Setting HAG on the Main menu lets you take accurate below-ground

depth measurements without having to place the receiver on the ground.

Max Mode

Max Mode helps obtain depth/data readings in high-interference areas

when readings are unstable.

l The drill head must remain still during Max Mode readings.

l Hold the trigger at least five seconds to enter Max Mode. Do not

consider the data useful unless the reading is stable before the Max

Mode timer is full.

l Always take three Max Mode readings; all must be consistent.

See the system operator's manual for add itional important information on

the use of this feature.

Signal Attenuation

An A icon may appear on the roll indicator and FO results when the

receiver is attenuating the Tx signal for depths shallower than 3m. This is

normal. See the operator's manual if the signal strength is flashing,

indicating extreme interference.

Watch our DigiTrak®training videos at

www.YouTube.com/DCIKent

Printed:

10/9/2018

Page 5

Basic Locating

1.

Find the FLP and RLP by centering the target ball in the box.

2.

At the FLP, hold trigger for predicted depth reading.

3.

Find the LL by centering the li ne in the box between the FLP and RLP

(see Locate screen on previous page).

4.

View depth by holding the trigger at the LL on the line between the

FLP and RLP.

5. Holding the trigger longer than five seconds enables Max Mode (see

page4).

Transmitter Signal Field Geometry

Level Transmitter

1. Side view

2. RLP: Rear L ocate Point

3. LL: Locate Line

4. FLP: Front Locate Point

Pitched Transmitter

- 5 -

1. Bird's-e ye view

2. RLP

3. LL

4. FLP

5. Drillrig

6. Bore path

7. Side view

FLP and RLP are not equidistant from the LL when the transmitter is

pitched.

Page 6

Bird’s-Eye View on Locate Screen

Receiver Locate Screen,

Appr oaching LL

Actual Position of

Receiver and Tx

Transmitter Depth and Predicted Depth

Trigger held at LL

1. Front or Rear L ocate Point (FLP

or RLP)

2. Bird's-eye view

3. Line-in-the-Box at LL

4. HAG on

5. Max Mode timer

6. Max Mode icon

7. Tx depth

Depth Screen

Trigger held at FLP

1. Re ference indicator

2. Ball-in-the-Box at FLP only

3. Roll/pitch update meter

4. Tx predicted depth

5. Tx battery strength

6. Horizontaldistance between Tx

and FLP

Predicted Depth Screen

- 6 -

1. LL (Tx)

2. Box (re ceiver)

3. Locating ball

4. Tx (underground)

5. Receiver

For detailed information, see your system operator's manual, available at

www.digital-control.com. If you have ques tions, contact your regional DCI office

or U.S.Customer Service at1.425.251.0559.

Loading...

Loading...