Digitax DBE140, DBE420, DBE220, DBE1100S, DBE750 User Manual

...

RGB ELEKTRONIKA AGACIAK CIACIEK

SPÓŁKA JAWNA

Jana Dlugosza 2-6 Street

51-162 Wrocław

Poland

biuro@rgbelektronika.pl

+48 71 325 15 05

www.rgbautomatyka.pl

www.rgbelektronika.pl

DATASHEET

www.rgbautomatyka.pl

www.rgbelektronika.pl

OTHER SYMBOLS:

DBE 140

DBE140, DBE 140

CONTROL TECHNIQUES

YOUR

PARTNER IN

MAINTENANCE

At our premises in Wrocław, we have a fully equipped servicing facility. Here we perform all the repair

works and test each later sold unit. Our trained employees, equipped with a wide variety of tools and

having several testing stands at their disposal, are a guarantee of the highest quality service.

OUR SERVICES

ENCODERS

SERVO

DRIVERS

LINEAR

ENCODERS

SERVO AMPLIFIERS

CNC

MACHINES

MOTORS

POWER

SUPPLIERS

OPERATOR

PANELS

CNC

CONTROLS

INDUSTRIAL

COMPUTERS

PLC

SYSTEMS

Repair this product with RGB ELEKTRONIKA

ORDER A DIAGNOSIS

∠

Buy this product at RGB AUTOMATYKA

BUY

∠

User Guide

DigitAx

AC Servo Drive

1.4kW to 22kW

Part Number: 0415-0008

Issue Number

: 4

General information

The manufacturer accepts no liability for any

consequences resulting from inappropriate,

negligent or incorrect installation or adjustment of

the optional operating parameters of the equipment

or from mismatching the variable speed drive

(Drive) with the motor.

The contents of this User Guide are believed to be

correct at the time of printing. In the interests of a

commitment to a policy of continuous development

and improvement, the manufacturer reserves the

right to change the specification of the product or

its performance, or the contents of the User Guide,

without notice.

All rights reserved. No parts of this User Guide may

be reproduced or transmitted in any form or by any

means, electrical or mechanical including

photocopying, recording or by any information-

storage or retrieval system, without permission in

writing from the publisher.

Important...

Drive software version

This product is supplied with the latest version of

user-interface and machine-control software. If this

product is to be used in a new or existing system

with other DigitAx Drives, there may be some

differences between their software and the

software in this product. These differences may

cause this product to function differently. This may

also apply to Drives returned from a Control

Techniques Service Centre.

If there is any doubt, contact a Control Techniques

Drive Centre.

Use within the European Union, etc

The following information applies where the end use

of the Drive is within the European Union, the

European Economic Area, or other regions which

have implemented Directives of the European

Council or equivalent measures.

The Drive complies with the Low Voltage Directive

73/23/EEC.

The installer is responsible for ensuring that the

equipment into which the Drive is incorporated

complies with all relevant Directives.

The complete equipment into which the Drive is

incorporated must comply with the EMC Directive

89/336/EEC.

If the Drive is incorporated into a machine, the

manufacturer is responsible for ensuring that the

machine complies with the Machinery Directive

98/37/EC. In particular, the electrical equipment

should generally comply with European Harmonised

Standard EN60204-1.

Copyright © January 1999

Control Techniques Drives Ltd

Author: RFD

Issue Code: dgxu4

Issue Date: January 1999

S/W Version: V04.XX.XX

DigitAx User Guide

Issue code: dgxu4

i

Contents

1 Introduction 1-1

1.1 Case styles 1-1

1.2 Method of operation 1-2

1.3 How best to use this User Guide 1-2

2 Safety Information 2-1

3 Data 3-1

3.1 Model range 3-1

3.2 Ingress protection (IP and NEMA 1) 3-1

3.3 AC supply 3-1

3.4 Drive output 3-1

3.5 Ambient temperature and humidity 3-1

3.6 Derating 3-1

3.7 Starts per hour 3-1

3.8 PWM switching frequencies 3-1

3.9 Vibration 3-1

3.10 Serial communications 3-2

3.11 Resolver specification 3-2

3.12 Resolver resolution 3-2

3.13 Response times 3-2

3.14 Electromagnetic compatibility (EMC) 3-2

3.15 Frequency accuracy 3-3

3.16 Weights 3-3

3.17 Power ratings 3-3

3.18 Losses and efficiency 3-3

3.19 DC bus choke ratings 3-4

3.20 Dimensions 3-4

4 Mechanical Installation 4-1

4.1 EMC wiring recommendations 4-1

4.2 Planning the installation 4-2

4.3 Environment 4-4

4.4 RFI filters 4-4

4.5 Ferrite absorber ring 4 -4

4.6 Ferrite rings 4-5

4.7 Control Keypad 4-5

4.8 Installing an external DC

braking resistor 4-6

4.9 Installing a DC bus choke 4-6

4.10 Heat dissipation in a

sealed enclosure 4-6

4.11 Heat dissipation in a

ventilated enclosure 4-7

4.12 Motor cooling 4-7

5 Electrical Installation 5-1

5.1 Hazardous areas 5-1

5.2 Access to the power connectors 5-1

5.3 EMC wiring recommendations 5-3

5.4 AC supply cables and fuses 5-8

5.5 Ground connections 5-8

5.6 DC bus choke 5-8

5.7 Protecting the Drive with line reactors 5-8

5.8 Connecting an internal or

external braking resistor 5-9

5.9 Example calculations for

a braking resistor 5-12

5.10 Control Keypad connections 5-14

5.11 Signal connections 5-15

DigitAx User Guide

Issue code: dgxu4

ii

6 Control Keypad 6-1

6.1 Models DBE140, DBE220, DBE420,

DBE600, DBE750, DBE1100S 6-1

6.2 Models DBE1500, DBE2200 6-1

6.3 Display and controls 6-1

7 Parameters 7-1

8 Programming Instructions 8-1

8.1 Displaying a parameter 8-1

8.2 Changing a parameter value 8-1

8.3 Saving parameter values 8-1

9 Security 9-1

9.1 Setting up a security code 9-1

9.2 Security access 9-1

9.3 Changing a security code 9-1

10 Getting Started 10-1

10.1 Setting jumpers 10-1

10.2 Setting parameter values 10-1

10.3 Protection parameters 10-2

10.4 PID parameters 10-3

10.5 Speed calibration 10-3

10.6 Resolver phasing 10-4

10.7 Commissioning 10-4

10.8 Calibration 10-5

10.9 Methods of speed control 10-6

10.10 Methods of torque control 10-7

10.11 Methods of position control 10-8

10.12 Quick reference 10-10

10.13 Programmable outputs 10-11

11 List of Parameters 11-1

11.1 Variable parameters 11-1

11.2 Bit parameters 11-5

11.3 Summary of default values 11-11

12 Trip codes and Fault Finding 12-1

12.1 Trip codes 12-1

12.2 Fault finding 12-2

13 Serial Communications 13-1

13.1 Introduction 13-1

13.2 Connecting the Drive 13-1

13.3 Serial communications connector 13-1

13.4 Serial communications configuration 13-1

13.5 Message structure 13-2

13.6 Messages from host to Drive 13-3

13.7 Write data to the Drive 13-3

13.8 Terminal mode 13-4

13.9 Parameters related to serial

communications 13-5

Appendix A PID Loop A1

A.1 Setting the PID gains A-1

A.2 Evaluating the PID gains A-2

A.3 Setting the bandwidth limit A-2

DigitAx User Guide

Issue code: dgxu4

iii

Declaration of Conformity

Control Techniques plc

The Gro

Newtown

Powys

UK

SY16 3BE

DBE140 DBE220 DBE420

DBE600 DBE750 DBE1100S

DBE1500 DBE2200

The DigitAx servo drive products listed above have

been designed and manufactured in accordance

with the following European harmonised, national

and international standards:

EN60249 Base materials for printed circuits

IEC326-1 Printed boards: general information for the

specification writer

IEC326-5 Printed boards: specification for single- and

double-sided printed boards with

plated-through holes

IEC326-6 Printed boards: specification for multilayer

printed boards

IEC664-1 Insulation co-ordination for equipment

within low-voltage systems: principles,

requirements and tests

EN60529 Degrees of protection provided by

enclosures (IP code)

UL94 Flammability rating of plastic materials

UL508C * Standard for industrial control equipment

* Applies to models DBE1500 and DBE2200 only

These products comply with the Low Voltage

Directive 73/23/EEC and the CE Marking Directive

93/68/EEC.

W. Drury

Technical Director

Newtown

Date: 11th November 1998

These electronic Drive products are

intended to be used with an

appropriate motor, controller,

electrical protection components and

other equipment to form a complete

end product or system. The Drive must

be installed only by a professional

assembler who is familiar with the

requirements for safety and

electromagnetic compatibility (EMC).

The assembler is responsible for

ensuring that the end product or

system complies with all the relevant

laws in the country where it is to be

used. This User Guide or the related

EMC Data Sheet should be referred to

for further information on the EMC

standards that the product complies

with, as well as for guidance on

installation.

DigitAx User Guide

Issue code: dgxu4

iv

DigitAx User Guide

Issue code: dgxu4

1-1

1 Introduction

1.1 Case styles

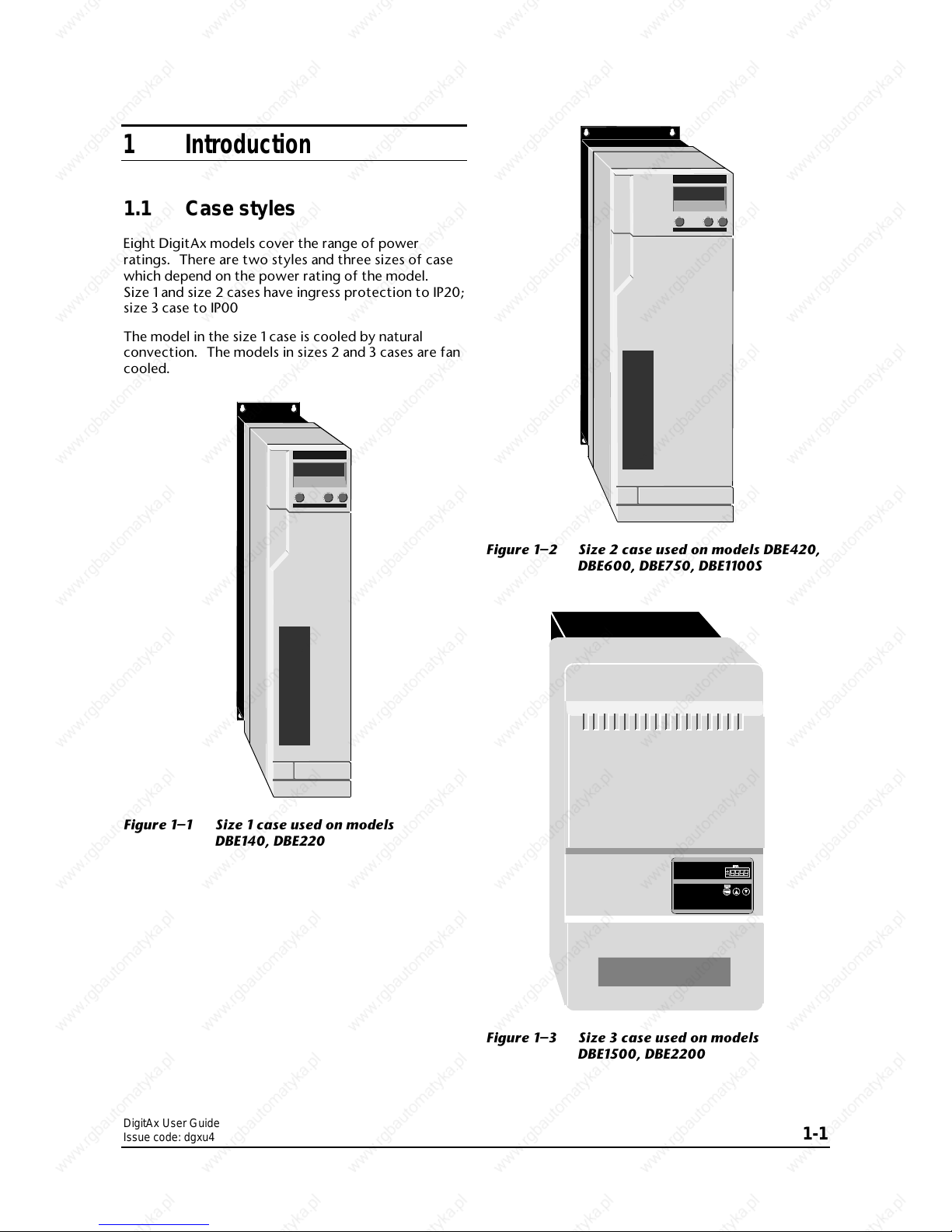

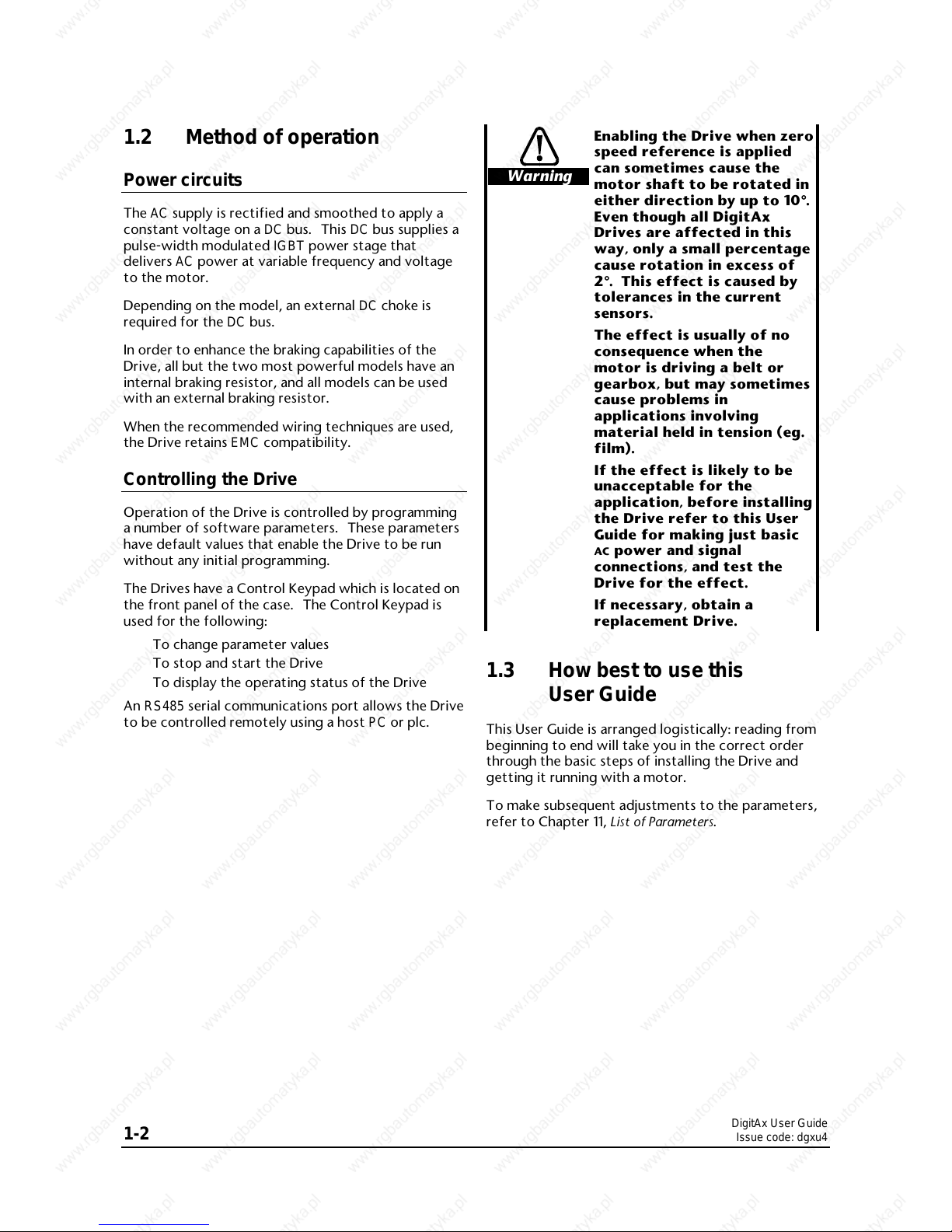

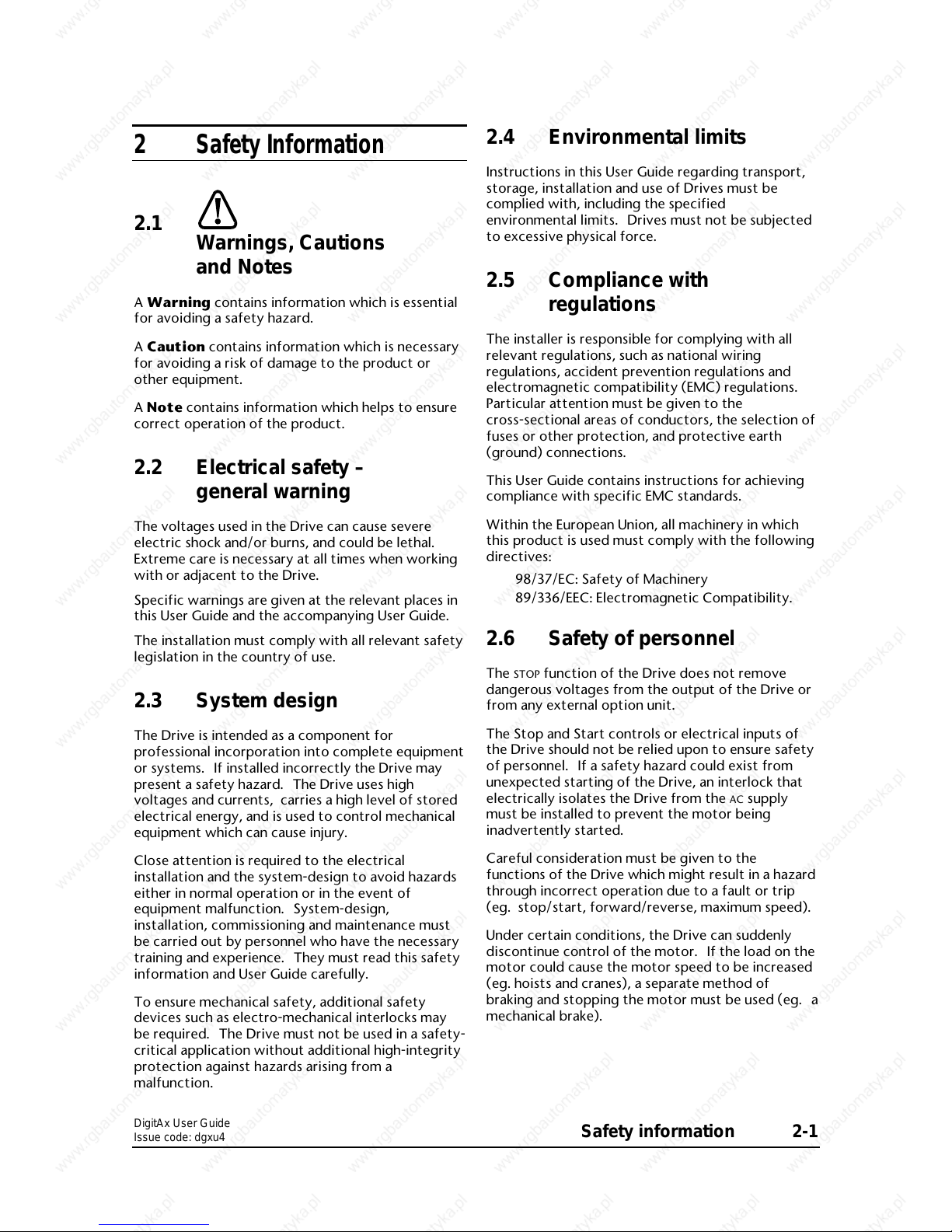

Eight DigitAx models cover the range of power

ratings. There are two styles and three sizes of case

which depend on the power rating of the model.

Size 1 and size 2 cases have ingress protection to IP20;

size 3 case to IP00

The model in the size 1 case is cooled by natural

convection. The models in sizes 2 and 3 cases are fan

cooled.

Figure 1–1 Size 1 case used on models

DBE140, DBE220

Figure 1–2 Size 2 case used on models DBE420,

DBE600, DBE750, DBE1100S

Figure 1–3 Size 3 case used on models

DBE1500, DBE2200

DigitAx User Guide

Issue code: dgxu4

1-2

1.2 Method of operation

Power circuits

The AC supply is rectified and smoothed to apply a

constant voltage on a DC bus. This DC bus supplies a

pulse-width modulated IGBT power stage that

delivers AC power at variable frequency and voltage

to the motor.

Depending on the model, an external DC choke is

required for the DC bus.

In order to enhance the braking capabilities of the

Drive, all but the two most powerful models have an

internal braking resistor, and all models can be used

with an external braking resistor.

When the recommended wiring techniques are used,

the Drive retains EMC compatibility.

Controlling the Drive

Operation of the Drive is controlled by programming

a number of software parameters. These parameters

have default values that enable the Drive to be run

without any initial programming.

The Drives have a Control Keypad which is located on

the front panel of the case. The Control Keypad is

used for the following:

To change parameter values

To stop and start the Drive

To display the operating status of the Drive

An RS485 serial communications port allows the Drive

to be controlled remotely using a host PC or plc.

Warning

Enabling the Drive when zero

speed reference is applied

can sometimes cause the

motor shaft to be rotated in

either direction by up to 10°°.

Even though all DigitAx

Drives are affected in this

way, only a small percentage

cause rotation in excess of

2°°. This effect is caused by

tolerances in the current

sensors.

The effect is usually of no

consequence when the

motor is driving a belt or

gearbox, but may sometimes

cause problems in

applications involving

material held in tension (eg.

film).

If the effect is likely to be

unacceptable for the

application, before installing

the Drive refer to this User

Guide for making just basic

AC power and signal

connections, and test the

Drive for the effect.

If necessary, obtain a

replacement Drive.

1.3 How best to use this

User Guide

This User Guide is arranged logistically: reading from

beginning to end will take you in the correct order

through the basic steps of installing the Drive and

getting it running with a motor.

To make subsequent adjustments to the parameters,

refer to Chapter 11, List of Parameters.

DigitAx User Guide

Issue code: dgxu4

Safety information 2-1

2 Safety Information

2.1

Warnings, Cautions

and Notes

A Warning contains information which is essential

for avoiding a safety hazard.

A Caution contains information which is necessary

for avoiding a risk of damage to the product or

other equipment.

A Note contains information which helps to ensure

correct operation of the product.

2.2 Electrical safety –

general warning

The voltages used in the Drive can cause severe

electric shock and/or burns, and could be lethal.

Extreme care is necessary at all times when working

with or adjacent to the Drive.

Specific warnings are given at the relevant places in

this User Guide and the accompanying User Guide.

The installation must comply with all relevant safety

legislation in the country of use.

2.3 System design

The Drive is intended as a component for

professional incorporation into complete equipment

or systems. If installed incorrectly the Drive may

present a safety hazard. The Drive uses high

voltages and currents, carries a high level of stored

electrical energy, and is used to control mechanical

equipment which can cause injury.

Close attention is required to the electrical

installation and the system-design to avoid hazards

either in normal operation or in the event of

equipment malfunction. System-design,

installation, commissioning and maintenance must

be carried out by personnel who have the necessary

training and experience. They must read this safety

information and User Guide carefully.

To ensure mechanical safety, additional safety

devices such as electro-mechanical interlocks may

be required. The Drive must not be used in a safety-

critical application without additional high-integrity

protection against hazards arising from a

malfunction.

2.4 Environmental limits

Instructions in this User Guide regarding transport,

storage, installation and use of Drives must be

complied with, including the specified

environmental limits. Drives must not be subjected

to excessive physical force.

2.5 Compliance with

regulations

The installer is responsible for complying with all

relevant regulations, such as national wiring

regulations, accident prevention regulations and

electromagnetic compatibility (EMC) regulations.

Particular attention must be given to the

cross-sectional areas of conductors, the selection of

fuses or other protection, and protective earth

(ground) connections.

This User Guide contains instructions for achieving

compliance with specific EMC standards.

Within the European Union, all machinery in which

this product is used must comply with the following

directives:

98/37/EC: Safety of Machinery

89/336/EEC: Electromagnetic Compatibility.

2.6 Safety of personnel

The STOP function of the Drive does not remove

dangerous voltages from the output of the Drive or

from any external option unit.

The Stop and Start controls or electrical inputs of

the Drive should not be relied upon to ensure safety

of personnel. If a safety hazard could exist from

unexpected starting of the Drive, an interlock that

electrically isolates the Drive from the

AC supply

must be installed to prevent the motor being

inadvertently started.

Careful consideration must be given to the

functions of the Drive which might result in a hazard

through incorrect operation due to a fault or trip

(eg. stop/start, forward/reverse, maximum speed).

Under certain conditions, the Drive can suddenly

discontinue control of the motor. If the load on the

motor could cause the motor speed to be increased

(eg. hoists and cranes), a separate method of

braking and stopping the motor must be used (eg. a

mechanical brake).

DigitAx User Guide

Issue code: dgxu4

2-2 Safety information

Before connecting the AC supply to the Drive, it is

important that you understand the operating

controls and their operation. If in doubt, do not

adjust the Drive. Damage may occur, or lives put at

risk. Carefully follow the instructions in this User

Guide.

Before making adjustments to the Drive, ensure all

personnel in the area are warned. Make notes of all

adjustments that are made.

2.7 Risk analysis

In any application where a malfunction of the Drive

could lead to damage, loss or injury, a risk analysis

must be carried out, and where necessary, further

measures taken to reduce the risk. This would

normally be an appropriate form of independent

safety back-up system using simple electro-

mechanical components.

2.8 Motor

Ensure the motor is installed in accordance with the

manufacturer’s recommendations. Ensure the

motor shaft is not exposed.

2.9 Adjusting parameters

Some parameters have a profound effect on the

operation of the Drive and protection of the motor.

They must not be altered without careful

consideration of the impact on the controlled

system. Measures must be taken to prevent

unwanted changes due to error or tampering.

DigitAx User Guide

Issue code: dgxu4

3-1

3 Data

Warning

The voltages present in the

Drive are capable of

inflicting a severe electric

shock and may be lethal. The

Stop function of the Drive

does not remove dangerous

voltages from the Drive or

the driven machine.

AC supplies to the Drive

must be disconnected at

least 15 minutes before any

cover is removed or

servicing work is performed.

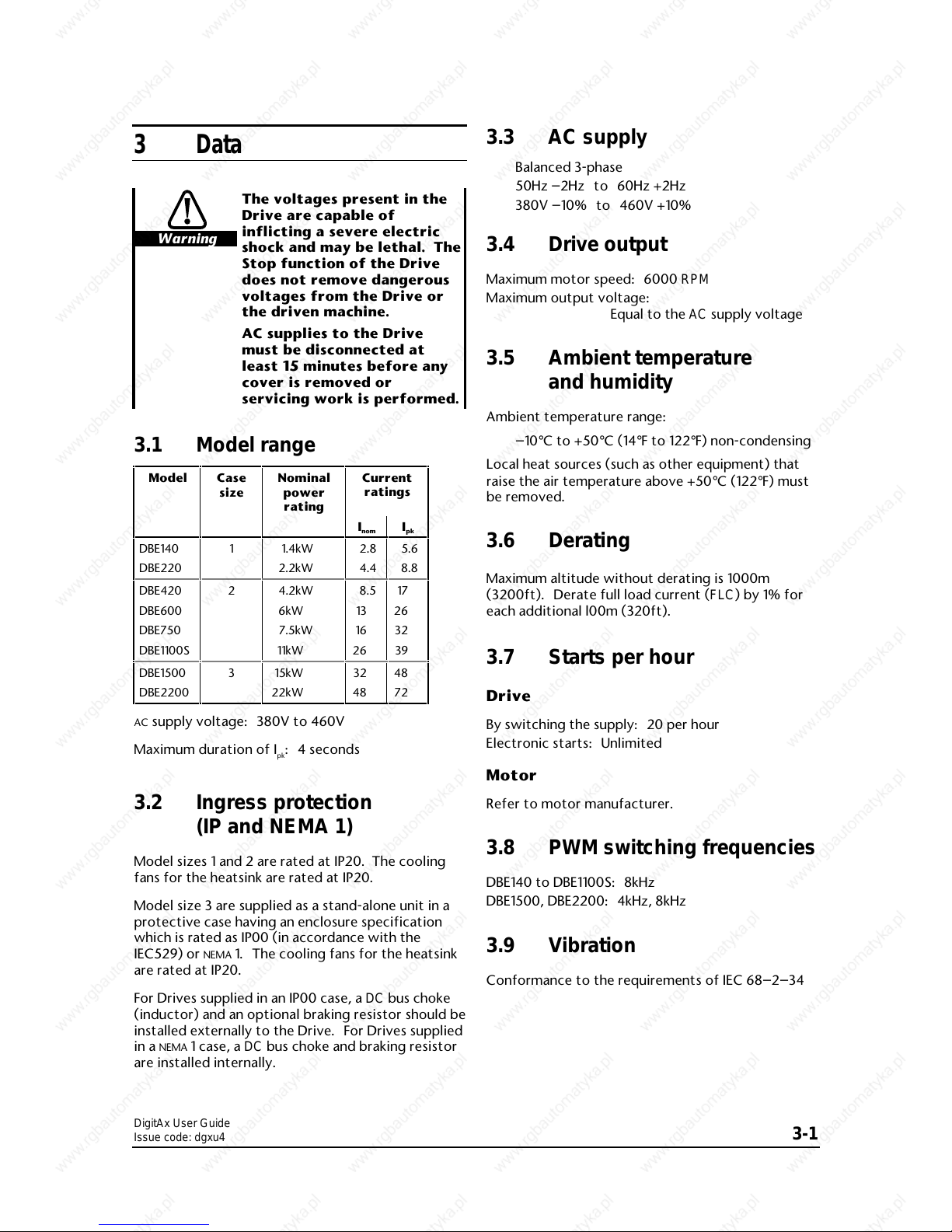

3.1 Model range

Model Case

size

Nominal

power

rating

Current

ratings

I

nomIpk

DBE140

DBE220

1 1.4kW

2.2kW

2.8

4.4

5.6

8.8

DBE420

DBE600

DBE750

DBE1100S

2 4.2kW

6kW

7.5kW

11kW

8.5

13

16

26

17

26

32

39

DBE1500

DBE2200

3 15kW

22kW

324848

72

AC supply voltage: 380V to 460V

Maximum duration of I

pk

: 4 seconds

3.2 Ingress protection

(IP and NEMA 1)

Model sizes 1 and 2 are rated at IP20. The cooling

fans for the heatsink are rated at IP20.

Model size 3 are supplied as a stand-alone unit in a

protective case having an enclosure specification

which is rated as IP00 (in accordance with the

IEC529) or

NEMA 1. The cooling fans for the heatsink

are rated at IP20.

For Drives supplied in an IP00 case, a DC bus choke

(inductor) and an optional braking resistor should be

installed externally to the Drive. For Drives supplied

in a

NEMA 1 case, a DC bus choke and braking resistor

are installed internally.

3.3 AC supply

Balanced 3-phase

50Hz –2Hz to 60Hz +2Hz

380V –10% to 460V +10%

3.4 Drive output

Maximum motor speed: 6000 RPM

Maximum output voltage:

Equal to the AC supply voltage

3.5 Ambient temperature

and humidity

Ambient temperature range:

–10°C to +50°C (14°F to 122°F) non-condensing

Local heat sources (such as other equipment) that

raise the air temperature above +50°C (122°F) must

be removed.

3.6 Derating

Maximum altitude without derating is 1000m

(3200ft). Derate full load current (FLC) by 1% for

each additional l00m (320ft).

3.7 Starts per hour

Drive

By switching the supply: 20 per hour

Electronic starts: Unlimited

Motor

Refer to motor manufacturer.

3.8 PWM switching frequencies

DBE140 to DBE1100S: 8kHz

DBE1500, DBE2200: 4kHz, 8kHz

3.9 Vibration

Conformance to the requirements of IEC 68–2–34

DigitAx User Guide

Issue code: dgxu4

3-2

3.10 Serial communications

RS485 half-duplex (RS422 can also be used)

Protocol: ANSI x 3.28–2.5–A4–N, positive logic

Timing

Write to Drive:

25ms at 9600 Baud

l5ms at 19.2 kBaud

Read from the Drive:

30ms at 9600 Baud

16ms at 19.2 kBaud

3.11 Resolver specification

Voltage 6V RMS

Frequency 10kHz

Primary Rotor

Number of poles 2

Transformation ratio 0.28 ±10%

Phase shift –14° nominal

Primary current 40mA nominal

Power input 120mW

Electrical error ±15 minutes

Impedance ZRO 73 + j129 Ω

Impedance ZSO 116 + j159 Ω

Impedance ZSS 95 + j162 Ω

Excitation winding

resistance

28Ω

Stator winding

resistance

18Ω

Temperature range –55°C to 155°C

–97°F to 240°F

Inertia 2.0gm2 x 10

–5

3.12 Resolver resolution

14-bit when Pr99 < 3200 RPM

12 bit when Pr99 ≥ 3200 RPM

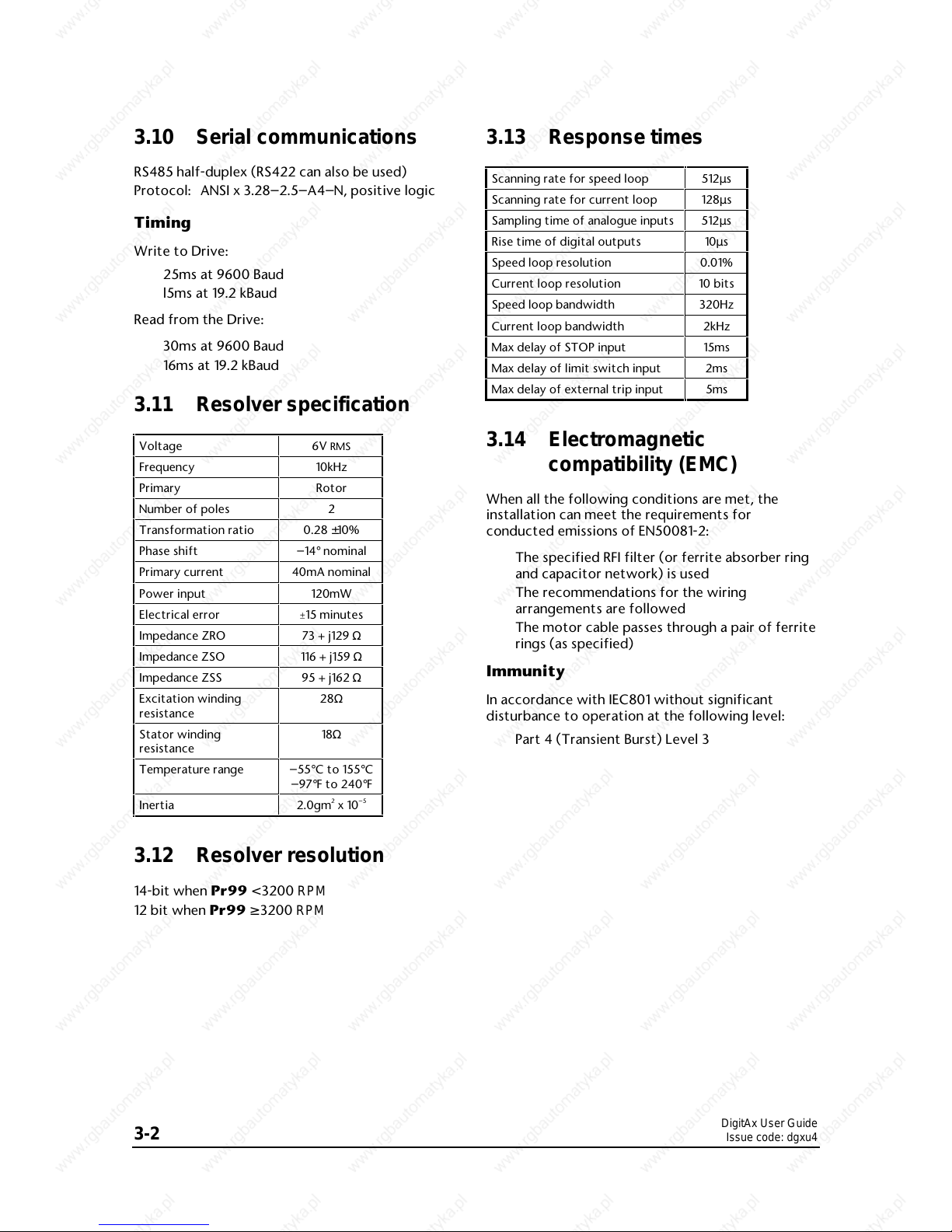

3.13 Response times

Scanning rate for speed loop 512µs

Scanning rate for current loop 128µs

Sampling time of analogue inputs 512µs

Rise time of digital outputs 10µs

Speed loop resolution 0.01%

Current loop resolution 10 bits

Speed loop bandwidth 320Hz

Current loop bandwidth 2kHz

Max delay of STOP input 15ms

Max delay of limit switch input 2ms

Max delay of external trip input 5ms

3.14 Electromagnetic

compatibility (EMC)

When all the following conditions are met, the

installation can meet the requirements for

conducted emissions of EN50081-2:

The specified RFI filter (or ferrite absorber ring

and capacitor network) is used

The recommendations for the wiring

arrangements are followed

The motor cable passes through a pair of ferrite

rings (as specified)

Immunity

In accordance with IEC801 without significant

disturbance to operation at the following level:

Part 4 (Transient Burst) Level 3

DigitAx User Guide

Issue code: dgxu4

3-3

3.15 Frequency accuracy

Output frequency is within 100ppm of the

demanded frequency.

3.16 Weights

The weights of the most powerful model in each

model size are as follows:

Model size 1: 5.5kg (12lb)

Model size 2: 9.5kg (21lb)

Model size 3: 22.3kg (49lb)

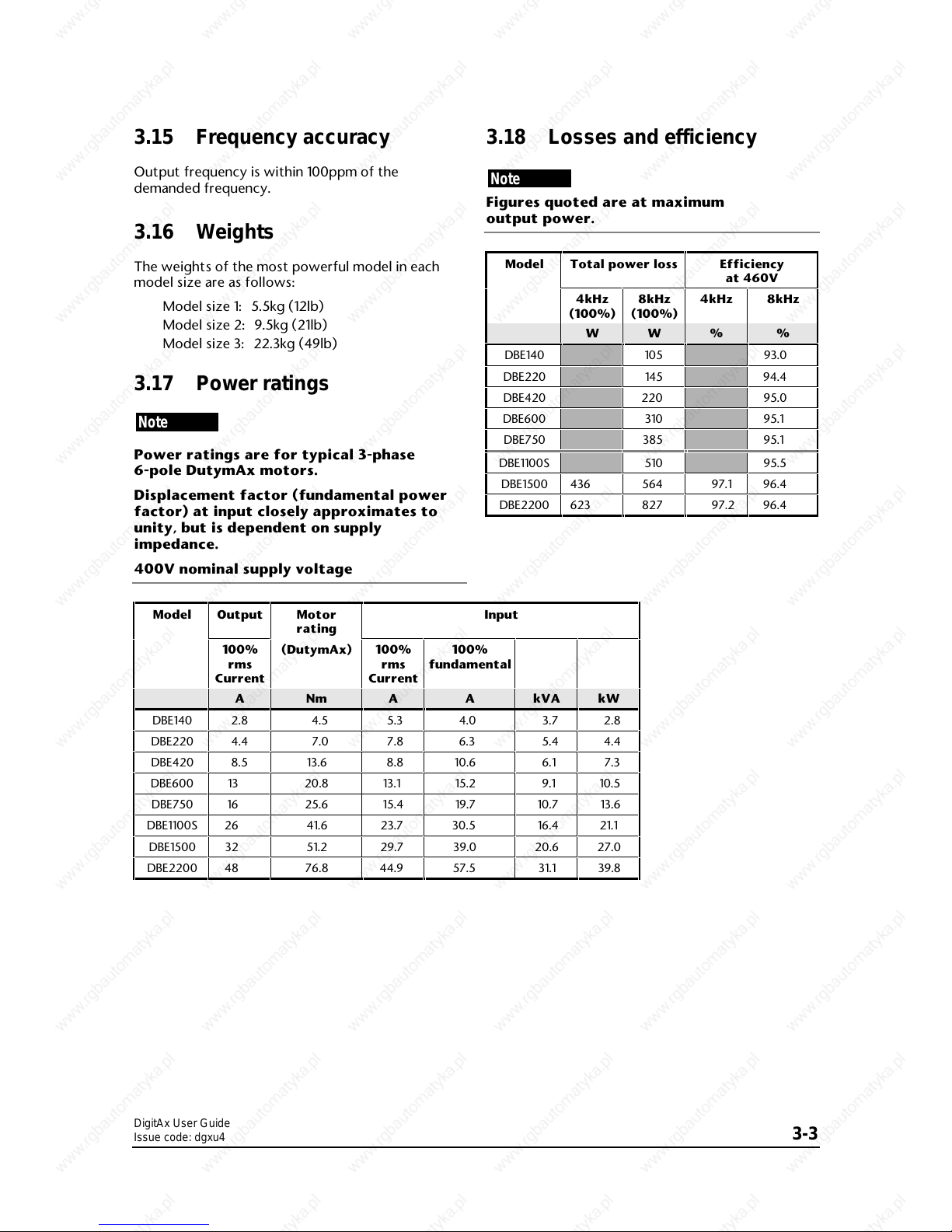

3.17 Power ratings

Note

Power ratings are for typical 3-phase

6-pole DutymAx motors.

Displacement factor (fundamental power

factor) at input closely approximates to

unity, but is dependent on supply

impedance.

400V nominal supply voltage

3.18 Losses and efficiency

Note

Figures quoted are at maximum

output power.

Model Total power loss Efficiency

at 460V

4kHz

(100%)

8kHz

(100%)

4kHz 8kHz

W

W

% %

DBE140

105

93.0

DBE220

145

94.4

DBE420

220

95.0

DBE600

310

95.1

DBE750

385

95.1

DBE1100S

510

95.5

DBE1500 436

564

97.1 96.4

DBE2200 623

827

97.2 96.4

Model Output Motor

rating

Input

100%

rms

Current

(DutymAx) 100%

rms

Current

100%

fundamental

A Nm A A kVA kW

DBE140 2.8 4.5 5.3 4.0 3.7 2.8

DBE220 4.4 7.0 7.8 6.3 5.4 4.4

DBE420 8.5 13.6 8.8 10.6 6.1 7.3

DBE600 13 20.8 13.1 15.2 9.1 10.5

DBE750 16 25.6 15.4 19.7 10.7 13.6

DBE1100S 26 41.6 23.7 30.5 16.4 21.1

DBE1500 32 51.2 29.7 39.0 20.6 27.0

DBE2200 48 76.8 44.9 57.5 31.1 39.8

DigitAx User Guide

Issue code: dgxu4

3-4

3.19 DC bus choke ratings

DC bus chokes are fitted internally on the DBE420 to

DBE1100S drives. No DC bus choke is needed for

models DBE140 and DBE220.

Ripple frequency = 6 × supply frequency

Ratings and values quoted are design minima.

Drive

model

Choke ratings Weight

mH ARMS Apk kg lb

DBE1500 1.50 45 85 6.4 14

DBE2200 0.70 75 143 8.4 19

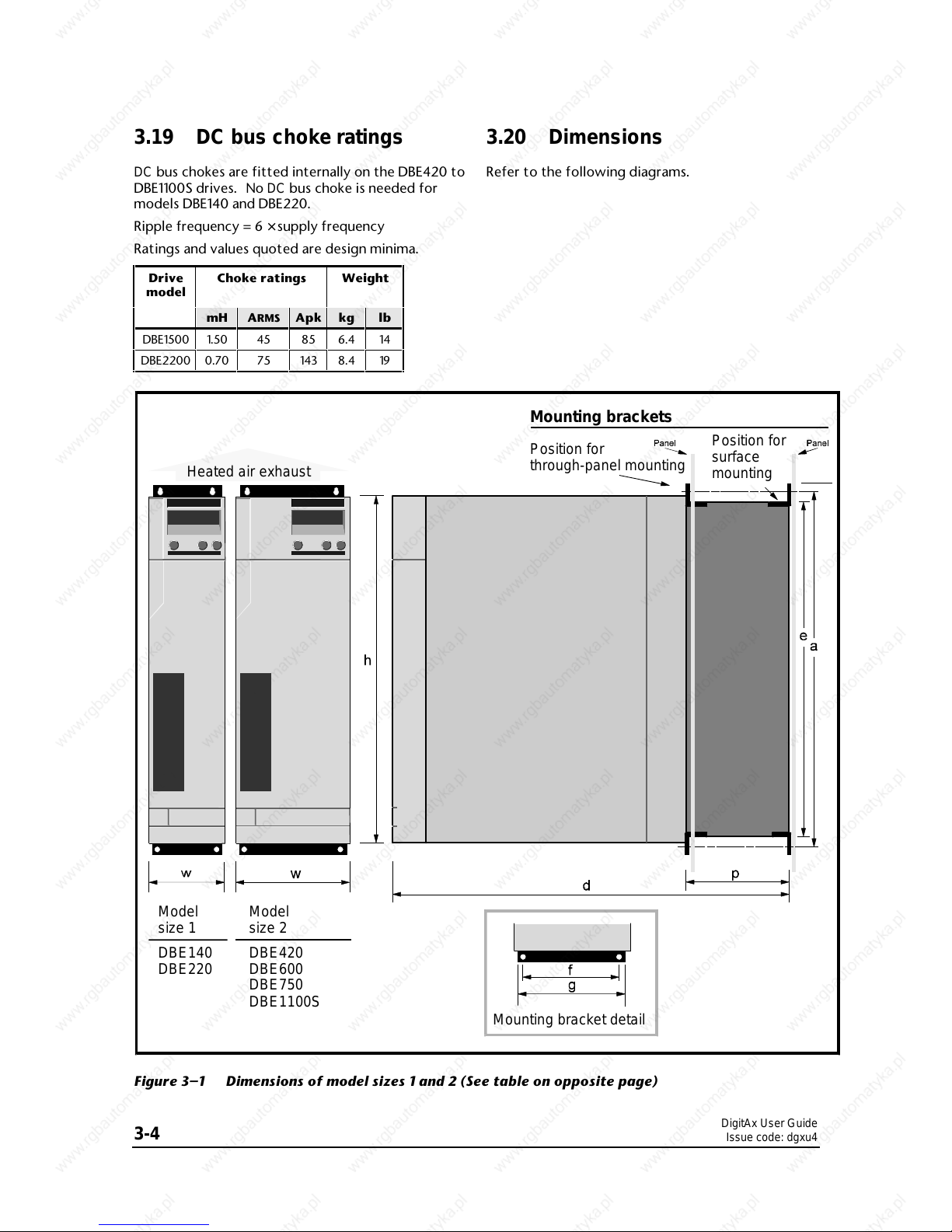

3.20 Dimensions

Refer to the following diagrams.

Heated air exhaust

Mounting brackets

Position for

through-panel mounting

Position for

surface

mounting

Model

size 1

DBE140

DBE220

Model

size 2

DBE420

DBE600

DBE750

DBE1100S

Mounting bracket detail

Figure 3–1 Dimensions of model sizes 1 and 2 (See table on opposite page)

DigitAx User Guide

Issue code: dgxu4

3-5

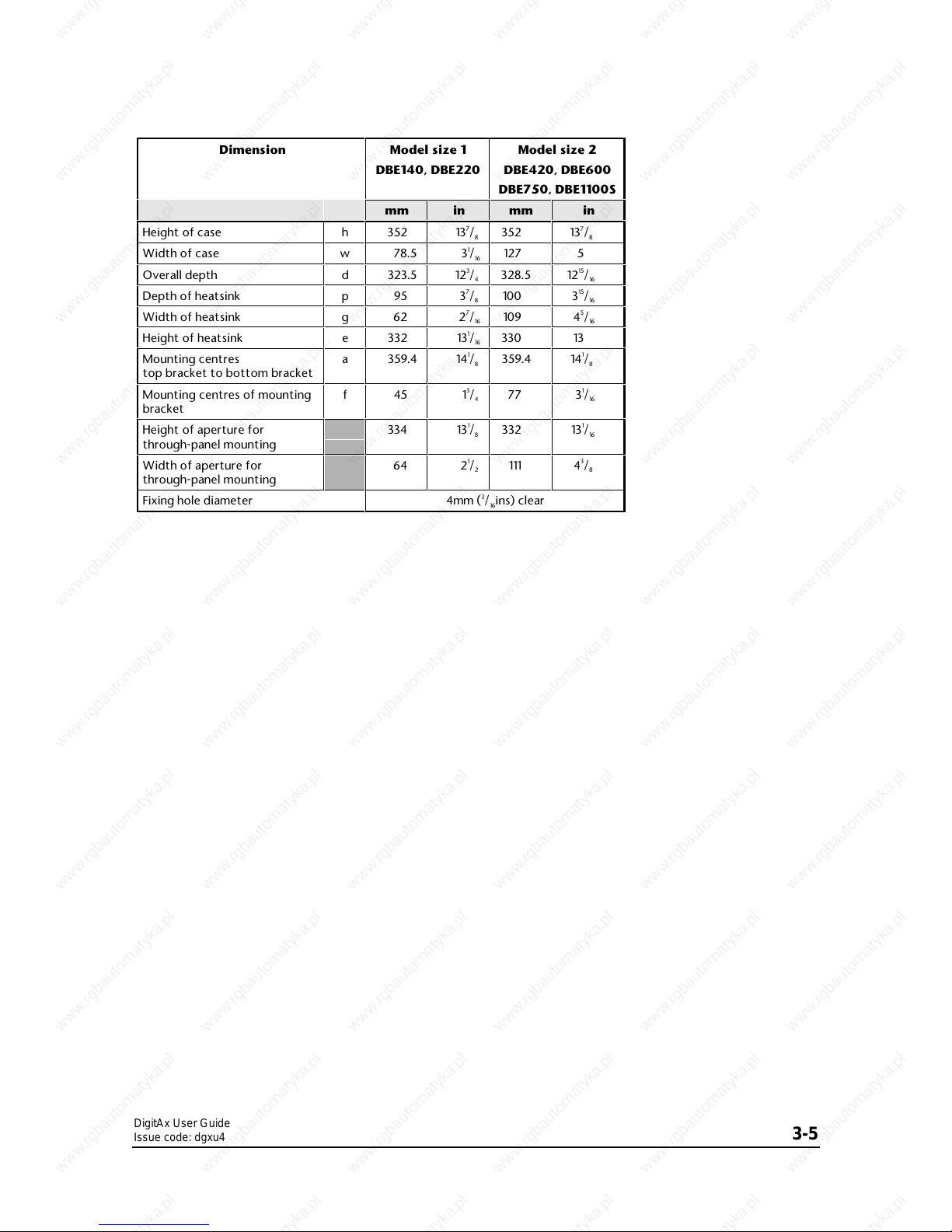

Dimension Model size 1

DBE140, DBE220

Model size 2

DBE420, DBE600

DBE750, DBE1100S

mm in mm in

Height of case h 352 137/8352 137/

8

Width of case w 78.5 31/16127 5

Overall depth d 323.5 123/4328.5 1215/

16

Depth of heatsink p 95 37/8100 315/

16

Width of heatsink g 62 27/16109 45/

16

Height of heatsink e 332 131/16330 13

Mounting centres

top bracket to bottom bracket

a 359.4 141/8359.4 141/

8

Mounting centres of mounting

bracket

f45 1

3

/477 31/

16

Height of aperture for

through-panel mounting

334 131/8332 131/

16

Width of aperture for

through-panel mounting

64 21/

2

111 43/

8

Fixing hole diameter 4mm (3/16ins) clear

DigitAx User Guide

Issue code: dgxu4

3-6

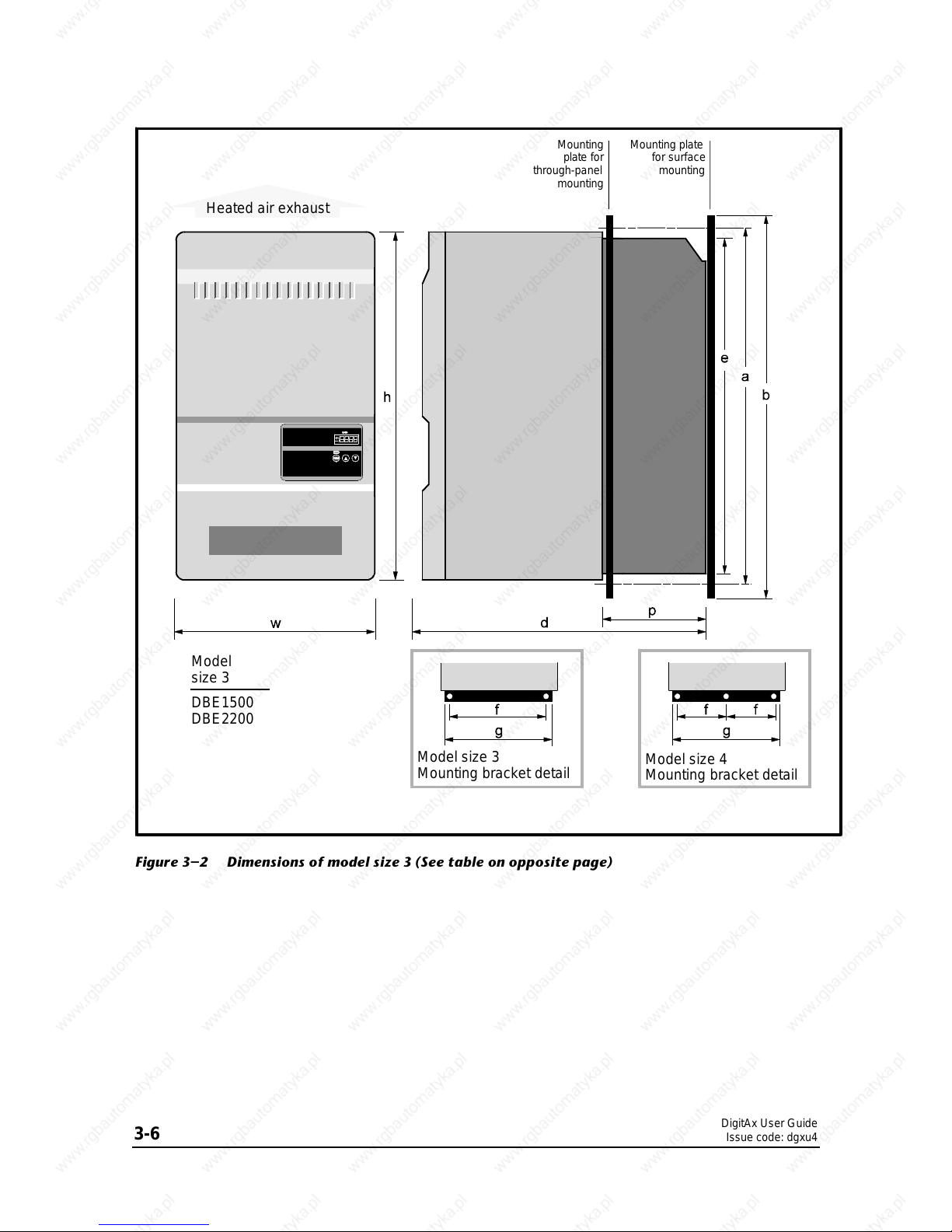

Heated air exhaust

Model

size 3

DBE1500

DBE2200

Mounting

plate for

through-panel

mounting

Mounting plate

for surface

mounting

Model size 3

Mounting bracket detail

Model size 4

Mounting bracket detail

Figure 3–2 Dimensions of model size 3 (See table on opposite page)

DigitAx User Guide

Issue code: dgxu4

3-7

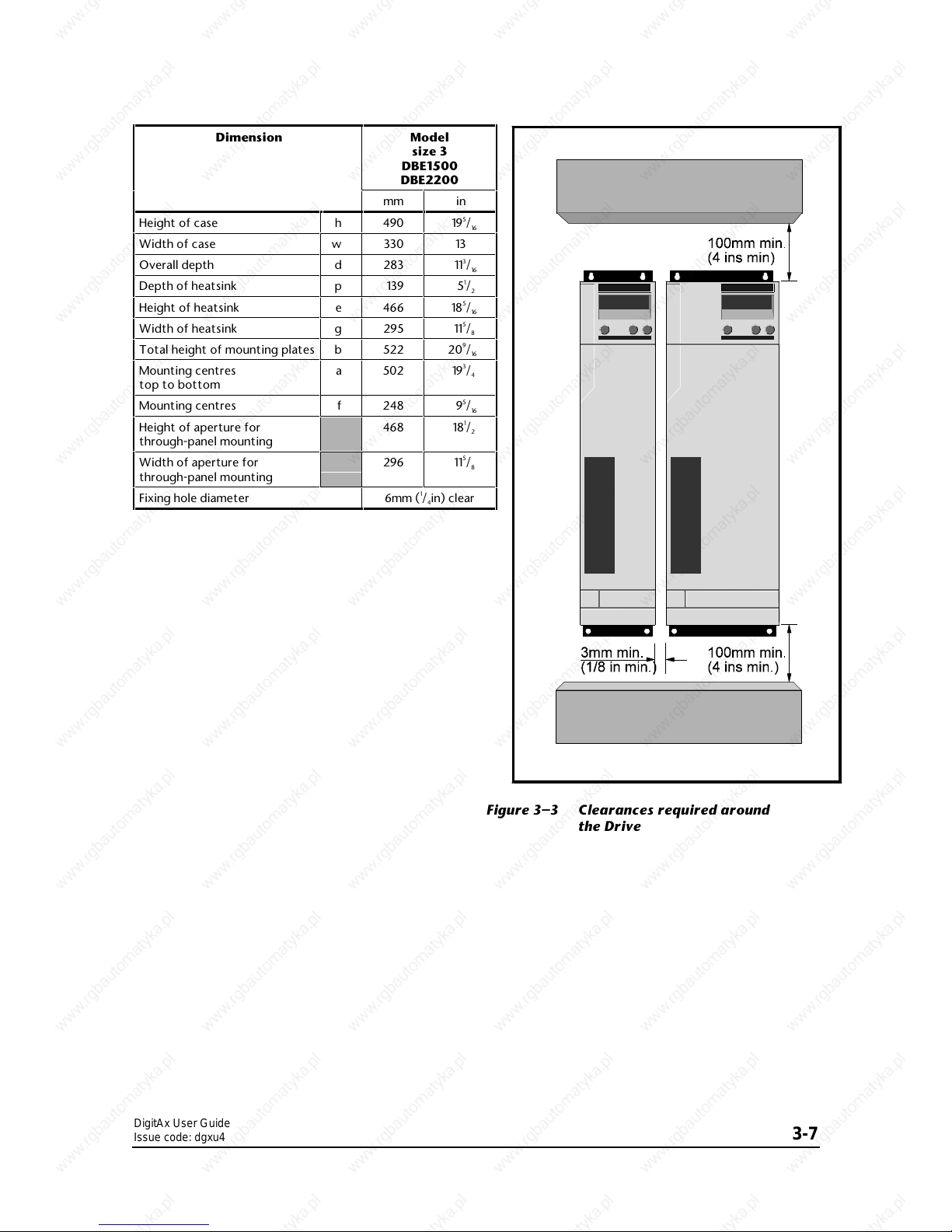

Figure 3–3 Clearances required around

the Drive

Dimension Model

size 3

DBE1500

DBE2200

mm in

Height of case h 490 195/

16

Width of case w 330 13

Overall depth d 283 113/

16

Depth of heatsink p 139 51/

2

Height of heatsink e 466 185/

16

Width of heatsink g 295 115/

8

Total height of mounting plates b 522 209/

16

Mounting centres

top to bottom

a 502 193/

4

Mounting centres f 248 95/

16

Height of aperture for

through-panel mounting

468 181/

2

Width of aperture for

through-panel mounting

296 115/

8

Fixing hole diameter 6mm (1/4in) clear

DigitAx User Guide

Issue code: dgxu4

3-8

DigitAx User Guide

Issue code: dgxu4

4-1

4 Mechanical Installation

Warning

The equipment enclosure is

rated at IP20 in accordance

with IEC539. It is designed

for installation within a

protective enclosure which

prevents unauthorised

access except for trained

service personnel, and

prevents contamination with

conductive dust and

condensation.

4.1 EMC wiring

recommendations

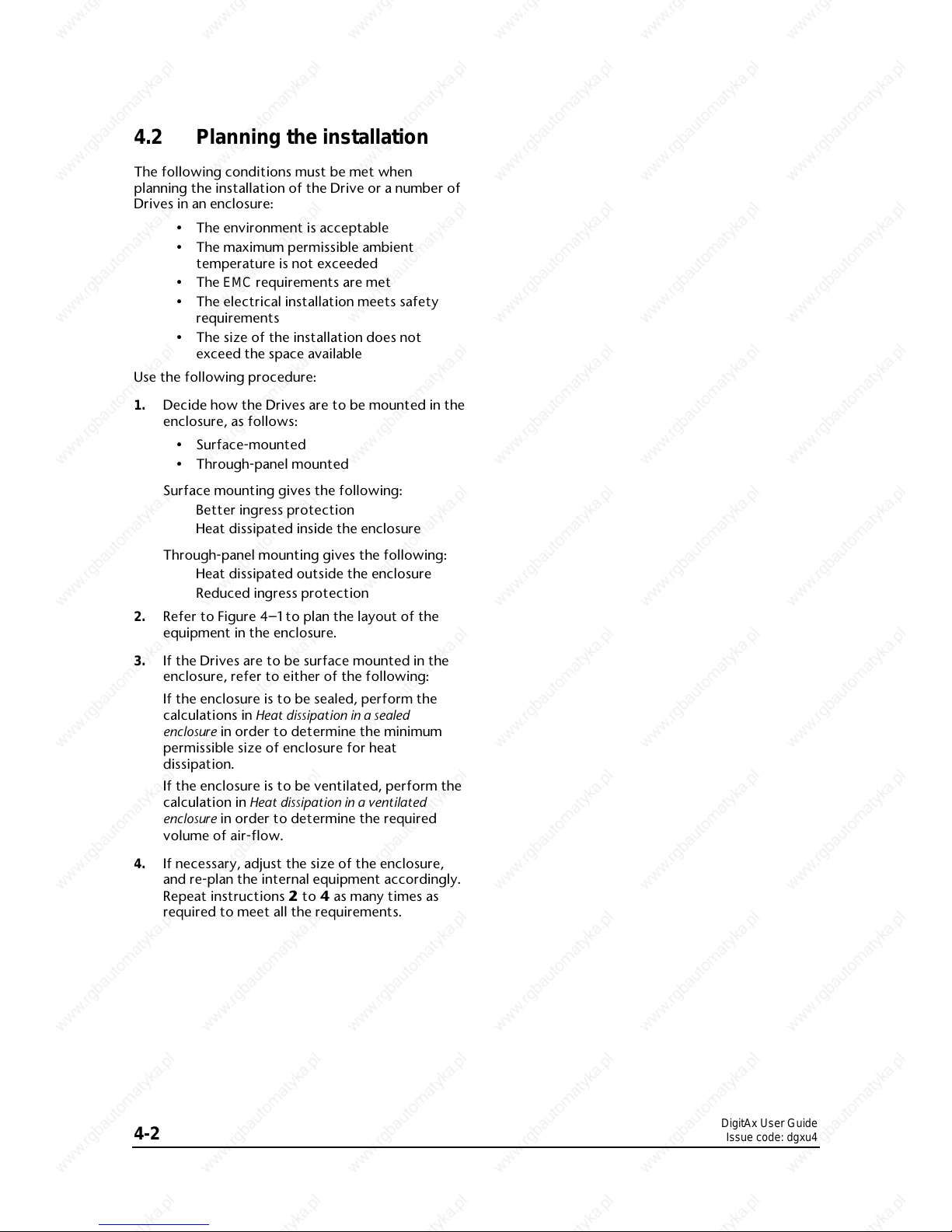

To minimize radio-frequency emissions, it is

necessary to install the Drive in a steel enclosure and

pay attention to the arrangement of the wiring

inside the enclosure. Figure 4–1 shows

recommendations for the layout of the enclosure.

Figures 5–1 and 5–3 in Chapter 5 Electrical Installation

show examples of wiring arrangements for minimum

radio-frequency emissions. The actual arrangement

will have to be adapted to individual requirements.

When planning the installation, refer to Chapter 5 in

addition to this chapter.

The essential requirements are as follows:

RFI filter

• Mount an RFI filter above the Drive at a

distance of 125mm (5 in).

• Make the AC power cables from the RFI

filter to the Drive as short as possible.

• Use a flat conductor at least 10mm (

1

/2in)

wide and as short as possible to make the

ground connection from the RFI filter to the

Drive.

Motor cable

• Use armoured or shielded cable to connect

the motor to the Drive. Connect the

armour or shield to the Drive and to the

motor frame. Make these connections no

longer than 50mm (2in).

• If the length of cable used to connect the

motor to the Drive exceeds 50m (150 feet),

output chokes may be required in order to

prevent cable capacitance effects causing

over-current trips (OC) in the Drive. For

difficult cases, consult the supplier of the

Drive.

Resolver wiring

Simulated-encoder wiring

• Signal connections from the resolver and

from the simulated encoder input of the

CNC controller must be connected to the

Drive using cable consisting of three

twisted-pairs of wire. Each twisted pair

must be screened, and the cable must have

an overall screen. Connect the screens of

the resolver cable only to terminal B18 of the

Drive. Connect the screens of the simulated

encoder output only to the CNC controller

ground terminal.

• When a motor thermistor is to be used,

connect it to the Drive using a fourth

twisted-pair in the screened cable to the

resolver. Connect the screen for this

twisted-pair only to terminal B18 on the

Drive.

Analog speed reference wiring

• Use shielded twisted-pair cable to connect

the analog speed reference to the Drive. It

is strongly recommended that a true

differential signal source is used in order to

maximize immunity to electrical noise.

Connect the cable shield only to the ground

connection of the CNC controller.

• A single-ended signal source may be used,

but electrical noise immunity is reduced.

Use shielded twisted-pair cable. Apply the

signal to terminal B9 or B10 of the Drive, as

required. Connect the 0V common to

terminal B11. Connect the unused

differential input (terminal B10 or B9) to

terminal B11.

Ground connections

• Bus-bars must be used to make certain

ground connections, as shown in Figure 5–4.

These bus-bars must be made of copper bar

of the dimensions shown.

Ferrite absorber ring

• When a number of Drives are installed in an

enclosure, it is recommended that a ferrite

absorber ring is fitted over the AC supply

cables to each Drive. (See also Capacitor

network.)

• Part numbec: 4200-3608

Capacitor network

• When three or more Drives are installed in

an enclosure, a capacitor network may be

required. Refer to Figure 5–4.

DigitAx User Guide

Issue code: dgxu4

4-2

4.2 Planning the installation

The following conditions must be met when

planning the installation of the Drive or a number of

Drives in an enclosure:

• The environment is acceptable

• The maximum permissible ambient

temperature is not exceeded

• The EMC requirements are met

• The electrical installation meets safety

requirements

• The size of the installation does not

exceed the space available

Use the following procedure:

1. Decide how the Drives are to be mounted in the

enclosure, as follows:

• Surface-mounted

• Through-panel mounted

Surface mounting gives the following:

Better ingress protection

Heat dissipated inside the enclosure

Through-panel mounting gives the following:

Heat dissipated outside the enclosure

Reduced ingress protection

2. Refer to Figure 4–1 to plan the layout of the

equipment in the enclosure.

3. If the Drives are to be surface mounted in the

enclosure, refer to either of the following:

If the enclosure is to be sealed, perform the

calculations in Heat dissipation in a sealed

enclosure in order to determine the minimum

permissible size of enclosure for heat

dissipation.

If the enclosure is to be ventilated, perform the

calculation in Heat dissipation in a ventilated

enclosure in order to determine the required

volume of air-flow.

4. If necessary, adjust the size of the enclosure,

and re-plan the internal equipment accordingly.

Repeat instructions 2 to 4 as many times as

required to meet all the requirements.

DigitAx User Guide

Issue code: dgxu4

4-3

≥3mm

( in)

Optional external braking

resistor for each Drive

External: Mount on top

surface of enclosure.

Internal: Mount in top part of

enclosure.

Controller

Locate as required.

Signal cables

Plan for all signal cables to

be routed at least 300mm

(12in) distant from any AC

power cable.

Drives

Ensure minimum clearances are

respected.

RFI filters

When required, install a separate

RFI filter for each Drive.

AC supply cables

These can enter the

enclosure and be

routed as required.

AC supply

distribution

(and fuses or MCB)

Locate as required.

All AC power cables or bus-bars

Locate as required (see Electrical

Installation for more details)

Enclosure

Layout when EMC

requirements do not apply

Alternative

locations of fuses

Locate as required

125mm

(5 in)

Back-plate

Mount all Drives and RFI filters

on the back-plate.

≥3mm

( in)

Ferrite rings

Use two rings for each Drive. Mount

each pair of rings as close as

possible to each Drive.

Figure 4–1 Planning the layout of the enclosure

DigitAx User Guide

Issue code: dgxu4

4-4

4.3 Environment

1. In accordance with the IP20 rating of the Drive,

the Drive must be located in an environment

that is free from dust, corrosive vapours, gases

and all liquids, including condensation of

atmospheric moisture.

2. If condensation is likely to occur when the Drive

is not in use, install an anti-condensation heater.

This heater must be switched off when the

Drive is in use; automatic switching is

recommended.

3. Do not locate the Drive in a classified hazardous

area, unless the Drive is installed in an approved

enclosure and the installation is approved.

4. Install the Drive vertically for best flow of

cooling air.

5. Install the Drive as low as possible in the

enclosure without contravening EMC

requirements.

6. Observe the requirements for ambient

temperature if the Drive is to be mounted

directly above any heat generating equipment,

such as another Drive.

7. If the Drive is to be installed directly beneath

other equipment, such as another Drive, ensure

the Drive does not cause the ambient

temperature requirements of the equipment to

be exceeded.

8. Allow at least 100mm (4in) clearance above and

below the Drive.

9. Allow at least 3mm (

1

/8in) clearance each side of

the Drive.

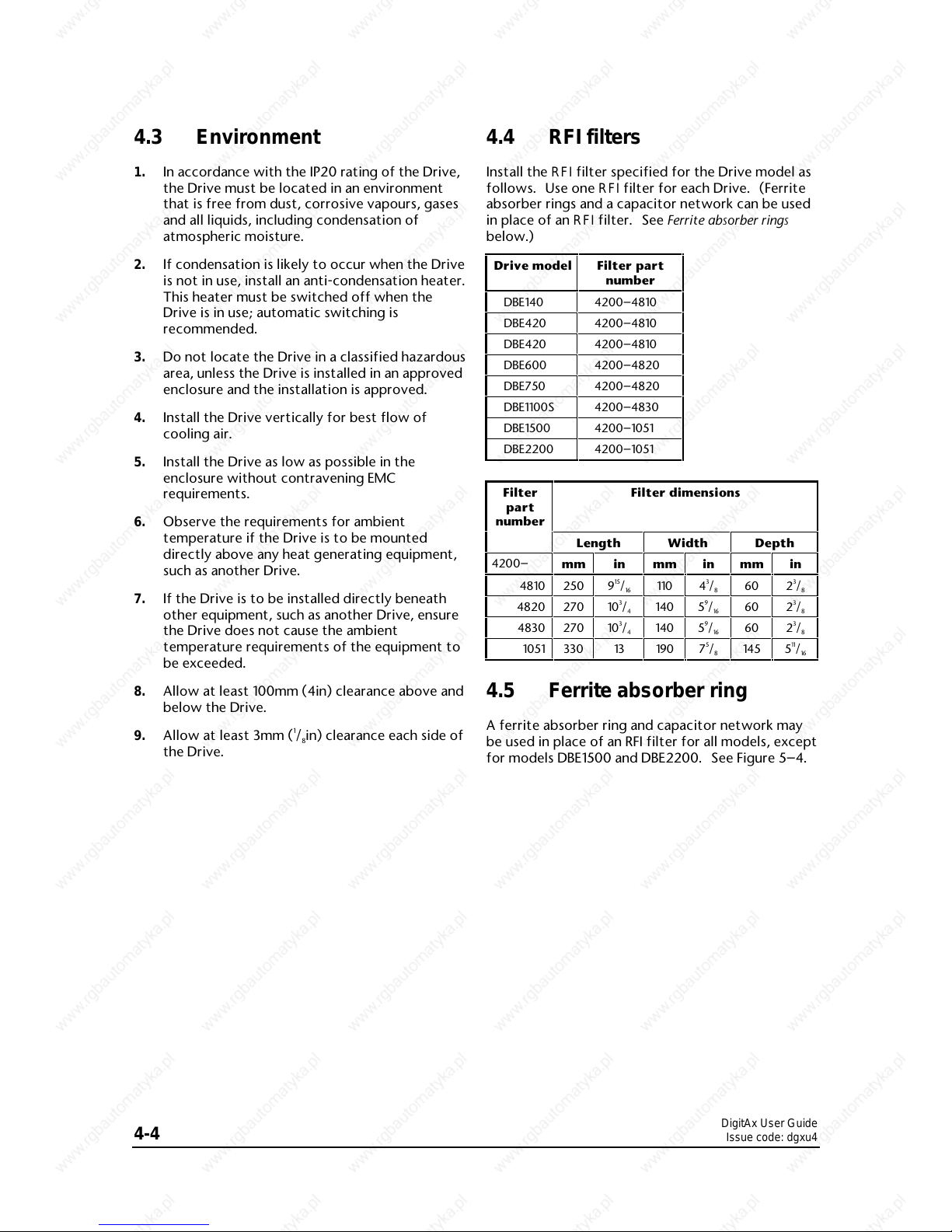

4.4 RFI filters

Install the RFI filter specified for the Drive model as

follows. Use one RFI filter for each Drive. (Ferrite

absorber rings and a capacitor network can be used

in place of an RFI filter. See Ferrite absorber rings

below.)

Drive model

Filter part

number

DBE140

4200–4810

DBE420

4200–4810

DBE420

4200–4810

DBE600

4200–4820

DBE750

4200–4820

DBE1100S

4200–4830

DBE1500

4200–1051

DBE2200

4200–1051

Filter

part

number

Filter dimensions

Length Width Depth

4200–

mm in

mm

in mm in

4810 250 915/

16

110

43/860 23/

8

4820 270 103/

4

140

59/

16

60 23/

8

4830 270 103/

4

140

59/

16

60 23/

8

1051 330 13

190

75/8145 511/

16

4.5 Ferrite absorber ring

A ferrite absorber ring and capacitor network may

be used in place of an RFI filter for all models, except

for models DBE1500 and DBE2200. See Figure 5–4.

DigitAx User Guide

Issue code: dgxu4

4-5

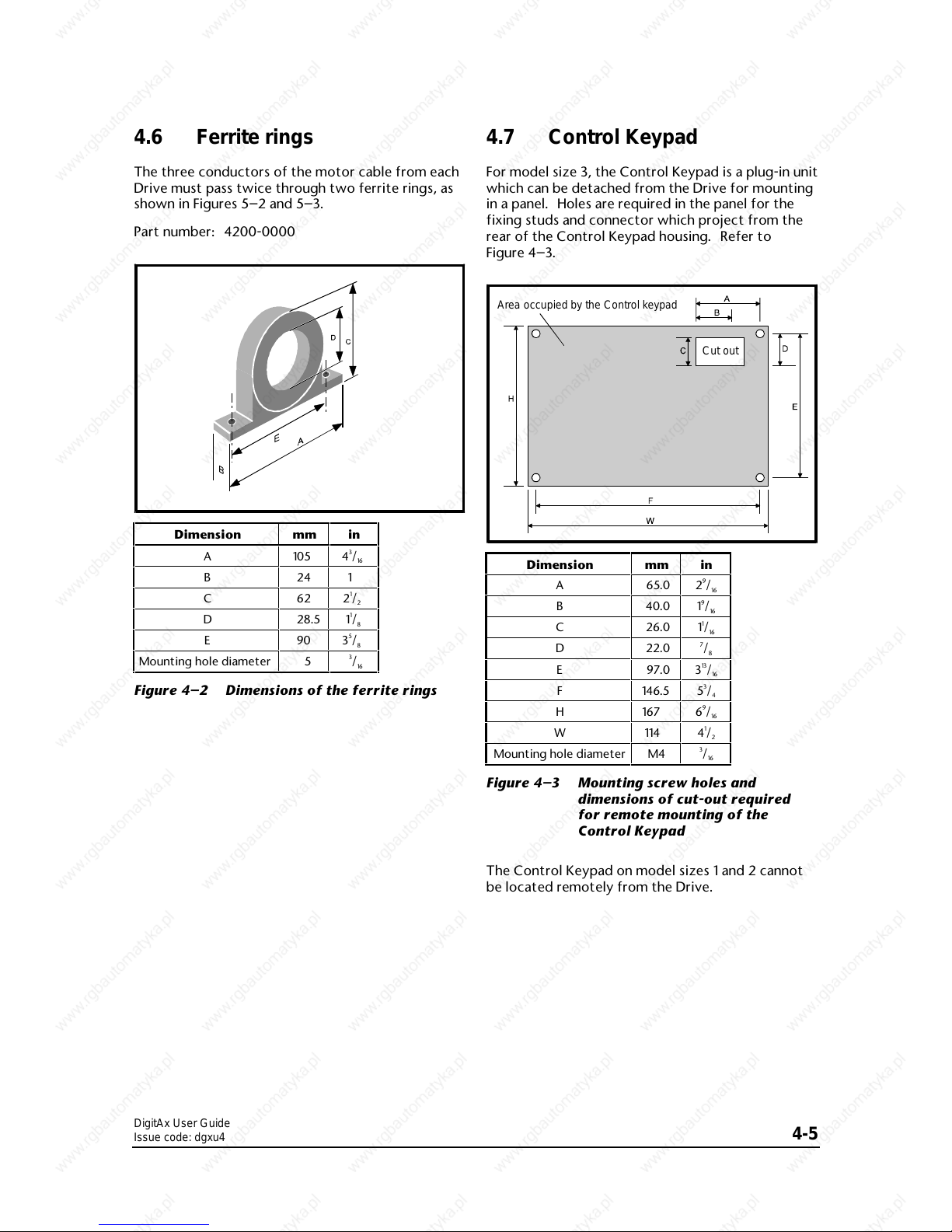

4.6 Ferrite rings

The three conductors of the motor cable from each

Drive must pass twice through two ferrite rings, as

shown in Figures 5–2 and 5–3.

Part number: 4200-0000

Dimension mm in

A 105 43/

16

B241

C622

1

/

2

D 28.5 11/

8

E903

5

/

8

Mounting hole diameter 5

3

/

16

Figure 4–2 Dimensions of the ferrite rings

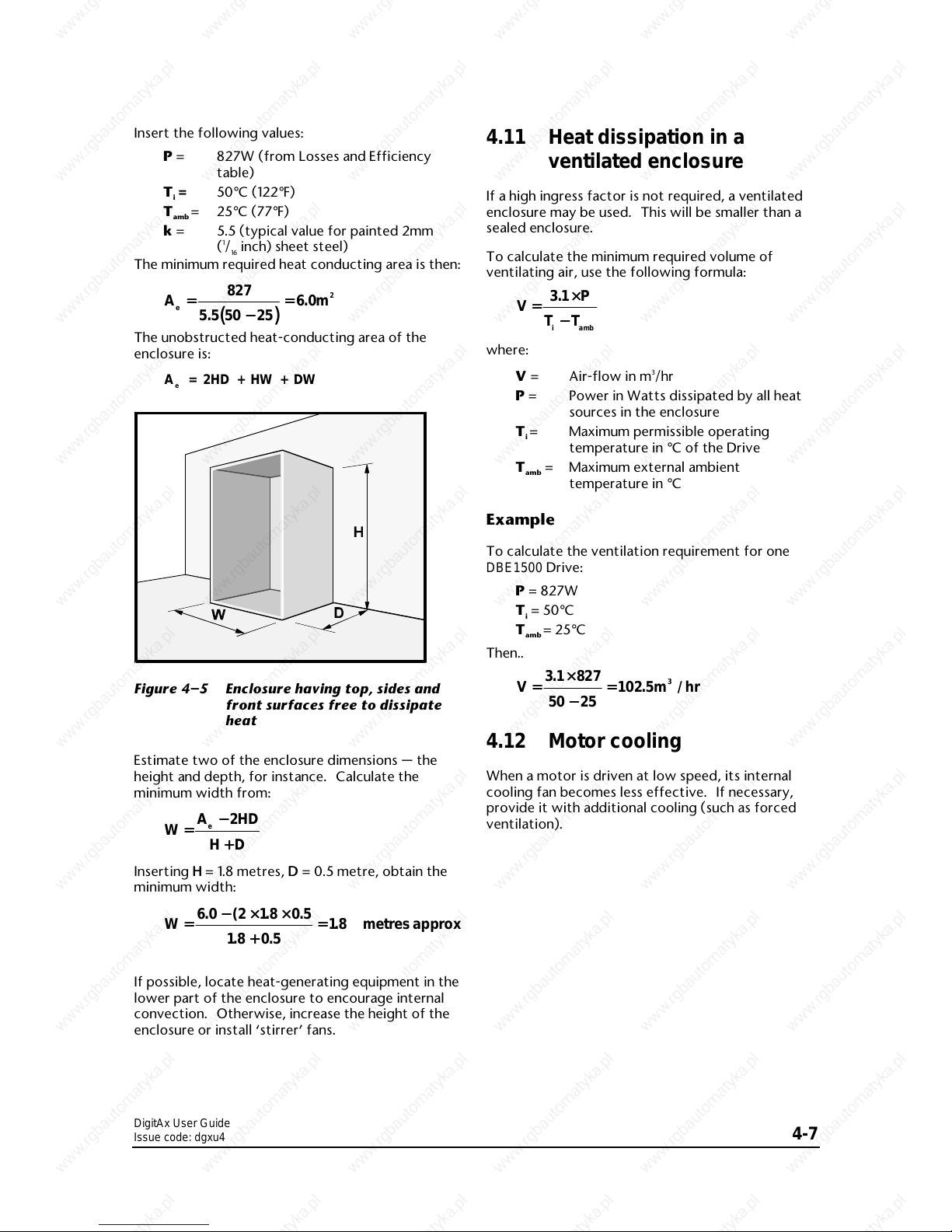

4.7 Control Keypad

For model size 3, the Control Keypad is a plug-in unit

which can be detached from the Drive for mounting

in a panel. Holes are required in the panel for the

fixing studs and connector which project from the

rear of the Control Keypad housing. Refer to

Figure 4–3.

Area occupied by the Control keypad

Cut out

Dimension

mm

in

A

65.0

29/

16

B

40.0

19/

16

C

26.0

11/

16

D

22.0

7

/

8

E

97.0

313/

16

F

146.5

53/

4

H

167

69/

16

W

114

41/

2

Mounting hole diameter

M4

3

/

16

Figure 4–3 Mounting screw holes and

dimensions of cut-out required

for remote mounting of the

Control Keypad

The Control Keypad on model sizes 1 and 2 cannot

be located remotely from the Drive.

DigitAx User Guide

Issue code: dgxu4

4-6

4.8 Installing an external DC

braking resistor

When an external braking resistor is to be installed,

it should be installed in accordance with the

manufacturer’s instructions. Refer to Calculating the

braking resistor value in Chapter 5 Electrical Installation.

4.9 Installing a DC bus choke

For model size 3, an external DC bus choke is

required. The choke may be mounted in the same

enclosure as the Drive.

No external DC bus choke is required for model

sizes 1 and 2.

Note

Drives supplied in NEMA 1 case contain the

required DC bus choke.

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

Value A B C D E Terminal

size

mH mminmminmminmminmm

in

1.50 137

5

7

/

16

84

3

5

/

16

175

6

7

/

8

24

15

/

16

10

3

/

8

M8

0.70 137

5

7

/

16

116

4

9

/

16

175

6

7

/

8

24

15

/

16

10

3

/

8

M8

Figure 4–4 Dimensions of the DC bus choke

4.10 Heat dissipation in a

sealed enclosure

To maintain sufficient cooling of the Drive when it is

installed inside a sealed enclosure, heat generated

by all the equipment in the enclosure must be taken

into account and the enclosure must be of adequate

size. To calculate the minimum acceptable size of

enclosure, use the following procedure.

Calculate the minimum required surface area A

e

for

the enclosure from:

(())

A

P

kT T

e

iamb

==

−−

where:

A

ee

= Unobstructed heat-conducting area in m

2

k = Heat Transmission coefficient of the

enclosure material in Watts/m

2

/°C

T

i

= Maximum permissible operating

temperature in °C of the Drive

T

amb

= Maximum external ambient

temperature in °C

P = Power in Watts dissipated by all heat

sources in the enclosure

Example

To calculate the size of an enclosure for one

DBE2200 Drive. The following conditions are

assumed:

The installation is to conform to IP54, requiring

the Drive to be surface-mounted within a

sealed enclosure

Only the top, front and two sides of the

enclosure are free to dissipate heat

The enclosure is constructed of painted

2mm (

3

/32 inch) sheet steel

Maximum external ambient temperature:

25°C (77°F)

Drive PWM switching frequency: 8kHz

DigitAx User Guide

Issue code: dgxu4

4-7

Insert the following values:

P = 827W (from Losses and Efficiency

table)

T

i

= 50°C (122°F)

T

amb

= 25°C (77°F)

k = 5.5 (typical value for painted 2mm

(

1

/16 inch) sheet steel)

The minimum required heat conducting area is then:

(())

Am

e

==

−−

==

827

5 5 50 25

60

2

.

.

The unobstructed heat-conducting area of the

enclosure is:

A = 2HD + HW + DW

e

Figure 4–5 Enclosure having top, sides and

front surfaces free to dissipate

heat

Estimate two of the enclosure dimensions — the

height and depth, for instance. Calculate the

minimum width from:

W

AHD

HD

e

==

−−++2

Inserting HH = 1.8 metres, D D = 0.5 metre, obtain the

minimum width:

W metresapprox==

−−××××

++

==

60 2 18 05

18 0 5

18

.( . .

..

.

If possible, locate heat-generating equipment in the

lower part of the enclosure to encourage internal

convection. Otherwise, increase the height of the

enclosure or install ‘stirrer’ fans.

4.11 Heat dissipation in a

ventilated enclosure

If a high ingress factor is not required, a ventilated

enclosure may be used. This will be smaller than a

sealed enclosure.

To calculate the minimum required volume of

ventilating air, use the following formula:

V

P

TT

iamb

==

××

−−

31.

where:

V = Air-flow in m3/hr

P = Power in Watts dissipated by all heat

sources in the enclosure

T

i

= Maximum permissible operating

temperature in °C of the Drive

T

amb

= Maximum external ambient

temperature in °C

Example

To calculate the ventilation requirement for one

DBE1500 Drive:

P = 827W

T

i

= 50°C

T

amb

= 25°C

Then..

V m hr==

××

−−

==

3 1 827

50 25

102 5

3

.

. /

4.12 Motor cooling

When a motor is driven at low speed, its internal

cooling fan becomes less effective. If necessary,

provide it with additional cooling (such as forced

ventilation).

DigitAx User Guide

Issue code: dgxu4

4-8

DigitAx User Guide

Issue code: dgxu4

5-1

5 Electrical Installation

Warning

The voltages present in the

Drive are capable of

inflicting a severe electric

shock and may be lethal. The

Stop function of the Drive

does not remove dangerous

voltages from the Drive or

the driven machine. AC

supplies to the Drive must

be disconnected using an

approved isolation device

before any cover is removed

or service work is

performed.

Warning

Electric shock risk

If the Drive has been

energized, the supply must

be isolated for at least

fifteen minutes. This allows

the internal capacitors to

discharge fully before work

may continue. Refer to

Safety information on the

inside front cover of this

user guide.

5.1 Hazardous areas

Approval and certification for hazardous areas

should be obtained for the complete installation of

the motor and Drive.

5.2 Access to the power

connectors

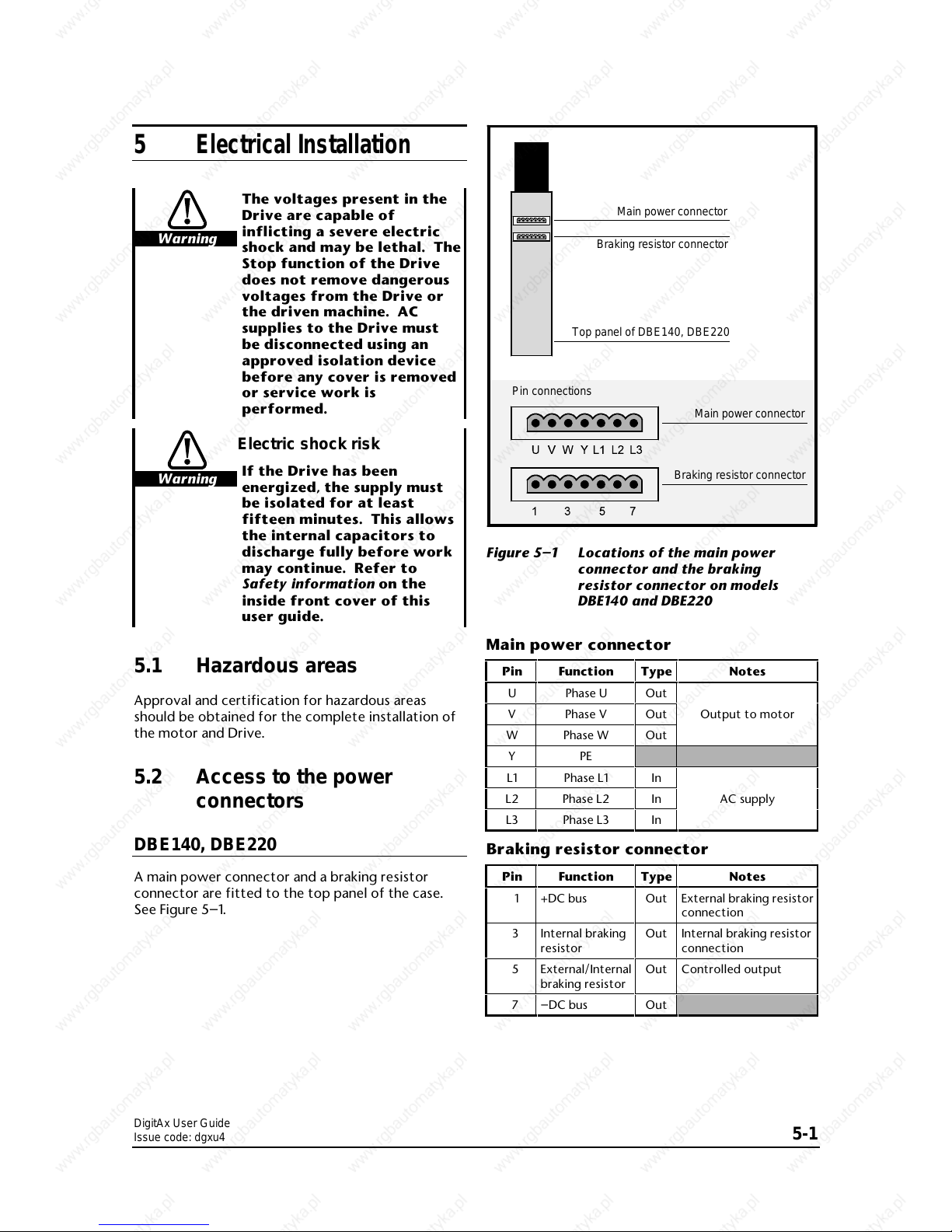

DBE140, DBE220

A main power connector and a braking resistor

connector are fitted to the top panel of the case.

See Figure 5–1.

Main power connector

Braking resistor connector

Top panel of DBE140, DBE220

Main power connector

Braking resistor connector

Pin connections

Figure 5–1 Locations of the main power

connector and the braking

resistor connector on models

DBE140 and DBE220

Main power connector

Pin Function

Type

Notes

U Phase U

Out

V Phase V

Out

Output to motor

W Phase W

Out

YPE

L1 Phase L1

In

L2 Phase L2

In

AC supply

L3 Phase L3

In

Braking resistor connector

Pin Function

Type

Notes

1 +DC bus

Out

External braking resistor

connection

3 Internal braking

resistor

Out

Internal braking resistor

connection

5 External/Internal

braking resistor

Out

Controlled output

7 –DC bus

Out

Loading...

Loading...