Page 1

Quick Start Guide Quick Start Guide

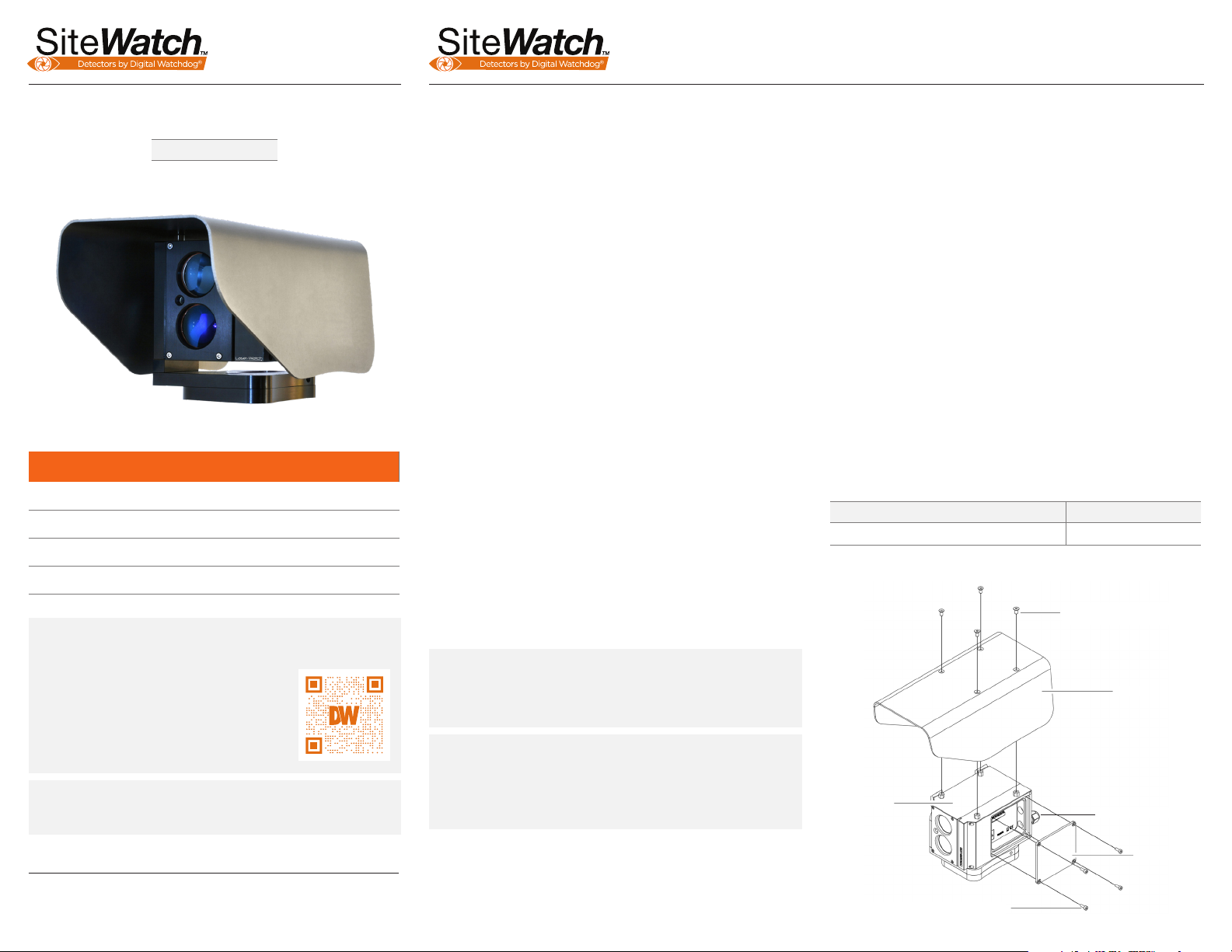

1640FT LASER SURVEILLANCE SENSOR

DW-DTLA500

WHAT’S IN THE BOX

1 x laser s ensor

1 x M12 ca ble gland

1x 0.09 8” (2.5mm) allen key

1 x quick setup guide

STEP 1 – PREPARING TO MOUNT THE

LASER SENSOR

1. Do not stare directly into the red alignment laser.

Do not leave the red alignment laser turned on after

nstallation process is complete.

2. Only use wall brackets and tripod with

compatible mounting.

3. Install the product only on a solid surface.

4. Install the product so that the detection line is not

obscured by interference from tall grass or tree branches

waving in the wind.

5. For perimeter protection, the unit should be placed at

desired detection height and parallel to ground.

6. Do not install or leave the product in a location exposed to

heat, vibration or impact.

7. The SiteWatch™ laser sensor is compatible with a number

of conventional wall brackets used for surveillance

cameras, all standard accessories, such as

pole mounts, corner mounts etc., can be used.

8. When using the product for mobile applications, the

threaded UNC 5/8” - 11 hole is compatible with most

surveyor tripods.

9. Using the mounting accessory, mark and drill all necessary

holes in the mounting surface.

STEP 2 – CABLING THE LASER SENSOR

The SiteWatch™ laser sensor is powered with PoE and all

communication is made with TCP/IP. For applications that

require cables over 328ft (100m) between unit location

and nearest switch or router it is necessary to use network

extenders or fiber optics.

1. Remove the shell and service lid.

2. Insert the network cable without a connector through the

cable gland. Crimp RJ45 connector to the cable then plug

into the RJ45 jack.

3. Tighten the cable gland to secure the cable and seal

the casing.

4. If the relay is desired to be used, replace the plug on the

backside with supplied cable gland.

5. Connect the signal cable to the terminals. Choose

connection for desired function, normally open (N/O) or

normally closed (N/C).

6. Refit the service lid and shell.

Power input Power consumption

Power over Ethernet (48V DC) or 12V DC 4W, class 2

NOTE: Download all your support mate rials and tools in one place .

1. Go to: http://www.digital-watchdog.com/resources.

2. Se arch for your produ ct by entering the part

number in the ‘S earch by Product’ search bar.

Results for applicable part numbers will

populate automatically based on the part

number you enter.

3. Click ‘Search’. All supported materials, including

manuals and quick start guide (QSGs) will

appear in the results.

Attention: This document is intended to serve as a quick reference

for initial setup. It is recommended that the user read the entire

instruction manual for complete and proper installation and usage.

Tel: +1 (866) 446-3595 / (813) 888-9555

Technical Support Hours:

9:00AM – 8:00PM EST, Monday thru Friday

digital-watchdog.com

NOTE: The sensor must always be mounted on a

steady foundation, such as a wall or a pole that

is well secured to minimize risk of misalignment

due to vibrations.

NOTE: The sensor has a maximum detection range of

up to 1640.42ft (500m). Recommended range

for demanding applications is 984.25ft (300m),

to ensure detection of small objects such as

people, even in dicult weather conditions.

Main unit

Service lid screw (M3x8 mm)

Shell screw

(Countersunk M4x6 mm)

Shell

Cable gland

Service lid

Page 2

Quick Start Guide

STEP 3 – INSTALLING THE LASER SENSOR

1. Install wall bracket and additional items according to

their associated descriptions.

2. Mount the unit on the wall bracket with the four

M6 screws.

3. Make a rough alignment with the adjustable wall

bracket head.

STEP 4 – ALIGN THE LASER SENSOR

The final alignment adjustment of the sensor is made with

the adjustment screws on the sensor. To facilitate alignment,

horizontal and vertical adjustments have been separated.

Vertical Alignment Adjustment

Horizontal Alignment Adjustment

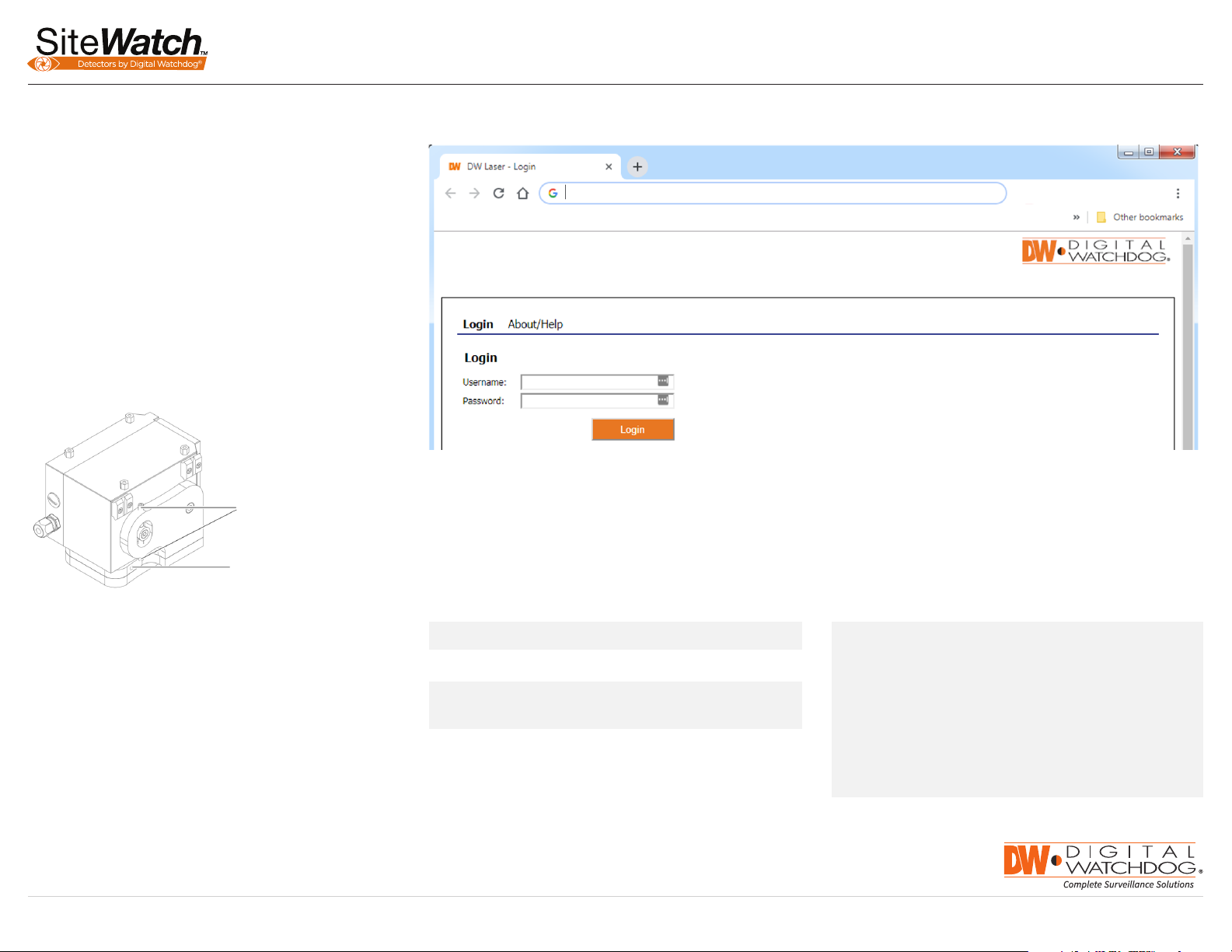

STEP 5 – CONFIGURE

The DW-DTLA500 can be setup remotely via the detector’s web interface. To open the detector’s web interface:

1. Open a web browser.

2. Enter the detector’s default IP address in the in the address bar. The detector’s default IP address is 192.168.0.10.

3. Enter the detector’s username and password. The default username and password are admin | admin.

If this is your first time accessing the detector remotely, it is highly recommended that you change the password.

1. Remove the shell.

2. Release all adjustment screws using a 2.5mm Allen key.

3. Screw on one side to push the sensor in the desired

direction. 3/4 turns of the adjustment screw equals to

3.28ft (1m) movement at 109yd (100m), 6.56ft (2m) at

218yd (200m) and so on.

4. When the sensor is aligned, tighten the screws from both

sides to lock the alignment.

5. Confirm that alignment is correct after all screws have

been tightened.

6. Refit the shell.

NOTE: Default IP address: 192.168.0.10

*

NOTE: Please see the full product manual for web

viewer setup, functions and camera settings

options.

Resetting the laser sensor:

1. Remove the shell and service lid.

2. Press and hold reset button for 8~10 seconds

until the network activity lights go out then

start blinking.

3. Refit the service lid and shell.

4. The unit will change IP address to default IP.

5. The unit will restart in the boot loader.

6. Click “Clear settings” to reset admin password

and erase previous configurations.

Rev Date: 0 9/19

Speci fications and pricing are subject to change without notice.

Copyright © Digital Watchdog. All ri ghts res erved .

Loading...

Loading...