Page 1

INSTALLATION 521LX and LXT Addressable Smoke Detectors

Description

The Model 521LX and 521LXT Smoke Detectors are the

industry’s finest smoke detectors with analog features such

as remote maintenance reporting (CleanMe™), drift

compensation, and multi-criteria detection. These smoke

detectors incorporate an addressable single point module

for connection to the LX-Bus™ of an XR200 Command

Processor™ Panel with firmware version 1.04 (6/11/98) or

higher. The 521LXT also includes multi-criteria fast response

heat sensor algorithms for detection of a broad range of

fires.

Single Point Addressable

The 521 incorporates a factory mounted, addressable

single point zone expander on the back of the smoke

detector. The included 4-wire harness allows a direct

connection to the LX-Bus of an XR200 panel . The integrated

zone expander reports smoke detector alarm and service

conditions to the panel as a single zone. Also included is a

TXD LED that flashes when data is sent to the XR200

panel.

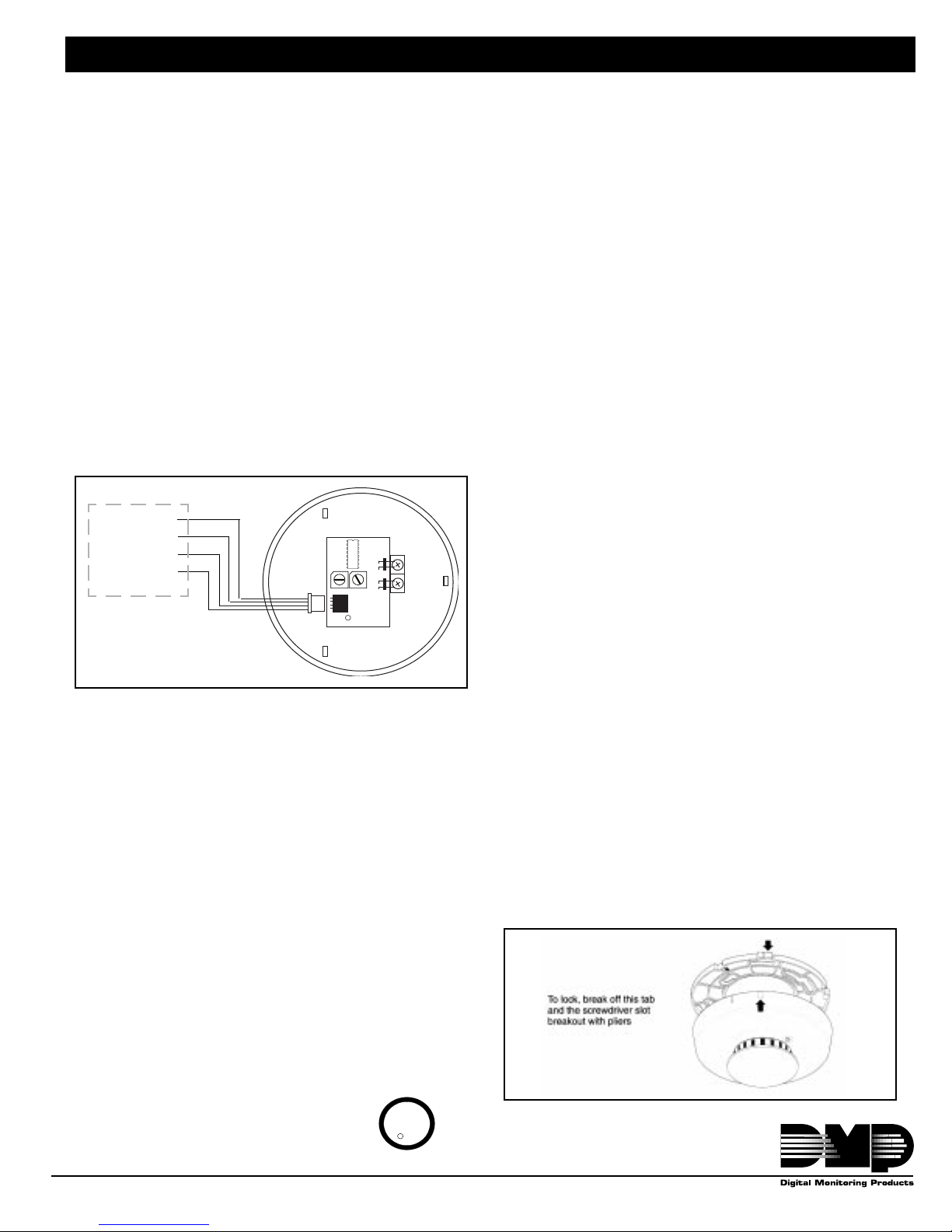

Figure 1

Black (common)

Green (data)

0

0

1

1

9

9

2

2

8

8

3

3

7

7

4

4

6

6

5

5

onestens

J1

Bottom view

J7

J4

Yellow (data)

Red (Smoke

power)

XR200 LX-Bus

Requires Model 462N,

462P, 472, or 481

Interface Cards.

TXD

521 Power and Data Bus Wiring

CleanMe™ Remote Maintenance/Trouble

Reporting Feature

The 521 detectors have a unique feature that allows a

service signal to be sent to the XR200 when the smoke

detector has drifted outside UL sensitivity ranges or a

hardware fault exists. In most cases, the signal will be the

result of the detector becoming dirty over time and, as a

result, are over sensitive. This condition could result in a

false alarm. The CleanMe™ signal enables the XR200 to

receive a service signal allowing an installer time to clean

the detector by replacing the inexpensive optical chamber

with a new one (DMP Model 525). This service information

can be transmitted to the Central Station.

Self-Diagnostics with Automatic Sensitivity

Testing

Each 521 photoelectric smoke detector monitors its own

sensitivity and operational status. Once a day, and

immediately upon first power up, it performs a full diagnostic

test that includes a dynamic test of the sensing chamber

and internal electronics. If the detector drifts out of its

sensitivity range or fails internal diagnostics, the alarm LED

flashes once every second to indicate trouble. This meets

NFPA 72 field sensitivity testing requirements without the

need for external meters.

Drift Compensation Built-In

The 521 detector is the industry’s first addressable smoke

detector with built-in drift compensation. The 521

automatically adjusts sensitivity, up to a maximum of 1.0%/

ft., as it becomes dirty. This feature increases immunity to

dust and dirt by 30-50%.

Installation

Consult Local Authority Having Jurisdiction (AHJ) and

NFPA 72 for specific installation information regarding

smoke detector spacing, placement, and special

applications.

The 521 detectors wire directly to the XR200 panel 4-wire

LX-Bus™. See Compatible LX-Bus Interface Cards. When

wired to the panel LX-Bus, the 521 uses only one of the

available expansion zone numbers allowing you to assign

additional zone expanders to the next zone number address.

See Addressing the 521LX and LXT.

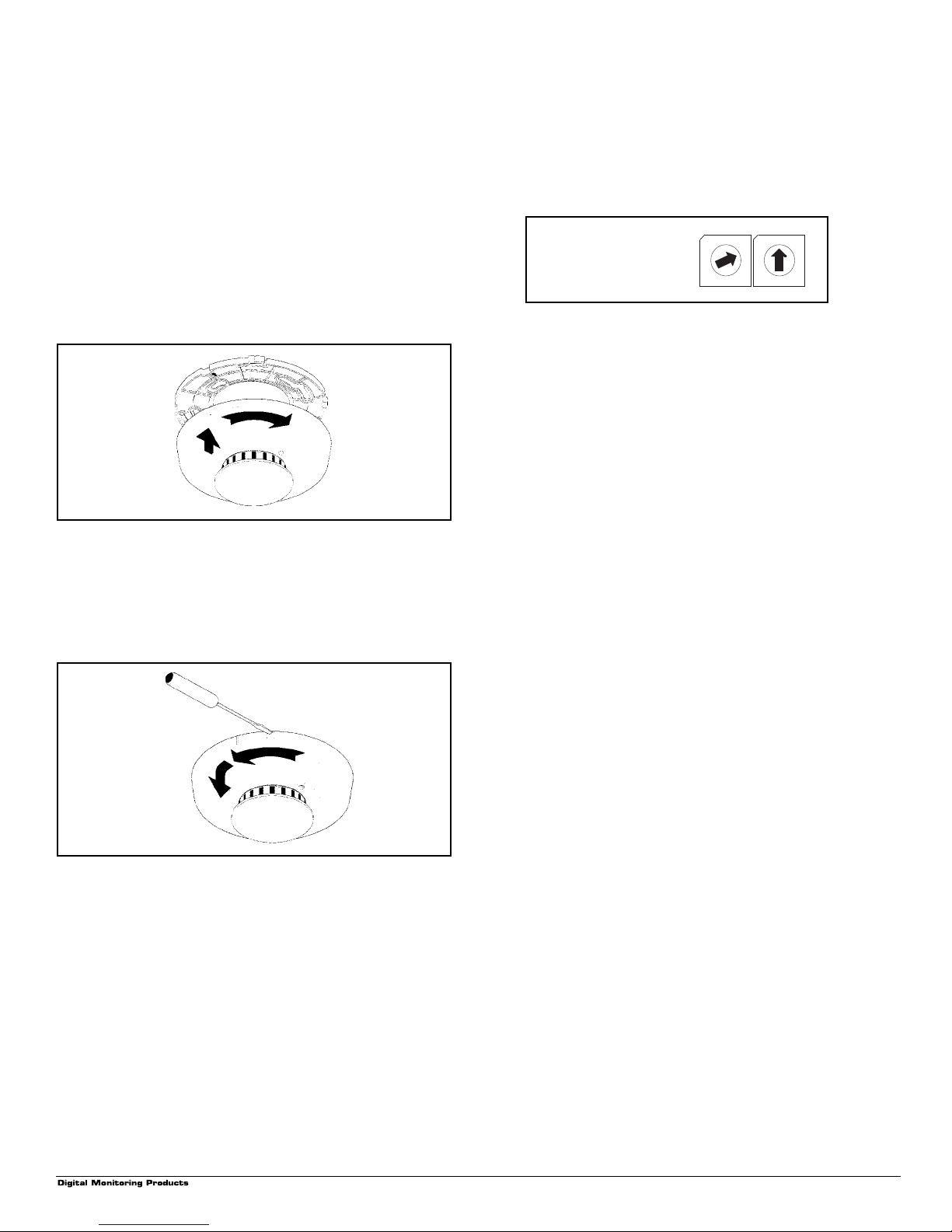

Consider the Locking Mechanism BEFORE

Installation

Each 521 detector head is equipped with a break away

locking tab slot to prevent unauthorized removal of the

detector head . For installations where unauthorized removal

of the detector head is not a concern, i.e. high ceilings, no

action is required. The head can be removed by simply

turning counterclockwise.

However, when the head must lock to the base, simply

break away the locking tab and the “knock out” for the

screwdriver slot with a pair of pliers. Then, to remove the

detector head, insert a small screwdriver into the slot of the

side of the base and press in while simultaneously turning

the detector head counterclockwise (see Figure 2).

Figure 2

CleanMe™ is a trademark of Sentrol, Inc.

2841 E. Industrial Drive Springfield, MO 65802-6310 800-641-4282

U

R

L

LISTED

LT-0403 (7/98)

Page 2

Installing the Mounting Base

The mounting base included with each 521 makes the

smoke detector easy to install and remove if necessary.

The detector head simply twists off of its 4.75" mounting

base.

The mounting base connects directly to standard singlegang electrical boxes, three-inch round, or four-inch

octagonal boxes. The base may also be mounted without

electrical boxes if approved by the AHJ or if codes allow.

Installing the Detector Head to Mounting Base

To install a detector head, simply line up the raised marking

on the side of the detector with the arrow on the mounting

base. Insert the head and rotate it clockwise approximately

15 degrees to snap into place (see Figure 3).

Figure 3

Removing the Detector Head

To remove the detector head, simply turn counterclockwise.

However, if the locking tab slot has been removed, insert a

small screwdriver into the locking tab slot on the side of the

base and press in while simultaneously turning the detector

head counterclockwise (see Figure 4).

Figure 4

Wiring

First, pull wire through electrical box, then through center

opening of the 521 mounting base. Connect the 4-wire

harness to the J1 terminal according to the wiring diagram

in Figure 1.

Follow the wiring in Figure 1 when connecting the 521

detector to the XR200 LX-Bus. The maximum distance for

any one LX-Bus circuit is 2,500 feet. The maximum number

of LX-Bus devices on any one 2,500 foot circuit is 40. To

increase the wiring distance and/or number of devices, you

must install a DMP 710 Bus Splitter/Repeater Module.

Refer to page 4 for more information about the Model 710.

Addressing the 521LX and LXT

Addressing the 521 requires setting two on-board rotary

switches to match the address of the XR200 LX-Bus zone

number. For zone numbers 100 to 199, set the switches to

match the last two digits of the zone number. For example,

to assign the 521 detector to zone number 120, you would

set the left rotary switch (labeled "TENS") to 2 and the right

rotary switch (labeled "ONES") to 0.

Example:

Rotary switches on the

521 module set for zone

address 120.

0

9

8

7

6

TENS

5

0

2

3

9

8

7

6

5

ONES

1

2

3

4

1

4

Figure 5: Address switches

Testing Each Detector

All 521 smoke detectors are shipped with a plastic dust

cover for use in areas where construction is continuous.

Smoke detectors will not work with the dust cover in place.

Remove the dust cover when installation is completed,

prior to testing. Also, disconnect alarm notification

appliances, releasing service devices, and extinguishing

systems prior to detector tests. Be sure to reconnect all

devices at the conclusion of testing.

Per NFPA 72, “all smoke detectors shall be tested in place

annually, to ensure smoke entry into the sensing chamber

and alarm response. Testing with smoke or listed aerosol

acceptable to the manufacturer, shall be permitted.” Annual

functional testing is best accomplished using Smoke! In a

can, Model 526, available from DMP. Carefully follow the

directions on the can.

The detector performs a smoke test every 9 seconds while

flashing its LED. If smoke is detected, the rate of sampling

increases to every 4.5 seconds. Excessive smoke must be

detected in three consecutive tests for the alarm to sound.

Therefore, when testing the detector with smoldering punks

or cotton wicks, hold the smoke source near the opening for

smoke entry and gently direct smoke into the detector for 20

seconds or until an alarm is indicated.

PROPERLY EXTINGUISH THE SMOKE SOURCE AFTER

TESTING!

This is a gross, go/no-go test and is not a reliable indication

of detector sensitivity. If it is successful, the LED will remain

lit. For in-depth sensitivity testing, see Sensitivity Level

Test Mode below. Reset the detector, then blow or brush off

the optical block base and snap a new optical block

chamber (see Figure 8) back in place, replace the cap and

verify sensitivity with the Sensitivity Level Test.

BE SURE TO

521LX and LXT Installation

2

2841 E. Industrial Drive Springfield, MO 65802-6310 800-641-4282

Page 3

Additional Diagnostics Available with

Sensitivity Level Test Mode

Each smoke detector also includes a special sensitivity

level test mode that is activated by holding a magnet near

the integral reed switch for more than one second (see

Figure 6). Once the routine starts, the alarm LED will flash

one to nine times, indicating actual sensitivity and whether

or not service is required.

Figure 6

After the sequence of blinks, if the sensitivity is found to be

within limits and if all other tests pass, the detector will go

into alarm until reset by the panel. If the sensitivity is not

within limits, or an unserviceable hardware fault has been

detected, the alarm LED will continue to flash once per

second until the detector is reset by the panel. If sensitivity

test indicates an unacceptable level, take action

recommended above. See the 521 Sensitivity Table.

etamixorppA

noitarucsbOnoitarucsbO

noitarucsbOnoitarucsbO

noitarucsbO

).tf%().tf%(

).tf%().tf%(

).tf%(

otohP

53.42

58.33

06.34

01.35

06.26

01.27

58.18

53.19

sknilBnoitacidnInoitcA

1

tonsirotceteD

hguoneevitisnes

nihtiwsirotceteD

stimilytivitisnesstimilytivitisnes

stimilytivitisnesstimilytivitisnes

stimilytivitisnes

ootsirotceteD

evitisnes

Figure 7: 521 Sensitivity Table

Smoke Detector Dip Switches

If the 521 smoke detector includes dip switches to the left

of the screw terminals, they are factory preset and must not

be changed.

2841 E. Industrial Drive Springfield, MO 65802-6310 800-641-4282

Maintenance, Cleaning & Sensitivity

The 521 smoke detectors are designed for easy field

service and maintenance. If a smoke detector drifts beyond

its approved sensitivity range for more than 24 hours or fails

internal diagnostic tests during power-up, the unit

automatically indicates trouble by flashing its LED every

second. Under normal conditions the LED flashes every 9

seconds. Therefore, a simple visual check of the LED

status meets NFPA 72 field sensitivity testing requirements

without the need for external meters or ladders. In

accordance with NFPA 72-7-3.2.1, smoke detector

sensitivity should be checked within one year after

installation and every alternate year thereafter, in

commercial installations, or every three years in residential

sites.

Figure 8

Model 525

▲

The sensing chamber of the 521 photoelectric detector

ytivitisnesnur-erdnatinuteseR

ehtsniamernoitacidnifi,tset

.tinuecalper,emas

teseR.snoitcurtsnirepnaelC

,tsetytivitisnesnur-erdnatinu

.tinuecalper

enoN

.snoitcurtsni

,emasehtsniamernoitacidnifi

kcolblacitpoerusebotkcehC

nwoddeppanssirevoc

repnaelC.yletelpmoc

unsnaps for easy field cleaning and service. Whenever the

status LED indicates cleaning is necessary, remove the

photoelectric detector cap, snap off and throw away the

optical block. Then blow or brush off the optical block base

and snap a new optical block chamber (see Figure 8) back

in place, replace the cap and verify sensitivity with the

Sensitivity Level Test.

Compatible LX-Bus Interface Cards

The following Expansion Interface Cards are compatible

with the 521 smoke detectors: 462N, 462P, 472, and 481.

Specifications

egnargnitarepOCDV0.51-8.8

)kpotkp(elppirmumixaMV(%01

tnerrucgnitarepoybdnatSAm8.8

tnerrucgnitarepomralAAm82

cirtceleotohpytivitisneS%00.1-05.0+%1.3

erutarepmetgnitarepO23

egnarytidimuhgnitarepOgnisnednoc-noN%59ot0

ytinummIIFRzHM0001-0;muminimm/V02

roloCesabdnadaehetihW

)ylnoTXL(rosnestaeH531

:esirfoetaR51

emitpu-rewoPsdnoces51

tnemtsujdanoitasnepmoctfirD.xam.tf/%0.1

:snoisnemiddaehrotceteDretemaid"5thgieh"2

:snoisnemidgnitnuoMretemaid"57.4thgieh"3.

sgnitsiL862LU

)

p-p

o

o

o

o

001otF

F

F

o

501>dnanim/F

F

521LX and LXT Installation

3

Page 4

LX-Bus™ Installation Specifications

e

.

Three factors determine the performance characteristics of the DMP LX-Bus™: the

devices connected, and the

amount

of current required by the devices. The three specifications to keep in mind when

planning an LX-Bus installation are:

1. Maximum cumulative distance for any one LX-Bus circuit is 2,500 feet. This number can be increased to 50 if

the wire run remains under 2,000 feet.

2. Maximum number of LX-Bus devices per 2,500 feet is 40 regardless of the gauge of wire. This distance can be

in the form of one long wire run or multiple branches with all wiring totalling no more than 2,500 feet.

3. Maximum voltage drop between the panel (or auxiliary power supply) and any device connected to the LX-Bus

is rated at 2.0 VDC. As an example of the voltage drop, if the voltage across the red and black wires at the panel

is 13.8 VDC the voltage measured at each device on the circuit must be equal to or greater than 11.8 VDC.

If the voltage at any device, including a 710 module, is less than the required level, a UL listed auxiliary power supply

should be added at the end of the circuit. (The voltage drop can also be reduced by increasing the gauge of wire

used on the circuit.) The 2.0 VDC rule applies to LX-Bus circuits powered either by the panel or by an auxiliary power

supply.

length

of wire used, the

number

of

Voltage across red and

black here is 13.8 VDC

Voltage across red and black at all devices

along the LX-Bus must be 11.8 VDC or greater

Panel

LX-Bus Devices LX-Bus Devices

If the wiring distance between the two auxiliary power

Do not connect the Red wire between

the panel and the first device.

Voltage across red and

black here is 13.8 VDC

Panel

LX-Bus Devices

Voltage across red and black at all

devices along the LX-Bus must be

11.8 VDC or greater

▲

Power Supply

supplies is less than 250 feet, do not connect the Red

wire between the 710 and the first device.

LX-Bus Devices

710 Bus Module

A second power supply is only

required if the voltage drop from th

first supply is greater than 2.0 VDC

Power Supply

Multiple LX-Bus circuits

In this example, the first 710 module is in close proximity to the panel. At this point, the 710 is used to branch the LX-Bus

into three separate circuits. Each of these circuits can be run a distance of 2,500 feet. At the end of the 2,500 feet, another

710 module can be installed to add another 2,500 feet of LX-Bus capability.

Note: The total distance of all circuits cannot exceed 15,000 feet.

LX-Bus Devices

710 LX-Bus Module

Panel

Install the 710 module at the

point where the circuits divide.

2,500 feet

2,500 feet

2841 E. Industrial Drive Springfield, MO 65802-6310 800-641-4282

2,500 feet

2,500 feet

2,500 feet

2,500 feet

Digital Monitoring Products

710 Module

Specifications

Power: 8.0 to 15.0 VDC

Current: 30mA

Dimensions: 4.5"x2.75"x1.75"

Accepts 14 to 22 AWG Wire.

For more 710 information see

LT-0310.

Loading...

Loading...