Page 1

X ID 8300

Retransfer

Printer

Instruction

Manual

•

Thank for purchasing this product.

•

Please read this manual carefully before use to ensure correct operation.

It is particularly important to read the Safety Precautions for safe operation. After

reading, retain this manual carefully for future reference.

•

The product number is important for quality control. Upon purchase, check the back of

the unit to make sure that the product number is correctly displayed.

Notes about this manual

(1) This manual may not be reprinted in any way without permission.

(2) The contents of this manual, as well as the specifications and design of this product,

may change without notice.

(3) The illustrations used in this manual may differ slightly from the actual product.

Page 2

Before Use

2

About this Manual

●

"Contents of this manual" A page 3

●

"How to read this manual" A page 3

Precautions

●

"Safety precautions" A page 3

●

"Precautions during use" A page 4

Disclaimer

●

"Disclaimer" A page 6

Name and functions of parts

●

"Internal mechanism diagram" A page 6

●

"Front" A page 7

●

"Rear" A page 7

●

"Right" A page 7

●

"Left" A page 7

●

"When printer door is open" A page 7

●

"Ink ribbon cassette" A page 8

●

"Retransfer film cassette" A page 8

Specifications

●

"Main specifications" A page 9

●

"Outline dimensional drawing" A page 9

Accessories/separately sold items

●

"Accessories" A page 9

●

"Sold separately" A page 9

Options

●

"Functions" A page 10

●

"Options" A page 10

Contents

Before Use

Contents .................................................................................. 2

About this Manual ................................................................... 3

Precautions ............................................................................. 3

Disclaimer ............................................................................... 6

Name and functions of parts ................................................... 6

Specifications .......................................................................... 9

Accessories/separately sold items .......................................... 9

Options .................................................................................. 10

Operation

Operation Panel .................................................................... 10

Setting Mode ......................................................................... 12

Setting Mode Flow ............................................................. 13

Setting using the operation panel .......................................... 16

Printing a Card ...................................................................... 25

Replacement

Precautions on cards ............................................................ 25

Ink Ribbon ............................................................................. 26

Retransfer Film ...................................................................... 29

Maintenance

Servicing of Parts .................................................................. 32

Servicing Based on Print Output ........................................... 41

Troubleshooting?

When an Error Message is Displayed ................................... 41

Precautions on cards ............................................................ 43

Ink Ribbon ............................................................................. 49

Retransfer Film ...................................................................... 49

Unable to produce desired printing results ............................ 50

Printer not operating as desired ............................................ 50

Before sending printer for repair ........................................... 51

Setup

Installation and Connection ................................................. .. 51

Printing Media ....................................................................... 52

Printer and Computer Connection ......................................... 56

Printer Setting ....................................................................... 57

Operation Panel ................................................................. 57

Setting using the operation panel ...................................... 57

List o Error Codes ……………………................................. 58

Page 3

Before Use

3

About this Manual

Contents of this manual

●

The copyright of this manual belongs to DIS. Reprint and duplicate of

this manual in part or full without the prior consent of DIS is strictly prohibited.

●

Windows is the registered trademark of Microsoft Corporation in the

United States.

●

Product names of other companies described in the manual are the

trademarks or registered trademarks of the respective companies.

Symbols such as

E

, T, and R are omitted in this manual.

●

Designs, specifications, or other details described in this manual may

be modified for improvement without prior notice.

How to read this manual

●

Information in this frame is for reference purposes, such as information

on functions and usage restrictions.

●

Precautions are described in this frame.

●

Click this frame to display the details page.

●

Click this icon to return to the top page.

●

Click this icon to open the PDF file for printing.

●

The 「Adobe Reader」 application is needed to browse the PDF file.

Precautions

Safety precautions

●

Please read through all the following items before using the

printer.

Graphical symbols

Warnings

Page 4

Before Use

4

Caution

Precautions during use

●

Please read through all the following items before using the

printer.

Handling instructions

●

Pay careful attention of the following when handling a printing media

(retransfer film or ink ribbon) or card.

Page 5

Before Use

5

●

Using a deformed or scratched card may cause card feed errors.

●

Touching the printing surface of the printing media or card directly with your hand may cause the print to turn out uneven.

●

Foreign particles attached to the printed areas ma y result in

printing voids. Attach the printing media in a clean e nvironment.

●

Use of electrically-charged printing media or cards may cause

printing errors. Do not allow static to occur, such as due to

cards rubbing against each other.

●

When replacing or replenishing a printing media or card that is

stored under a low temperature, use after leaving the media or

card at the operating ambient temperature of the printer for at

least one hour.

Otherwise, condensation may occur, causing printing errors or

malfunction of the printer.

Storage

Storage instructions

●

The storage conditions of the printing media (retransfer film or

ink ribbon) and card have a significant effect on the printing

quality. Store the printing media or card in one of the following

locations.

Storage environment

●

Temperature: 5 7C to 25 7C

●

Relative humidity: 40 % to 60 %

Storage location

Do not store the printing media or card in the following locations.

Doing so may cause the media or card to deteriorate.

●

Places exposed to direct sunlight.

●

Places with a high humidity.

●

Places near organic solvents or diazo copiers.

Storage period

●

Use the printing media (retransfer film or ink ribbon) within half

a year after purchase. For details on the cards, please consult

our authorized dealers.

Printer Installation

●

When the printer is not in use, it is recommended that you turn off the

power, and cover it with a plastic sheet.

●

Do not place the printer unit in the following locations. Doing so may

have adverse effects on the printer.

●

Carpeted room.

●

Places with a busy flow of people.

●

Places where paper (corrugated boards, etc.) is handled or stored.

●

Places near photocopiers.

●

Places exposed to direct sunlight or near a heating equipment

(such as a stove).

●

Inclined or unstable surfaces.

●

Places exposed directly to cold air, such as near an air-conditioner outlet, or places subject to high temperatures.

Precautions on retransfer films/ink ribbons

●

Put on the supplied gloves when handling the retransfer film/ink ribbon.

Direct contact of your hand with the printing surface may result in printing errors.

When retransfer film/ink ribbon is dismantled

●

Winding misalignment may occur. If an improperly wound retransfer film/ink ribbon is installed, the resulting color may vary,

or errors may occur.

When attaching the retransfer film/ink ribbon

●

Use your hands to adjust the media at the supply and take-up

sides so that they are parallel to each other.

When doing so, make sure you do not touch the printing surface.

●

Refer to the label adhered to the cassette for alignment of th e

screen position. Printing errors may occur if the position is not

properly aligned.

During transport or moving

●

Make sure to set to the transport mode.

"Transport mode setting"

(A page 24)

Precautions on cards

Handling and storage of cards after printing

Avoid storing cards at places that are exposed to direct sunlight

or subject to high temperatures and humidity.

Discoloration or fading may occur if a card comes into contact

with the following chemicals or stationery.

●

Organic solvents, including alcohol, film cleaner, or diazo copies.

●

Files, document cases, pass holders, or erasers made of flexible polyvinyl chloride.

●

Hair wax or cosmetic products.

Card types

Thin cards and certain card materials may not be suitable for

printing using this printer. For details on the card material to use

and other specifications, please consult our authorized dealers in

advance.

Note:

●

If the card thickness is not properly adjusted, printing error or

printer malfunction may occur.

"Adjusting Card Thickness"

(A page 55)

When a card is jammed inside the printer

Cards may not be discharged correctly such as when the retransfer setting for the card is inappropriate.

Stop using and remove the jammed cards immediately. Otherwise,

you may have problems removing the cards, and fire or electric

shock may also occur as a result.

●

When a card jam occurs, make use of the jog dial to remove the

jam.

●

If the card cannot be removed, consult a servicing personnel or

our authorized dealers.

Page 6

Before Use

6

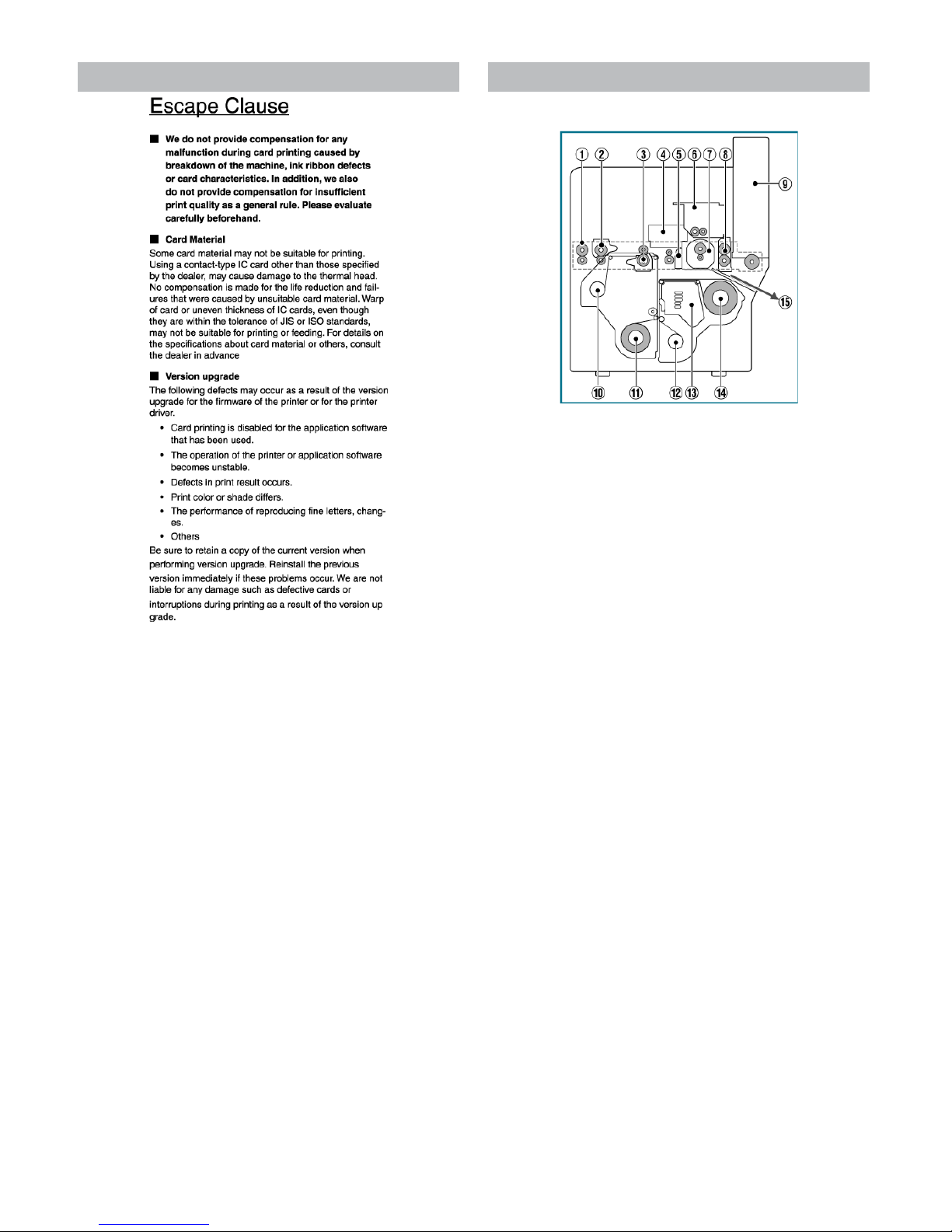

Disclaimer Name and functions of parts

Internal mechanism diagram

① Card feeder unit

●

This is the roller for feeding cards. Each of the feed rollers needs to

be cleaned daily.

② Warpage correction heating roller

●

Some types of cards may warp. Adjust accordingly until warpage is

eliminated. Set using the host computer.

③ Retransfer heating roller

●

You can adjust the temperature and retransfer time for some retransfer films and cards. Set using the host computer.

④ Non-contact IC encoder

●

You can adjust the position to stop the card when a non-contact IC

card is used. Set using the host computer.

⑤ Contact IC

●

You can adjust the position to stop the card when a contact IC card

is used. Set using the host computer.

⑥ Magnetic encoder

●

You can select the coercivity when writing data to the magnetic stripe

card. Set using the host computer.

⑦ Card turnover unit

●

Inverts the card.

⑧ Cleaning roller

●

Removes any dust or dirt attached to the card. The cleaning roller

needs to be cleaned daily.

⑨ Card hopper

●

For loading cards.

⑩ Retransfer film (take-up side)

●

For attaching the take-up side of the retransfer film.

⑪ Retransfer film (supply side)

●

For attaching the unused side of the retransfer film.

⑫ Ink ribbon (take-up side)

●

For attaching the take-up side of the ink ribbon.

⑬ Thermal head

●

The thermal head is a consumable part. For details on its replacement, please consult our authorized dealers.

⑭ Ink ribbon (supply side)

●

For attaching the unused side of the ink ribbon.

⑮ NG card outlet

●

Discharges NG cards, such as during card jams.

Page 7

Before Use

7

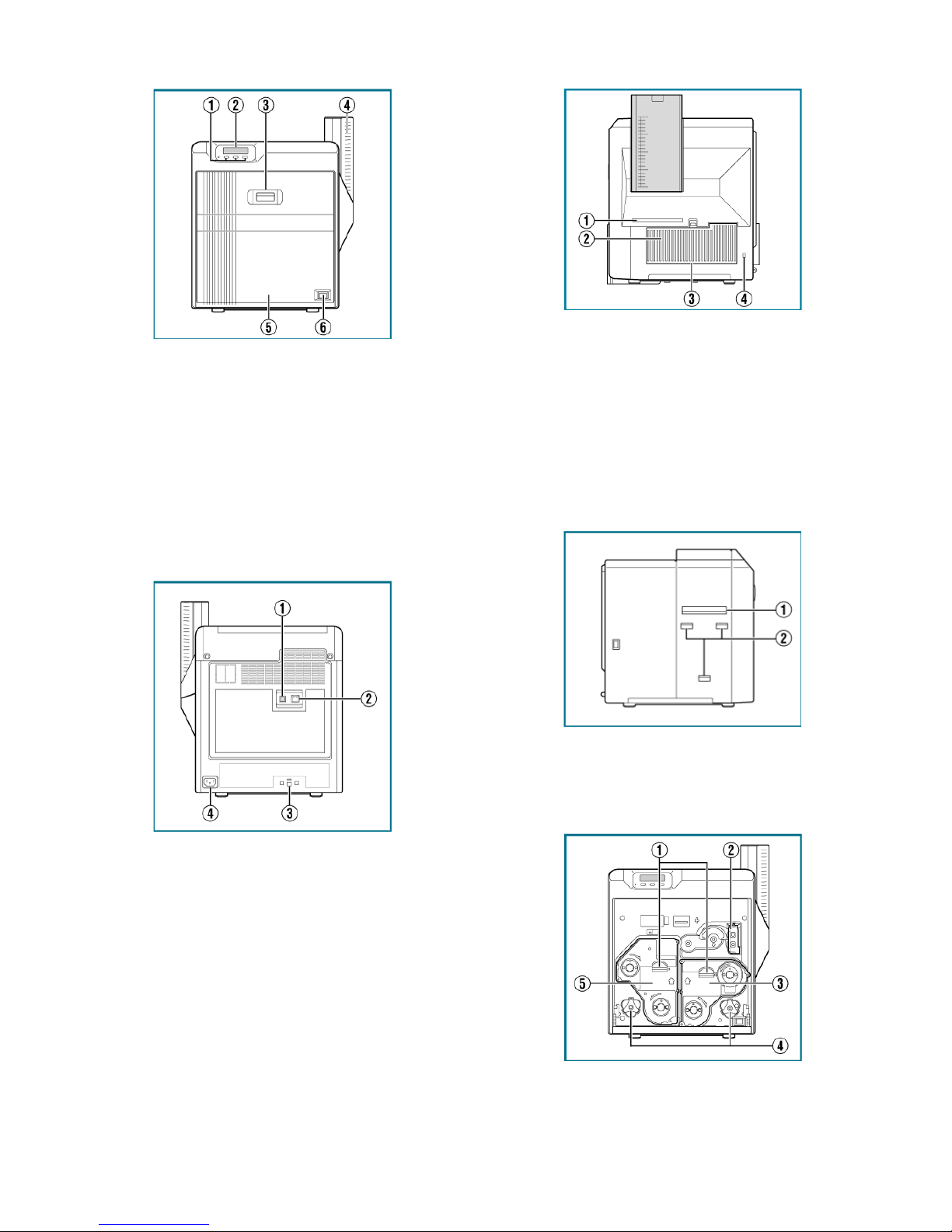

Front

① Operation buttons

●

For selecting and confirming information on the operation panel.

② Operation panel

●

Displays menus and error messages.

③ Sliding knob

●

Opens/Closes the printer door.

●

Slide it upward, and pull toward you to open the printer door.

④ Card hopper

●

For loading cards.

⑤ Printer door

⑥ Power switch

●

Turns the power On/Off.

Rear

① USB cable connection terminal

●

For connecting a USB 2.0 interface cable.

② LAN cable connection terminal

●

For connecting an Ethernet interface cable.

③ Cable clamp

●

For securing the supplied USB cable.

"Connection"

(

A

page 56)

④ [AC INLET] power supply terminal

●

For connecting the power cord.

Right

① NG card outlet

●

If a card is left inside the printer when the power is turned on or reset, the card will be automatically discharged.

●

Cards in the printer are discharged when an error occurs on the

magnetic card or IC card.

② Air suction fan opening

●

This is the air inlet for the internal cooling fan.

③ Filter cover

●

This is the cover of the fan filter.

④ Security slot

●

For attaching the Kensington lock.

Left

① Card outlet

●

Outlet for discharging the cards.

② Card stacker (supplied) attachment slot

●

For attaching the supplied card stacker.

When printer door is open

① Cassette buttons

●

Press these buttons in order to pull out the ink ribbon cassette or retransfer film cassette.

② Cleaning unit

●

Removes any dust or dirt attached to the card.

③ Ink ribbon cassette

Page 8

Before Use

8

●

For attaching the ink ribbon.

④ Jog dials

●

When there is card jam in the cleaning unit, turnover unit, or retransfer unit, detach the jog dial from the printer body, and attach it accordingly to turn the rollers of the corresponding parts.

⑤ Retransfer film cassette

●

For attaching the retransfer film.

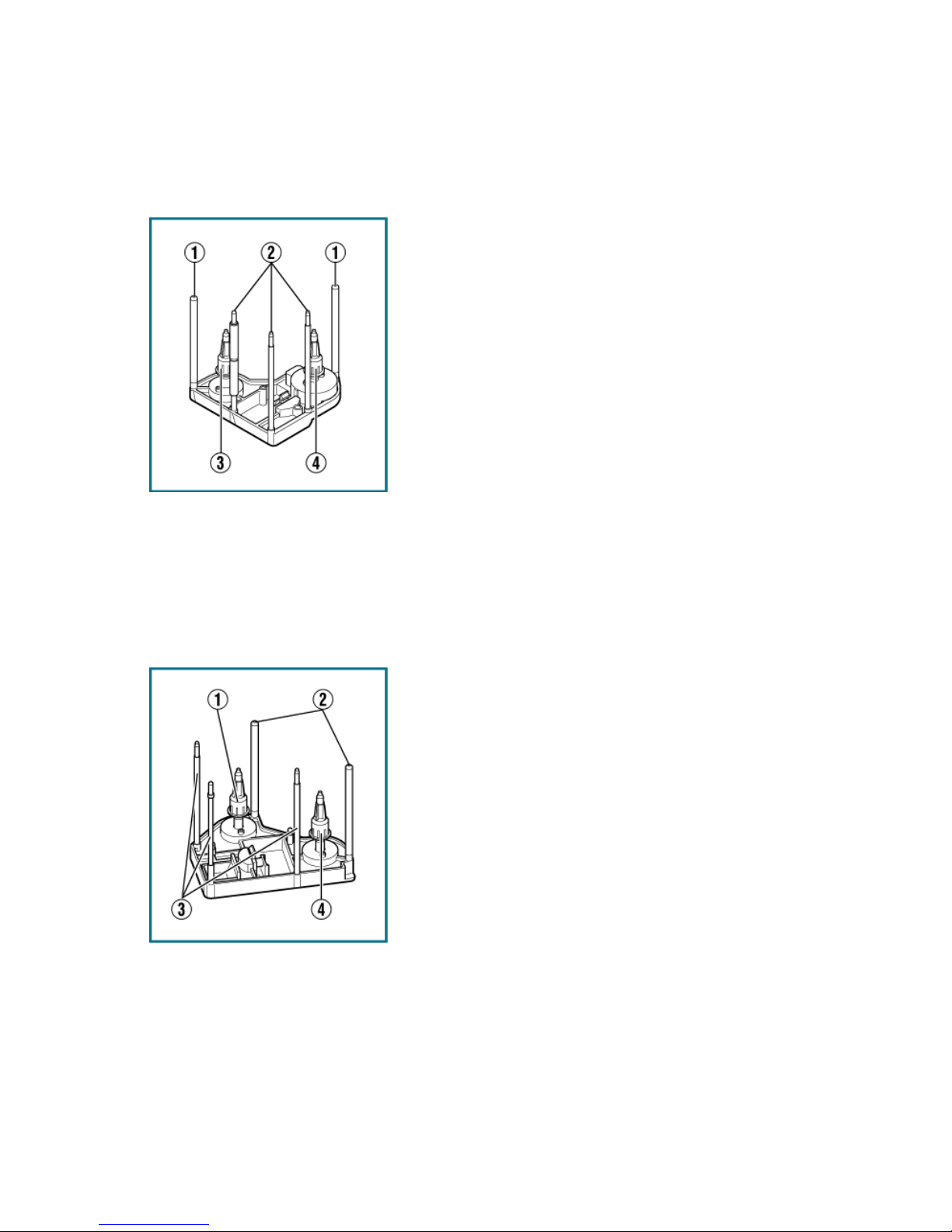

Ink ribbon cassette

① Guide shaft

●

Provides guide to the position for attaching the cassette.

② Shafts

●

When attaching an ink ribbon, unwind it along the shafts.

③ Bobbin holder (black)

●

For securing the take-up side of the ink ribbon.

④ Bobbin holder (yellow)

●

For securing the unused side of the ink ribbon.

Retransfer film cassette

① Bobbin holder (black)

●

For securing the take-up side of the retransfer film.

② Guide shaft

●

Provides guide to the position for attaching the cassette.

③ Shafts

●

When attaching a retransfer film, unwind it along the shafts.

④ Bobbin holder (green)

●

For securing the unused side of the retransfer film.

Page 9

Before Use

9

Specifications

Main specifications

Item Description

Recording system Dye sublimation retransfer

Paper feed mode Automatic

Recording density 300 dpi

Reproduction gradation 256 levels each for Y, M and C: 2 levels for Bk

Interface USB 2.0 (Hi-Speed/Full-Speed)

Interface Ethernet(100BASE-TX/10BASE-T)

Operating environment conditions Temperature between 15

7

C and 30 7C

Temperature between 17

7

C and 28 7C (When using peel-off ink)

Operating environment conditions No condensation

Humidity between 35 % and 70 %

Humidity between 35 % and 60 % (When using peel-off ink)

Storage environment conditions Temperature between -15

7

C and 557C

Storage environment conditions Humidity between 20 % and 80 %

Power supply AC 100 V - 120 V/AC 220 V - 240 V(tolerance: 510 %) 50 Hz/60 Hz (5 5 %)

Current consumption 3.5 A (100 V system)

Power consumption 310 W (max.)

Mass (Standard) approx. 13.9 kg (excluding optional built-in items)

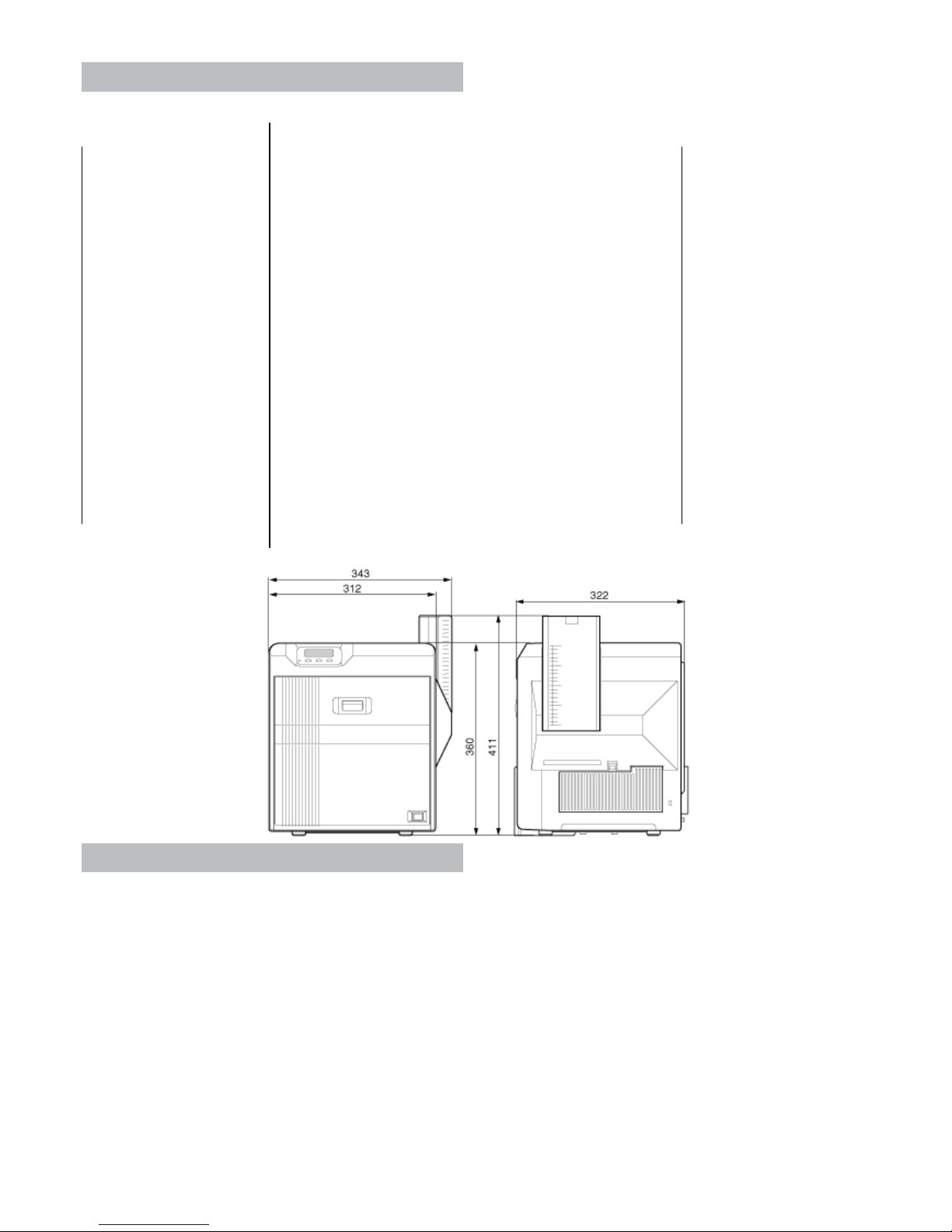

Dimensions (cm) 343 mm x 360 mm x 322 mm (W x H x D)

Outline dimensional drawing

Accessories/separately sold items

Accessories

Please check to ensure that the printer accessories are in place

when unpacking the product package.

●

CD-ROM x 1

●

Getting started guide x 1

●

Read Me First(LST1013) x 1

●

Power Cord (2 m) x 2

●

Cleaning Card x 1

●

Card Stacker x 1

●

USB 2.0 Cable: QAM1196 (2 m) x 1

●

Gloves x 1 Pair

Products sold separately

To purchase these items, please consult our authorized dealers.

●

Ink Ribbon (YMCK), 1,000 frames/roll (Model: DIC10216)

●

Ink Ribbon (YMCKK), 750 frames/roll (Model: DIC10217)

●

Ink Ribbon (YMCK-PO), 750 frames/roll (Model: DIC10218)

●

Ink Ribbon (YMCK-UV), 750 frames/roll (Model: DIC10313)

●

ART Retransfer Film, 1,000 frames/roll (Model: DIC10319)

●

Cleaning Kit (Model: DIK10044)

Set incl. 10 print head cleaning swabs, 10 cleaning tissues for

rollers and 10 special cleaning cards

●

Magnetic Stripe Encoder Head Cleaning Cards (Model:

DIC10311)

Box of 10 cards

Page 10

Before Use

10

Options

Functions

●

Double-sided printer

Printer that supports double-sided printing.

●

Single-sided printer

Printer that supports single-sided printing.

Options

●

Warpage correction

Device for correcting card warpage after printing.

●

Magnetic encoder

Device for writing data to a magnetic stripe card.

Installation is applicable only for double-sided printer.

●

Contact IC encoder

Device for writing data to a contact IC card.

●

Non-contact IC encoder

Device for writing data to a non-contact IC card.

Operating the printer

●

"Operation Panel" A page 10

●

"Setting using the operation panel" A page 16

●

"Printing a Card" A page 25

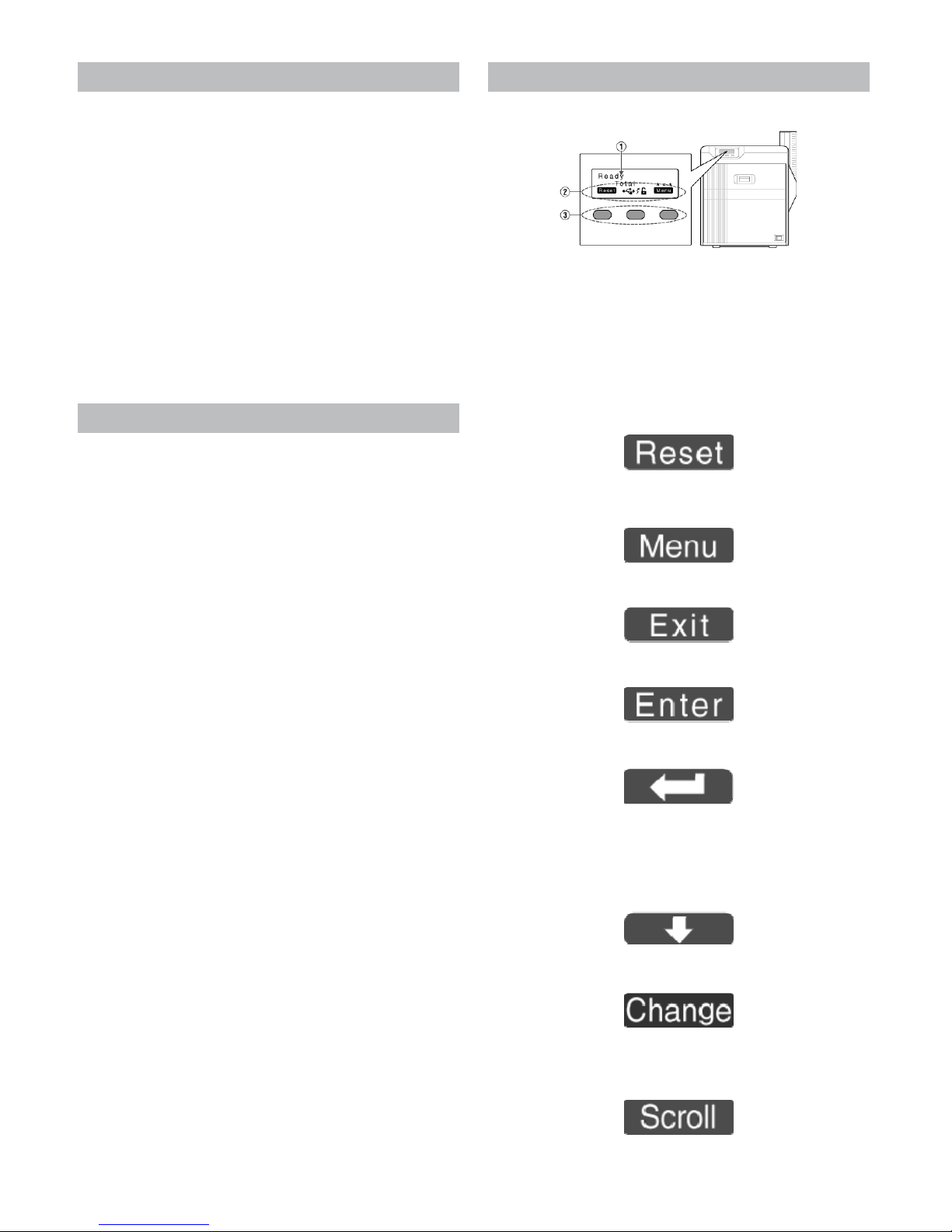

Operation Panel

Name and functions of parts

① Operation panel

●

Displays the mode settings, operating status, and error messages.

② Status icon/operation button display

●

Displays the status icon or the function of the operation button during

mode setting.

③ Operation buttons

●

For selecting the operation button displayed on the operation panel.

Operation buttons

Resets the printer.

●

After clearing an error, press in the order of [Reset]

DB

.

Displays the setting mode mode.

Exits setting.

Displays the setting mode in the next lower level.

Confirms or executes a setting.

●

The display does not change if an item cannot be altered using the operation panel.

Pressing it each time displays the next setting item.

Pressing it each time displays the next setting value.

Displays the settings change mode.

●

If [Change] is not displayed for an item, you can adjust the settings

on the status monitor of a PC.

Displays the scroll mode for the displayed characters.

Page 11

11

Operation

Scrolls to the next displayed character on the left.

Scrolls to the next displayed character on the right.

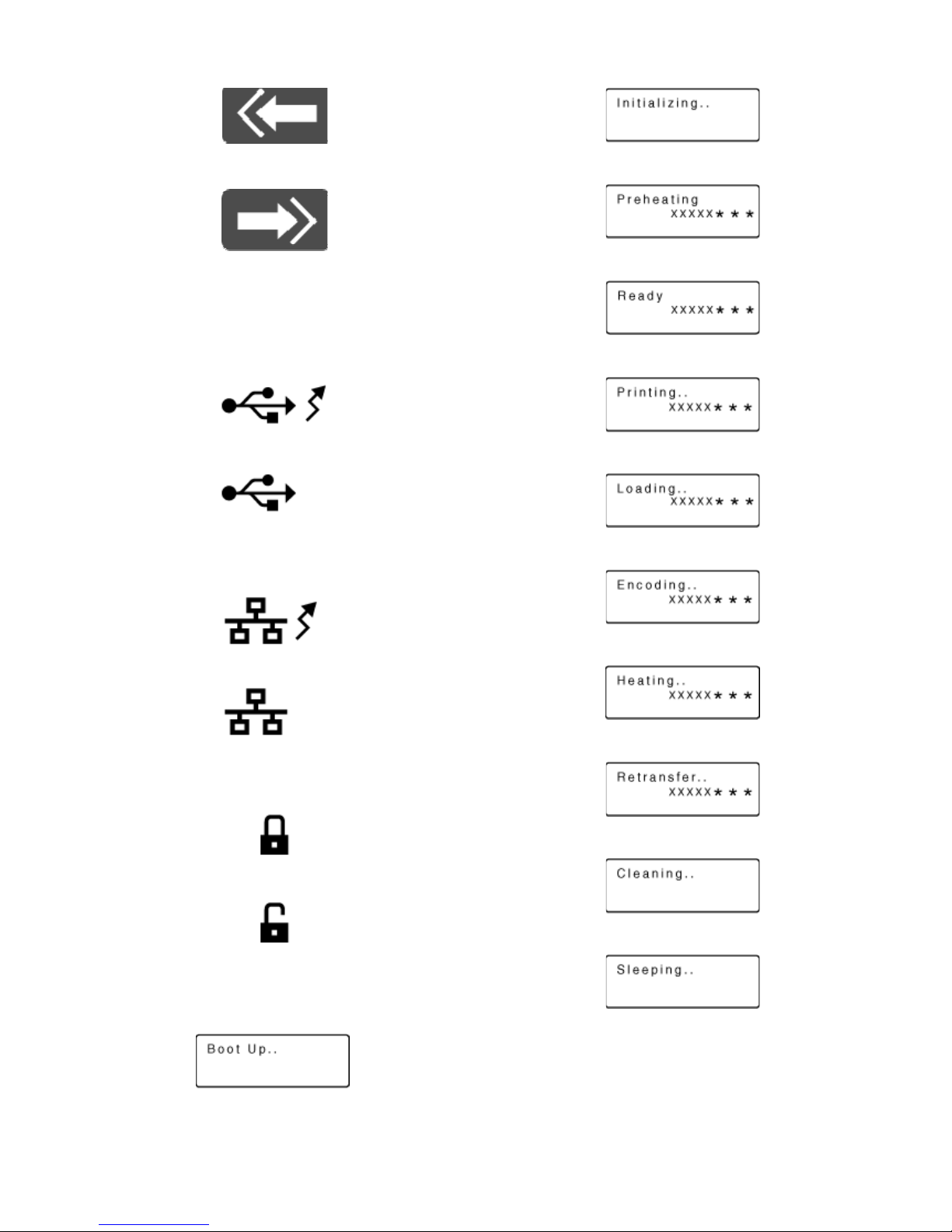

Operation Panel Display

USB connection

●

IP address established

Printer information can be viewed through the network. However, printing

is performed through USB connection.

●

IP address not established

Network connection

●

IP address established

●

IP address not established

Security status

●

Locked

●

Unlocked

Operation panel operation display

Starting up

Initializing

Preheating

Ready

Printing

Loading

Encoding

Adjusting heat roller to the preset temperature

Retransferring

Cleaning

Heater OFF

Page 12

12

Operation

Setting Mode

●

Settings can be viewed on the printer’s operation panel.

●

Settings can be changed on the status monitor of the computer.

"Setting using the operation panel"

(A page 16)

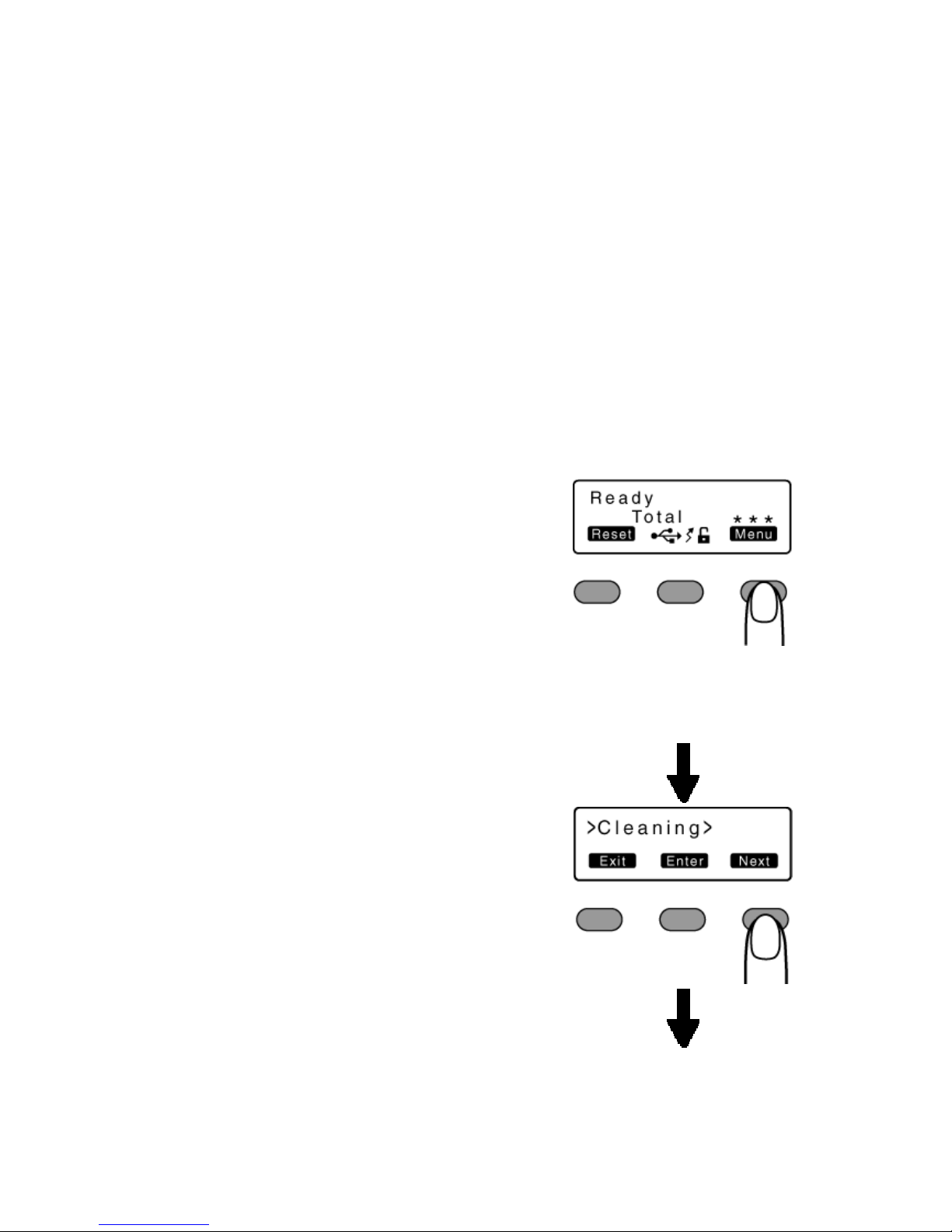

Cleaning

●

For setting during cleaning of the card feed roller or magnetic head.

Setting values

●

Rollers

Select this value when cleaning the card feed roller.

●

MG

Select this value when cleaning the magnetic head.

Counter Reset

●

Resets the free counter and error counter.

Test Print

●

Prints the printer’s built-in test pattern, or the different setting values.

●

When system troubles occur, printing can be performed using settings

on the printer or computer by operating only the printer.

Setting values

●

Test Print: Test Pattern, Printer Setting, Network, Lami Setting

Down load

●

Updates the firmware.

Transport Mode

●

For setting the transport mode.

Media

●

Displays the settings of the printing media.

Setting values

●

Ink Type: YMCK, YMCKPO, YMCKK, YMCKUV

Set according to the type of ink ribbon.

●

Film Type: 1000, 750

Set according to the type of retransfer film.

●

Card Thickness: Standard, Thin

Set according to the thickness of the card.

Standard: Supports card thickness of 0.76 mm

Thin: Supports card thickness of 0.25 mm

Print

●

Displays the printing settings.

Setting values

●

YMC Level: -3, -2, -1, 0, 1, 2, 3

For setting the YMC (color) concentration level.

Selecting a larger value increases the concentration level.

●

Black Level: -3, -2, -1, 0, 1, 2, 3

For setting the K(Black) concentration level.

Selecting a larger value increases the concentration level.

●

Black Mode: Standard, Fine

For setting the K(Black) printing mode.

If the characters still appear faded after raising the [BlackLevel],

set to [Fine].

However, printing time required will be longer than the [Stand-

ard] setting.

●

UV Level: -3, -2, -1, 0, 1, 2, 3

For setting the UV ink concentration level.

Selecting a larger value increases the concentration level.

During UV printing, card warpage may increase if the card has a

low heat resistance or under an environment with high temperature.

●

PO Level: -3, -2, -1, 0, 1, 2, 3

For setting the concentration level of the peel- off ink.

Selecting a larger value increases the concentration level.

Retransfer

●

Displays the retransfer mode settings.

Setting values

●

Temp Level: -2, -1, 0, 1, 2

For setting the retransfer roller temperature.

Selecting a larger value increases the temperature.

Retransfer may fail depending on the card used. If retransfer fails,

raise the setting to the next higher value.

A higher retransfer roller temperature helps to enhance card retransfer, but the stronger heat may also cause the card to deform.

If the printer is not initialized after changing the temperature setting, temperature is adjusted after the printing operationstarts.

●

Speed (Front): -3, -2, -1, 0, 1, 2

For setting the surface retransfer speed.

Selecting a larger value increases the speed.

Retransfer may not be successful for some parts of thecard depending on the card used. Lowering the setting value helps to enhance retransfer, but the stronger heat may also cause the card to

deform.

●

Speed (Back): -3, -2, -1, 0, 1, 2

For setting the rear surface retransfer speed.

Selecting a larger value increases the speed.

Some types of cards may warp during double-sided printing. If

card warpage occurs, raise the setting to the next higher value.

●

MG Peel Mode: Standard, MG Stripe

For setting the method for peeling the retransfer film.

●

Standby Mode: Front wait, Back wait

For setting the laminator standby position.

Select whether to standby at the front or rear surface during double-sided printing.

Bend Remedy

●

Displays the warpage correction mode settings.

Setting values

●

Temp Level: -5, -4, -3, -2, -1, 0, off

For setting the warpage correction roller temperature.

Selecting a larger value increases the temperature.

If the printer is not initialized after changing the temperature setting, temperature is adjusted after the printing operationstarts.

●

Speed: -2, -1, 0, 1, 2

For setting the warpage correction mode speed.

Selecting a larger value increases the speed.

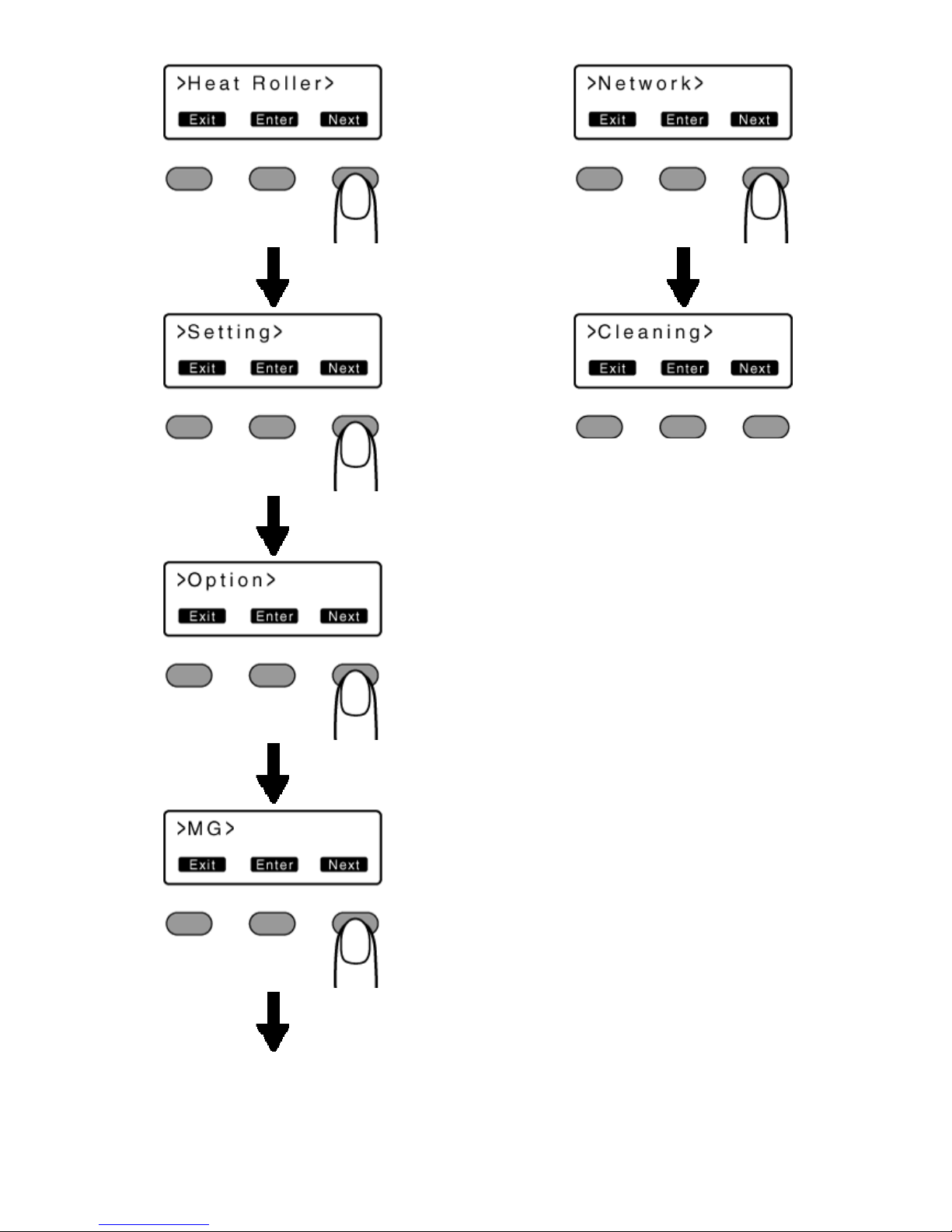

Heat Roller

●

Displays the settings of the power save mode or low temperature

standby mode.

Setting values

●

Power Saving: 5 mins, 10 mins, 15 mins, 20 mins, 25 mins,

30mins, 45 mins, 60 mins, off

For setting the time of the power save mode.

While in the [Ready] mode, if the printer is not operated during a

specific time interval, the retransfer roller, warpage correction

roller, and backlight of the operation panel are turned off to save

power.

●

HR Control: Off, On

Page 13

1

3

Operation

For setting whether to standby the printer by lowering the retransfer heat roller temperature if cards are not issued for 30 minutes

or longer.

The printer will automatically restored to the original mode during

the next card issuance, but it may take a longer time before the

first card is printed. Set this to On during normal use.

Setting

●

Displays the printer settings.

Setting values

●

Display:

Mode: Counter

Counter: Total Cnt, Head Cnt, Free Cnt, Cleaning Cnt, Error Cnt

Contrast: -3, -2, -1, 0, 1, 2, 3

For setting the display status the operation panel.

●

Buzzer: On, Off

For setting whether to sound the buzzer when an error occurs or

when settings are changed.

●

Unit No: No.1 to No.10

For setting the printer’s unit number according to the USB environment.

Option

●

Displays the optional settings.

Setting values

●

MG: None, ISO

Displays the availability of a magnetic encoder or the type of encoder used.

●

IC Antenna: None, Installed

Displays the availability of a non-contact IC encoder.

●

IC Contact: None, ISO Type

Displays the availability of a contact IC encoder or the type of encoder used.

●

Contact IC R/W: None, Installed

Displays the availability of an IC contact.

●

Bend Remedy HR: None, Installed

Displays the availability of a warpage correction heat roller.

●

Turn Over: None, Installed

Displays the availability of retransfer unit.

MG

●

Displays the coercivity settings.

Setting values

●

ISO Type: Loco, Hico

For setting the coercivity when writing data to an ISO magnetic

stripe card.

●

Retry Count: 0, 1, 2, 3

For setting the number of retries during data writing.

Network

●

Displays the network settings.

Setting values

●

Printer Name: ASCII character strings (10 characters)

For setting the printer name.

●

Host IF: LAN, USB

For setting the interface.

If the printer is connected via USB interface, the setting switches

automatically to the USB setting even if it is set to LAN during initialization.

●

[@TREX[OSD::]IPv4:

DHCP: On, Off

Setting: IP Address, Subnet Mask, Gateway

Efective IP: IP Address]

For setting IPv4.

●

[@TREX[OSD::]IPv6:

Adrs Config: Auto, Manual

Setting: IP Address, Prefix Len, Gateway

Efective IP: IP Address1, IP Address2, IP Address3]

For setting IPv6.

●

Session Time Out: Off, 10 mins, 20 mins, 30 mins, 60 mins

For setting the session timeout interval.

●

MAC Address: Hexadecimal character strings

Displays the MAC address.

●

IP Sec Mode: Off, On

For setting the availability of IP Sec.

●

IP Sec Type: not Setting, Preshard, Certificate

Displays the method for IP Sec verification.

Setting Mode Flow

●

Settings can be viewed on the printer’s operation panel.

●

Settings can be changed on the status monitor of the computer.

1

Press [Menu]

●

A setting item appears.

2

Press [Next]

●

Pressing it each time displays the next setting item.

●

Pressing [Enter] or [Change] displays the setting value.

●

Pressing [Next] or A displays the next setting value.

●

Pressing [Exit] displays the setting mode of the next higher level.

Page 14

14

Operation

Page 15

15

Operation

Page 16

16

Operation

Setting using the operation panel

Initialization

●

Whenever the power is turned on, cue (initialization) is performed automatically on the ink ribbon and retransfer film.

●

You can also perform initialization using the operation button

on the operation panel.

1

Press [Reset]

●

A [Initialize] message appears.

2

Press B

●

An [Initializing] message appears, and initialization of the printer starts.

Initializing printer when attaching the cassette

Memo:

●

When detaching the ink ribbon cassette or retransfer film cassette from

the printer body, dust may adhere to the ink ribbon or retransfer film.

Printing errors such as discoloring and retransfer error may occur depending on the size of the dust particles.

To prevent printing errors from occurring, initialize the printer when you

attach the cassette.

●

When attaching a new retransfer film, it is recommended that you forward the film by one or two images before printing.

1

Turn on the power.

2

Check to ensure that [Ready] or [Preheating] is displayed on the

operation panel of the printer.

3

Press [Reset]

●

A [Initialize] message appears.

Initializing printer without feeding the image

① Press B

●

An [Initializing] message appears, and initialization of the

printer starts.

Initializing printer after feeding by one image

① Press [Next]

Page 17

17

Operation

●

A [Next Panel, OK?] message appears.

② Press B

●

An [Initializing] message appears, and the printer is initialized

after feeding the ink ribbon and retransfer film by one image.

Initializing printer after feeding by two images

① Press [Next]

●

A [2'nd Panel, OK?] message appears.

② Press B

●

An [Initializing] message appears, and the printer is initialized

after feeding the ink ribbon and retransfer film by two images.

Firmware update

1

Press [Menu]

●

A [Cleaning] message appears.

2

Press [Next] to set to [Down load]

●

Pressing the [Next] button each time displays the next screen.

3

Press [Enter]

●

Data download from the host computer starts.

●

A [Downloading] message during data download from the host com-

puter.

Note:

●

Do not turn off the power during data download from the host computer.

Doing so may damage the printer firmware and cause malfunction.

●

A [Please Power Off] message when data download from the host

computer is complete.

Page 18

18

Operation

4

Press [Exit]

●

Pressing [Exit] each time returns you to the previous screen.

Counter setting

●

This is used for setting the type of counter displayed on the operation

panel.

Counter types

●

Total Cnt: total counter

Displays the total number of cards that are correctly printed.

●

Head Cnt: Head counter

Displays the total number of printed sides for the same head.

●

Free Cnt: free counter

Displays the number of cards that are correctly printed. This number can be reset.

●

Cleaning Cnt: Cleaning counter

Displays the number of cards that are correctly printed. This number can be reset.

●

Error Cnt: Error counter

Displays the number of cards that are not correctly printed. This

number can be reset.

1

Press [Menu]

●

A [Cleaning] message appears.

2

Press [Next] to display [Setting]

●

Pressing the [Next] button each time displays the next screen.

3

Press [Enter]

●

A [Display] message appears.

4

Press [Enter]

●

A [Mode] message appears.

Page 19

19

Operation

5

Press [Next]

●

A [Counter] message appears.

6

Press [Change]

●

A setting change screen appears.

7

Press A and select a setting value.

8

Press B to confirm the setting value.

●

Pressing B confirms the setting and returns you to the previous

screen.

9

Press [Exit]

●

Pressing [Exit] each time returns you to the previous screen.

Page 20

20

Operation

Resetting the counter

●

Resets the free counter and error counter.

1

Press [Menu]

●

A [Cleaning] message appears.

2

Press [Next] to set to [Counter Reset]

3

Press B

●

Resets the free counter and error counter.

Checking reset

●

Select [Free Cnt] or [Erorr Cnt] under [Counter setting].

Test print

●

Prints the printer’s built-in test pattern, or the different setting values.

●

When system troubles occur, printing can be performed using settings

on the printer or computer by operating only the printer.

Test types

●

Test Pattern:

Prints color patterns on a single side of a card.

●

Printer Setting:

Prints according to the values preset in the setting mode.

●

Network:

Prints according to the values preset through the network.

●

Lami Setting:

Prints according to the values preset in the laminator’s user

mode.

1

Press [Menu]

●

A [Cleaning] message appears.

2

Press [Next] to display [Test Print]

3

Press [Change]

●

A [Test Pattern] message appears.

4

Press A and select a test type.

5

Press B

●

Test print starts.

Contrast setting

●

This is used for setting the contrast of the operation panel display.

Setting values

-3, -2, -1, 0, 1, 2, 3

●

Selecting a larger value increases the contrast.

1

Press [Menu]

●

A [Cleaning] message appears.

2

Press [Next] to set to [Setting]

●

Pressing the [Next] button each time displays the next screen.

Page 21

21

Operation

3

Press [Enter]

●

A [Display] message appears.

4

Press [Enter]

●

A [Mode] message appears.

5

Press [Next]

●

A [Contrast] message appears.

6

Press [Change]

●

A setting selection screen appears.

7

Press A and select a setting value.

8

Press B to confirm the setting value.

●

Pressing B confirms the setting and returns you to the previous

screen.

9

Press [Exit]

●

Pressing [Exit] each time returns you to the previous screen.

Page 22

22

Operation

Buzzer sound setting

●

This is used for setting the buzzer sound when an error occurs.

Setting values

On: turns on buzzer sound, Off: turns off buzzer sound

1

Press [Menu]

●

A [Cleaning] message appears.

2

Press [Next] to set to [Setting]

3

Press [Enter]

●

A [Display] message appears.

4

Press [Next] to set to [Buzzer]

5

Press [Change]

●

A setting selection screen appears.

6

Press A and select a setting value.

7

Press B to confirm the setting value.

●

Pressing B confirms the setting and returns you to the previous

screen.

●

To display the next setting value, press A.

8

Press [Exit]

●

Pressing [Exit] each time returns you to the previous screen.

Page 23

2

3

Operation

Unit number setting

●

For setting the printer’s unit number according to the USB environment.

Setting values

No.1 ~ No.10

1

Press [Menu]

●

A [Cleaning] message appears.

2

Press [Next] to set to [Setting]

3

Press [Enter]

●

A [Display] message appears.

4

Press [Next] to set to [Unit No]

5

Press [Change]

●

A setting selection screen appears.

6

Press A and select a setting value.

7

Press B to confirm the setting value.

●

Pressing B confirms the setting and returns you to the previous

screen.

8

Press [Exit]

●

Pressing [Exit] each time returns you to the previous screen.

Page 24

24

Operation

Transport mode setting

Note:

●

Make sure that you set to the transport mode when transporting or

moving the printer.

Failure to do so may result in malfunction of the printer.

●

When transporting or moving the printer, ensure that the heat roller is

secured to a safe position.

1

Open the printer door.

2

Press and hold down the cassette button, and remove the ink ribbon

cassette (on the right) to remove the ink ribbon.

3

Press and hold down the cassette button, and remove the retransfer

film cassette (on the left) to remove the retransfer film.

4

Close the printer door.

5

Turn on the power.

6

Check to ensure that [Film Search] is displayed on the operation

panel of the printer.

7

Press [Menu]

●

A [Cleaning] message appears.

8

Press [Next] to set to [Transport Mode]

9

Press B

●

After setting to the transport mode, a [Please Power Off] message

appears.

10

Turn off the power, and attach the cassette.

Note:

●

When in the transport mode, the retransfer film cassette cannot be installed to the printer with the retransfer film attached.

Reset the Transport mode

●

With the printer door closed. turn on the power, and reset the

transport mode.

Page 25

25

Operation

Printing a Card

Note:

●

If you see an [Initializing...] or [Preheating..] message on the LCD panel

of the printer, this means the printer is not ready yet. Printing cannot be

performed in this case.

●

Printing the card on the side with the magnetic stripe may cause printing errors or damage to the card’s functions. If you want to do so, consult our authorized dealers in advance.

Printing a Card

1

Turn on the power.

2

Check to ensure that cards are inserted into the card hopper.

3

Open the print settings screen.

4

Select this printer from [Name].

●

If there are multiple printers, select the name of the printer that you

want to perform printing on.

5

After ensuring that a [Ready] message appears on the LCD panel of

the printer, start printing.

Precautions on cards

●

"Card has run out" A page 25

Ink Ribbon

●

"Ink ribbon has run out" A page 26

●

"Ink ribbon is broken" A page 27

Retransfer Film

●

"Retransfer film has run out" A page 29

●

"Retransfer film is broken" A page 30

Precautions on cards

Card has run out

●

Loads the cards.

Print this page

Note:

●

If the security lock function is turned on, the card hopper will be locked.

Turn off the security from the computer. After loading the card, turn on

the security again from the computer.

●

Do not touch the printing surface of the card. Touching it may cause

printing errors. Put on the supplied gloves when handling the cards.

●

When using new cards, separate them one by one before setting them

in the printer. Cards may be adhered to each other due to static, thus

causing card jams.

●

Align the cards before setting them in the printer. Otherwise, the card

hopper cover may not close properly, and this may damage the printer.

●

Printing the card on the side with the magnetic stripe may cause printing errors or damage to the card’s functions. If you want to do so, consult our authorized dealers in advance.

●

To set cards with both functions (magnetic stripe and contact IC), follow the procedure for setting the contact IC card.

1

Set the card hopper knob to [OPEN].

2

Lift to remove the card hopper cover.

3

Align the orientation of the cards, and set them in the printer.

Page 26

26

Replacement

Magnetic cards

●

Set the card with the magnetic stripe facing upward and toward

the printer, or facing downward and toward you.

ISO contact IC cards

●

Set the card with the Contact IC terminal facing upward and toward the rear of the printer, or downward and toward the front

of the printer.

4

Install the card hopper cover.

Ink Ribbon

Ink ribbon has run out

●

Replace with a new ink ribbon.

Print this page

Note:

●

If the security lock function is turned on, turn off the function from the

computer to unlock the printer. After closing the door, turn on the function again from the computer.

●

Stand the cassette on a flat surface as illustrated in the diagram. Avoid

doing so on a floor as dust attached to the retransfer film may cause

printing errors.

●

Do not touch the inked surface (the side that faces outward when installed) with your hand. Touching it may cause printing errors. Put on

the supplied gloves when handling the ink ribbon.

●

When installing a used ink ribbon, align the yellow side of the unused

ribbon with the arrow indicated on the label of the cassette. If the position of the yellow side is not properly aligned, the print may turn out

light.

●

When handling the cassette, hold it with both hands. Accidentally dropping the cassette may damage it or result in injuries.

●

Do not perform work on the printer door. Do not place heavy objects or

apply load on the printer. Doing so may damage it.

●

During replacement, clean the four bobbin holders on the printer. Burrs

generated by friction between the bobbins and bobbin holders may be

adhered to the ink ribbon or retransfer film, causing printing errors.

1

Open the printer door.

2

Press and hold down the cassette button, and pull out the ink ribbon

cassette (on the right) to remove the ink ribbon.

3

Install a new ink ribbon.

●

Install while referring to the indication on the label of the cassette.

Page 27

27

Replacement

① With the inked surface facing outward, align the yellow side of the

unused ribbon with the arrow on the cassette, and unwind it along

the three shafts.

② Insert the ink ribbon firmly into the bobbin holders with the ribbon set

to the far end of the guides.

●

A: take-up side (black)

●

B: unused side (yellow)

4

Remove any slack in the ink ribbon.

① Hold the cassette.

② Turn the knob in the direction indicated by the arrow.

5

Insert the cassette all the way in along the guide rail until a “click”

sound is heard. Close the printer door.

6

Press [Reset]

DB

to reset the printer.

"Initializing printer when attaching the cassette" (A

page 16)

Ink ribbon is broken

●

Repair the ink ribbon.

Print this page

Note:

●

If the security lock function is turned on, turn off the function from the

computer to unlock the printer. After closing the door, turn on the function again from the computer.

●

Stand the cassette on a flat surface as illustrated in the diagram. Avoid

doing so on a floor as dust attached to the retransfer film may cause

printing errors.

●

Do not touch the inked surface (the side that faces outward when installed) with your hand. Touching it may cause printing errors. Put on

the supplied gloves when handling the ink ribbon.

●

When handling the cassette, hold it with both hands. Accidentally dropping the cassette may damage it or result in injuries.

●

When installing a used ink ribbon, align the yellow side of the unused

ribbon with the arrow indicated on the label of the cassette. If the position of the yellow side is not properly aligned, the print may turn out

light.

Page 28

28

Replacement

●

Do not perform work on the printer door. Do not place heavy objects or

apply load on the printer. Doing so may damage it.

●

During replacement, clean the four bobbin holders on the printer. Burrs

generated by friction between the bobbins and bobbin holders may be

adhered to the ink ribbon or retransfer film, causing printing errors.

1

Open the printer door.

2

Press and hold down the cassette button, and pull out the ink ribbon

cassette (on the right) to remove the ink ribbon.

3

Cut away the broken portion, and attach the unused portion at the supply side to the other end at the take-up side using an adhesive tape.

4

Attach the ink ribbon, and turn the take-up side until the cut section is

out of sight.

●

Install while referring to the indication on the label of the cassette.

① With the inked surface facing outward, align the yellow side of the

unused ribbon with the arrow on the cassette, and unwind it along

the three shafts.

② Turn the knob in the direction of the arrow to remove any slack.

③ Insert the ink ribbon firmly into the bobbin holders with the ribbon set

to the far end of the guides.

5

Insert the cassette all the way in along the guide rail until a “click”

sound is heard. Close the printer door.

6

Press [Reset]

DB

to reset the printer.

Page 29

29

Replacement

"Initializing printer when attaching the cassette" (A

page 16)

Retransfer Film

Retransfer film has run out

●

Replace with a new retransfer film.

Print this page

Note:

●

If the security lock function is turned on, turn off the function from the

computer to unlock the printer. After closing the door, turn on the function again from the computer.

●

Stand the cassette on a flat surface as illustrated in the diagram. Avoid

doing so on a floor as dust attached to the retransfer film may cause

printing errors.

●

Do not touch the retransfer face (the side that faces outward when installed) with your hand. Touching it may cause printing errors. Put on

the supplied gloves when handling the retransfer film.

●

When handling the cassette, hold it with both hands. Accidentally dropping the cassette may damage it or result in injuries.

●

When installing a used retransfer film, align the unused side of the film

with the arrow indicated on the label of the cassette. Failure to do so

may result in errors, or the print may turn out light.

●

When installing a new film, make sure that at least three black lines are

wound onto the take-up side. Insufficient winding may cause the printer

to malfunction.

●

Do not perform work on the printer door. Do not place heavy objects or

apply load on the printer. Doing so may damage it.

●

During replacement, clean the four bobbin holders on the printer. Burrs

generated by friction between the bobbins and bobbin holders may be

adhered to the ink ribbon or retransfer film, causing printing errors.

1

Open the printer door.

2

Press and hold down the cassette button, and pull out the retransfer

film cassette (on the left) to remove the retransfer film.

Page 30

30

Replacement

3

Install a new retransfer film.

●

Install while referring to the indication on the label of the cassette.

① When installing the retransfer film, make sure that at least three

black lines are wound onto the take-up side.

② With the retransfer face facing outward, align the unused side of the

film with the arrow on the cassette, and unwind it along the three

shafts.

③ Insert the retransfer film firmly into the bobbin holders with the film

set to the far end of the guides.

●

A: take-up side (black)

●

B: unused side (green)

4

Remove any slack in the film.

① Hold the retransfer film cassette.

② Turn the knob in the direction indicated by the arrow.

5

Insert the cassette all the way in along the guide rail until a “click”

sound is heard. Close the printer door.

6

Press [Reset]

DB

to reset the printer.

Memo:

●

When attaching a new retransfer film, it is recommended that you forward the film by one or two images before printing.

"Initializing printer when attaching the cassette"

(

A

page 16)

Retransfer film is broken

●

Repair the retransfer film.

Print this page

Note:

●

If the security lock function is turned on, turn off the function from the

computer to unlock the printer. After closing the door, turn on the function again from the computer.

●

Stand the cassette on a flat surface as illustrated in the diagram. Avoid

doing so on a floor as dust attached to the retransfer film may cause

printing errors.

Page 31

31

Replacement

●

Do not touch the retransfer face (the side that faces outward when installed) with your hand. Touching it may cause printing errors. Put on

the supplied gloves when handling the retransfer film.

●

When handling the cassette, hold it with both hands. Accidentally dropping the cassette may damage it or result in injuries.

●

When installing a used retransfer film, align the unused side of the film

with the arrow indicated on the label of the cassette. Failure to do so

may result in errors, or the print may turn out light.

●

Do not perform work on the printer door. Do not place heavy objects or

apply load on the printer. Doing so may damage it.

●

During replacement, clean the four bobbin holders on the printer. Burrs

generated by friction between the bobbins and bobbin holders may be

adhered to the ink ribbon or retransfer film, causing printing errors.

1

Open the printer door.

2

Press and hold down the cassette button, and pull out the retransfer

film cassette (on the left) to remove the retransfer film.

3

Cut away the broken portion, and attach the unused portion at the supply side to the other end at the take-up side using an adhesive tape.

4

Attach the retransfer film, and turn the take-up side until the cut section

is out of sight.

① With the retransfer face facing outward, align the unused side of the

film with the arrow on the cassette, and unwind it along the three

shafts.

② Insert the retransfer film firmly into the bobbin holders with the film

set to the far end of the guides.

③ Turn the knob in the direction of the arrow to remove any slack.

5

Insert the cassette all the way in along the guide rail until a “click”

sound is heard. Close the printer door.

6

Press [Reset]

DB

to reset the printer.

Page 32

32

Maintenance

"Initializing printer when attaching the cassette" (A

page 16)

Servicing of Parts

●

"Cleaning roller" A page 32

●

"Fan filter" A page 33

●

"Card feed roller/heating roller" A page 34

●

"Magnetic head" A page 38

●

"Bobbin holders" A page 36

●

"Thermal head" A page 39

Servicing Based on Print Output

●

"Colors appear faded or dirt is conspicuous" A page 41

●

"Card jams" A page 41

●

"Error during writing/reading" A page 41

●

"Lines appear on card after printing" A page 41

Note:

●

After servicing or cleaning is complete, check to ensure that all dismantled parts are restored to their original positions. Failure to restore the

parts may result in malfunction of the printer.

Servicing of Parts

Cleaning roller

●

The function of the cleaning roller is to remove any dirt or dust attached

to the card.

●

Card jams may occur if the cleaning roller is dirty.

●

The color of the printed card may appear faded or dirt may appear conspicuous if the cleaning roller is dirty.

Print this page

Note:

●

If the security lock function is turned on, turn off the function from the

computer to unlock the printer. After closing the door, turn on the function again from the computer.

●

If the printer is used everyday, make sure to clean the cleaning roller

daily at the end of the operation.

●

Do not perform work on the printer door. Do not place heavy objects or

apply load on the printer. Doing so may damage it.

●

After washing, allow the cleaning roller to dry completely before installing it to the printer.

●

Do not wash the cleaning roller with anything other than water (e.g., alcohol).

●

Replace the cleaning unit with a new one after using it for about one

year. For details on its replacement, please consult our authorized

dealers.

●

After cleaning is complete, check to ensure that all dismantled parts

are restored to their original positions. Failure to restore the parts may

result in malfunction of the printer.

1

Open the printer door.

2

Pull out the cleaning unit.

3

Wash the cleaning roller with water.

●

Wash the roller with water, and remove any dirt from the surface of the

cleaning roller with your finger.

Request for Routine Servicing

●

In order to prevent printing errors and malfunctions from occurring in advance, please request for routine servicing by the

servicing personnel. For details on servicing, please consult

our authorized dealers.

Page 33

3

3

Maintenance

4

Allow the cleaning roller to air dry.

5

Set the cleaning unit, and close the printer door.

●

With the roller facing the right, insert it all the way in.

Fan filter

●

The color of the printed card may appear faded or dirt may appear conspicuous if the fan filter is dirty.

●

Perform cleaning after printing about 10,000 cards.

Print this page

Note:

●

After cleaning is complete, check to ensure that all dismantled parts

are restored to their original positions. Failure to restore the parts may

result in malfunction of the printer.

1

Remove the filter cover located on the side of the printer.

2

Remove the fan filter.

3

Remove any dirt that is attached to the fan filter using a vacuum clean-

er.

4

Set the fan filter.

Page 34

34

Maintenance

5 Set the filter cover.

Card feed roller/heating roller

●

The color of the printed card may appear faded or dirt may appear conspicuous if the card feed roller/heating roller is dirty.

●

Perform cleaning after printing about 1,000 cards.

Print this page

Note:

●

If the security lock function is turned on, turn off the function from the

computer to unlock the printer. After closing the door, turn on the function again from the computer.

●

Before cleaning the card feed roller/heating roller, make sure that you

clean the cleaning roller. Otherwise, dirt on the cleaning roller may be

attached to the cleaning card, causing its cleaning capability to deteriorate.

●

Stand the cassette on a flat surface as illustrated in the diagram. Avoid

doing so on a floor as dust attached to the retransfer film may cause

printing errors.

●

If card jam occurs when the cleaning card is inserted, turn off and on

the power of the printer. Doing so automatically discharges the card.

●

Do not perform work on the printer door. Do not place heavy objects or

apply load on the printer. Doing so may damage it.

●

Each cleaning card can only be used once. Reusing a dirty card may

dirty the roller or cause the printer to malfunction. For details on the

cleaning card, please consult our authorized dealers.

●

After cleaning is complete, check to ensure that all dismantled parts

are restored to their original positions. Failure to restore the parts may

result in malfunction of the printer.

●

For details on separately sold items, please consult our authorized

dealers.

1

Open the printer door. Press and hold down the cassette button, and

remove the retransfer film cassette (on the left).

2

Close the printer door, and remove the card hopper.

Page 35

35

Maintenance

3

Turn on the power.

4

Press [Menu] to set to [Cleaning]

5

Press [Enter] to set to [Rollers]

6

Peel off the backing paper from the cleaning card (sold separately).

7

Press B

●

A [Cleaning Start OK?] message appears.

8

Press B

●

A [Cleaning...] message appears.

Note:

●

If the retransfer heating roller is hot, a[HR is too hot]message will be

displayed. Turn off the power, and perform cleaning after the retransfer

heating roller has cooled down completely.

9

Insert the cleaning card (sold separately) within 20 seconds.

●

The roller draws in the card, and cleaning starts automatically. Reverse

the adhesive face, and insert the card again.

Note:

●

Insert the card within 20 seconds after pressing B.

●

After pressing B, the buzzer sounds upon a lapse of 20 seconds, and

a [Jam (Hopper)] error message appears 10 seconds later.

Press [Reset]

DB

to cancel the error.

●

When a standard-sized card is inserted, the card is automatically discharged from the NG card outlet, and the printer returns to the [Cleaning Start OK?] screen.

10

After the cleaning card is discharged, turn off the power, and install

the retransfer film cassette and card hopper.

Page 36

36

Maintenance

●

To turn on the power again, do so after an interval of at least 10 seconds.

Magnetic head

●

Writing/Reading errors may occur if the magnetic head is dirty.

●

Perform cleaning after printing about 1,000 cards.

Print this page

Note:

●

If the security lock function is turned on, turn off the function from the

computer to unlock the printer. After closing the door, turn on the function again from the computer.

●

Before cleaning the magnetic head, make sure that you clean the

cleaning roller. Otherwise, dirt on the cleaning roller may be attached to

the cleaning card, causing its cleaning capability to deteriorate.

●

After cleaning is complete, check to ensure that all dismantled parts

are restored to their original positions. Failure to restore the parts may

result in malfunction of the printer.

●

Do not perform work on the printer door. Do not place heavy objects or

apply load on the printer. Doing so may damage it.

●

For details on separately sold items, please consult our authorized

dealers.

1

Turn on the power.

2

Check to ensure that [Ready] or [Preheating] is displayed on the

operation panel of the printer.

3

Remove the card hopper.

Page 37

37

Maintenance

4

Press [Menu] to set to [Cleaning]

5

[Enter]D Press [Next] to set to [MG]

6

Apply alcohol on the magnetic head cleaning card (sold separately).

●

Apply about three to four drops of alcohol on the magnetic stripe.

7

Press B

8

Insert the magnetic head cleaning card within 20 seconds.

Note:

●

Insert the card within 20 seconds after pressing B.

●

After pressing B, the buzzer sounds upon a lapse of 20 seconds, and

a [Jam (Hopper)] error message appears 10 seconds later.

Press [Reset]

DB

to cancel the error.

9

After the cleaning card is discharged, turn off the power, and install the

card hopper.

●

To turn on the power again, do so after an interval of at least 10 seconds.

Page 38

38

Maintenance

Bobbin holders

●

The color of the printed card may appear faded or dirt may appear conspicuous if burrs are attached to the bobbin holders.

Print this page

Note:

●

If the security lock function is turned on, turn off the function from the

computer to unlock the printer. After closing the door, turn on the function again from the computer.

●

Stand the cassette on a flat surface as illustrated in the diagram. Avoid

doing so on a floor as dust attached to the retransfer film may cause

printing errors.

●

Do not perform work on the printer door. Do not place heavy objects or

apply load on the printer. Doing so may damage it.

●

Perform cleaning each time you replace the ink ribbon or retransfer

film.

Otherwise, burrs attached to the bobbin holders may fall onto the card,

ink ribbon, or retransfer film, causing printing errors.

●

After cleaning is complete, check to ensure that all dismantled parts

are restored to their original positions. Failure to restore the parts may

result in malfunction of the printer.

●

For details on separately sold items, please consult our authorized

dealers.

1

Open the printer door.

2

Press and hold down the cassette button, and remove the ink ribbon

cassette (on the right).

3

Press and hold down the cassette button, and remove the retransfer

film cassette (on the left).

4

Apply alcohol to a cotton swab (large), and use it to wipe the four bobbin holders.

(Cotton swab and alcohol: sold separately)

5

Insert the retransfer film cassette along the guide rail until a “click”

sound is heard.

6

Insert the ink ribbon cassette along the guide rail until a “click” sound is

heard. Close the printer door.

Page 39

39

Maintenance

Thermal head

●

Lines may appear on the card after printing if the thermal head is dirty.

Print this page

Note:

●

If the security lock function is turned on, turn off the function from the

computer to unlock the printer. After closing the door, turn on the function again from the computer.

●

Stand the cassette on a flat surface as illustrated in the diagram. Avoid

doing so on a floor as dust attached to the retransfer film may cause

printing errors.

●

Do not perform work on the printer door. Do not place heavy objects or

apply load on the printer. Doing so may damage it.

●

Touching the thermal head with your body electrostatically charged

may cause damage to the head. Make sure that you touch the metallic

part of the printer before commencing work.

●

Pay attention to prevent metallic objects from knocking against the

thermal head. Doing so may damage it.

●

After cleaning is complete, check to ensure that all dismantled parts

are restored to their original positions. Failure to restore the parts may

result in malfunction of the printer.

●

For details on separately sold items, please consult our authorized

dealers.

1

Open the printer door.

2

Press and hold down the cassette button, and remove the ink ribbon

cassette (on the right).

3

Press and hold down the cassette button, and remove the retransfer

film cassette (on the left).

Page 40

40

Maintenance

4

Apply alcohol to a cotton swab (large), and use it to wipe the thermal

head.

(Cotton swab and alcohol: sold separately)

●

Wipe the thermal head with care in the horizontal direction.

5

Insert the retransfer film cassette along the guide rail until a “click”

sound is heard.

6

Insert the ink ribbon cassette along the guide rail until a “click” sound is

heard. Close the printer door.

Page 41

41

Maintenance

Servicing Based on Print Output

Colors appear faded or dirt is conspicuous

●

"Clean the cleaning roller." A page 32

●

"Clean the fan filter." A page 33

●

"Clean the card feed roller/heating roller." A page 34

●

"Clean the bobbin holders." A page 38

Card jams

●

"Clean the cleaning roller." A page 32

Error during writing/reading

●

"Clean the magnetic head." A page 36

Lines appear on card after printing

●

"Clean the thermal head." A page 39

When an Error Message is Displayed

●

"Identifying errors using the error code" A page 41

Precautions on cards

●

"Card jams" A page 43

●

"Card has run out" A page 48

Ink Ribbon

●

"Ink ribbon has run out" A page 26

●

"Ink ribbon is broken" A page 27

Retransfer Film

●

"Retransfer film has run out" A page 29

●

"Retransfer film is broken" A page 30

●

"Unable to fit retransfer film cassette into printer" A page 49

Unable to produce desired printing results

●

"Lines appear on card after printing" A page 50

●

"Colors on card appear faded after printing" A page 50

●

"Peeling occurs on card after printing" A page 50

●

"Overall printing quality is poor" A page 50

●

"Card is printed in a single color" A page 50

●

"Strange characters or images are printed" A page 50

●

"Retransfer cannot be performed successfully" A page 50

Printer not operating as desired

●

"Card is not fed into the printer" A page 50

●

"Power does not turn on" A page 50

●

"Printing does not start or stops halfway" A page 50

When an Error Message is Displayed

Identifying errors using the error code

List of error codes

●

Click on an error code below to jump to the page with the corresponding error descriptions.

"44"

A

page 42 "90" A page 41 "91" A page 41 "92" A page

41 "93"

A

page 41 "94" A page 41

"A1"

A

page 41 " A2" A page 42 " A8" A page 42 " AB" A

page 42 " AC"

A

page 42

"B0"

A

page 42 " B1" A page 42 " B2" A page 42

"C1"

A

page 42 " C2" A page 42 " C3" A page 43

"D1"

A

page 42 " D8" A page 42

"F0"

A

page 42 " F1" A page 42 " F2" A page 42 " F3"

A

page 42 " F4" A page 42 " F5" A page 42 " F6" A page 43

" F8"

A

page 43

No Card

●

"Cards have run out. Loads the cards." A page 48 Or, “The card

hopper is not attached. Attach the card hopper.”

Jam(Hopper) 90

●

"Card jam in the card hopper unit. Remove the jammed card." A page

43

Jam(TurnOver) 91

●

"Card jam in the turnover unit. Remove the jammed card." A page

44

Jam(MG) 92

●

"Card jam in the magnetic encoder unit. Remove the jammed card." A

page 46

Jam(Transfer) 93

●

"Card jam in the retransfer unit. Remove the jammed card." A page

47

Jam(Discharge) 94

●

Card jam in the discharge unit. Remove the jammed card.

Film Search A1

●

"Retransfer film is broken. Repair it." A page 30

Page 42

42

Troubleshooting?

MG Test Err A8

●

MG writing error occurred during MG self-diagnosis. Reset the printer.

Ink Error B0

●

An incorrect printer ink is installed. Attach a correct ink.

Ink Search B1

●

"Ink ribbon is broken. Repair it." A page 27

Door Open D1

●

Printer door is open. Close the door. Or, “The cleaning roller is not attached. Attach the cleaning roller.”

Film Run Out A2

●

"Retransfer film has run out. Replace with a new one." A page 29

Ink Run Out B2

●

"Ink ribbon has run out. Replace with a new one." A page 26

Hard ware 44

●

A hardware failure has occurred on the printer. Turn off and on the

power. If the same problem recurs, turn off the power and consult our

authorized dealers.

MG Mechanical AB

●

An error has occurred in the mechanical component of the MG unit.

Turn off and on the power. If the same problem recurs, turn off the

power and consult our authorized dealers.

MG Hardware AC

●

A hardware failure has occurred on the MG unit. Turn off and on the

power. If the same problem recurs, turn off the power and consult our

authorized dealers.

Cam Error C1

●

Heating roller operation failure. Turn off and on the power. If the same

problem recurs, turn off the power and consult our authorized dealers.

HR Overheat C2

●

The temperature of the warpage correction heating roller or retransfer

heating roller is too high. Turn off and on the power. If the same problem recurs, turn off the power and consult our authorized dealers.

Hardware D8

●

A hardware error has occurred during initialization. Turn off and on the

power. If the same problem recurs, turn off the power and consult our

authorized dealers.

TR Overheat F0

●

The temperature of the retransfer roller is too high. Turn off and on the

power. If the same problem recurs, turn off the power and consult our

authorized dealers.

TR Heater F1

●

Retransfer roller failure. Turn off and on the power. If the same problem

recurs, turn off the power and consult our authorized dealers.

TR Thermister F2

●

Retransfer roller thermister failure. Turn off and on the power. If the

same problem recurs, turn off the power and consult our authorized

dealers.

RR Overheat F3

●

The temperature of the warpage correction roller is too high. Turn off

and on the power. If the same problem recurs, turn off the power and

consult our authorized dealers.

RR Heater F4

●

Warpage correction roller failure. Turn off and on the power. If the

same problem recurs, turn off the power and consult our authorized

dealers.

RR Thermister F5

Page 43

4

3

Troubleshooting?

●

Warpage correction roller thermister failure. Turn off and on the power.

If the same problem recurs, turn off the power and consult our authorized dealers.

Overcool F6

●

The operating ambient temperature of the printer is too low. Check the

temperature. If the same problem recurs at the same operating ambient temperature, turn off the power and consult our authorized dealers.

Head Overheat F8

●

The temperature of the thermal head is too high. Turn off and on the

power. If the same problem recurs, turn off the power and consult our

authorized dealers.

Power Int. C3

●

A 24 V interruption is detected.

●

Turn off and on the power again.

Precautions on cards

Card jams

●

Check the error code on the operation panel.

Error code 90

●

Card jam in the card hopper unit.

Note:

●

Do not apply excessive force on the card hopper. Doing so may damage it.

●

Do not touch the printing surface of the card. Touching it may cause

printing errors. Put on the supplied gloves when handling the cards.

1

Remove the card hopper cover.

2

Remove the loaded cards, and pull out the jammed card with a hand.

3

Install the card hopper cover.

If the card cannot be pulled out by hand

① Open the printer door.

② Use the jog dial to turn the retransfer unit and cleaning unit

in the clockwise direction.

Page 44

44

Troubleshooting?

.

③ Close the printer door, and press[RESET]

DB

to reset the

printer.

Error code 91

●

Card jam in the turnover unit.

1

Remove the card hopper.

2

Open the printer door, and remove the cleaning unit.

When the cleaning unit cannot be detached

① Use the jog dial to turn the cleaning unit in the clockwise di-

rection.

Page 45

45

Troubleshooting?

② Open the card hopper cover, and remove the card if this is

possible.

3

Use the jog dial to turn the turnover unit slightly in both the left and

right directions.

●

If the card is protruded from the turnover unit, the turnover unit cannot

be turned.

Turn the turnover unit and cleaning unit at the same time in opposite

directions to move the card to the turnover unit.

4

Move the card to the turnover unit.

●

Turn the turnover unit and cleaning unit in opposite directions.

5

Close the printer door, and press [RESET]

DB

to reset the printer.

Page 46

46

Troubleshooting?

●

The card is discharged from the NG card outlet or card stacker.

Error code 92

●

Card jam in the magnetic encoder unit.

1

Open the printer door.

2

Restore the card to the magnetic encoder unit.

●

Use the jog dial to turn the cleaning unit.

3

Turn the jog dial at the turnover unit to adjust the unit to a vertical position.

●

While doing so, make use of the printer’s label as a reference.

4

Move the card to the center of the turnover unit

① Maintain the turnover unit in the vertical position.

② Turn the jog dial at the cleaning unit.

●

Check to ensure that the card moves to the turnover unit.

5

Turn the jog dial attached to the turnover and cleaning units at the

same time in opposite directions.

●

Set the turnover unit to the horizontal position.

6