Page 1

SERVICE MANUAL

SUBLIMATION TYPE RETRANSFER PRINTER

EDI secure

XID580i

SPECIFICATIONS

Recording method : Sublimation type retransfer

Feed format : Automatic feed

Recording density : 300 dpi

Expression gradation

Printing time : Approx. 29 seconds (for

Interface : USB2.0 (standard)

Operating environment conditions

Storage environment conditions

Power supply : 100 — 120 V AC/

Current dissipation : 7.0A (for 100V system)/

Mass : Standard 22.0kg

: 256 gradations for each

color

single-sided printing,

excluding data transfer

time)

Temperature: 15°C ~ 30°C

Humidity: 35% ~ 70%

(no condensation)

Temperature: -15°C ~ 55°C

Humidity: 20% ~ 80%

220 — 240 VAC

(allowance±10%)

5.0A (for 200V system)

Excluding the built-in

magnetic encoder

Accessories : Power cable

*

The detached power cords and the Instruction

manual vary according to model and country of

purchase.

For 120 V AC

x 1

Dark gray (North America)

For 220 to 240 V AC

x 1

(Europe)

Instruction manual

English

x 1

Card stacker

×1

Ink ribbon cassette

×1

Retransfer film cassette

×1

Jog lever (contained in the

card tray)

×1

CX21ICL Series (Large-type IC unit)

Power supply : Fed from the printer.

5V±5% DC, 12V±5% DC, 24V±5%

DC

Current dissipation : 500mA, 300mA, 1A

Mass : 3.5kg

Dimension (mm) : 110(W) × 221(D) × 255(H)

Accessories :Joint plate × 1

Inter-unit cable × 1

CX21ICS Series (Small-type IC unit)

Power supply : Fed from the printer.

Mass : 0.5kg

Dimension (mm) : 50(W) × 152(D) × 115(H)

Accessories : Screw (with washer) × 3

Screw (without washer) × 2

Products sold separately

: Ink ribon, retransfer film : Cleaning card

1,000 frames/set 10 card /set

Model : CY-P340A Model : CX210-CC1

: Laminator Unit :

Model : ILU

: Card tray

When setting paper feeding feature on the right

Model: CF-3NTR

: Hand gloves M Size (U105-M)

L Size (U105-L)

KAS-T099-002

May 2006

Page 2

CONTENTS

IMPORTANT SAFETY PRECAUTIONS

INSTRUCTIONS

MODEL NAME ................................................................................. 1

1. Detailed specifications .................................................................... 1

HOW TO CONNECT SEPARATELY SOLD PARTS .................. 2

1. Connecting the Small IC Unit ..........................................................2

2. Connection of the Magnetic/Contact-type IC Encoder ....................3

3. Connecting card tray .......................................................................4

BLOCK DIAGRAM .......................................................................... 5

1. OVERALL BLOCK DIAGRAM .........................................................5

2. BLOCK DIAGRAM OF PRIMARY SIDE OF POWERUNIT .............6

3. INTERLOCK SW BLOCK DIAGRAM .............................................. 7

4. BLOCK DIAGRAM OF THE FPGA CIRCUMFERENCE

ON A CPU BOARD ................................................................... 8

WIRING DIAGRAM ....................................................................... 9

Main Parts Layout..........................................................................10

1. Sensor-related...............................................................................10

2. Related to Thermal Head and Rollers ........................................... 10

3. Motor-related ................................................................................. 11

4. Solenoid-RELATED ....................................................................... 11

5. Switch-related ............................................................................... 12

6. Related to Circuit Boards, Power Supply Unit, and Fans .............. 12

7. RF-ID .............................................................................................14

REMOVAL AND EXCHANGE OF THE MAIN PARTS ............ 15

1. CHECKING AT THE TIME OF SERVICING .................................. 15

1.1 REMOVE THE TOP COVER AND THE REAR PANEL. ..........15

1.2 REMOVE THE MG CIRCUIT BOARD. .................................... 15

1.3 SWING DOWN THE POWER SUPPLY UNIT. ........................ 16

2. REMOVAL AND EXCHANGE OF THE MAIN PARTS ...................16

2.1 REMOVAL OF THE HEAT ROLLER ....................................... 16

2.1.1 Removal of the Bend Remedy Roller ............................... 16

2.1.2 Removal of the Heat Roller .............................................. 16

2.2 REMOVAL OF THE CAM MOTOR .......................................... 17

2.2.1 Installation of the Cam Motor ........................................... 18

2.3 REMOVAL OF THE RETRANSFER FILM SUPPLY

MOTOR............................................................................18

2.3.1 Installation of the Retransfer Film Supply Motor...............19

2.4 REMOVAL OF THE RETRANSFER FILM TAKE UP

FILM WINDING MOTOR .................................................. 20

2.5 REMOVAL OF THE CARD FEED MOTOR .............................20

2.5.1 Installation of the Card Feed Motor .................................. 20

2.6 REMOVAL OF THE INK SUPPLY MOTOR AND

THE INK TAKE-UP MOTOR ............................................. 21

2.7 REMOVAL OF THE TURNOVER MOTOR AND

THE TURNOVER CARD FEED MOTOR.......................... 21

2.8 REMOVAL OF THE CARD PICKUP MOTOR ......................... 21

2.9 REMOVAL OF THE FRONT PANEL ....................................... 21

2.10 REMOVAL OF THE PLATEN SOLENOID ............................ 22

2.10.1 Installation of the Platen Solenoid .................................. 22

2.11 REMOVAL OF THE POWER SUPPLY UNIT ........................22

2.12 REMOVAL OF SENSORS AND SWITCHES .......................23

2.12.1 Removal of the Cam Sensor ..........................................23

2.12.2 Removal of the Card Outlet Sensor ............................... 23

2.12.3 Removal of the Ink Encoder Circuit Board ..................... 23

2.12.4 Removal of the External Unit Power Circuit Board ........ 23

2.12.5 Removal of the Turnover Initial Position sensor ............. 24

2.12.6 Removal of the Card Near-empty Sensor ......................24

2.12.7 Removal of the No Card Sensor .................................... 24

2.12.8 Removal of the Retransfer roller/

Remedial Roller Sensor ....................................... 24

2.12.9

Removal of the Retransfer Film Mark/Ink Start Position

Sensor Circuit Board and the Card Edge Sensor ...

2.12.10 Removal of the C.L. Interlock Circuit Board and

the Card Supply Sensor .......................................25

2.12.11 Removal of the Door Interlock Circuit Board .............. 26

2.12.12 Removal of the Cassette Interlock Circuit Board ....... 26

2.12.13 Removal of the Card Tray Interlock Circuit Board ...... 27

2.12.14 Removal of the Turnover Card Sensor

Circuit Board ........................................................27

2.13 REMOVAL OF THE TURNOVER UNIT ................................ 27

2.14 FAN REMOVAL .................................................................... 28

2.14.1 Removal of the Thermal Head Cooling Fan ................... 28

2.14.2 Removal of the Suction Fan ........................................... 28

2.14.3 Removal of the Card Cooling Fan .................................. 28

2.14.4 Removal of the Ventilation Fan.......................................29

2.15 ROLLER REMOVAL ............................................................. 30

2.15.1 Feed Roller Removal ..................................................... 30

2.15.2 Platen Roller Assy Removal .......................................... 31

2.16 CIRCUIT BOARD REMOVAL ............................................... 32

2.16.1 Removal of the Main Circuit Board ................................ 32

2.17 Thermal Head Exchange Method .........................................33

25

USE OF SERVICE MODE ........................................................... 35

1. Entry into Service Mode ................................................................35

2. Explanation of the Various Modes ................................................. 37

2.1 Download ................................................................................ 37

2.2 Maintenance ........................................................................... 37

2.2.1 Offset Prt Y Setting ........................................................... 37

2.2.2 Offset Prt X Setting ........................................................... 37

2.2.3 Offset Trf X Setting ........................................................... 38

2.2.4 Card Stop Position Setting (Offset Card X) ...................... 38

2.2.5 Default LUT Setting .......................................................... 38

2.2.6 Device Type Setting .......................................................... 38

2.2.7 Card Fan Setting .............................................................. 38

2.2.8 TUR Response Setting ..................................................... 38

2.2.9 Compatible Mode Setting ................................................. 38

2.2.10 Setting of the ink sensor level ........................................ 38

2.3 Off-line Test ............................................................................. 39

2.3.1 Pattern setting .................................................................. 39

2.3.2 Printing Side ..................................................................... 40

Page 3

2.3.3 Times ................................................................................ 40

2.3.4 Test Select ........................................................................ 40

2.4 Diag. Test ................................................................................ 40

2.4.1 Sensor .............................................................................. 40

2.4.2 Actuator ............................................................................ 40

2.4.3 Memory ............................................................................ 41

2.4.4 SIO ................................................................................... 41

2.4.5 Display .............................................................................. 41

2.4.6 Back Color ........................................................................41

2.4.7 Buzzer .............................................................................. 41

2.4.8 Registers .......................................................................... 41

2.5 Information .............................................................................. 41

2.6 Parameter Push and Pop ........................................................ 41

OPERATION OF THE MECHANISM ......................................... 42

1. Single-side Printing ....................................................................... 42

2. Double-side Printing ...................................................................... 42

3. Initial Operation .............................................................................42

4. Card Supply and Card Feed.......................................................... 43

5. Printing Operation ......................................................................... 45

6. Retransfer Operation .....................................................................47

7. Operation in Case of Peeling with Return in Direction Towards

the Turnover Unit ..................................................................... 49

8. Operation of the Turnover Unit ...................................................... 50

9. Others ........................................................................................... 51

9.1 Position Relation with Ink Ribbon and Retransfer Film ...........51

9.2 Ink Ribbon and Retransfer Film End Treatment ...................... 51

TROUBLESHOOTING..................................................................52

1. LCD Error Code Correspondence ................................................. 52

2. Printing Defects and Countermeasures ........................................ 57

3. Power Supply Check ..................................................................... 61

LARGE IC UNIT ....................................................................73

1. Removal of Each Part ................................................................... 73

1.1 Removal of the Top Cover ....................................................... 73

1.2 Removal of the Front Panel .................................................... 73

1.3 Removal of the Mechanical Unit ............................................. 73

1.4 Removal of the IC Main Circuit Board ..................................... 73

1.5 Others ..................................................................................... 73

2. Block Diagram ............................................................................... 74

3. DIP Switch Specifications ............................................................. 75

3.1 Specifications .......................................................................... 75

3.2 IC Card Stop Position Adjustment .......................................... 75

4. Error Messages ............................................................................. 76

5. Specifications of Connector on the IC Main Board ....................... 77

EXPLODED VIEW AND ASSEMBLY LISTS ............................ 78

HOPPER ASSEMBLY1/2 — 2/2 ................................................... 79

FRAME ASSEMBLY1/7 — 7/7 ..................................................... 81

PLATEN ASSEMBLY1/1 ............................................................... 88

PICK UP MOTOR ASSEMBLY1/1 ................................................ 89

FEED MOTOR ASSEMBLY1/1 ..................................................... 90

MEDIA W MOTOR ASSEMBLY1/1 ............................................... 91

MEDIA S MOTOR ASSEMBLY1/2 — 2/2 ..................................... 92

INK S&W MOTOR ASSEMBLY1/1 ............................................... 94

HEATER CAM MTR ASSEMBLY1/1 .............................................95

TURN MOTOR ASSEMBLY1/1 .....................................................96

TURN UNIT ASSEMBLY1/1 ......................................................... 97

MECHANISM ASSEMBLY1/12 — 12/12 ...................................... 98

FRONT PANEL ASSEMBLY1/2 — 2/2 ....................................... 109

PR COMMON ASSEMBLY1/4 — 4/4 ......................................... 111

FINAL ASSEMBLY1/14 — 14/14 ................................................ 115

MAINTENANCE INSPECTIONS ................................................62

1. Cleaning ........................................................................................62

2. Lubrication.....................................................................................62

3. Maintenance Inspections for Main Parts and

Execution Standard.................................................................62

4. Periodic Inspection Items .............................................................. 63

5. Trouble Diagnosis Sheet ............................................................... 64

ADJUSTMENT ............................................................................... 65

1. Layout of the adjustment elements ............................................... 65

2. Adjustment .................................................................................... 65

3. Caution Items for the Time of Exchange of

the CPU Circuit Board ............................................................ 65

MG ENCODING UNIT ..................................................................66

1. MG Encoding Specifications ......................................................... 66

1.1 Magnetic Encoder Specifications ............................................ 66

1.2 General Equipment Specifications .......................................... 66

2. Block Diagram ............................................................................... 67

2.1 MG Unit Block Diagram .......................................................... 67

2.2 Connection Diagram ............................................................... 68

3. MG Encoding Unit Exchange Method ...........................................69

3.1 Repair Classification ............................................................... 69

3.2 Exchange Method ................................................................... 69

3.3 DIP Switch Specifications ....................................................... 71

3.4 MG-related Error Messages ................................................... 72

Page 4

Important Safety Precautions

1.25

2.0

5.5

Crimping tool

Prior to shipment from the factory, VDS products are strictly inspected to conform with the recognized product safety and electrical codes of the

countries in which they are to be sold. However, in order to maintain such compliance, it is equally important to implement the following precautions

when a set is being serviced.

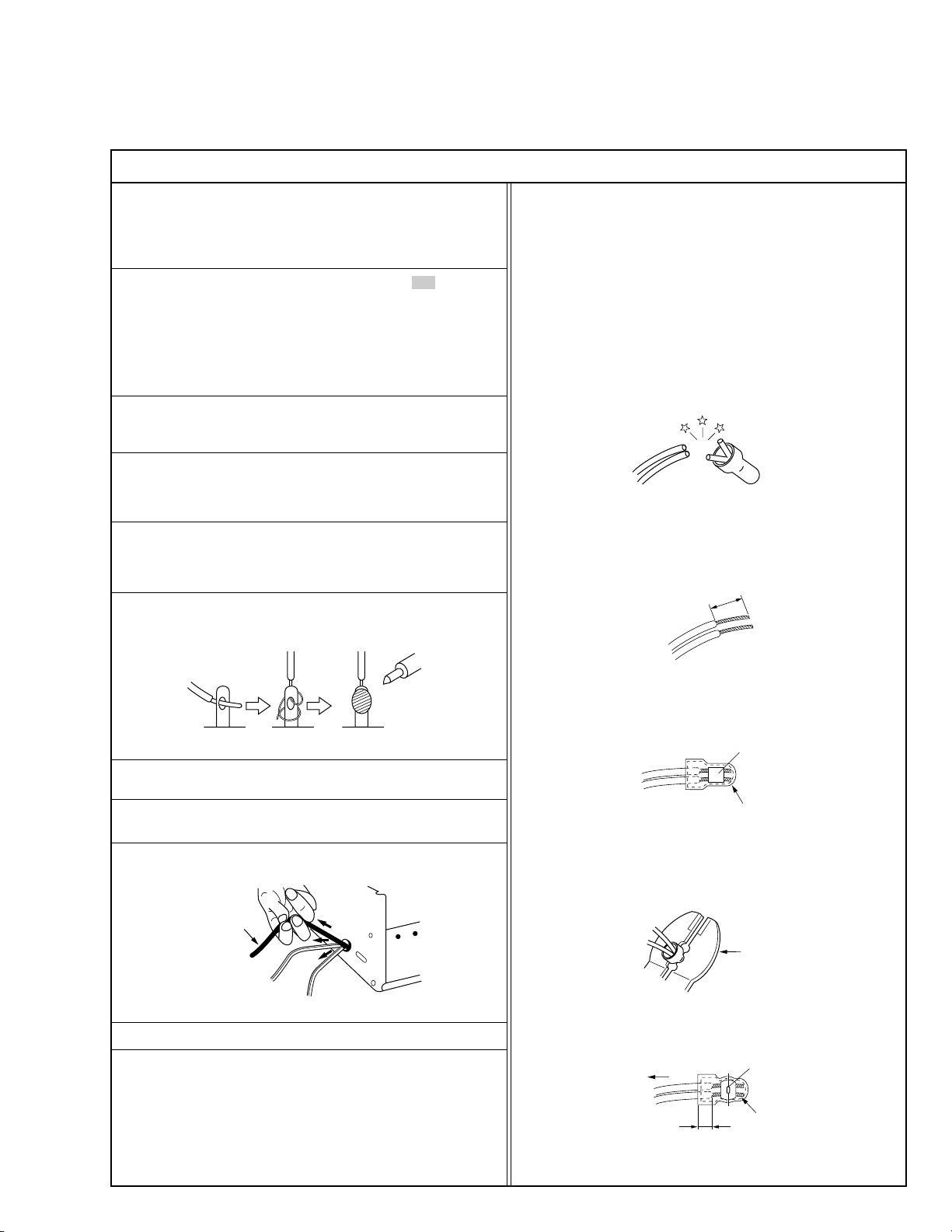

Precautions during Servicing

•

1. Locations requiring special caution are denoted by labels and inscriptions on the cabinet, chassis and certain parts of the product.

When performing service, be sure to read and comply with these

and other cautionary notices appearing in the operation and service manuals.

2. Parts identified by the ! symbol and shaded ( ) parts are

critical for safety.

Replace only with specified part numbers.

Note: Parts in this category also include those specified to com-

ply with X-ray emission standards for products using

cathode ray tubes and those specified for compliance

with various regulations regarding spurious radiation

emission.

3. Fuse replacement caution notice.

Caution for continued protection against fire hazard.

Replace only with same type and rated fuse(s) as specified.

4. Use specified internal wiring. Note especially:

1) Wires covered with PVC tubing

2) Double insulated wires

3) High voltage leads

5. Use specified insulating materials for hazardous live parts. Note

especially:

1) Insulation Tape 3) Spacers 5) Barrier

2) PVC tubing 4) Insulation sheets for transistors

6. When replacing AC primary side components (transformers, power

cords, noise blocking capacitors, etc.) wrap ends of wires securely

about the terminals before soldering.

12. Crimp type wire connector

In such cases as when replacing the power transformer in sets

where the connections between the power cord and power transformer primary lead wires are performed using crimp type connectors, if replacing the connectors is unavoidable, in order to prevent

safety hazards, perform carefully and precisely according to the

following steps.

1) Connector part number : E03830-001

2) Required tool : Connector crimping tool of the proper type which

will not damage insulated parts.

3) Replacement procedure

(1) Remove the old connector by cutting the wires at a point

close to the connector.

Important : Do not reuse a connector (discard it).

cut close to connector

Fig.3

(2) Strip about 15 mm of the insulation from the ends of the

wires. If the wires are stranded, twist the strands to avoid

frayed conductors.

15 mm

Fig.4

(3) Align the lengths of the wires to be connected. Insert the

wires fully into the connector.

Fig.1

7. Observe that wires do not contact heat producing parts (heatsinks,

oxide metal film resistors, fusible resistors, etc.)

8. Check that replaced wires do not contact sharp edged or pointed

parts.

9. When a power cord has been replaced, check that 10-15 kg of

force in any direction will not loosen it.

Power cord

Fig.2

10. Also check areas surrounding repaired locations.

11. Products using cathode ray tubes (CRTs)

In regard to such products, the cathode ray tubes themselves, the

high voltage circuits, and related circuits are specified for compliance with recognized codes pertaining to X-ray emission.

Consequently, when servicing these products, replace the cathode ray tubes and other parts with only the specified parts. Under

no circumstances attempt to modify these circuits.

Unauthorized modification can increase the high voltage value and

cause X-ray emission from the cathode ray tube.

I

(4) As shown in Fig.6, use the crimping tool to crimp the metal

sleeve at the center position. Be sure to crimp fully to the

complete closure of the tool.

(5) Check the four points noted in Fig.7.

Not easily pulled free

Wire insulation recessed

more than 4 mm

Metal sleeve

Connector

Fig.5

Fig.6

Crimped at approx. center

of metal sleeve

Conductors extended

Fig.7

S40888-01

Page 5

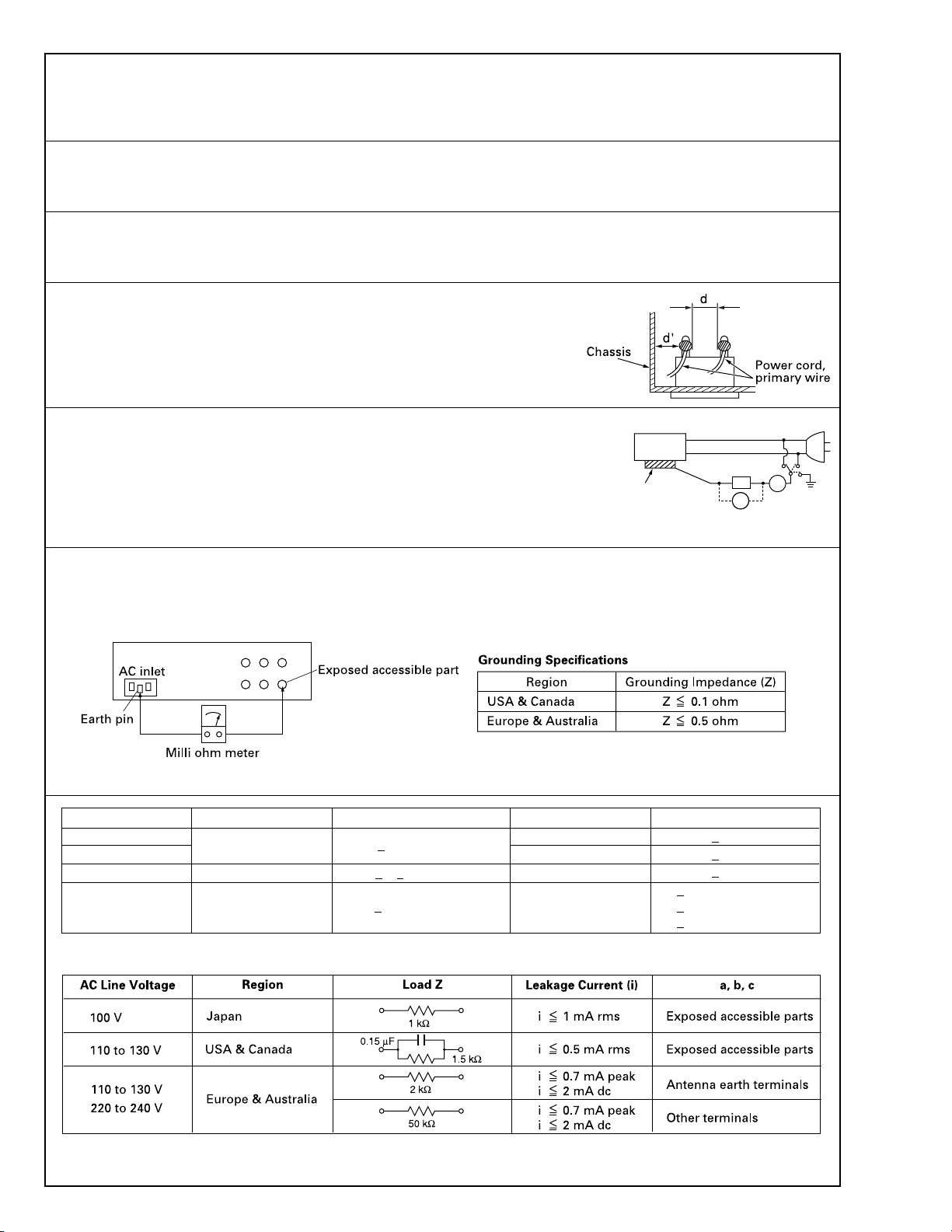

Safety Check after Servicing

•

Examine the area surrounding the repaired location for damage or deterioration. Observe that screws, parts and wires have been returned

to original positions, Afterwards, perform the following tests and confirm the specified values in order to verify compliance with safety

standards.

1. Insulation resistance test

Confirm the specified insulation resistance or greater between power cord plug prongs and externally exposed parts of the set (RF terminals, antenna terminals, video and audio input and output

terminals, microphone jacks, earphone jacks, etc.). See table 1 below.

2. Dielectric strength test

Confirm specified dielectric strength or greater between power cord plug prongs and exposed accessible parts of the set (RF terminals, antenna terminals, video and audio input and output terminals,

microphone jacks, earphone jacks, etc.). See table 1 below.

3. Clearance distance

When replacing primary circuit components, confirm specified clearance distance (d), (d’) between soldered terminals, and between terminals and surrounding metallic parts. See table 1

below.

Fig. 8

4. Leakage current test

Confirm specified or lower leakage current between earth ground/power cord plug prongs and

externally exposed accessible parts (RF terminals, antenna terminals, video and audio input and

output terminals, microphone jacks, earphone jacks, etc.).

Measuring Method : (Power ON)

Insert load Z between earth ground/power cord plug prongs and externally exposed accessible

parts. Use an AC voltmeter to measure across both terminals of load Z. See figure 9 and following

table 2.

Externally

exposed

accessible part

Fig. 9

Z

V

ab

A

c

5. Grounding (Class 1 model only)

Confirm specified or lower grounding impedance between earth pin in AC inlet and externally exposed accessible parts (Video in, Video out,

Audio in, Audio out or Fixing screw etc.).

Measuring Method:

Connect milli ohm meter between earth pin in AC inlet and exposed accessible parts. See figure 10 and grounding specifications.

Fig. 10

AC Line Voltage

100 V

100 to 240 V

110 to 130 V

110 to 130 V

200 to 240 V

Region

Japan

USA & Canada

Europe & Australia R 10 MΩ/500 V DC

Insulation Resistance (R)

≤

R 1 MΩ/500 V DC

≥≥

1 MΩ R 12 MΩ/500 V DC

≤

Tab le 1 Specifications for each region

Dielectric Strength

AC 1 kV 1 minute

AC 1.5 kV 1 miute

AC 1 kV 1 minute

AC 3 kV 1 minute

AC 1.5 kV 1 minute

(Class 2)

(Class 1)

Clearance Distance (d), (d')

≤

d, d' 3 mm

≤

d, d' 4 mm

≤

d, d' 3.2 mm

≤

d 4 mm

≤

d' 8 mm (Power cord)

≤

d' 6 mm (Primary wire)

Table 2 Leakage current specifications for each region

Note: These tables are unofficial and for reference only. Be sure to confirm the precise values for your particular country and locality.

II

S40888-01

Page 6

MODEL NAME

The letters and numbers following the model name are used to differentiate between destinations and specifications.

Model name: XID580i - #

1. Detailed specifications

# Portion – Internal option

Nil ......... No option (Standard model)

B...........Equipped with ISO magnetic encorder / IC contact

1

Page 7

HOW TO CONNECT SEPARATELY SOLD PARTS

1. Connecting the Small-type IC Unit

1.

Remove the cover on the side of the printer.

Remove the screw, and then raise the cover to remove it.

2.

Connect the connector.

Please note that the connector has directionality.

3.

Install the unit with three screws.

Install the screws so that the cable of the connector

is not caught.

4.

Install the cover with two screws.

Screw with washer

(provided)

Pass the cable through the notch.

Screw

(provided)

2

Page 8

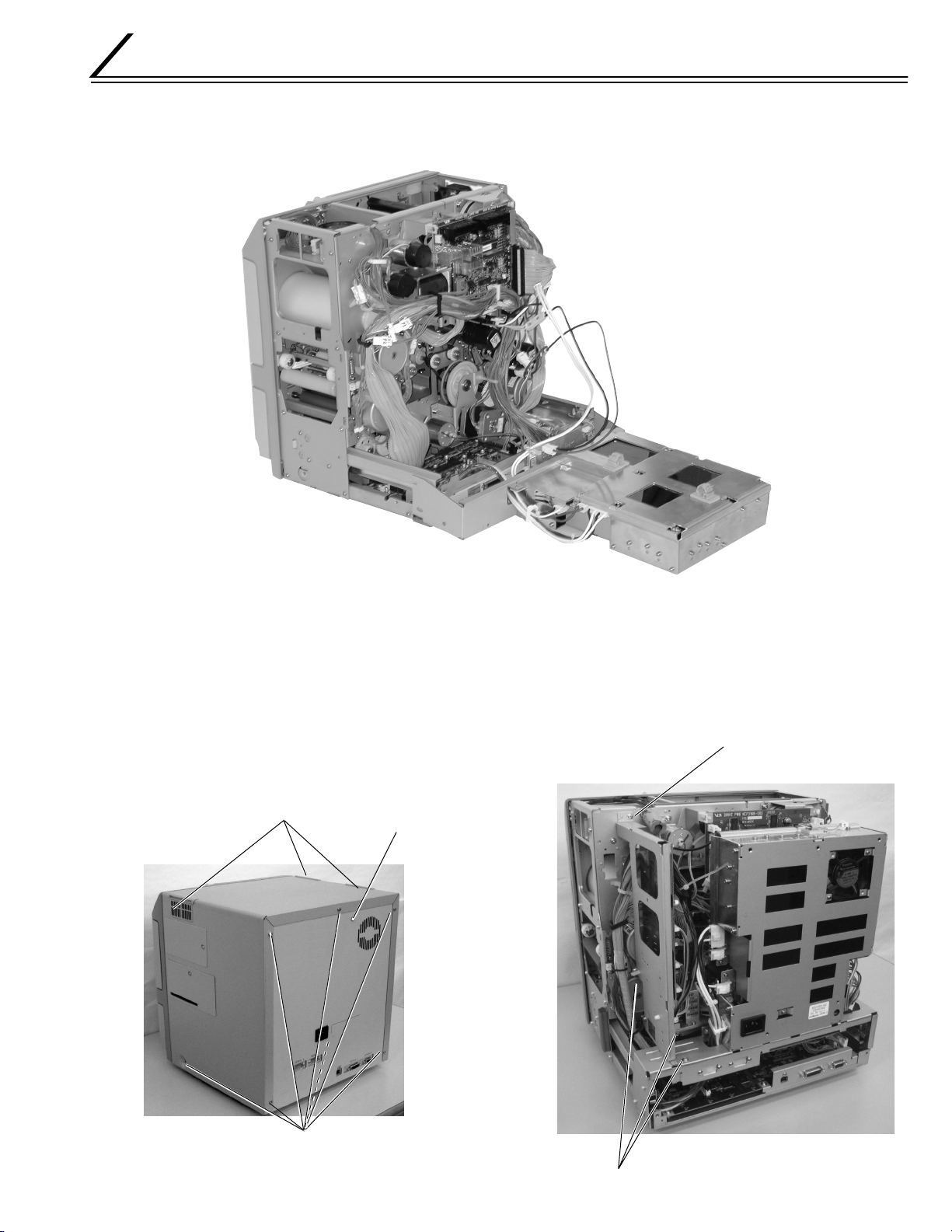

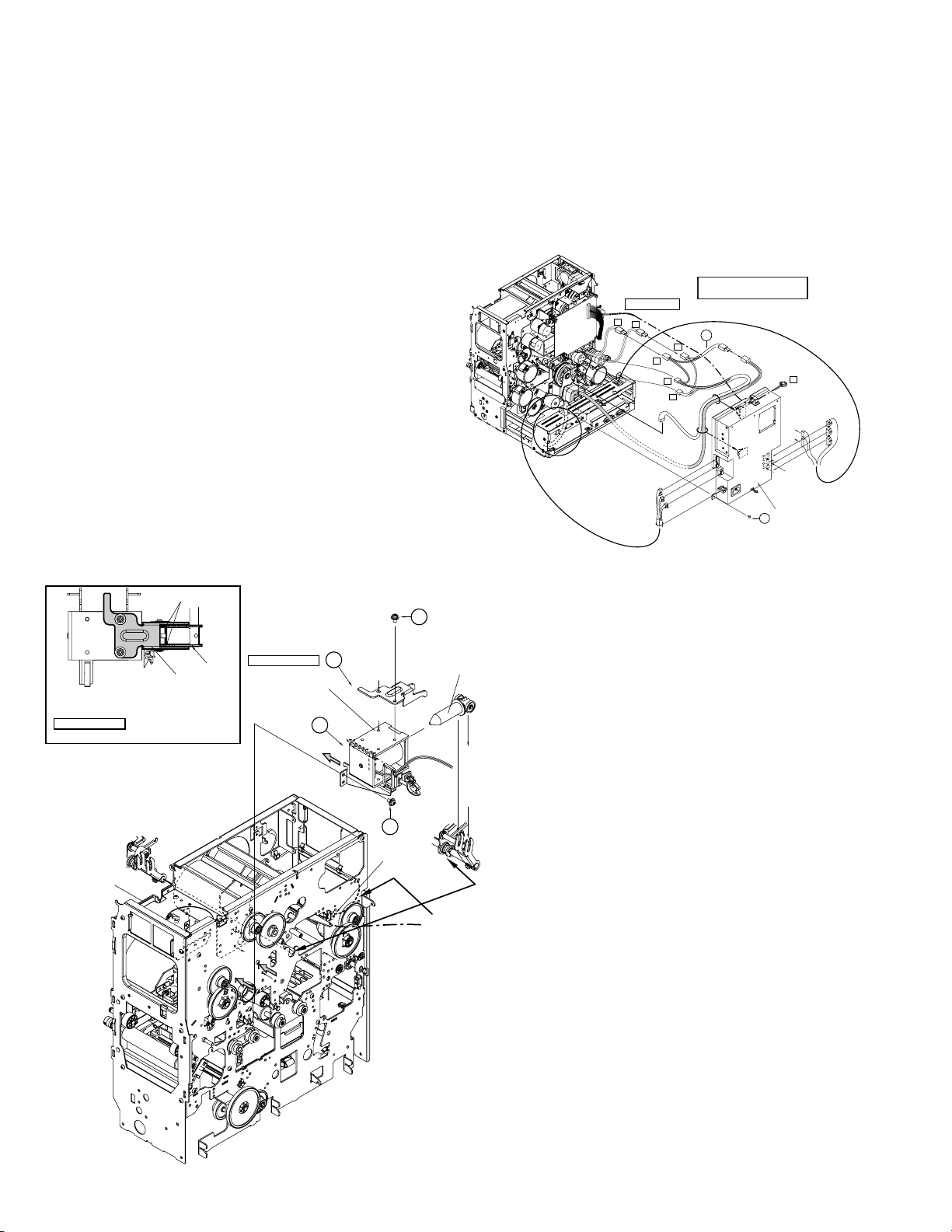

2. Connection of the Magnetic/Contact-type IC Encoder

When the separately sold magnetic/contact-type IC encoder is to be connected to a standard printer, connect it according to the following procedure.

For details in regard to the removal method for each part, refer to “Removal and exchange of the Main Parts”.

1) Remove the top cover.

2) Swing down the power supply.

3) Remove the front panel.

4) Install the magnetic unit. Fix with three black screws 8 at the front and four black screws 8 at the rear.

5) Install the bracket fixing the MG circuit board with four screws 6.

6

Pass the wires of

power switch.

CN3

13

KWS0744-001

KWR18416-001

x6

9

8

12

Clamp

1

(TFA0023)

J10

J9

Explanation drawing 1

J14

(TSA0141)

G.NO.004

Make the cable routed

away from the rail

2

MG PWB SA

Explanation

drawing 1

J10

8

CLAMP

Explanation

drawing 2

14

6

KWS0767-002

15

J14

J10

KWS0768-001

Clamp

6

J1

J8

J7

Explanation

drawing 2

J4

J5

J3

J10

J14

8

8

3pin

CLAMP

Explanation drawing 1

CN12

11

KWR17110-001

Clamp

CLAMP

6

6

3

Page 9

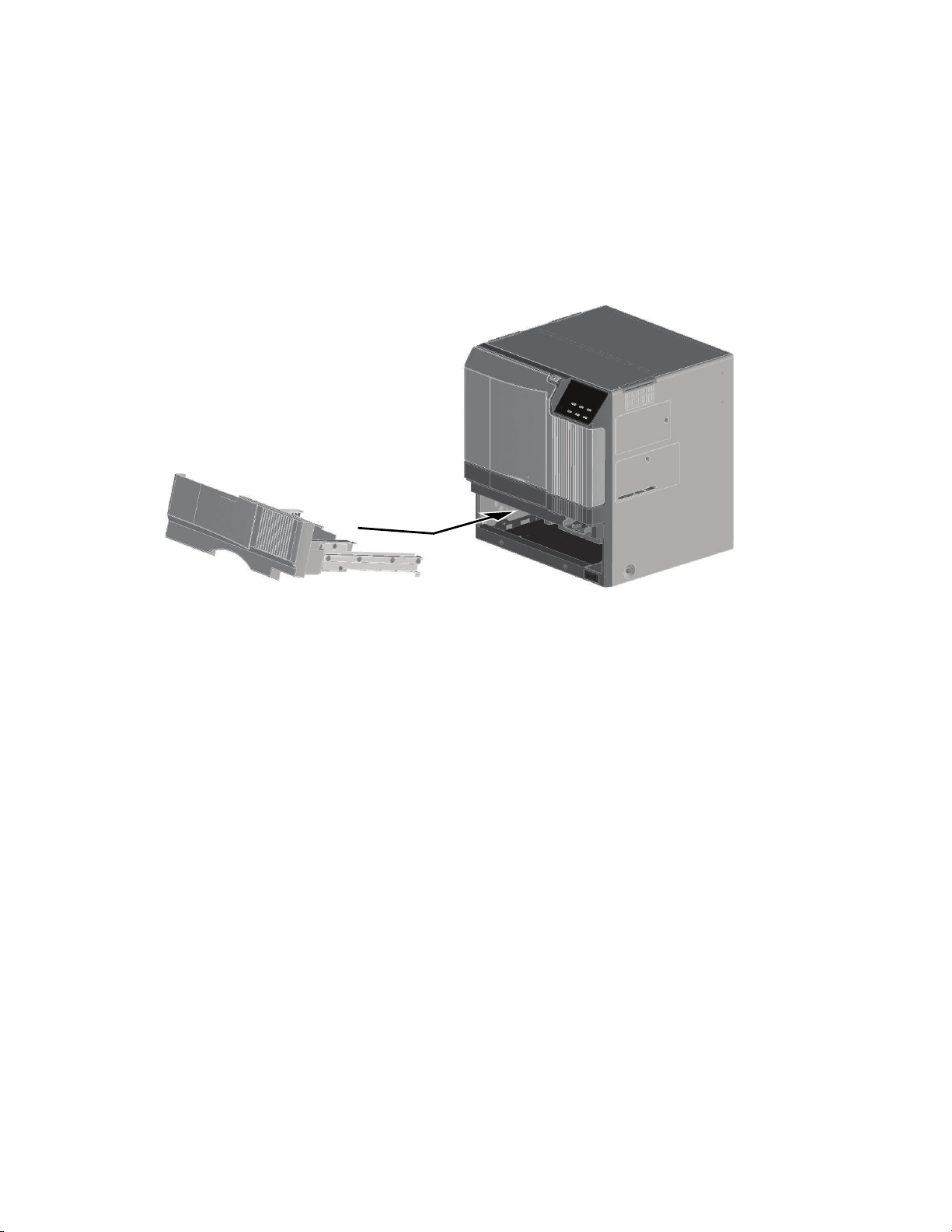

3. Connecting card tray

Upon issuing the card using paper feeding feature on the right, as the NG cards transported to the printer will be ejected,

replace the standard hopper unit with an optional card tray.

Mount the card tray according to the following procedures:

1. Pull out the standard hopper unit diagonally upwards.

2. Insert the optional card tray diagonally downwards.

(Note: The cleaning roller should be left as it is.)

3. Enter the service mode of the printer main unit, select “Card Loading” under the maintenance items and switch from

“standard” to “Right Side”.

4. Settings other than this and operating procedures are dependent to the user system.

Note: If there are 10 cards accumulated continuously in the card tray, the printer will display “Card Tray Full”. Remove

the cards immediately.

5. Keep the removed hopper unit safely.

4

Page 10

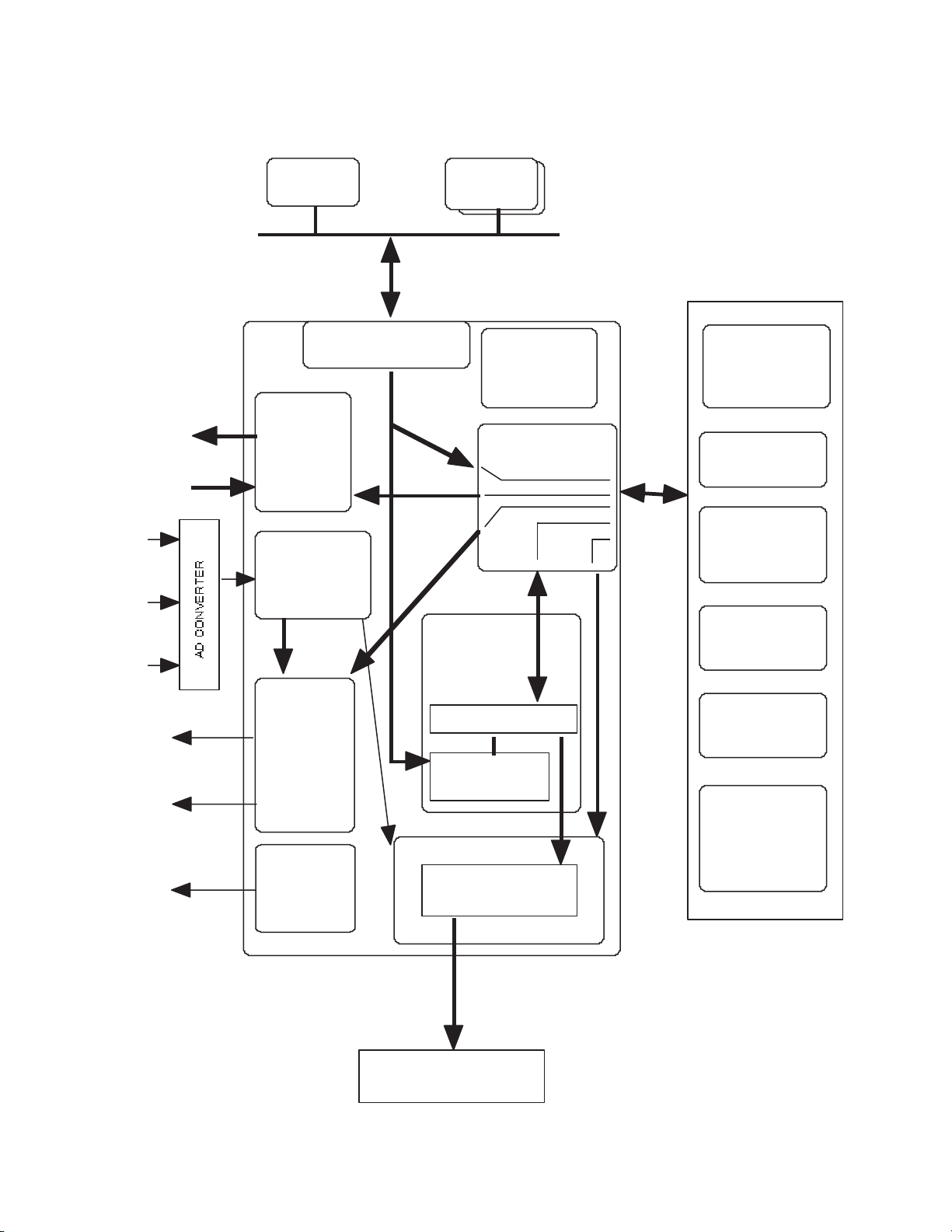

THERMAL HEAD

HEAD

CONN

PWB

U1

EEPROM

32Kbit

HEAD BLOCK

MAIN PWB

FRONT PWB

POWER

SUPPLY

UNIT

U1

CPU

X1

XTAL

66.67MHz

U7

EEPROM

32Kbit

U2

SDRAM

64Mbit

U3

FLASH ROM

16Mbit

TR THERMISTOR

RR

THERMISTOR

DRIVE PWB

NO CARD

CARD IN

CARD (MG POSITION) (PWB)

(OPTION(MGIC))

CARD (TURN) (PWB)

TURN POSITION

EDJE (PWB)

CARD OUT (PWB)

FILM MARK (PWB)

CAM POSITION

TR POSITION

RR POSITION

INK FG (PWB)

CARD NEAR EMPTY

INK FG

(MOTOR built-in)

FILM F G (MOTOR built-in)

SENSORS

U5

SDRAM

64Mbit

U5

FLASH ROM

16Mbit

SENSORS

THERMISTOR &

CONNECTOR (PWB)

EXTERNAL UNIT

HEATER PROTECTOR PWB

USB

I/F

Q13

REGULATOR

(A+5V)

U8

REGULATOR

(3.3V)

Q11

REGULATOR

(1.5V)

U10

REGULATOR

(1.8V)

DC-DC circuit

U11

FPGA

U12

SDRAM

64Mbit

U1

DAConverter

LCD module

(16columX2line)

SWX6

COLOR

LED

LEDX2

BUZZER

U17

USB

chip

X1

XTAL

48MHz

U7

STEP MOTOR DRIVER

Q2

Q3

TRANSISTOR

Q5

TRANSISTOR

Q6

TRANSISTOR

Q7

TRANSISTOR

U8

STEP MOTOR DRIVER

U11

STEP MOTOR DRIVER

U13

DC MOTOR DRIVER

U14

DC MOTOR DRIVER

U15

DC MOTOR DRIVER

SOLENOID (PLATEN ROLLER)

SOLENOID (IC CONTACT(OPTION))

FAN (THERMAL HEAD)

FAN (CARD)

FAN (PRINTER)

CARD MOTOR

FILM MOTOR

CAM MOTOR

FILM MOTOR

INK MOTOR

INK MOTOR

TURN

MOTOR

CARD MOTOR (TURN)

CARD MOTOR (PICK UP )

U9

STEP MOTOR DRIVER

U10

STEP MOTOR DRIVER

U16

DC MOTOR DRIVER

EXTERNAL

UNIT

EXTERNAL

UNIT

MG/IC UNIT(OPTION)

RF-ID UNIT

U14~16

BUFFER

U32,U33

COMPARATOR

U22,36~U39

BUFFER

U2

Serial to Parallel

U19

INVERTER

CPU BUS

U13

ADConverter

U2

RESET IC

(5V)

CLEANING ROLLER INTERLOCK SW

DOOR INTERLOCK SW

CASSETTE INTERLOCK SW

CARD TRAY INTERLOCK SW

FAN (PRINTER)

U7

CLK

DRIVER

X2

XTAL

32MHz

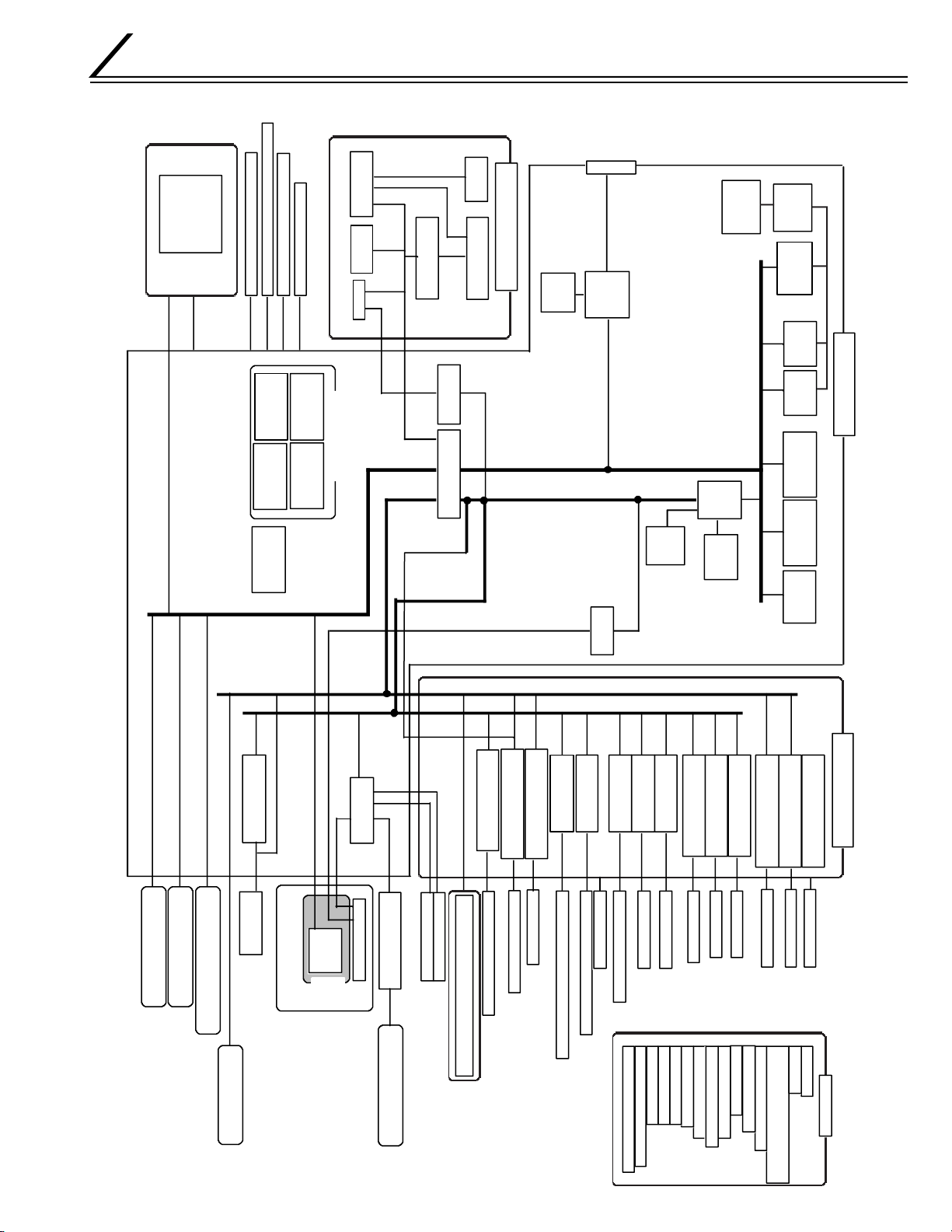

BLOCK DIAGRAM

1. OVERALL BLOCK DIAGRAM

5

Page 11

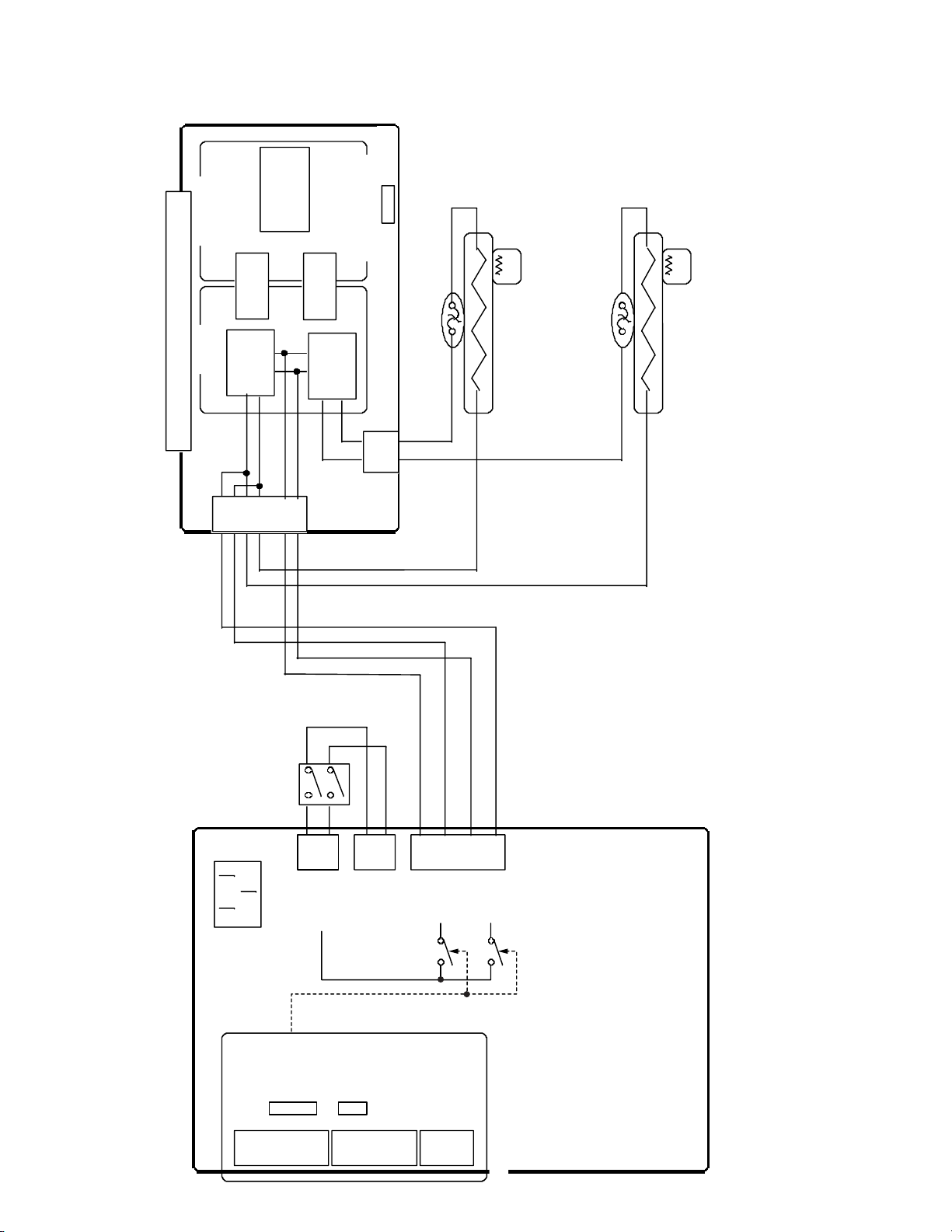

2. BLOCK DIAGRAM OF PRIMARY SIDE OF POWERUNIT

THERMOSTAT

HEATROLLER

(REMEDIAL)

t˚

THERMISTOR

(to DRIVE PWB)

THERMOSTAT

HEATROLLER

(RETRANSFER)

t˚

THERMISTOR

(to DRIVE PWB)

POWER

SUPPLY

UNIT

N(AC IN)

L(AC IN)

SSR2N

SSR2L

SSR1N

SSR1L

CN3

VTH

CN1

5V

12V

CN2

24V

CN8

24V_RC

CN4

CONTROL

SIGNAL

N(AC OUT)

L(AC OUT)

(to ANALOG POWER PWB)

FAIL SIGNAL

(to DRIVE PWB)

HEATER PROTECTOR PWB

POWER

SWITCH

CN1

CN2

AC

VOLTAGE

DETECT

PHOTO

COUPLER

ABNORMAL

CURRENT

DETECT

PHOTO

COUPLER

Primary

Secondary

SSR1L

SSR2L

ON/OFF

CN5

SSR

CN7

CN6

SSR

6

Page 12

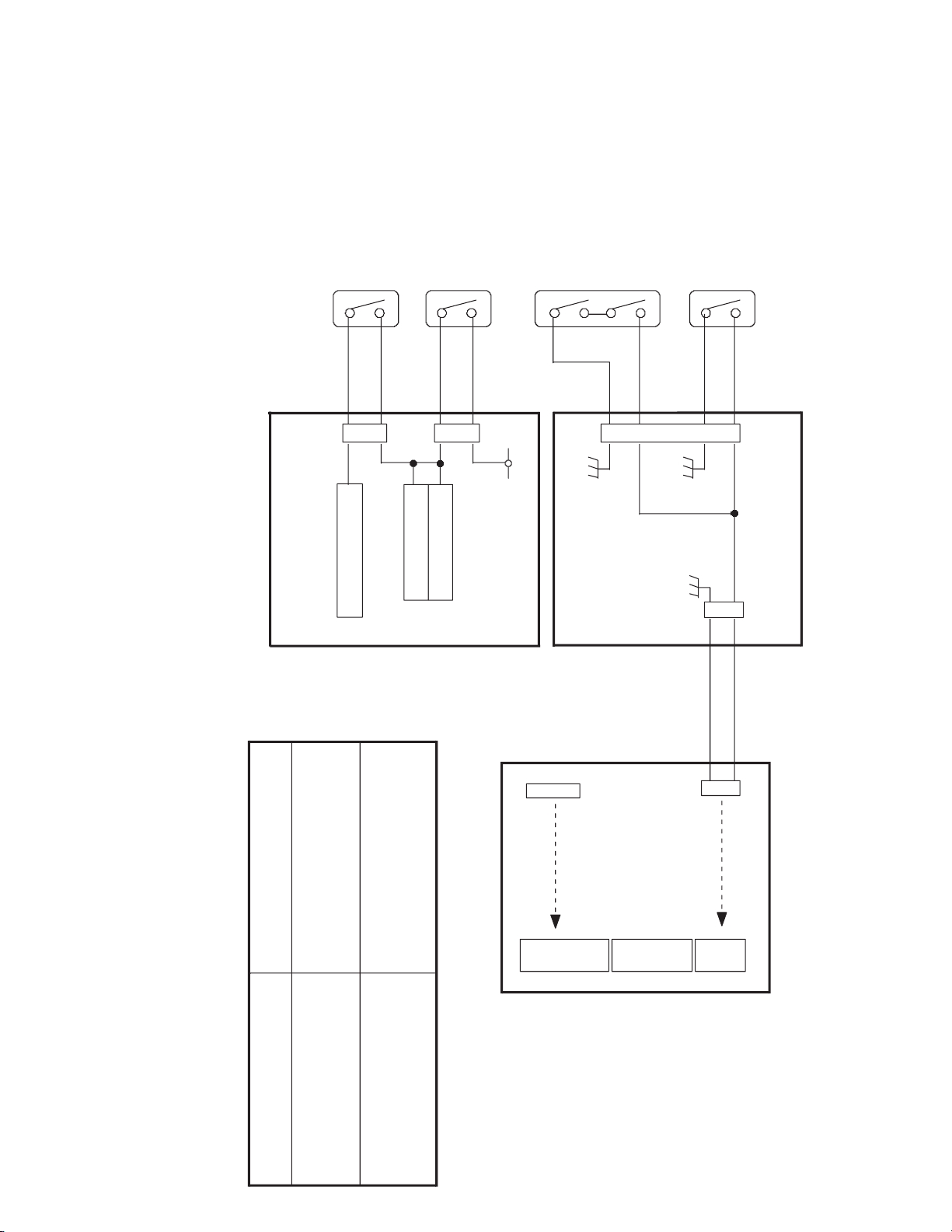

3. INTERLOCK SW BLOCK DIAGRAM

24V

U9

TURN MOTOR DRIVER

U10

CARD MOTOR DRIVER

U16

PICK UP MOTOR DRIVER

Cleaning roller SW (PWB)

Card Tray SW (PWB)

24V_RC

POWER

SUPPLY

UNIT

DRIVE PWB

Cassette SW (PWB)

Door SW (PWB)

J16

J18

J7

J6

CN8

Door SW (PWB) OPEN

and

Cassette SW (PWB) OPEN

24V OFF

Cleaning roller SW (PWB) OPEN

Card Tray SW (PWB) OPEN

Turn Motor STOP

Card Motor STOP

Pick up Motor STOP

Pick up Motor STOP

Specification of Interlock Switch

CN3

Vth

CN1

5V

12V

CN2

24V

CN4

24V_RC

Vth_RC

MAIN PWB

7

Page 13

4.

BLOCK DIAGRAM OF THE FPGA CIRCUMFERENCE ON A MAIN BOARD

Motor

Solenoid

Control

Signals

Sensor input

Retransfer

Heater

Temperature

7

Bend Remedial

Heater

Temperature

8

TPH

Temperature

9

Retransfer

Heater

Control Signal

Bend Remedial

Heater

Control Signal

INK Sensor

LED Driver

CPU

CPU I/F BLOCK

MOTOR

CONTROL

BLOCK

AD

CONVERTER

CONTROL

BLOCK

78

HEATER

CONTROL

BLOCK

(The Heaters

are controlled

by each

temperature.)

D/A

Interface

16bit

Data

6

1

2

PRINT BLOCK

(Temperature

correction,

Outline emphasis,

LUT)

Data Processor

Microcode

Memory(*1)

512Word x 16bit

9

TPH I/F BLOCK

Line Buffer Memory

Flash

Memory

INTERNAL

CLOCK

GENERATOR

SDRAM I/F BLOCK

x 2

32bit CPU BUS

4

56

SDRAM

4MWordx16bit

1

Step Motor

Speed Up/Down

Table

(CPU generates

the table data.)

2

Heater control

Table(*2)

3

16bit

Data

3

TPH Control

Table(*2)

(Strobe)

4

Tables for

Print Data

Correction(*2)

5

Work Memory

for PRINT BLOCK

6

Plane Memory

2MByte

(*1)(*2)These data are copied

Print Data

Strobe

Lutch

Thermal Print Head

from Flash Memory.

*FPGA=

FieldPrgrambleGateArray

8

Page 14

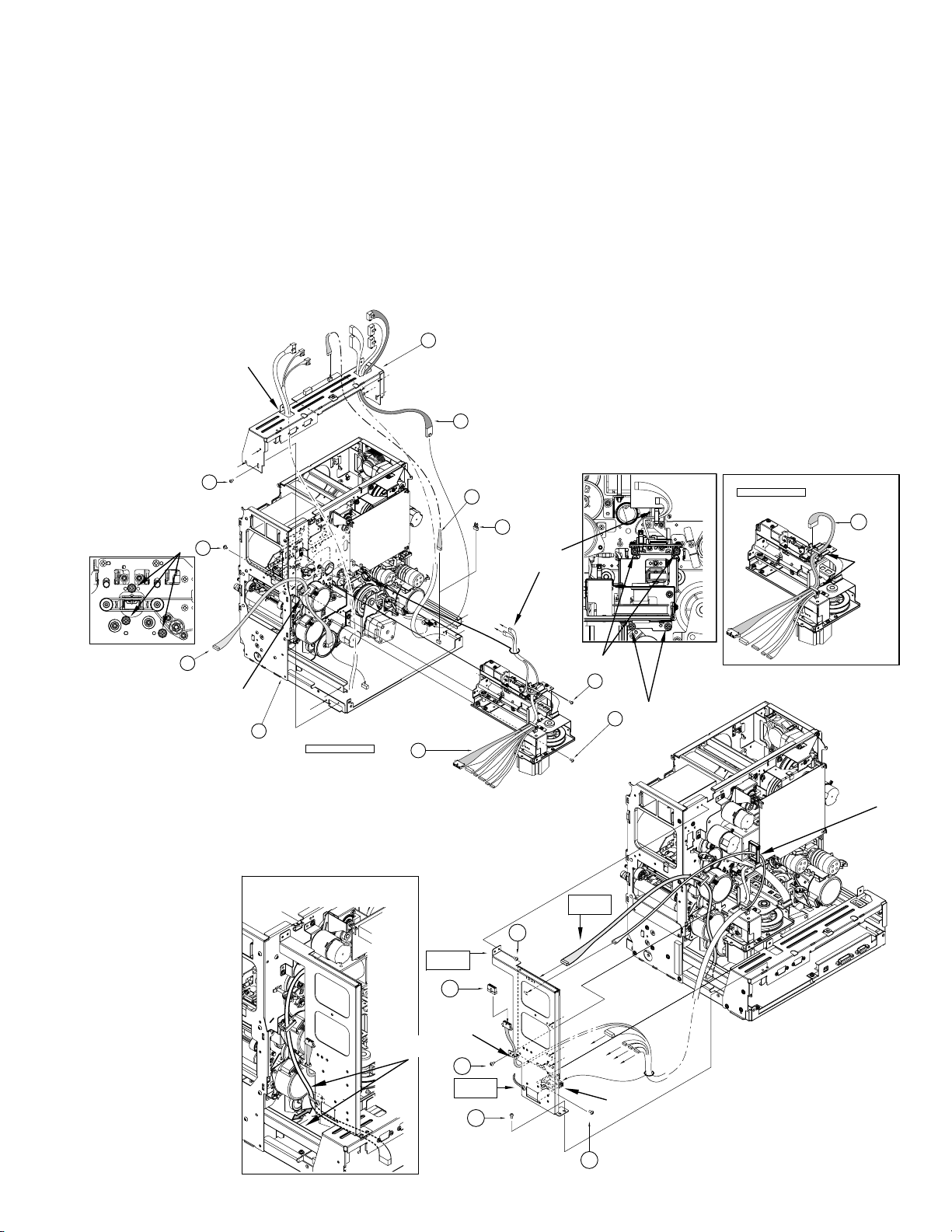

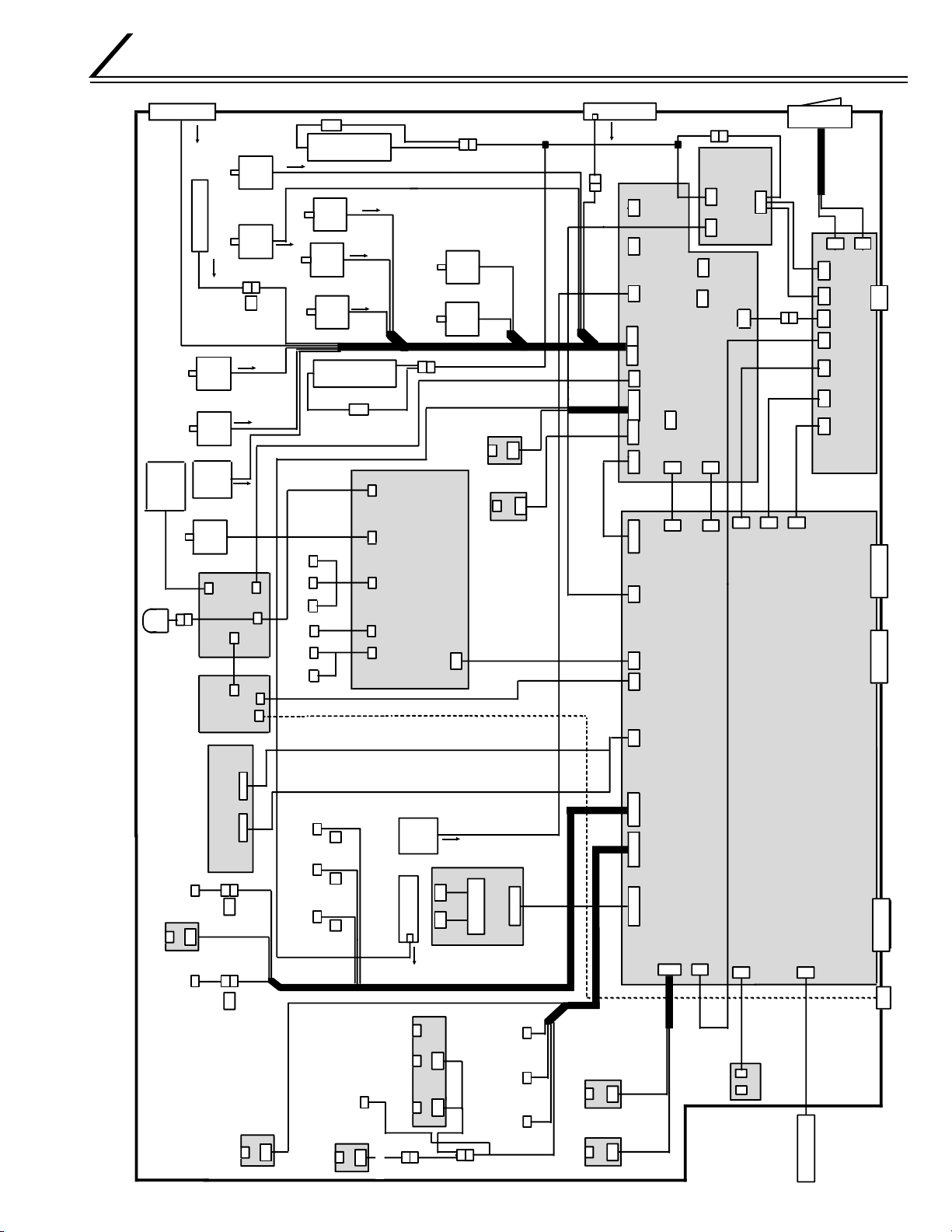

WIRING DIAGRAM

USB I/F

POWER SUPPLY

DRIVE PWB

Option1 I/FOption2 I/F Serial I/F

AC IN

DC5/12V

FRONT PWB

CTL1 V TH

HEAD PWB

MAIN PWB

CTL2ACAC

KWS0644-001

Step

Motor

Step

Motor

DC

Motor

CN8 CN9

Step

Motor

DC Motor

DC Motor

DC Motor

Step

Motor

OPTION

(MG/IC Block)

Step

Motor

S3

S1

S2

T2

F1

T1

Pick up motor

Turn over motor

Turnover feed

motor

Ink takeup

motor

Ink supply motor

INK FG

sensor

card supply sensor

Platen

roller

solenoid

Card edge

sensor

HEATER

PROTECTOR

PWB

CN1 CN2

KWR16003-001

Turnover

card sensor

Retranfer

film mark

sensor

No card

sensor

Turnover

initial position

sensor

Card near

empty sensor

Thermal Head

cooling fan

Thermostat

Retransfer film

Take up motor

Cam motor

Card feed

motor

Retransfer film

supply motor

Remedial

Heat Roller

Thermistor

Card outlet

sencer

Retransfer

Heat Roller

Thermistor

Cam sensor Retransfer

Heatroller

Positionning sensor

Card tray

interlock

Thermal Head

Cleanning roller

interlock

Door interlock Cassette

interlock

Ink start

position

sensor

Cooling fan

AC

AC

Cooling fan

POWER

SWITCH

Remedial

Heat roller

Retransfer

Heat roller

Thermostat

DC24V

DC5/12V/24V

Step

Motor

MG Feed Motor

IC CONTACT

Solenoid For

Head position1

Card position

210Encode

75Encode

IC FLAG

5V 12V

IC R/W

MG HEAD

IC

CONTACT

XID580i BLOCK DIAGRAM

Head position2

Head position3

Remedial

Heatroller

Positionning sensor

Card Cooling Fan

J6

J7

J4

J8

J13

J12

J11

J24

J23

J10

J9 J15

J5

J21

J22

J2

J18

J16

J17

J14

RF-ID PWB

J9

J8

J11

J12 J16

J14

J7 J6

J3

J4

J2

J1

CN1

CN2 CN3

to J13

J13 J15

J10

J9

J12

to

J16

to J9

to J12

to J8

to J13

to J13

to

J8

to J16

to J10

J1

to J11

CN1

CN1

CN3

to J15

CN3

CN301

CN1

CN201

CN4 CN5

CN6

CN7

to J8

CN2

9

Page 15

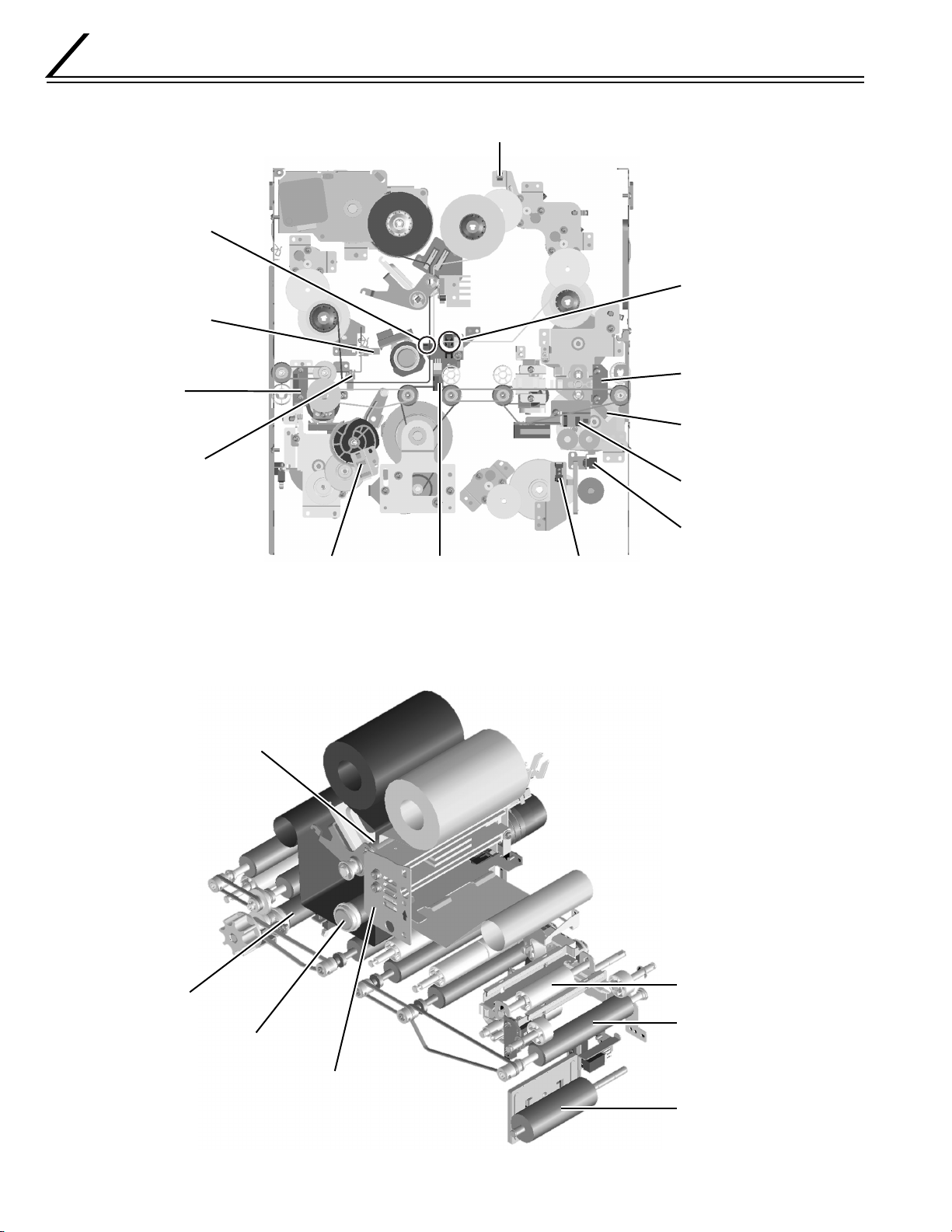

Main Parts Layout

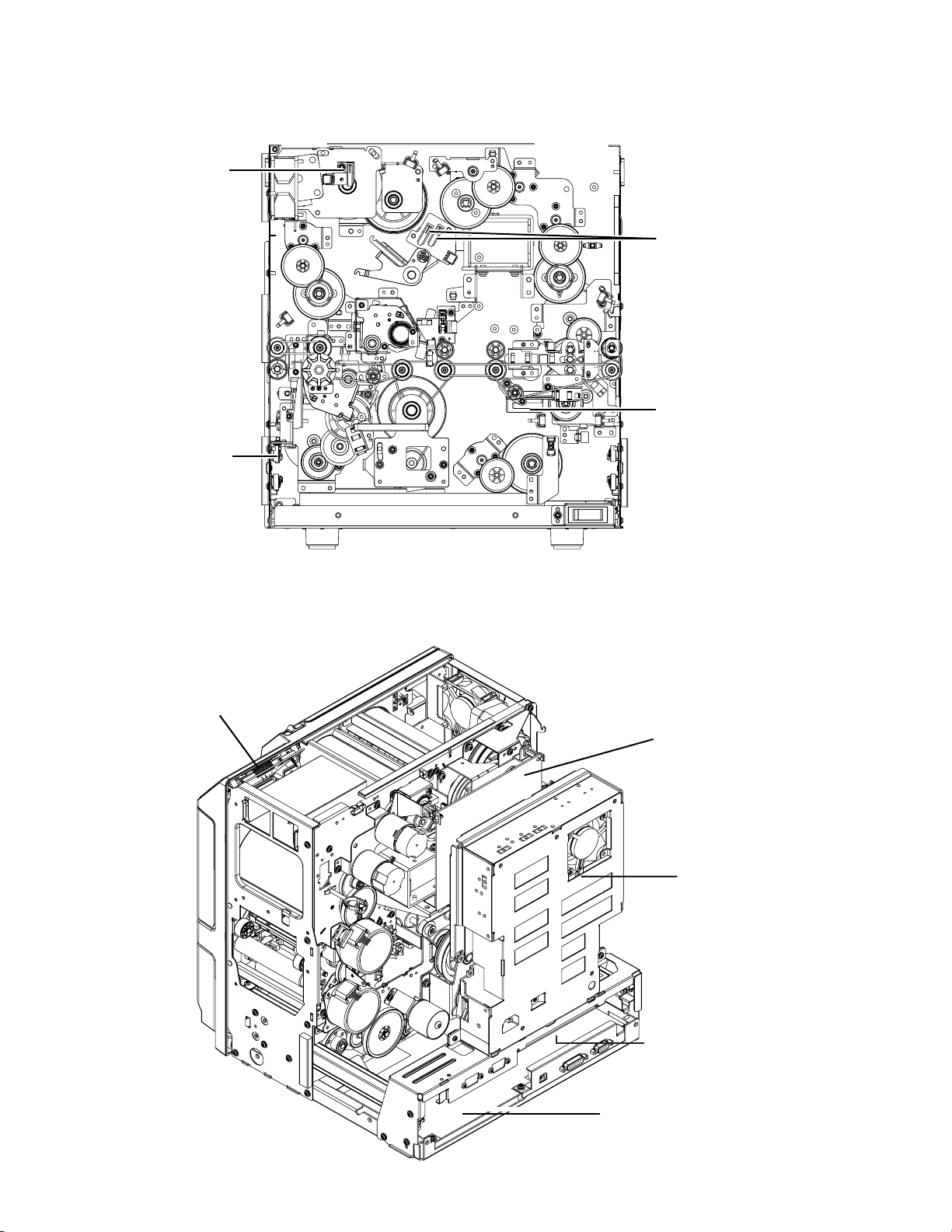

1. Sensors

Retransfer film

mark sensor

(circuit board)

Retransfer roller

sensor

Card outlet

sensor

Bend remedial

roller sensor

Ink FG sensor (encorder circuit board)

Ink start position

sensor (circuit board)

Turnover card

sensor (circuit board)

Turnover initial position

sensor

Card supply sensor

Cam sensor Card near empty sensor

2. Thermal Head and Rollers

Platen roller

No card

Card edgesensor

(Circuit board)

10

Bend remedial roller

Retransfer roller

Turnover unit

NG card

outlet roller

Thermal head

Card supply roller

Page 16

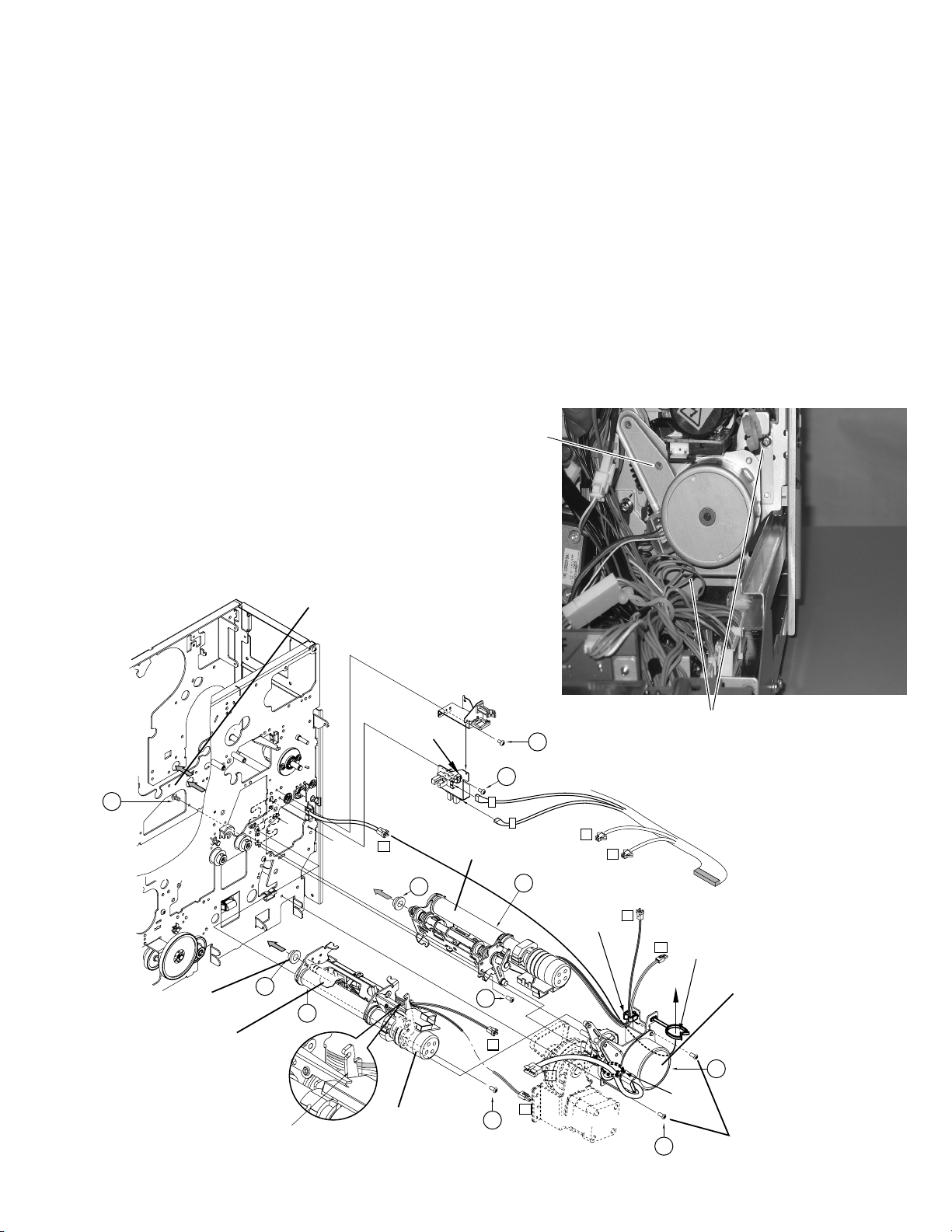

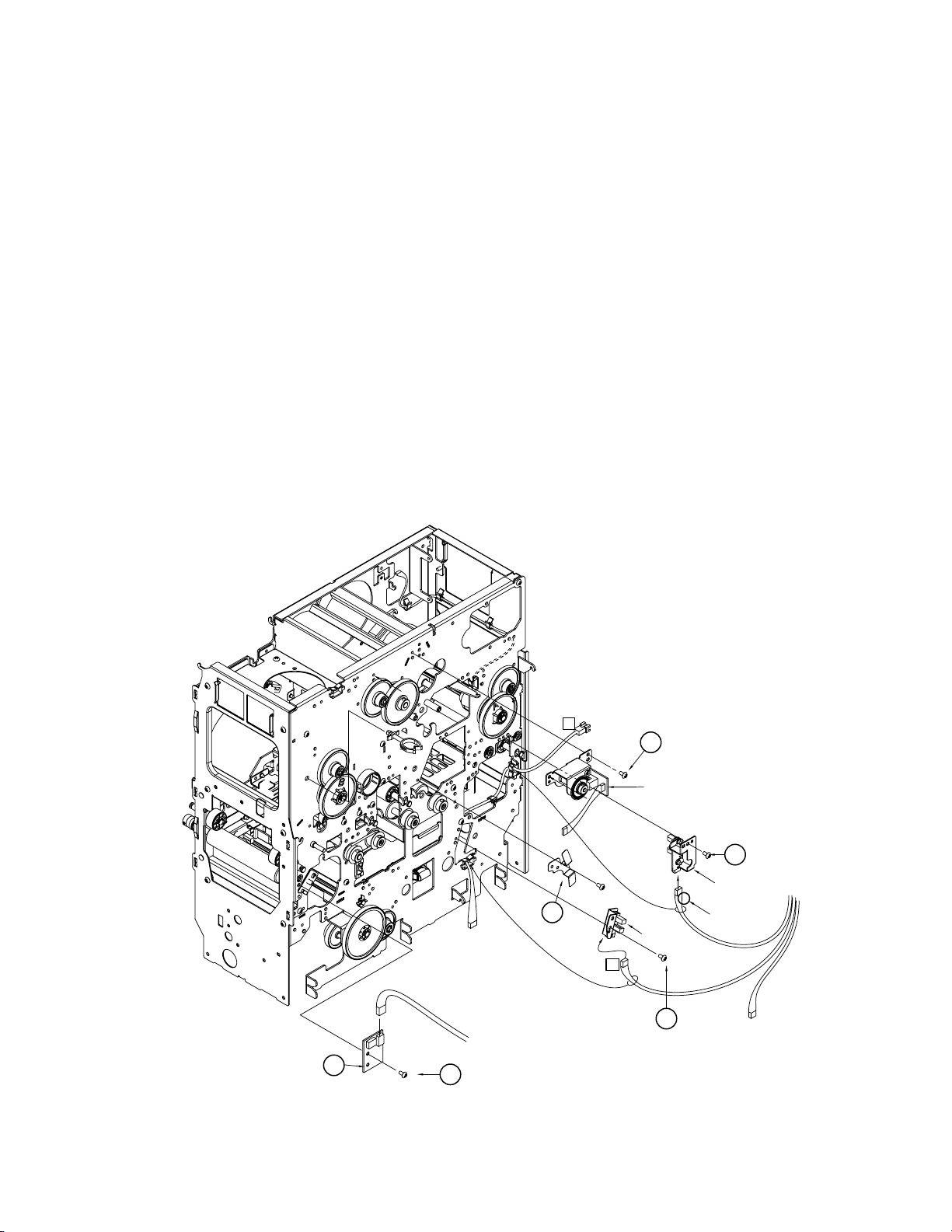

3. Motors

Ink take-up

motor

Ink supply

Motor

Retransfer

film supply

motor

Retransfer

film take-up

motor

Turn over

motor

Turn over

feed motor

4. Solenoid

Platen Solenoid

Cam motor

Card feed

motor

Card pick up motor

Rear veiw

11

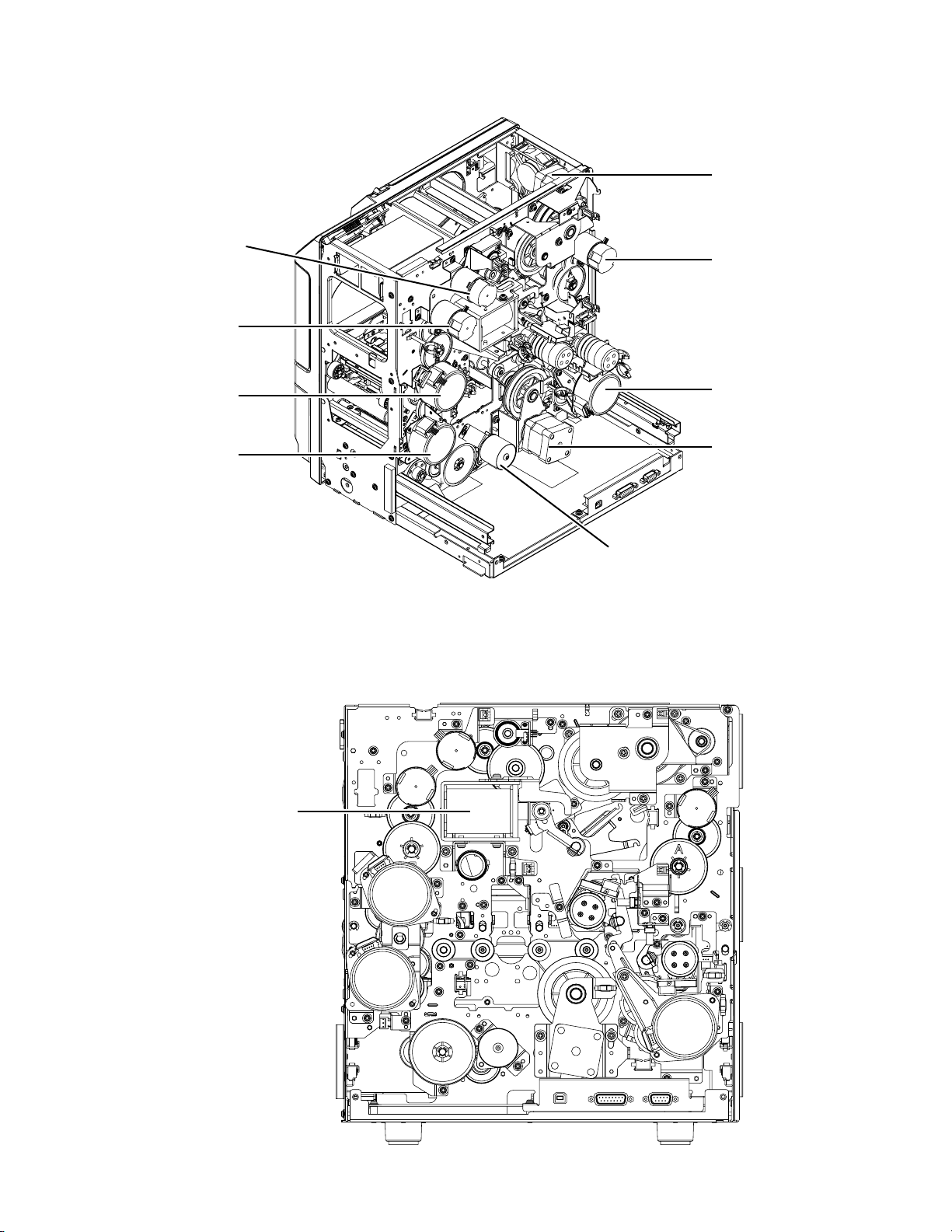

Page 17

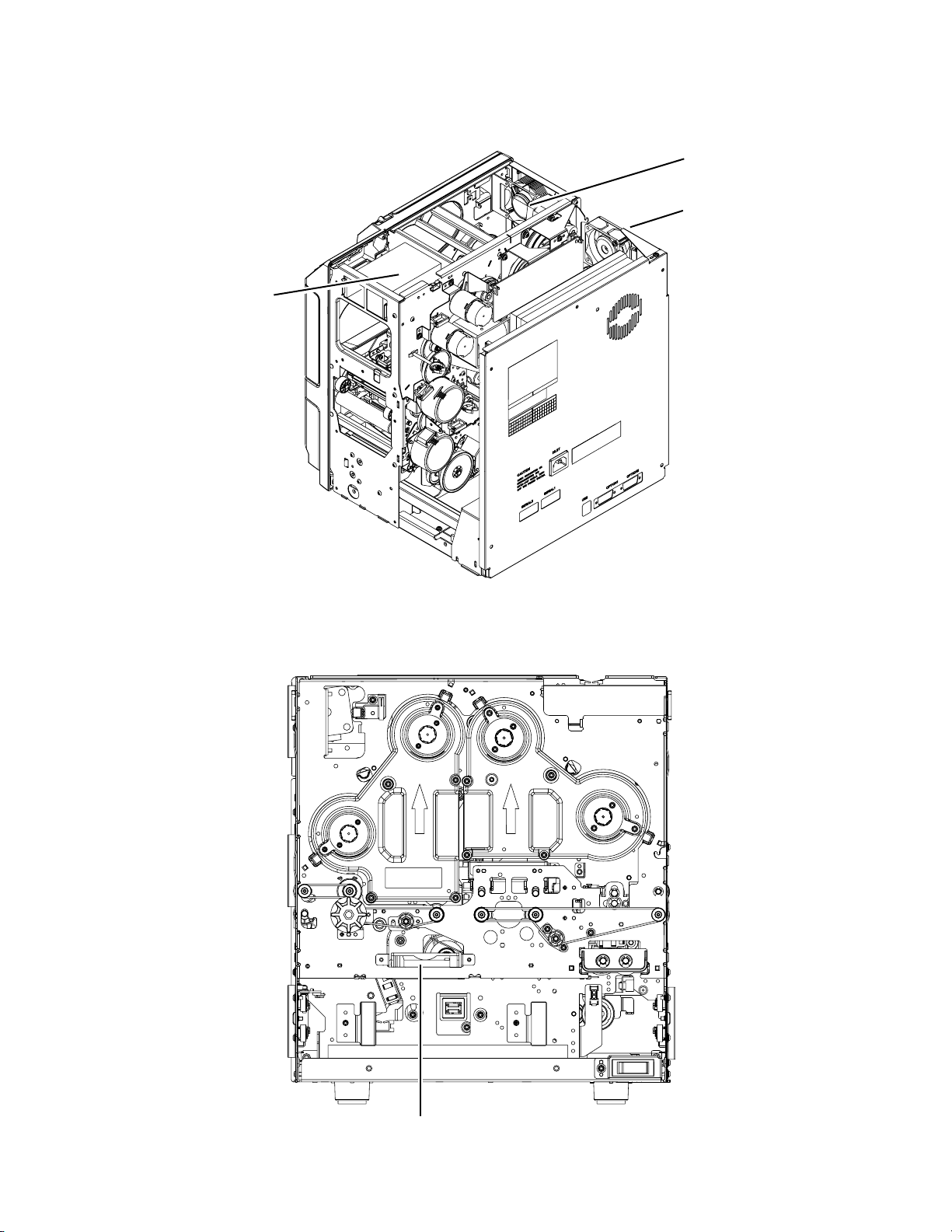

5. Switches

Door interlock

switch

Card tray

interlock switch

Cassette interlock

switch

Cleanning roller

interlock switch

6. Circuit Boards, Power Supply Unit, and Fans

Front PWB

Drive PWB

Power

supply unit

Heater protector

PWB

12

MAIN PWB

Page 18

Thermal head

cooling fan

Ventilation fan

Ventilation fan

Card cooling fan

13

Page 19

7. RF-ID

14

RF-ID unit

Page 20

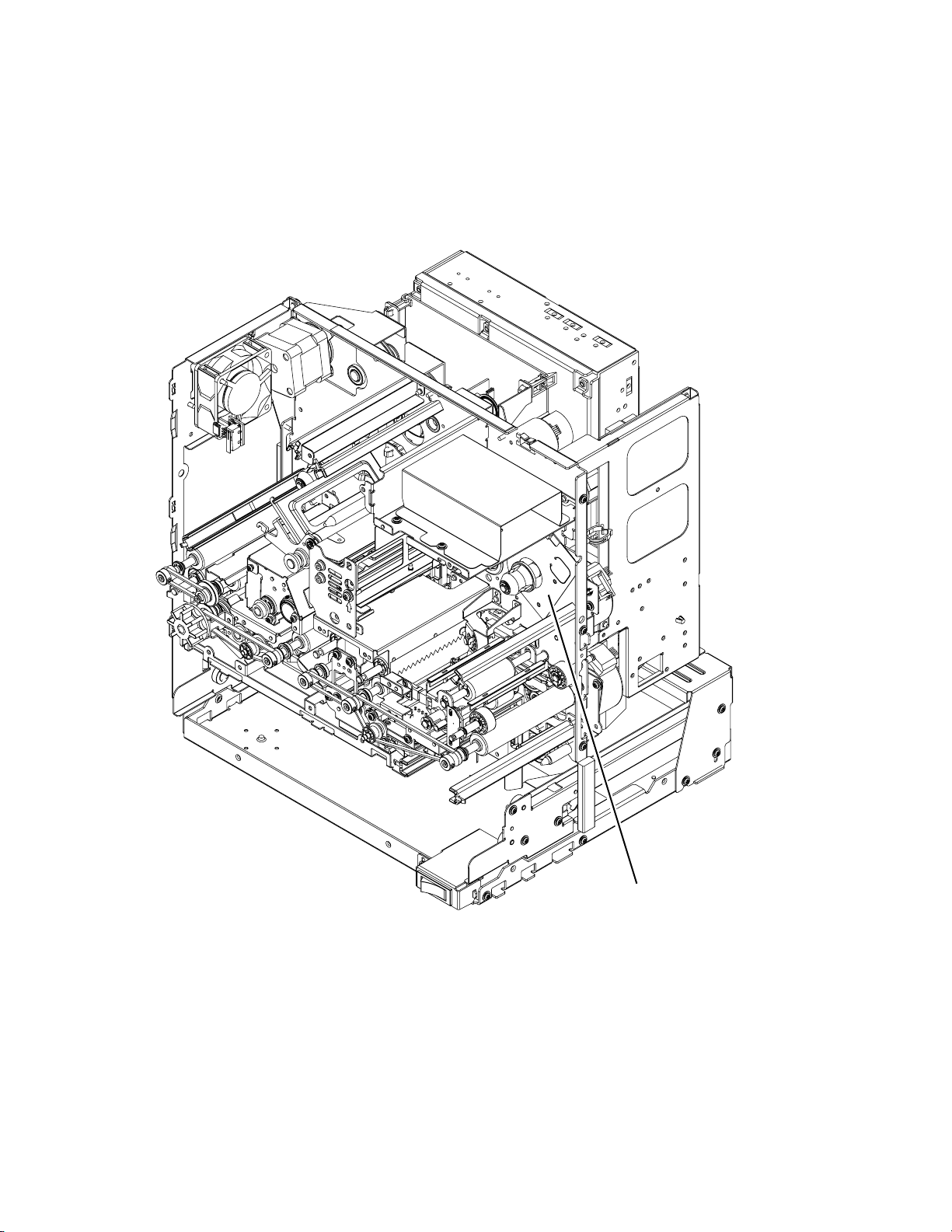

Screw B

Screw A

REMOVAL AND EXCHANGE OF THE MAIN PARTS

1. CHECKING AT THE TIME OF SERVICING

When confirming the symptoms, swing the power supply unit down as shown in the following figure and check the inside.

1.1 REMOVE THE TOP COVER AND THE

REAR PANEL.

1) Remove the filters on both sides of the top cover.

Caution: If they are not removed, the filters will be

damaged when the top cover is moved.

2) Remove the seven screws A and pull the top cover

to the rear to remove it.

3) Remove the screw B and take off the rear panel.

Filter

ScrewB

1.2 REMOVE THE MG CIRCUIT BOARD.

1) Remove the three screws A and the screw B.

2) After the power supply unit has been swung down,

use the screw B for provisional fixing, so that the

MG circuit board does not move.

ScrewA

15

Page 21

1.3 SWING DOWN THE POWER SUPPLY UNIT.

1) Remove the two screws B on both sides.

2) Loosen the four screws A on both sides.

3) Raise the power supply unit and swing it down.

4) Remove the thermostat cable from the clamper, raise

the power supply unit once, and then swing it down.

Power supply unit

Screw B

Screw A

2. REMOVAL AND EXCHANGE

OF THE MAIN PARTS

2.1 REMOVAL OF THE HEAT ROLLER

CAUTION:

Immediately after the power has been switched OFF,

the retransfer roller and the bend remedial roller are

still hot.

Please perform the work after these rollers have

cooled down sufficiently, as otherwise burns may

be caused.

Screw A Thermostat wire

Thermistor wirePower connector

2.1.2 Removal of the Retransfer Roller

1) Disconnect the right side of the spring.

2) Remove the screw A and bring the sensor bracket

to free condition.

For installation, match the notches so that they engage.

3) Disconnect the junction connectors of the thermistor and the thermostat of the retransfer roller.

Remove the power connector.

4) Remove the two screws B and remove the roller by

pulling it slowly to the front.

Notch Spring

Screw A

1) Refer to section 2.2 and remove the cam motor.

2) Remove each roller individually.

2.1.1 Removal of the Bend Remedial Roller

1) Disconnect the junction connectors of the thermistor and the thermostat of the bend remedial roller.

Remove the power connector.

2) Remove the two screws A.

3) The bend remedial roller can be removed when the

roller is turned upwards and slowly pulled to the front.

16

Screw BPower connector

Page 22

CAUTIONS FOR INSTALLATION AND

CLEANING OF BOTH ROLLERS

1) The oil bearing % is on the tip of the roller assembly.

Do not forget it at the time of installation and removal.

2) When installing a new roller, take care that it will not

hit the bracket.

3) AC 100 V is impressed to this heater. Use sufficient

care for the wire processing.

4) Do not turn the roller by hand. The thermistor may

become damaged when the roller is turned by hand.

Accordingly, when a roller is to be turned for

cleaning etc., do the turning while the bracket

on which the thermistor is installed has been

raised a little.

2.2 REMOVAL OF THE CAM MOTOR

1) Remove the two screws A.

Please use a long screwdriver for the lower screw.

If the power supply unit is in the way, raise it once

and use the gap underneath to perform the work.

2) Remove the screw B from front side.

Refer to section 2.9 to remove the front panel.

3) Insert the screwdriver to the hole fixing the card cooling fan, and remove another screw B.

(Refer to section 2.14.3)

4) Disconnect the flat wire and the other cables.

5) Raise the bend remedial roller and pull out the motor, taking care that the motor bracket will not hit

circuit boards etc.

Screw B

(Front side)

18

QYSPSPD

4008N

Bearing

Thermistor bracket

Pass the wires

behind the lever

15

(-010)

screw B

1

(TSS0181)

Clamp

F1

(-010)

15

Retransfer roller

17

KJJ46271-003

17

A

B

Bend remedial roller

(TSS0182)

3

12

KJJ46271

-003x2

T1

H1

17

KJJ46271

-003x2

KJJ46271-003

T1

Clamp

(T2,H2)

P4

(FD M.MOTOR ASY)

Screw A

T2

T2

Clamp

H2

(F1)

Cam motor

5

(TSS0189)

Clamp

(P4)

17

KJJ46271

-003x2

Screw A

17

Page 23

2.2.1 Installation of the Cam Motor

1) The gear of the cam motor has a phase. When it is

removed at the time of roller cleaning, exchange,

etc., it can be installed again in the same condition,

but setting in the following way should be done when

the cam gear is exchanged.

Apply grease to this side also

20

Apply grease to

this side also

12

Apply grease to this side also

13

20

Apply sufficient grease

to the hole for the shaft.

Please use care, as the

installation orientation

can be mistaken easily.

Apply a sufficient quantity

of grease to the two

holes for the shaft.

Install so that the slit of the

cam gear comes to the gear

edge of the double gear

when seen from above.

Gear setting method

Apply grease to a small

gear by one grain of rice.

QYSPSPD3006Nx2

Cam gear

Slit

Double gear

9

7

Apply grease to

this side also

14

QYREE4000X

Engage with

20

10

the cam gear.

Upper

side

Lower

side

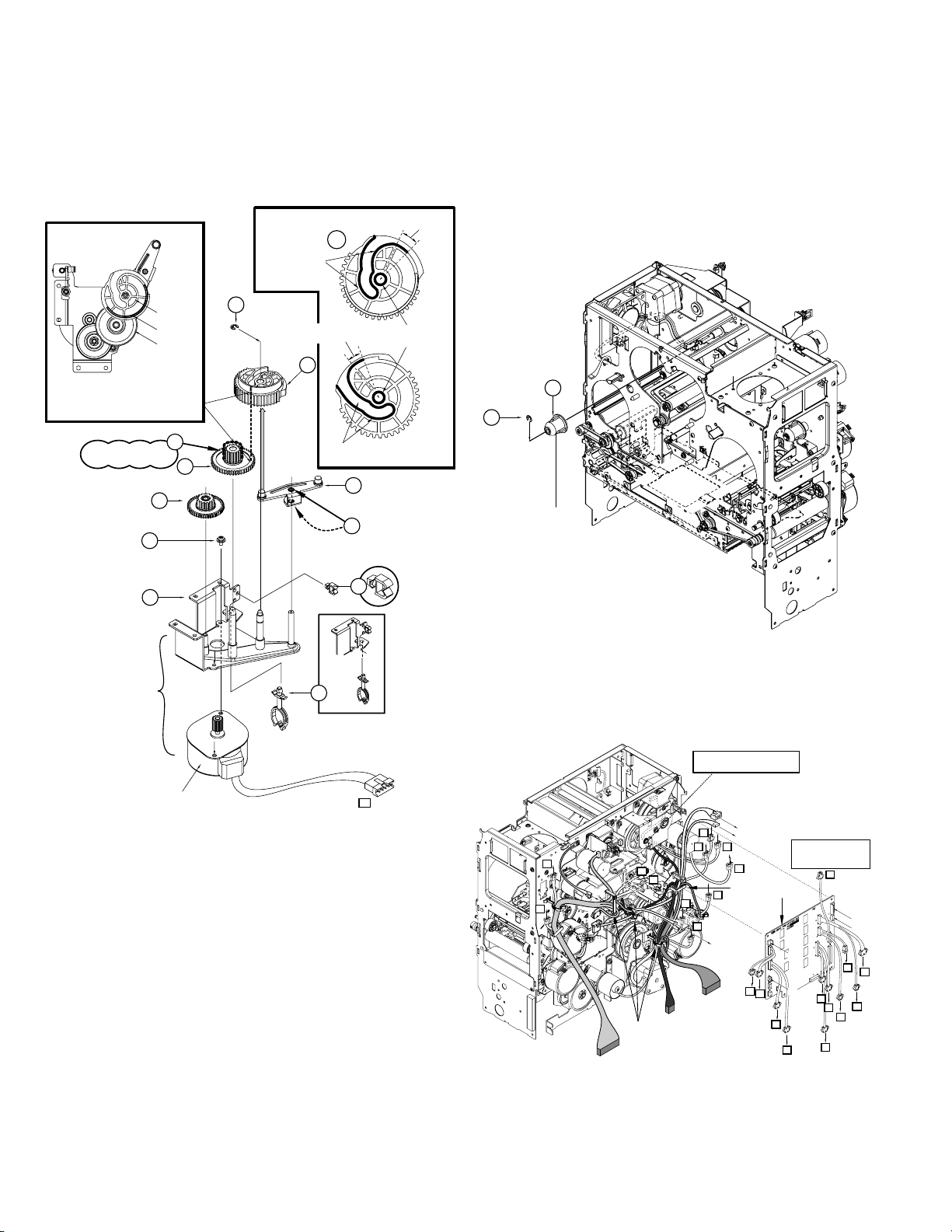

2.3 REMOVAL OF THE RETRANSFER FILM

SUPPLY MOTOR

1) Remove the ink ribbon and the retransfer film cassette.

2) Remove the bobbin holder 7 on the film supply side.

Perform the work while using your hand to prevent

that the E-ring drops down.

7

QYREE4000X

8

Bobbin holder

17

18

P4

Cam motor

Before installing the gear,

install it on the bracket.

6

Stepping motor SA

2) When installing the cam motor, first insert the longest shaft into the hole while raising the bend remedial roller a little.

Next, insert the second shaft into its hole while turning the motor bracket a little. The bend remedial roller

will move down.

Finally, confirm that the projecting part is in the heater

lever hole.

At this time, raise the bend remedial roller by hand,

confirm that it is locked, and tighten the screws.

3) Check the cam movement as described in Service

mode "Diag. TEST cam motor".

3) Remove the drive circuit board.

Disengage the clampers and the connector.

Disengage the two clampers fixing the circuit board

and remove the circuit board by pulling it in diagonal

direction.

DRIVE PWB is attached after checking

that the wire passes along 3set in EDGE

SADDLE

(Front sensor)

J7

F2

J6

P3

F1

J11

(KWS0751-002)

(Tray interlock)

D3

Clamp

D1

P5

P1

P2

J5

D1

Clampx3

(KWS0757-002)

D2

D4

P4

(Door interlockSA)

DRIVE PWB SA

D2

P1

The relay connector confirms

and connects with number as

which the connector number

is same.

J5

J11

P2

F3

J7

J6

F2

D3

P5

D4

P3

F1

P4

18

4) Remove the tensioning spring @ .

(Refer to the figure on the lower part of next page.)

5) When the five screws

are removed, the film

&, (

supply motor assembly can be removed.

(Refer to the figure on the lower part of next page.)

Page 24

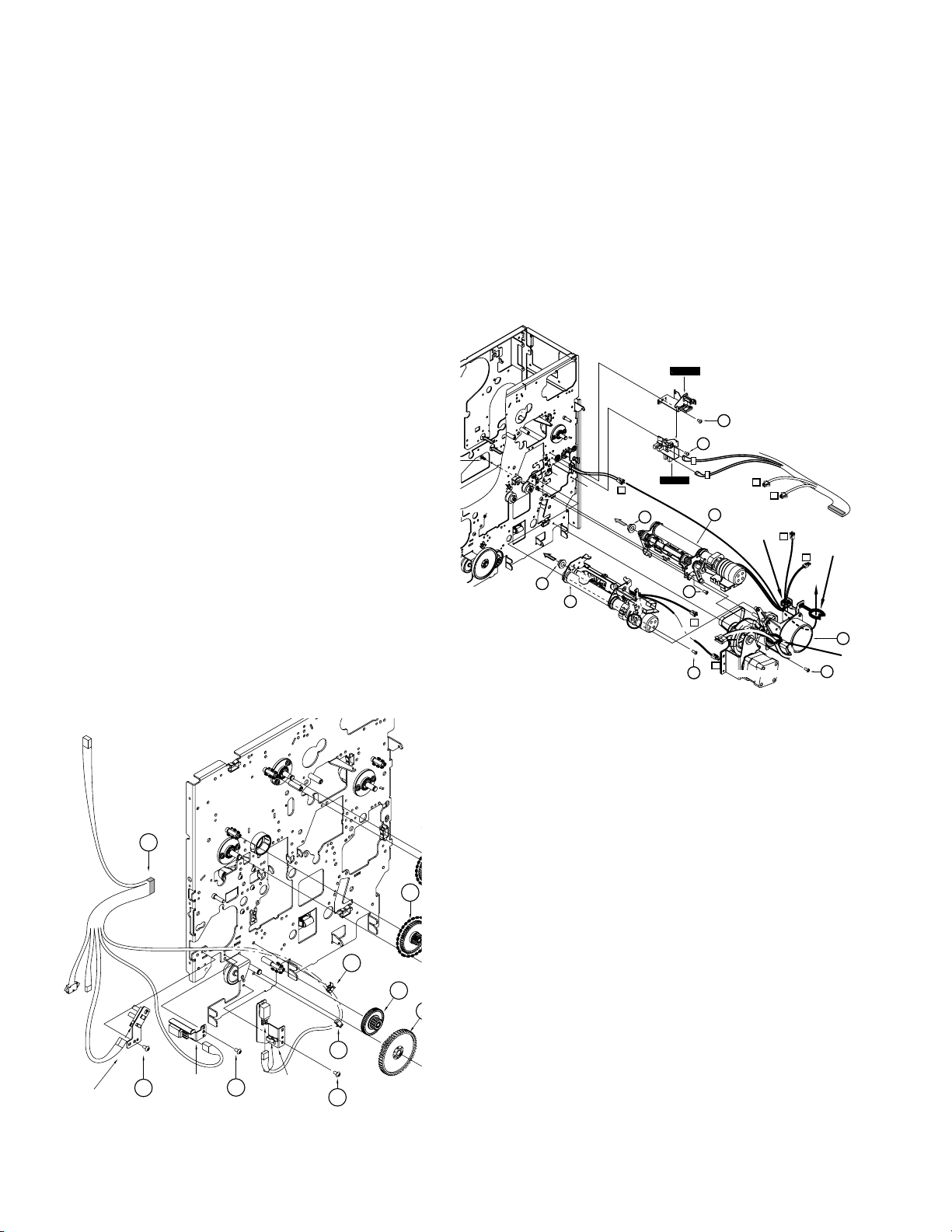

2.3.1 Installation of the Retransfer Film Supply Motor

(TSS0187)

5

18

D3

11

12

17

QYSPSPD4008Nx2

(-007)

P3

19

19

QYSPSPD4008Nx3

Retransfer film supply motor

Tighten provisionally.

KJJ46271

-003x2

Clanp

Clanp

Retransfer film take up motor

20

1) When the motor has been disassembled or exchanged, first the belt @ tension must be adjusted.

2) After assembly has been performed, leave the screw

tightened provisionally.

#

3) Turn the motor all the way in arrow direction and

tighten the screw # securely.

Tighten the screw B securely to turn the

motor in arrow direction to tighten the belt,

and then tighten the screw A securely.

Tighten provisionally.

7

F689ZZ

4) When installing the motor assembly, the tension adjustment of another belt % is required.

5) Install the two screws &.

6) Tighten the four screws

7) Hook the tension spring @.

8) Tighten the four screws securely.

9) Install the bobbin holder.

(, )

provisionally.

QYSPSPD3006Nx2

13

11

15

80S2M224

A

B

F689ZZ

11

QYSBST3006Nx2

14

10

15

80S2M224

8

19

Page 25

2.4 REMOVAL OF THE RETRANSFER FILM

TAKE UP FILM WINDING MOTOR

With the drive circuit board removed, the Retransfer film

take up motor can be removed after the screw * in the

above figure has been removed. (Refer to a front page.)

Ink supply motor

Ink take-up motor

KJJ46271-001x2

18

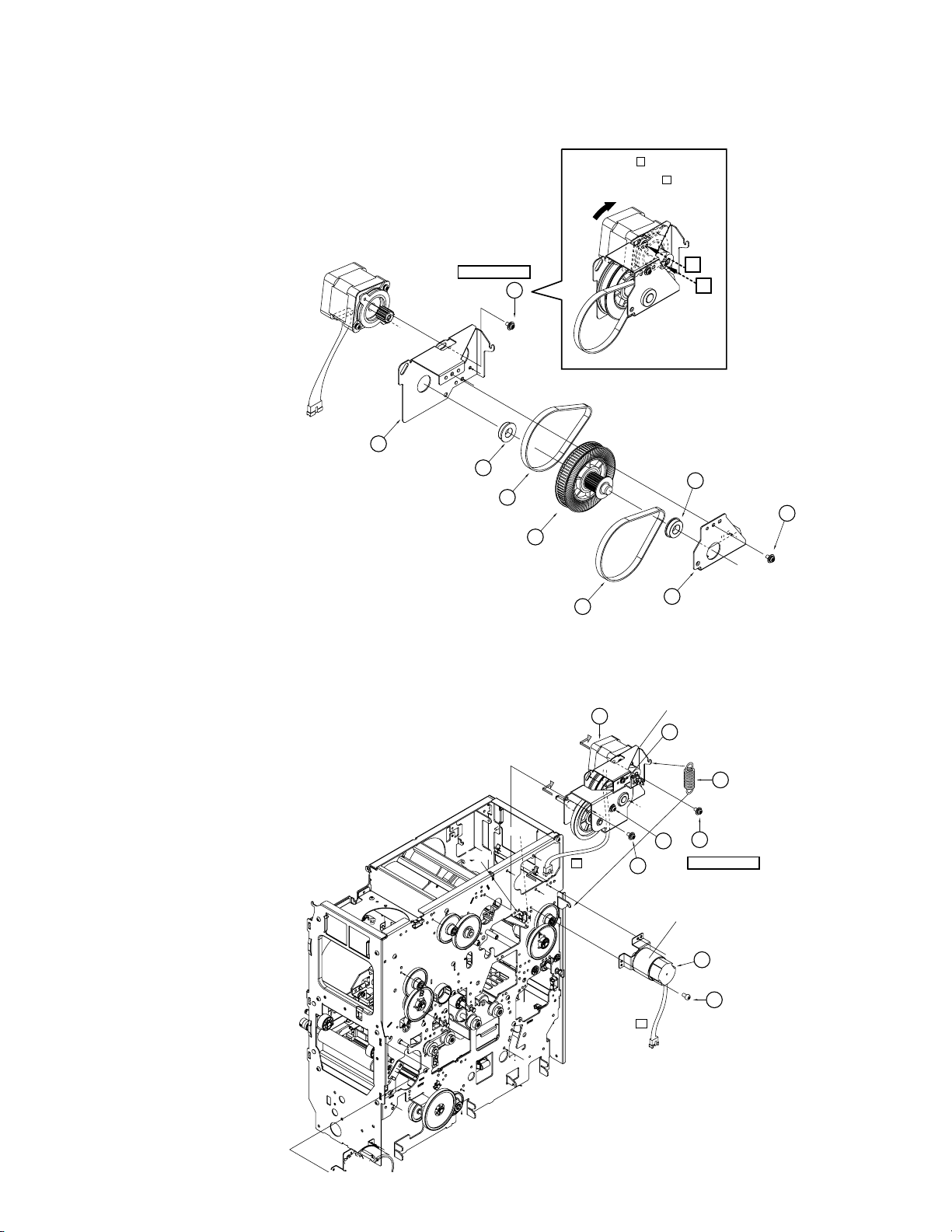

2.5 REMOVAL OF THE CARD FEED MOTOR

1) Remove the tensioning spring

2) Remove the two screws (. Disengage the belt from

the roller.

3) The card feed motor can be removed by pulling it to

the front.

2.5.1 Installation of the Card Feed Motor

1) When the motor has been disassembled or exchanged, first the belt tension must be adjusted.

2) After assembly has been performed, leave the screw

tightened provisionally.

8

3) Turn the motor all the way in arrow direction and

tighten the screw 8 securely.

4) Engage the belt and tighten the screw ( provisionally.

5) Apply the tensioning spring %.

6) Securely tighten the screws ( which have been tightened provisionally.

QYSBST3006Zx2

8

%.

7

P1 P2

D1

D2

3

Turnover card feed motor

Turnover motor

KJJ46271

20

-001x3

Clamp

Clamp

Set the belt

to the pulley.

P5

Card feed motor

Tighten provisionally

DPSP4008Nx2

Set the springs to tighten the belt,

and then tighten securely.

(-006)

15

19

11

12

(M180)

13

(M224)

Tighten the screw B securely to turn

the motor in arrow direction to tighten

10

11

15

Tighten provisionally

DPSP3006Nx2

16

Motor SA

the belt, and then tighten the screw A

securely.

A

B

20

Page 26

2.6 REMOVAL OF THE INK SUPPLY MOTOR AND THE INK TAKE-UP MOTOR

2.9 REMOVAL OF THE FRONT PANEL

1) When there is an MG circuit board, remove the circuit board screws and move the circuit board to the

side.

2) Disengage the hook on the left side of the drive circuit board. Disengage the wire clamp.

3) The ink motor assembly can be removed after the

two screws * have been removed. (Refer to a front

page.)

2.7 REMOVAL OF THE TURNOVER MOTOR

AND THE TURNOVER CARD FEED

MOTOR

1) The turn over motor and the turn over card feed

motor assembly can be removed after the three

screws ) have been removed. (Refer to a front

page.)

Remove the spring, as one of the screws is hidden

by the spring.

2.8 REMOVAL OF THE CARD PICKUP

MOTOR

1) Remove the retransfer film and the ink ribbon cassette.

2) Remove the card tray.

3) Remove the cleaning unit.

4) When the six screws

and the screw 5 for earth

4

wire have been removed, the front panel can be removed.

Installation of the Front Panel

1) There are two claws at the rear of the front panel.

Insert into the frame by lightly hitting on the claws.

And then secure the six screws 4.

Front Panel

5

1) The card pickup motor assembly can be removed

after the two screws * have been removed.

Insert the gear shaft

Card pikup motor

18

KJJ46271

-001x2

Insert the front panel

into the frame by lightly

hitting on the claws.

M

G

IS

O

I

C

4

SDSP4008Nx6

21

Page 27

2.10 REMOVAL OF THE PLATEN SOLENOID

100V/200VCommon

H1

H2

CN8

CN4

CN5

CN6

CN7

CN8

CN4

CN2

CN1

CN3

H1

H2

6

KWS0639-001

POWER SUPPLY SA

F3

H1

H2

10

KJJ46271-003x2

H1=Retransfer heater

H2=Bend Remedial heater

1) Remove the drive circuit board.

2) Disengage the wire from the clamp. (2 places)

3) Remove the two screws

and then remove the so-

(

lenoid support @ and #.

4) Remove the two screws

, raise the solenoid body

&

once, and pull it to the rear.

5) Be careful not to damage the disk of ink encoder

located above when removing the screw

(

.

2.10.1 Installation of the Platen Solenoid

1) Insert the plunger by itself into the cutout.

2) Fix the solenoid body with two screws

&

.

3) Fix the solenoid support with two screws (. At this

time, Pay attention to the following item.

4) Before tightening the screws, adjust the gap uniformly so that there will be no interference with the

platen lever and the solenoid support when the

plunger moves in and out.

5) Be careful not to damage the disk of ink encoder

located above when securing the screw (.

2.11

REMOVAL OF THE POWER SUPPLY UNIT

1) Disconnect the wires and the connectors.

2) Remove the two screws

0

.

3) When ordering a power supply unit, also order the

wire clamps around it at the same time.

Gap

Platen lever

Before tightening the screws, adjust the gap uniformly so

that there will be no interference with the platen lever and

the solenoid support when the plunger moves in and out.

Explanation drawing 1

Caution for the time of installation of the solenoid support

Solenoid support

22

Explanation drawing 1

Platen solenoid

(TSS0179)

11

QYSPSPD4008Nx2

19

12

QYSPSPD

17

4008Nx2

Clamp

Plunger

Engage the bearing with

the rear frame.

Lead the wire along the

bracket so that it does not

become an obstacle on the

inside of the bracket.

Page 28

2.12 REMOVAL OF SENSORS AND SWITCHES

2.12.1 Removal of the Cam Sensor

Function

This sensor decides the origin position for pressurizing

the retransfer roller and the bend remedial roller.

1) Refer to section 2.2 and remove the cam motor.

2) The sensor can be removed after the screw * has

been removed.

2.12.2 Removal of the Card Outlet Sensor

Function

This sensor detects card jams. An error will be caused

when no card passes the sensor within a fixed time after completion of retransfer.

1) The sensor can be removed after the screw ( has

been removed.

2.12.3 Removal of the Ink Encoder Circuit Board

Function

The ink feed quantity is decided by the pulses of this

encoder. Start position is decided by the ink start position sensor.

1) The bracket can be removed after the two screws

have been removed.

2.12.4 Removal of the External Unit Power Circuit

Board

Function

When a small external IC unit is connected, power is

supplied from this power supply.

The thermistor detecting the environment temperature

is installed on this board.

1) Refer to section 2.2 and remove the cam motor.

2) The circuit board can be removed after the screw

has been removed.

)

⁄

EXT. unit power

F1

11

S3

7

KJJ46271-003

21

KJJ46271

20

-003x2

Ink Encoder

Cam sensor

18

KJJ46271

-003

19

KJJ46271-003

Card outlet

sensor

Yellow

23

Page 29

2.12.5 Removal of the Turnover Initial Position

1

sensor

2.12.8 Removal of the Retransfer roller/Remedial

Roller Sensor

Function

This sensor decides the origin position for the turn unit.

1) Refer to section 2.7 and remove the turnover and

card feed motor.

2) The sensor can be removed after the screw

&

been removed.

2.12.6 Removal of the Card Near-empty Sensor

Function

When the number of remaining cards drops to about 20

cards (for the card 0,76mm thick) , the electronic buzzer

sounds.

1) Refer to section 2.16.1 and remove the Main circuit

board.

2) Remove the card tray.

3) The sensor can be removed after the screw ( has

been removed with a long screwdriver from the hole

in which the Main circuit board is located.

2.12.7 Removal of the No Card Sensor

This sensor checks whether there are remaining cards

or not. An error is caused when the remaining quantity

becomes zero.

1) Refer to section 2.7 and remove the turnover and

card feed motor.

2) The sensor can be removed after the screw * has

been removed.

has

Function

This sensor detects the origin of the retransfer roller and

the bend remedial roller.

Energization is performed only when a roller is in this

position.

1) Remove the screw &.

2) Slide the sensor to the side, as the lever is inserted

into the sensor.

DR PCB BKT SA

TSS0239-V

17

17

A

B

(-010)

TSS0239-U

HEATER SENSOR SA

F1

(-010)

15

15

1

(TSS0181)

(TSS0182)

12

T1

17

3

H1

T1

CLAMP

(T2,H2)

P4

(FD M.MOTOR ASY)

T2

T2

CLAMP

(F1)

H2

(TSS0189)

5

CLAMP

(P4)

17

Head cooling fan

Turnover initial

position sensor

24

KWS0757-002

15

17

KJJ46271

-003

No Card

sensor

Card near-empty

18

sensor

KJJ46271

-003

11

11

19

1

12

KJJ46271-003

Page 30

2.12.9 Removal of the Retransfer Film Mark/Ink

Start Position Sensor Circuit Board and the

Card Edge Sensor

Function

Card edge sensor

•

This sensor decides the card position at the time of

card retransfer.

Retransfer Film mark sensor

•

This sensor detects the black bar on the film and

selects the panel for printing.

Ink start position sensor

•

This sensor detects the boundary between magenta

and cyan ink. Next, the pulses of the rotary encoder

are detected and movement is made to yellow.

1) When a magnetic encoder is built-in, refer to "Connection of optional parts" and remove the encoder.

2.12.10 Removal of the C.L. Interlock Circuit Board

and the Card Supply Sensor

Function

C.L. interlock switch

•

This sensor detects the presence or absence of the

cleaning unit.

When the switch is OFF, no power is supplied to the

driver IC for the card supply motor and the turnover

motor.

Card supply sensor

•

This sensor checks whether cards are being supplied or not.

1) Refer to section 2.9 and remove the front panel.

2) The sensor bracket holding these two sensors can

be removed when the screw 6 has been removed.

2) Remove the feed roller marked with* in the lower

drawing of section 2.15.1 “feed roller removal”.

3) The sensor bracket holding the sensor can be removed when the screw # has been removed.

Ink start position

sensor

Explanation

drawing 4

Route the edge sensor

wire underneath the film

mark sensor between

the circuit boards.

Card edge sensor

Retransfer film mark sensor

( side)

Explanation

drawing 4

13

Pass the wire through the notch

in the bracket.

REAR PLATE SA

F1

Card supply sensor

C. LInterlock switch

6

25

Page 31

2.12.11 Removal of the Door Interlock Circuit Board

16

KJJ46271-001x2

Cassette

interlock

2.12.12

Removal of the Cassette Interlock Circuit Board

Function

This circuit board detects opening of the front door.

The DC 24 V power put out from the power supply unit

is cut off when the door interlock switch and the cassette interlock switch are not both ON.

1) Refer to section 2.9 and remove the front panel.

2) The door interlock circuit board can be removed after the screw

KJJ46271-003

15

has been removed.

(15)

8

Door interlock

RED

J4

J3

Function

This circuit board detects the presence or absence of

the retransfer film and the ink ribbon cassette.

The DC 24 V power put out from the power supply unit

is cut off when the door interlock switch and the cassette interlock switch are not both ON.

1) Refer to section 2.10 and remove the platen solenoid.

2) The cassette interlock circuit board can be removed

after the screw

has been removed.

(16)

26

Page 32

2.12.13 Removal of the Card Tray Interlock Circuit

Board

Function

This circuit board detects whether the card tray is presence or absence. When the tray is absence, the power

is not supplied to the driver IC for the card pickup motor.

1) Remove the card tray.

2) Remove the three screws 9 and the rail on the left

side of the card tray.

3) When the screw is removed with a small screwdriver,

the cassette interlock circuit board can be removed.

QYREE4000X

5

10

4

5

10

QYREE4000X

KJJ46271-003

9

x3

2.13 REMOVAL OF THE TURNOVER UNIT

1) Refer to section 2.9 and remove the front panel.

2) Refer to section 2.8 and remove the turnover motor

and the turnover card feed Motor.

3) Remove the E-rings

4) The turnover unit can be removed after the oil bearing # has been removed by sliding it along the shaft.

Installation

1) Install the front E-ring and the oil bearing first.

2) As the gears 5 and 6 are not fixed, hold them by

hand while installing the oil bearing and the E-ring.

3) Turn the turnover unit by hand and check that the

wire does not get caught.

Attachment position of

the serial number

and %.

$

Install so that the bracket

of the turn unit goes under

the plate of the rear frame.

QYREE5000X

15

7

QYREE4000X

14

KWR

10303-010

KJJ46271-003

Card tray

interlock

L. FRAME SA

Pass the wire

underneath

the sumi tube.

Pay attention to the wire

passing direction.

Explanation

drawing 2

QYREE5000X

2.12.14 Removal of the Turnover Card Sensor

Circuit Board

15

11

10

Explanation

drawing 2

Connect

the connector.

16

(-002)

13

Q03093-836

Tu r nover

Card Sensor

Board

1

Install the gear, holding it so

that it will not drop down.

5

x2

6

Explanation

drawing 1

8

13

(-002)

QYREE5000X

15

(-002)

13

Function

This sensor checks for correct card storage at the time

of card supply and card turning.

1) Refer to section 2.9 and remove the front panel.

2) Turn the turn unit so that the sensor circuit board

comes to the top.

3) The sensor circuit board can be removed after the

two screws

have been removed.

1

27

Page 33

2.14 FAN REMOVAL

2.14.1 Removal of the Thermal Head Cooling Fan

1) Remove the two screws and the air duct

2

.

2) The thermal head cooling fan can be removed after

the two screws $ have been removed.

2.14.2 Removal of the Suction Fan

1) The Suction fan can be removed after the two screws

have been removed.

#

Insert the red wire first, so that

the wires will be arranged

nicely after connector insertion.

Red

Clamp the wire of suction fan.

Pass the fan wire through

the notch.

Loosen the two screws of

the duct frame for joint

tightening.

2

QYSPSPD

14

3012Nx2

2.14.3 Removal of the Card Cooling Fan

1) Refer to section 2.9 and remove the front panel.

2) The card cooling fan can be removed after the two

screws 6 have been removed.

Card cooling fan

KJJ46271-003x2

6

F1

13

QYSDSP

3030Rx2

Suction fan

Thermal head

cooling fan

28

Page 34

2.14.4 Removal of the Ventilaion Fan

1) Remove the rear panel and the junction connector.

2) Remove the two screws for the fan.

Remove the clump

Remove the junction connctor

QYSDSP

11

4008N

F3

F3

Rear Panel SA

QYSPSPD3030N

X2

12

Rear Panel SA

29

Page 35

2.15 ROLLER REMOVAL

2.15.1 Feed Roller Removal

1) Refer to section 2.9 and remove the front panel.

2) Remove the card feed motor and the retransfer roller

as required.

3) Tension adjustment is required for the belt at the

front. Please refer to the following figure.

(M132)

(Use for 5 only)

12

2

4

13

8

7

17

(M266)

4

22

QYYASPW4004F

3

(-012)

19

20

6

A side with the stage

22

QYYASPW4004F

(-011)

1

x2

5

x1

MAIN ROLLER SA

Please (Insert from the front.)

ANTI BEND ROLLER SA

(EPDM)

15

QYREE5000X

5

12

(-002)

CARD OUT ROLLER SA

QYYASPW4004F

15

(-011)

Hardness : 77

At the time of installing

the main roller SA, also

engage the front belt.

QYREE5000X

15

A side with the stage

(-011)

21

22

25

QYREE5000X

ANTI BEND ROLLER SA

QYREE5000X

25

21

Hardness : 60

MAIN ROLLER SA

Belt setting

Tension the belt and

tighten the screw securely.

QYREE5000X

15

2

12

12

(-002)

14

QYYASPW4004Fx3

22

6

x3

20

x3

(-011)

(-002)

9

10

(M118)

x4

1

AL ROLLER SA

JOG DIAL SA

1

14

(-002)

11

x4

20

4

REE5000

Engage the bearing

with the frame, pull

it to the front, and fix

it with an E-ring.

17

2

QYYASPW4004F

17

10

16

KJJ46271

-003 x2

20

14

(-002)

3

Explanation drawing 1

JOG DIAL SA

(M116)

6

11

7

(50S2M192)

Belt setting

Tension the belt and tighten

the screw securely.

30

QYREE5000X

15

(-002)

12

7

CARD OUT ROLLER SA

(EPDM)

AL ROLLER SA

7

*

x2

8

QYREE5000X

15

QYREE5000X

15

1

3

3

MAIN ROLLER SA

x2

8

Page 36

2.15.2 Platen Roller Assy Removal

1) Remove the thermal head to prevent damage to it.

2) After removing the thermal head, remove the front

panel , E-ring

and the worm screw *, then the

^

platen roller can be removed.

Be careful not to damage the platen roller, other-

wise print quality may be affected.

3) After assembling, remove the protection sheet.

13

Platen roller

(With protection sheet)

3

long

15

14

(-007)

QYREE5000X

16

short

QYSPSPD

4008N x2

9

B

(-007)

1

14

QYYASPW3004F

18

PLATEN ARM SA(F)

5

PLATEN ARM SA

(F)

7

(-003)

9

2

A

PLATEN ARM SA

(R)

PLATEN ARM SA(R)

7

(-003)

C

Projected side

8

(-010)

A

6

10

QYREE7000X

17

20

C

3

QYSPSPD4008N

31

Page 37

2.16 CIRCUIT BOARD REMOVAL

2.16.1 Removal of the Main Circuit Board

1) When the three screws

are removed and the cir-

0

cuit boards are pulled out.

Caution at the time of exchange of the

Main circuit board

1) Values set in user mode and service mode are stored

on the Main circuit board.Accordingly, when the circuit board has been replaced by a new one, these

set values must be stored.

For details, refer to Service Mode “Parameter Push

and Pop”.

From power supply unit

1

MAIN PWB SA

TPS0242-001

J23,J24through the inner part of the cable

2) The connectors tend to break in performing removal

and attachment of a Main circuit board, please work

carefully enough.

J18

J22

KJJ46271-003x3

10

J15

J21

J17

J2

J5

J22

J18

J23

MAIN PWB SA

J23

J11

J24

J11

J24

32

Page 38

2.17 Thermal Head Exchange Method

Head exchange cover

1) Remove the ink ribbon and the retranster film cassette.

2) When the locking claws on both sides of the head are spread, the connector can be disconnected. Remove the

connector by pulling it.

3) Remove the screw

. Pull the thermal head to the front to remove it.

!

Installation method

1) Install a new thermal head.

2) Tighten the screw.

3) Press the connector near its center and insert it. The

claws will lock.

When a part of the connector is difficult to see at

this time, the work can be facilitated by removing

the head exchange cover of the enclosure.

The head exchange cover can be removed by removing the screw and sliding the cover to the rear.

*Notes:

1) When the connector at the time of installation is inserted with the pins not correctly aligned, the connector will be

damaged. Please insert it after aligning it correctly.

2) When the heater element on the thermal head is hit at the time of exchange, it can become scratched white streaks

etc. can be caused for the printing results. Please handle the thermal head with sufficient care.

3) When the thermal head is touched by someone with an electrostatic charge, it may be damaged. Please touch the

frame of the unit before the start of work.

Locking claw

Thermal head

QYSDSP4008N

11

33

Page 39

The check after head exchange

After thermal head is exchanged, a printing position may move in the direction of Y. In this case, please adjust in the

following procedures.

Enter into “Service mode”, “Maintenance” and “Offset Prt Y”. See the next page.

1) Determines the displacement amount according to the print results (those owned by the user). Every step corresponds to a displacement of about 0.17 mm. The step can be varied in the range between -15 and +15.

2) Press ENTER to save the setting.

3) Print and check the result.

4) To adjust to the standard setting:

In the service mode, print color patterns on single sides of 4 to 5 sheets.

Adjust so that the distance from the card edge to the box enclosing the line (A) is about 2.15 mm. (Check the third to

fifth cards.)

A=2.15mm

R

G

B

Printing startCard shifting direction

(+)

Y

(-)

34

Page 40

USE OF SERVICE MODE

At the time of operation by the user, the "User mode" is used, while the "Service mode" is used at the time of servicing.

Refer to the instruction manual for the user mode.

1) Fine adjustment of the printing position

2) Printing of the built-in test pattern

3) Individual operation of motors

1. Entry into Service Mode

In ready condition, in preheating condition, or in error condition, press the buttons

button [MENU] is released first, the printer will enter into the following service mode.

[EXIT]

Power off

[MENU]

[MENU]

[MENU]

[MENU]

[MENU]

[MENU]

[MENU]

Lo-Co

[MENU]

[MENU]

[MENU]

Completion

0

0

0

0

8

Downloading..

Keep Power On

Start

The new firmware becomes eflective after power off.

[EXIT] End of Service mode.

Setting of the printing position Y

[-15(Front) – -1(Front),0,+1(Back) - +15(Back)]

Select with [↑][↓] and save with [ENTER].

Setting of the printing position X

[-7(Left) – -1(Left),0,+1(Right) – +7(Right)]

Select with [↑][↓] and save with [ENTER].

Setting of the retransfer position X

[-7(Left) – -1(Left),0,+1(Right) – +7(Right)]

Select with [↑][↓] and save with [ENTER].

Setting of the card stop position X

[-7(Left) – -1(Left),0,+1(Right) – +7(Right)]

Select with [↑][↓] and save with [ENTER].

Setting of the Vth gain (Supplementary function for the future

: Always set to 8. )

[0 - +15]

Select with [↑][↓] and save with [ENTER].

Setting of the printing density

[Standard Density,Low Density, High Density,User's LUT]

Select with [↑][↓] and save with [ENTER].

Card cooling fan ON/OFF

[On, Off]

Select with [↑][↓] and save with [ENTER].

Different type of JIS magnetic encoding

[Lo-Co, Hi-Co]

Select with [↑][↓] and save with [ENTER].

Card supplying direction

[Standard, Right Side]

Select with [↑][↓] and save with [ENTER].

Ajust the threshold level of the ink-Sensor

Select with [↑][↓] and save with [ENTER].

Answered On or Off. [off:transmission,on:interruption.]

Start of the firmware download function

The new firmware becomes effective after power OFF or rebooting.

>

Service Mode

>

After 1 sec

>

Download

>

Maintenance

>

OK?

[MENU]

[MENU]

>

[ENTER]

[EXIT]

[ENTER]

>

Download Ready

>

Download Ready

>>

Offset Prt Y

>>

Offset Prt X

>>

Offset Trf X

>>

Offset Card X

>>

VGAIN

>>

Default LUT

Standard Density

>>

Card Fan

On

>>

MG JIS TYPE

>>

Card Loading

Standard

>>

Ink Sensor OFF

107

MENU

and simultaneously. When the

The positions where the setting value of –15 was

actually setup by the version of a firmware differ.

Under user mode, when the “IC Antenna Pos.” is

“Ext. Unit/Ad.on” or the “IC Contact Pos.” is “Ext. Unit”,

the “Right Side” cannot be selected.

[EXIT]

>>

>

Off-line Test

>

Diag. Test

>

[MENU]

>

[MENU]

[ENTER]

[EXIT]

[ENTER]

Pattern

Color

[MENU]

>>

Printing Side

Single

[MENU]

>>

Times

>>

Test Select

>>

Sensor

1000010101010110

>>

Actuator

1

[MENU]

Print

[MENU]

[MENU]

> >>>

[MENU]

[EXIT]

[ENTER]

[EXIT]

[ENTER]

12

Test pattern setting

[Step,Vth,Registration,Addres,Color,Black,Gray,All,(YMCK+K),(K+YMCK)]

Select with [↑][↓] and set with [ENTER].

Switching between printing single side and both sides

[Single, Both]

Select with [↑][↓] and set with [ENTER].

Setting of the number of times for testing

[1,2,3,4,5,6,7,8,9,10,20,30,40,50,100,200,300,400,500,Endless]

Select with [↑][↓] and set with [ENTER].

>>

Test Select

OK?

Ink TUP Mo.

OK?

[MENU]

>>>

Ink SPY Mo.

OK?

[MENU]

>>>

Media TUP Mo.

OK?

[MENU]

>>>

Media SPY Mo.

OK?

[MENU]

[ENTER]

[ENTER]

[ENTER]

[ENTER]

[ENTER]

Testing

>>>

Ink TUP Mo.

Testing..

>>>

Ink SPY Mo.

Testing..

>>>

Media TUP Mo.

Testing..

>>>

Media SPY Mo.

Testing..

...

3

Setting the test type

[Print,Feed,IC(Contact),IC(Antenna),MG(JIS),

MG(ISO),]

Select with [↑][↓] and set with [ENTER].

Ink take-up motor

Ink supply motor

Retransfer Film take-up motor

Retransfer Film supply motor

35

Page 41

36

12

>>

Memory

>

Informations

[MENU]

>

Parameter Push